Washing and drying integrated machine and control method

a technology of integrated machines and control methods, which is applied in the direction of washing machines with receptacles, other washing machines, textiles and papermaking, etc., can solve the problems of waste of drying heat in the dryer, waste of drying hot wind in the dryer, and inside heating of the dryer, so as to improve the reutilization rate of energy, improve the drying efficiency, and improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

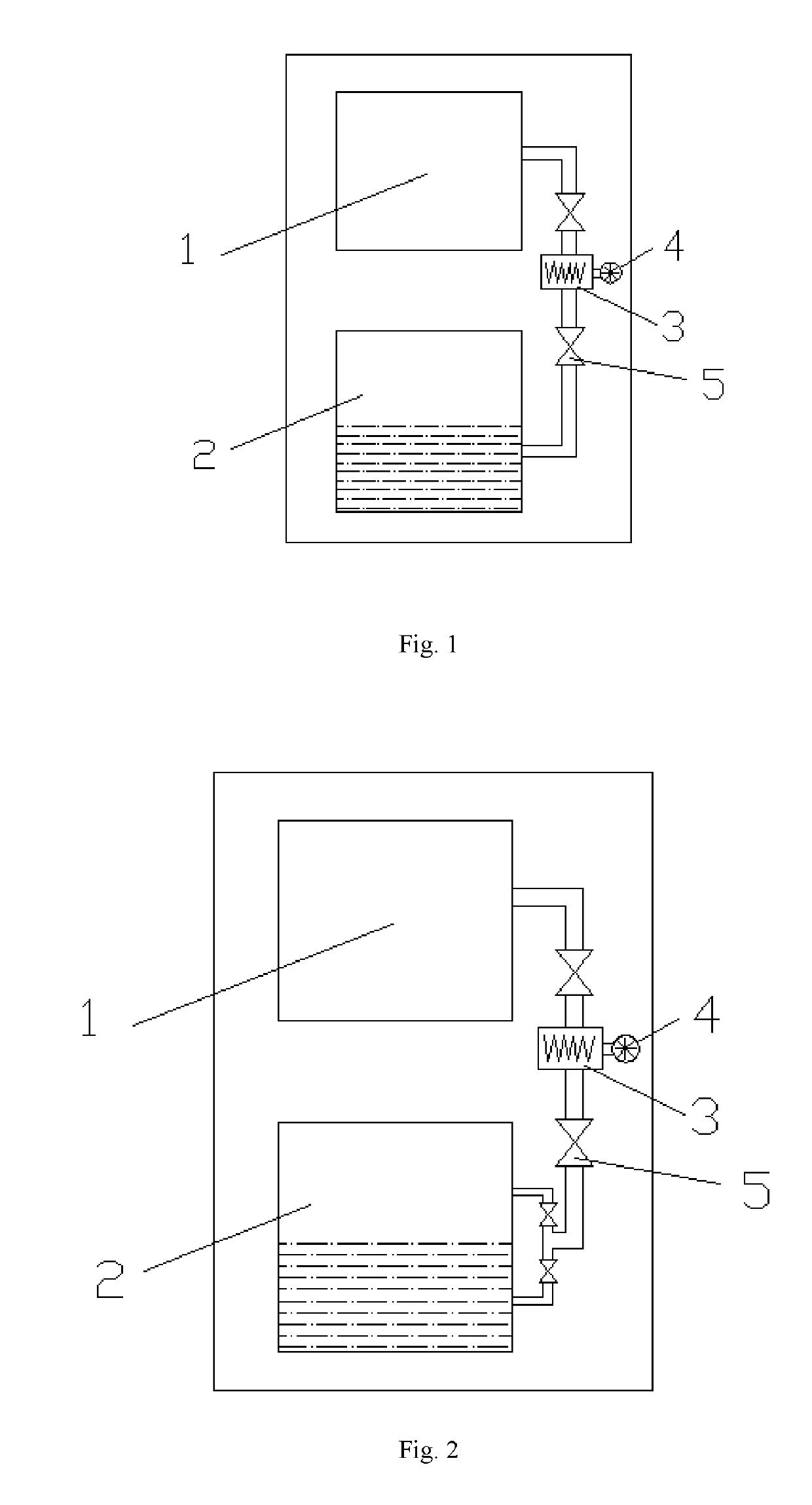

embodiment 1

[0034]As shown in FIG. 1, a washing and drying integrated machine in the present disclosure includes a housing; a drying drum assembly configured to dry clothes and a washing drum assembly configured to wash clothes, which are respectively arranged inside the housing and can operate independently. And the washing and drying integrated machine further includes a heating device, wherein a same heating device or a same set of heating devices is respectively connected with a drying drum in the drying drum assembly and a washing drum in the washing drum assembly via two ventilating ducts. The heating devices can provide hot wind to the drying drum and the washing drum separately or simultaneously.

