Patents

Literature

88 results about "Wood burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

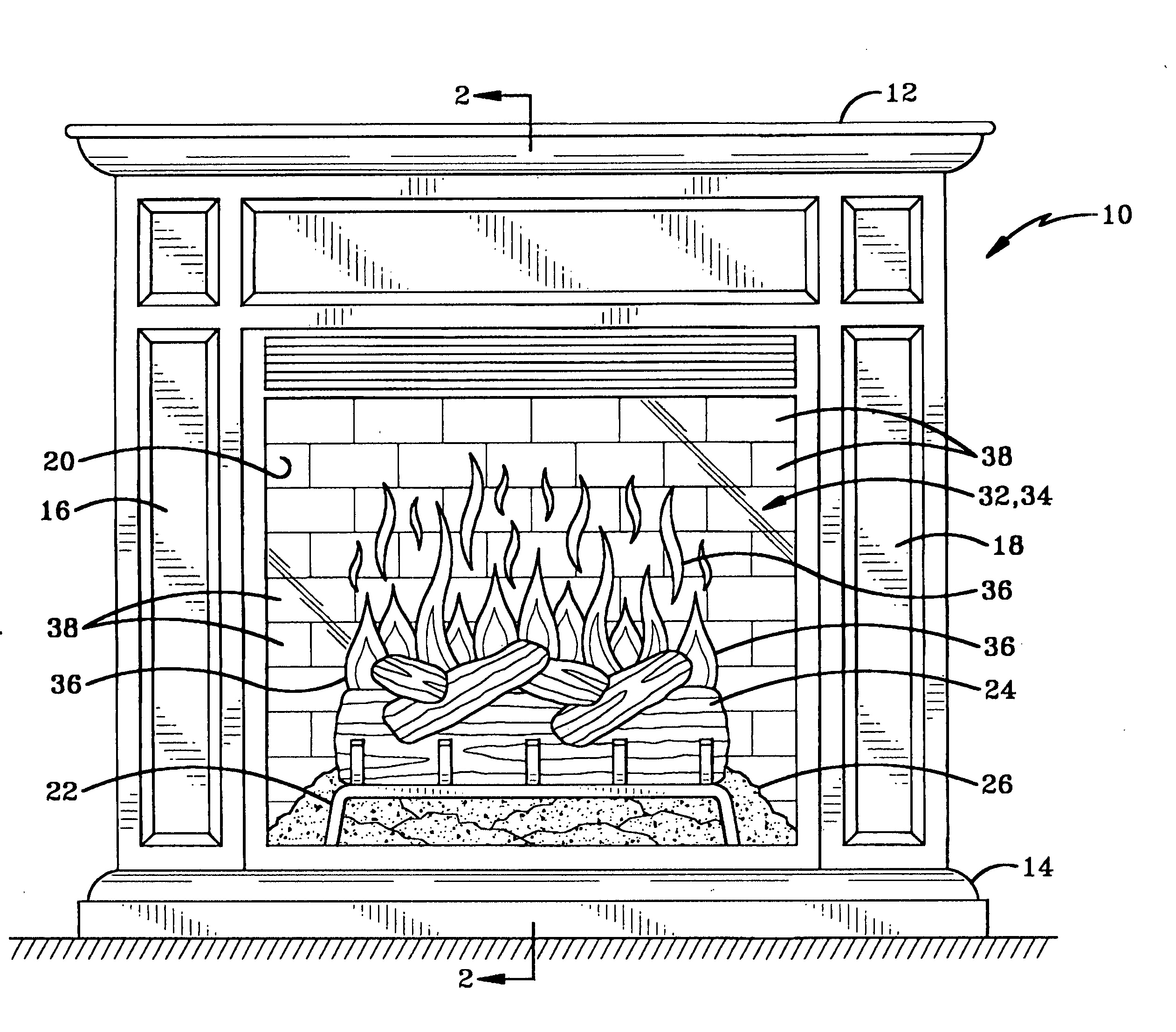

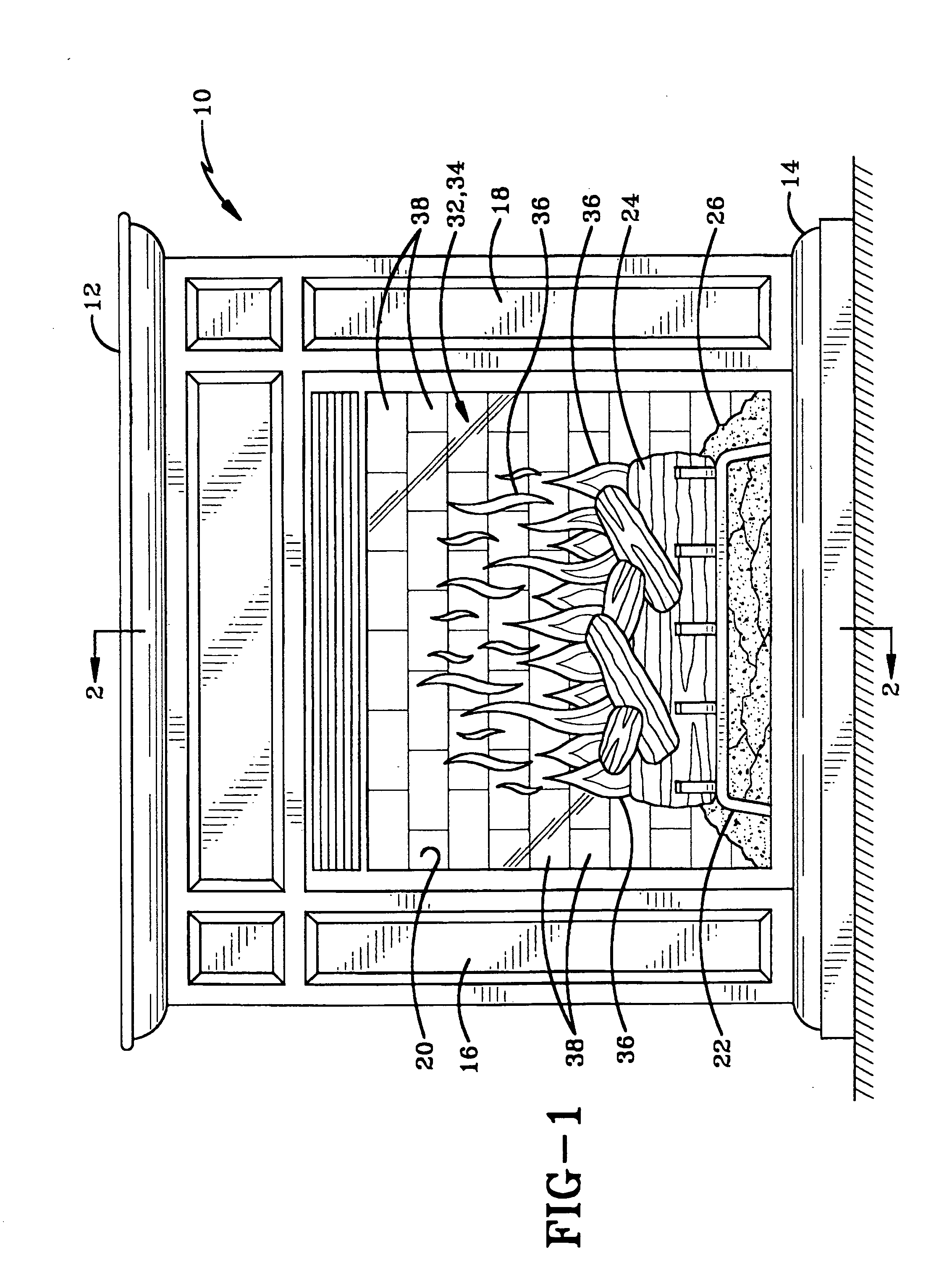

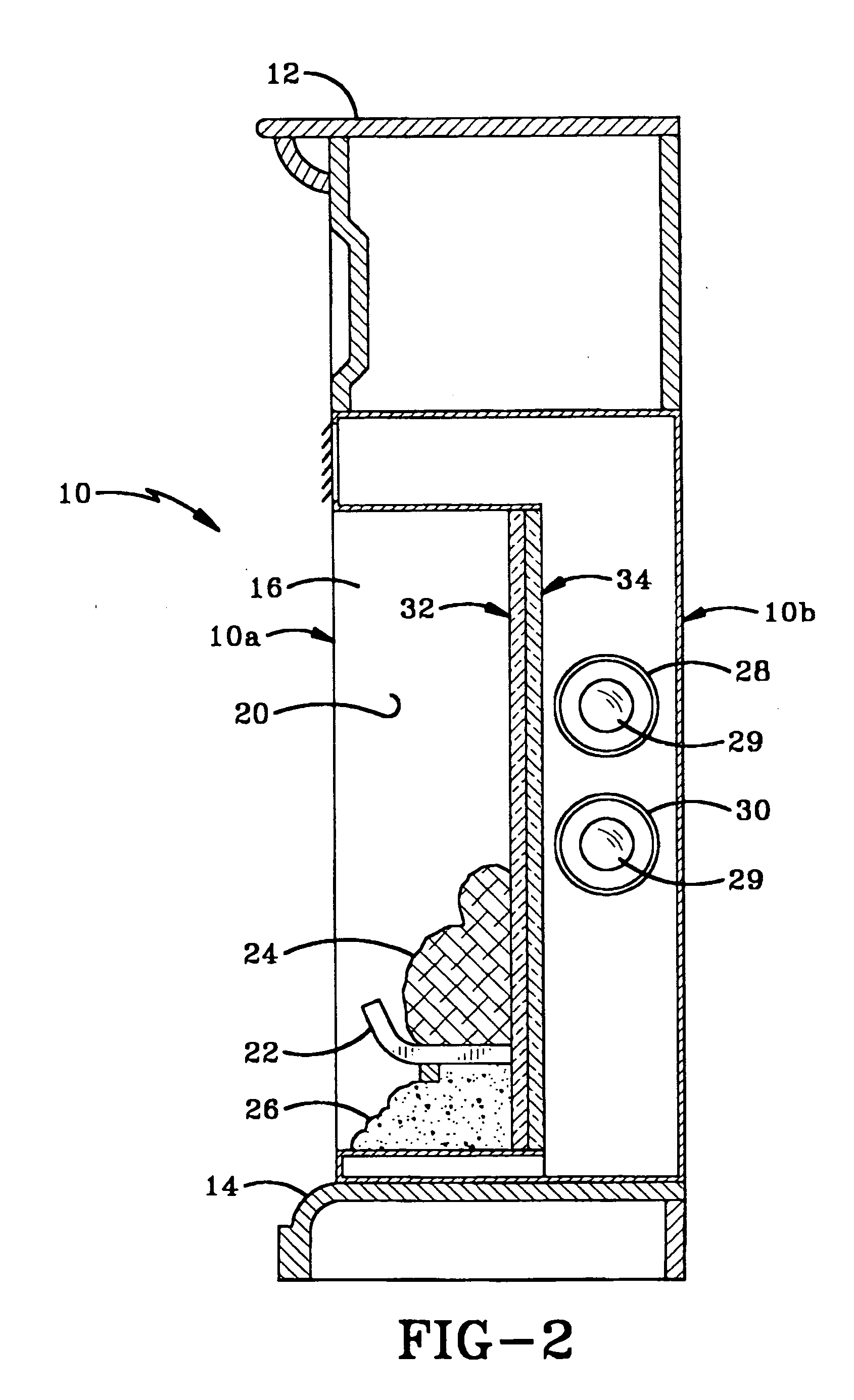

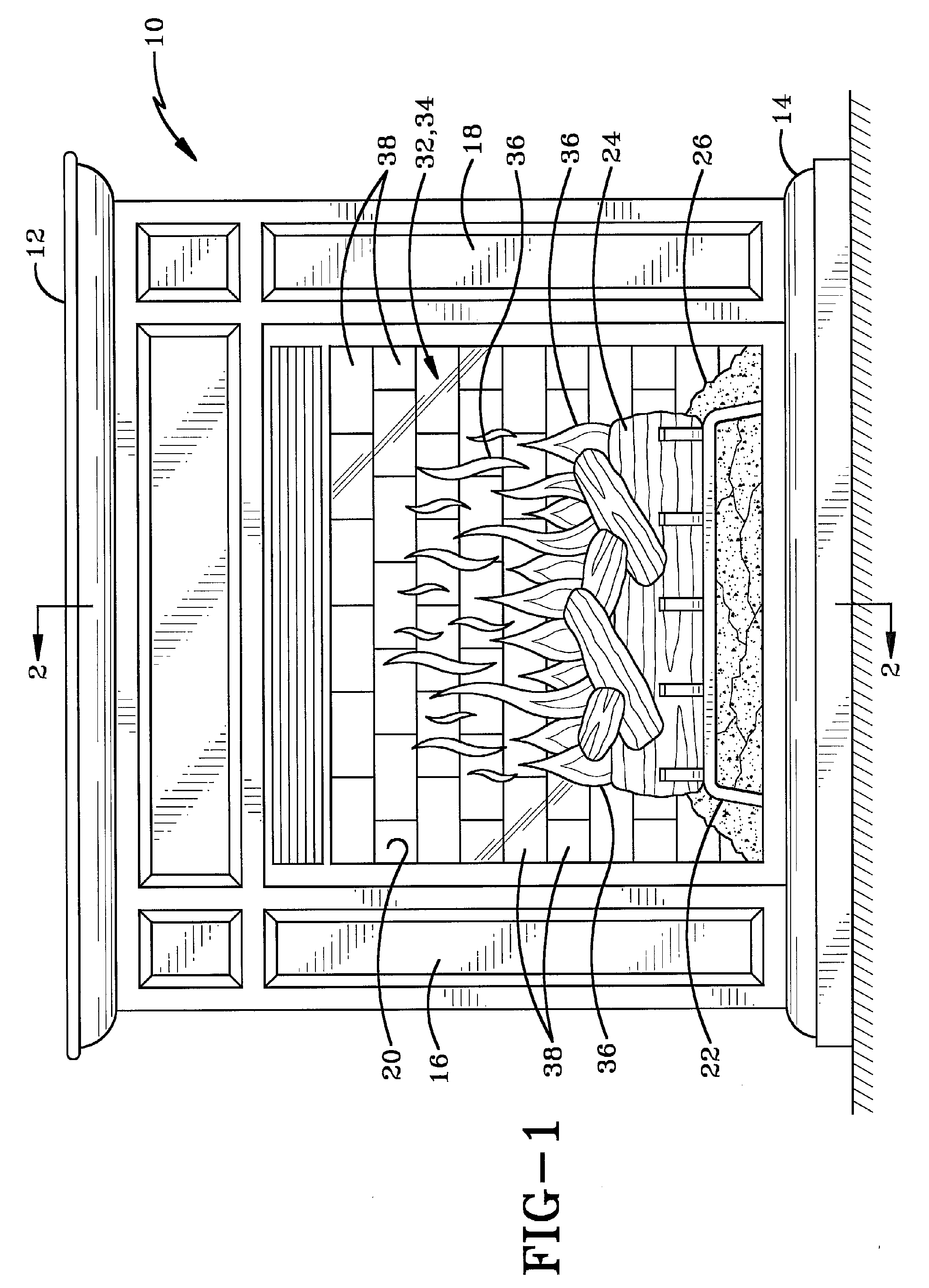

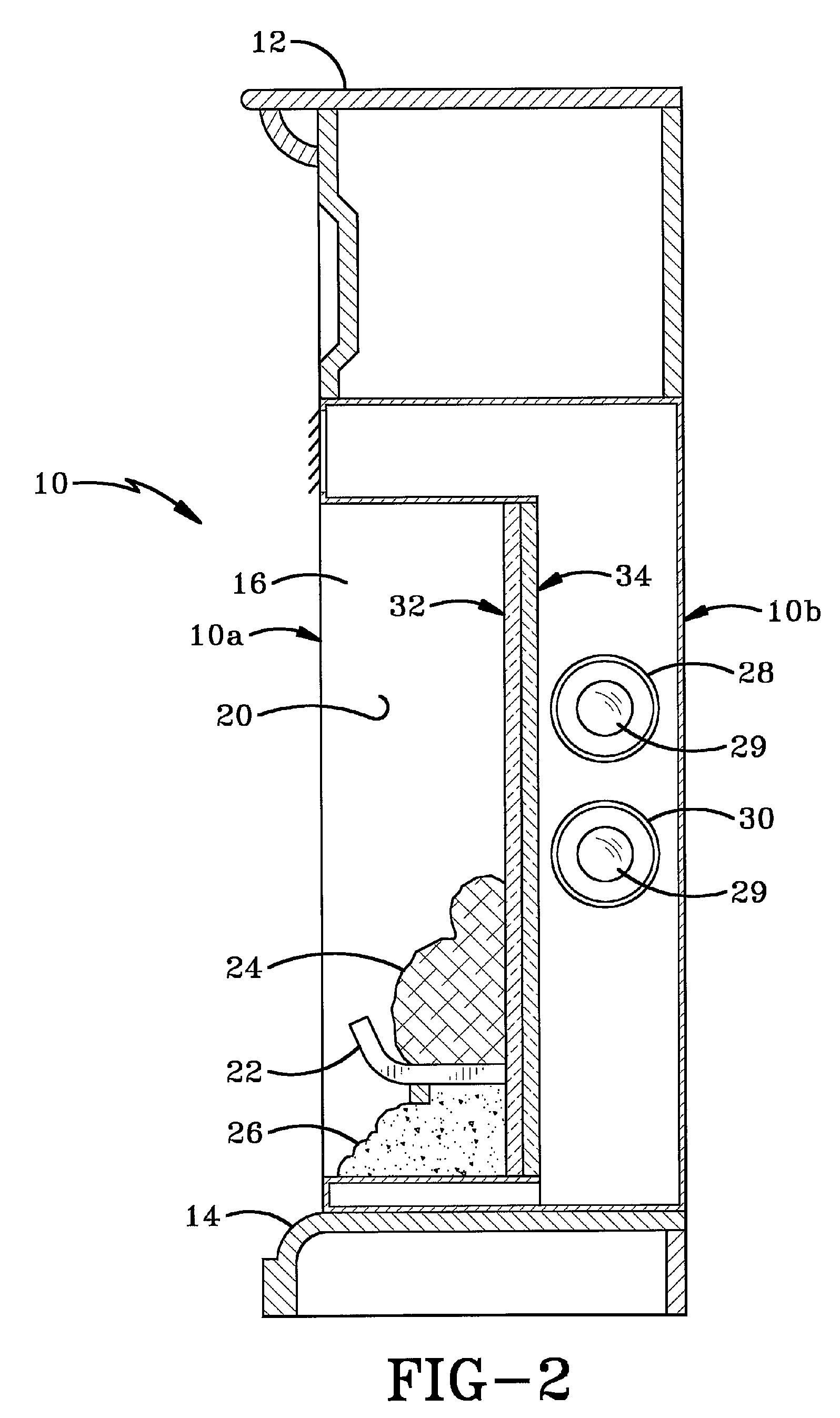

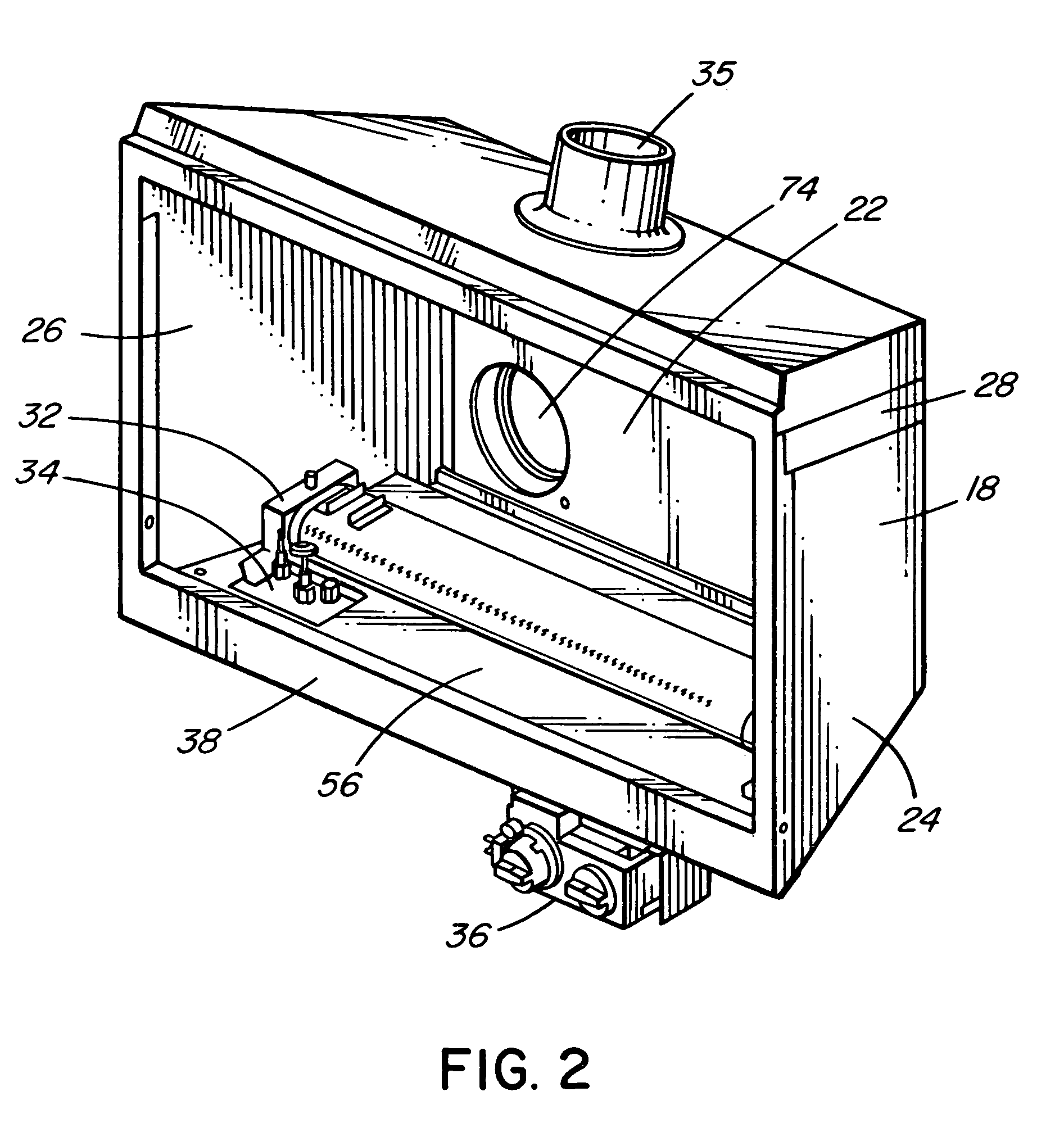

Panel for use in electric fireplace and fireplace incorporating the same

A panel for simulating a firebox for use in an electric fireplace and an electric fireplace incorporating the same. The electric fireplace includes housing with a grate, a plurality of artificial firelogs positioned on the grate and an ember bed positioned under the grate. A light source is positioned to transmit light through a plurality of apertures in a rotatable cylinder that is disposed rearwardly of the firelogs. The panel is a planar member that is positioned in the housing between the cylinder and the firelogs. The panel includes a pattern thereon which represents a firebox of a wood-burning fireplace. The pattern is formed by silk-screening, painting or etching a pattern of a flat wall of firebricks, a recessed wall of firebricks, stones, logs or any other markings that represent a firebox found in a fireplace. The light source preferably transmits light through flame-shaped apertures in the rotatable cylinder, thereby projecting flame-shaped images onto the panel or onto a screen that is positioned forwardly of the panel.

Owner:REFRACTORY SPECIALTIES

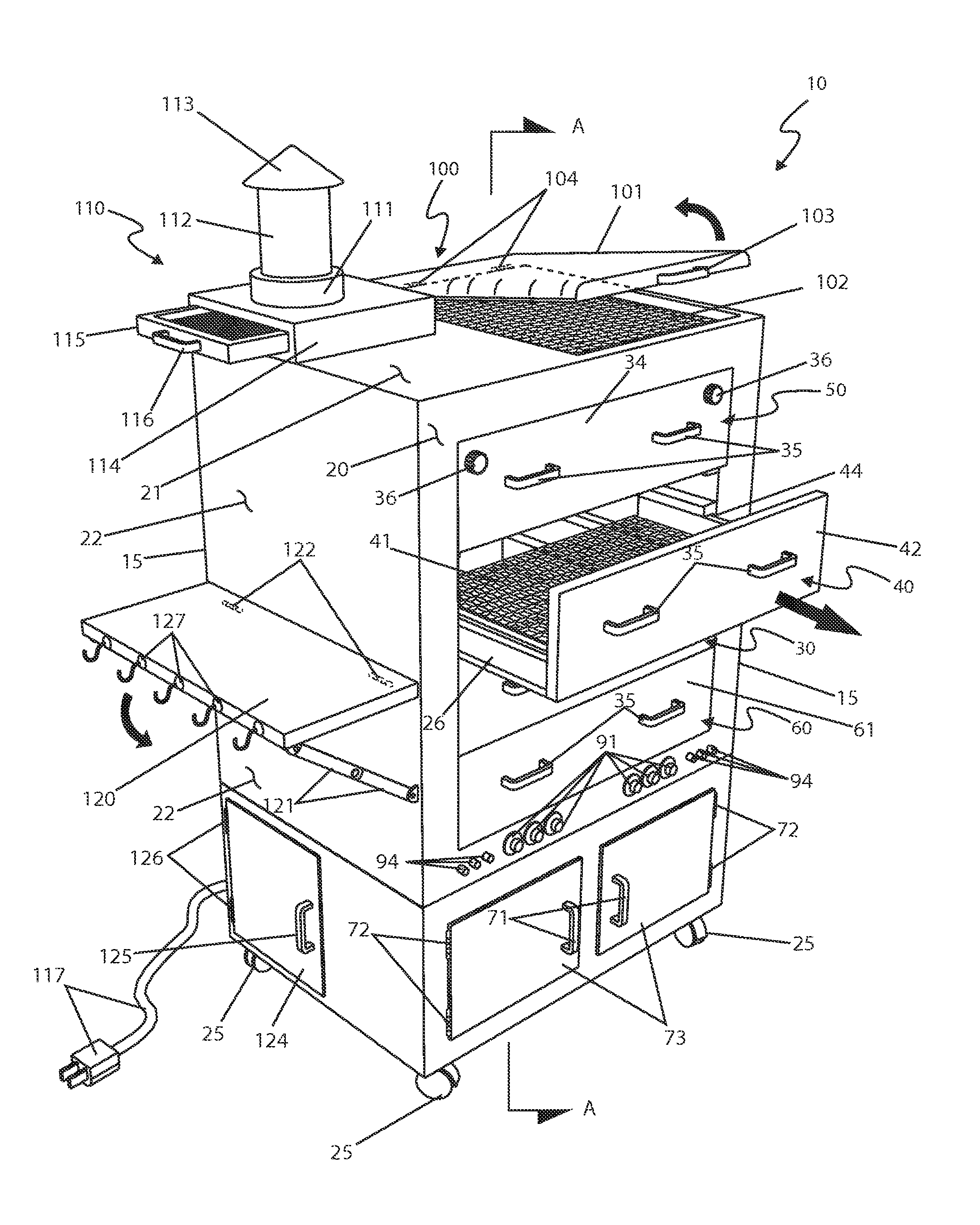

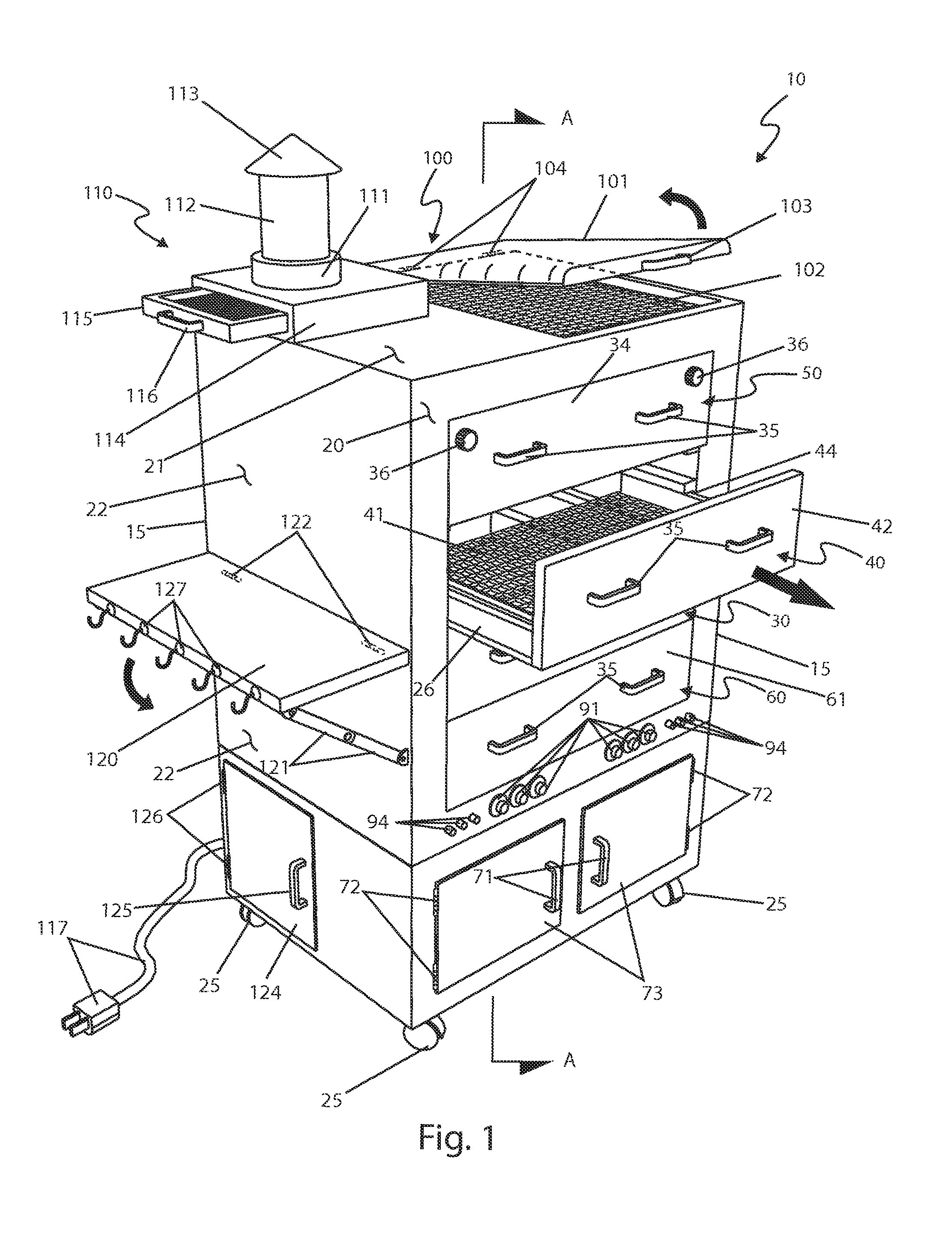

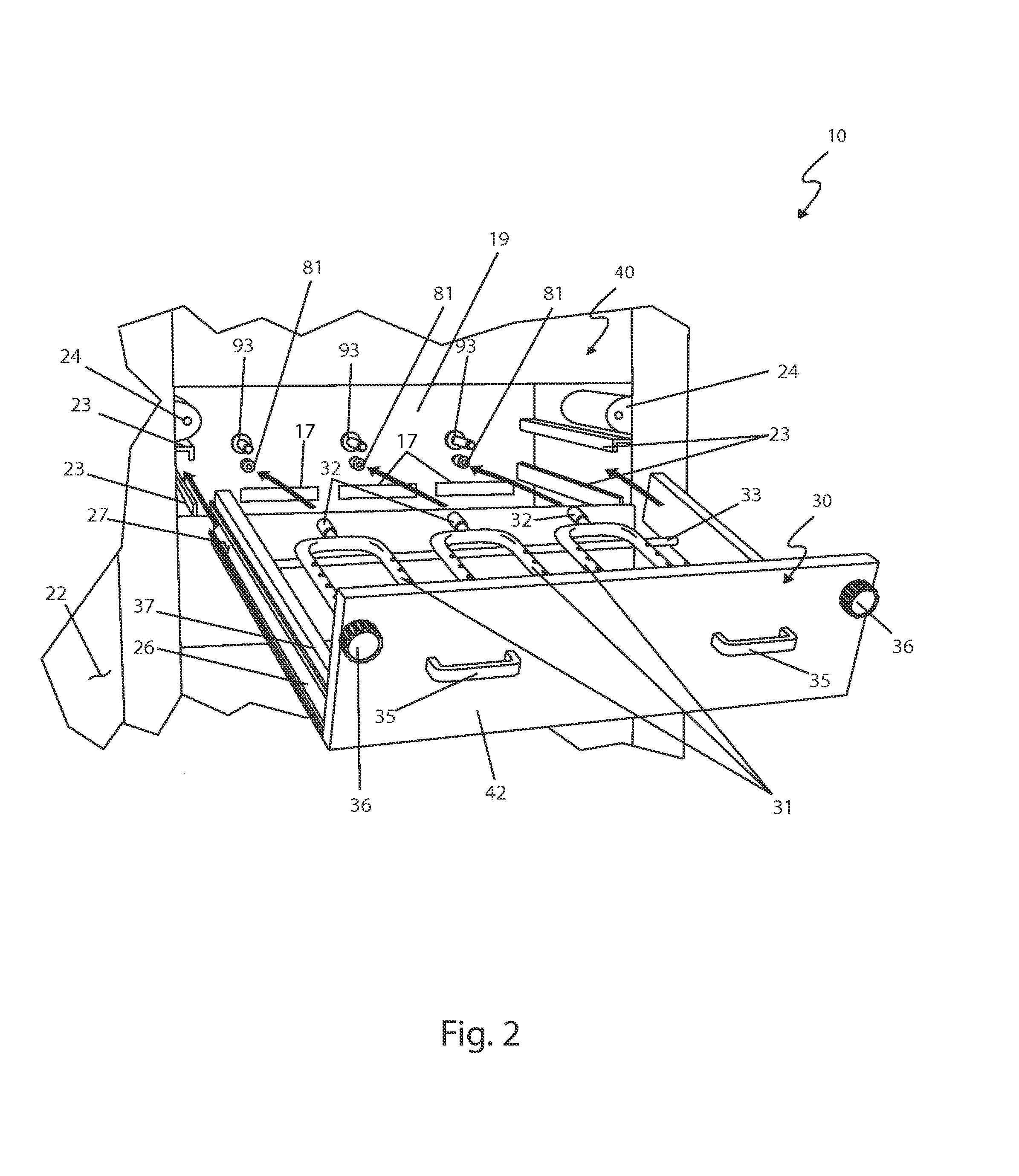

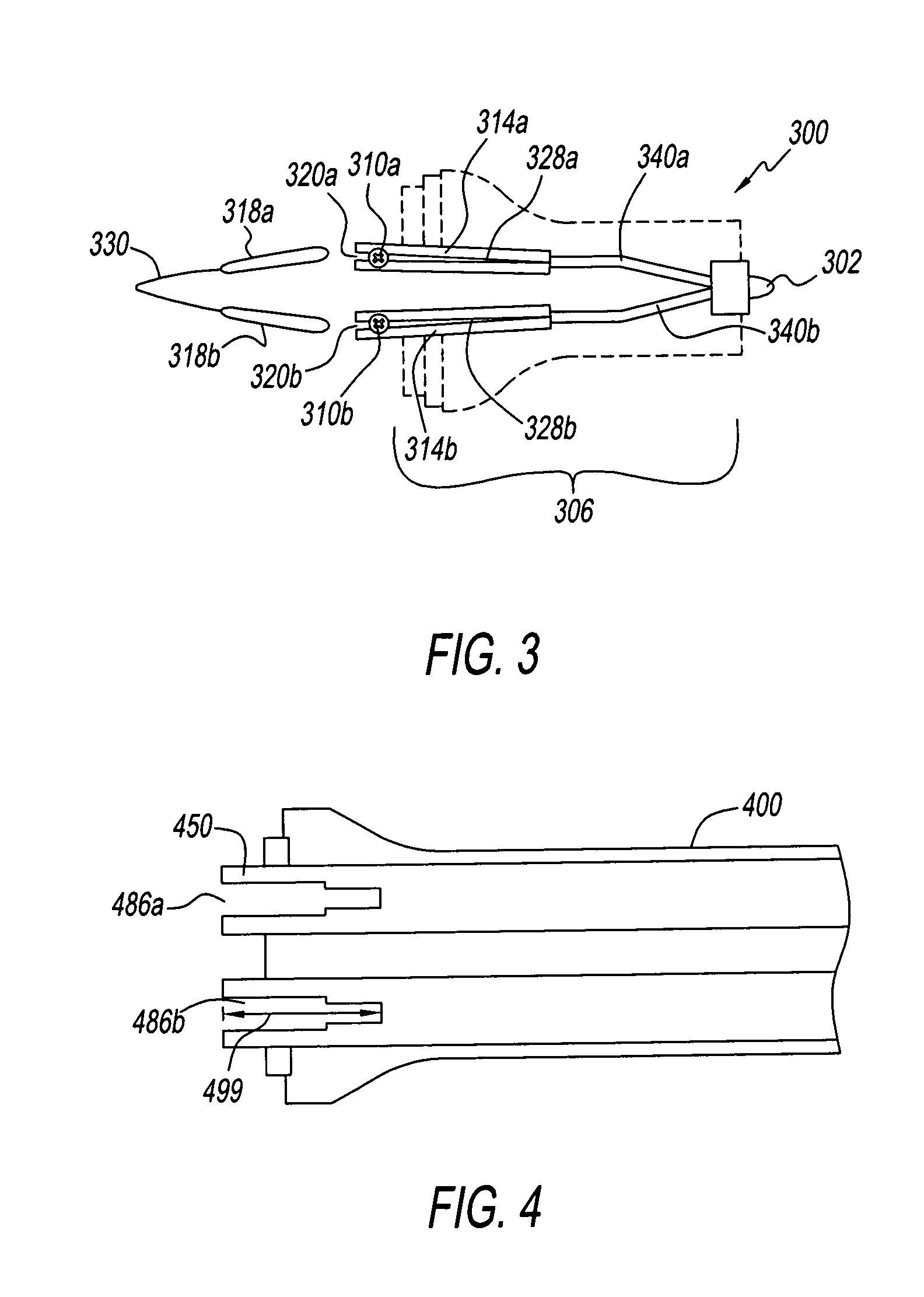

Residential flame broiler

InactiveUS8490614B1Avoid enteringEffective top and bottom cooking meanStoves/ranges foundationsLighting and heating apparatusCombustorBroiler chick

