Environment-friendly boiler and heating equipment

A boiler and environmental protection technology, applied in the field of heating, can solve the problems of low heat transfer efficiency of the boiler and high heating cost, and achieve the effects of convenient use process, zero emission of smoke and dust, and accelerated heating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

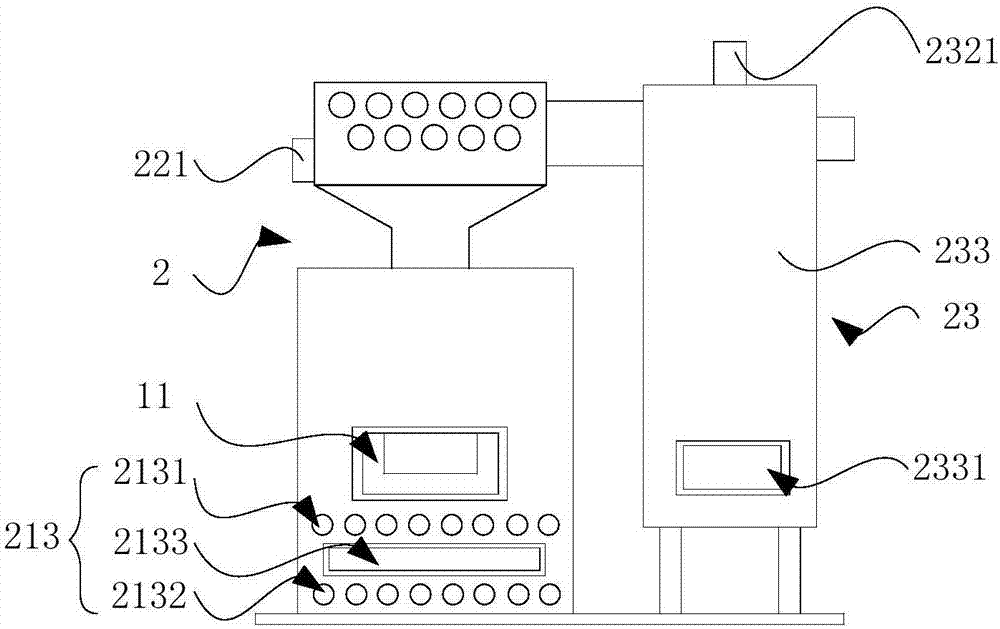

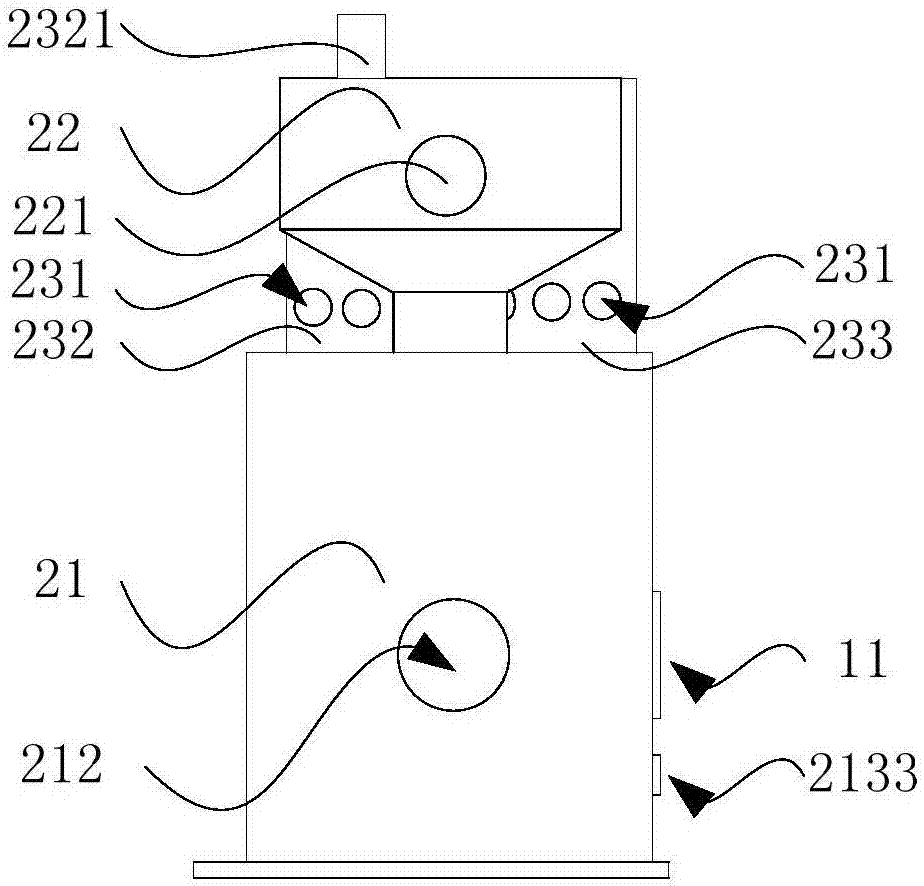

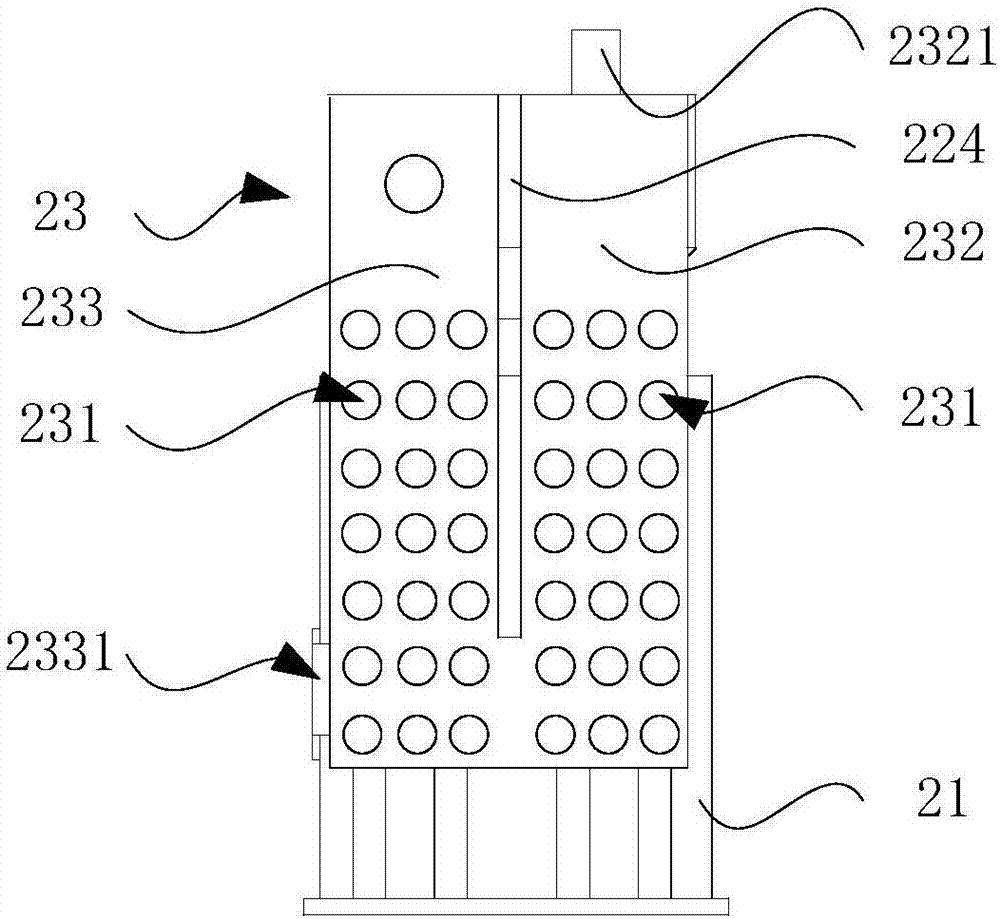

[0042] The purpose of this embodiment is to provide an environmentally friendly boiler, such as Figure 1 to Figure 8 As shown, it includes a shell 1 and a furnace 2 arranged inside the shell 1. A cavity for heating water flow is formed between the shell 1 and the furnace 2. The furnace 2 includes a main combustion furnace 21, an upper furnace 22 and side furnace 23, wherein: the main combustion furnace 21 is provided with a coal filling port 11 communicating with the external environment of the shell 1; the upper furnace 22 is at least partially arranged on the upper part of the main combustion furnace 21 and connected The furnace 21 is connected, and the upper furnace 22 is provided with a discharge port 221 for putting fire and a plurality of first pipes 222 for the circulation of heating water; the side furnace 23 forms a U-shaped channel for the circulation of smoke and dust, and the upper part of the side furnace 23 One side of the side furnace 23 communicates with the u...

Embodiment 2

[0069] The purpose of this embodiment is to provide a heating equipment. The heating equipment provided in the second embodiment includes the environmental protection boiler provided in the first embodiment above, such as Figure 6 to Figure 8 , also includes a dust remover 3 connected to the upper end of the side furnace 23, and the dust remover 3 is used to process the smoke and dust discharged from the side furnace 23.

[0070] The dust collector 3 is used to remove substances harmful to the atmosphere in the smoke discharged from the side furnace 23, so as to ensure that the smoke finally discharged into the atmosphere can meet the emission requirements, making the heating equipment provided by this embodiment more environmentally friendly.

[0071] Compared with the prior art, the heating equipment provided by the present invention includes the above-mentioned environmentally friendly boiler, and also includes a dust collector connected to the upper end of the side furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com