Patents

Literature

122results about How to "Extended heating range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

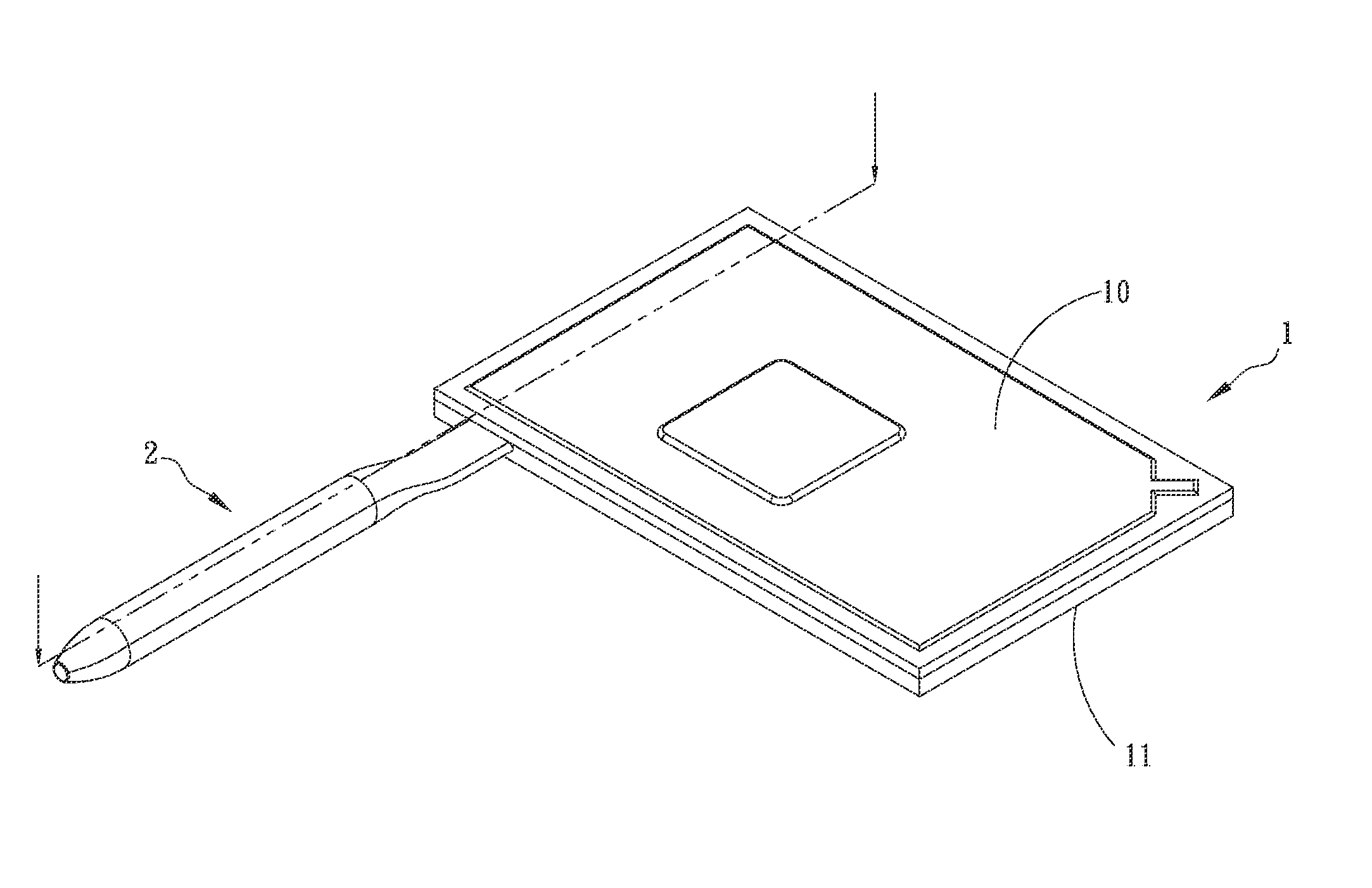

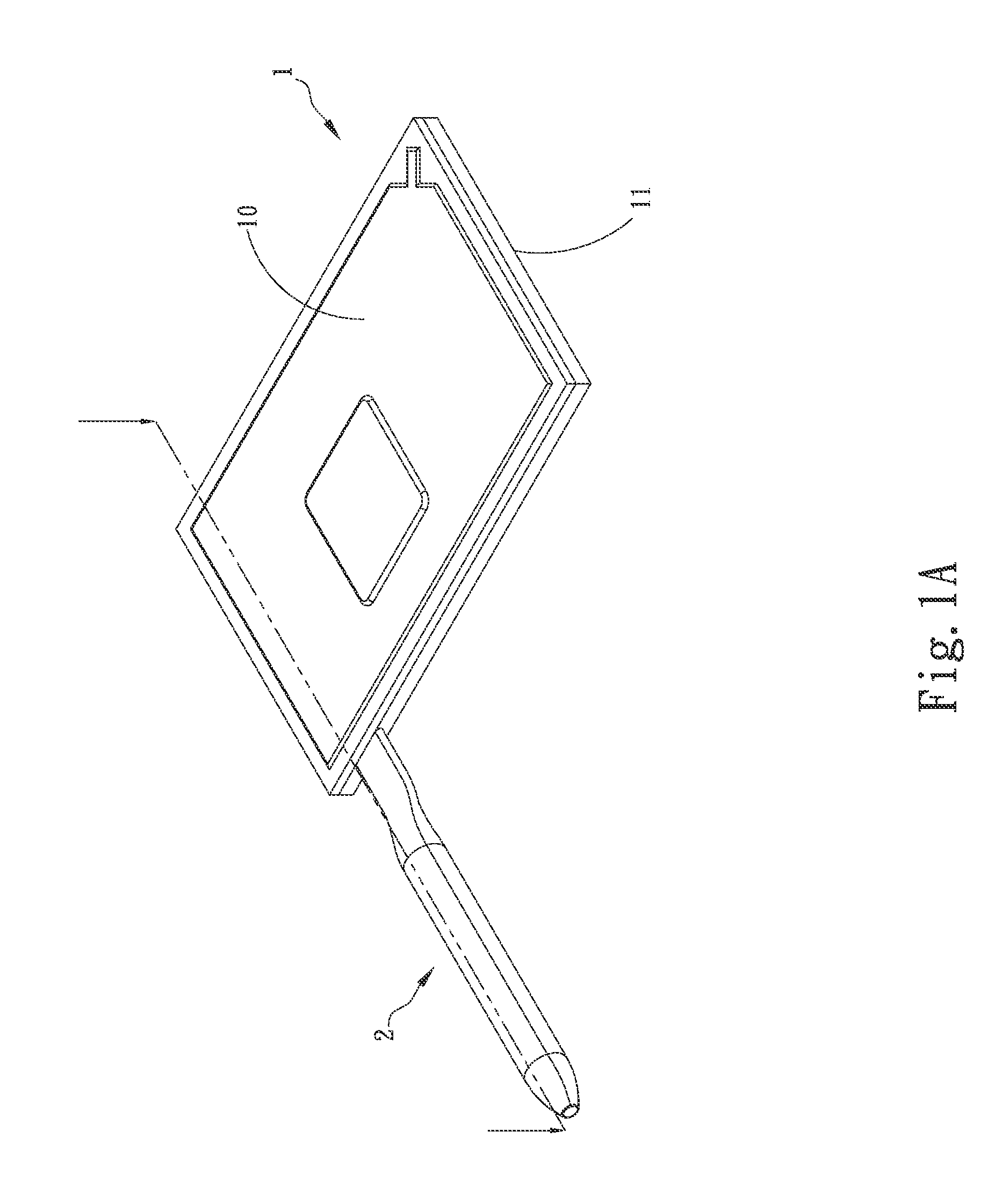

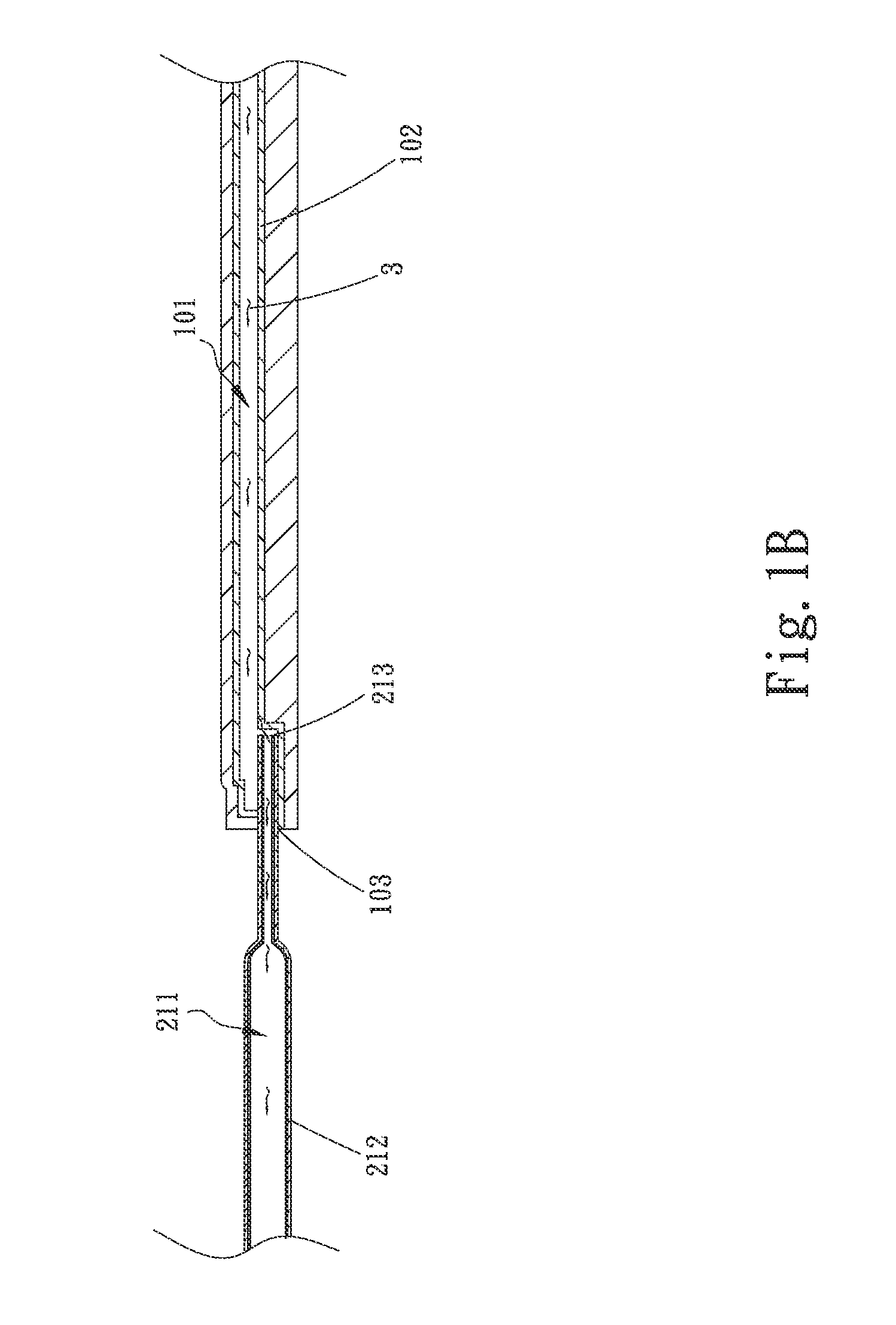

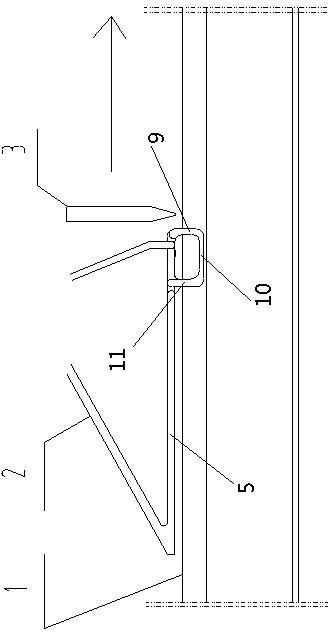

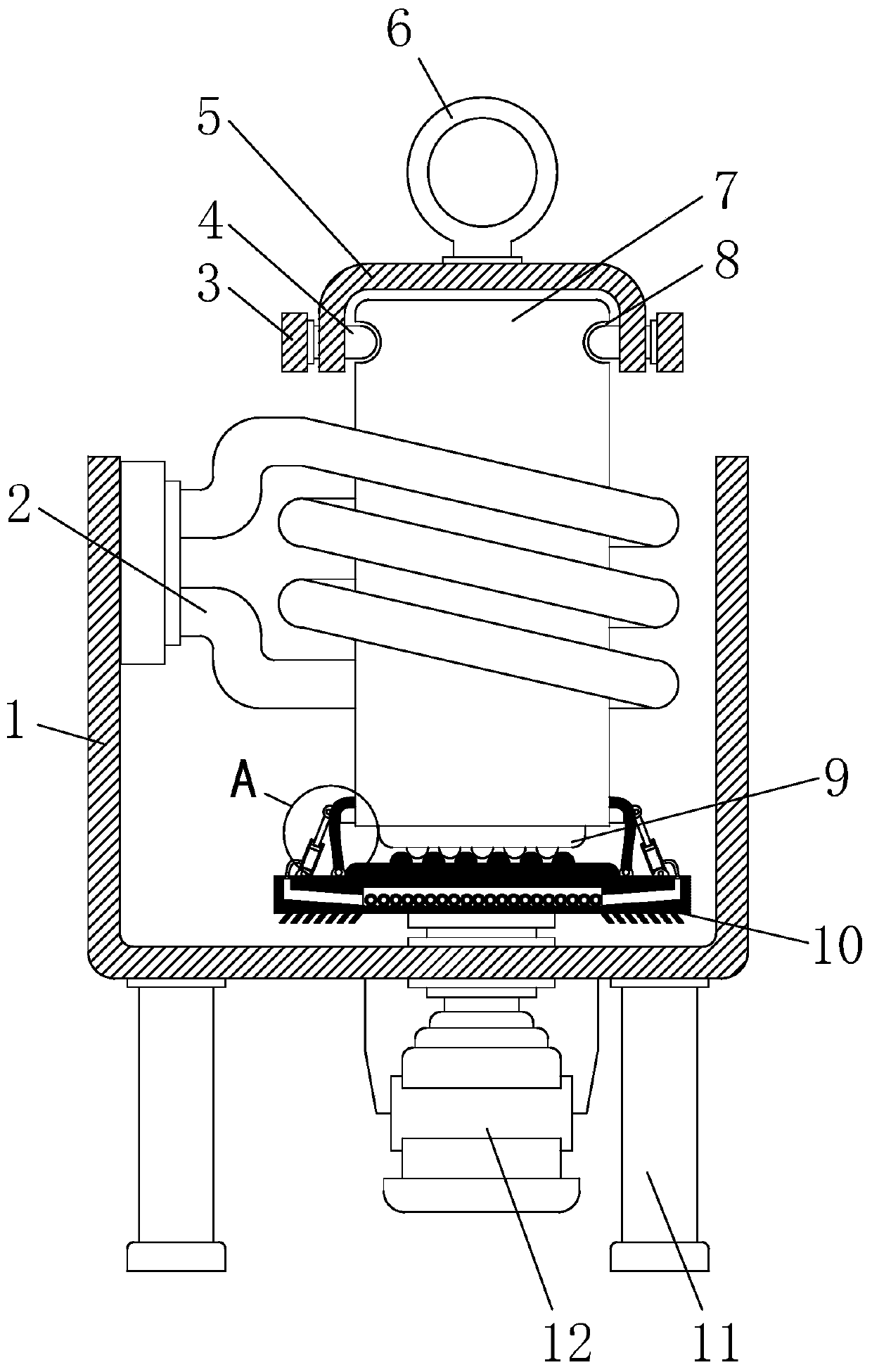

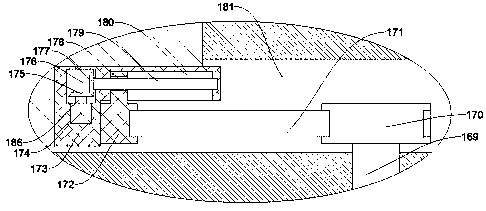

Heat dissipating device

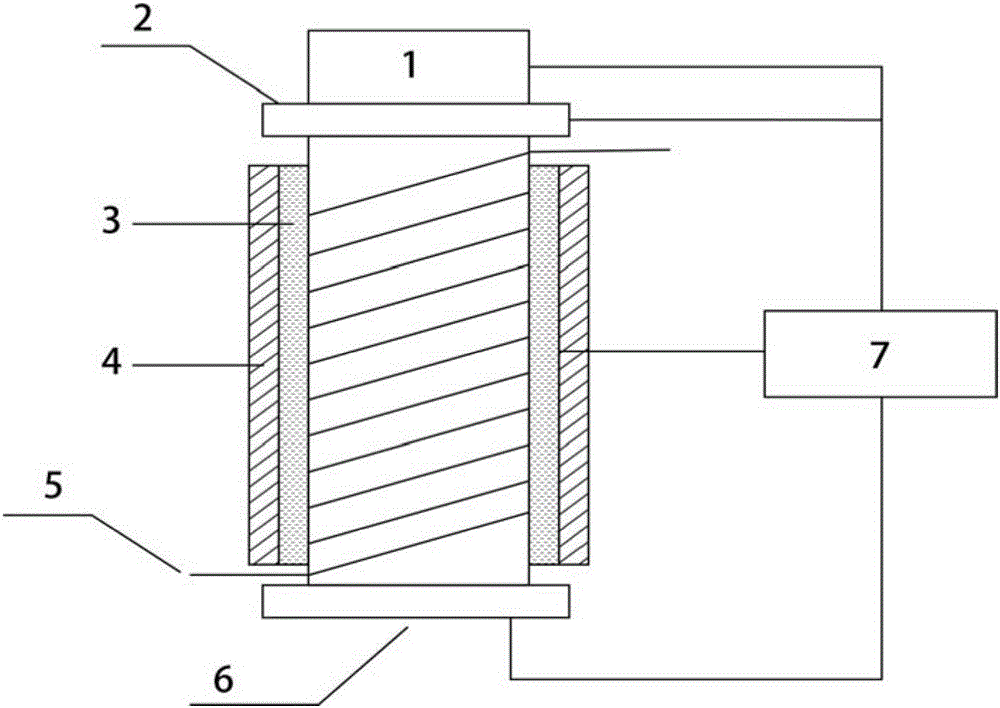

InactiveUS20140182819A1Extended heating rangeImprove cooling effectIndirect heat exchangersWorking fluidEngineering

A heat dissipating device comprises a first body, a second body, and a working fluid, the first body having a first plate and a second plate combining with each other to together define a first chamber, the second body connecting the