The invention discloses a gas grill with multiple enhancements to allow for easy grilling of foods, subsequent clean-up, and replacement of parts. In lieu of a top-opening lid, the apparatus provides a plurality of removable and insertable drawers, comprising a plurality of burner units, a plurality of grill trays, and a drip tray located in a vertical configuration therein a base unit. All drawers are interchangeable as desired. A storage compartment is located on the bottom directly below the drip tray and an exhaust assembly is located on the top for directing smoke away from the apparatus. The invention is adaptable to propane or natural gas. Additional drawers and burner assemblies are provided and may be used for charcoal or wood burning, bun or food warming, and water steaming. All drawers are easily removable on slides with a safety catch system for easy care and cleaning.

Owner:GREGORY MICHAEL S

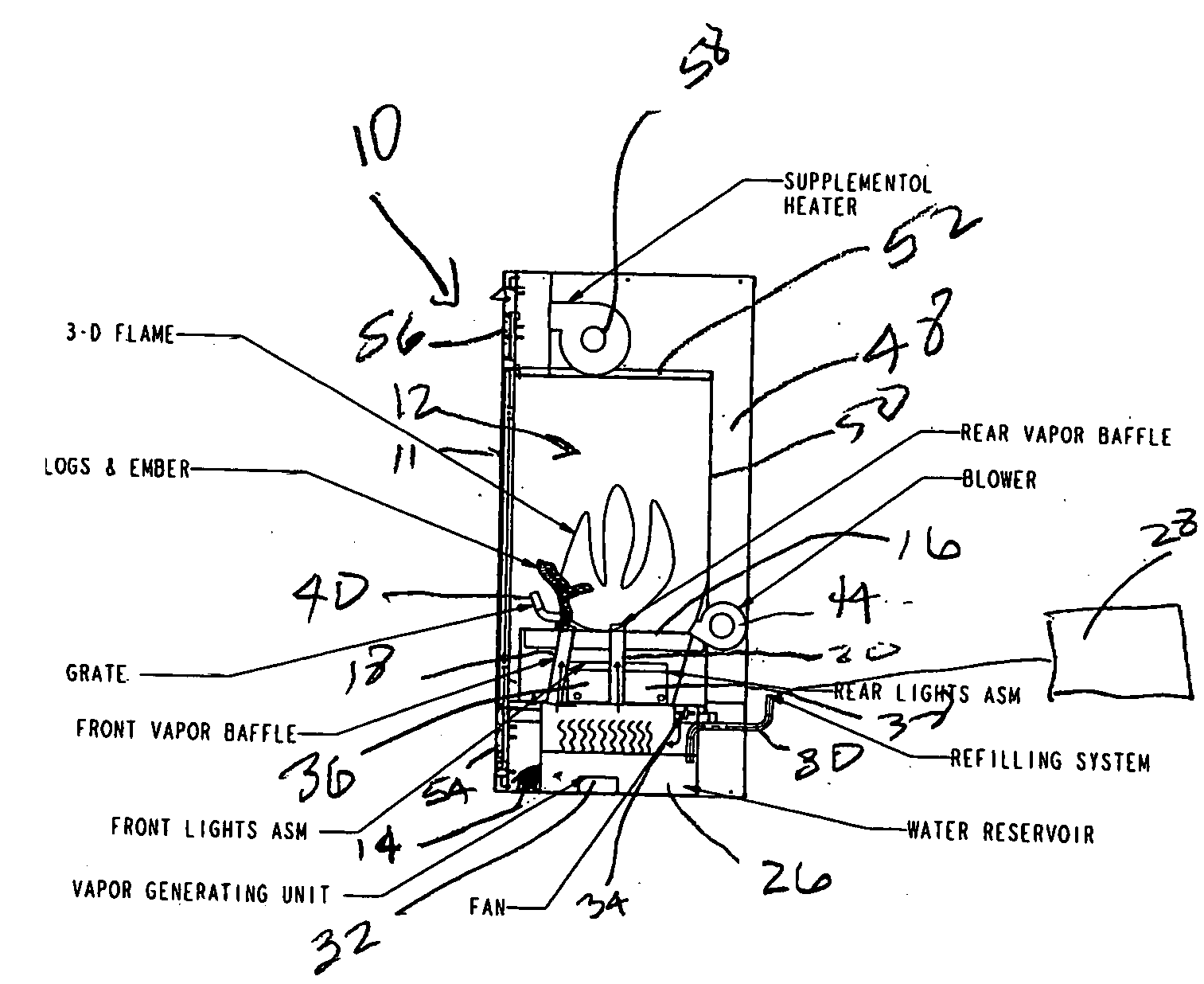

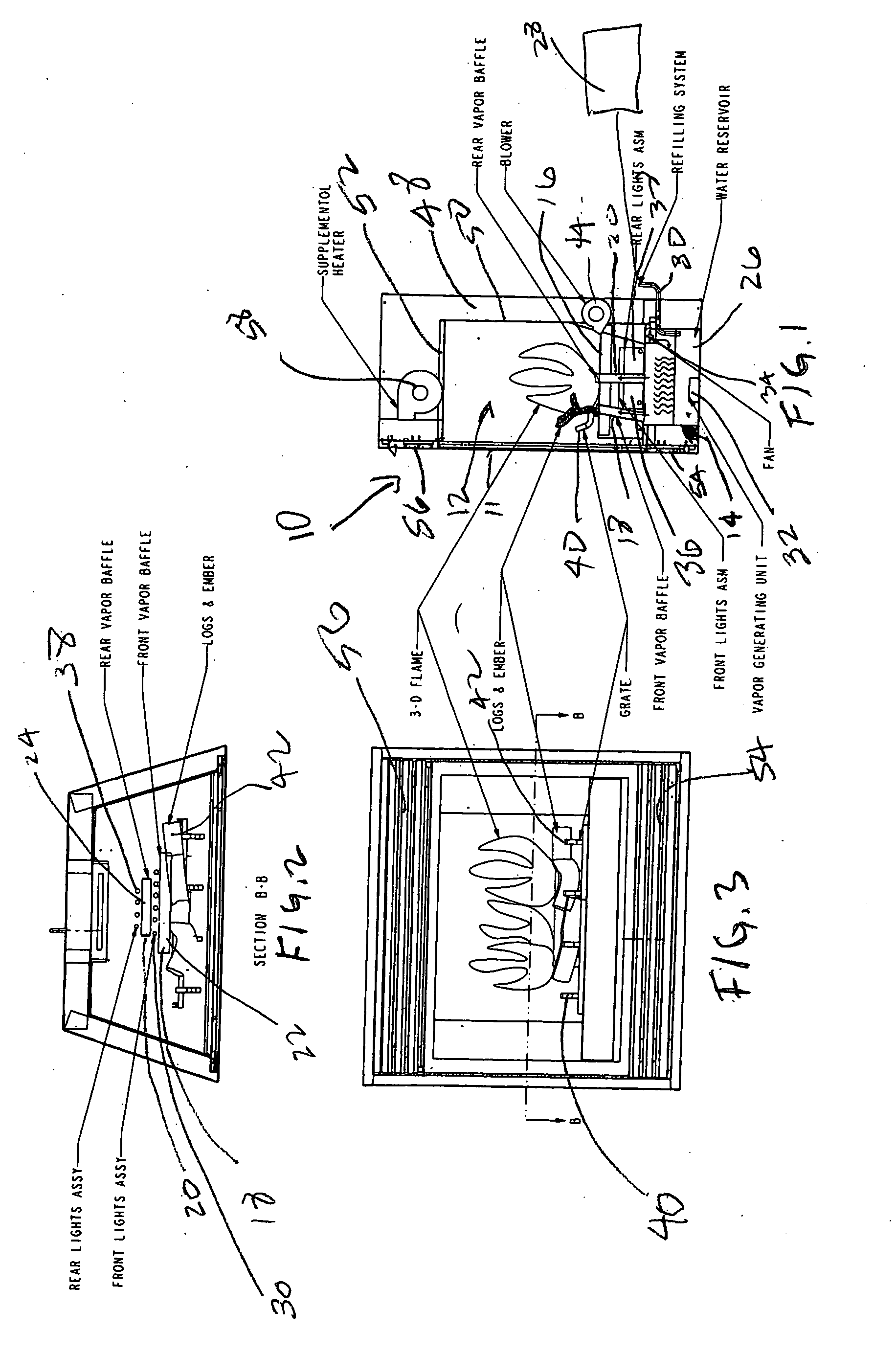

Systems for faux wood burning heating apparatuses, faux wood burning heating apparatuses and inserts for faux wood burning heating apparatuses producing realistic looking faux fire effects, and methods of emulating a wood burning heating apparatus

A faux wood burning heating apparatus is provided which includes a chamber having an opening for providing viewing access to the chamber, an opening for emitting a first curtain of mist in the chamber, a log in the chamber, and a light source for projecting a colored light on the curtain. The heating apparatus may be provided as an insert for incorporating in an opening. Moreover a system may be provided for creating the faux wood burning heating apparatus. A method for emulating a wood burning heating apparatus is also provided.

Owner:LENNOX HEARTH PRODS

Apparatus and method of automatically regulating intake of air into heating unit

InactiveUS6041771ACounteracting forceDischarge cleaningCombustion-air/flue-gas circulation for stovesCheck valvesCombustion chamberGas pressure

This invention relates to a novel apparatus and method for automatically and dynamically regulating the intake of air into the combustion chamber of a heating unit such as a wood burning stove, furnace, or fireplace to ensure even and efficient burning of fuel. More particularly, this invention pertains to a method and apparatus that uses negative gas pressure in the heating unit's flue, and no additional temperature or pressure sensors, to automatically and dynamically control a damper regulating intake of air into the combustion chamber in inverse relation to changes in negative flue gas pressure. This method and apparatus are especially useful in combination with a heating unit having two combustion chambers, one chamber for combustion of solid fuel and a second chamber for further combustion of exhaust gases and other byproducts from combustion in the first chamber. The two-stage combustion in a dual chamber heating unit is an especially dynamic situation where traditional static controls are not very effective.

Owner:HAYES CECIL JOSEPH

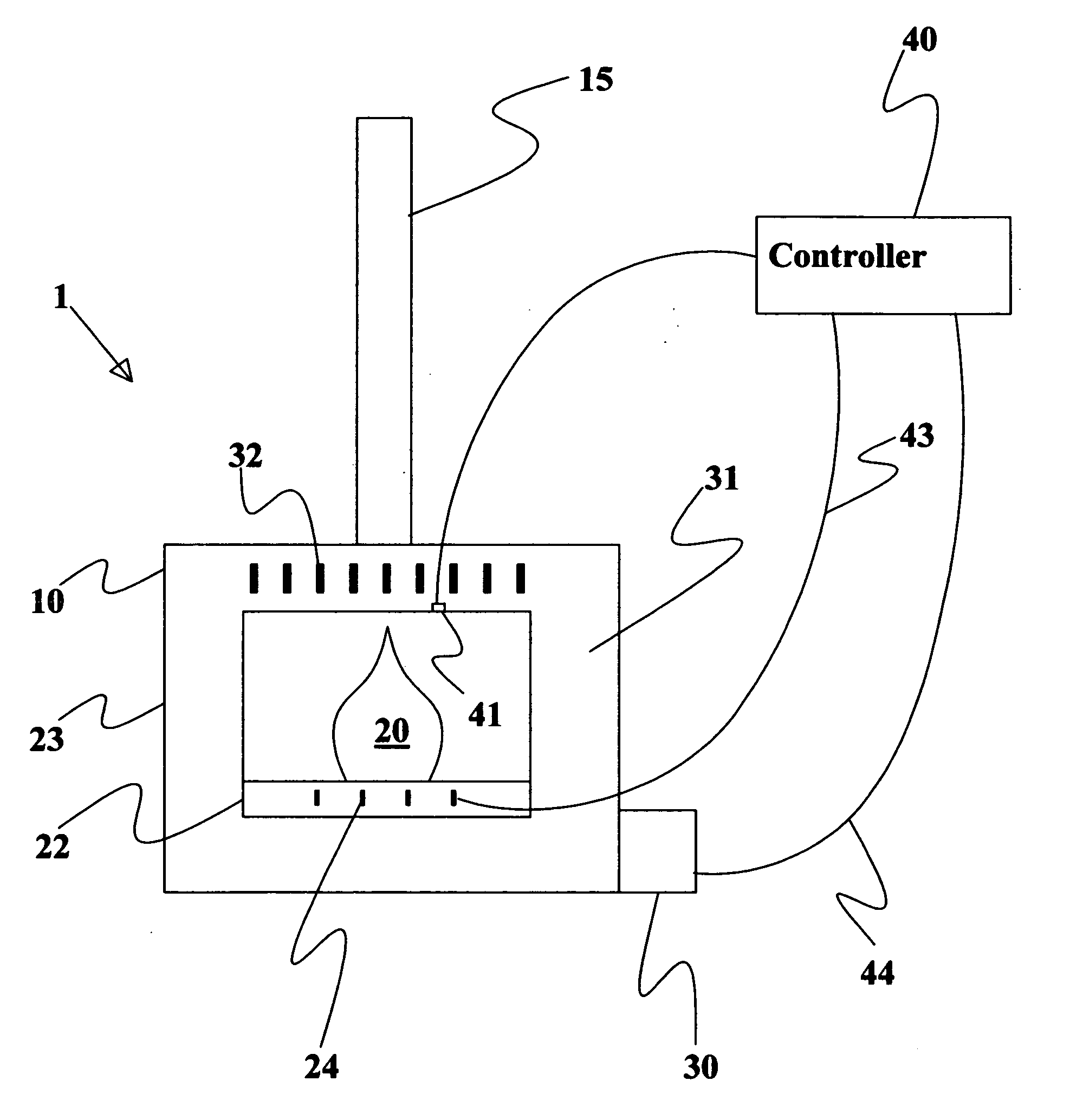

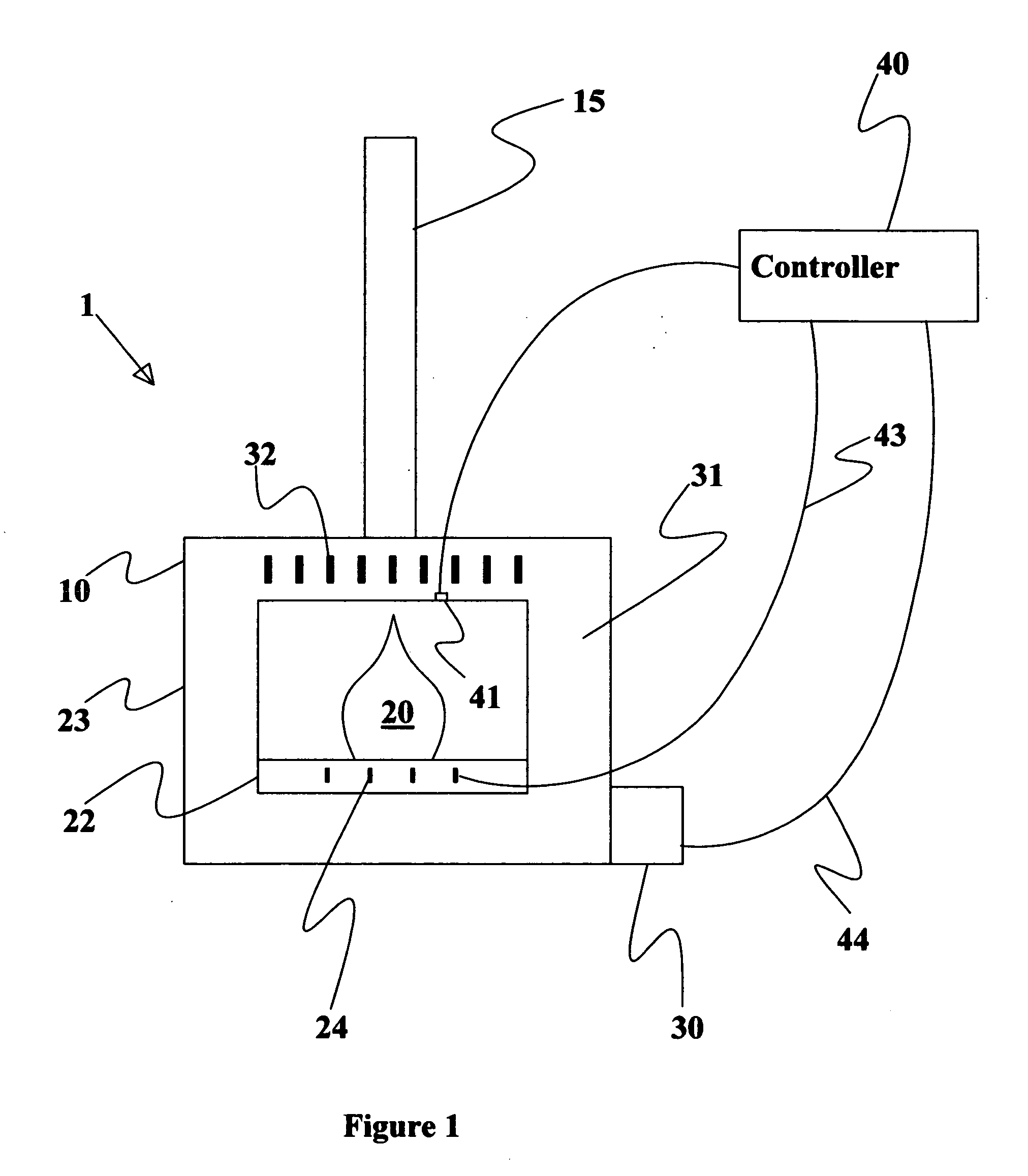

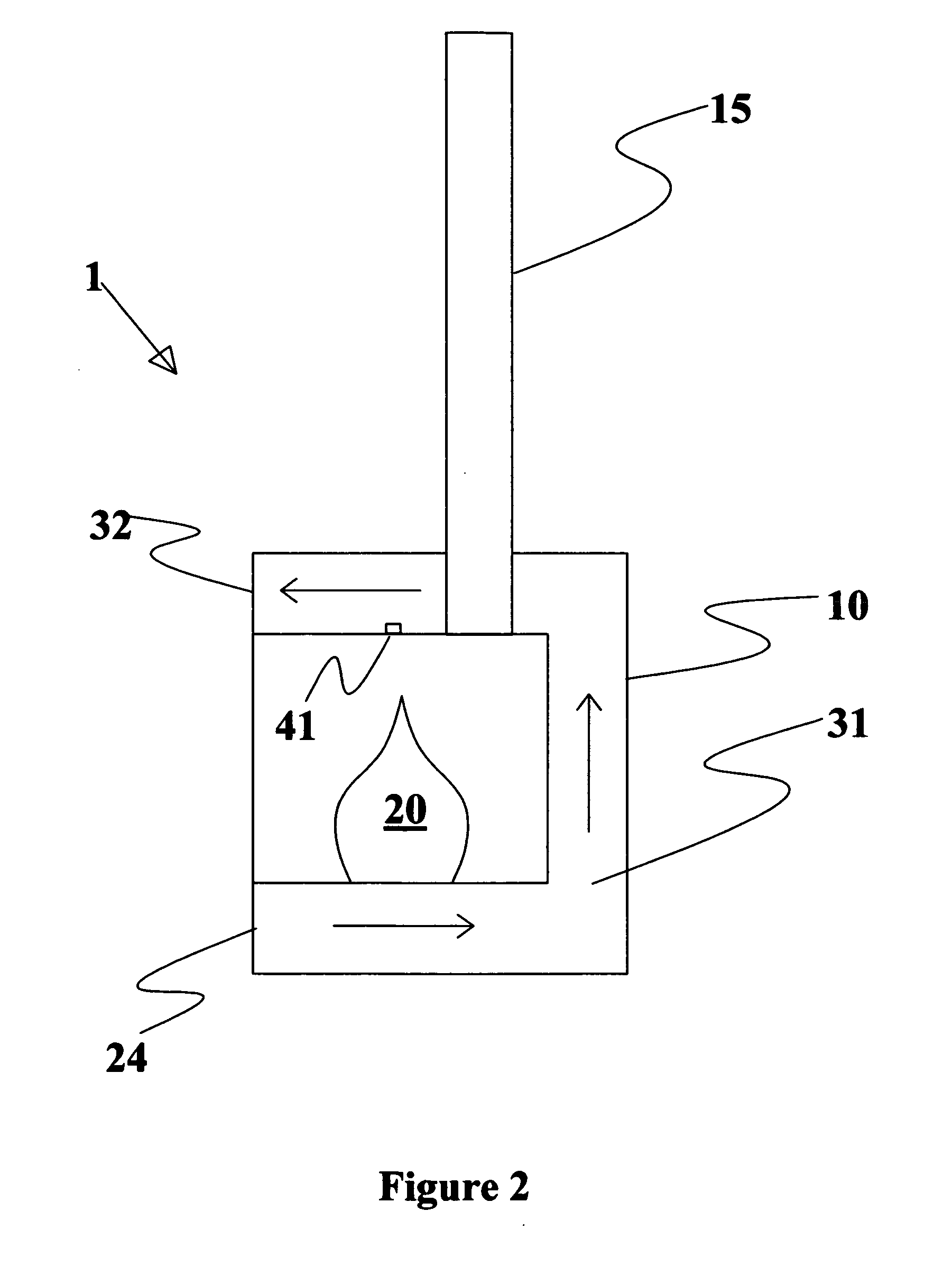

Intelligent and adaptive control system and method for wood burning stove

InactiveUS20070289589A1Maximum burn timeMaximum heating efficiencyDomestic stoves or rangesWater heatersCombustion chamberControl system

A control system and method for a wood stove adjustably operates in accordance with operational characteristics of the wood stove. The system operates air vents to the combustion chamber of the stove to control operating temperatures of the stove. The air vents are adjusted proportionally to changes in temperature of the stove. The temperature of the stove may be controlled to achieve desired operational and burn characteristics. The system further includes a heat exchange fan. The system controls the speed of the heat exchange fan based upon the operational characteristics of the stove.

Owner:MCFARLAND DANIEL T

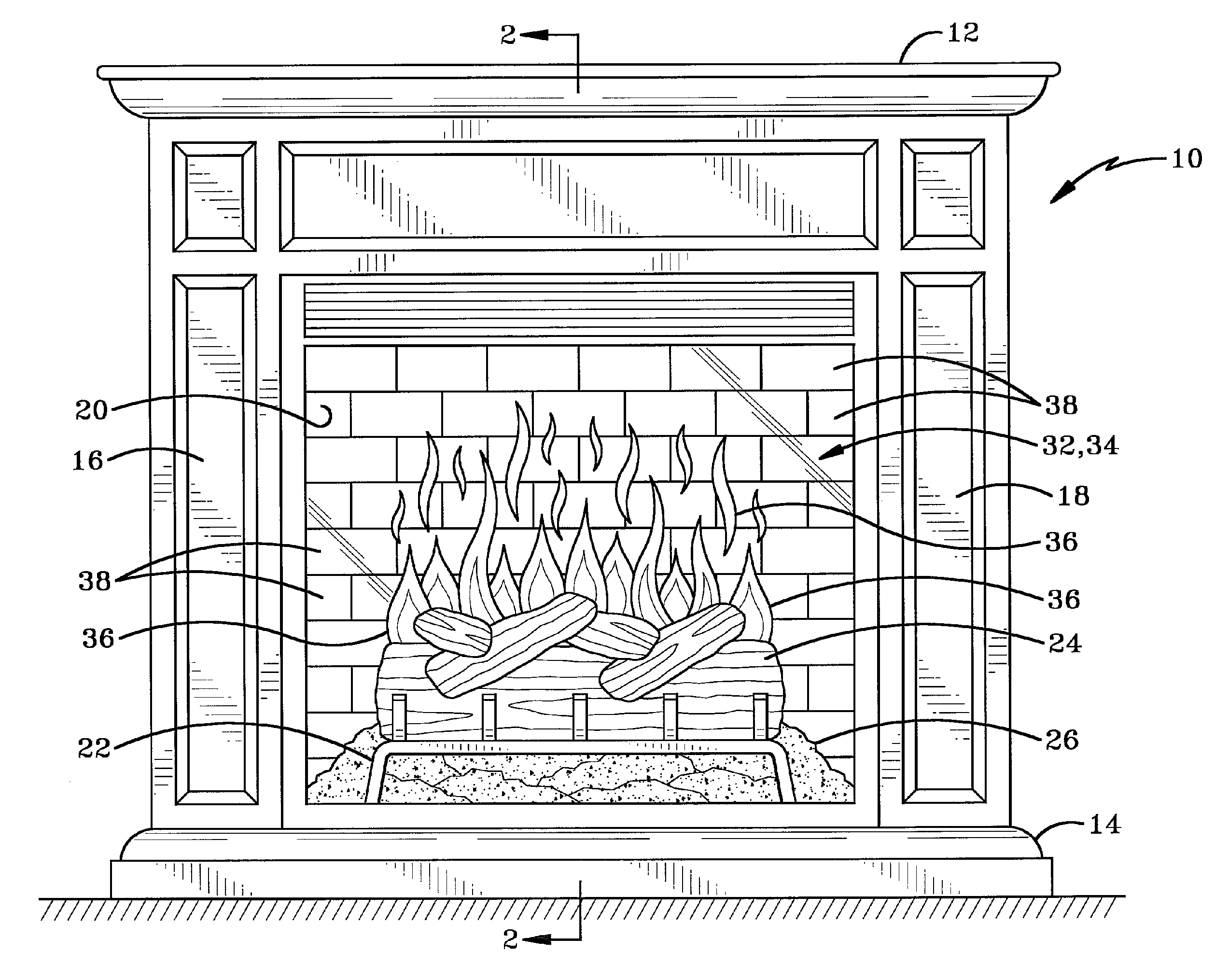

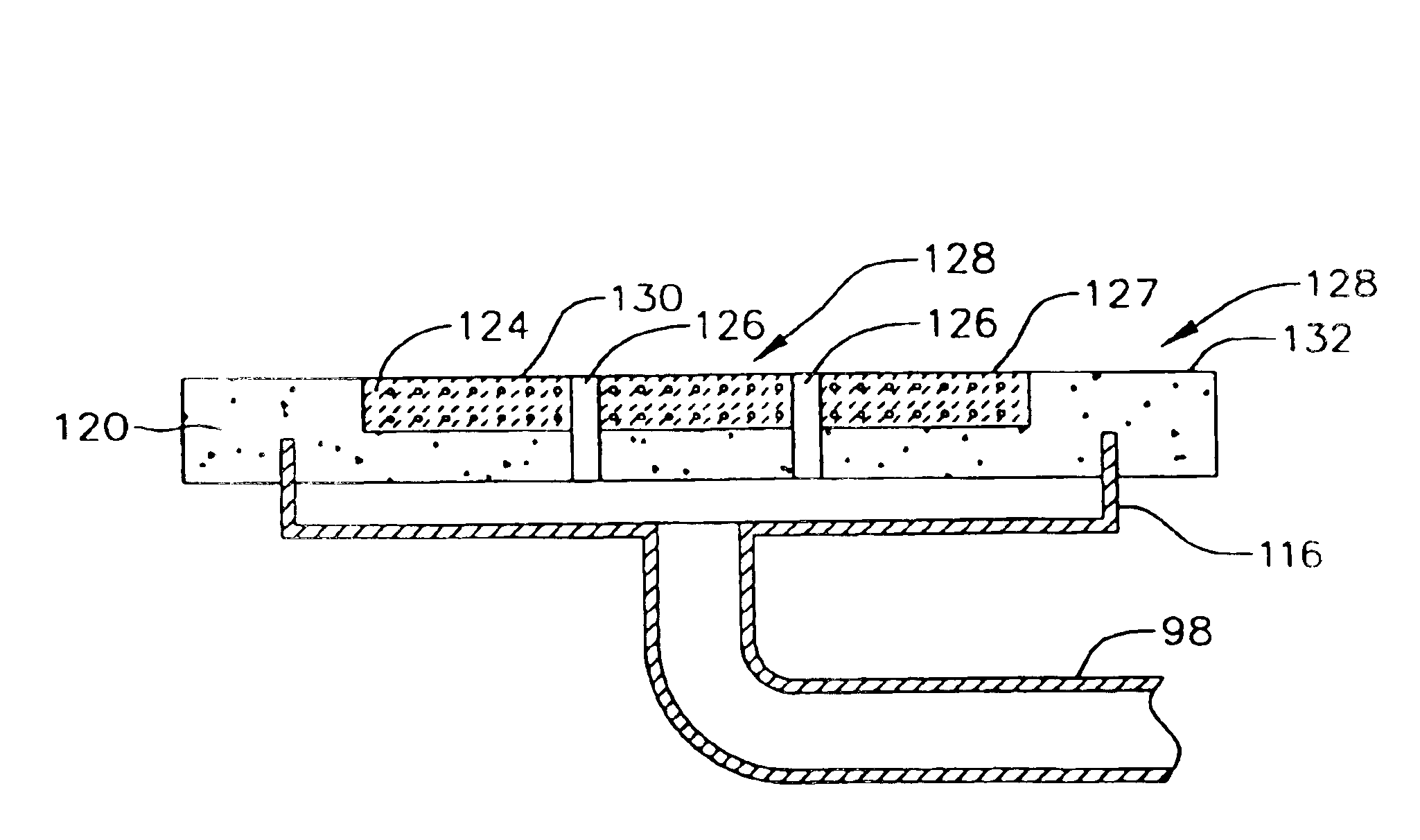

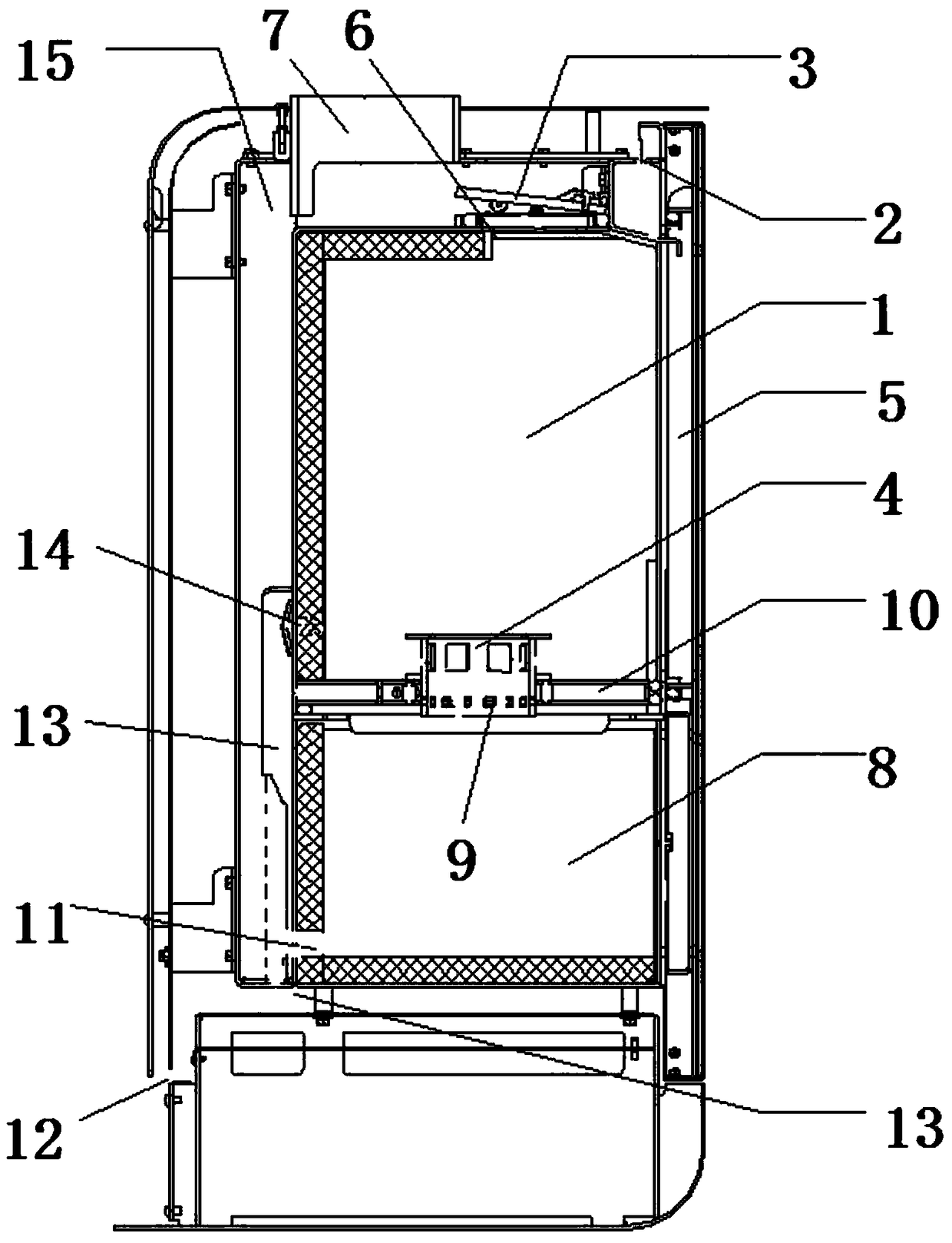

Three-dimensional panel for use in electric fireplaces and fireplace incorporating the same

A three-dimensional panel used in an electric fireplace to simulate a firebox of a wood burning fireplace and an electric fireplace incorporating the same. The electric fireplace includes housing having a light source positioned so as to transmit light through the panel. The panel is vacuum-molded to have a pattern formed therein and thereon. The pattern represents elements found in a wood burning fireplace such as firebricks, stoneworks, logs, a logset, a grate and embers or any other elements typically found in a wood-burning fireplace's firebox. The pattern is formed by a combination of molding these elements into the materials from which the panel is made and applying coloring agents to the panel either during the molding process or after the panel has been formed. The panel may be positioned between an artificial logset and the light source if the logset is not molded into the panel.

