Home cooling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

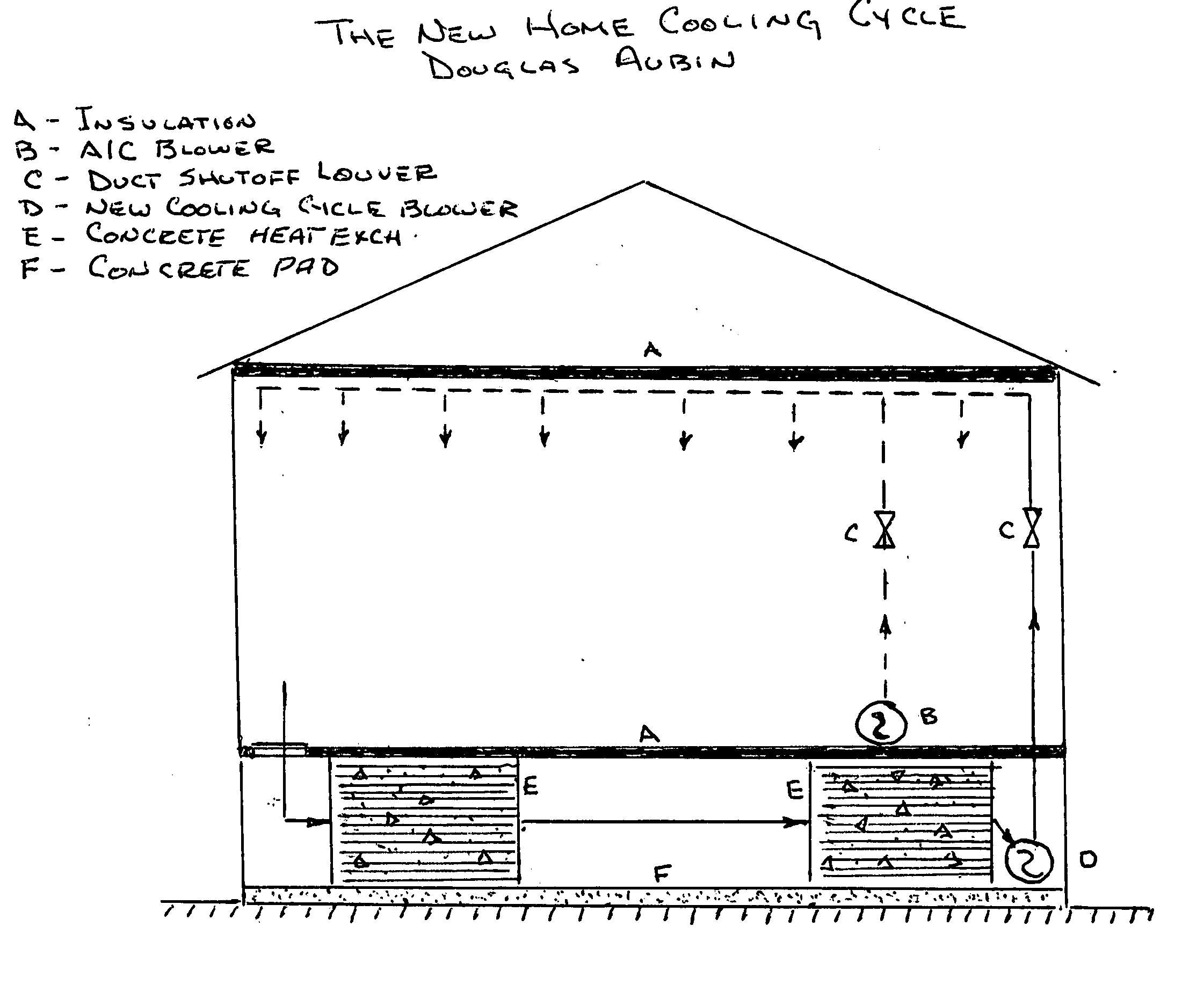

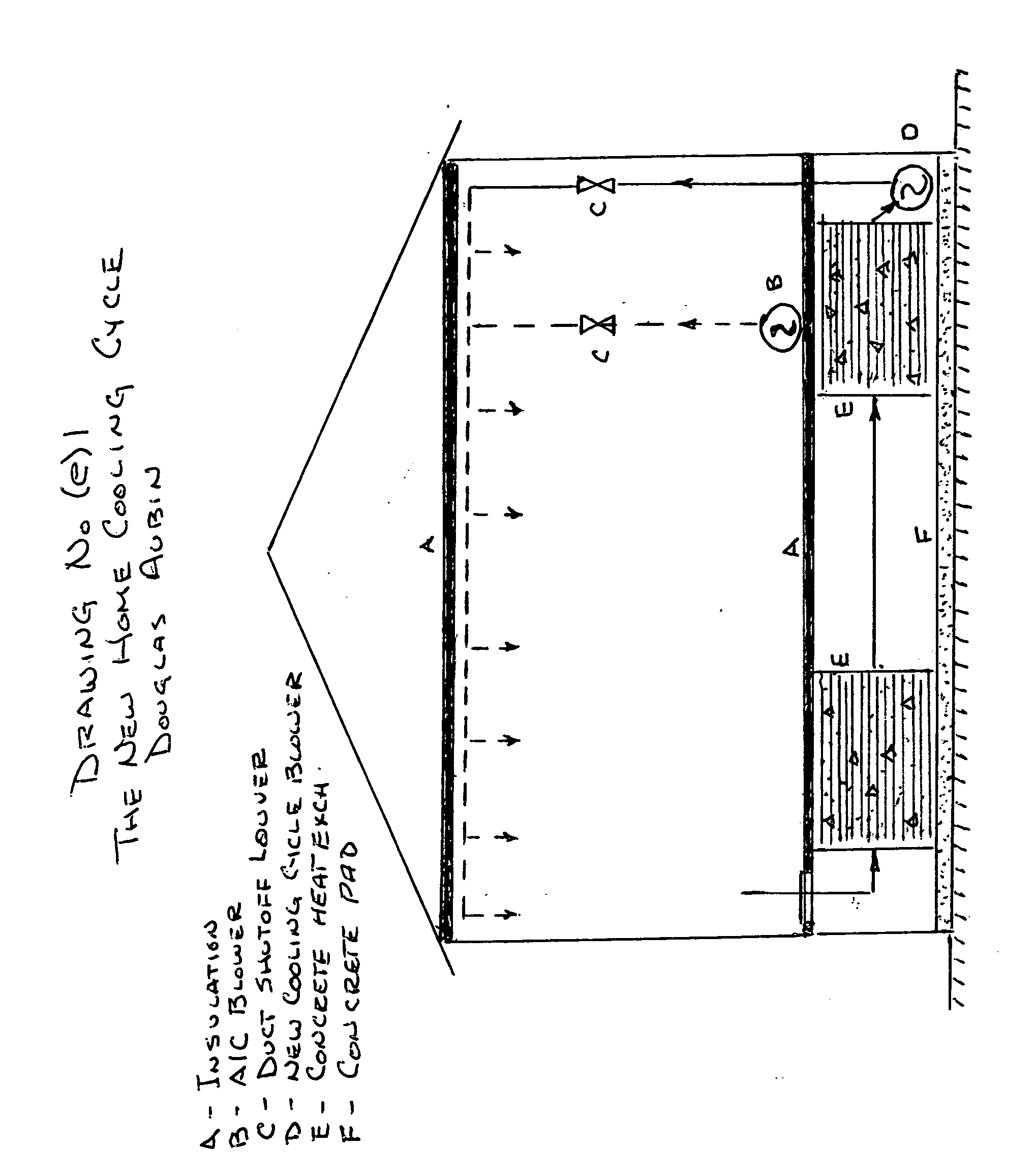

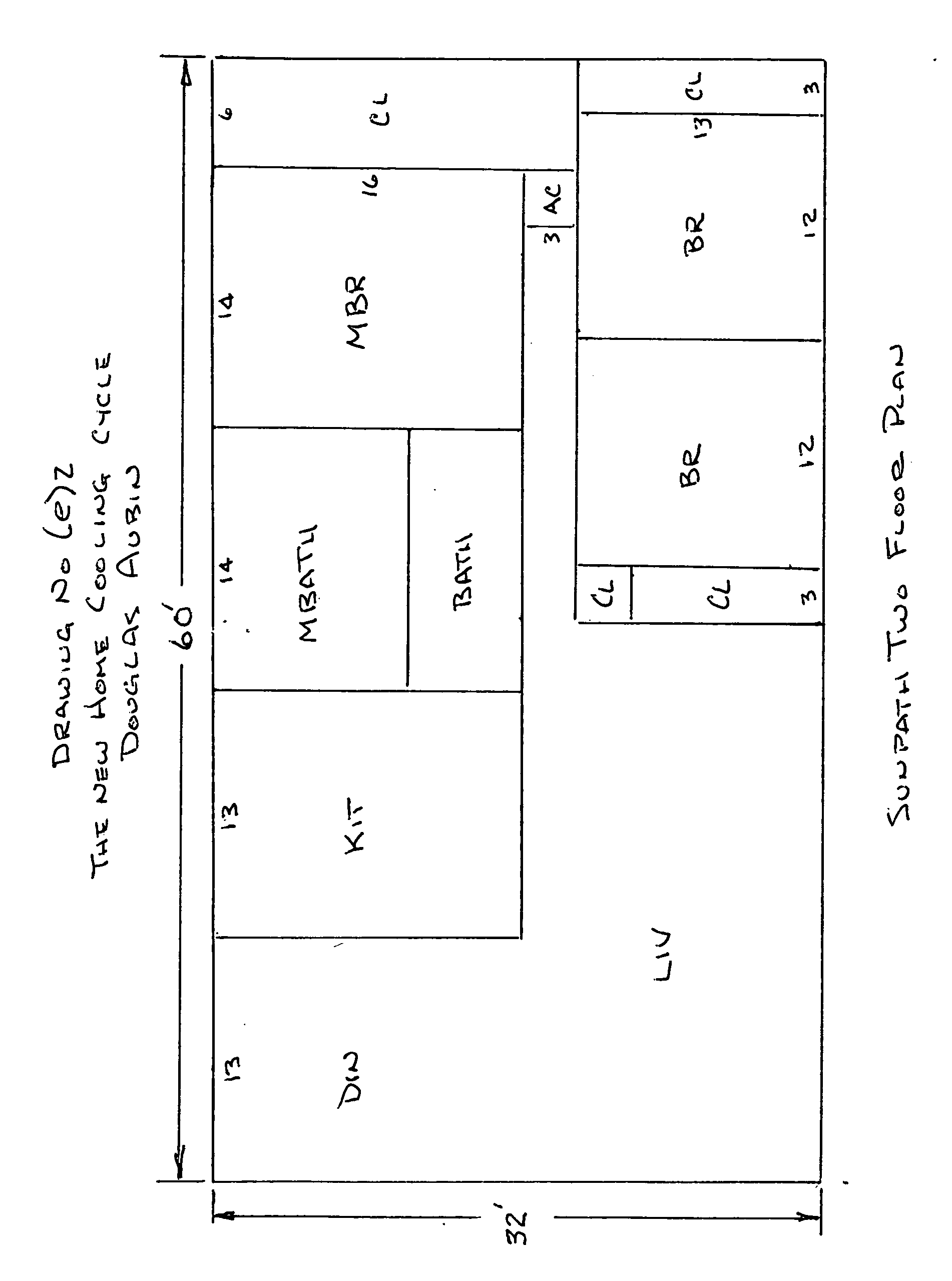

[0021] This invention proposes a home summer cooling cycle, in addition to the normal refrigerated air conditioning system. The cooling cycle utilizes a separate blower and a concrete mass located under the home between the floor and the ground. This blower and concrete mass are isolated from the home interior by the insulated flooring. The blower distributes air into the home interior using the normal air conditioning ductwork. It is important that this ductwork be located under the ceiling or under the flooring as in mobile homes and not in the attic.

[0022] Heat entering the home is absorbed into the air and interior walls and fixtures. Heated interior air is next routed via a filter-grill into the concrete mass area beneath the home. The concrete absorbs heat from the air, the air flows to the blower suction and returns to the home interior. See drawing (e)1. Calculations shown at the end of this section show that house daily interior air temperature should only rise 5° F. above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com