first body and having a second chamber communicating with the first chamber correspondingly, the working fluid filled in the first chamber and the second chamber. By means of the design of the structure of the present invention and through the circulation of the working fluid between the first chamber and the second chamber, the heat dissipating device of the present invention can achieve the effect of remote heat dissipation.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

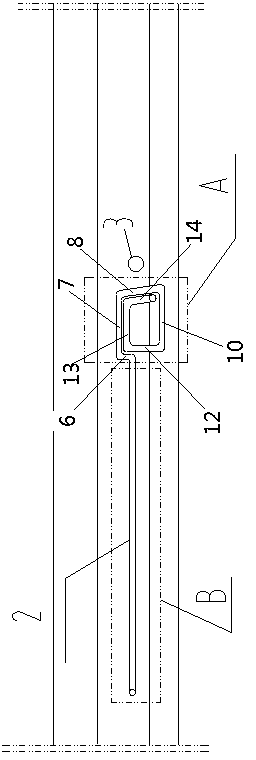

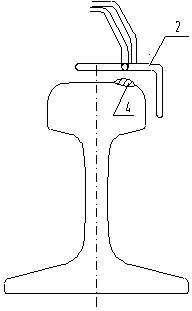

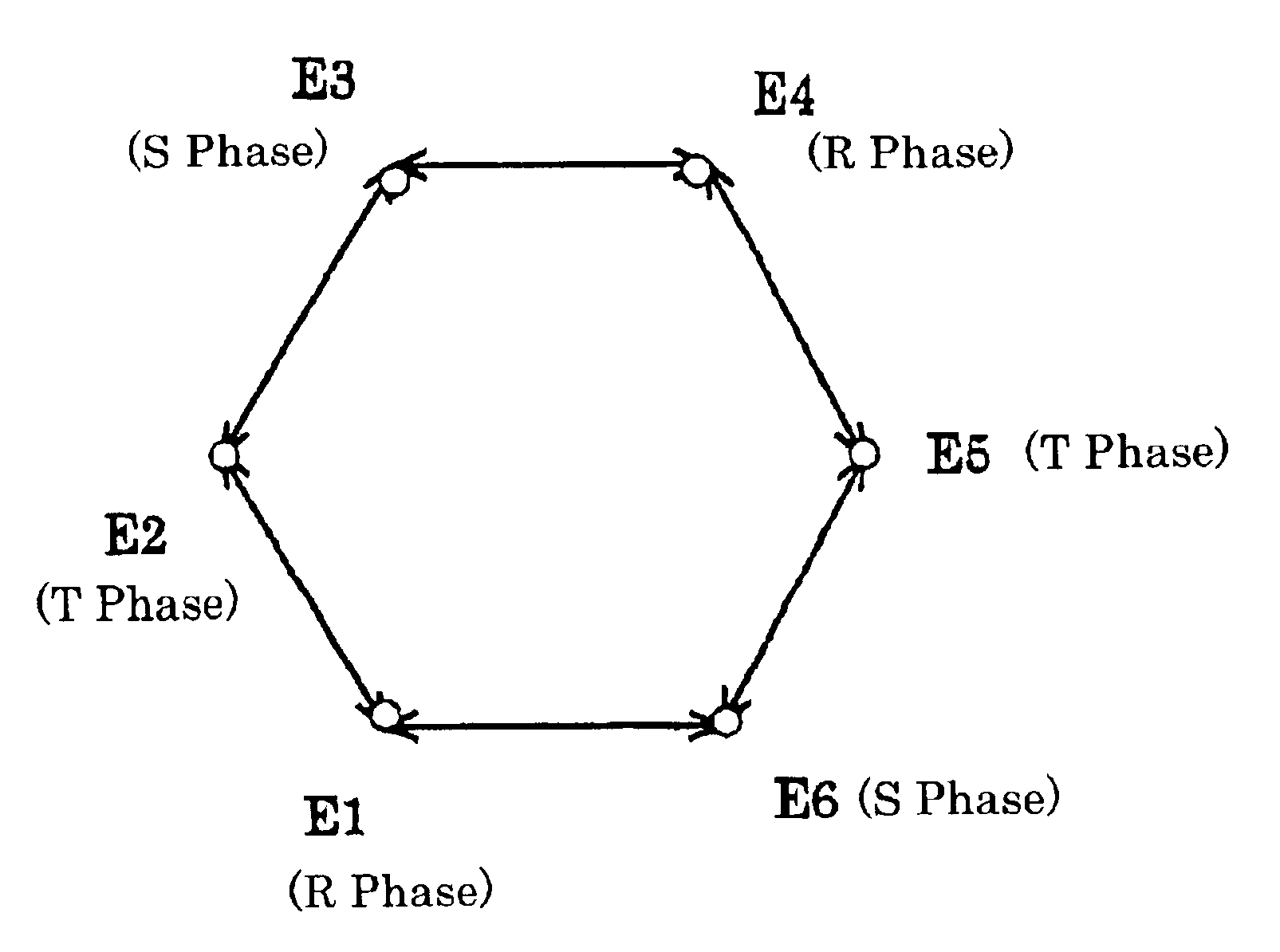

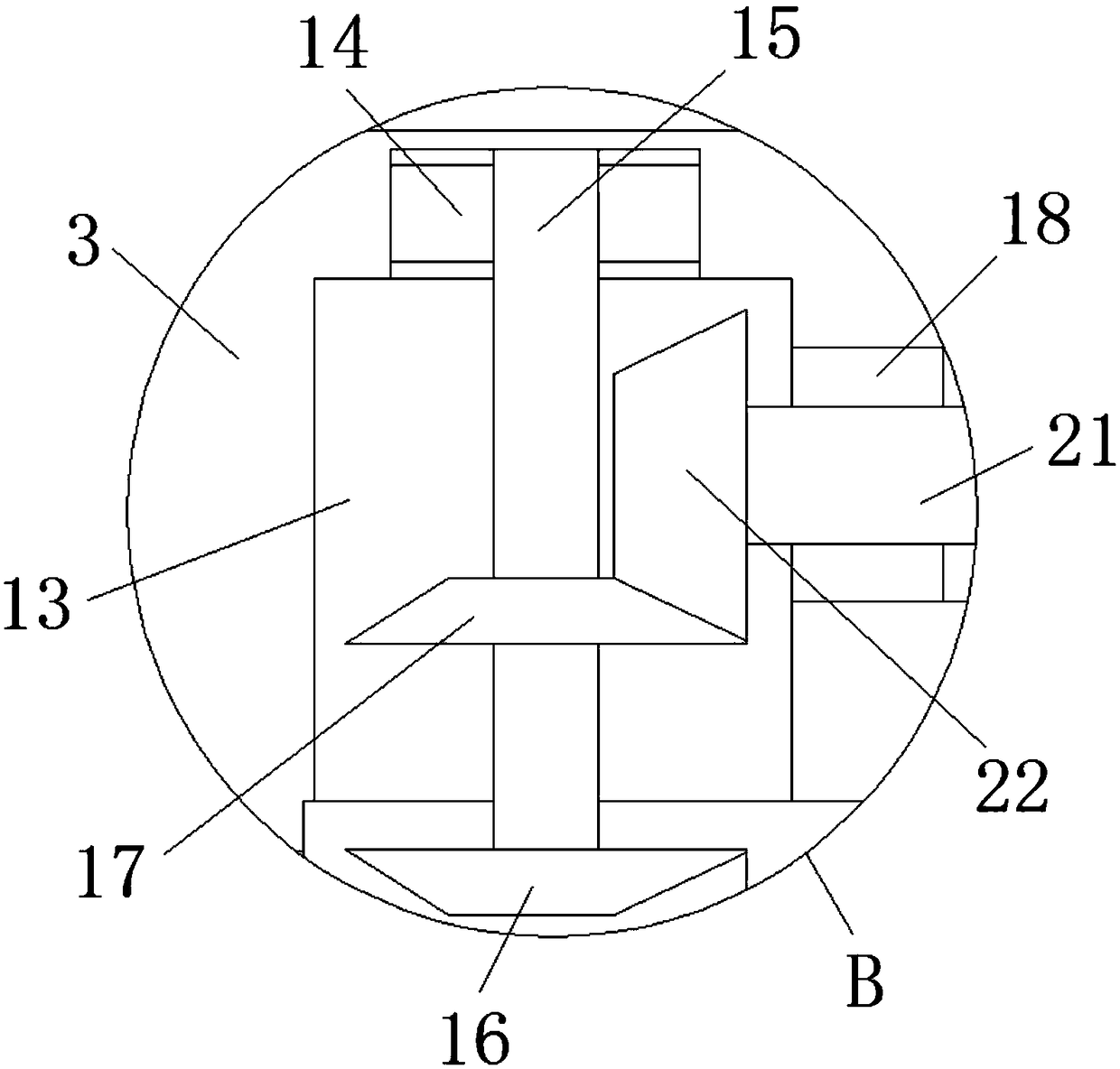

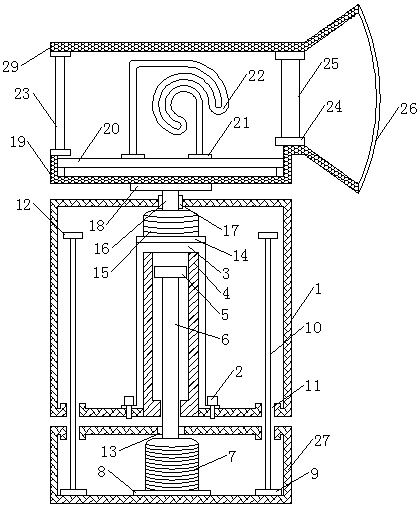

Induction heater and method for realizing non-preheating cladding of alloy on steel rail by using same