Owner:REFRACTORY SPECIALTIES

Gas burner

A gas burner is provided that simulates wood burning fire and the glowing ember effect of real wood or coal burning. The burner has a burner pan which is covered by a refractory material and a ceramic material. Burner ports are formed through the refractory and ceramic materials. Methods for forming such a burner are also provided.

Owner:INNOVATIVE HEARTH PROD

Wood firing technology for purple clay ware

The invention relates to a technology of purple clay ware and particularly relates to a wood firing technology for purple clay ware, belonging to the technical field of purple clay ware firing. A finished product of purple clay ware is prepared by a series of steps such as throwing and drying, fettling and drying, glazing and drying and kiln loading and wood firing. In the invention, a reduction firing way is realized by adding wood into an electric kiln and replaces the way of wood firing in a gas-fired kiln in the prior art; more than 30% of reducing gas CO2 generated by wood burning in the kiln is adopted for strong reduction of iron oxide in the purple clay so that the purple clay ware has magnetism and ability of improving water quality; and meanwhile, purple clay ware with rich and bright colors can be formed without adding a coloring agent, and the artistic value of the purple clay ware is increased.

Owner:管汝瑜

Wood burning stove

InactiveUS20080276924A1Fuel efficiencySimple and economical to manufactureDomestic stoves or rangesLighting and heating apparatusParticulatesCombustion chamber

A wood stove defining an upper combustion chamber and a lower fire box having two inwardly and downwardly angulated opposed fuel chutes for gravitational feeding of fuel to the fire box for extended burning. A rectilinear air channel spaced apart from a back wall of the stove, and structurally attached thereto, provides a channel for combustion products and byproducts to pass from an upper inner portion of the stove adjacent a chimney port downwardly to the fire box to pass through the primary fire zone for more complete combustion of the combustion products and combustion byproducts to enhances heat production and reduce wasting of smoke generating particulates and vapors.

Owner:MCMILLAN LOWELL A

Method for strengthening ceramicization of floated crystallizable glass

InactiveUS20120108414A1Reduced impact strengthReduce strength bending tensile strengthFire protectionMicrowave

A method of ceramicizing a floated glass is provided where the glass ceramic material obtained thereby has high stability because of the special quality of the atmosphere in the ceramicizing process. The glass ceramics thus obtained have special surface properties that avoid crack formation. Thereby very high bending tensile strengths are achieved. These glass ceramics can be used as fire protection glass, hot plate of a cooker having a coating on the lower side, safety glass, panes of wood-burning fireplace inserts, in colored form as hot plate of a cooker, base plate, thermally resistant panel lining in furnaces and microwave facilities.

Owner:SCHOTT AG

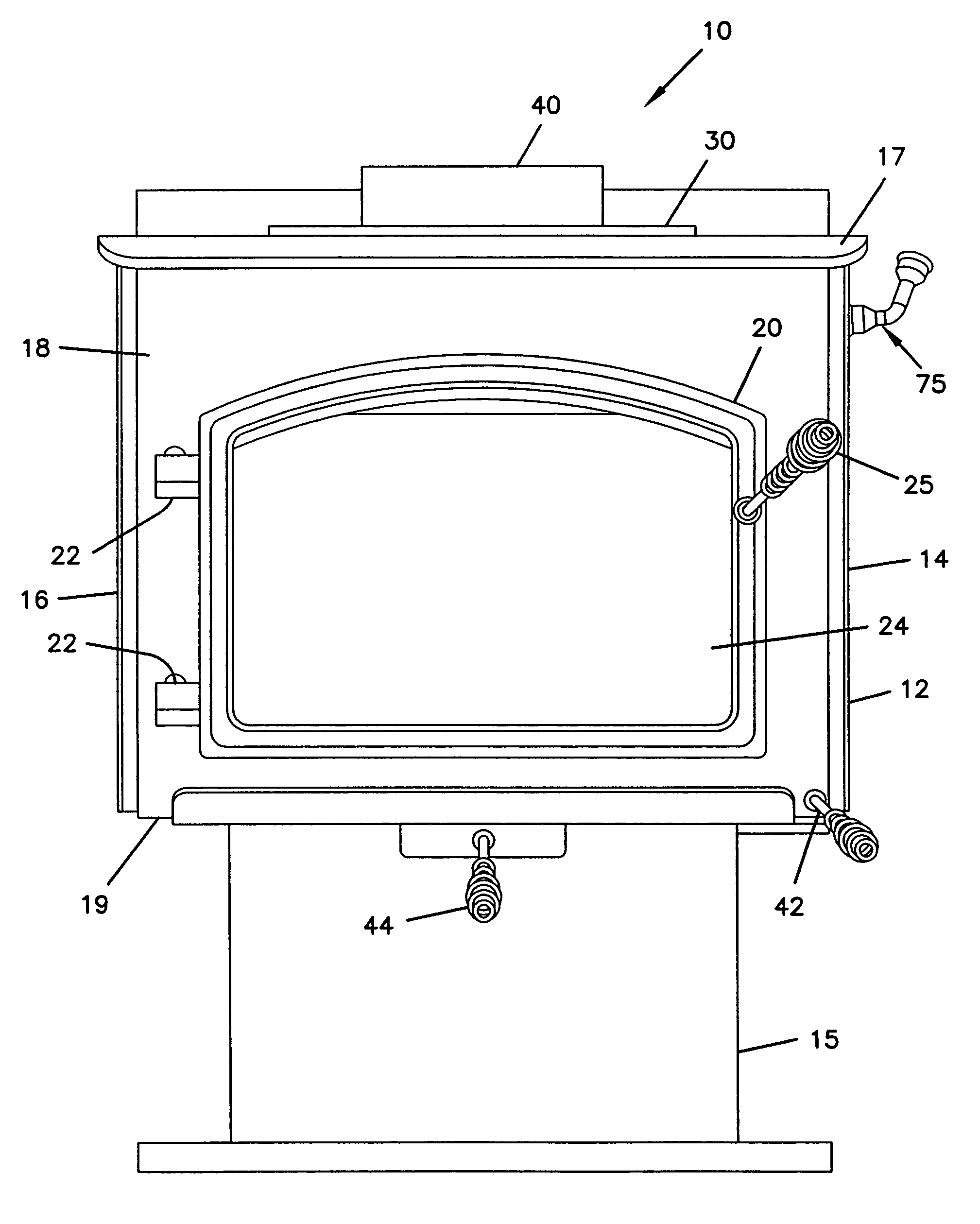

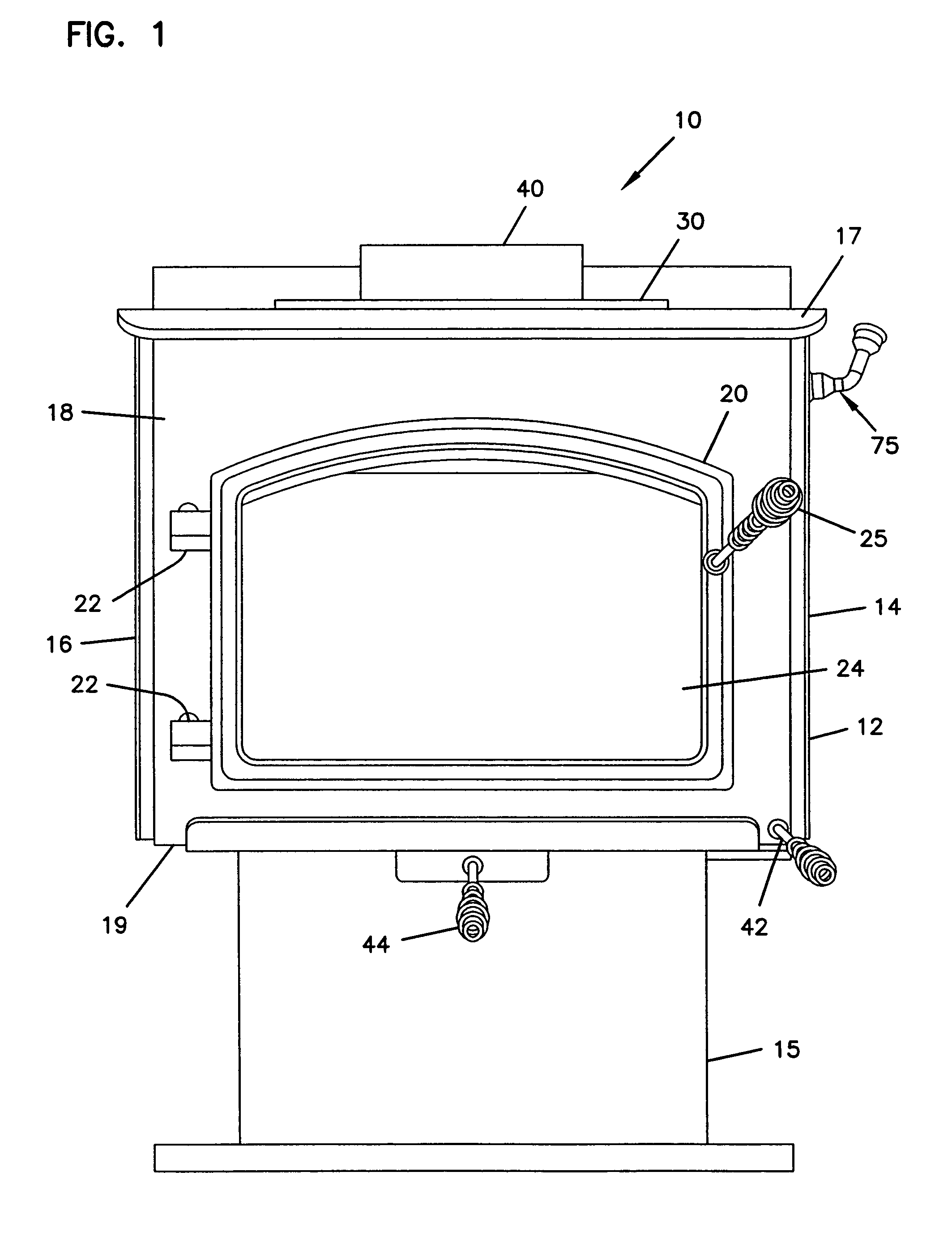

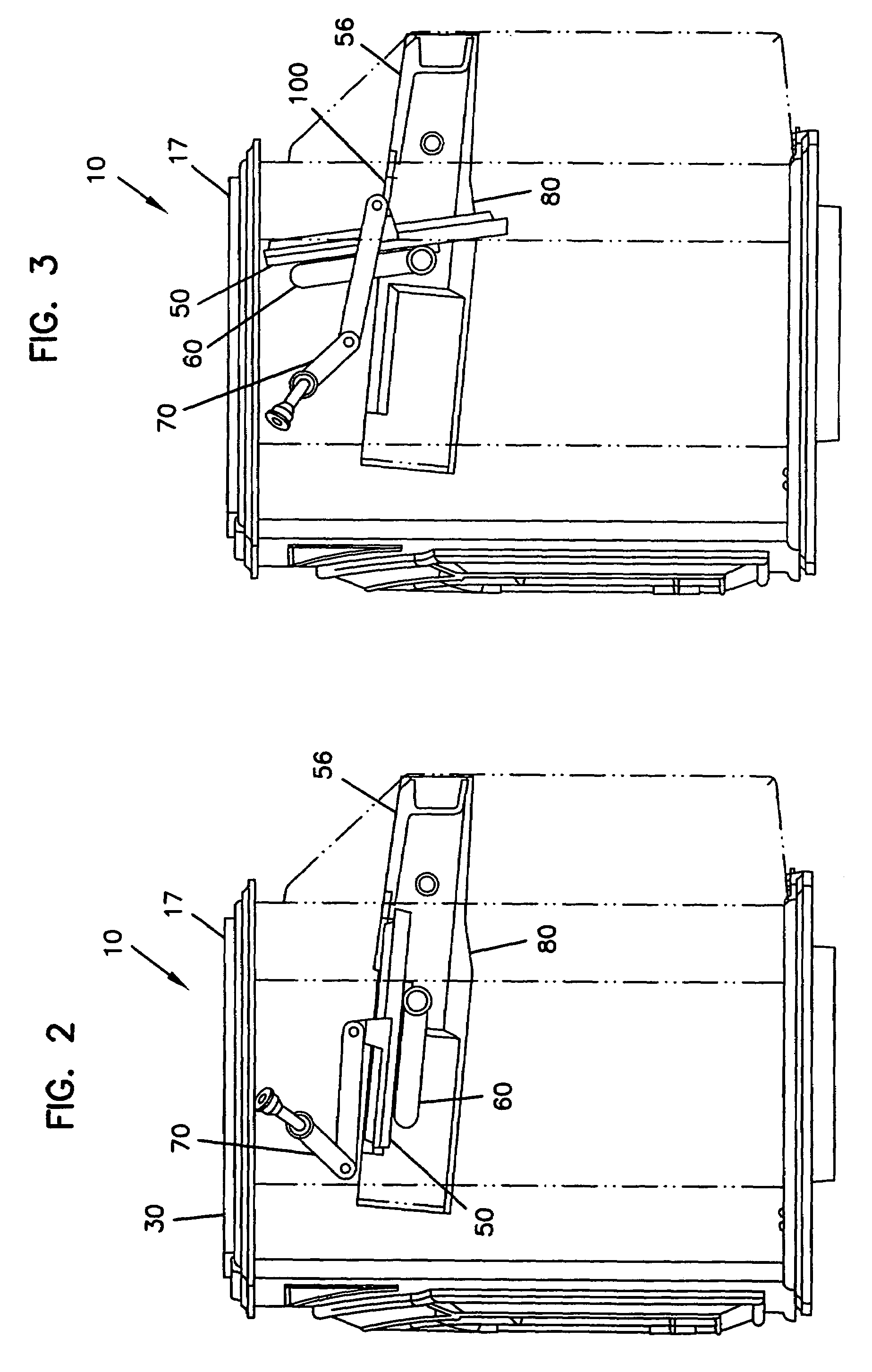

Wood burning stove having pivoting baffle and method

InactiveUS7216645B2Speed up the flowEasy accessCombustion-air/flue-gas circulation for stovesCooking fumes removalCombustion chamberFirst pathway

Owner:HEARTH & HOME TECH

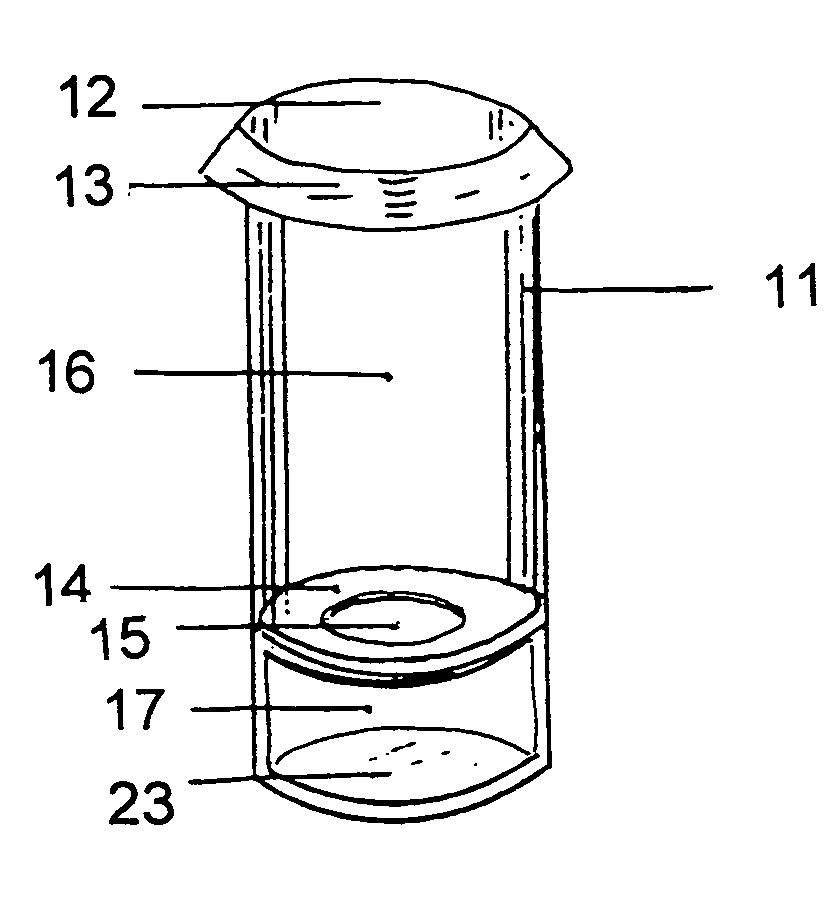

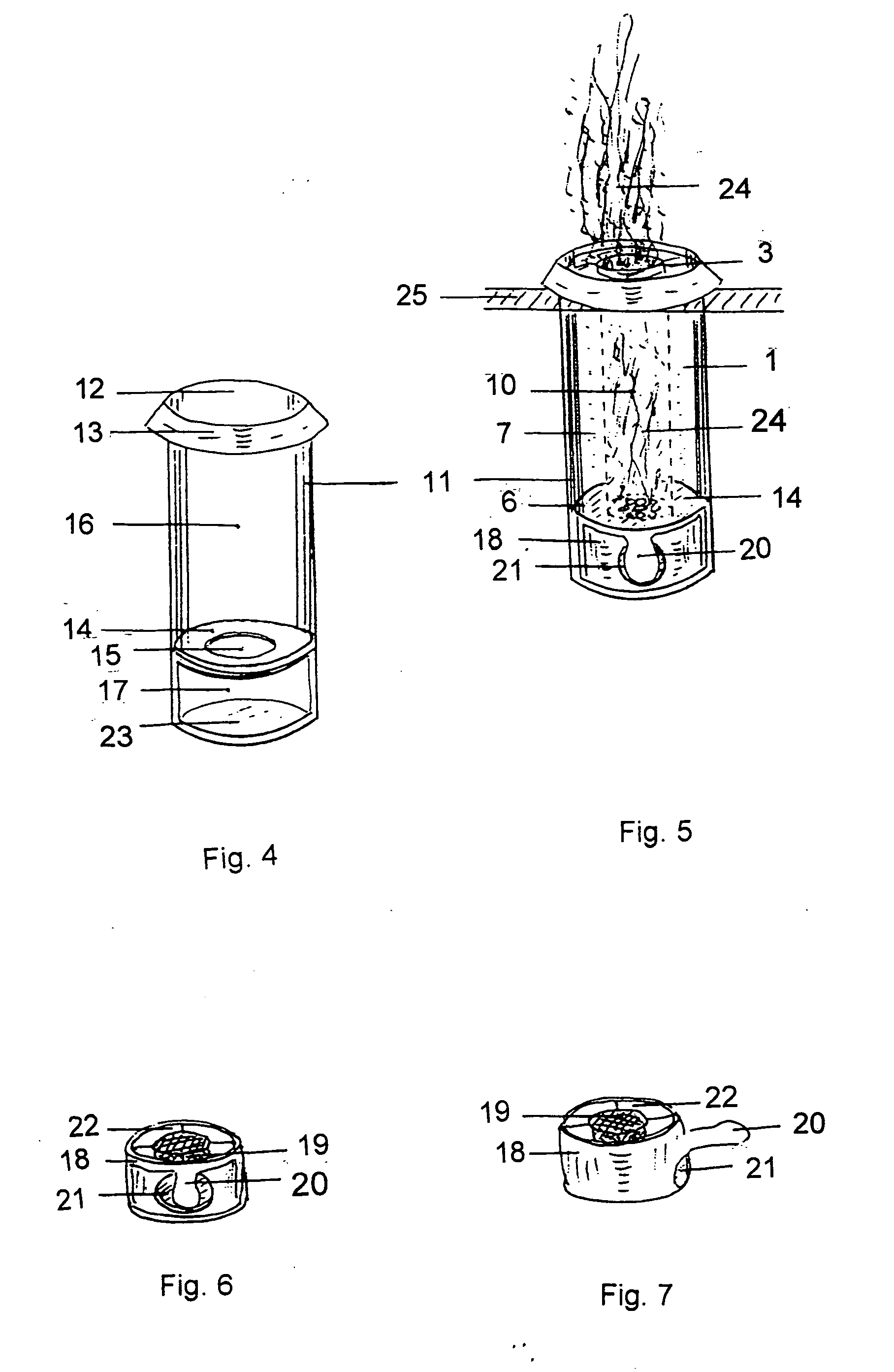

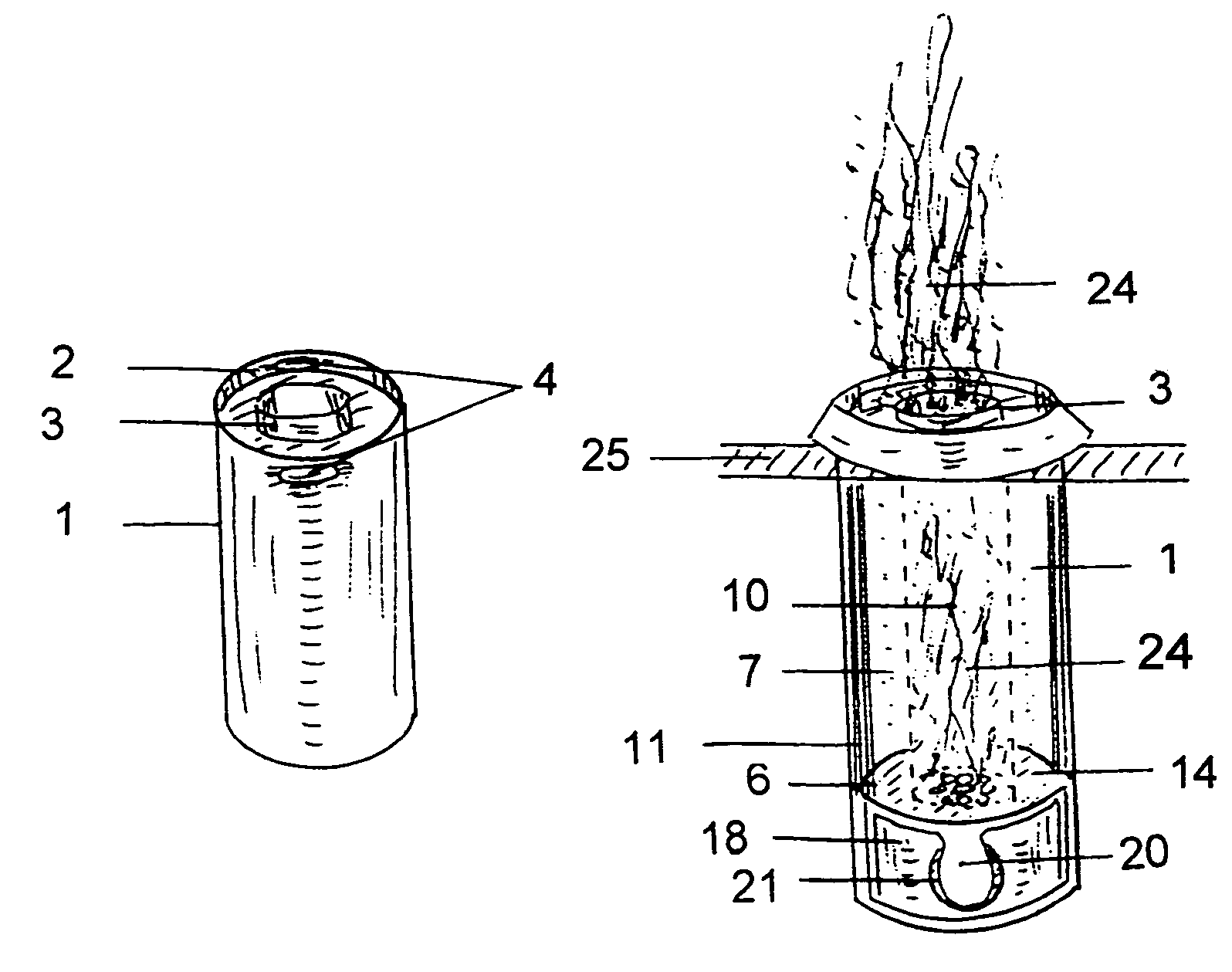

Log cartridge burning system

A Log Cartridge Burning System is provided comprising a simple, convenient and manageable wood burning system which can easily be applied for use to cook and heat. The log cartridge is comprised of a flammable body of compressed material and a bore formed and sealed by the use of a protective outer paperboard tube and a protective inner paperboard tube together with a top and bottom paperboard cover which serve to hold and maintain the integrity of the entire cartridge without the use of any wax binders. The flammable body of compressed material may be made partly or entirely from natural combustible materials such as sawdust or wheat hulls. The burn pot is specially designed to accommodate the log cartridge of the present invention. The log cartridge burning system can easily be utilized in a variety of appliances such as a patio heater or fireplace, barbecue or grill, or other cooking and heating appliances.

Owner:LEE HENRY K

Jun-porcelain wood burning glaze

The invention relates to a jun-porcelain wood burning glaze. The glaze is prepared from, by weight, 28-35 parts of quartz, 19-23 parts of potassium feldspar, 7-12 parts of albite, 15-18 parts of plant ash, 10-15 parts of limestone, 3-4 parts of talc and 1-2 parts of ferric oxide. The purposes of making the glaze surface of prepared jun porcelain cyan, making the glaze color uniform and mild and making the glaze surface slightly yellow can be achieved, and the jun-porcelain wood burning glaze has the advantages of being low in cost and high in rate of finished products.

Owner:温书强

Auxiliary smoke arresting unit

InactiveUS8011359B1Safe openDomestic stoves or rangesCombustion ventilatorsPulp and paper industryWood burning

Smoke escaping from an outdoor wood burning furnace may be effectively arrested with a smoke arresting unit. By mounting a smoke gathering manifold above the furnace door operatively connected to a vacuum source for drawing smoke discharging from the furnace chamber through an open furnace door, the gathered and arrested smoke may be discharged through a separate discharging chimney. The vacuum source may be activated when the furnace fan is switched off and the furnace door is opened for refueling.

