Intelligent and adaptive control system and method for wood burning stove

a control system and adaptive technology, applied in the direction of domestic stoves or ranges, water heaters, ways, etc., can solve the problems of incomplete combustion, difficult control, complex control of wood stoves, etc., and achieve the effect of maximum burn time, maximum heating efficiency, and maximum heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

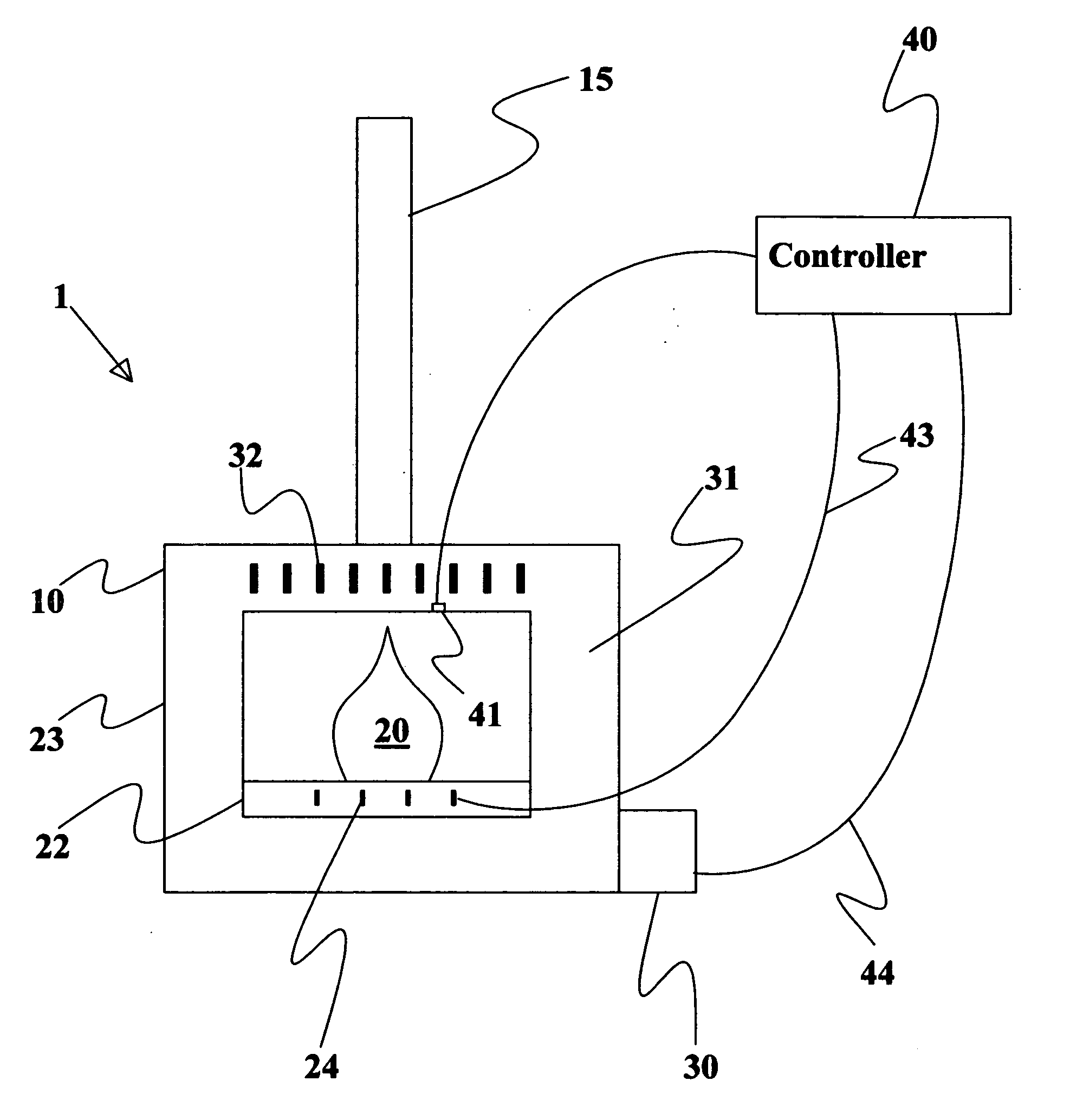

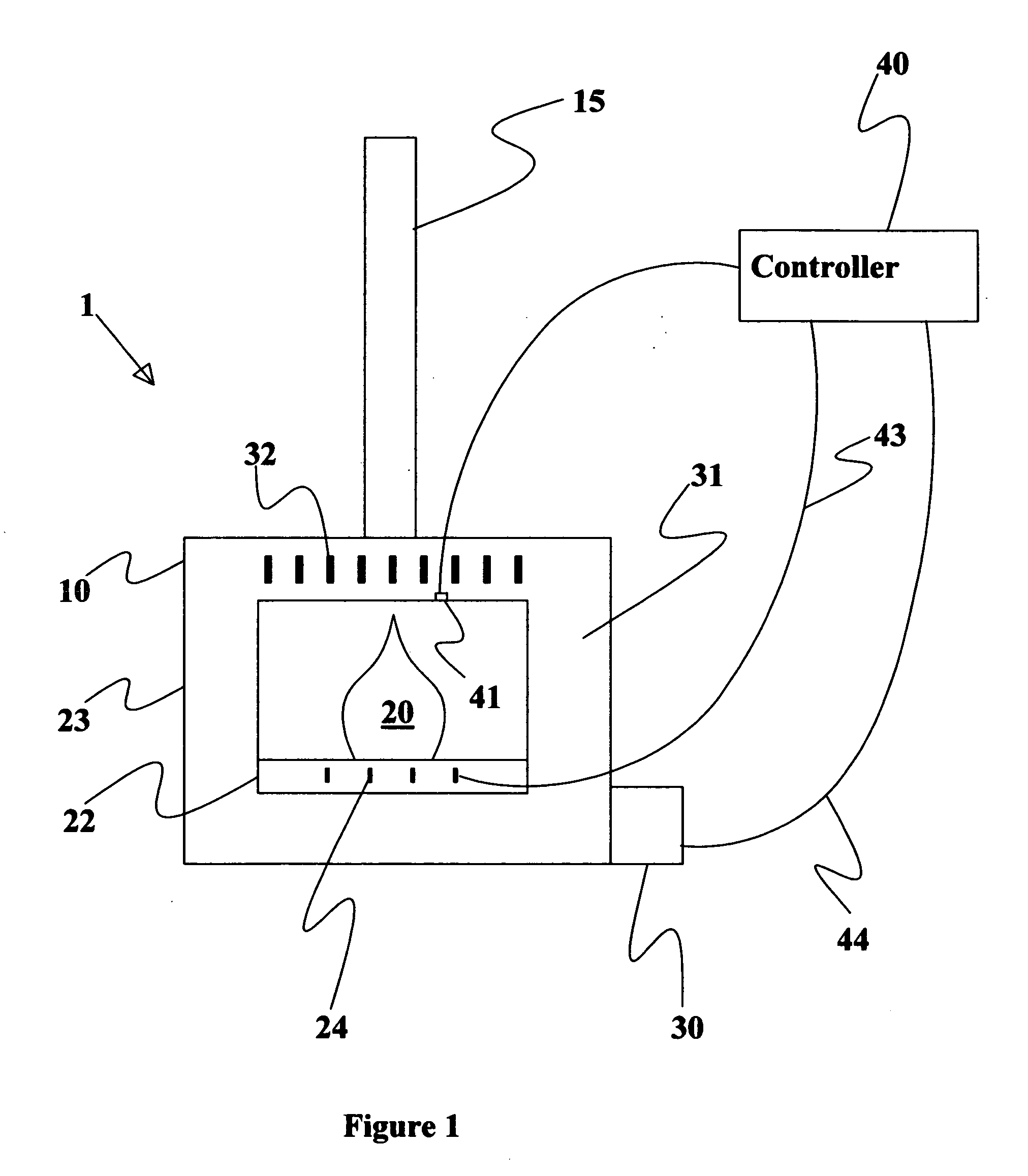

[0016]The present invention 1 provides a controller for improved performance of a wood stove. FIG. 1 illustrates a typical configuration of a wood stove 10 to which the controller of the present invention may be applied. The wood stove 10 is of typical construction. It includes a combustion chamber 20 in which wood is burned. A door (not shown) operates to allow wood to be placed within the combustion chamber 20 of the wood stove 10. According to current governmental regulations, the door provides an airtight seal to separate the combustion chamber 20 from the surrounding air of the stove. A flue 15 is connected to the combustion chamber 20 to allow smoke and gases to exit the combustion chamber 20.