InactiveCN103132008ASave energyExtended heating rangeMolten spray coatingHeat transmissionMiniaturization

The invention discloses an induction heater which comprises a heating zone 1 and a heating zone 2, wherein the heating zone 1 is divided into two heating surfaces; a first heating surface is shaped like a trapezoid without the bottom; a second heating surface is a U-shaped one; the two lateral sides of the trapezoid-shaped heating surface are connected with the U-shaped heating surface; and an included angle is formed between the first heating surface and the second heating surface. When the induction heater is used to perform alloy cladding on a steel rail, preheating does not need to be performed in advance, so that on the premise of the same steel rail cladding speed, heat energy required by the method is only one third or less of the prior art; and meanwhile, the method lays a foundation for miniaturization of a generator or even construction without the aid of a rail car. By performing detailed analysis on structure phase change and heat transmission of a steel rail in the cladding process, the invention breaks through the theory that the steel rail must be preheated prior to welding for the first time, and presents that the steel rail can be directly subjected to alloy cladding without being preheated while generation of martensite can be avoided. The technology disclosed by the invention is put forward for the first time at home and abroad.

Owner:CHENGDU ZHONGGUI TECH CO LTD

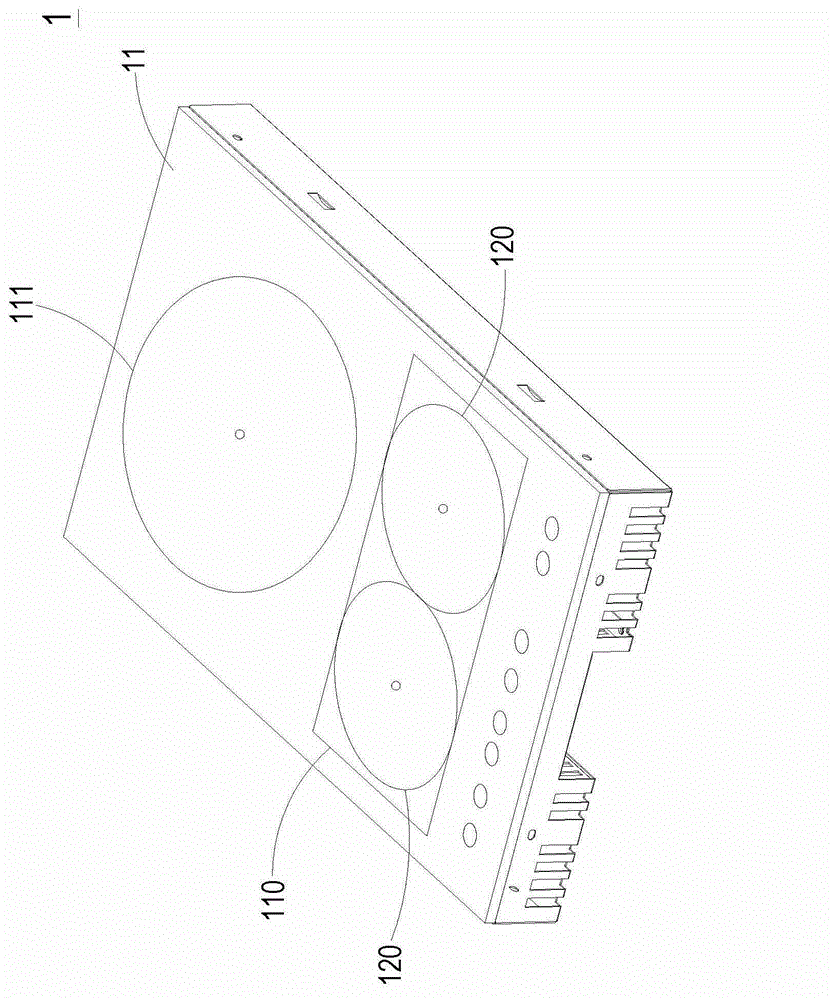

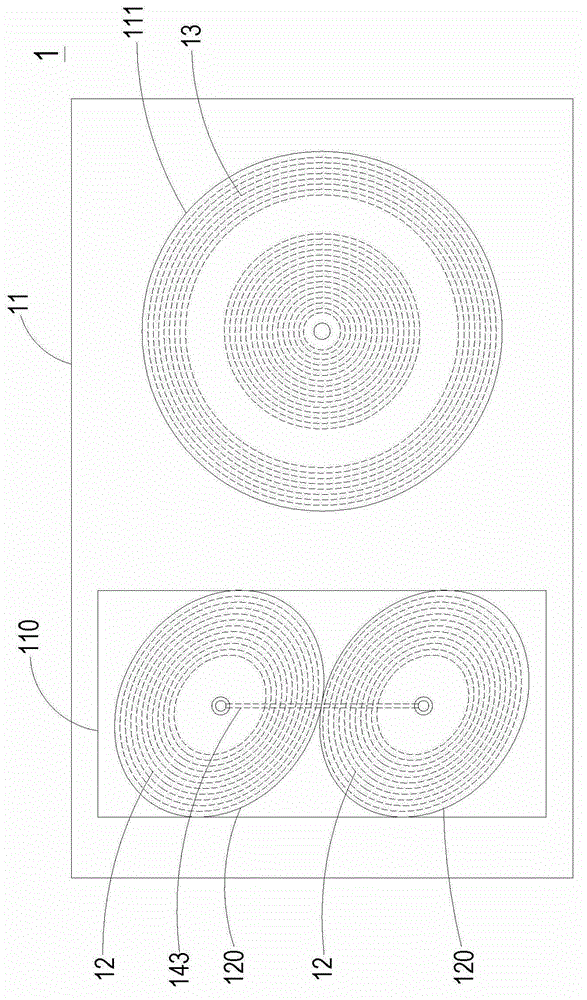

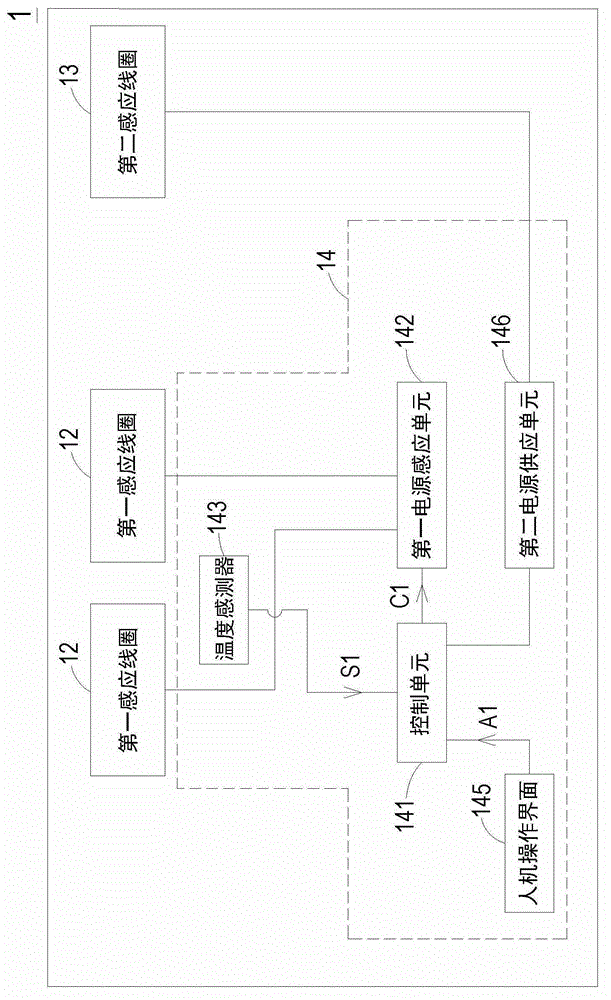

Electromagnetic induction heater capable of increasing heating scope

InactiveCN104039033AAvoid damageImprove heating efficiencyDomestic stoves or rangesCoil arrangementsEm inductionEngineering

The invention discloses an electromagnetic induction heater capable of increasing a heating scope. The heater comprises a bearing plate provided with a heating area for arranging at least one material container, and multiple first induction coils which are respectively of oval structures and are arranged on one side surface of the bearing plate, wherein each first induction coil respectively provides a sub heating area to form the heating area to heat the at least one material container. The electromagnetic induction heater capable of increasing the heating scope has a free area heating mode and can prevent an electromagnetic oven from being damaged due to improper position arrangement of the material container.

