Online water examining technology for blast furnace cooling wall and water tank applying the same

A cooling wall and water tank technology, applied in cooling devices, inspection devices, etc., can solve the problems of easy misjudgment, high labor intensity, and lack of science, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

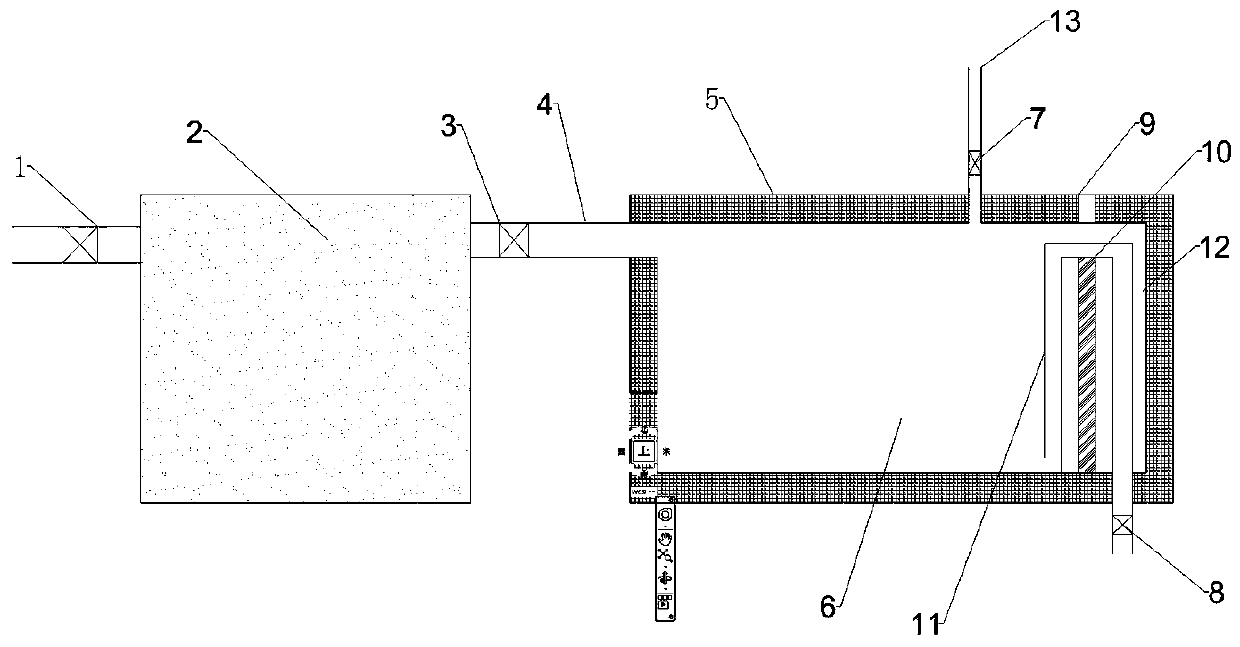

[0029] See figure 1 : A blast furnace cooling stave 2 online water checking process, the process flow is as follows:

[0030] a) Use toughened glass on the tank wall to make a sealed portable water tank 5. The water tank 5 is 1000mm long, 500mm high, and 500mm wide; a hole is made on the side of the water tank 5 at a height of 420mm, and the diameter of the hole is the same as that of the cooling wall 2. The same size is 50mm; an isolation plate 10 is installed in the water tank 5. The isolation plate 10 is in tangential contact with the three sides of the water tank 5. The height of the isolation plate 10 is 420mm. The isolation plate 10 divides the water tank 5 into the reservoir 6 and the reservoir. The volume of the air chamber 12, the reservoir 6 and the air reservoir 12 is 4:1. A hole is opened below the gas storage chamber 12 with a diameter of 30mm. A drain valve 8 is installed. The valve is a ball valve. The rubber pipe 11 is connected to the reservoir 6 through the iso...

Embodiment 2

[0041] b) In the smelting state of the blast furnace, the pressure in the furnace is 408KPa, the inlet pressure of the cooling stave 2 is 1200KPa, close the inlet valve of the cooling stave 2 to make the inlet pressure 320KPa, and connect the outlet pipe 4 of the cooling stave 2 to the water tank 5. Let the water from the cooling wall 2 flow into the water tank 5.

[0042] c) When the water tank 5 starts to store water, the gas detector 9 shows that the gas detection value is 0ppm. When the water level of the water tank 5 reaches the isolating plate 10, the gas detector 9 measures the gas value of 0ppm, and the cooling wall 2 has no leakage .

[0043] d) Open the drain valve 8 to gradually drain the water in the reservoir 6, and at the same time disconnect the water outlet pipe 4 of the cooling wall 2 from the water tank 5.

[0044] e) Open the pressure relief valve 7 to relieve the pressure in the water tank 5.

[0045] Use effect: by checking the water of the cooling stave 2 in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com