Efficient environmental-friendly automatic processing control system for dehydrated vegetables

An automatic processing and control system technology, applied in the fields of vegetable or fruit peeling, food processing, food science, etc., can solve the problems of uneven product color, low heat energy utilization rate, overheating, etc., to achieve uniform product color, High utilization rate of heat energy and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

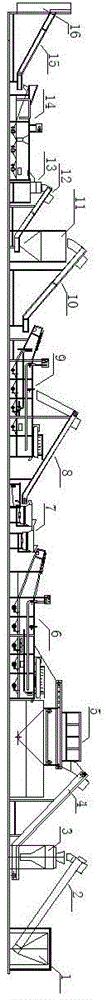

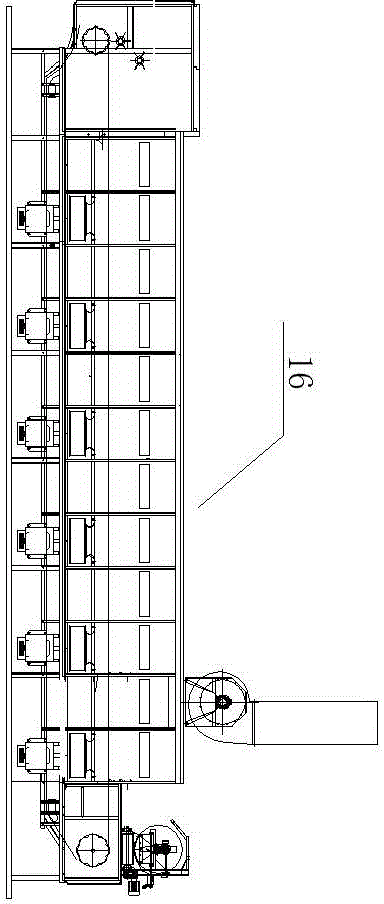

[0033] Further illustrate the present invention below in conjunction with accompanying drawing.

[0034] Such as figure 1 , figure 2As shown, a highly efficient and environmentally friendly automatic processing control system for dehydrated vegetables is characterized in that the processing technology specifically includes the following steps:

[0035] (1) Feeding: Put the vegetables to be dehydrated into the storage hopper, and the materials in the stainless steel revolving hopper are transported to the splitter by the auger feeder, and the feeding frequency of the auger feeder is controlled to 30 -40Hz, the flow rate is controlled by the frequency converter to 6-8 tons / h;

[0036] (2) Splitting and peeling: The splitting machine rotates and squeezes the garlic through two layers of silica gel plates and divides it into garlic cloves. Control the speed of the suction fan to 30-40Hz and the air volume to 3000-5000m 3 / h, remove the skin sucked out of the splitting machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com