Owner:DELTA ELECTRONICS INC

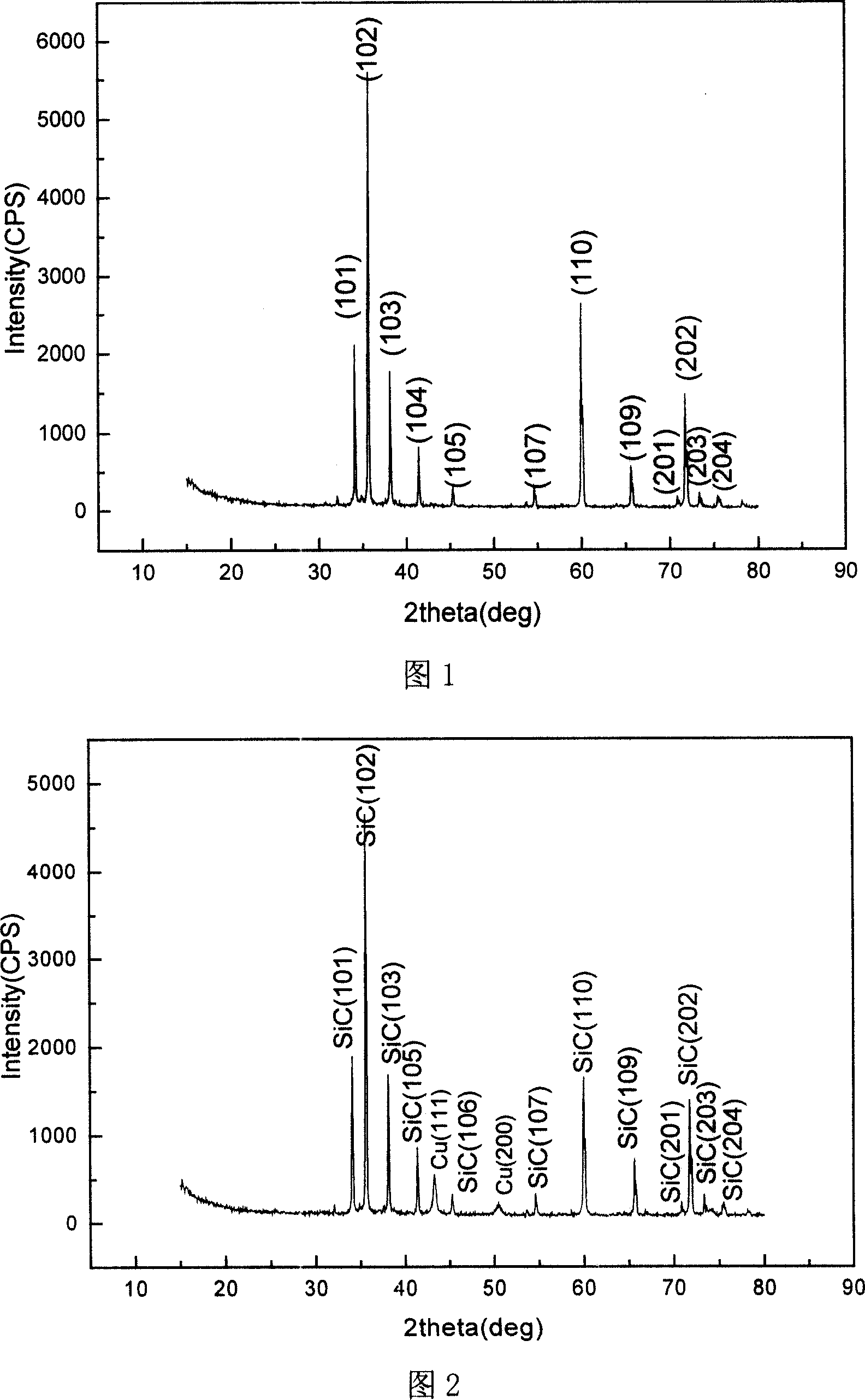

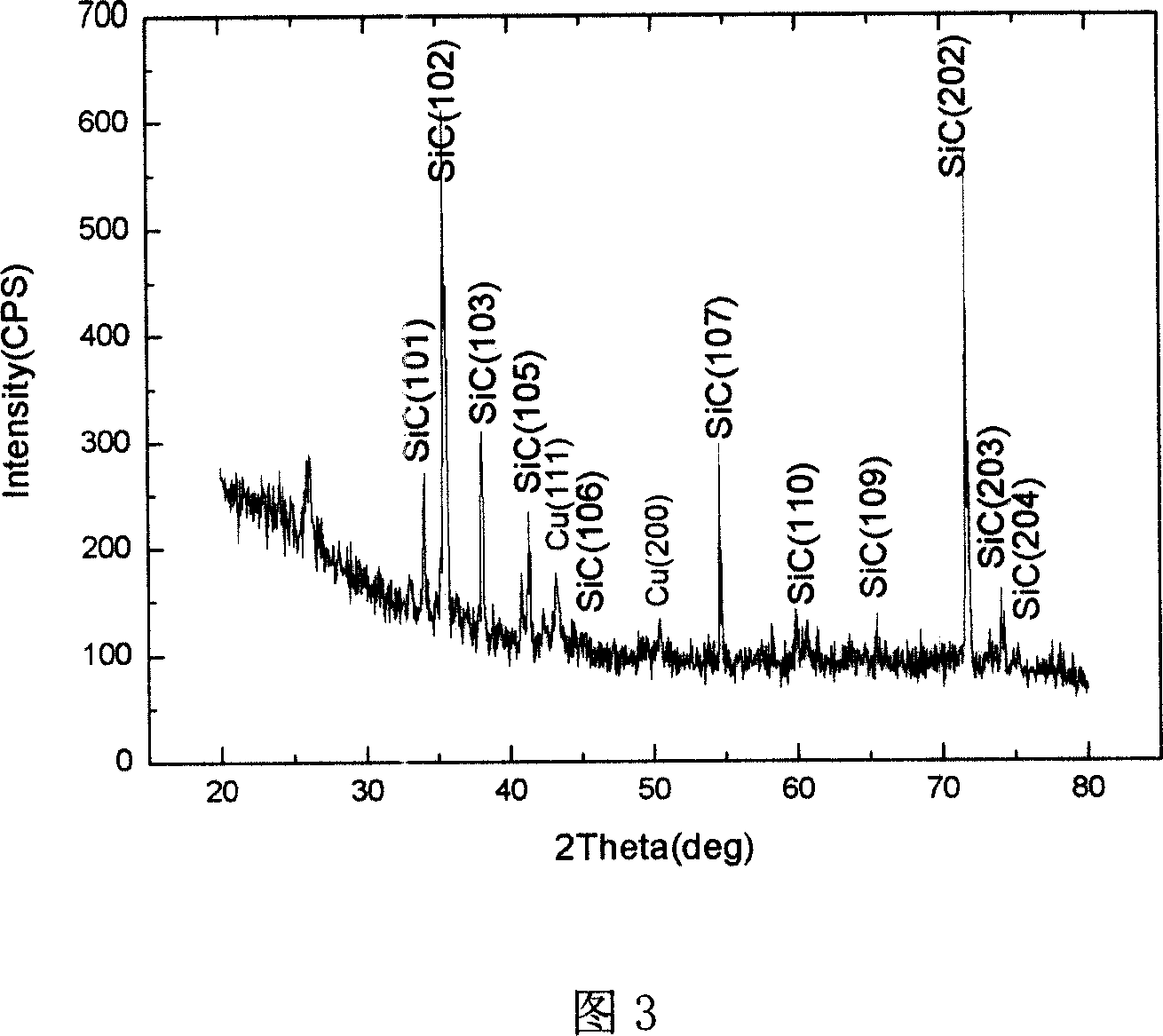

Method for magnetron sputtering coppering film on SiC micro-particle surface

InactiveCN101135045AUniform and continuous depositionImprove compactnessVacuum evaporation coatingSputtering coatingAtmospheric pressureCopper

The magnetically controlled sputtering process for coating copper film on the surface of SiC grain features that metal copper film is deposited on the surface of SiC grain in 0.1-500 micron size as the substrate inside magnetically controlled sputtering equipment with copper target of 99.999 % purity by means of regulating the vibrating power of ultrasonic wave and the oscillation frequency of sample holder to disperse SiC grains homogeneously and controlling the operation pressure inside the vacuum chamber, sputtering power, temperature, sputtering period and other technological conditions. The technological process is simple, low in cost and without waste pollution, and the prepared film is homogeneous and continuous.