Owner:SCHULTZ CHRISTOPHER T

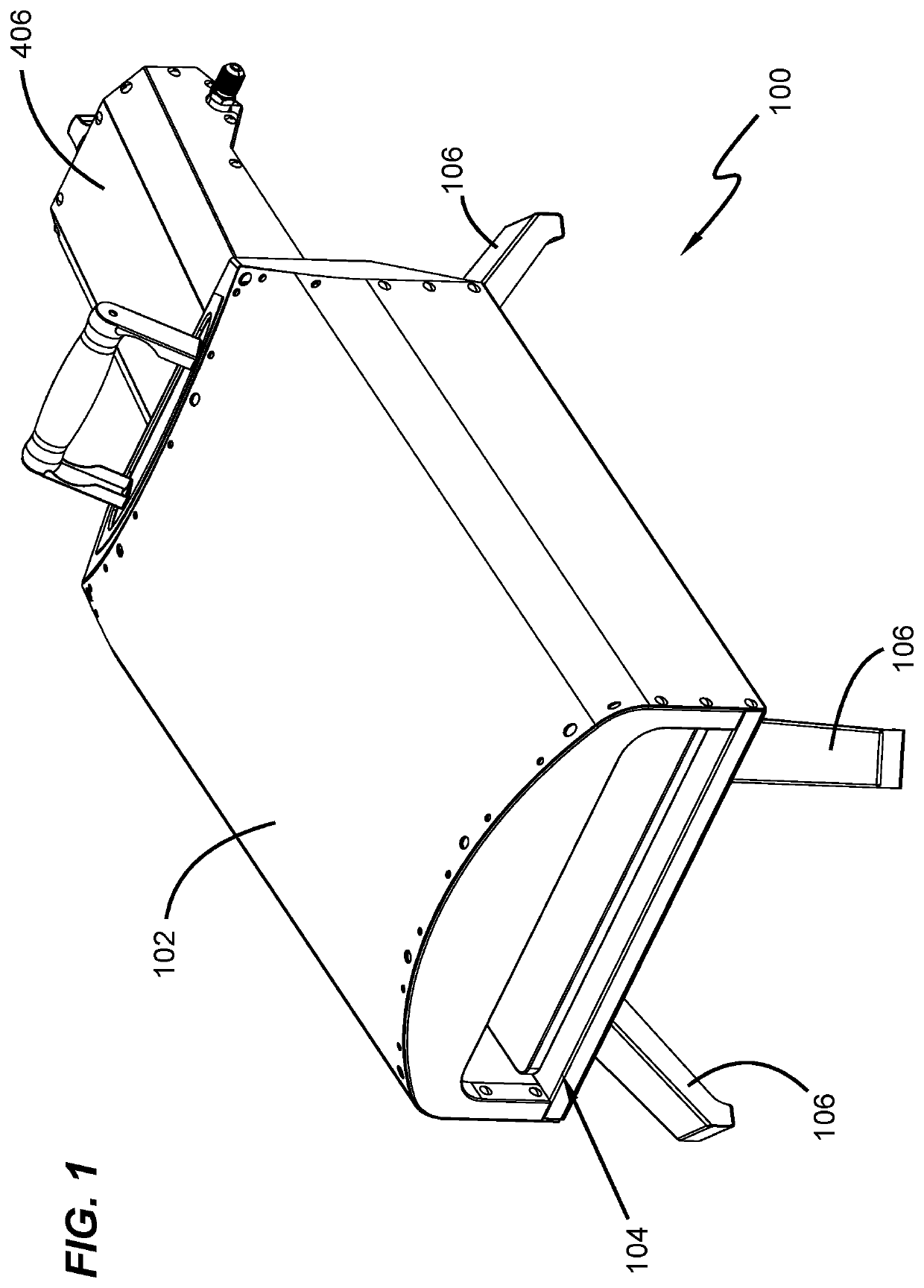

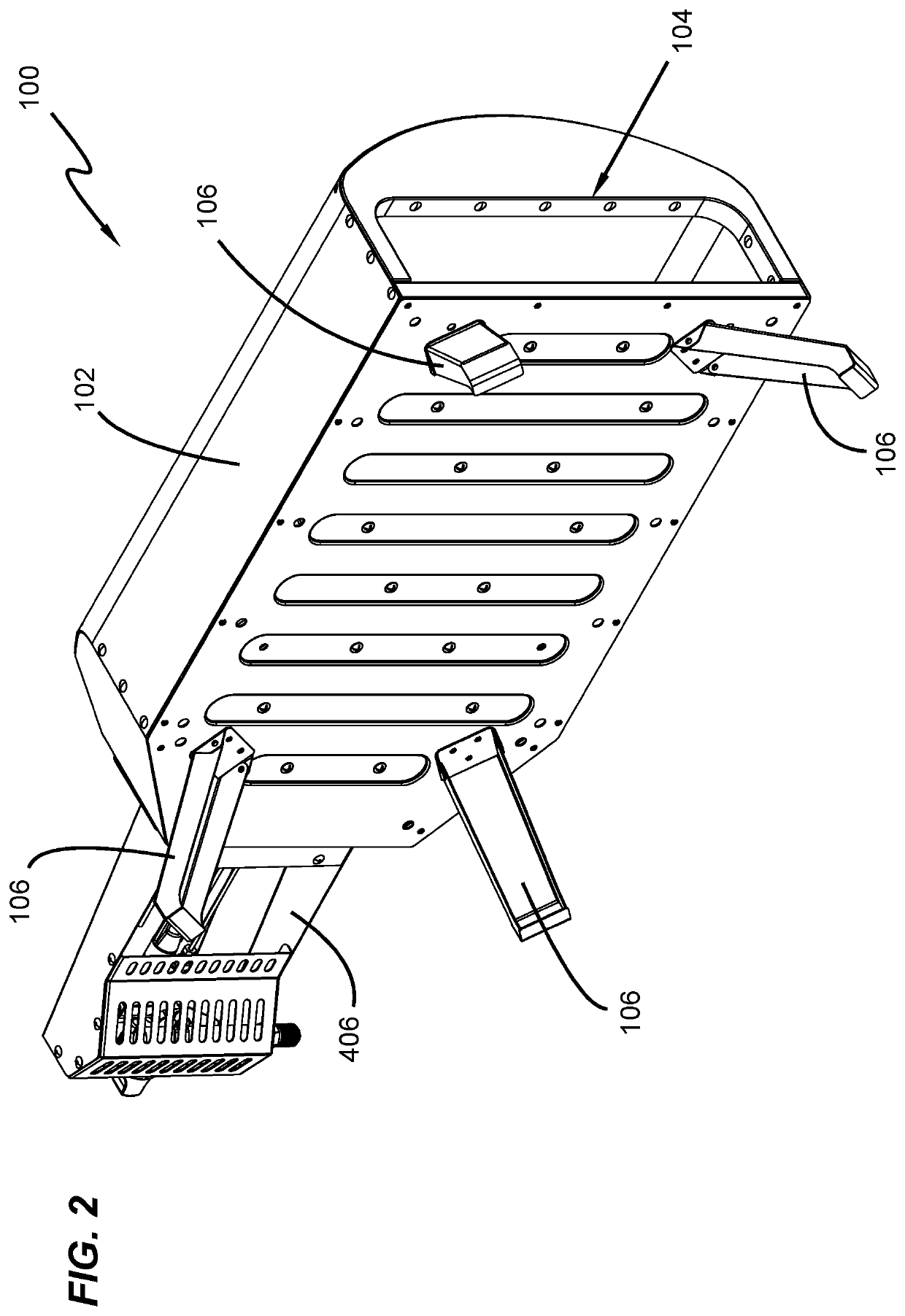

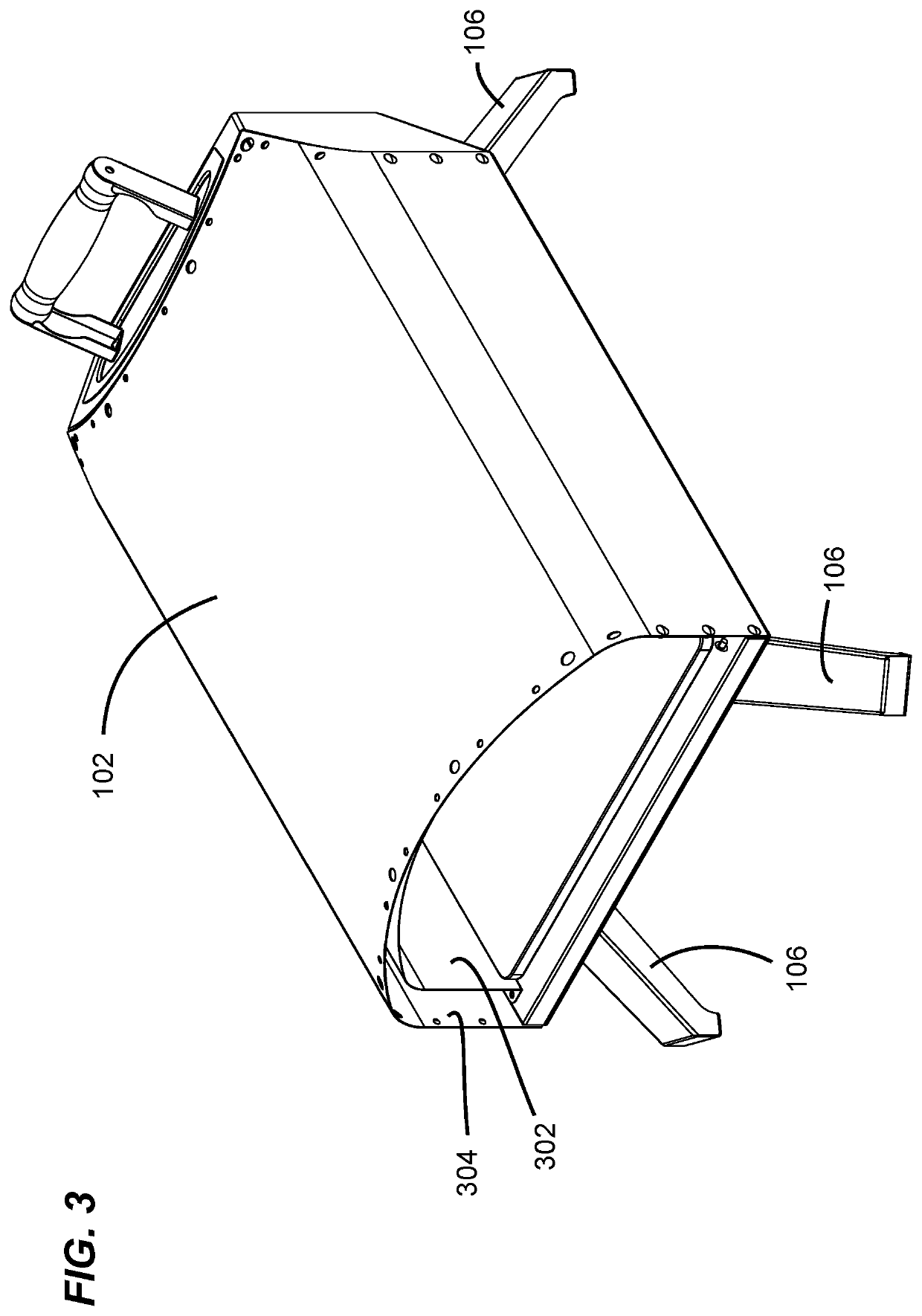

Fireplace insert

The invention provides an insert assembly to convert an existing fireplace hearth into a gas burning fireplace and a method for installing the insert assembly while conveying the appearance of a wood burning fireplace. The insert assembly comprises legs removably attachable to the base of the firebox for allowing the insert to be installed higher into the hearth. The inner walls of the firebox are colored so as to camouflage the structure of the assembly in the hearth and a decorative fender mimics a wood burning grill. Where the insert includes a heat exchanger, a guide plate is provided at the top of the insert to ensure that air exiting the heat exchange outlet at the top of the insert is directed into the room.

Owner:MILES INDS

Oven including gas burner and wood tray

ActiveUS20200345176A1Domestic stoves or rangesRoasters/grillsProcess engineeringMechanical engineering

An example oven can include: a main body with a cooking cavity; a front portion of the main body having a front opening for receiving a pizza and acting as an air vent; a wood burning tray assembly including a grate positioned in the main body; and a gas burner positioned adjacent to the wood burning tray assembly; wherein the gas burner is configured to combust a gas to heat the cooking cavity; and wherein the gas burner is positioned to ignite wood on the grate of the wood burning tray assembly to further heat the cooking cavity.

Owner:NAPOLI LLC

Acoustically Variable Burner System

An acoustically variable burner system is provided, having a burner wherein the flow of gas thereto, and consequently the flame pattern resulting from the ignition of the gas, is variable by transmission of acoustic waves therethrough via an acoustically-based control system. The preferred burner design produces a realistic, wood-burning type flame pattern. An acoustic controller, such as an APPLE® iPod®, MP3 player, computer, etc., may be utilized to drive / control electroacoustic transducers positioned adjacent the burner, the sound waves of which are produced thereby varying the flow rate of gas to the burner gas ports, thereby varying the flame height in direct correspondence with the audio signal. Further, the flame color may be altered by introduction of flame color variant compositions exposed to the flame via a flame color variation device removably positioned adjacent the burner. The system is preferably controlled via a specialized computer program running on the acoustic controller, which enables choice of flame patterns, duration, audible audio to accompany the flame display, etc.

Owner:MCBRIDE DARVIL BENJAMIN +1

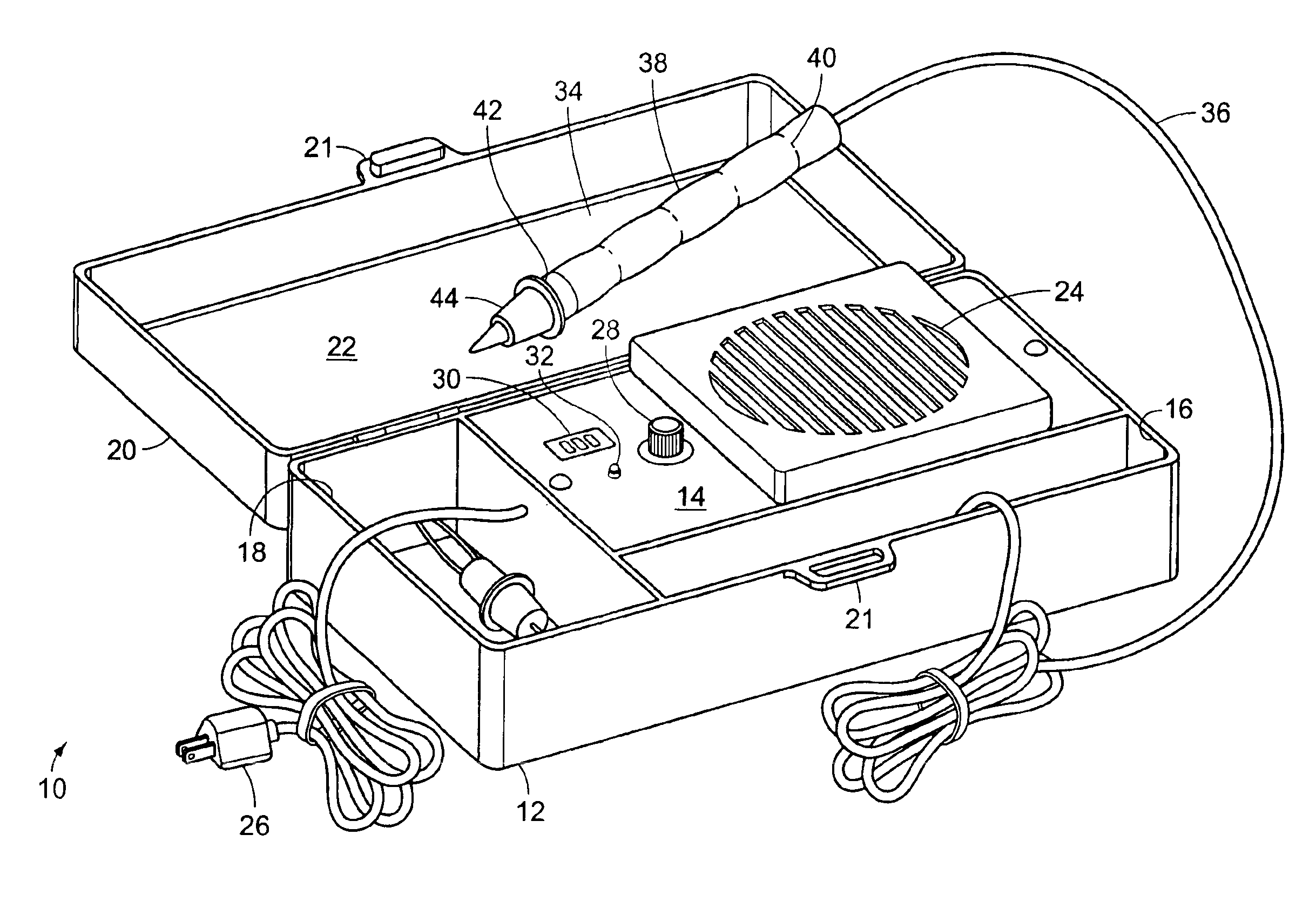

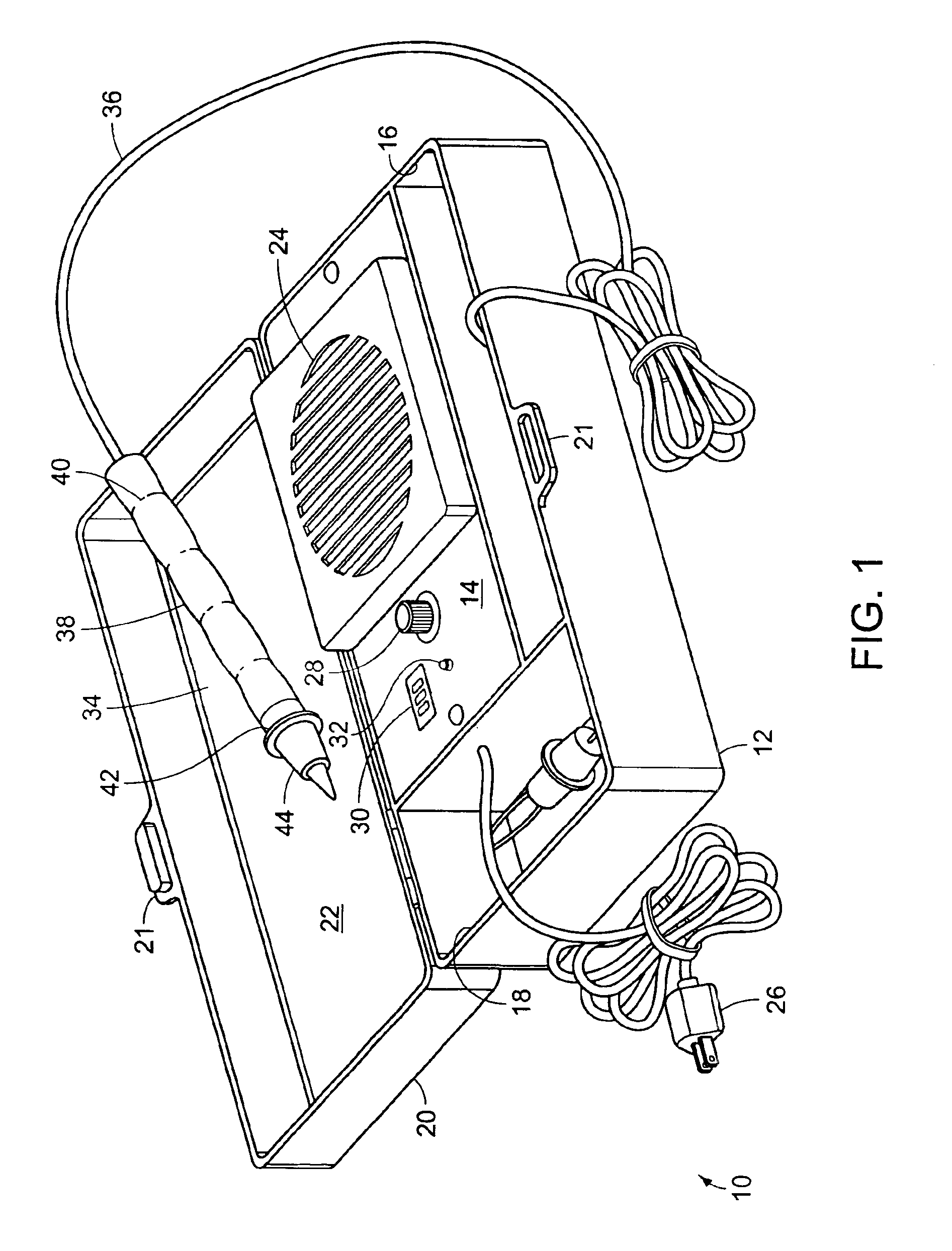

Variable wood burning tool

A variable wood burning tool for burning woods at varying temperatures and providing alternate uses essentially comprised of a container and a lid hingedly secured thereto. An interior surface of the lid has a heat resistant tray disposed therein. A heating element is disposed within the container. A burning wand is operatively coupled with the heating element. A plurality of tips are provided that are each adapted for removably coupling with the burning wand.

Owner:VERET VICTORIA

Jun porcelain jade glaze and preparation method thereof

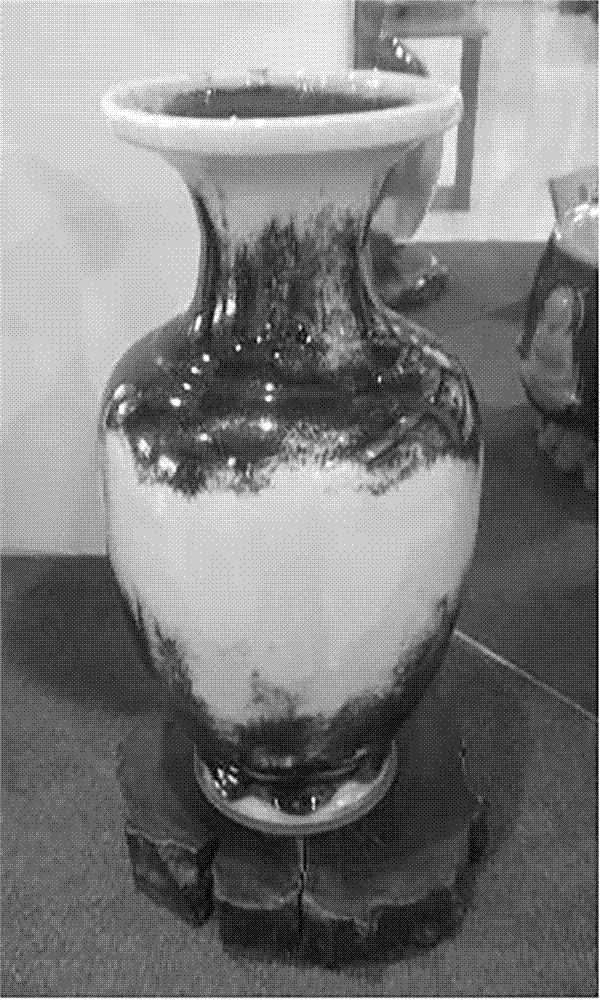

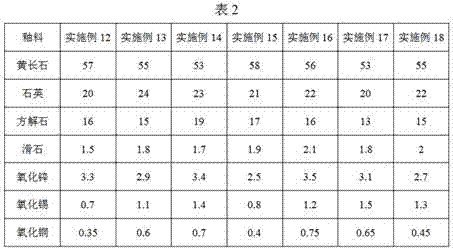

The invention provides a jun porcelain jade glaze, which is prepared from the following raw materials in parts by weight: 52 to 58 parts of yellow feldspar, 19 to 25 parts of quartz, 13 to 19 parts ofcalcite, 1.5 to 2.5 parts of talc, 2.5 to 3.5 parts of zinc oxide, 0.5 to 1.5 parts of tin oxide and 0.25 to 0.75 part of copper oxide. Compared with the prior art, the jun porcelain jade glaze provided by the invention not only has a simple glaze formula, but also has the advantages of sufficient artistic conception, luster, red spots and strong jade texture through a scientific and reasonable ratio of the raw materials and a wood burning control process, the yield is up to 99% or more, and the shortcoming of low wood burning yield is overcome.

Owner:禹州市锦丰源瓷业有限公司

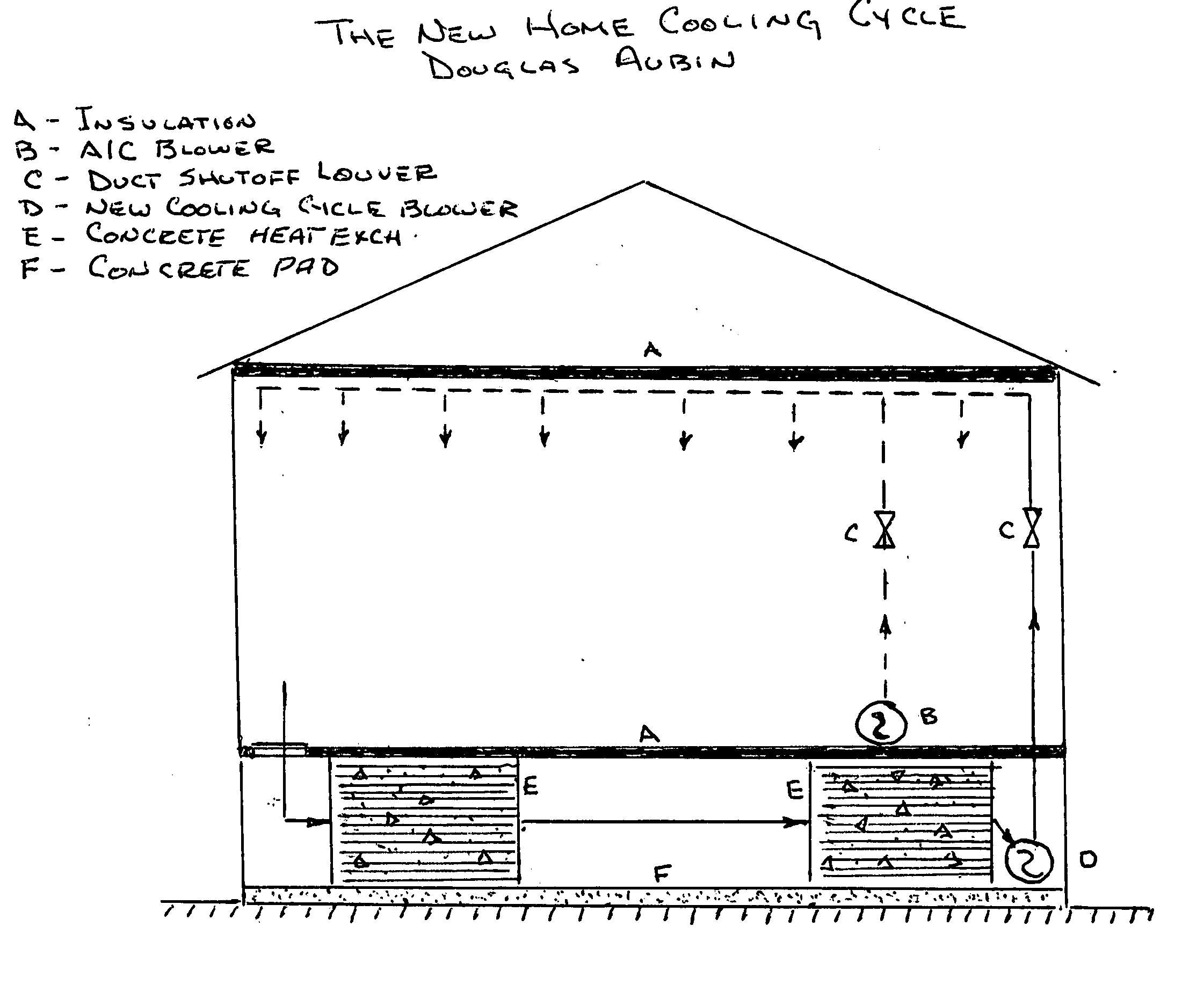

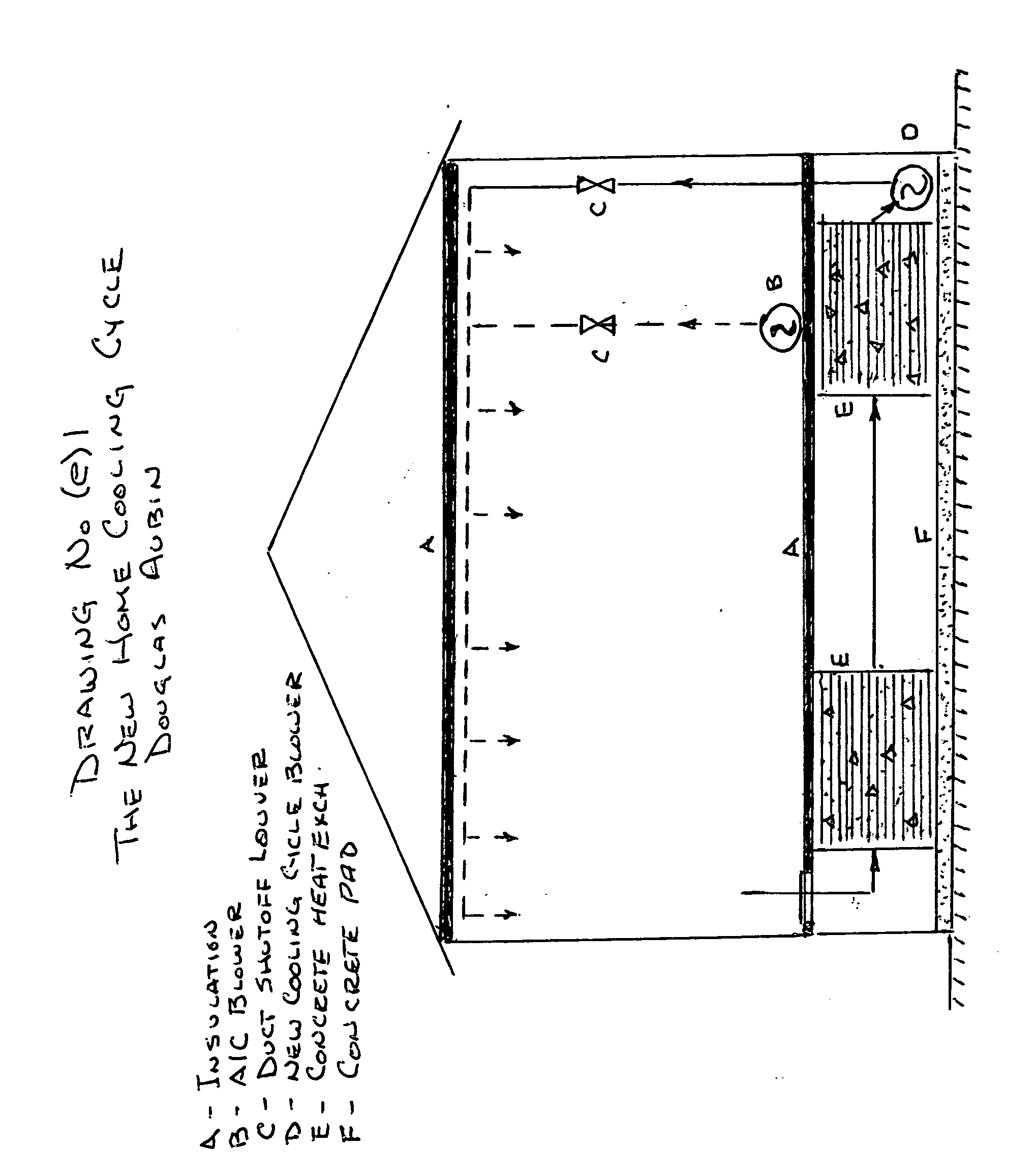

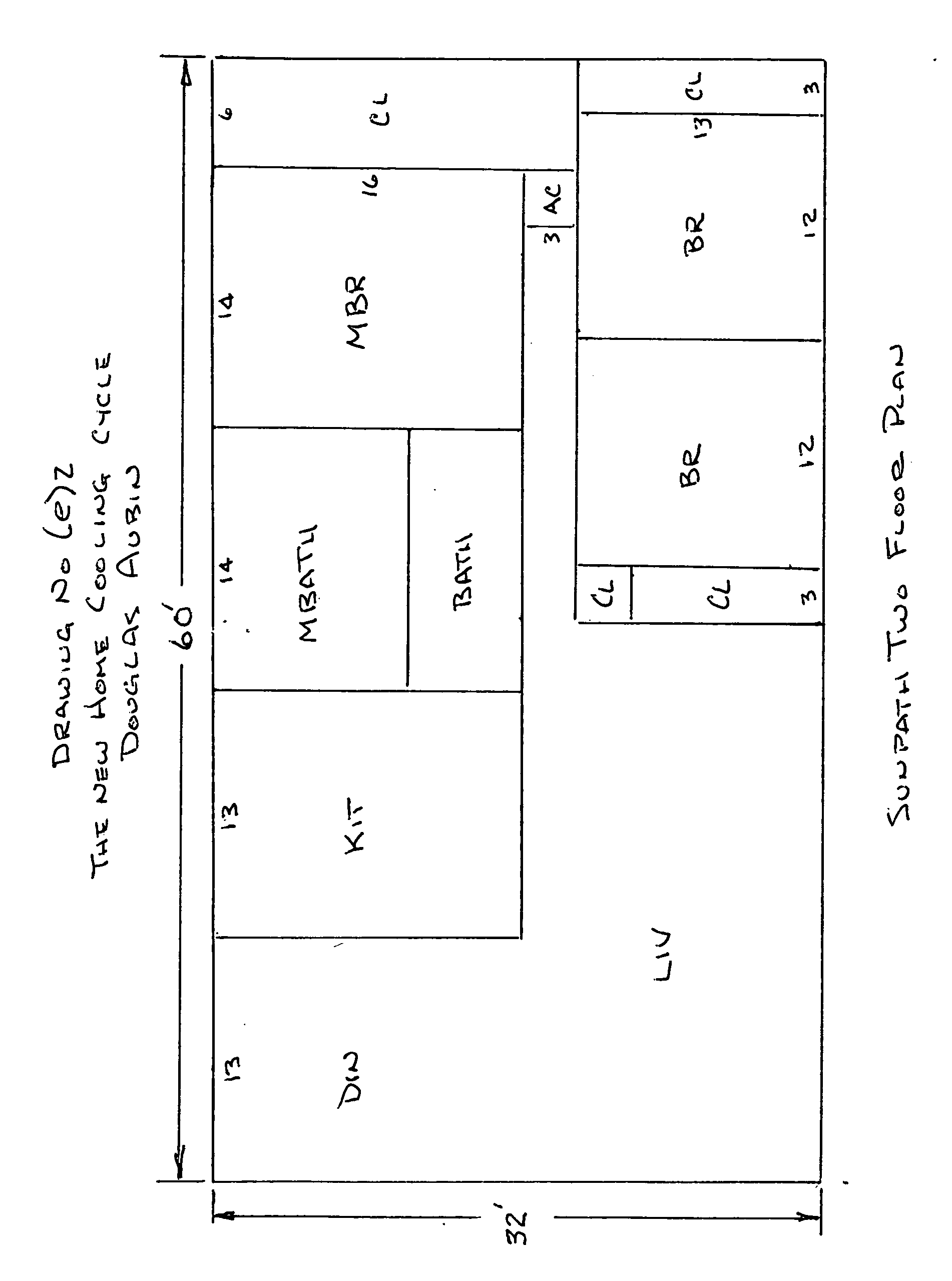

Home cooling cycle

InactiveUS20050183435A1Lower heating costsSmooth interior temperatureDomestic refrigeratorsAir heatersAir cycleOne pass

The heart of the “New Home Cooling Cycle” is a concrete heat exchanger located under the home. The heat exchanger is constructed of concrete and PVC piping. There are two flow passes. Each is ninety degrees from the other. On a hot sunny day, heat absorbed by air inside the home is routed through one pass of the heat exchanger where the heat is removed by absorption into the concrete, thus removing heat from the home. Air is circulated using a small electric blower. Air leaving the heat exchanger is cool and is returned to the home ready to absorb heat again. The recycled air absorbs additional heat and the cycle is repeated through the heat exchanger. Regeneration of the heat exchanger is accomplished at night. Cool night air is blown, using a small electric blower, through the heat exchanger second pass, ninety degrees to the absorbing pass. This cooling air absorbs heat from the heat exchanger and exhausts it back to the night air. The two heat exchanger passes are totally isolated to prevent moisture from entering the house circuit. This same cycle is used during winter. On a sunny winter day, solar heat and heat from a wood burning fireplace is absorbed by air inside the home and is routed through the heat exchanger as in the summer cooling cycle. Heat is removed and stored in the heat exchanger and cooled air is returned to the home where the cycle repeats. At night, heat stored in the heat exchanger is routed into the home. During winter, there is no regeneration required for the heat exchanger. Usage of refrigerated air conditioning is radically reduced. In some United States climates, it may be possible to eliminate refrigerated air conditioning.

