Crude gas ignition method of coke oven diffusing tubes and device thereof

A technology for coke oven gas and a release pipe is applied in the field of a method for igniting waste gas in a coke oven release pipe and its device, which can solve the problems of high maintenance requirements, high labor intensity, poor timeliness, etc., and achieves low investment cost and labor reduction. Strength, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

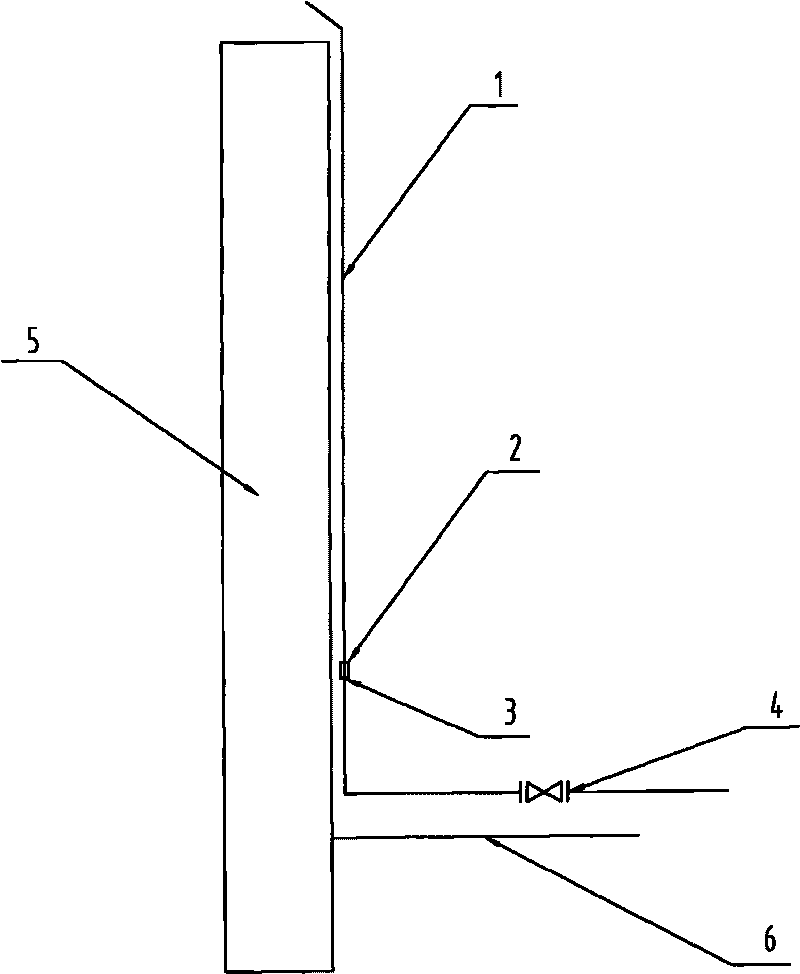

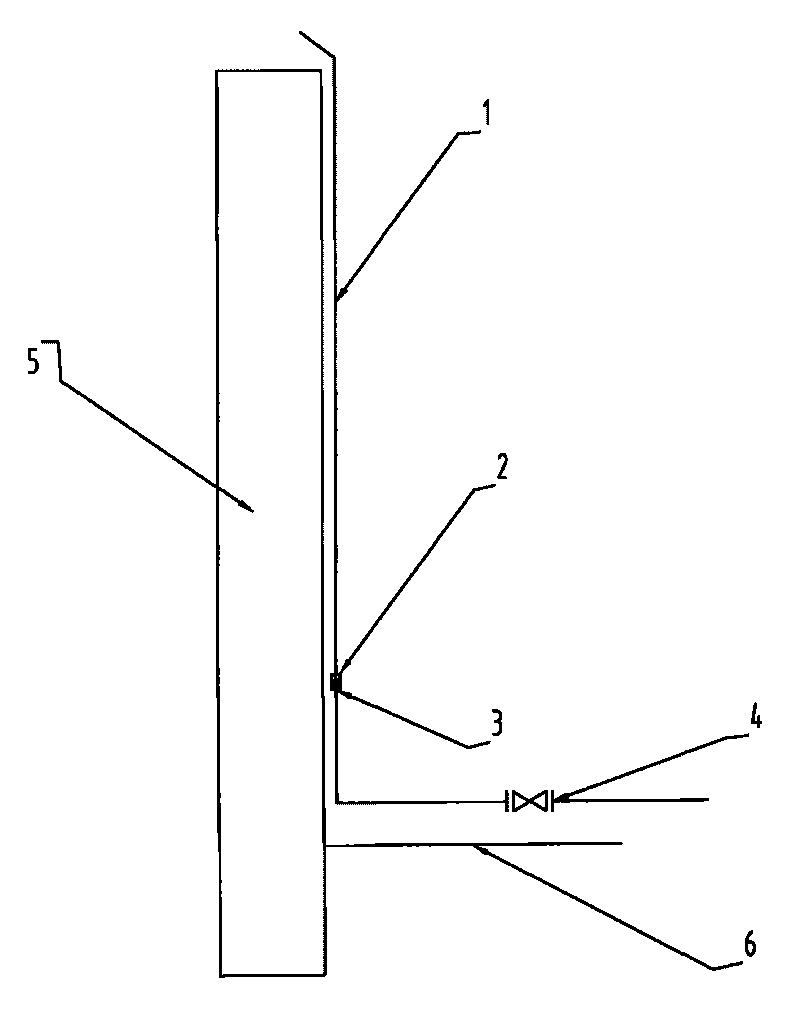

[0015] The structure of the waste gas point device of the coke oven release pipe of the present invention is as follows: figure 1 As shown, it consists of an L-shaped steel pipe 1 arranged in the same direction on the outside of the release pipe 5, a valve 4 installed in the horizontal section of the steel pipe, a tuyere 3 arranged in the vertical section of the steel pipe, and a damper 2 arranged on the tuyere. The top of the steel pipe 1 Bend to the nozzle of the release pipe 5, the front end of the horizontal section valve 4 of the steel pipe 1 is connected to the coke oven gas for heating the coke oven. A handle is welded on the damper 2 so that the damper 2 can slide up and down to adjust the air intake. Tuyere 3 is a rectangular hole (120mm * 10mm) as the ignition hole of this device and the primary air inlet of ignition burner.

[0016] Coke oven release pipe raw gas ignition method of the present invention is carried out according to the following steps:

[0017] On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com