Owner:CHINA NAT ACAD NANOTECH & ENG +2

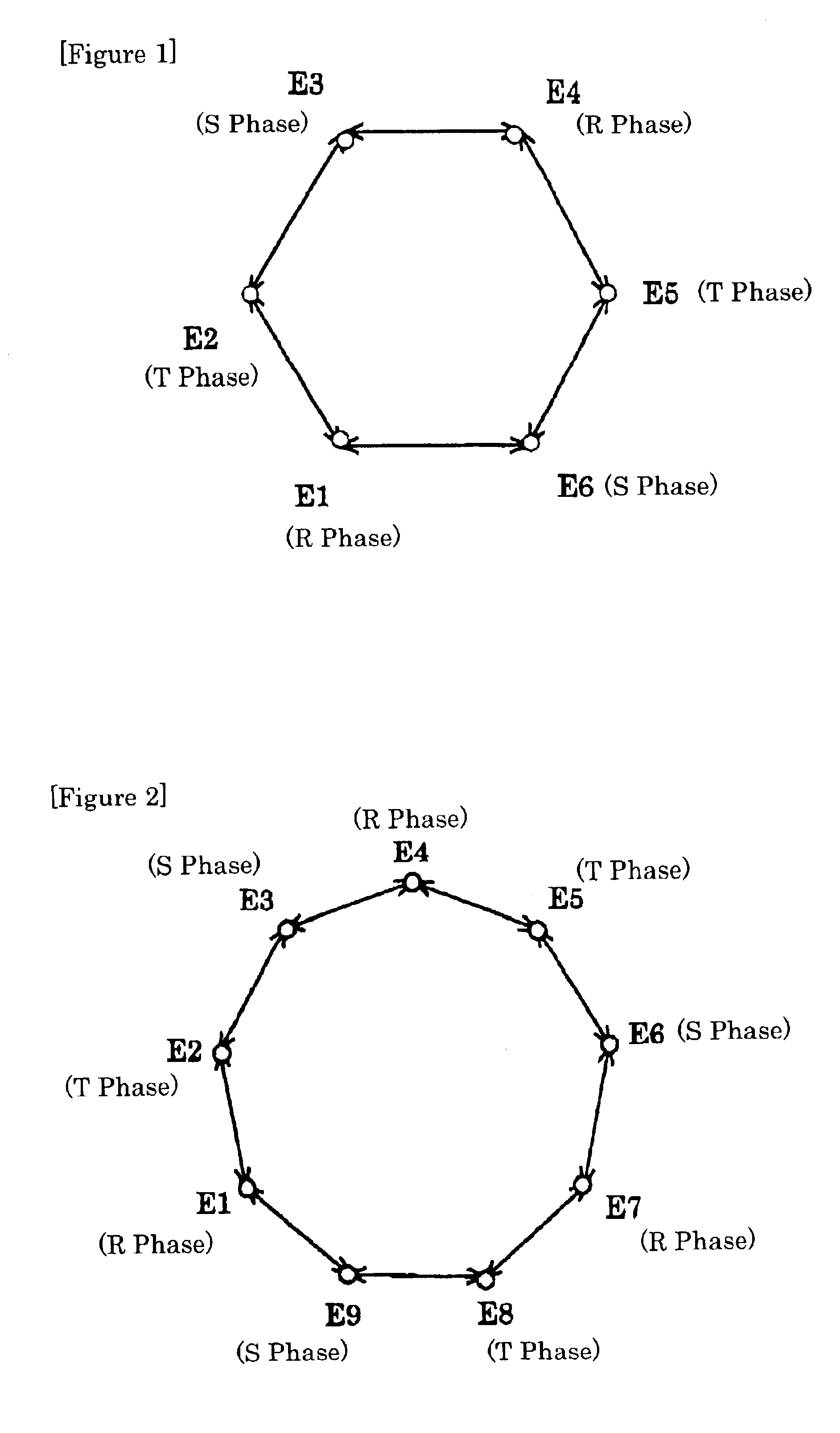

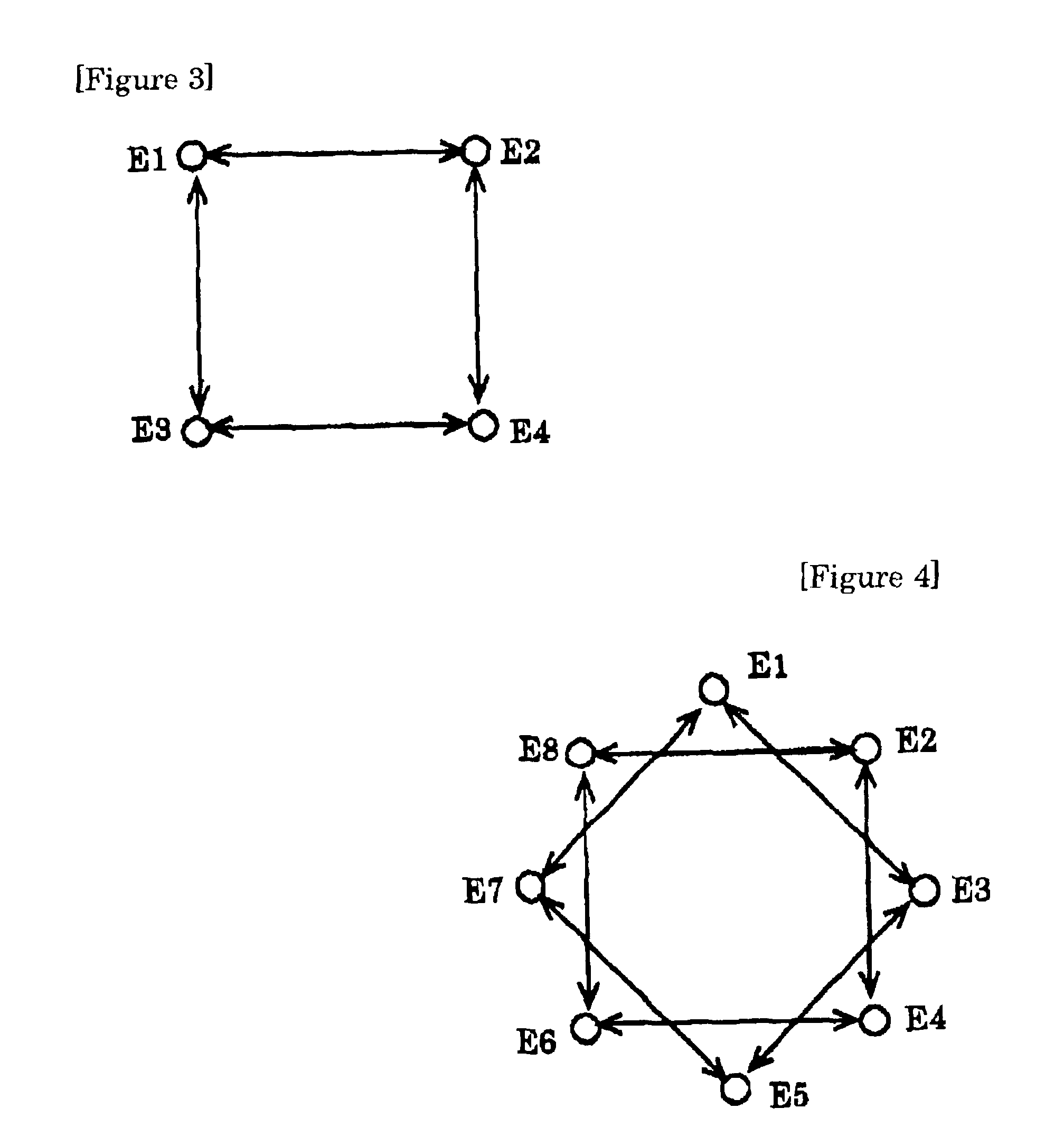

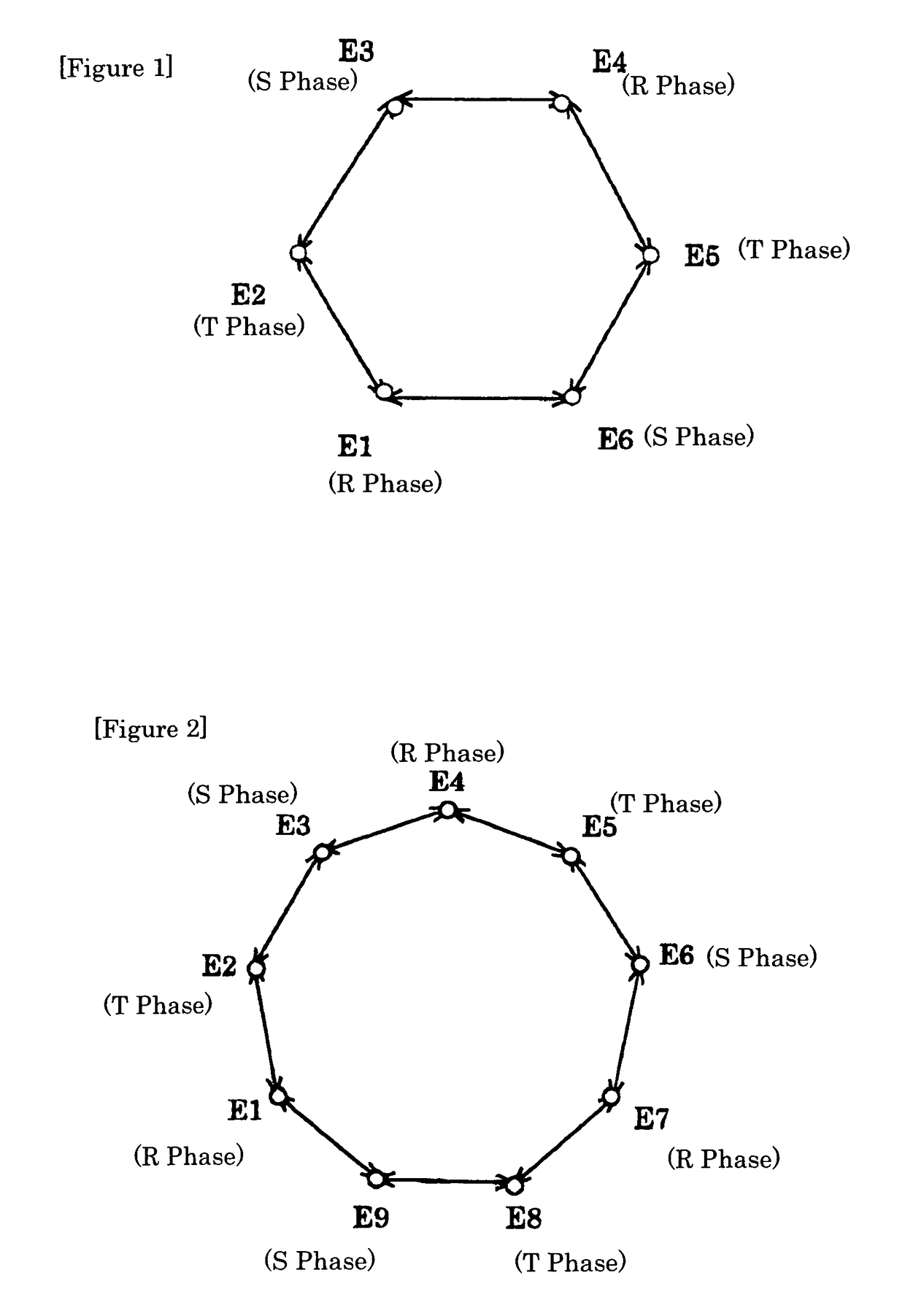

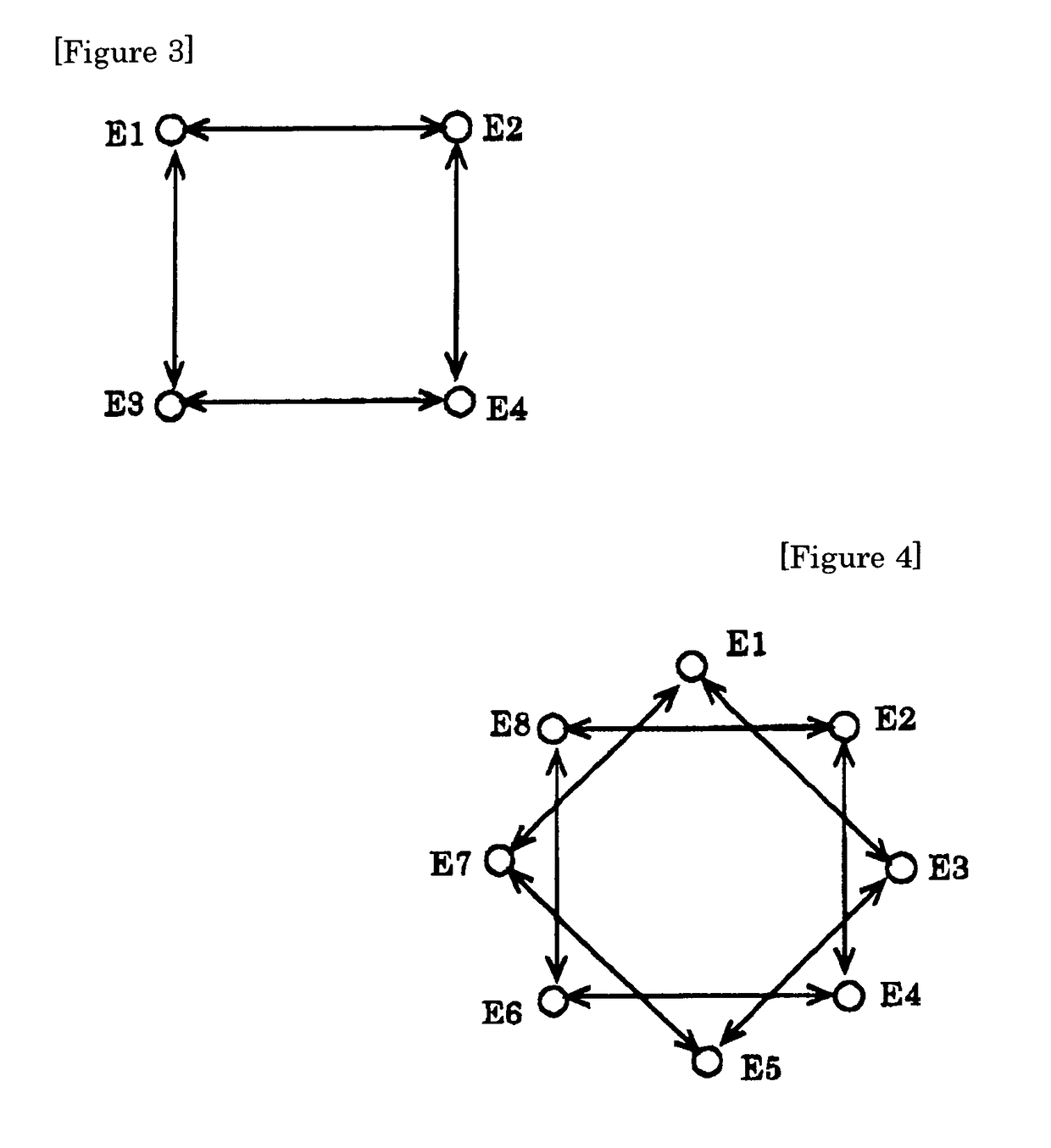

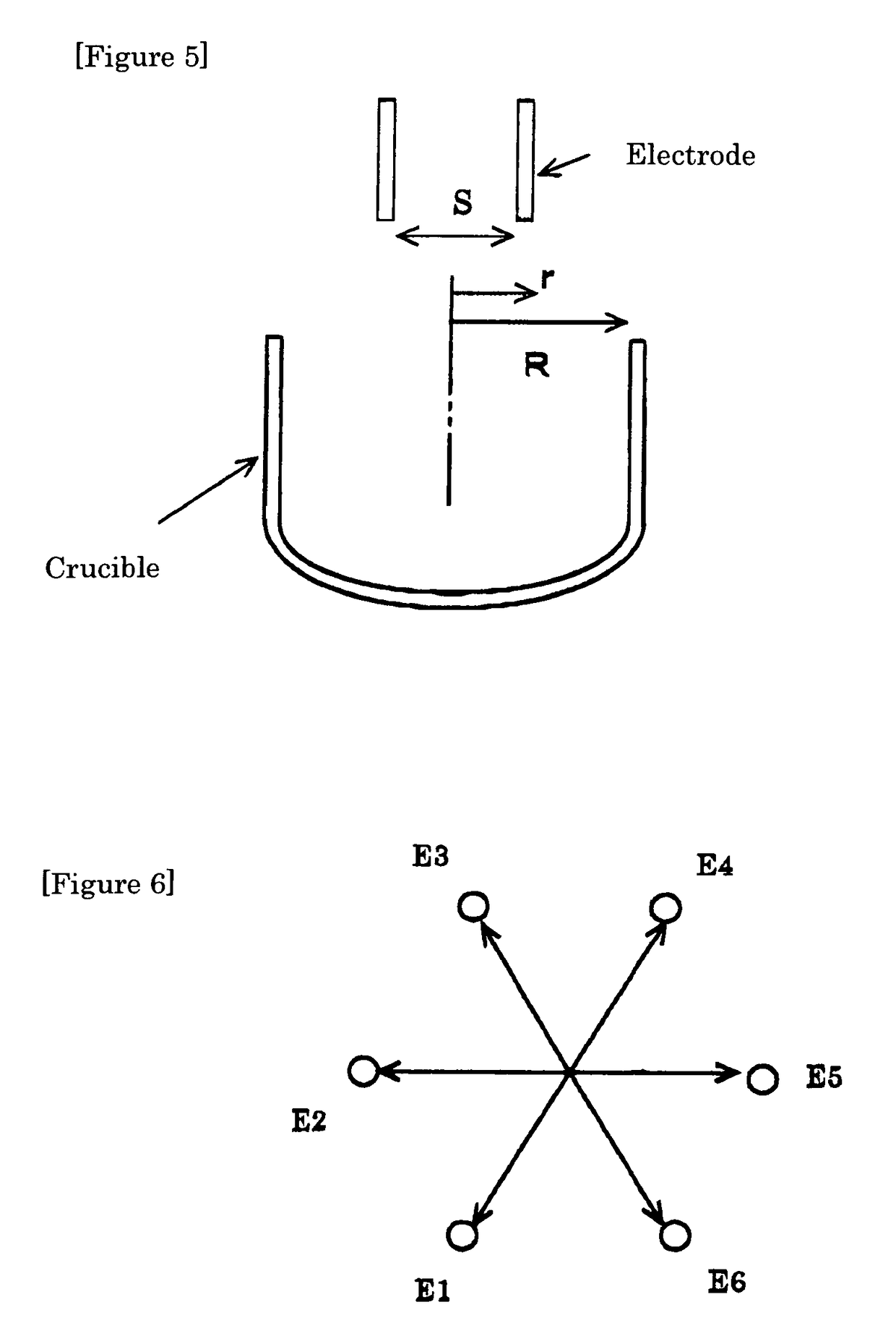

Process and device for producing a quartz glass crucible by ring-like arc, and its quartz glass crucible

InactiveUS6853673B2Extended heating rangeDistanceAfter-treatment apparatusElectric discharge heatingRotational axisCrucible

The present invention provides a process and a device for producing a quartz glass crucible, which generates a stable ring-like arc and is suitable for the production of an excellent crucible having the large open diameter.In a production process and a device for producing a quartz glass crucible, wherein a quartz powder in a mould is heated to be fused by an arc discharge of the electrodes being positioned at around of a rotational axis of a mould,this invention is characterized by using an electrode structure, in which electrodes neighboring each other are positioned at regular intervals in the ring configuration, to form the stable ring-like arc being generated between the electrodes neighboring each other without generating an continuous arc between electrodes facing each other across a central portion of the ring, and heating and fusing a quarts powder.