Owner:AUBIN DOUGLAS EDWARD

Preparation method of pottery pot

InactiveCN108725063ACrack water seepageCrack afraid of waterDecorative surface effectsOrnamental structuresSilicon oxideFermentation

The invention discloses a preparation method of a pottery pot. According to the preparation method of the pottery pot, Longshan Wuyuan river red clay and Chinese medical stone are used as raw materials and are appropriately proportioned; the production process of Longshan Degong black pottery is adopted, the processes of clay fermentation, vacuum pugging, moulding by throwing, polishing and sculpturing, engraving and calendering, shade drying and grinding and wood burning are adopted, and the techniques of pottery firing, fuming and carburizing through pine branches and pine leafs by Longshanancestors 4,600 years ago are adopted for reference, and the pottery pot is prepared through more than a dozen procedures and an all elaborately hand-crafted way. Through the preparation method, the wood burning process is adopted, natural kiln change is carried out, and the pottery pot is rich in mineral substance of calcium oxide, magnesium oxide, iron oxide, silicon oxide and trace element beneficial to human bodies and has the health care effect. Through the preparation method, the technical problems of the black pottery art water seepage, water avoidance and color difference are solved, the service life is prolonged, and the pottery pot is made high-end and elegant, and integrates the characteristics of being artistic, cultural, ornamental, practical and collectible, and accordingly people with the pottery pot can return to nature, enjoy nature, and prolong life.

Owner:刘德功

Wood burning furnace and heating method adopting wood burning furnace

PendingCN109442448ABurn fullyBurn completelyDomestic stoves or rangesDispersed particle filtrationCombustion chamberResource utilization

The invention discloses a wood burning furnace and a heating method adopting the wood burning furnace, and aims at providing a wood burning furnace sufficient in combustion and high in heat efficiencyand a method for adopting the wood burning furnace for wood burning heating. According to the designed wood burning furnace, a secondary combustion chamber is additionally arranged below an existingwood burning furnace, and an additional air inlet pipeline and an additional exhaust channel are arranged for the furnace to be jointly used by a combustion chamber and the secondary combustion chamber. Through the designed secondary combustion chamber, smoke generated by the combustion chamber can be combusted again, emission of carbon monoxide and other poison gas is reduced, atmosphere pollution is reduced, meanwhile, smoke combustion is sufficient, and the resource utilization rate is increased. The smoke is secondarily combusted through the secondary combustion chamber, more heat can be generated, and the heating effect of the whole wood burning furnace can be better through the arrangement of the secondary combustion chamber.

Owner:宁波圣菲机械制造有限公司

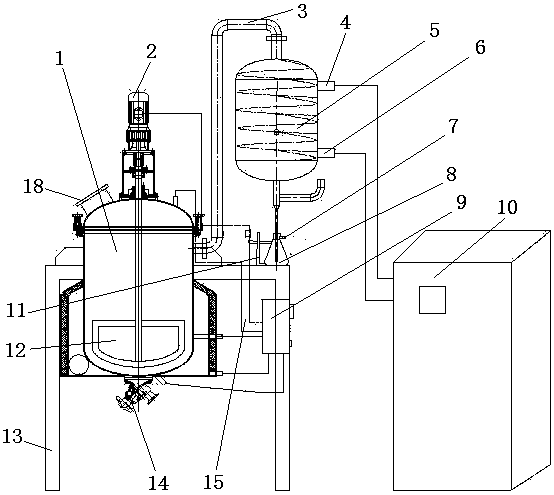

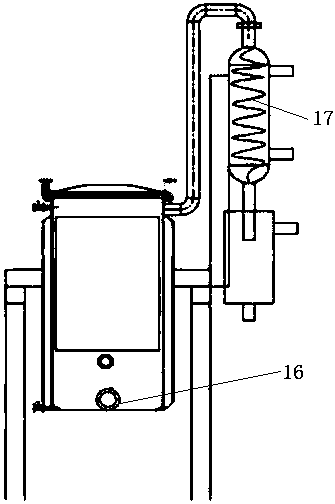

Automatic separation device for improving yield of Chinese Eaglewood essential oil, and process method thereof

The invention discloses an automatic separation device for improving the yield of Chinese Eaglewood essential oil, and a process method thereof. The device is characterized in that a distillation tankis connected with a cooling tank through a connecting tube, the cold water inlet and the cold water outlet of the cooling tank are connected with a refrigerating machine, the bottom opening of the cooling tank is connected with an oil-water separator, the oil-water separator is provided with an oil outlet and a hydrolat outlet, the hydrolat outlet is connected with the connecting tube, a controlbox is connected with the stirrer and relevant motor and electric appliances of the distillation tank through a leading wire, the stirrer is arranged at the top of the distillation tank, the distillation tank is arranged on a bearer, an inner liner and an outer liner are arranged in the distillation tank, and an interlayer is arranged between the inner liner and the outer liner. The device and themethod have the following advantages: hot air is used as a heat transfer medium, so wood burning for fire is avoided, sanitation and hygiene are achieved, the device adopting novel cooling oil-waterseparation for essential oil extraction allows the oil yield to be 30% or more than that of traditional process devices, and the device and the method are ideal Chinese Eaglewood essential oil extraction device and technology.

Owner:谢向东

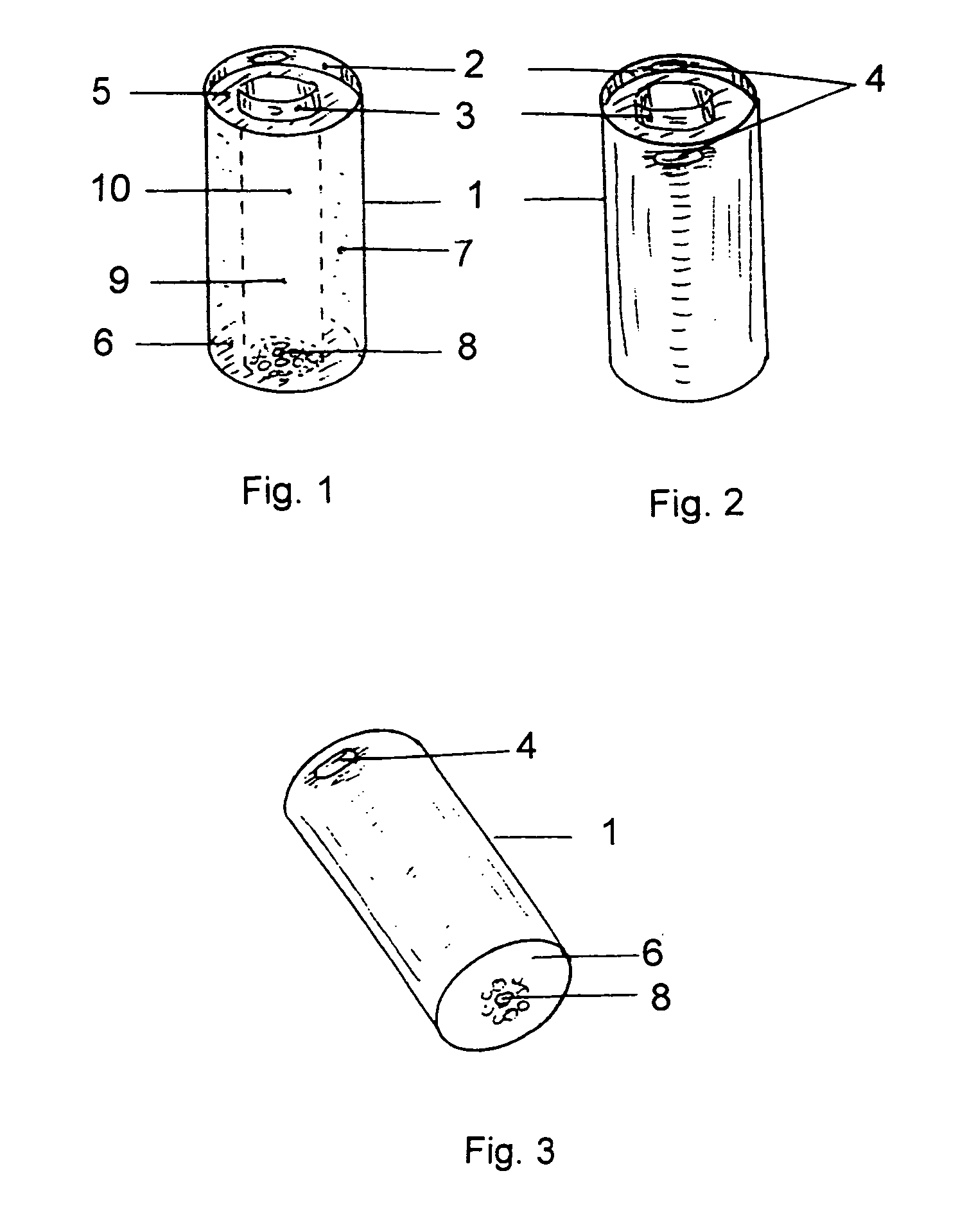

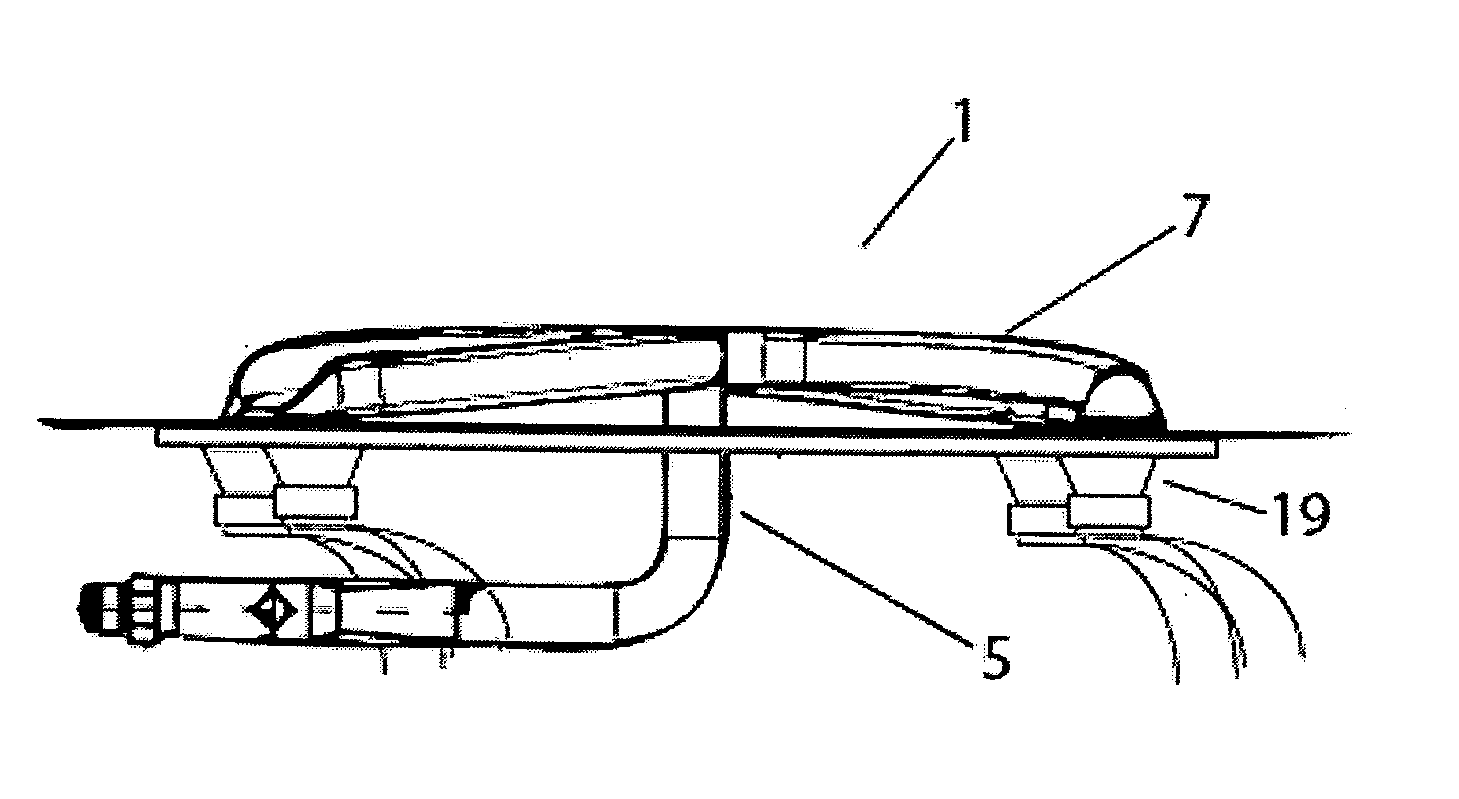

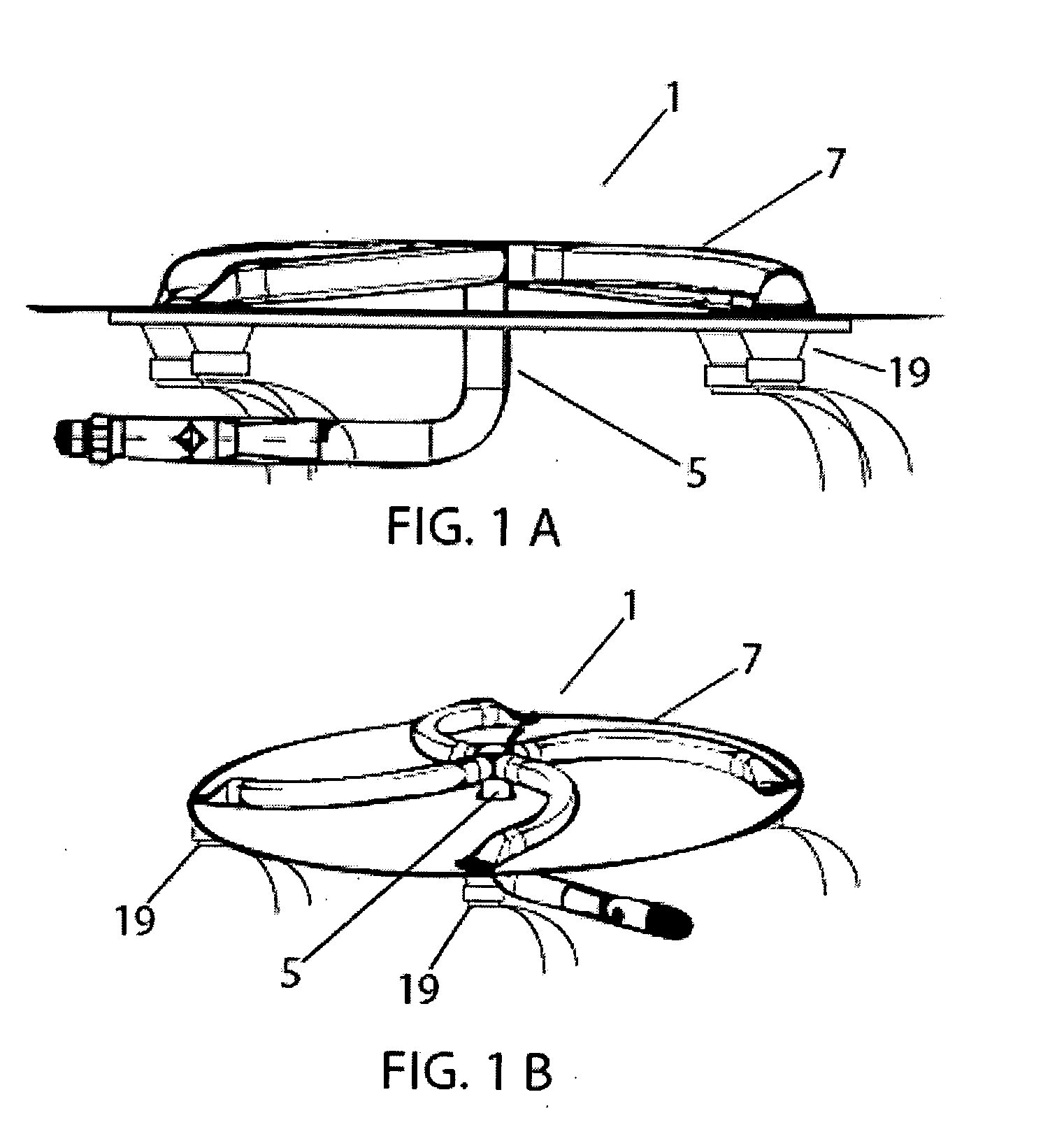

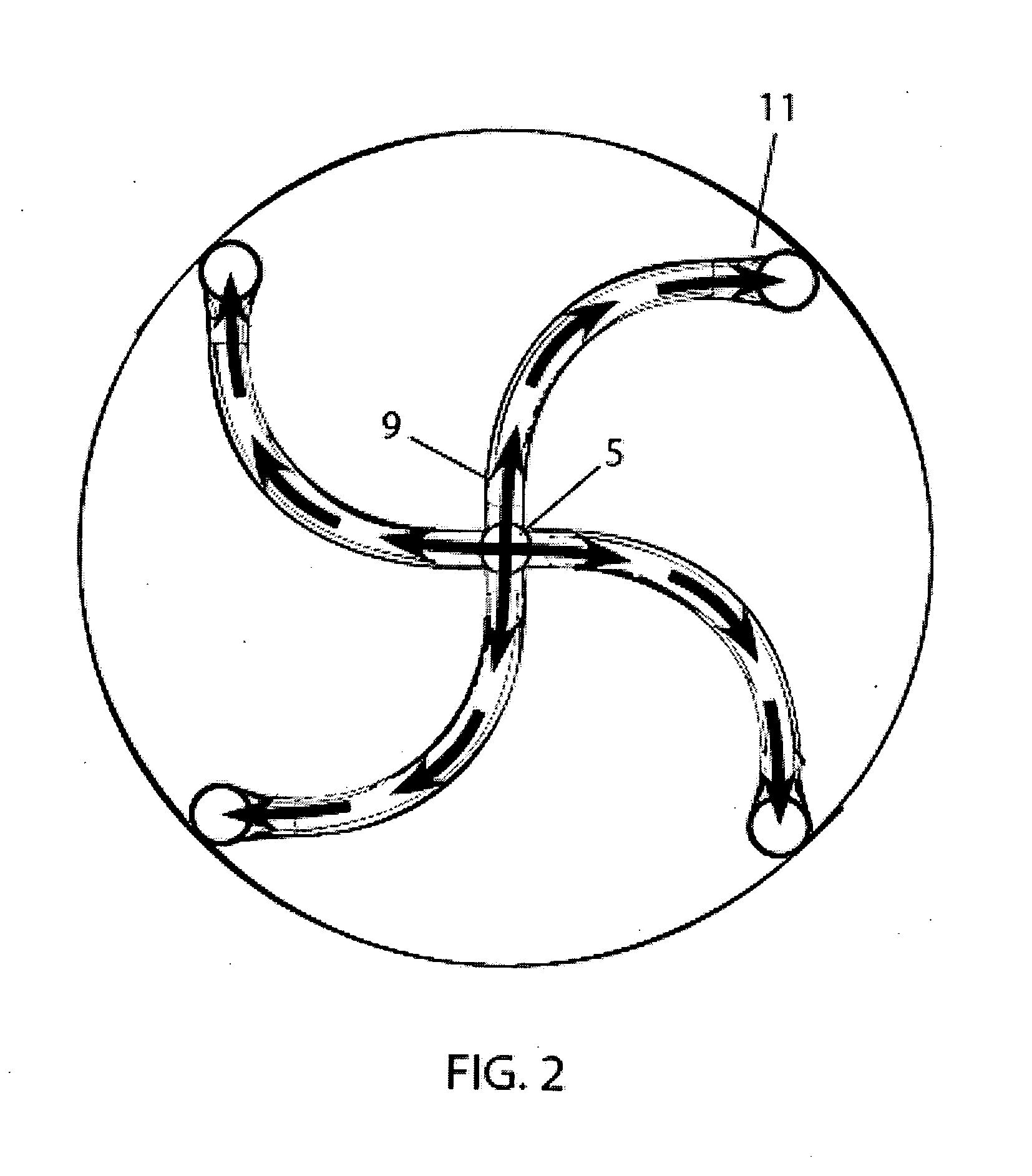

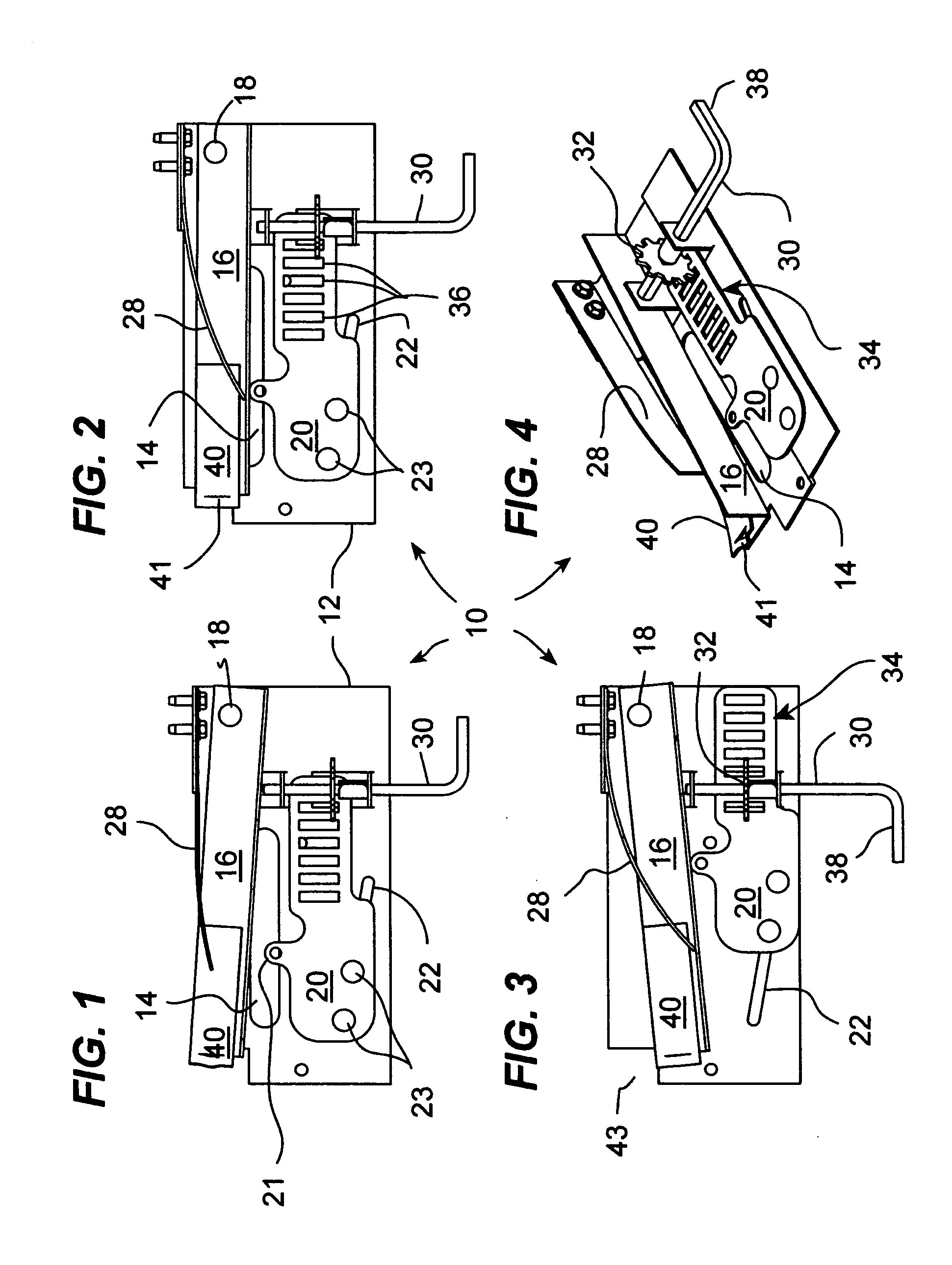

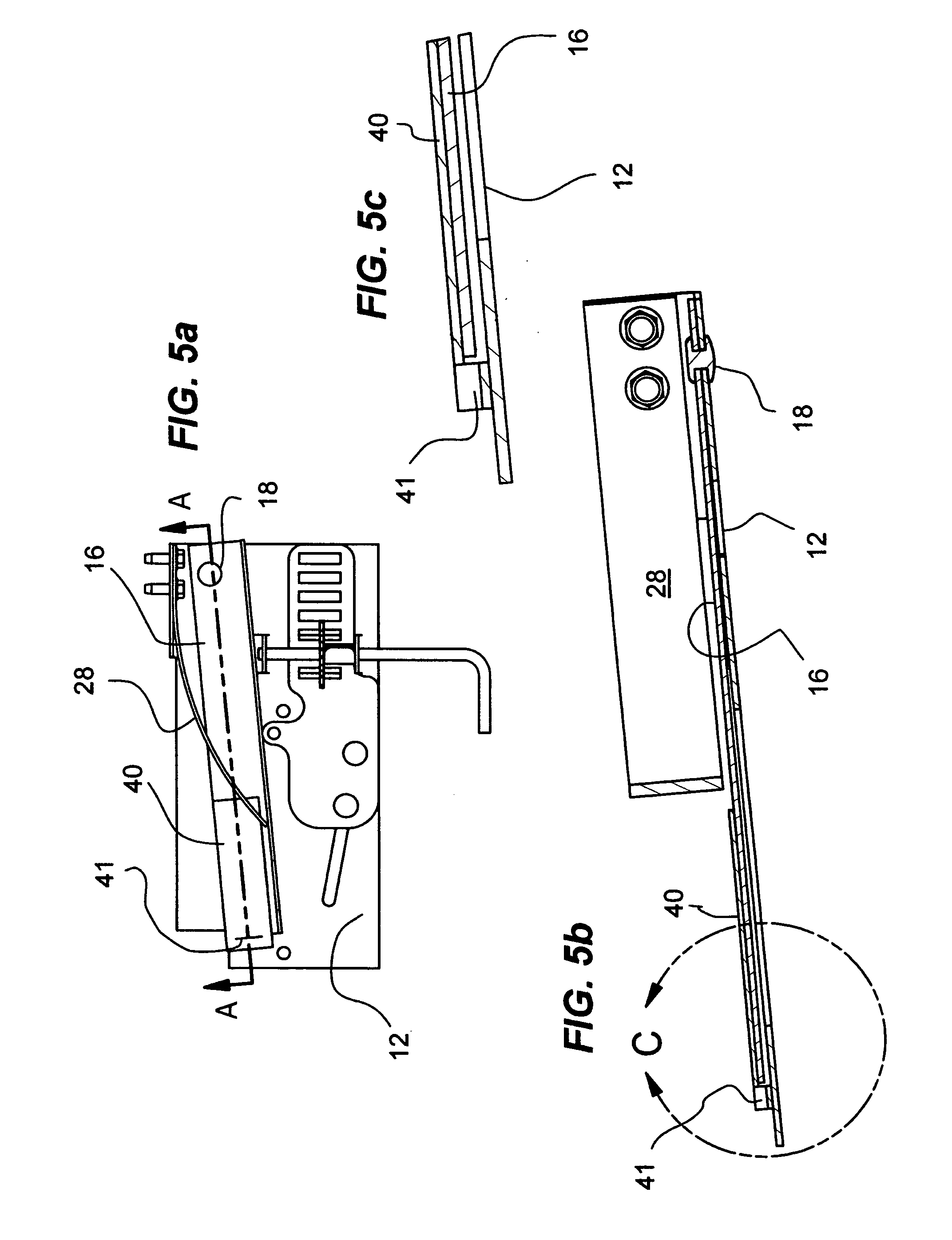

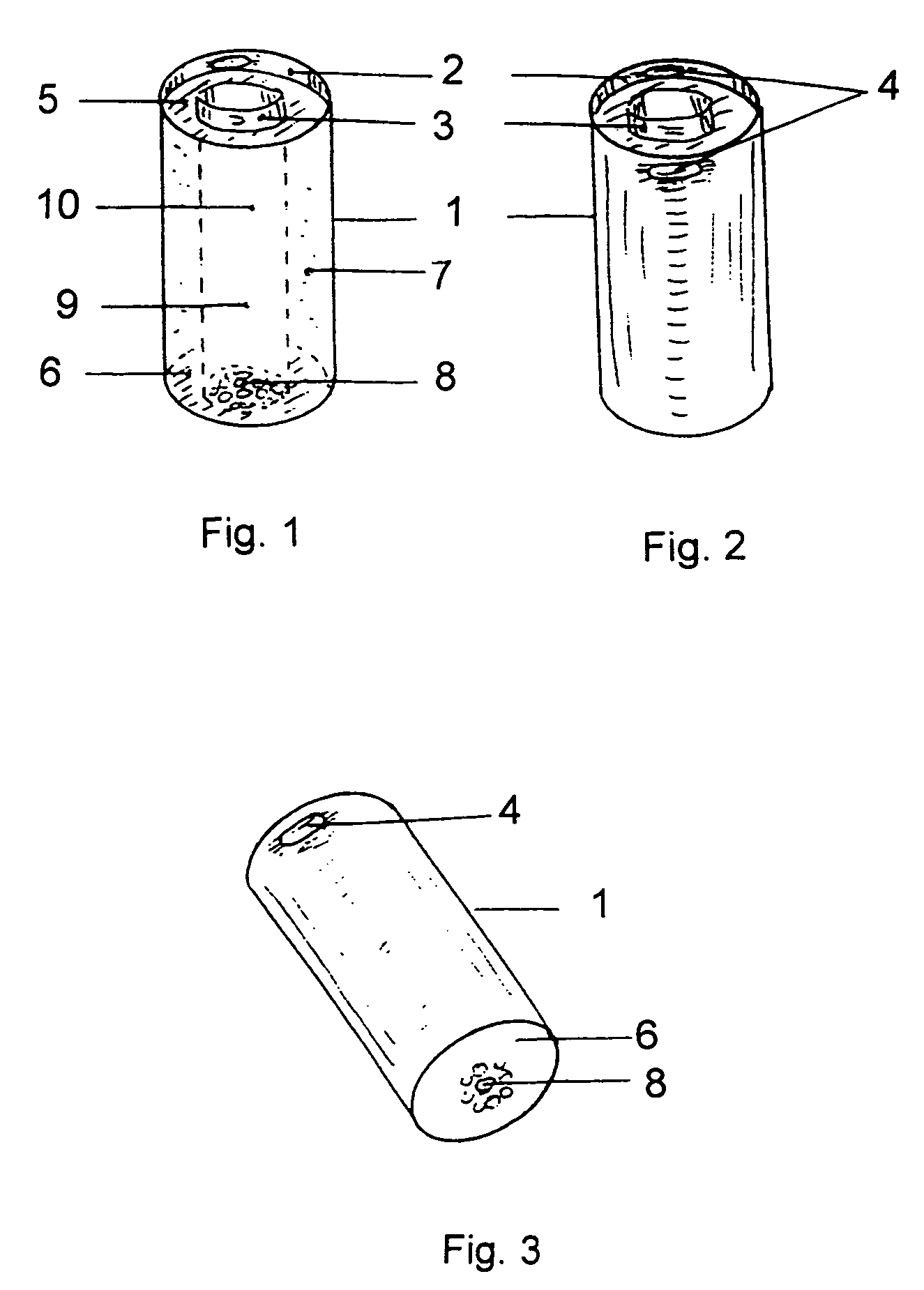

Adjustable primary air supply for wood burning device

ActiveUS7325541B2Efficient combustionAir supply regulationCombustion-air/flue-gas circulation for stovesFlammable gasWood burning

An adjustable primary air supply for wood burning device comprises at least one but preferably two thermostatic bimetal elements which, by bending with temperature variations, directly actuate a flap that opens and closes the air entry opening. Primary Air is the air used to control the burn rate and it is adjusted in order to achieve the desired burn rates and Secondary Air is the air used to complete the combustion and is not adjustable. Using these two sources of air, the invention consists of a device, which allows the primary air supply to remain open until proper burning is established. Therefore, when the temperature of the appliance rises, the combustion air gradually decreases to its preset value by having the primary air supply automatically shut off as temperature increases. A higher temperature indicates that the wood is sufficiently hot to decompose into flammable gases, so only secondary air is required to continue the combustion process.

Owner:MARCAKIS EMMANUEL

Adjustable primary air supply for wood burning device

ActiveUS20050284462A1Efficient combustionAir supply regulationCombustion-air/flue-gas circulation for stovesEngineeringFlammable gas

An adjustable primary air supply for wood burning device comprises at least one but preferably two thermostatic bimetal elements which, by bending with temperature variations, directly actuate a flap that opens and closes the air entry opening. Primary Air is the air used to control the burn rate and it is adjusted in order to achieve the desired burn rates and Secondary Air is the air used to complete the combustion and is not adjustable. Using these two sources of air, the invention consists of a device, which allows the primary air supply to remain open until proper burning is established. Therefore, when the temperature of the appliance rises, the combustion air gradually decreases to its preset value by having the primary air supply automatically shut off as temperature increases. A higher temperature indicates that the wood is sufficiently hot to decompose into flammable gases, so only secondary air is required to continue the combustion process.