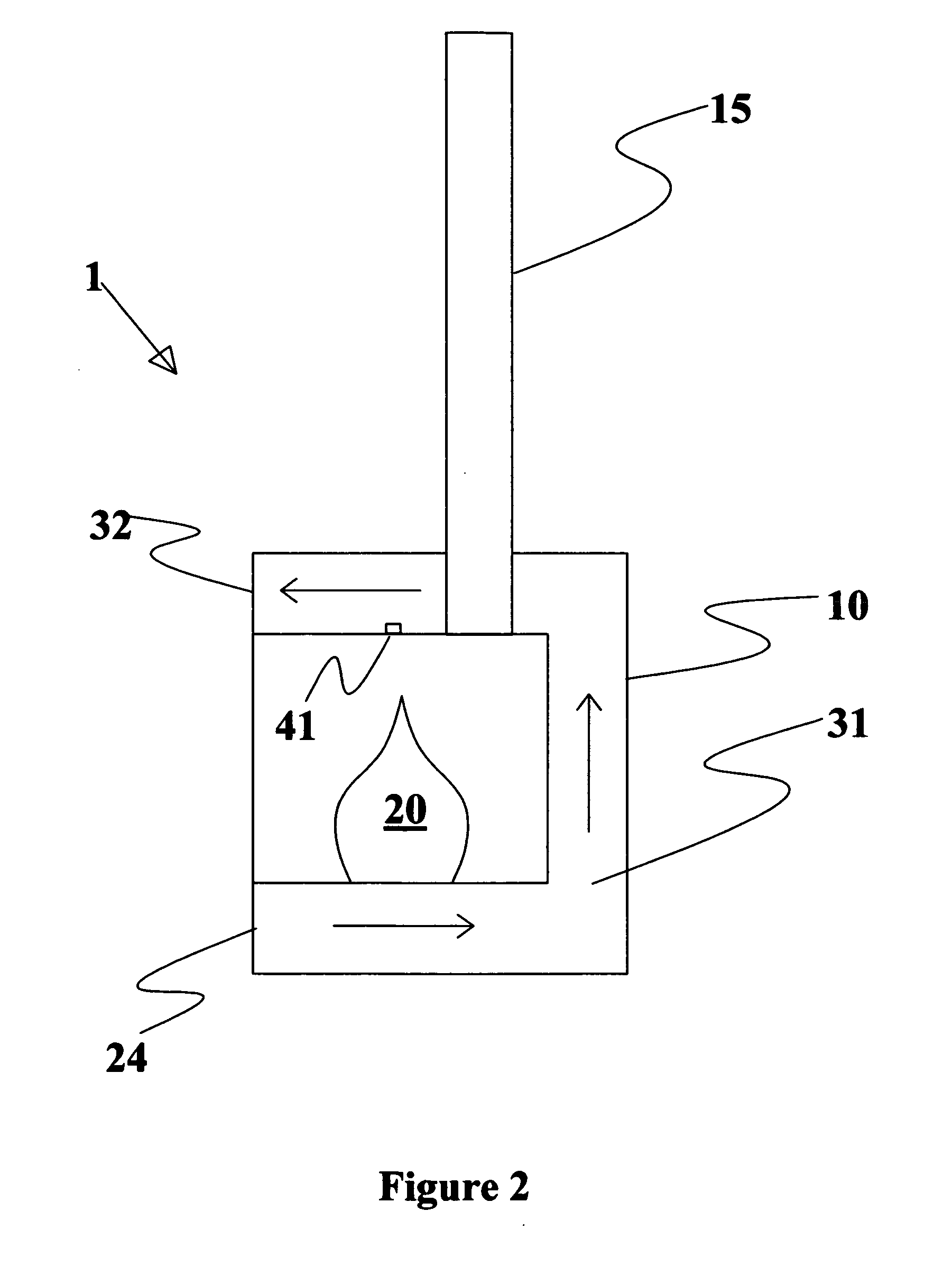

[0017]The stove 10 further includes a pair of spaced apart walls 22, 23. An inner wall 22 surrounds the combustion chamber 20. An outer wall 23 surrounds the inner wall. A heat transfer space 31 is formed between the two walls 22, 23. FIG. 2 is a cross sectional view of the stove. It illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com