Owner:SUMCO CORP

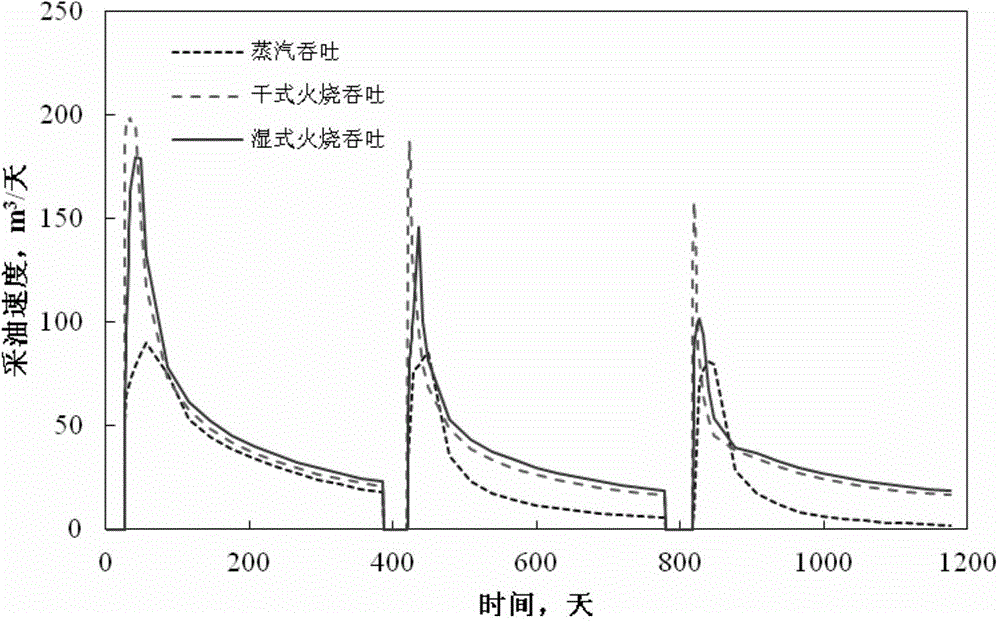

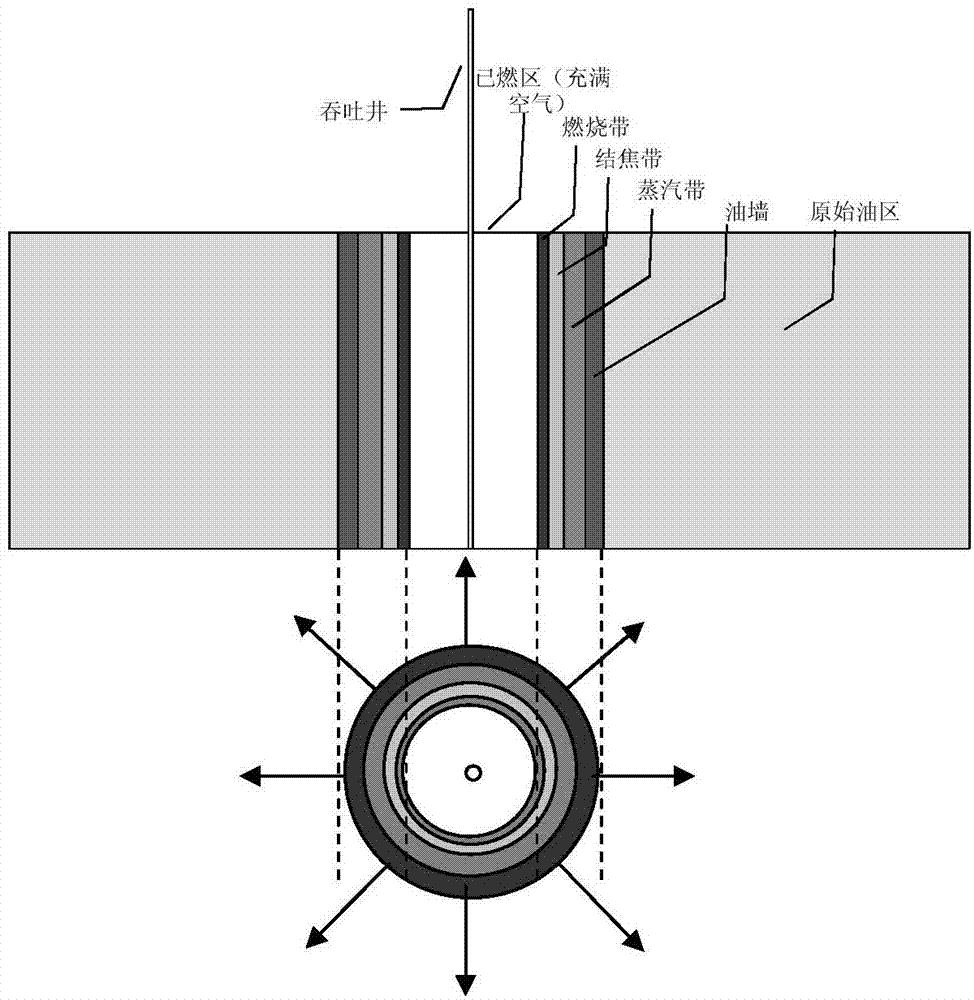

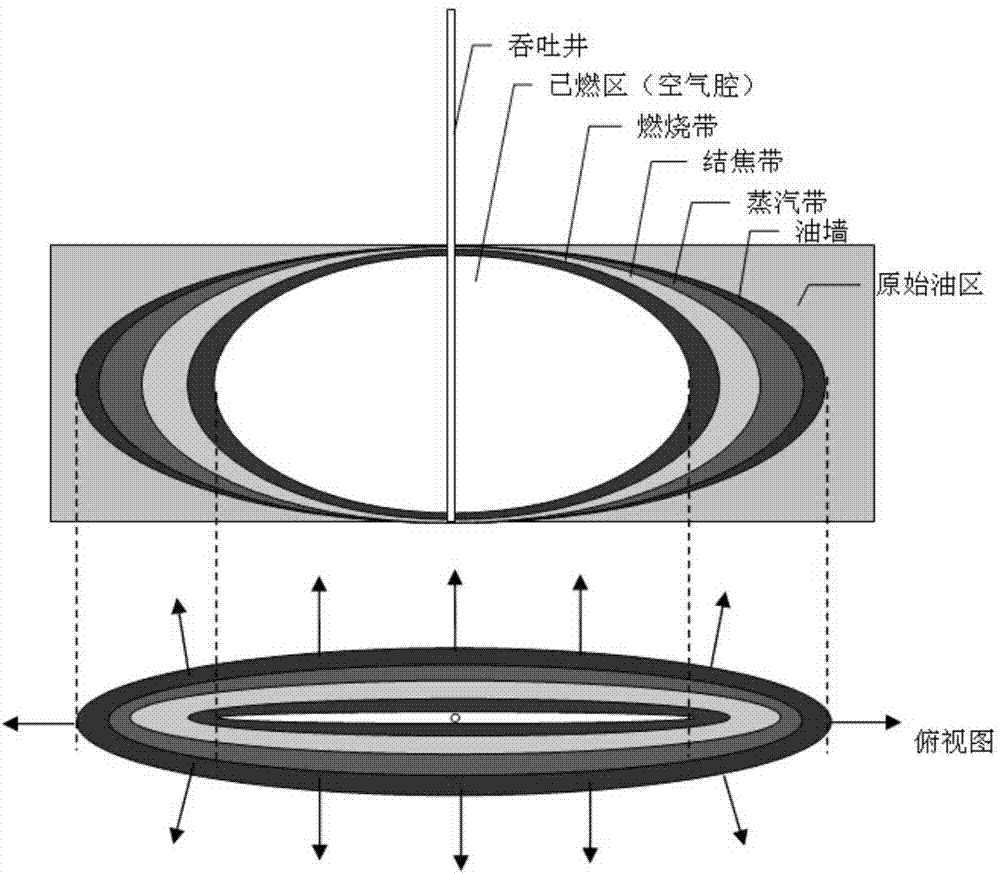

Wet type combustion huff-puff oil extraction method

The invention provides a wet type combustion huff-puff oil extraction method, comprising the steps of: 1, flushing an oil well, then injecting an oxidizing agent into an oil deposit, igniting to burn coke-like components generated by the oxidization and splitting decomposition of crude oil in the oil deposit to heat an oil layer; 2, while the oxidizing agent is completed injected or is injecting, injecting water to reduce the high temperature of a near wellbore formation, and extracting oil after soaking the well for 3-10 days; 3, after extracting oil for 100-700 days, performing a next round of processes of injecting the oxidizing agent, igniting, injecting water, soaking and extracting oil. According to the method provided by the invention, the water is injected into the oil deposit after the oxidizing agent is injected, and water flow flows through a combusted area and carries heat to the deep part of the oil deposit, so that the heating range of the oil deposit is enlarged, and the peripheral temperature of the oil well is prevented from being too high. According to the wet type combustion huff-puff oil extraction method, formation water and the injected water are vaporized to generate steam, heat, smoke and steam generated by combustion are comprehensively utilized to recover in a combined manner, the output and the recovery efficiency of the crude oil are improved, and the recovery efficiency is up to more than 70%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

CO2 high-temperature heat pump system

ActiveCN104676943AImprove cycle efficiencyExtended heating rangeHeat pumpsCompression machinesVapor–liquid separatorEngineering

The invention discloses a CO2 high-temperature heat pump system. The CO2 high-temperature heat pump system comprises a condenser, a vortex tube, a compressor, a gas-liquid separator, a first expansion valve, a second expansion valve and an evaporator, wherein an outlet of the compressor is connected with an inlet of the vortex tube; a high-temperature outlet of the vortex tube is connected with a refrigerating fluid inlet of the condenser; a low-temperature outlet of the vortex tube is connected with the gas-liquid separator; a refrigerating fluid outlet of the condenser is connected with the gas-liquid separator via the first expansion valve; a gas outlet of the gas-liquid separator is connected to an inlet of the compressor through a gas suction tube; a liquid outlet of the gas-liquid separator is connected to a first inlet of the evaporator via the second expansion valve; and a first outlet of the evaporator is connected with the gas-liquid separator. The vortex tube and an ejector are arranged on the heat pump system, a vortex shedding effect of the vortex tube is utilized, water with high temperature can be provided by the condenser under the condition that a heat pump has constant exhaust pressure, and the application range of the high-temperature heat pump is expanded further; and moreover, the air suction pressure of the compressor can be increased with the aid of the ejector, and the energy efficiency of the heat pump is improved.

Owner:NINGBO SAISEN ENERGY SAVING EQUIP CO LTD

Hydrogen-injection oil extraction method

The invention discloses a hydrogen-injection oil extraction method. An oilfield oil extraction area block is provided with a gas-injection well and surrounding production wells; the gas-injection well is connected with equipment for injecting hydrogen or hydrogen and carbon dioxide; the gas-injection well is connected with steam-injection heating ground layer equipment or electric heating equipment for heating gas injected into the ground layer at the bottom of the well; the production well is connected with oil extraction equipment; the hydrogen or the hydrogen and the carbon dioxide gas arecontinuously injected into the gas-injection well by using the equipment, the temperature of a near-well zone of the gas-injection well rises from 100 DEG C to 500 DEG C simultaneously through steam injection or electric heating when the temperature of an oil layer is less than 130 DEG C, and the gas injection amount is 5,000-7,000 cubic meters every day; when the hydrogen amount produced by someone well is above 500 cubic meters every day, the production well is closed down, while 50 percent of production wells are closed down, the hydrogen is stopped to inject and the hydrogen-injection oil extraction is ended; and the fluid in an aperture enclosed in a low-permeability oil reservoir is heated and expanded to swell the enclosed space burst to form a channel, so that crude oil in the enclosed aperture flows out.

Owner:PETROCHINA CO LTD

Reforming process of quartz glass crucible

InactiveUS7905112B2Heating evenlyLess heatPolycrystalline material growthBy pulling from meltForeign matterRotational axis

A reforming process of a quartz glass crucible in which the quartz glass crucible is reformed by an arc discharge generated by electrodes positioned around a rotational axis and configured to heat an inside surface of the crucible while the crucible is rotated. The process includes arranging electrodes in an electrode structure such that neighboring electrodes are positioned at regular intervals in a ring-like configuration; forming a stable ring-like arc between the neighboring electrodes, without generating a continuous arc between electrodes facing each other across a central portion of the ring-like configuration; heating the inside surface of the crucible; and removing a foreign substance located on the inside surface of the crucible or a bubble located under the inside surface of the crucible.

Owner:SUMCO CORP

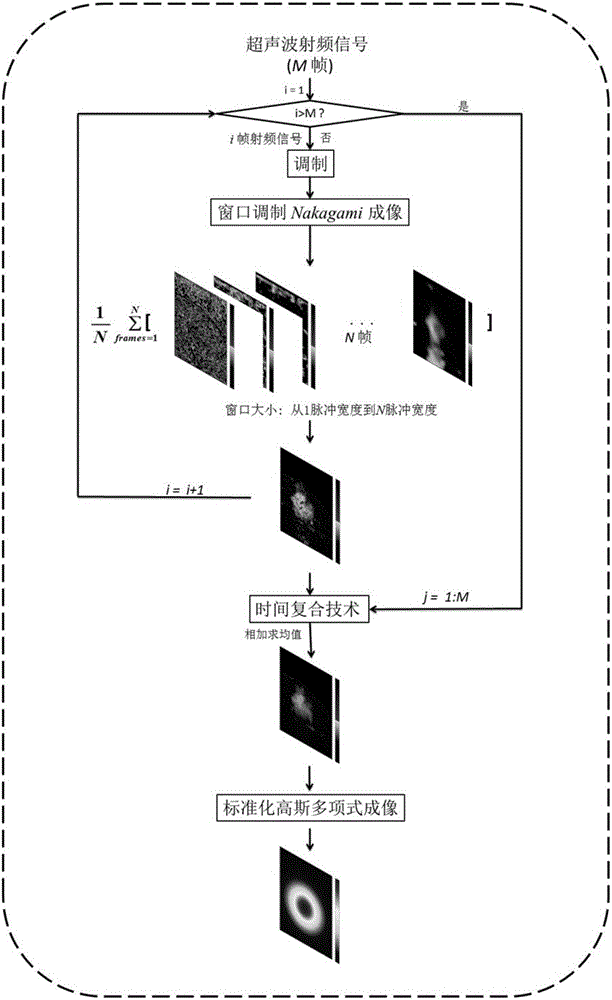

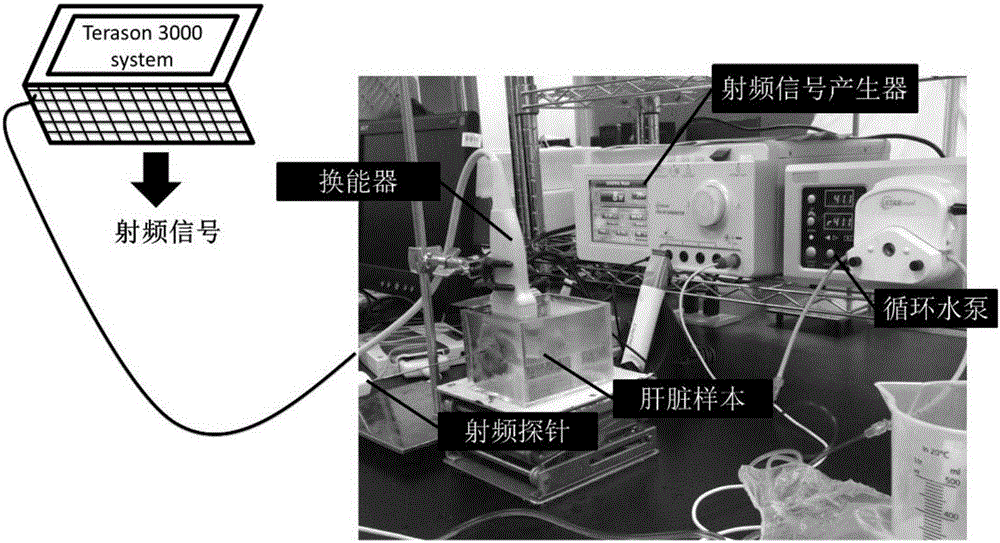

Apparatus and method for monitoring radiofrequency ablation by means of window modulation and Gauss polynomial fitting

