Wood burning stove

a wood burning stove and burner technology, applied in the field of stoves and furnaces, can solve the problems of waste of carbon particulates, incomplete combustion, oxidation of volatile gases, etc., and achieve the effect of more fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]As used herein, the term “bottom”, its derivatives, and grammatical equivalents refers to the portion of my stove that is closest to a supporting surface such as a floor. The term “top”, its derivatives, and grammatical equivalents refers to the portion of the stove that is most distant from the supporting surface. The term “outer”, its derivatives, and grammatical equivalents refers to a side portion of the stove as opposed to the laterally medial portion of the stove.

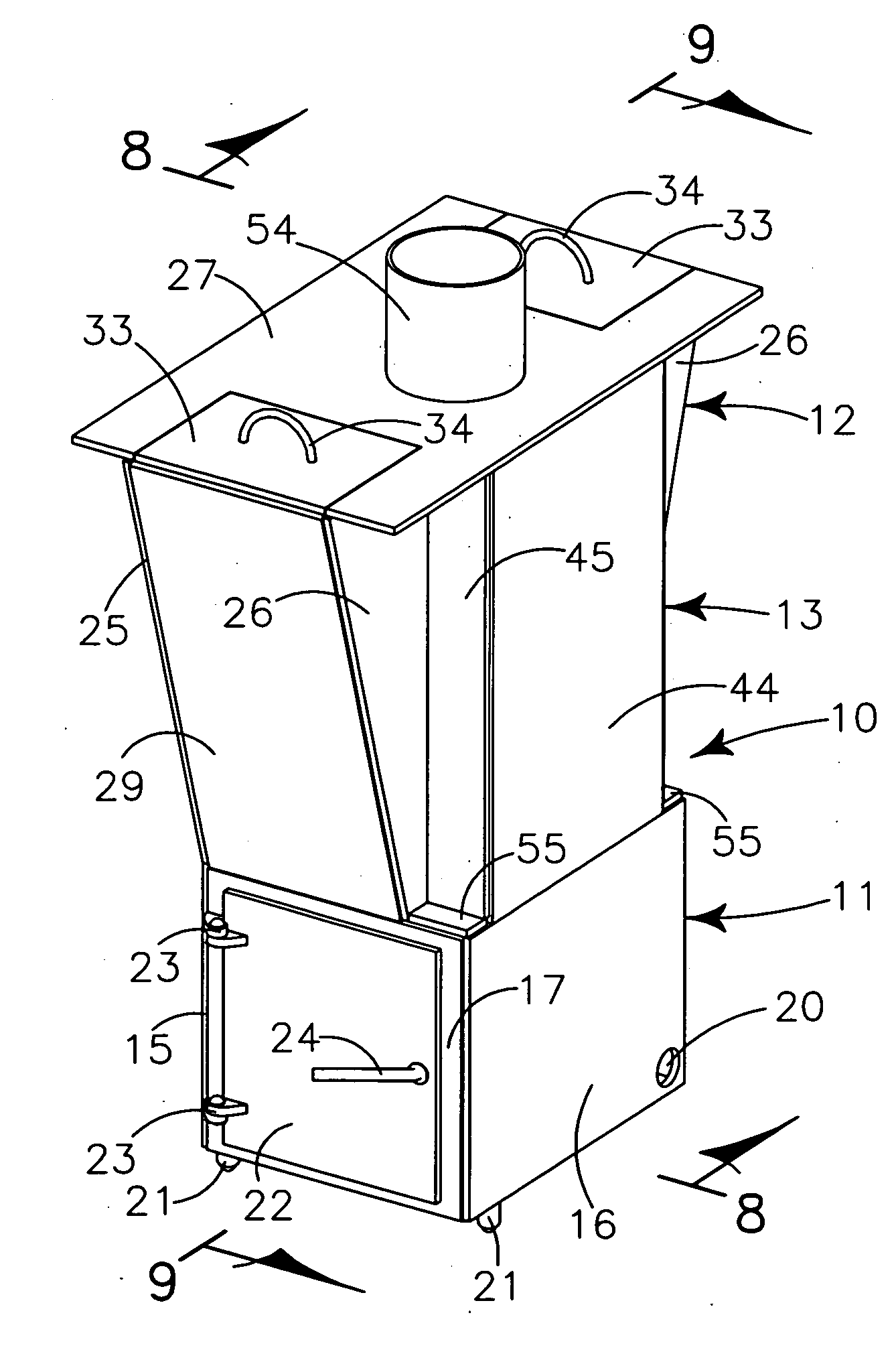

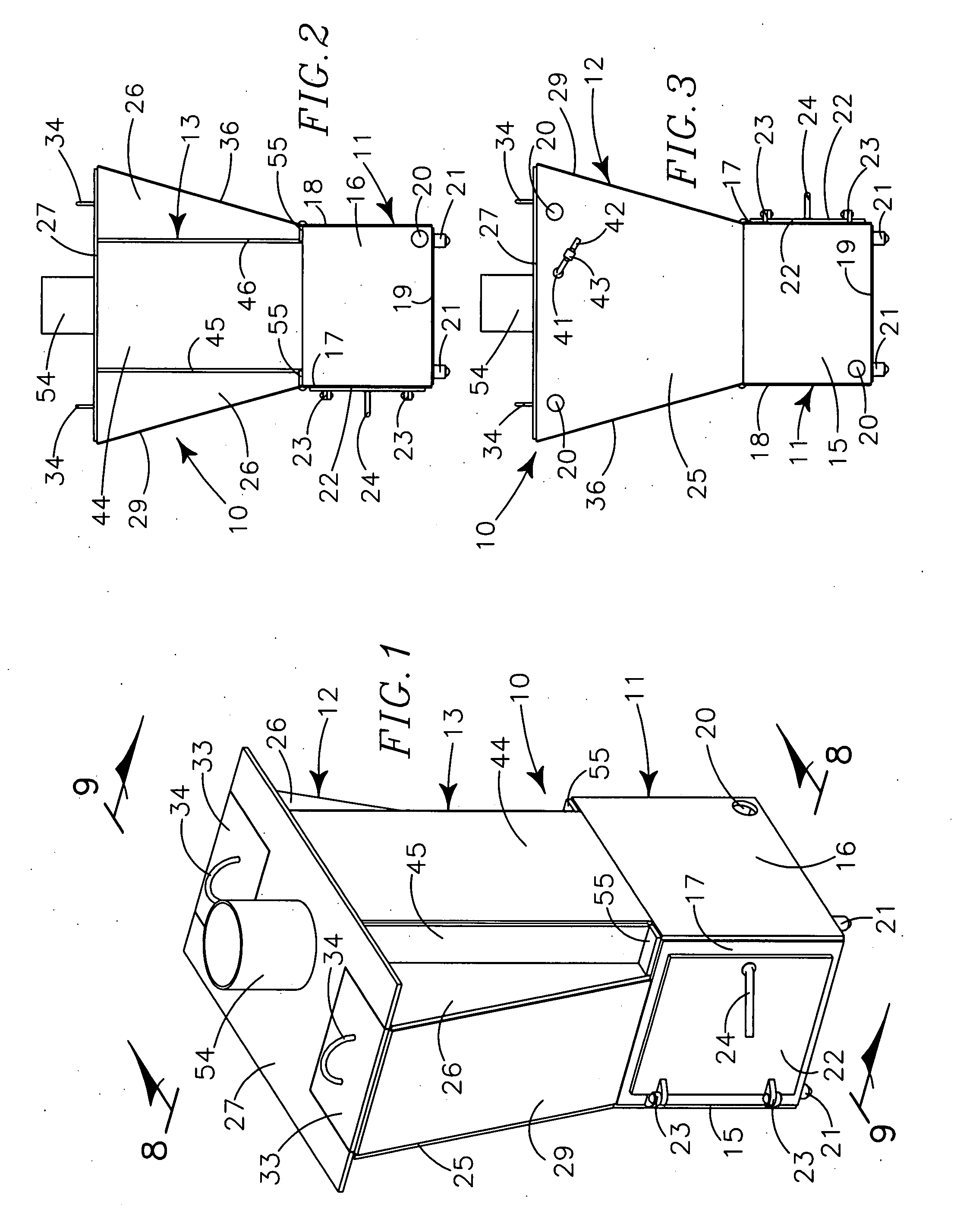

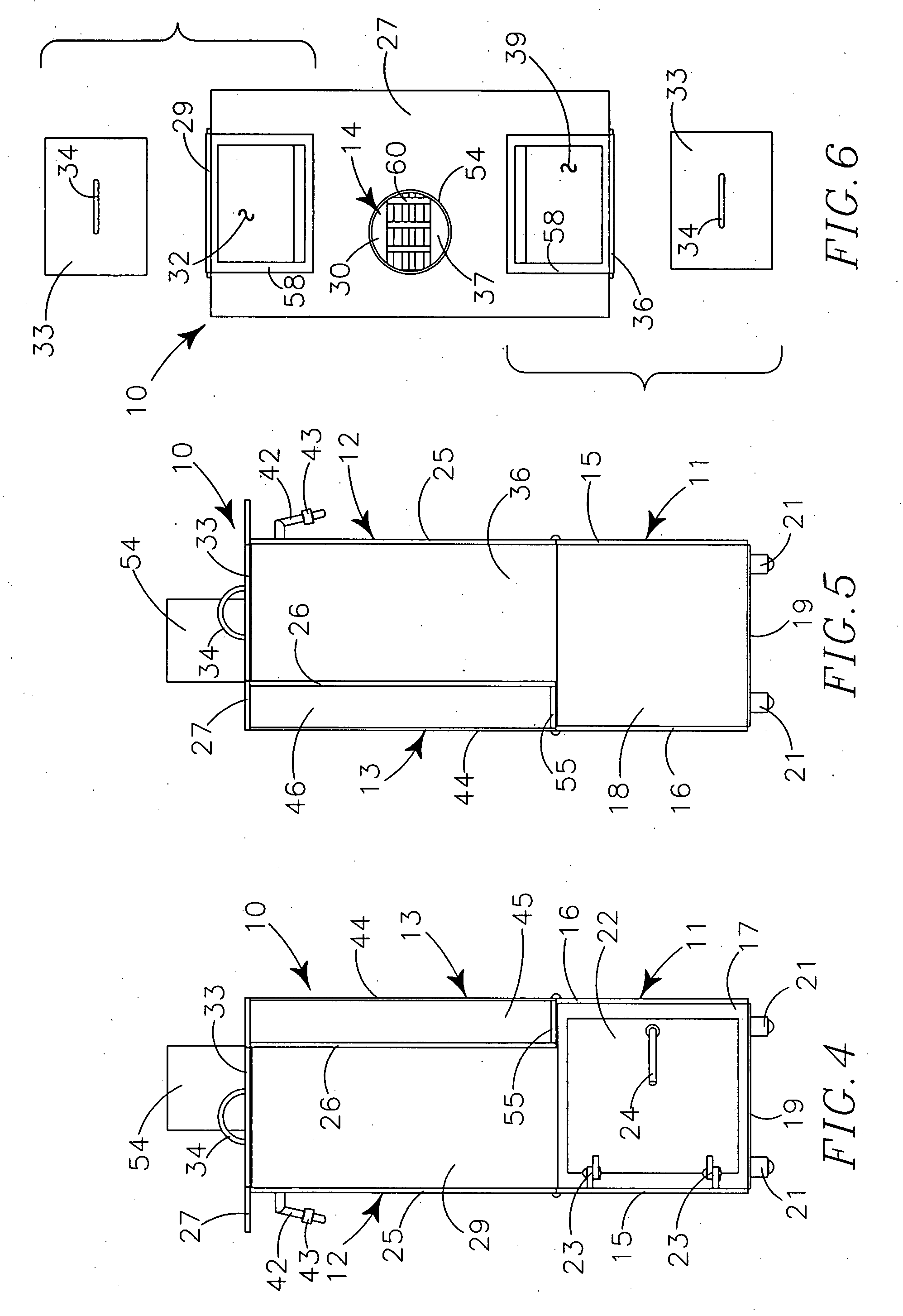

[0039]My wood stove is constructed of sheet steel with welded seams and provides a peripherally defined stove body 10 formed by a lower rectilinear fire box 11, an upper combustion chamber 12 having an inverted truncated triangle shape with two angulated fuel chutes 28, 35 therein, and a re-burner channel 13 communicating between the combustion chamber 12 and the fire box 11.

[0040]The fire box 11 has a front 15, a back 16, a bottom 19 and two sides 17, 18 that are welded together at adjoining edge portions formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com