Owner:MARCAKIS EMMANUEL

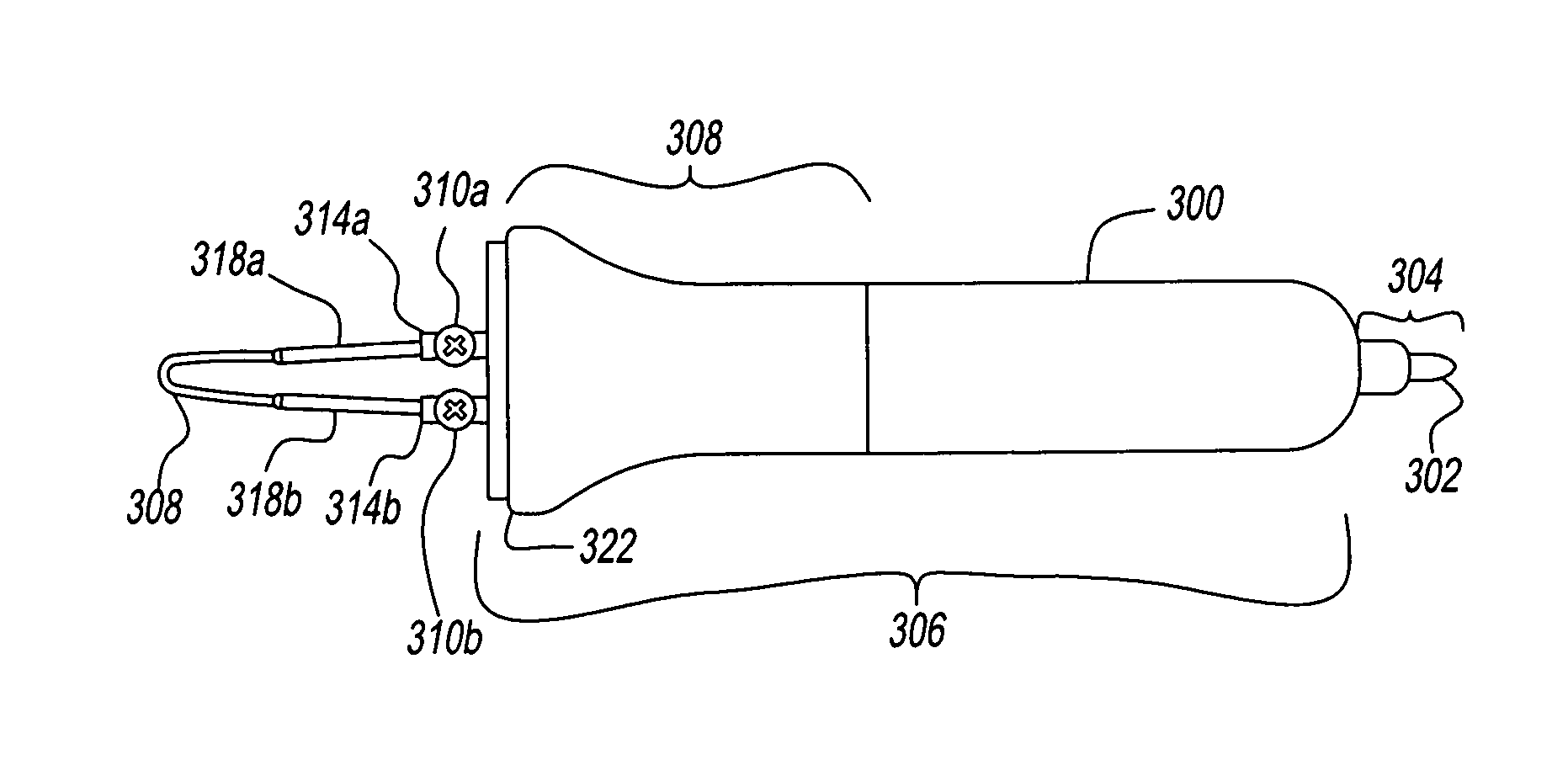

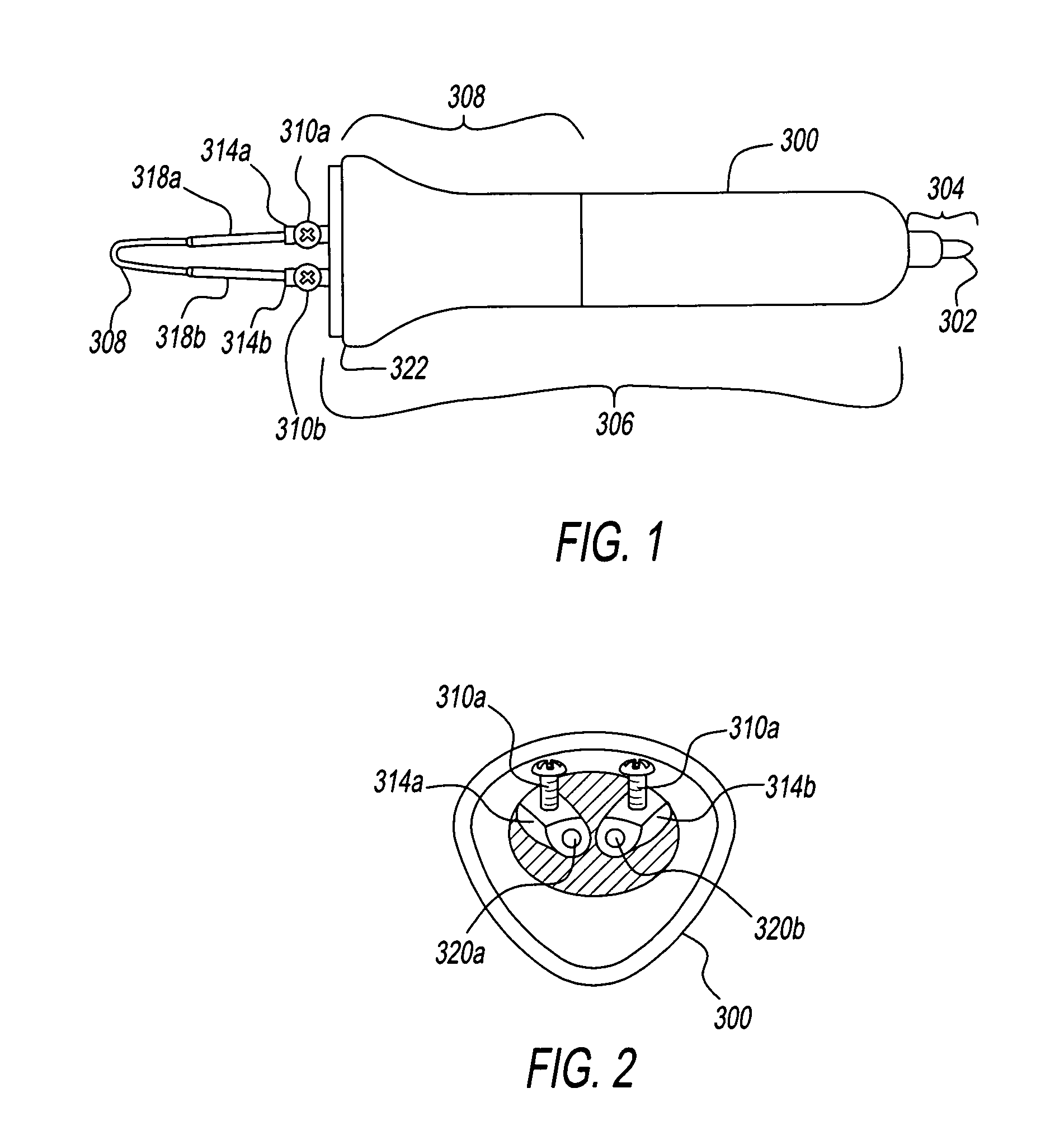

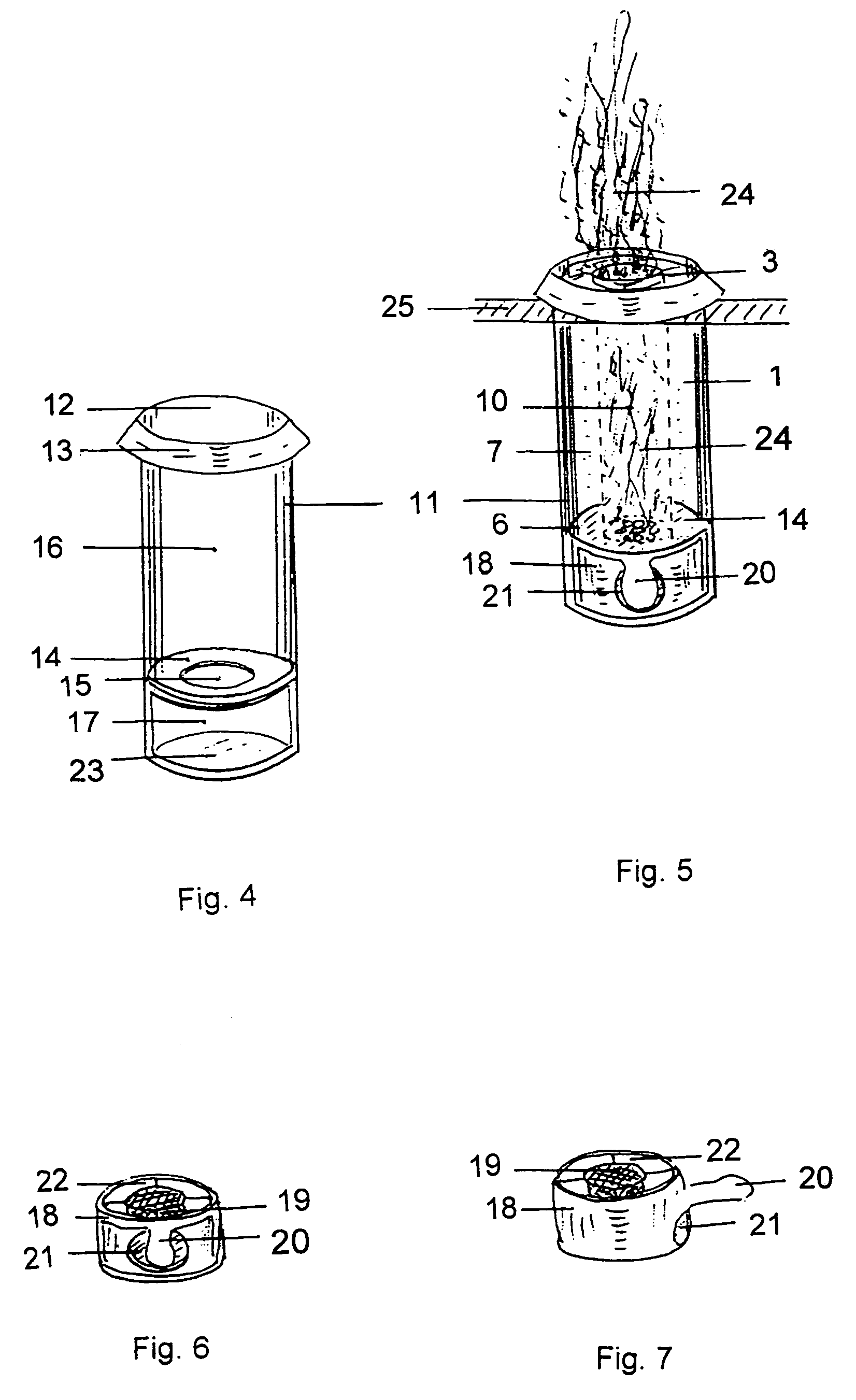

Wood burning apparatus

Systems efficiently using heat to create a creative design using a wood burning pen are disclosed. The embodiments a wood burning pen equipped with two receiver tubes angled 0.5°-4° away from each other, two screws capable of tightening the contact between two contact rods and the receiver tubes, and a tip wire connecting the two contact rods. The contact rods are inserted into the receiver tube openings. The contact rods are tightened into place with the screws. The two receiver tubes conduct electricity through the body of the wood burning pen. Because of the screws contact with the receiver, the electricity travels through the contact rods, heating tip wire. The tip wire may then be used to create decorative designs in wood.

Owner:EFFREM TIMOTHY

Log cartridge burning system

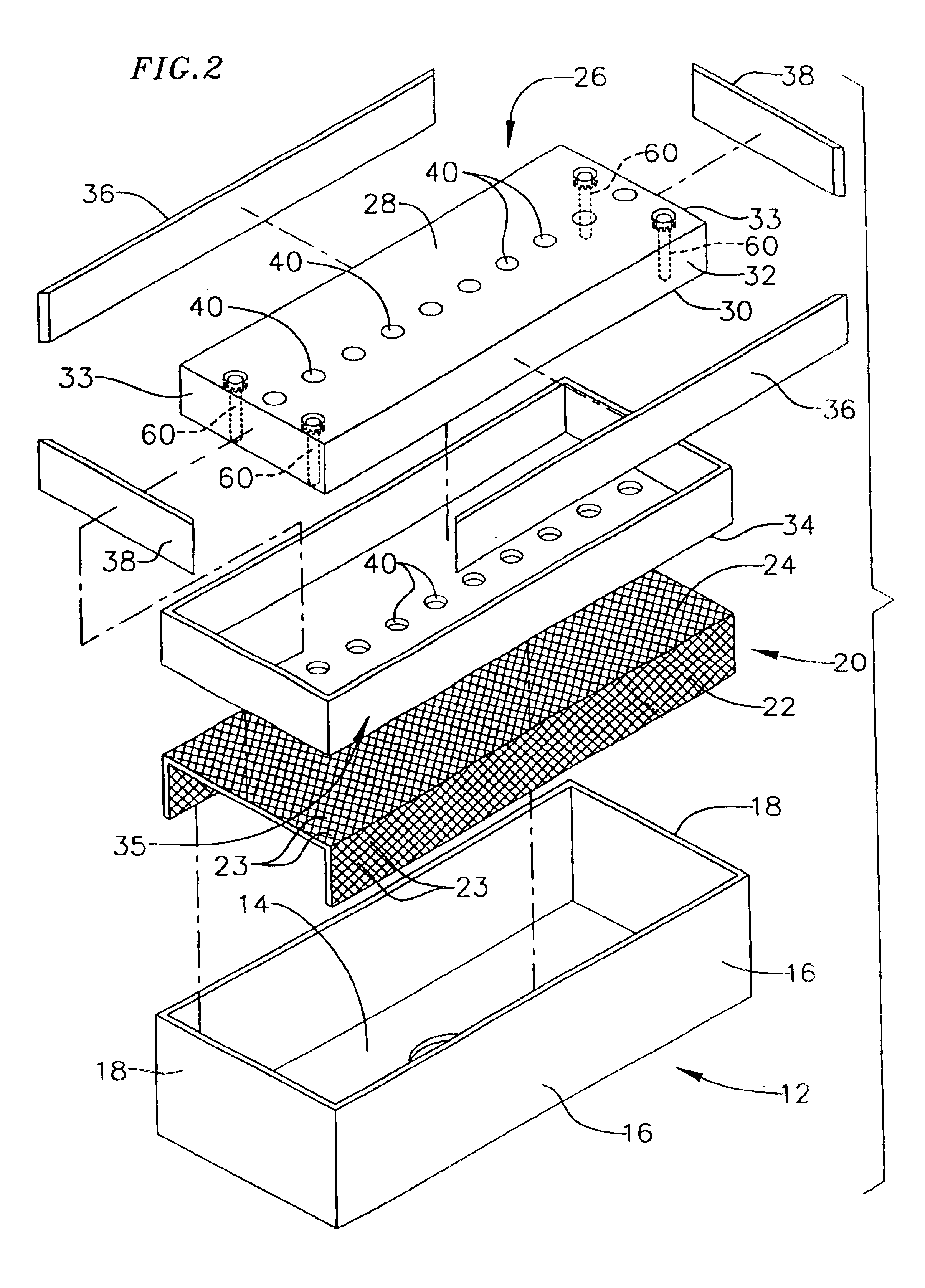

InactiveUS8250995B2Easy to optimizeImprove the heating effectDomestic stoves or rangesBiofuelsCardboardWax

A Log Cartridge Burning System is provided comprising a simple, convenient and manageable wood burning system which can easily be applied for use to cook and heat. The log cartridge is comprised of a flammable body of compressed material and a bore formed and sealed by the use of a protective outer paperboard tube and a protective inner paperboard tube together with a top and bottom paperboard cover which serve to hold and maintain the integrity of the entire cartridge without the use of any wax binders. The flammable body of compressed material may be made partly or entirely from natural combustible materials such as sawdust or wheat hulls. The burn pot is specially designed to accommodate the log cartridge of the present invention. The log cartridge burning system can easily be utilized in a variety of appliances such as a patio heater or fireplace, barbecue or grill, or other cooking and heating appliances.

Owner:LEE HENRY K

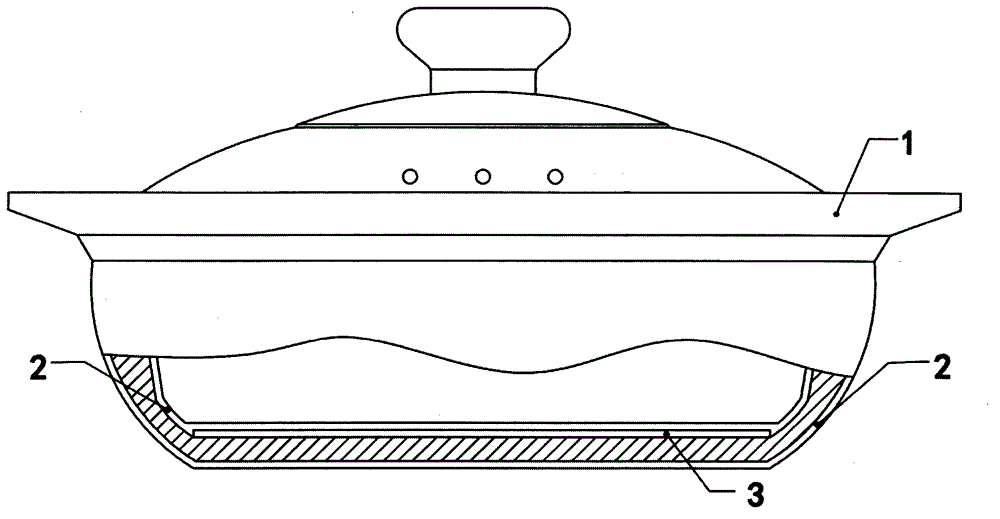

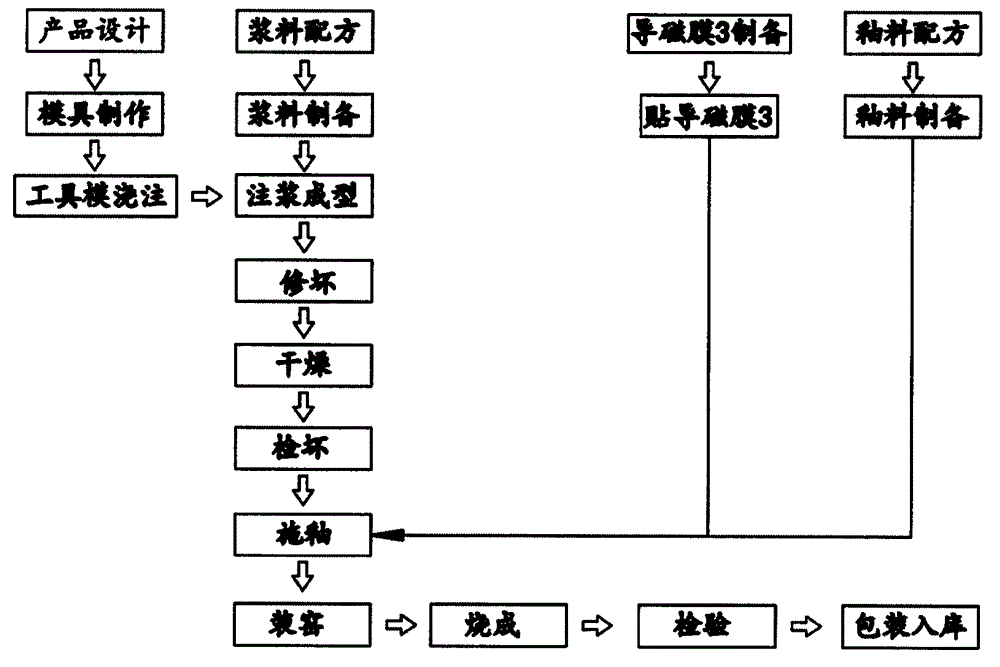

Manufacturing method of ceramic pot adaptable to various heat sources

InactiveCN105310460AKeep it authenticAvoid infringementCooking-vessel materialsUltrasound attenuationMaterials science

The invention discloses a manufacturing method of a ceramic pot adaptable to various heat sources. The manufacturing method includes: making a die, forming a size formula, preparing size, forming a glaze formula, preparing glaze, pouring a working die, fettling after slip casting, drying, and inspecting a blank. The manufacturing method is characterized by further including: preparing a magnetic conducting film, pasting the magnetic conducting film, entering a glazing process, placing the blank into a kiln, inspecting after firing, and packaging and warehousing. The ceramic pot produced by the method can be used in a common induction cooker and can be used in gas ovens, wood-burning ovens and electric ovens. The ceramic pot when being used in the induction cooker is quick in heat transfer, high in efficiency, free of attenuation after repeated use and capable of maintaining original taste and flavor of food and avoiding harm caused by elements, harmful to human bodies, including chromium, antimony, aluminum and lead in iron cookers.