InactiveCN106264722AImprove accuracyExtended heating rangeImage enhancementImage analysisRadio frequencyImage resolution

The invention relates to medical image processing and ultrasonic temperature imaging, provides a method for improving the resolution of monitored radiofrequency ablation surgical electrode locations and heating ranges, and discloses an apparatus and method for monitoring radiofrequency ablation by means of window modulation and Gauss polynomial fitting. The technical scheme includes that the apparatus for monitoring radiofrequency ablation by means of window modulation and Gauss polynomial fitting is provided with a frame data setting module, an envelope image acquiring module, a Nakagami image forming module, a compounding Nakagami image acquiring module and a temporal compounding image ImgT (temporal compounding image) acquiring module; the frame data setting module, the envelope image acquiring module, the Nakagami image forming module, the compounding Nakagami image acquiring module and the temporal compounding image ImgT acquiring module are arranged on a transducer of an ultrasonic instrument; the method includes carrying out post-processing on obtained temporal compounding images ImgT by the aid of one-dimensional Gauss polynomials to obtain images for monitoring radiofrequency ablation. The apparatus and method have the advantages that the heating ranges can be effectively expanded by the aid of the method during monitored radiofrequency ablation surgery, the accuracy of cancer cell killing ranges of the radiofrequency ablation surgery can be improved, and monitoring effects can be improved; the apparatus and method are mainly applied to image processing.

