Heat accumulative gas burner

A gas burner, regenerative technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of frequent ignition, poor performance, deflagration safety hazards, etc., to achieve sufficient combustion, convenient ignition, thermal efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

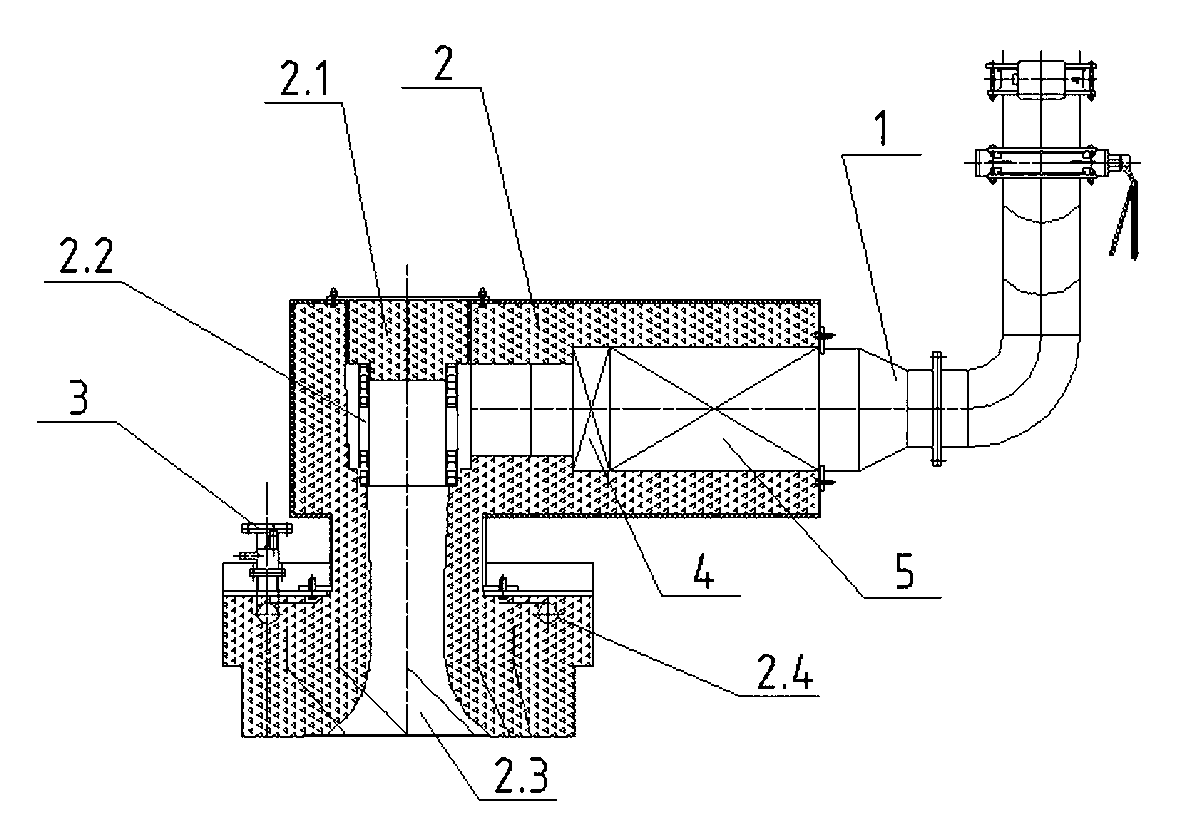

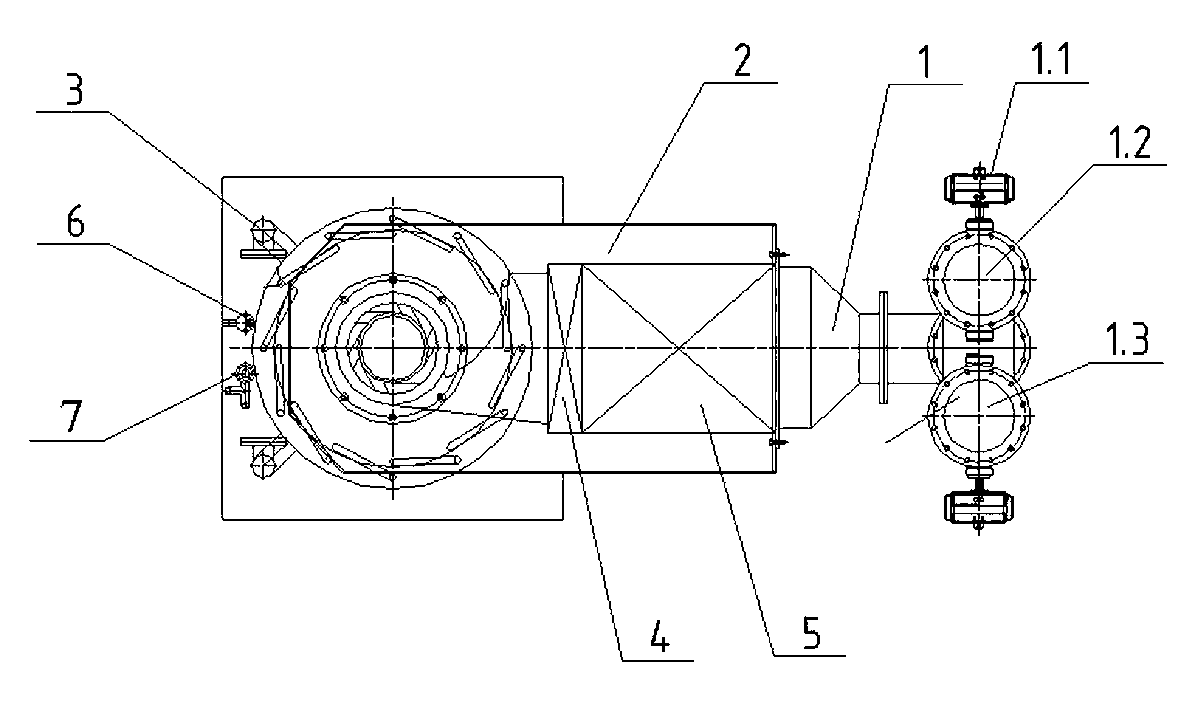

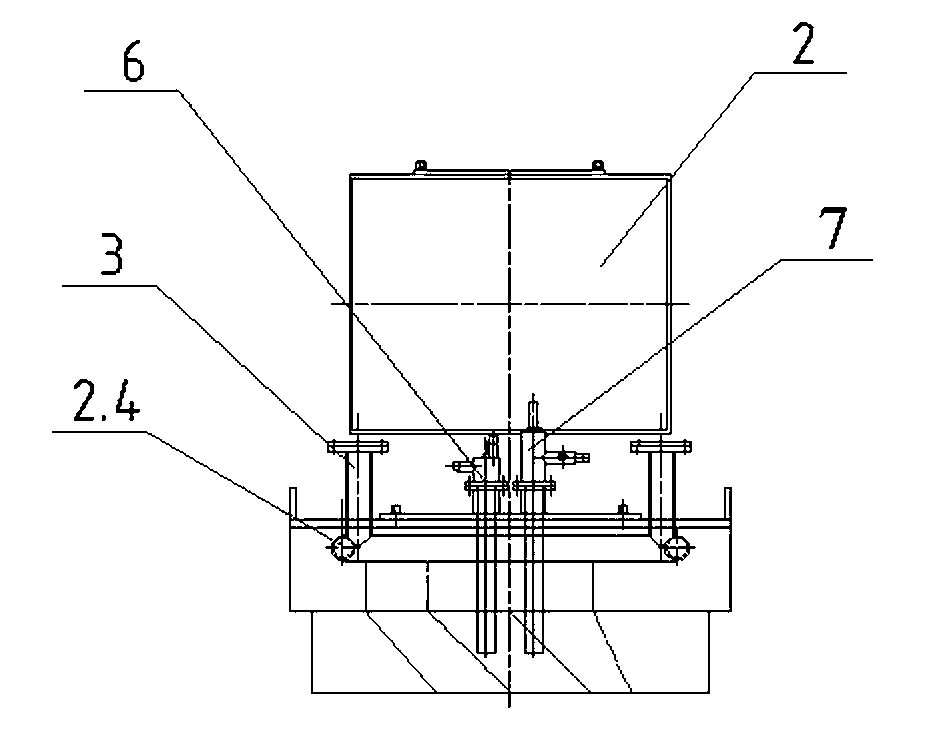

[0021] figure 1 The regenerative gas burner shown includes an air distribution device 1 , a nozzle 2 , a gas control assembly 3 , a block brick 4 , a heat storage body 5 , an ignition device 6 and a fire retention device 7 . The air distribution device 1 is a channel for introducing combustion-supporting air and exhausting exhaust gas. The channel is a three-way pipe fitting. The main pipe end is a rectangular pipe that is directly sealed and connected to the right end of the nozzle 2. The other pipe end is provided with two fork pipes. The forked pipe on one side is the air inlet pipe 1.2, and the other forked pipe arranged side by side is the smoke exhaust pipe 1.3. In order to control the medium flow and operating state in the fork pipe, the air inlet pipe 1.2 is equipped with a pulse device 1.1, and the smoke exhaust pipe 1.3 is equipped with a pulse device 1.1 and an air smoke proportional valve. The nozzle 2 is the core component. The present invention builds a cyclone ...

Embodiment 2

[0025] The gas volume of this embodiment is 175m 3 / h, although the specification is larger than embodiment 1, the overall structure is the same, only the annular road 2.4 of the nozzle 2 is evenly distributed with 6 helical nozzles, and its application effect is similar to that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com