Manufacturing method of ceramic pot adaptable to various heat sources

A manufacturing method and a technology for a ceramic pot are applied in the field of ceramic manufacturing to achieve the effects of fast heat transfer and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

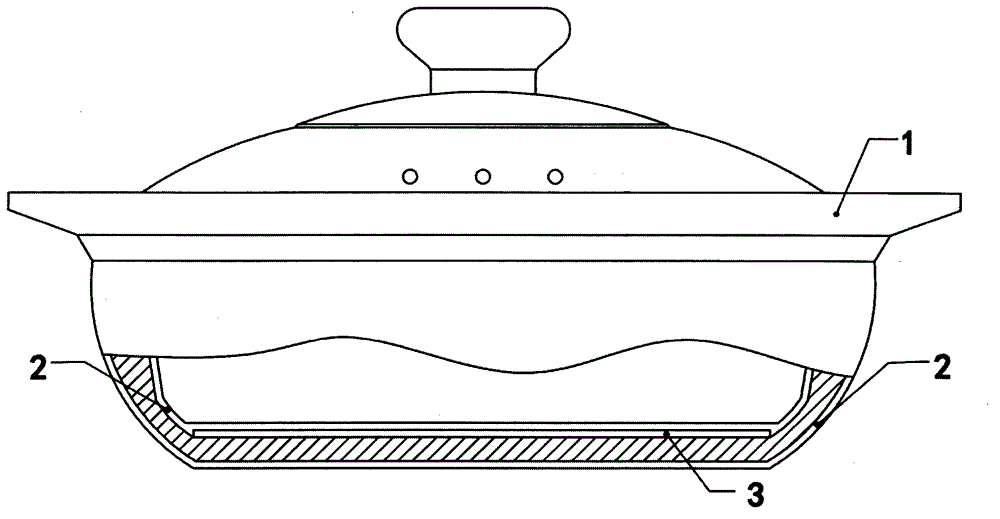

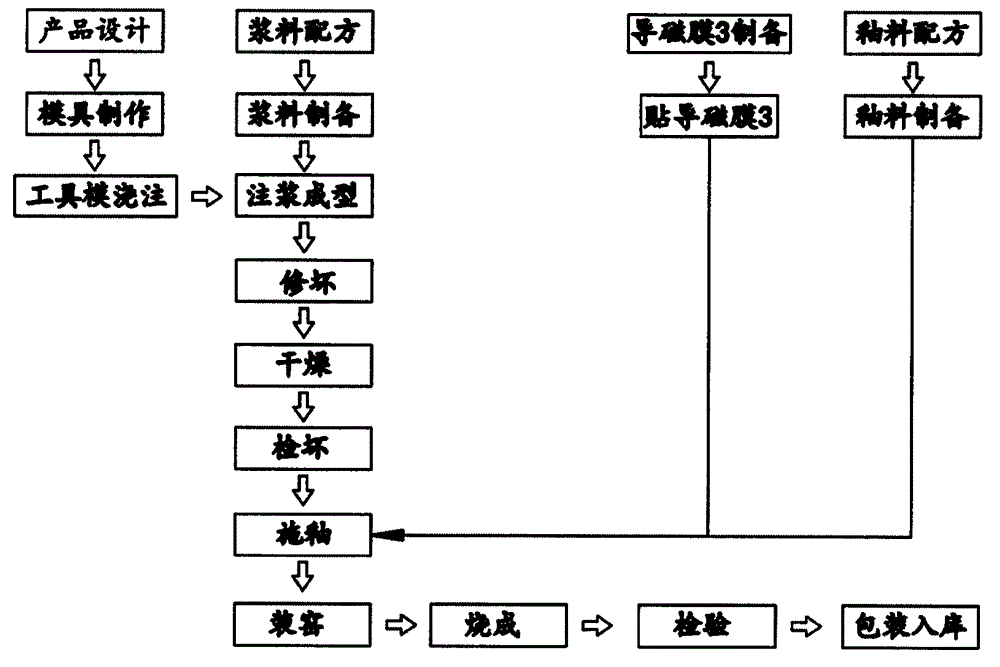

[0024] First carry out product design, mold making, slurry formula, slurry preparation, glaze formula, glaze preparation, and then pour the working mold. After the grouting is formed, trim the billet, then dry it, and then check the billet and magnetically conductive film 3 Preparation, then paste the magnetic film, and then enter the glazing process, then install the kiln, inspect after firing, and finally pack and store.

[0025] The magnetically permeable film 3 is made of iron thin film. The thickness of the magnetically permeable film 3 is 2 mm.

[0026] Paste the magnetic conductive film and stick the iron thin film on the inner bottom of the ceramic pot body 1 with an adhesive.

Embodiment 2

[0028] First carry out product design, mold making, slurry formula, slurry preparation, glaze formula, glaze preparation, and then pour the working mold. After the grouting is formed, trim the billet, then dry it, and then check the billet and magnetically conductive film 3 preparation, and then paste the magnetic film 3, and then enter the glazing process, then install the kiln, inspect after firing, and finally pack and store.

[0029] The magnetic permeable film is mixed and pressed with lithium oxide, adhesive, and pure silver powder to form a thin film, and after drying, it is sintered at 400°C to 700°C to form the magnetically permeable film 3 . The thickness of the magnetically permeable film 3 is 2mm.

[0030] Paste the magnetically conductive film with an adhesive to paste the sintered magnetically conductive film 3 on the inner bottom of the electric cooker gallbladder.

[0031] The raw materials of the embodiment are high-quality kaolin, imported spodumene, and Gui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com