Auto-ignition energy-saving burner of gas appliance

An automatic ignition and burner technology, which is applied in the direction of gas fuel burners, burners, combustion ignition, etc., to achieve the effects of solving the problem of difficult ignition, health protection, and gas resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

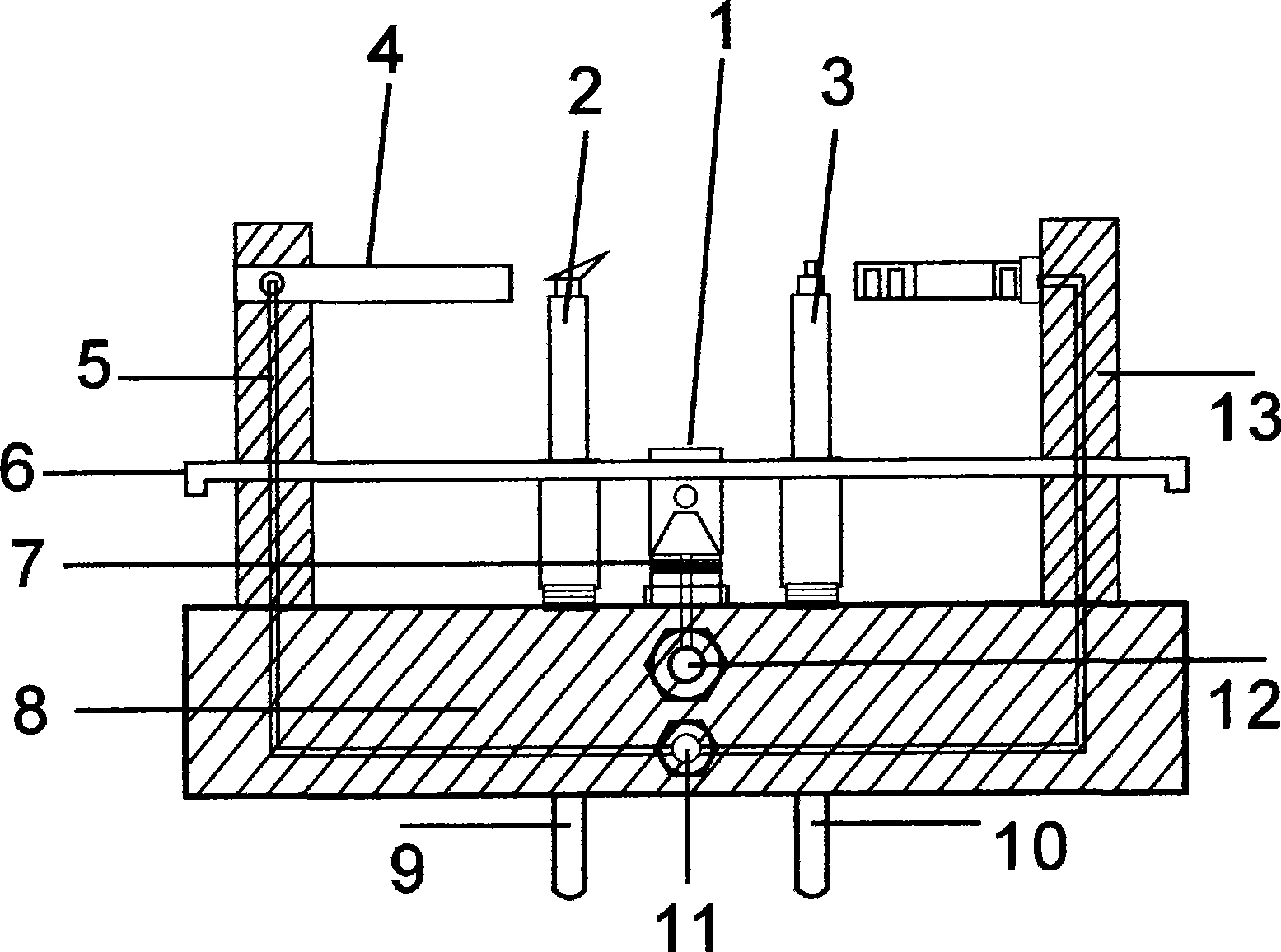

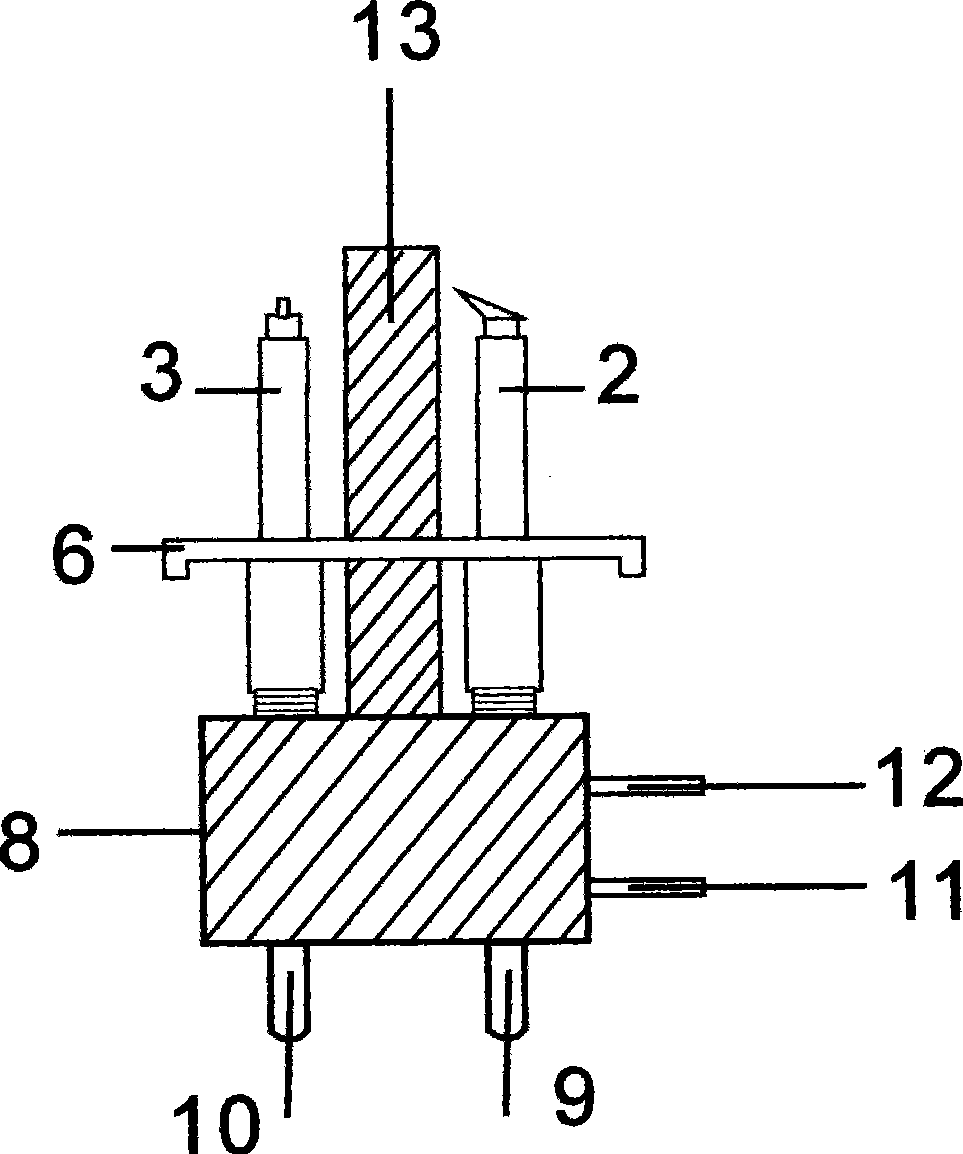

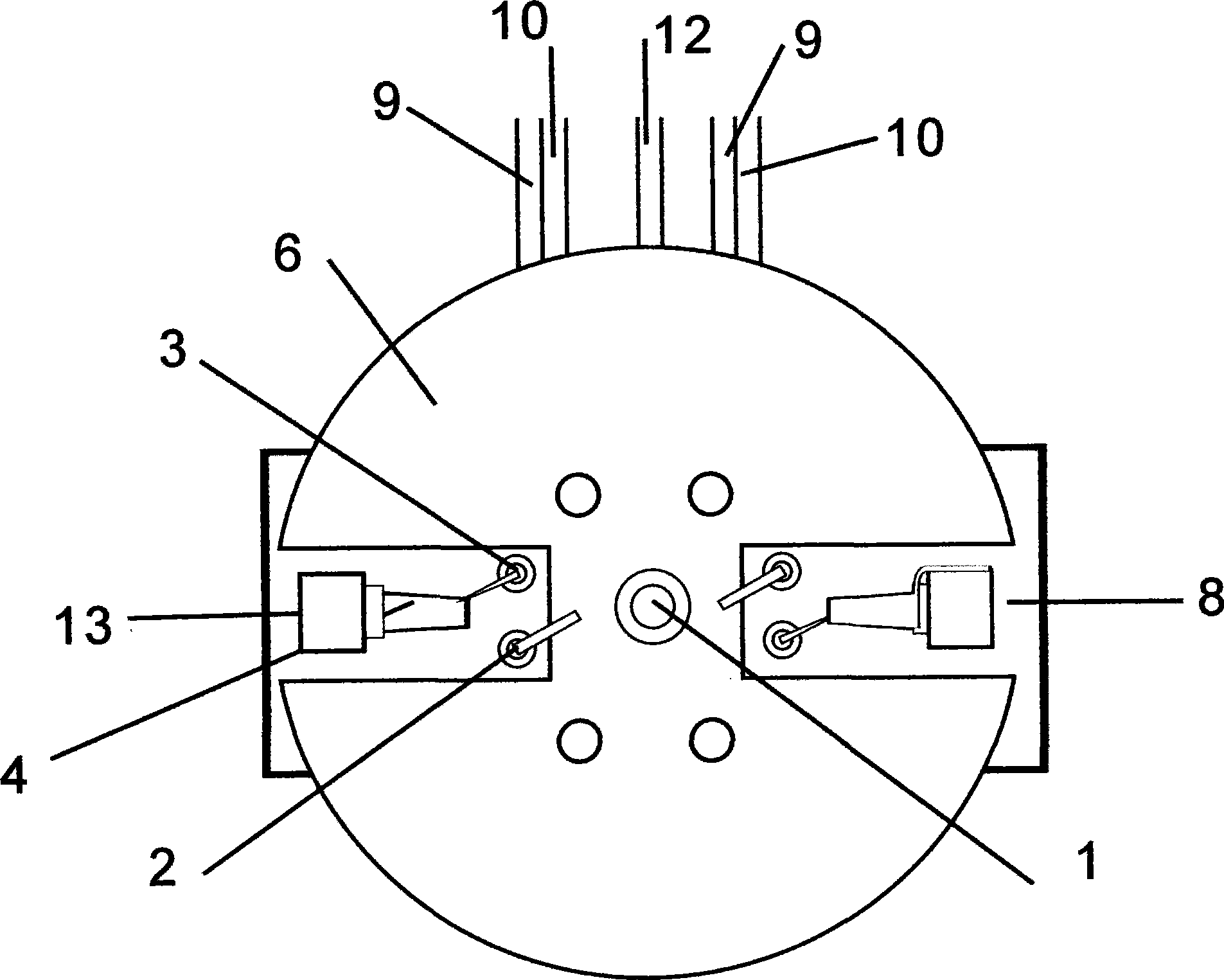

[0018] The present invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

[0019] For the energy-saving burner of automatic ignition gas appliances, there are two intake switches, large and small, designed on the gas input pipe, which are respectively connected to the burner (8) assembly through pipes, and the large intake pipe (12) is connected to the burner (8) In the center of the assembly, the gas is discharged through the main nozzle (7). The nozzle (7) adopts a conical design. 8) In the middle of the assembly, enter the assembly at the lower position, and design a channel of gas transmission (5) directly leading to both sides of the assembly, and transfer from both sides of the assembly to the top of the main nozzle (7) respectively through the pipe (13) The ignition nozzle (4), one nozzle (4) on both sides, the nozzle and the ignition needle (3) contact ignition, open the switch of the large air inlet hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com