Owner:刘德波

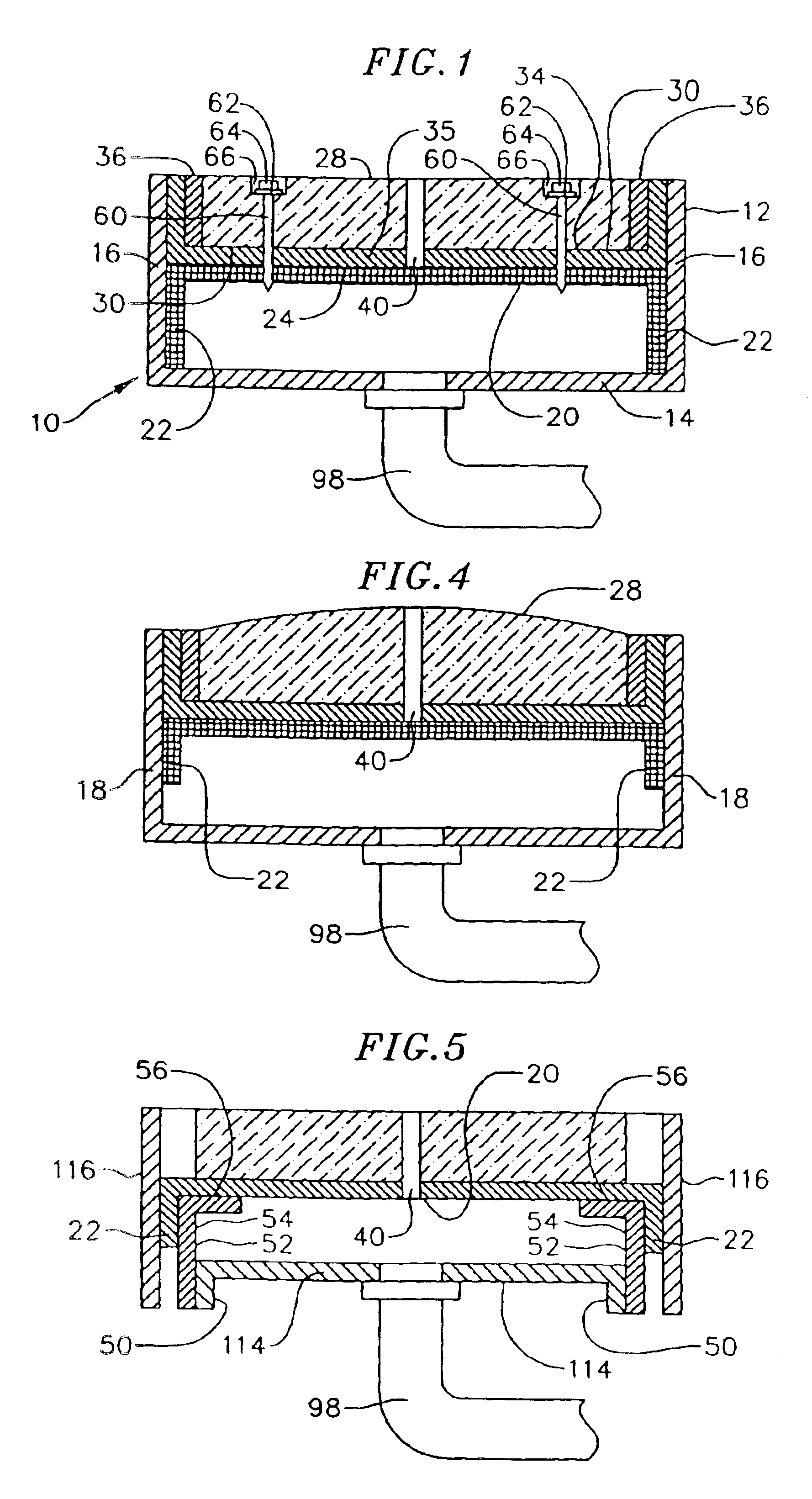

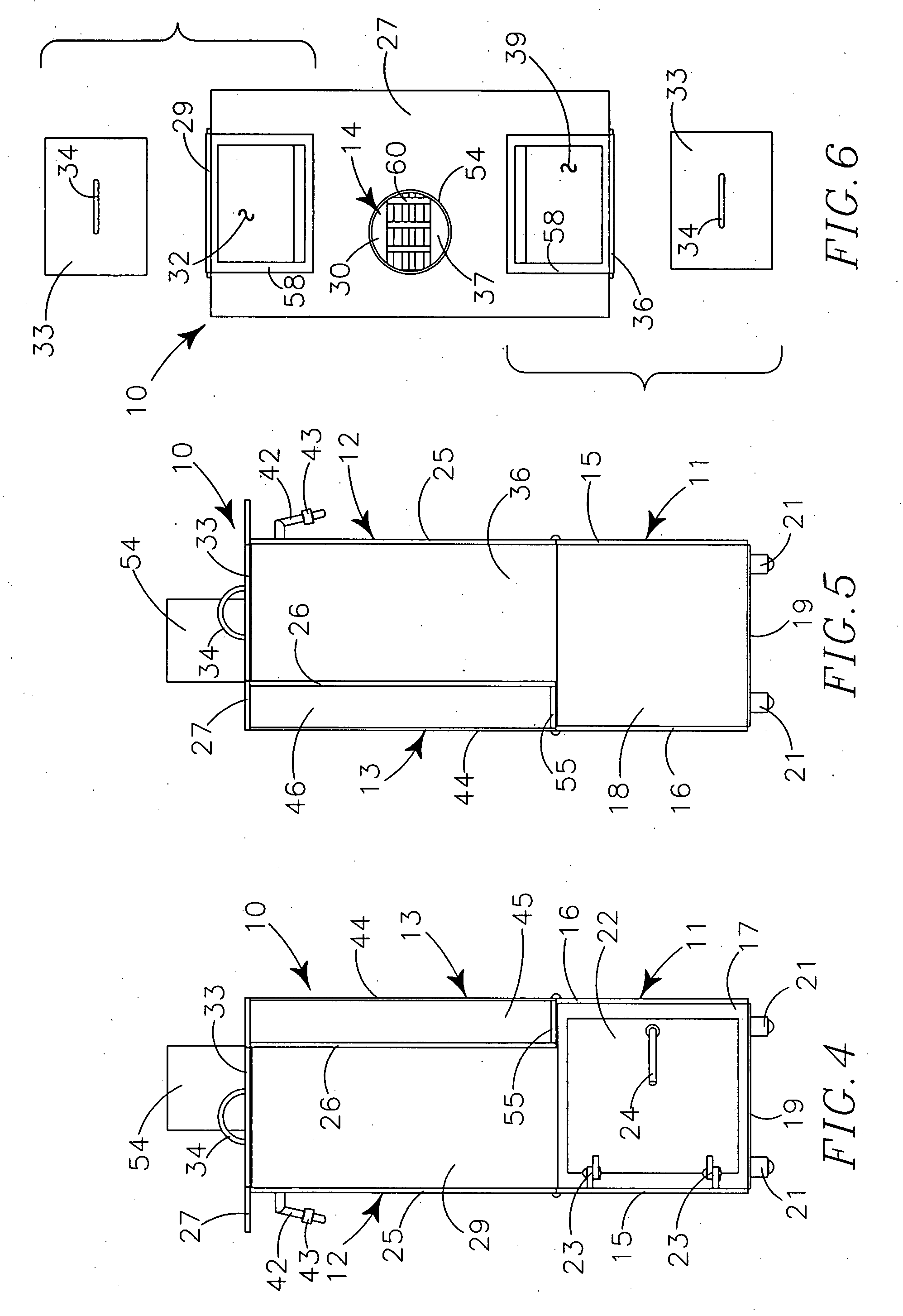

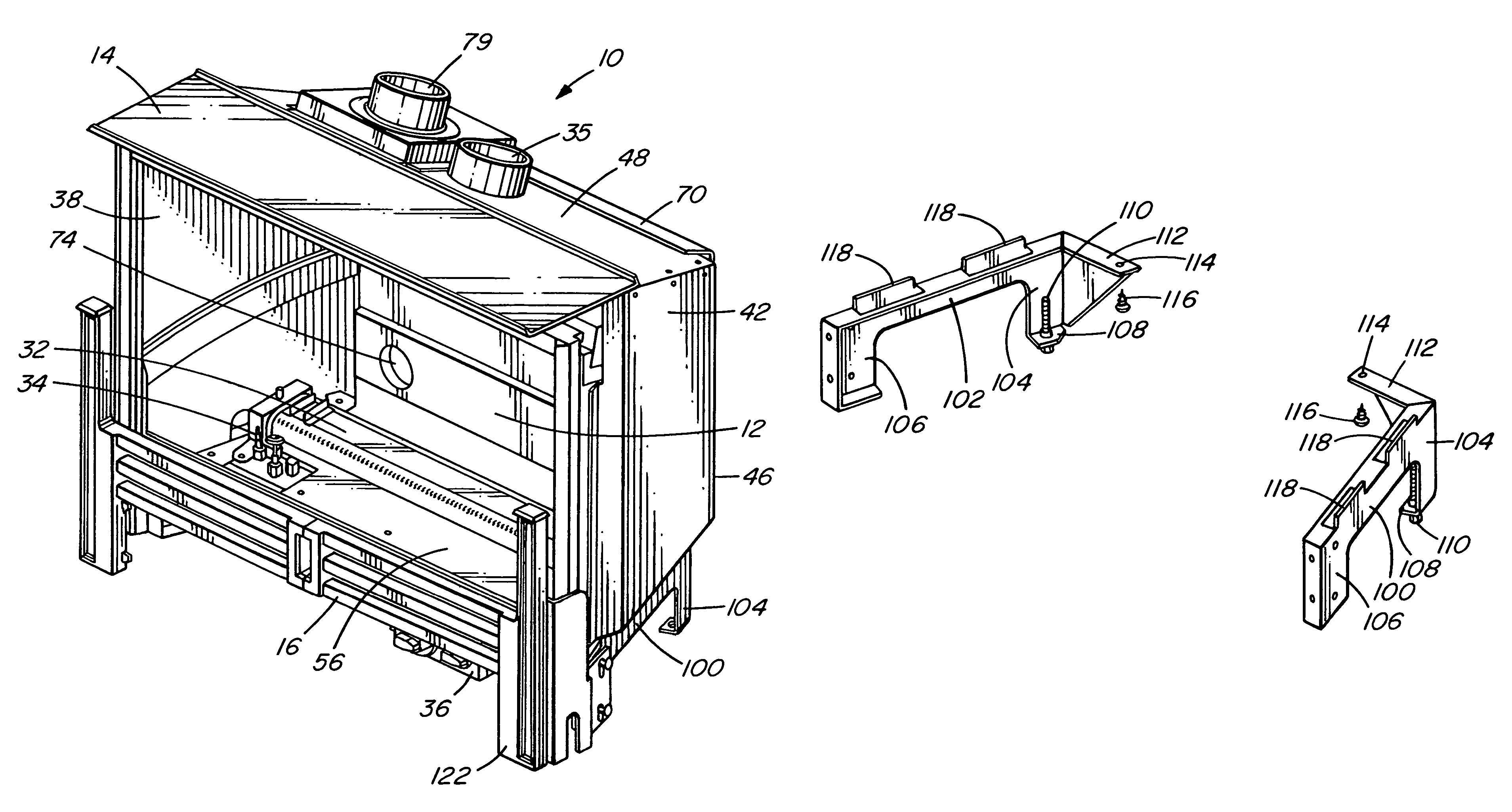

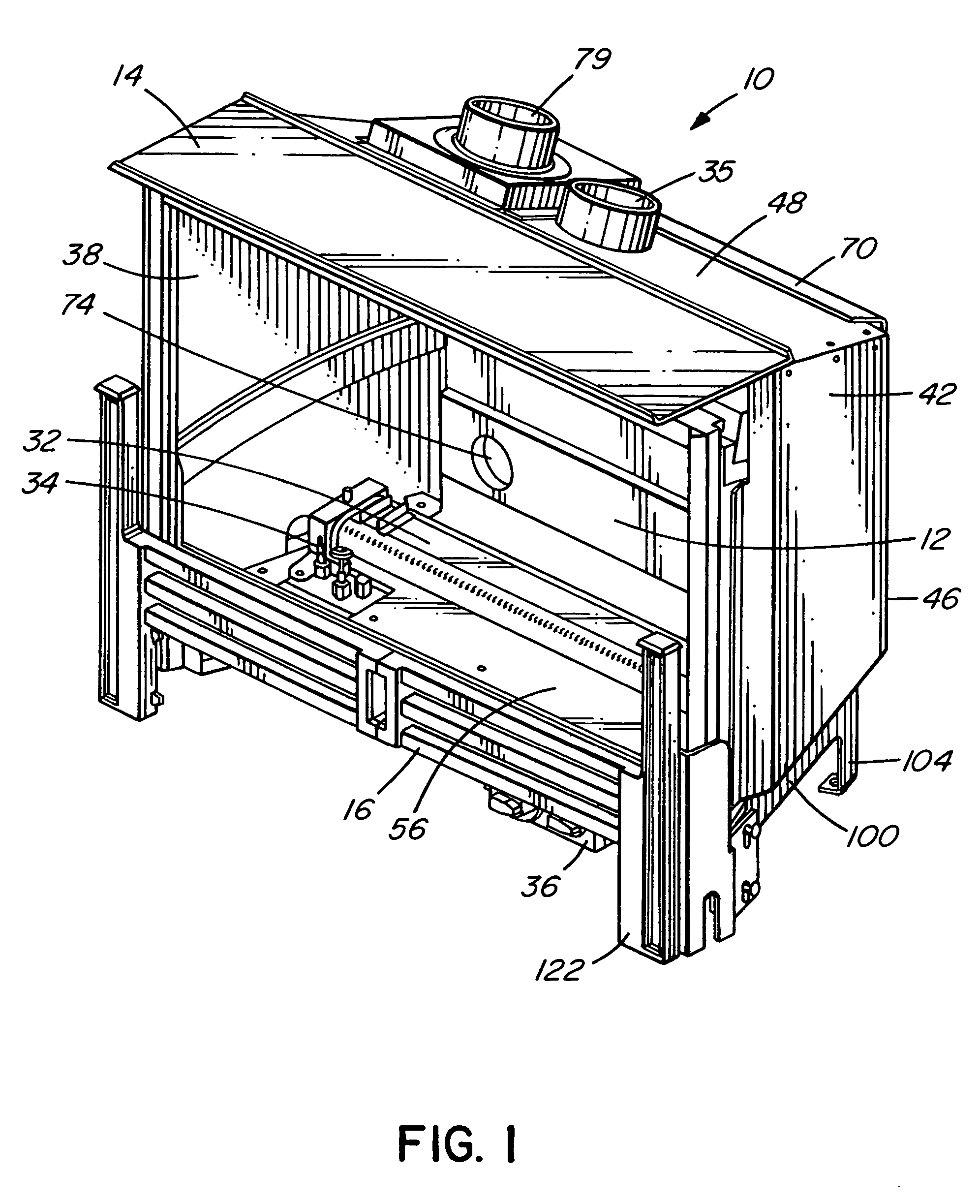

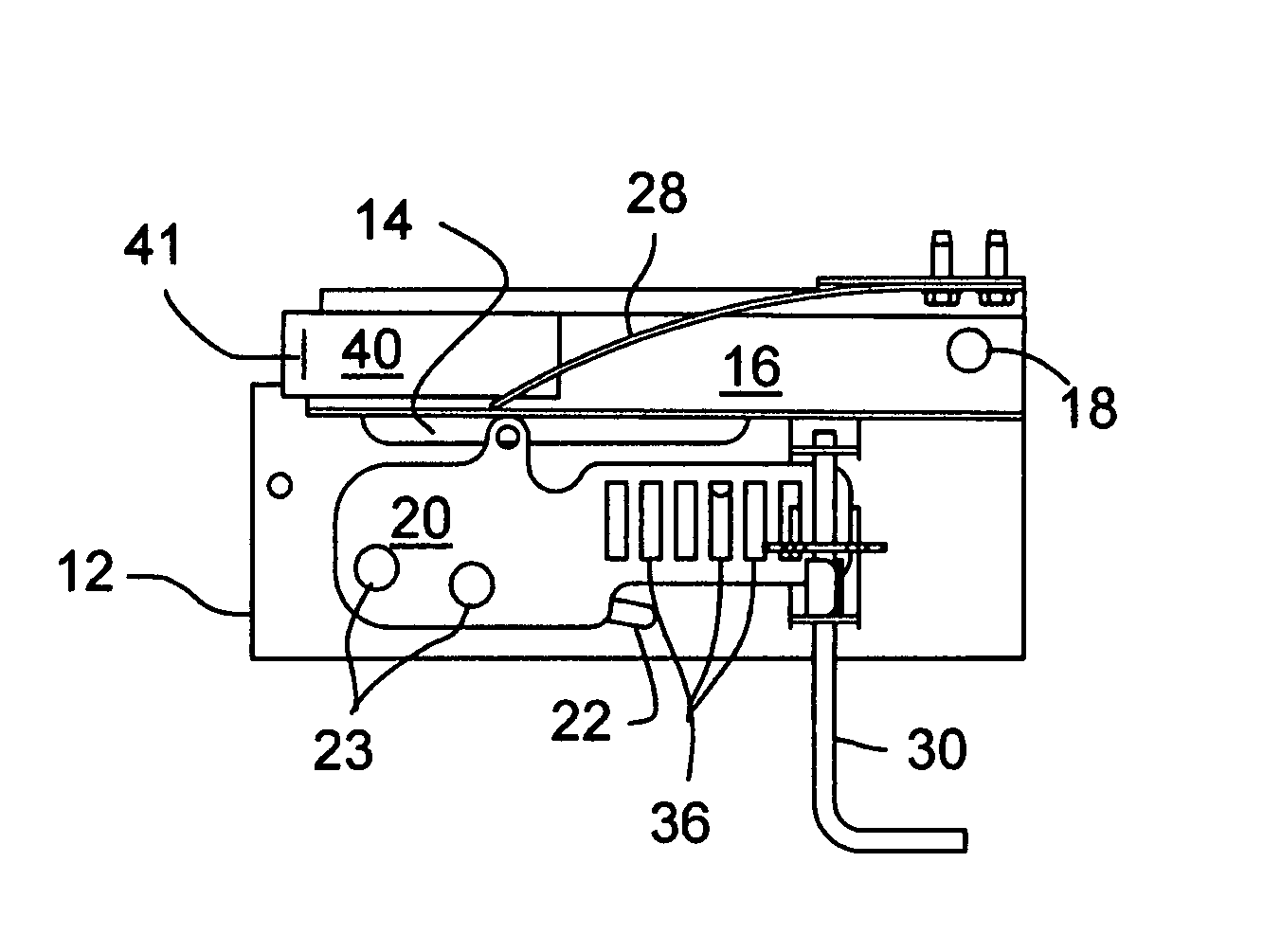

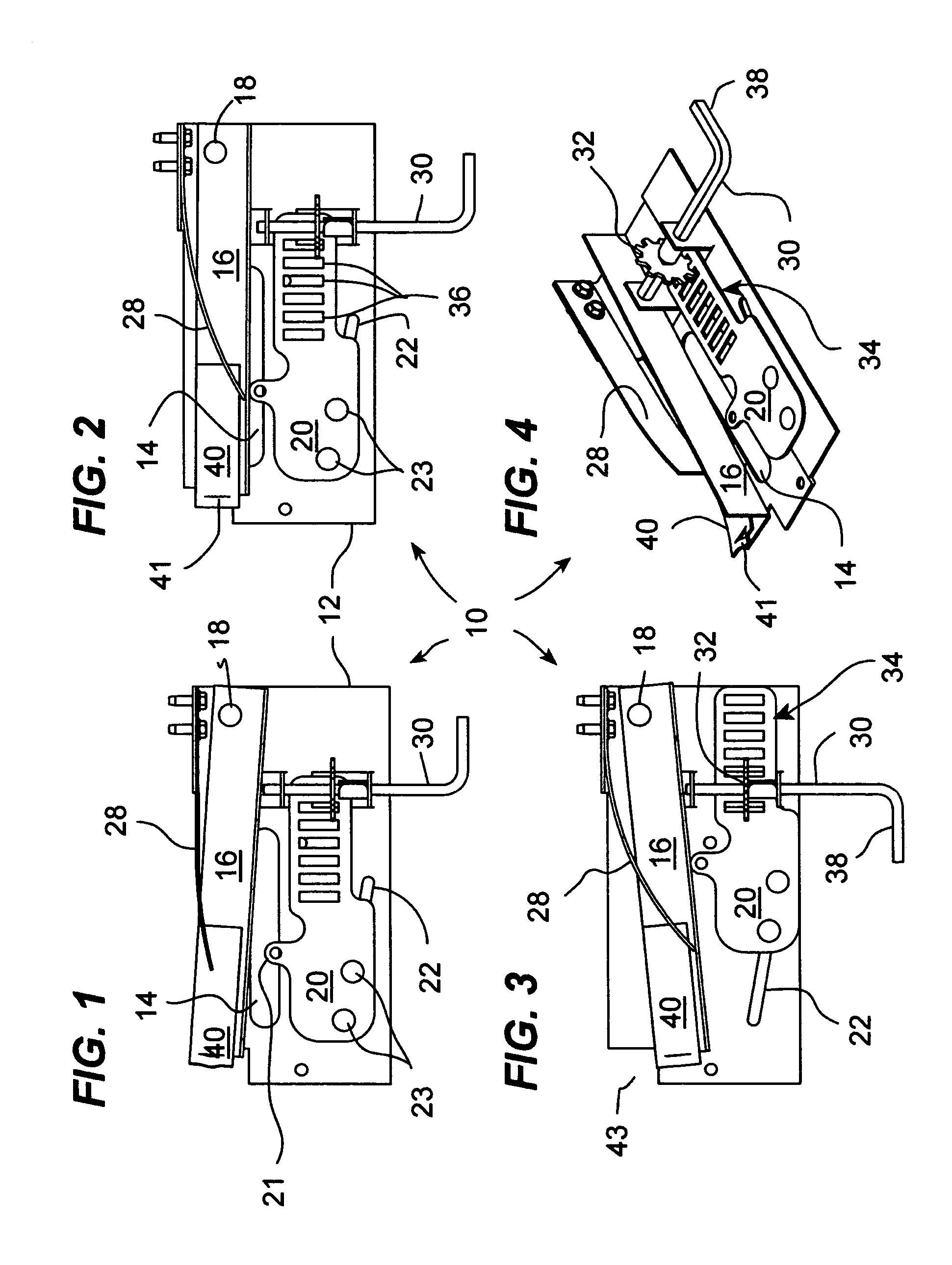

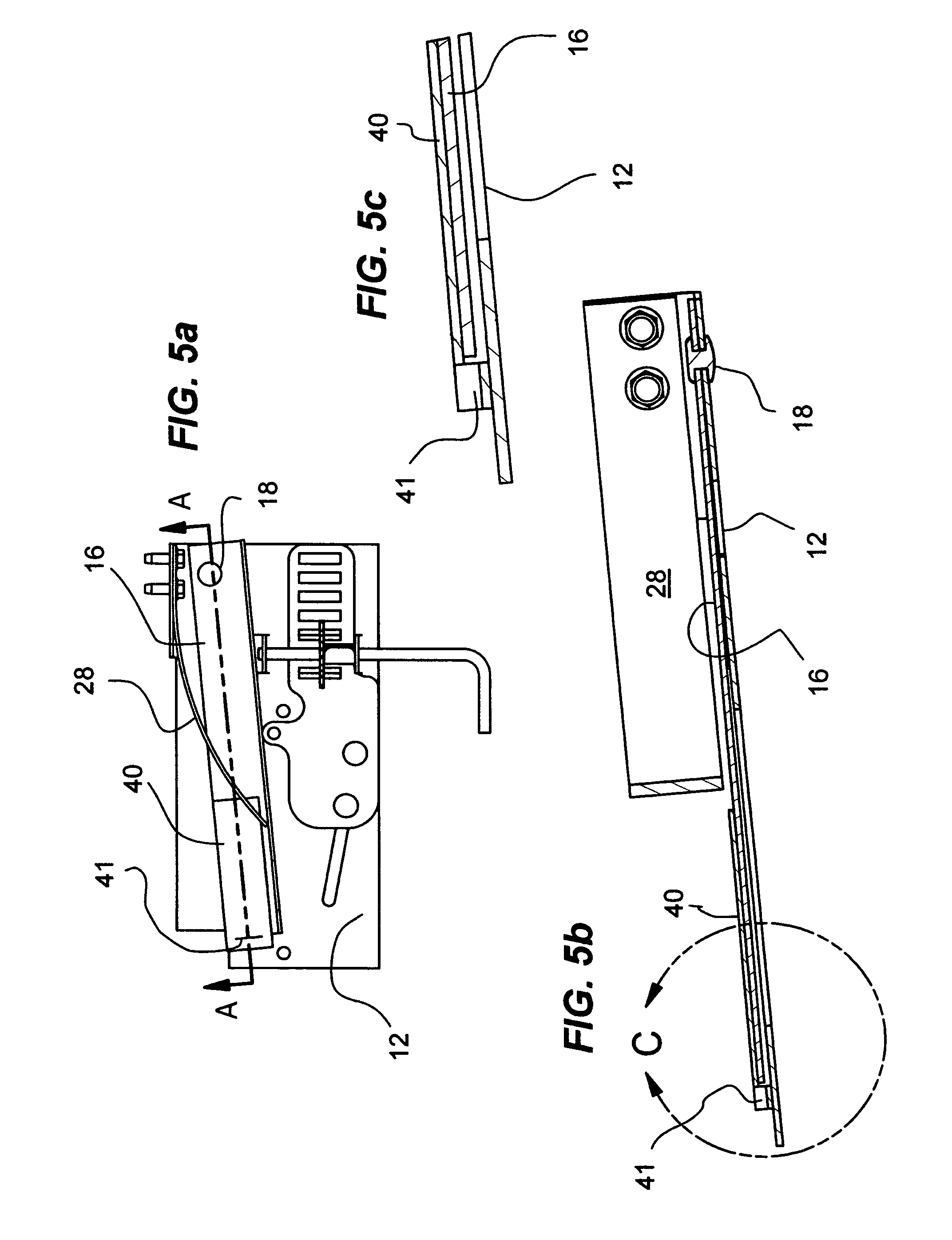

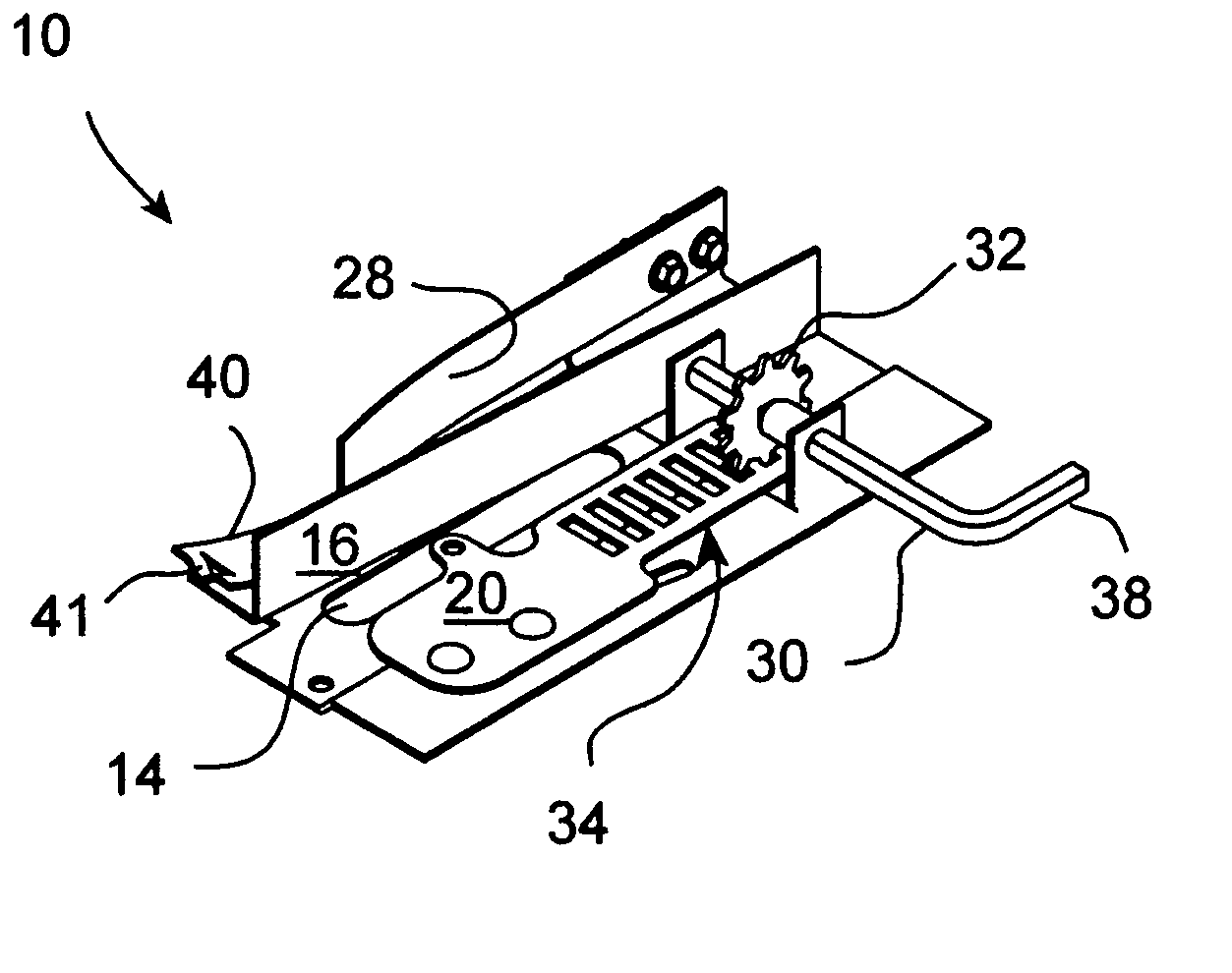

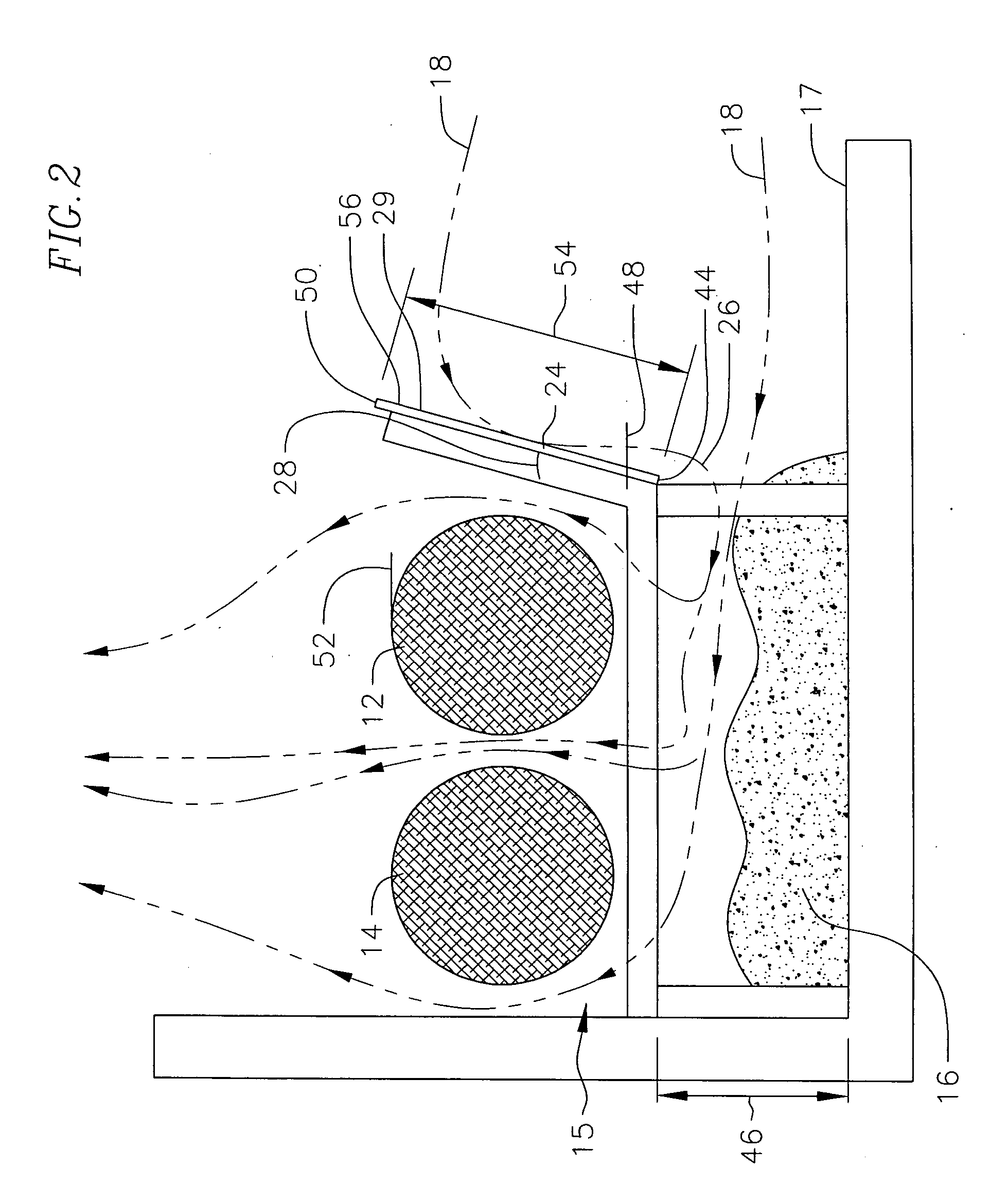

Fireplace firewood retainer assembly with air deflector, fireplace incorporating the same and method of reducing particulate emissions in a wood burning fireplace

A firewood retainer assembly and a fireplace incorporating the same are provided. The assembly includes a grate for supporting firewood at a level above a floor of a fireplace combustion chamber. The grate includes a first end opposite a second end such that a width of said grate is defined between these ends. The assembly also includes a deflector positioned adjacent the grate for deflecting air entering said combustion chamber below the level. A method of burning firewood is also provided which results in reduced particulate emissions. The method requires the deflection of air used for combustion below the firewood, heating the air with embers located below the firewood, and using the heated air for combustion.