[0035]In the present embodiment, the heating device includes a heater and a fan. The heater includes a case and a heater strip arranged inside the case. The case of the heater is respectively connected with the drying drum and the washing drum via two ventilating ducts, and the case of the heate...

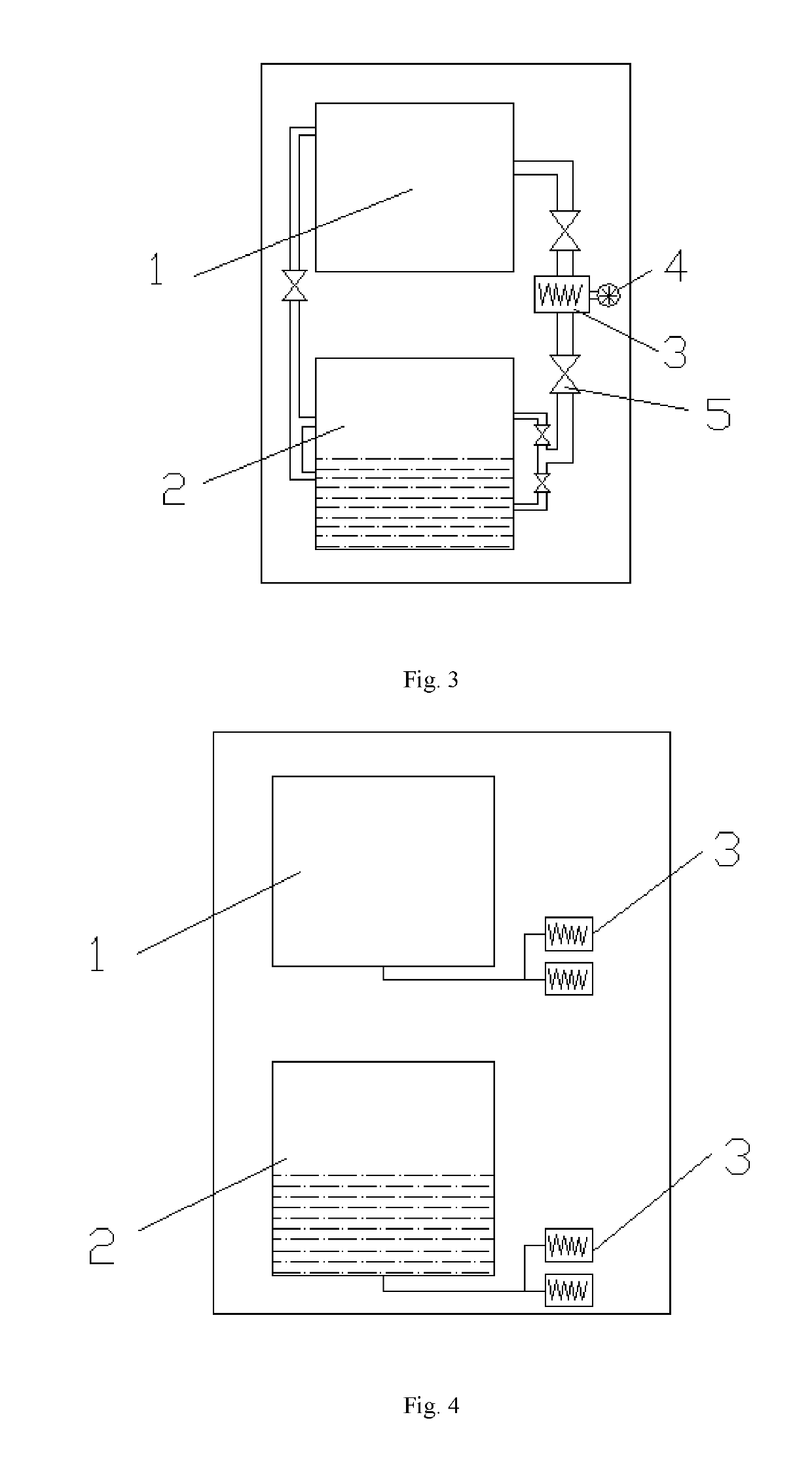

embodiment 2

[0042]As shown in FIG. 2, the present embodiment differs from embodiment 1 as follows: the ventilating duct which connects the heating device and the washing drum includes two branch ventilating ducts. Wherein a wind inlet of one branch ventilating duct is arranged below the water surface of the washing drum, so as to heat water in the washing drum, meanwhile, the blowing of air flow can be utilized to shake and loosen clothes. A wind inlet of another branch ventilating duct is arranged above the water surface of the washing drum, so as to heat the air inside the washing drum.

[0043]Valves are arranged on the two branch ventilating ducts. Through controlling the opening and closing of the valves, the heating device can separately or simultaneously provide hot wind to the water inside the washing drum and to the air inside the washing drum, so as to improve washing and decontamination effects.