Owner:INNOVATIVE HEARTH PROD

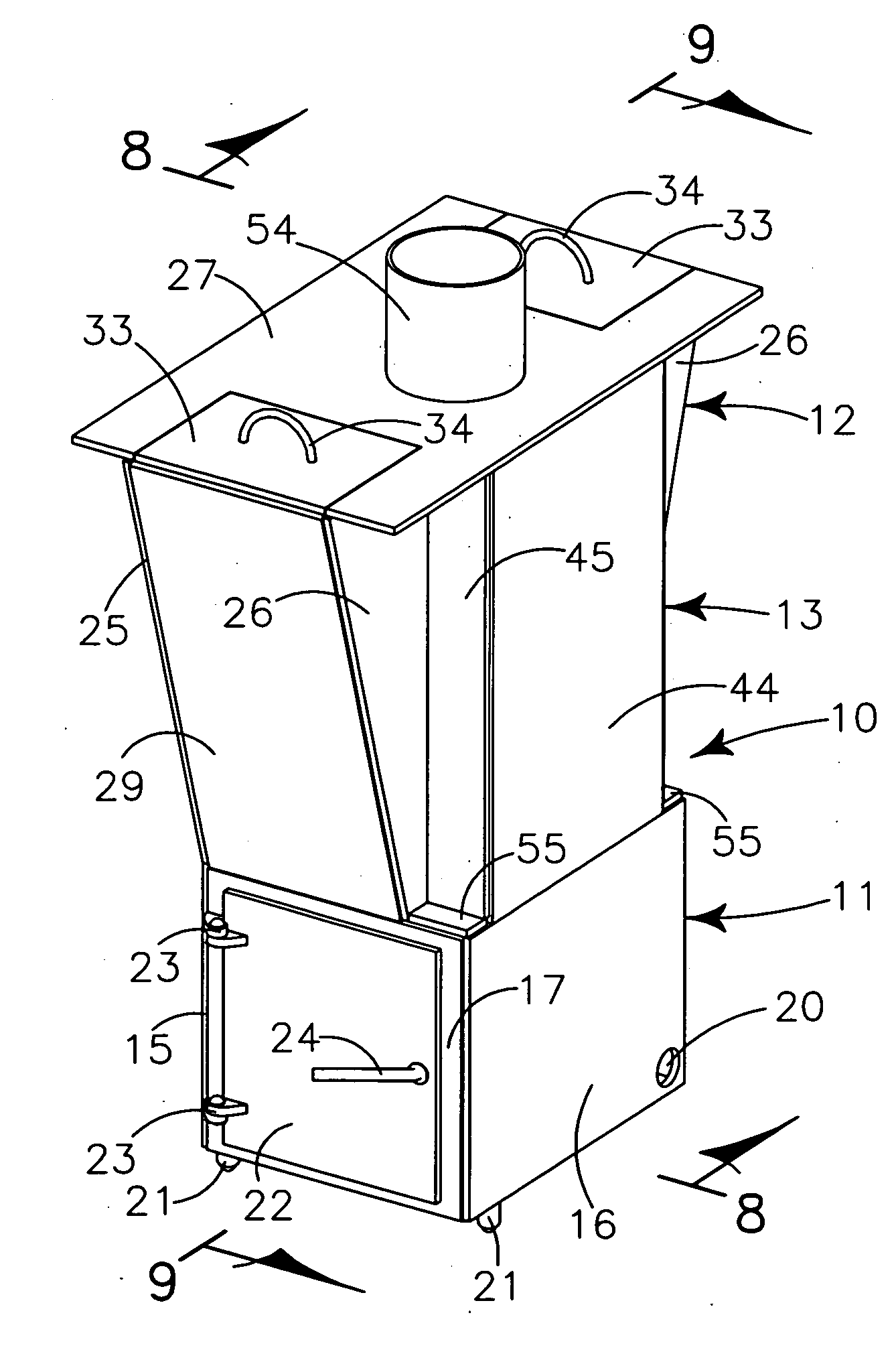

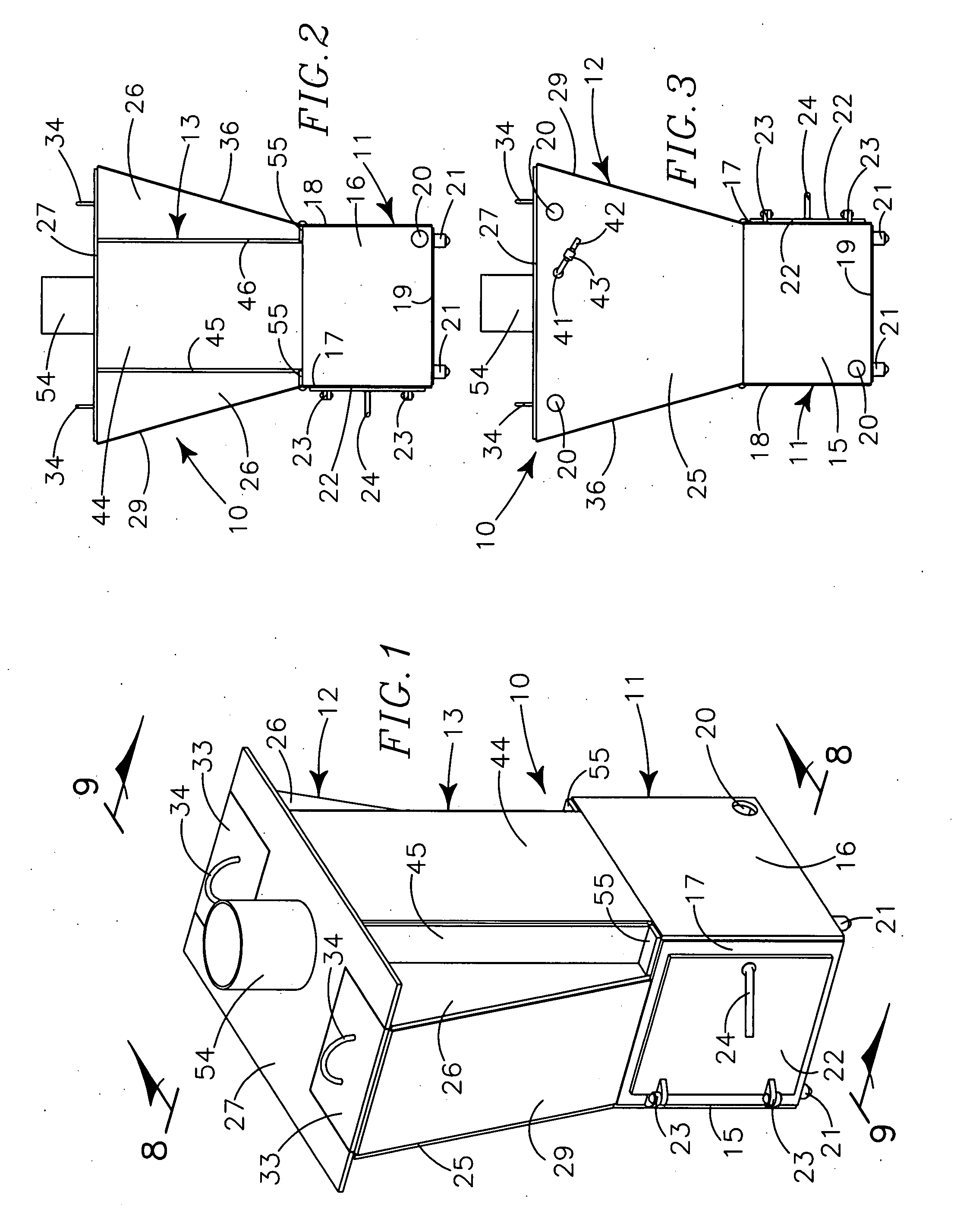

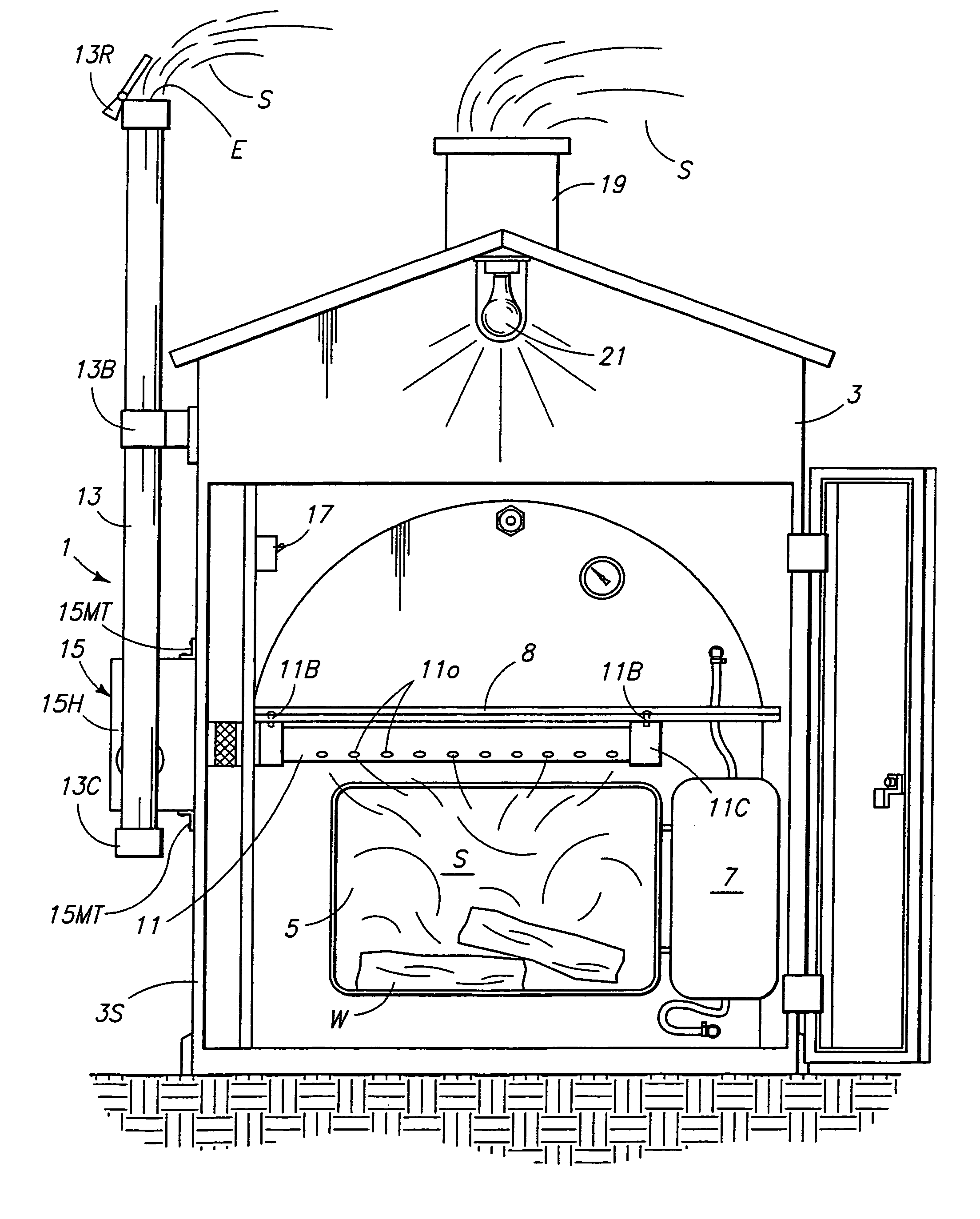

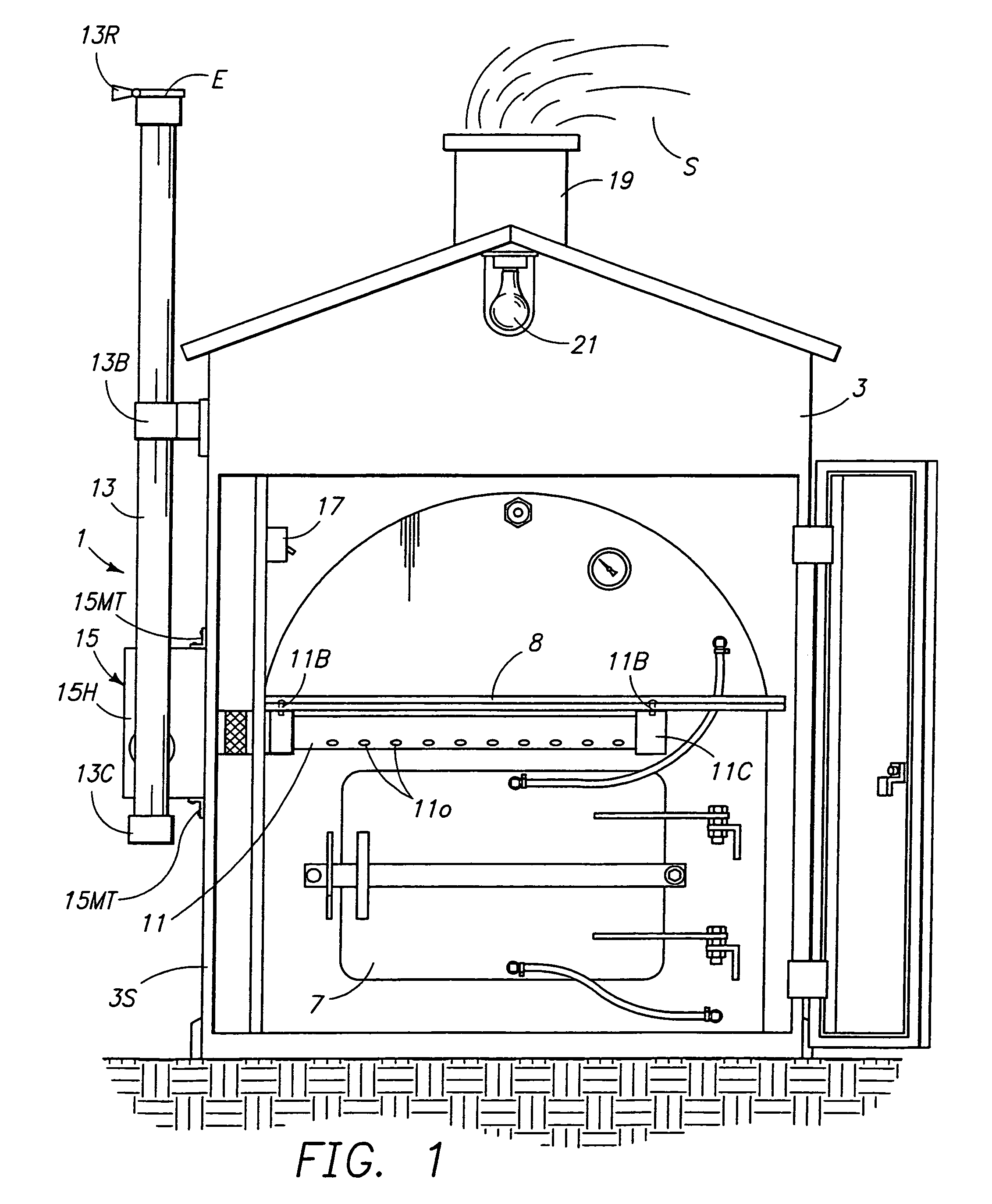

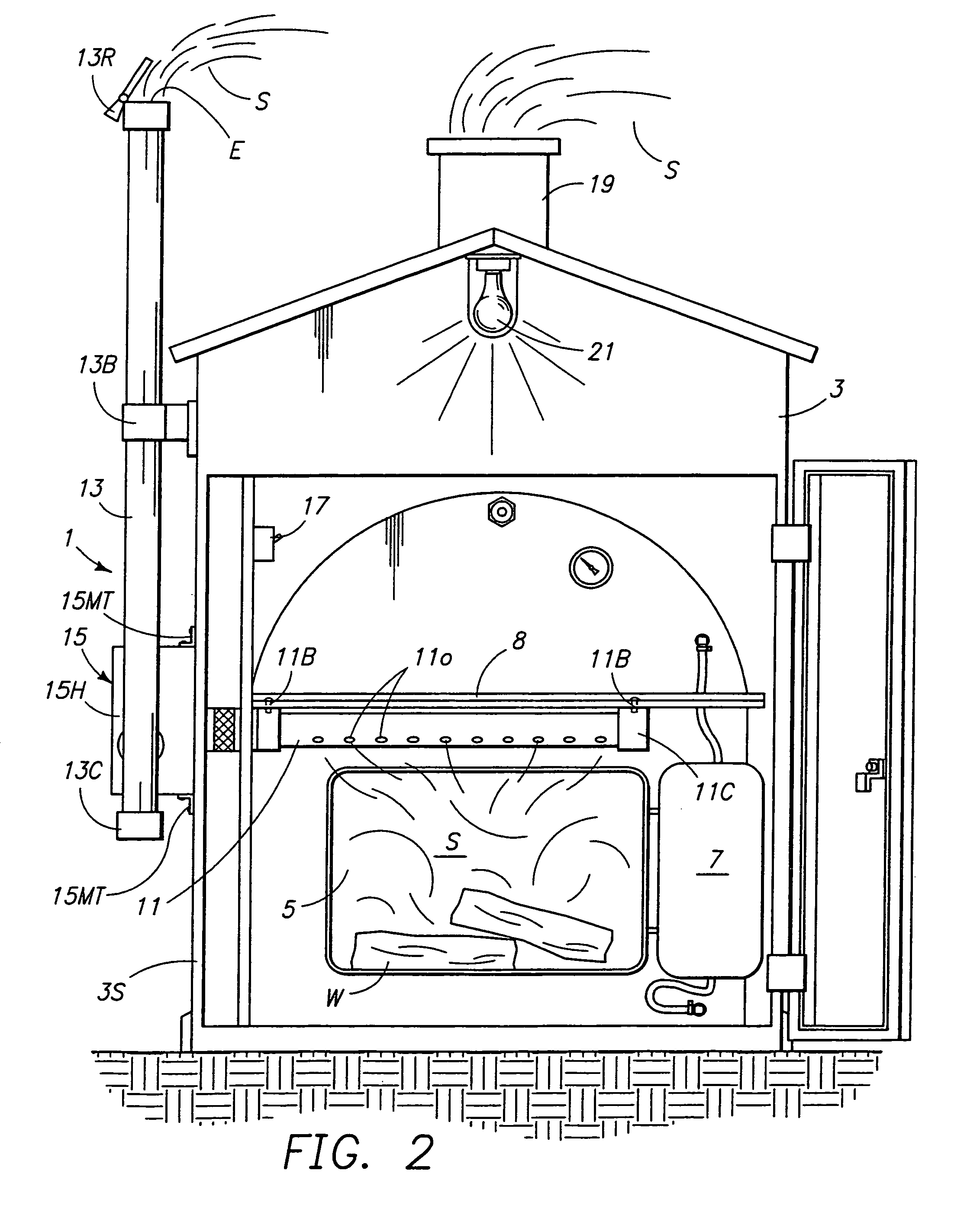

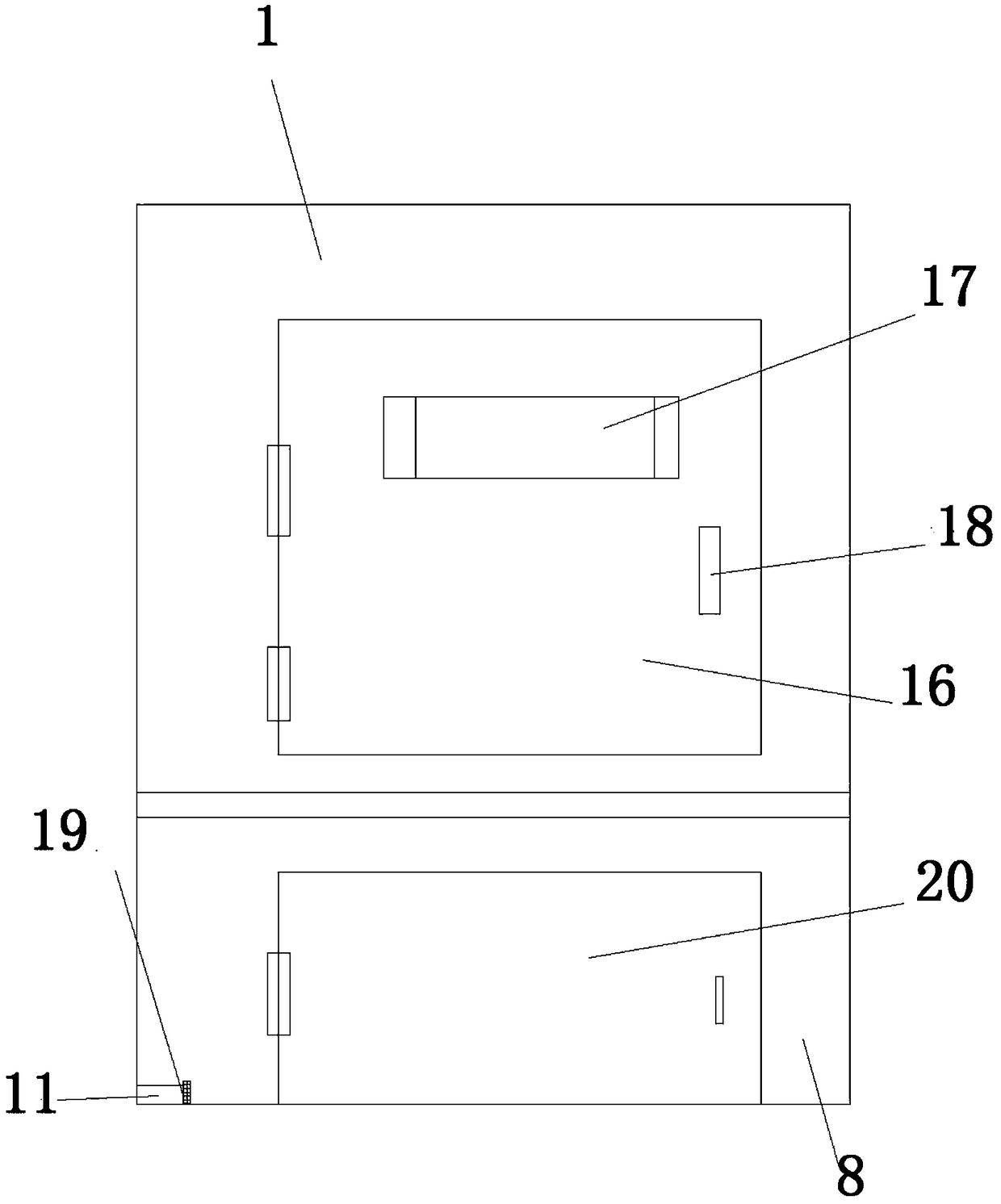

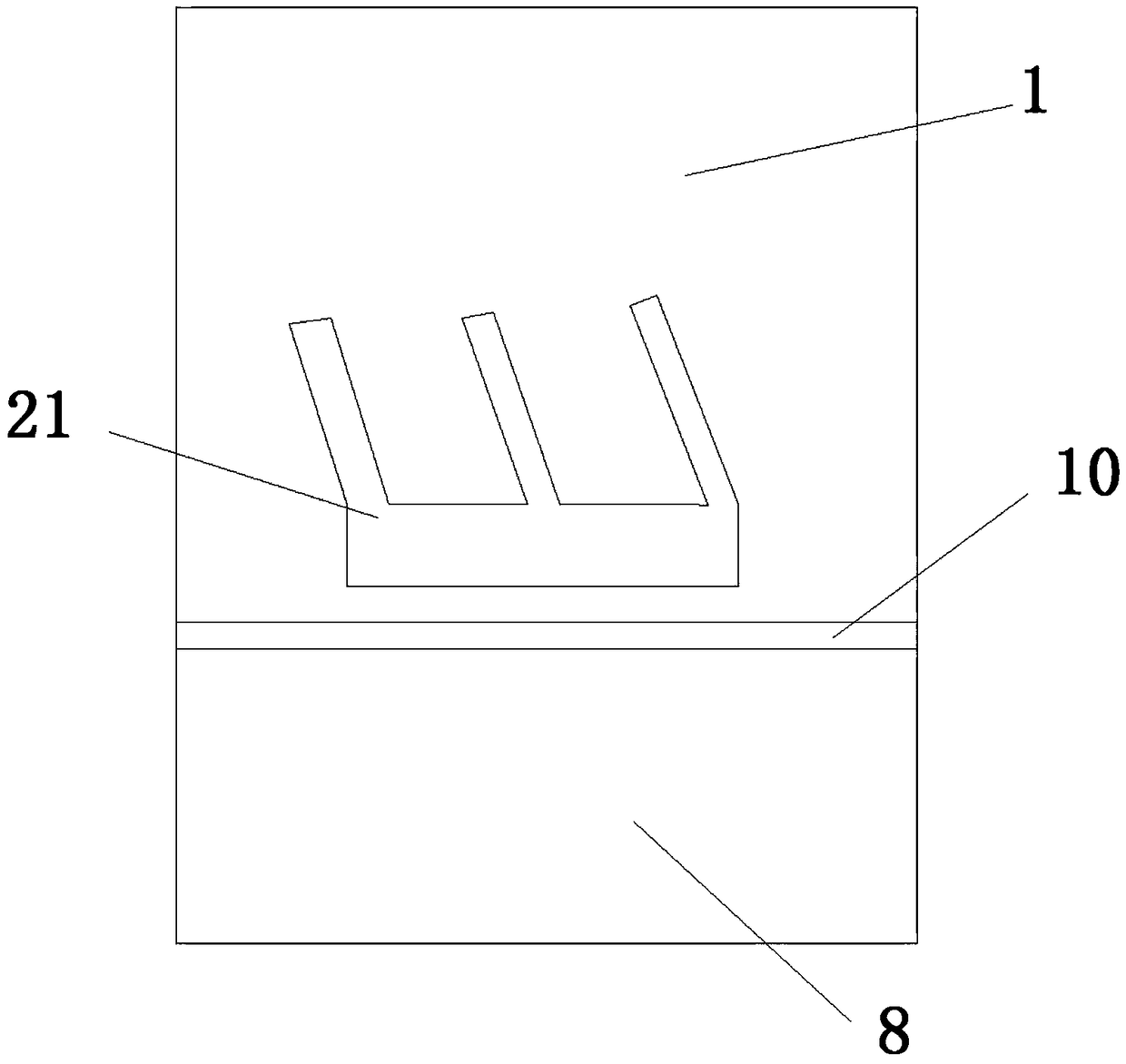

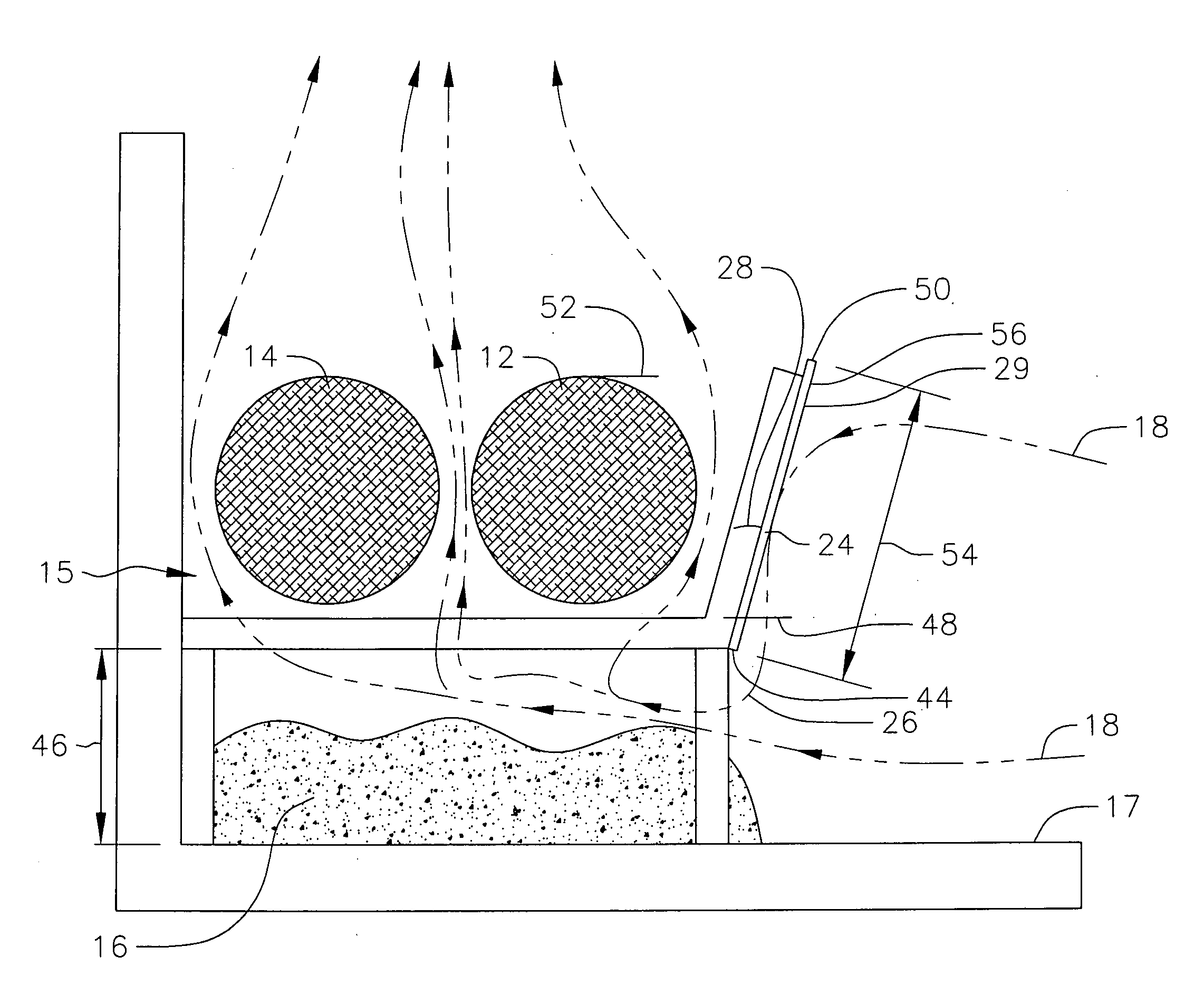

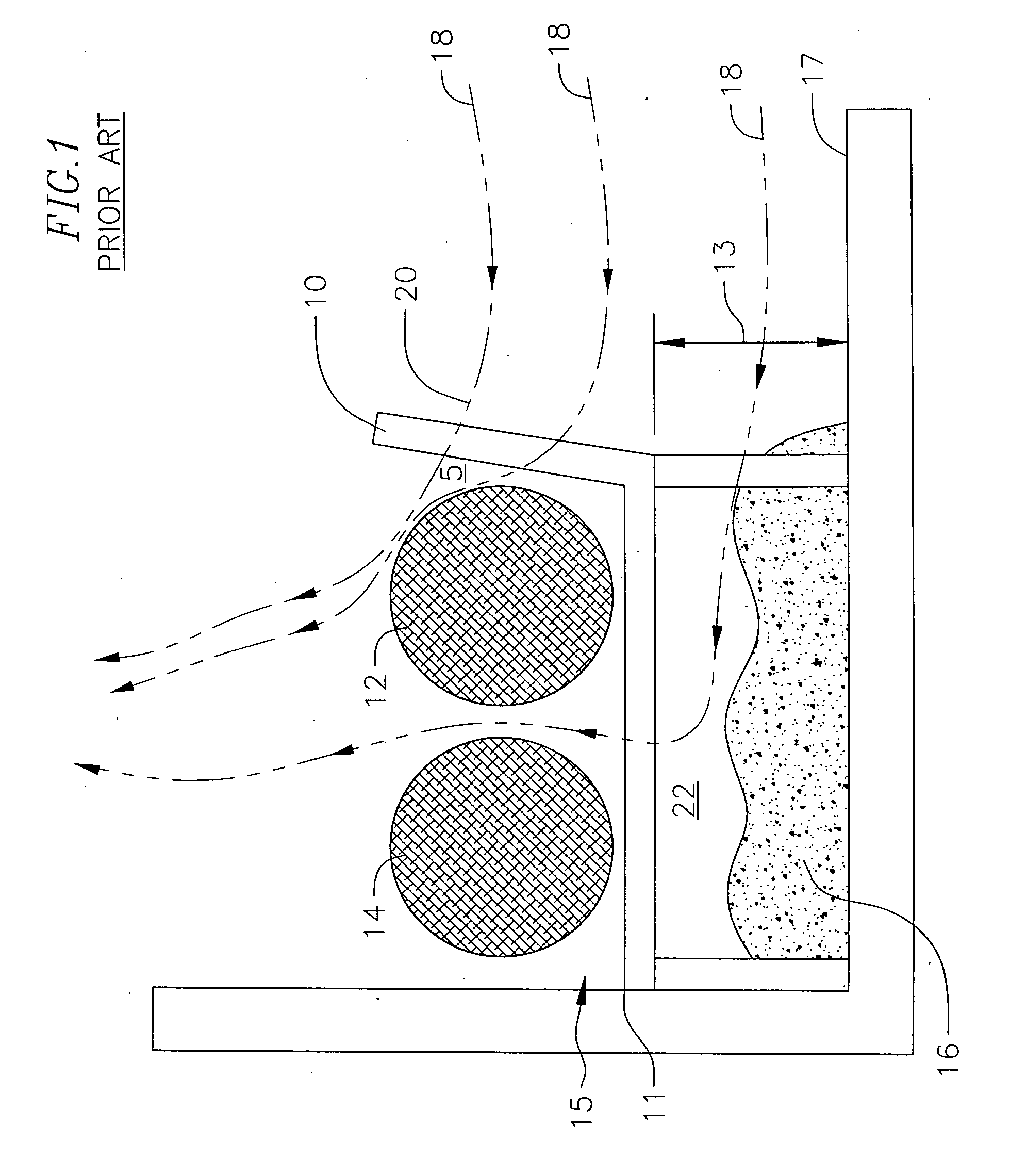

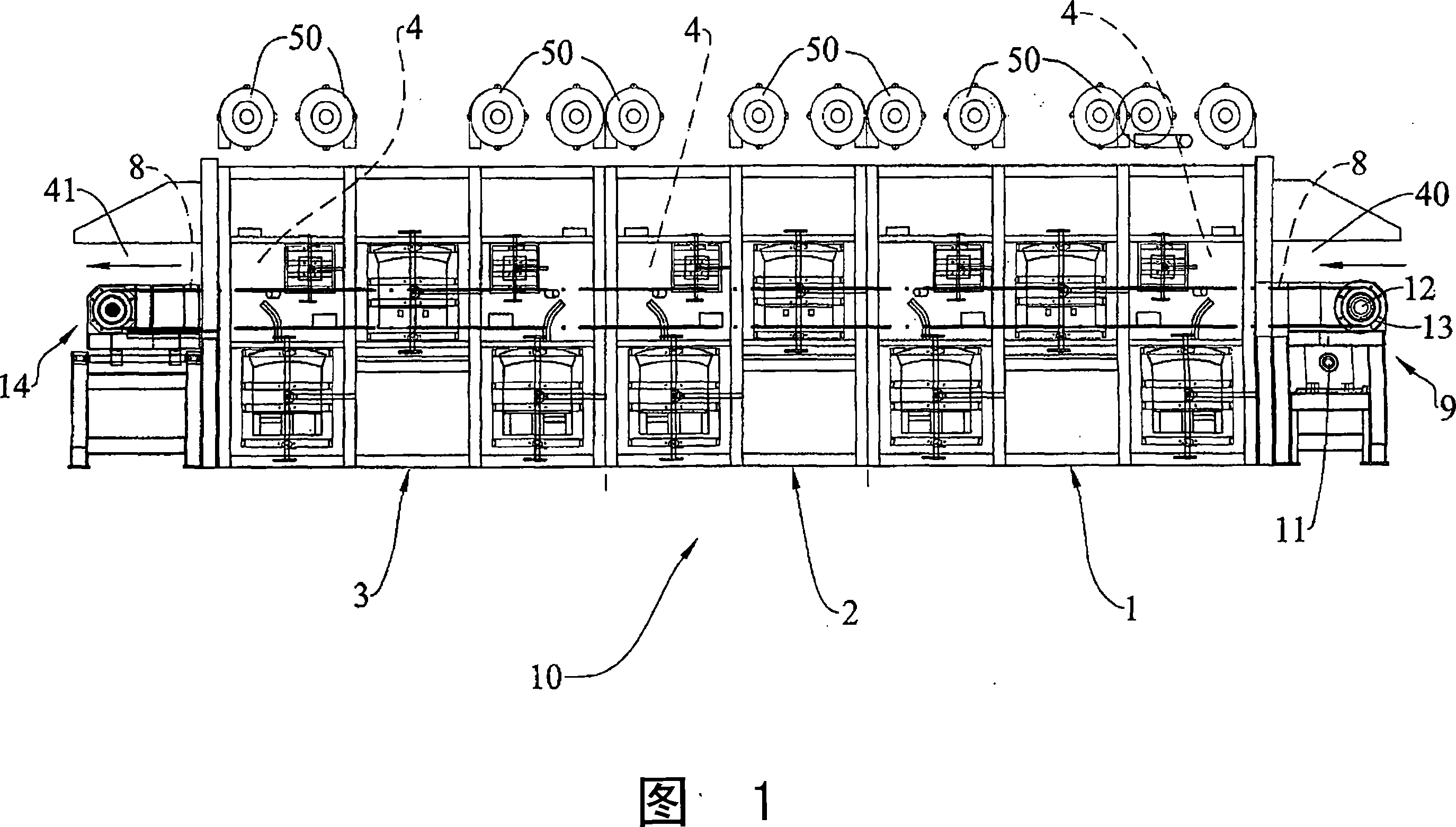

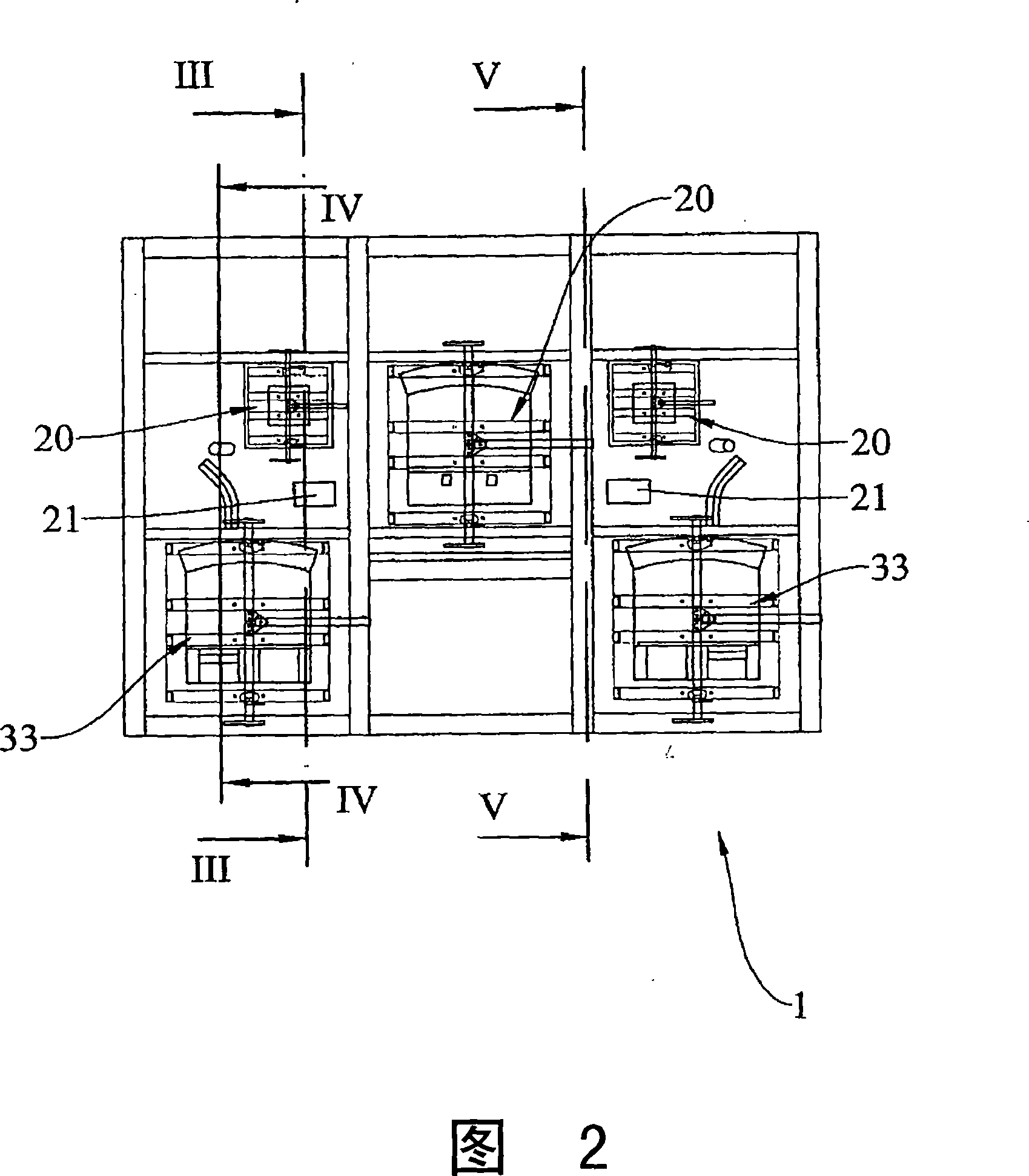

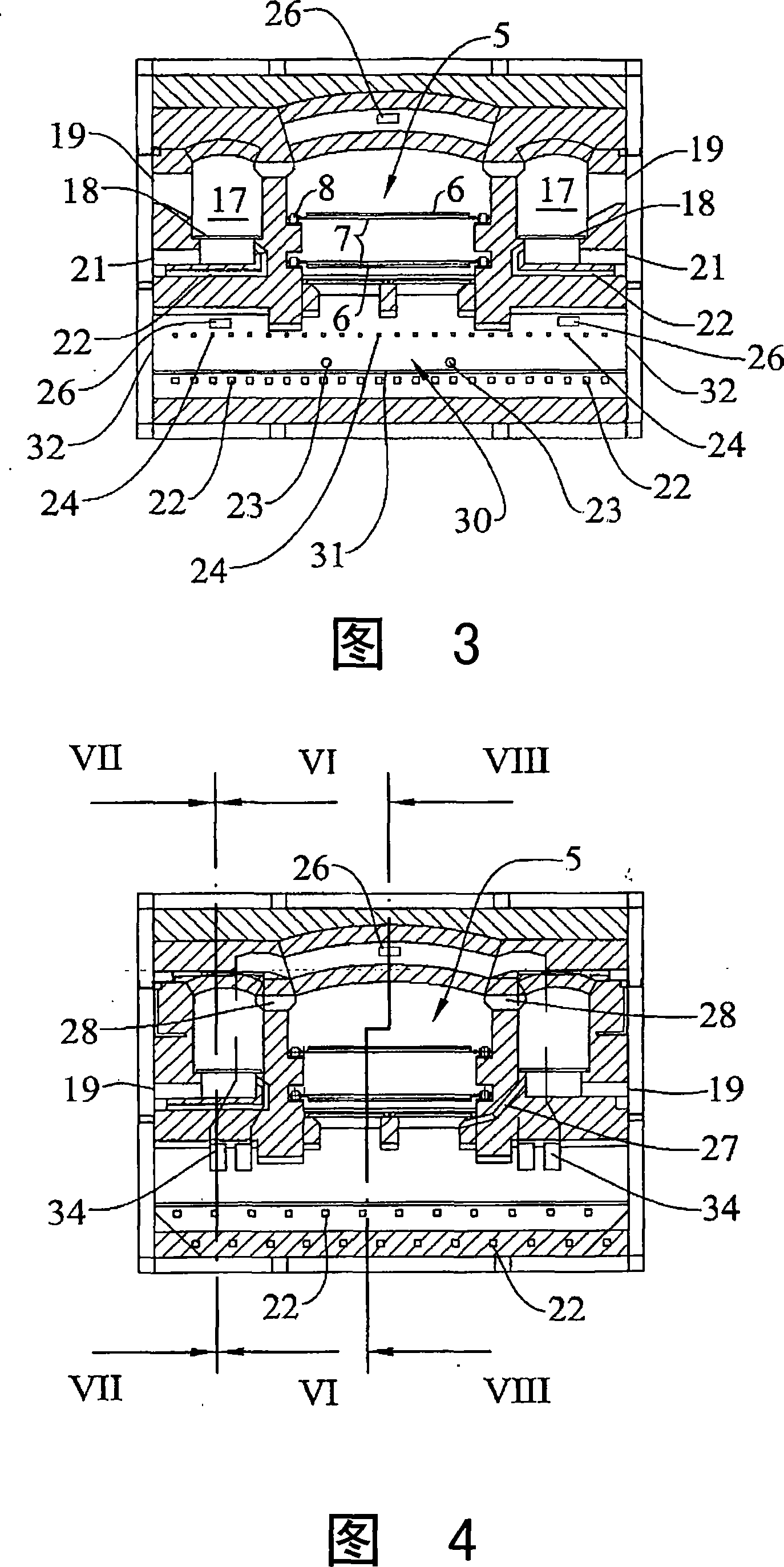

Industrial tunnel type wood burning oven for the baking of pizza and similar alimentary products

InactiveCN101179940AQuality improvementImprove productivityClimate change adaptationBaking ovenFirewoodCombustion chamber

An industrial oven with tunnel for the baking of pizza or similar alimentary products is disclosed, made up of a bearing structure (10) in refractory material comprising an inlet mouth (40) and one of outlet (41) connected by a passing through tunnel (4) along which a baking surface (5) supporting pizza or similar alimentary products slides. Said oven is heated with firewood and it comprises slits (22, 24) for the passage of primary air for the combustion of the firewood and air for the oxidation of the excess smoke, said primary and secondary air being moved by fans (50) controlled by a control unit which processes data on the composition of the air detected inside the oven by sensors (26), a top combustion chamber (15) housing top furnaces (17) made up of top grates (18) supporting combustible firewood and a bottom combustion chamber (16) housing bottom furnaces (30) made up of bottom grates (31) supporting combustible firewood.

Owner:泰克诺佛尼有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com