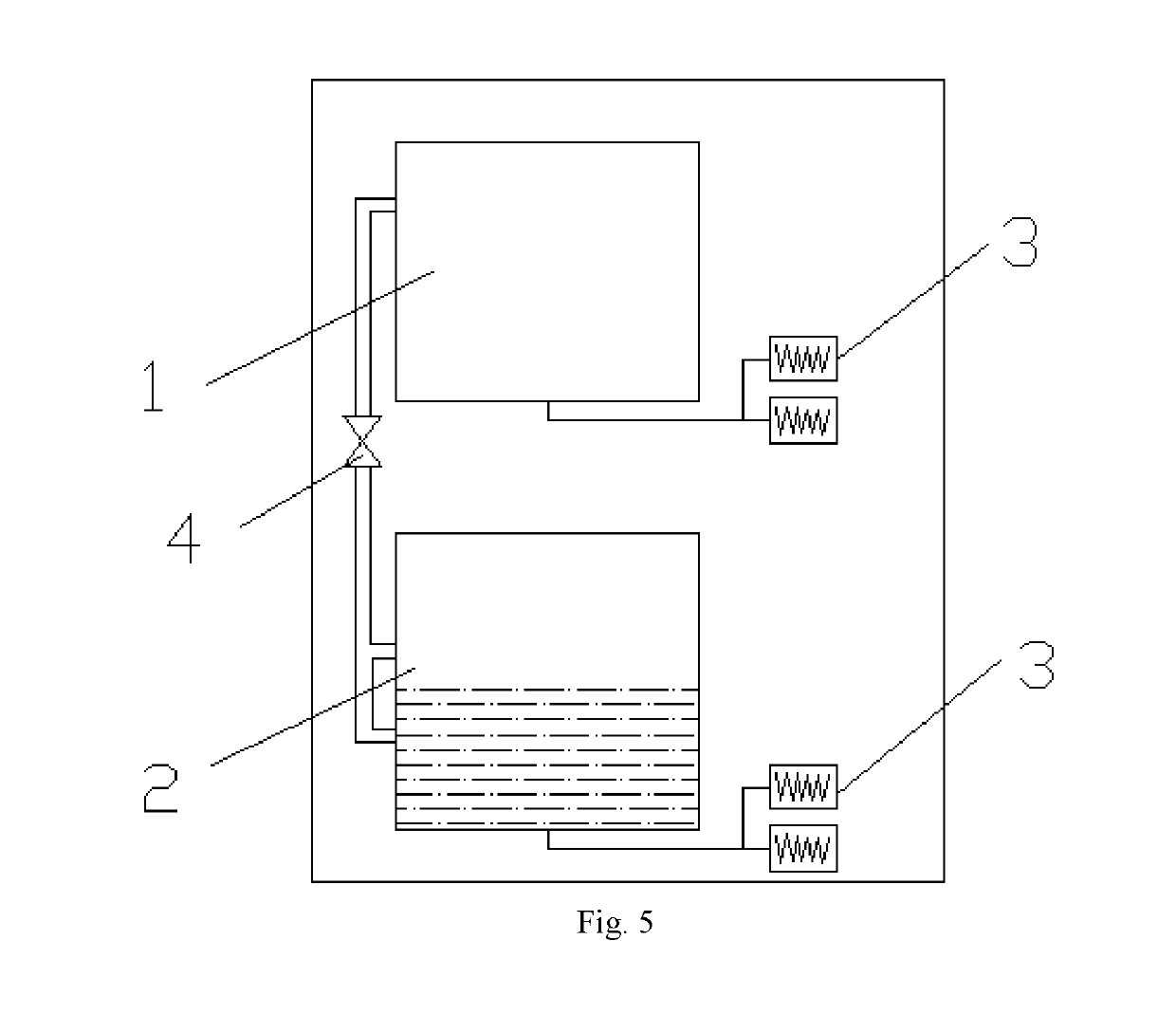

embodiment 3

[0044]As shown in FIG. 3, the present embodiment differs from embodiment 2 as follows: a wind outlet of the washing drum is connected with a wind-exhausting duct. And the wind-exhausting includes two branch wind-exhausting ducts, wherein one branch wind-exhausting duct is connected with the outside, or is connected to the heating device after being connected to a condenser so as to form recirculating air. Another branch wind-exhausting duct is connected to the washing drum, and this branch wind-exhausting duct is respectively connected with two wind inlets of the washing drum. Wherein one wind inlet is arranged above the water surface inside the washing drum, and the other wind inlet is arranged below the water surface inside the washing drum. Through the opening and closing of two valves (not shown in the figure) arranged at the two wind inlets, hot wind can be separately or simultaneously provided to the water in the washing drum and to the air in the washing drum. In the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com