Owner:TIANJIN UNIV

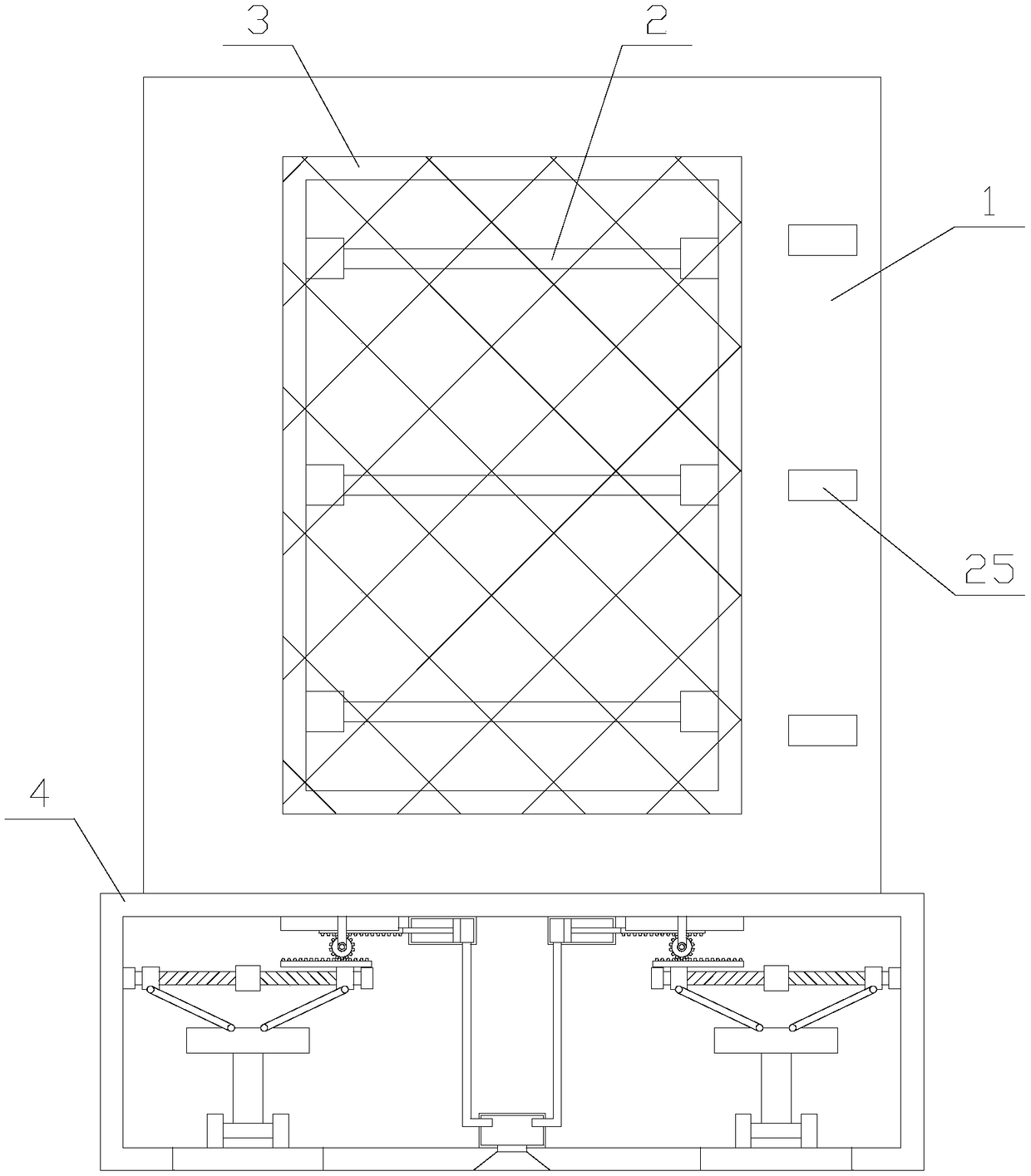

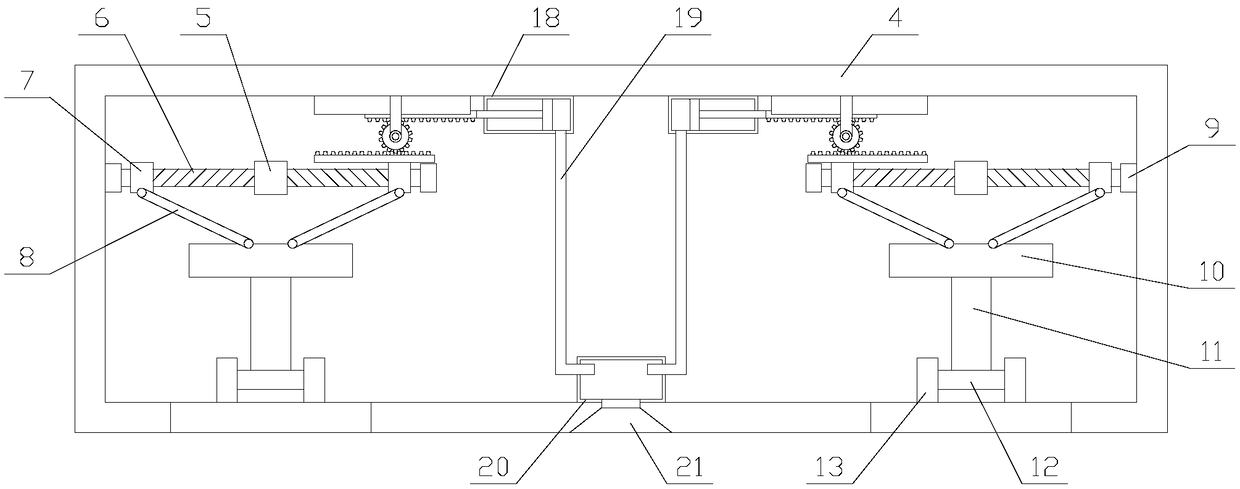

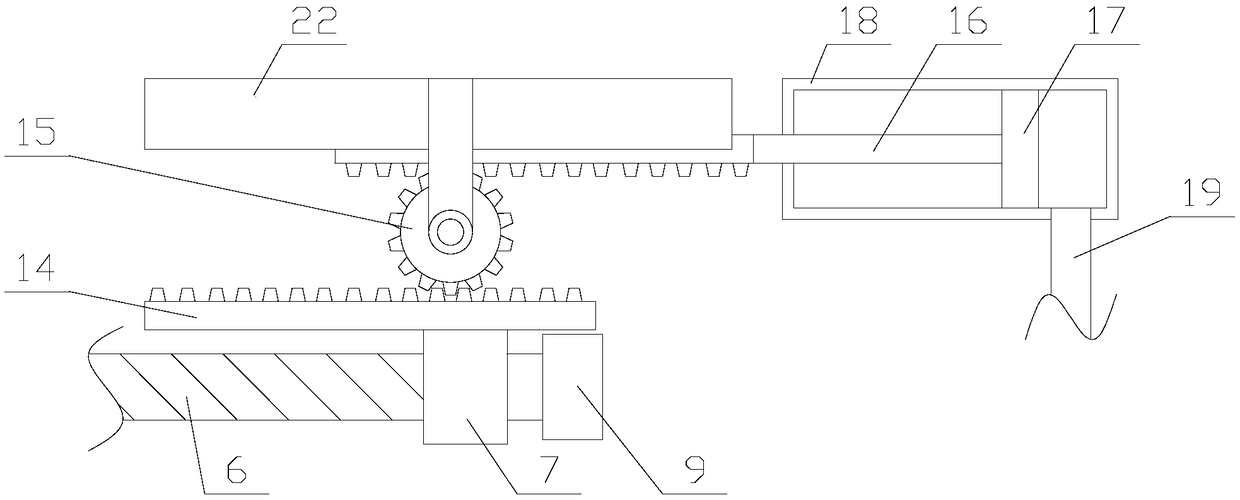

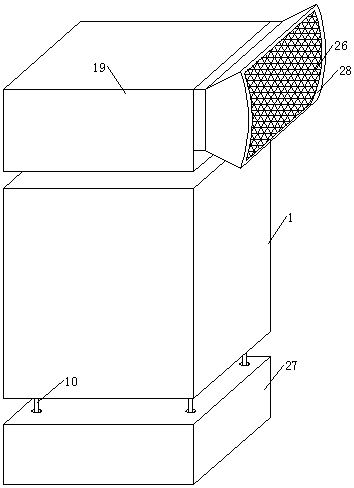

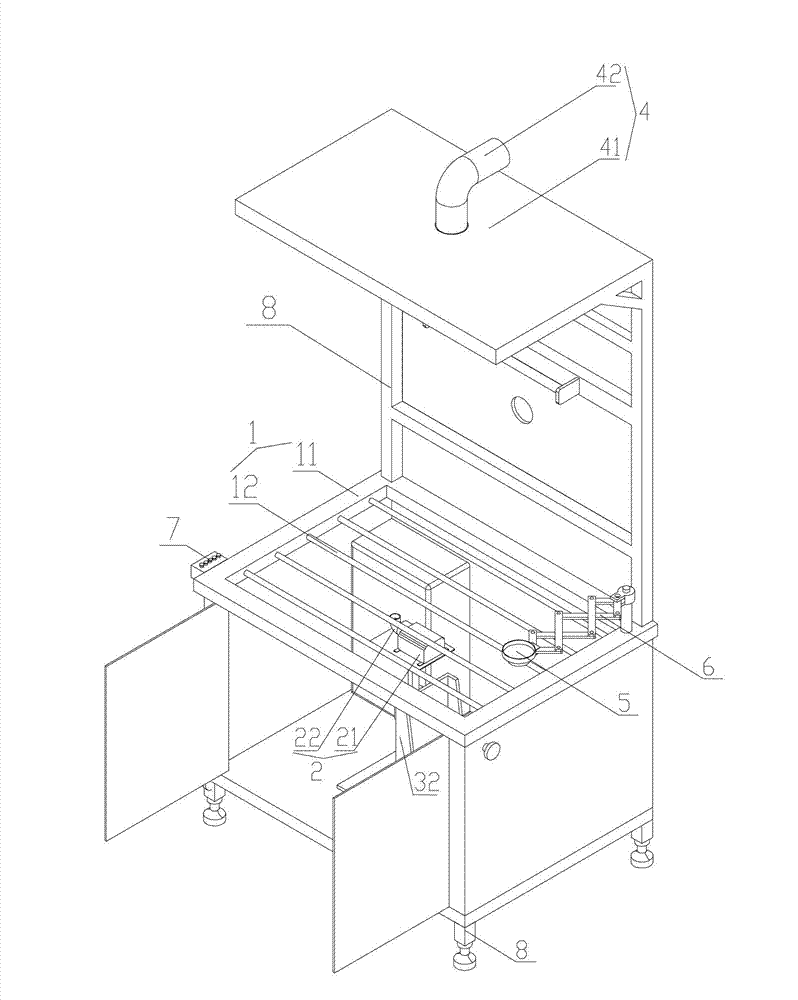

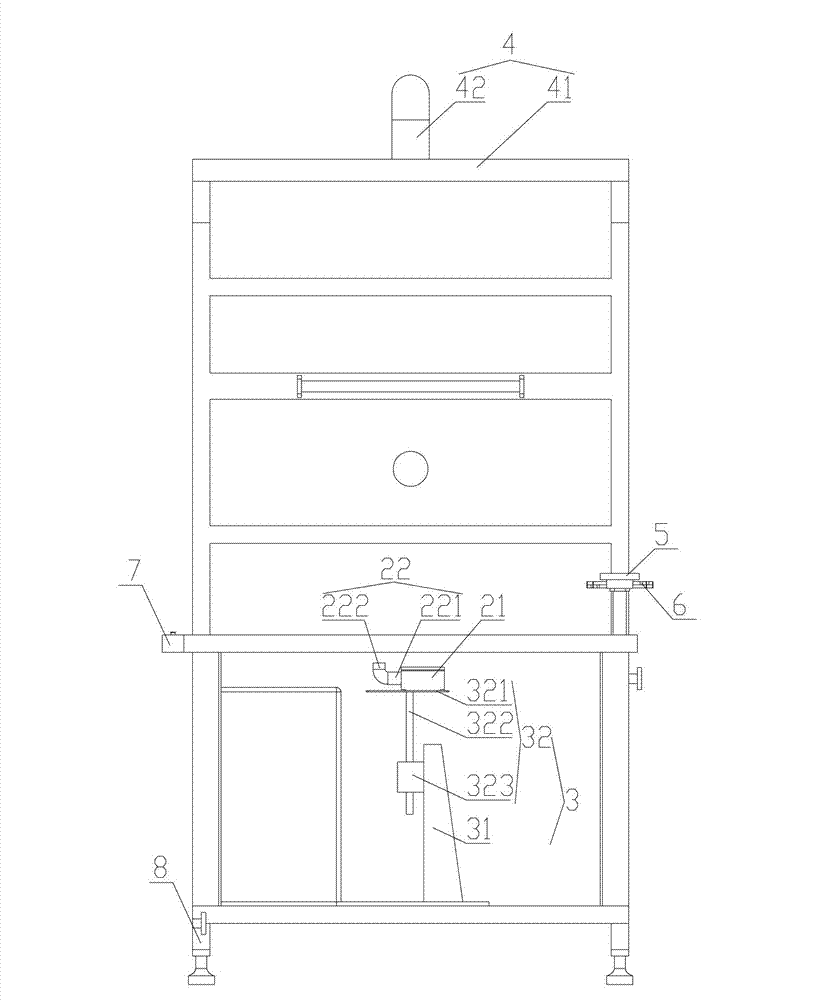

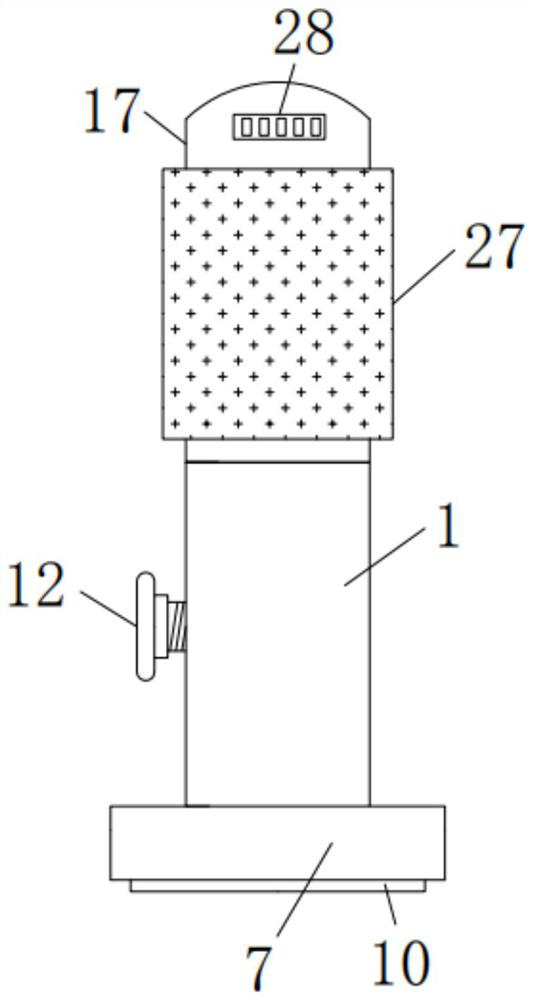

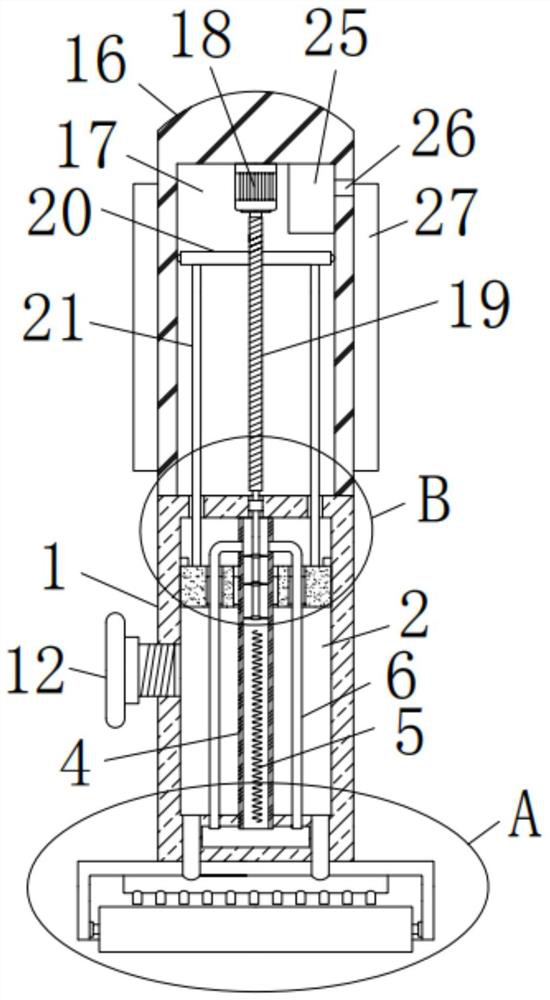

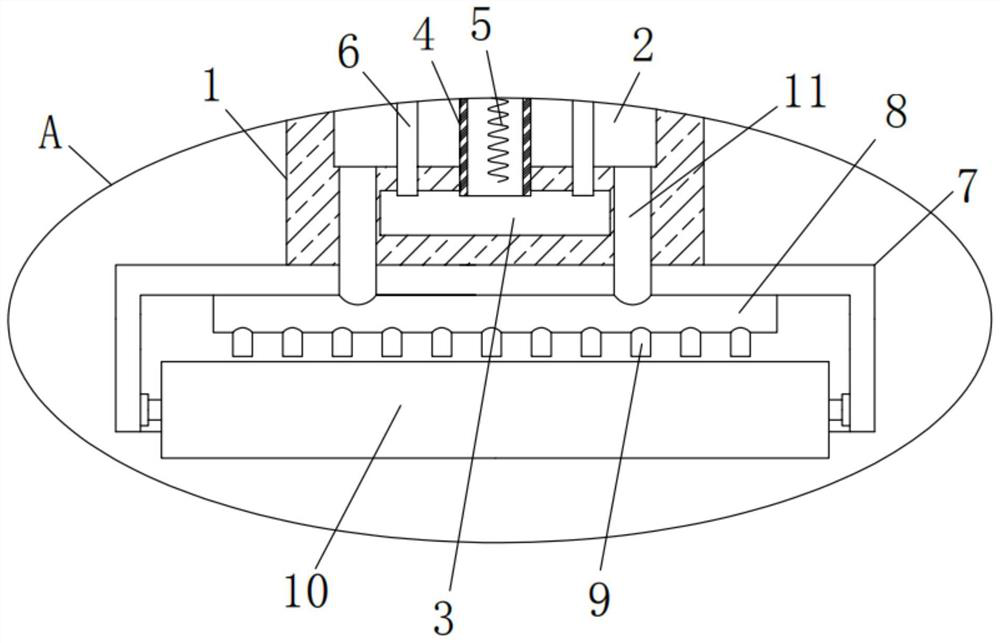

Convenient and rapid type heating device with stabilization function

InactiveCN109297078AEasy to moveExpand the scope ofHeating fuelLighting and heating apparatusPistonPower unit

The invention relates to a convenient and rapid type heating device with a stabilization function. The convenient and rapid type heating device with the stabilization function comprises a body, a meshenclosure and a base. A stabilizing mechanism and two moving mechanisms are arranged in the base. Each moving mechanism comprises a first motor, a lifting plate, a moving assembly and two drive assemblies. Each drive assembly comprises a rotating shaft, a sliding block and a lifting rod. The stabilizing mechanism comprises an air storage cylinder, a suction cup and two air exhaust assemblies. Each air exhaust assembly comprises a power unit, an air exhaust rod, an air exhaust cylinder, a piston and a connection pipe. According to the convenient and rapid type heating device with the stabilization function, through the moving mechanisms, the convenient and rapid type heating device is convenient to move, so that the heating range is expanded; by means of the stabilizing mechanism, the basecan be sucked to the ground through the suction cup, the situation that the convenient and rapid type heating device is inclined and damaged is avoided, and the safety of the convenient and rapid type heating device is improved.

Owner:扬州昌通照明器材有限公司

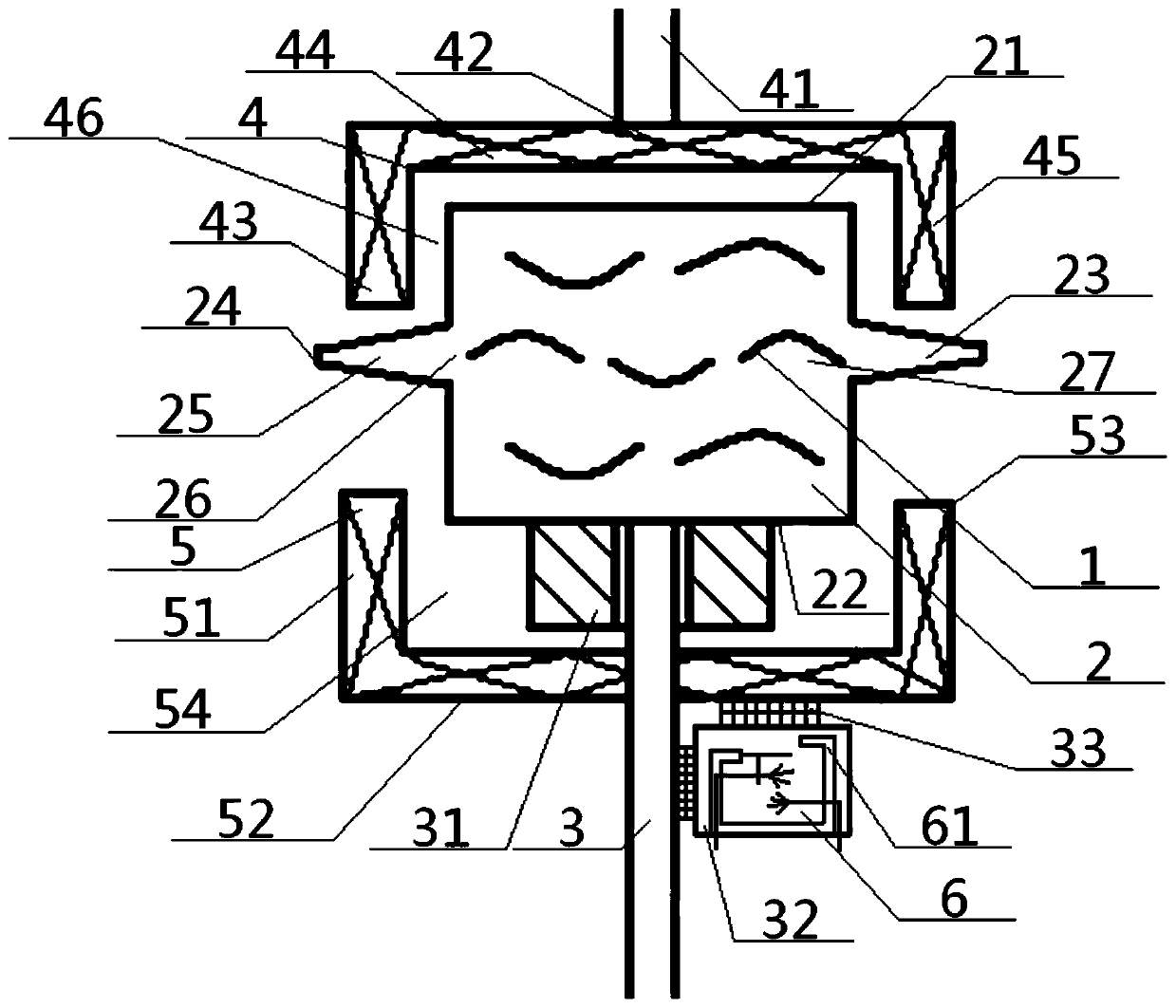

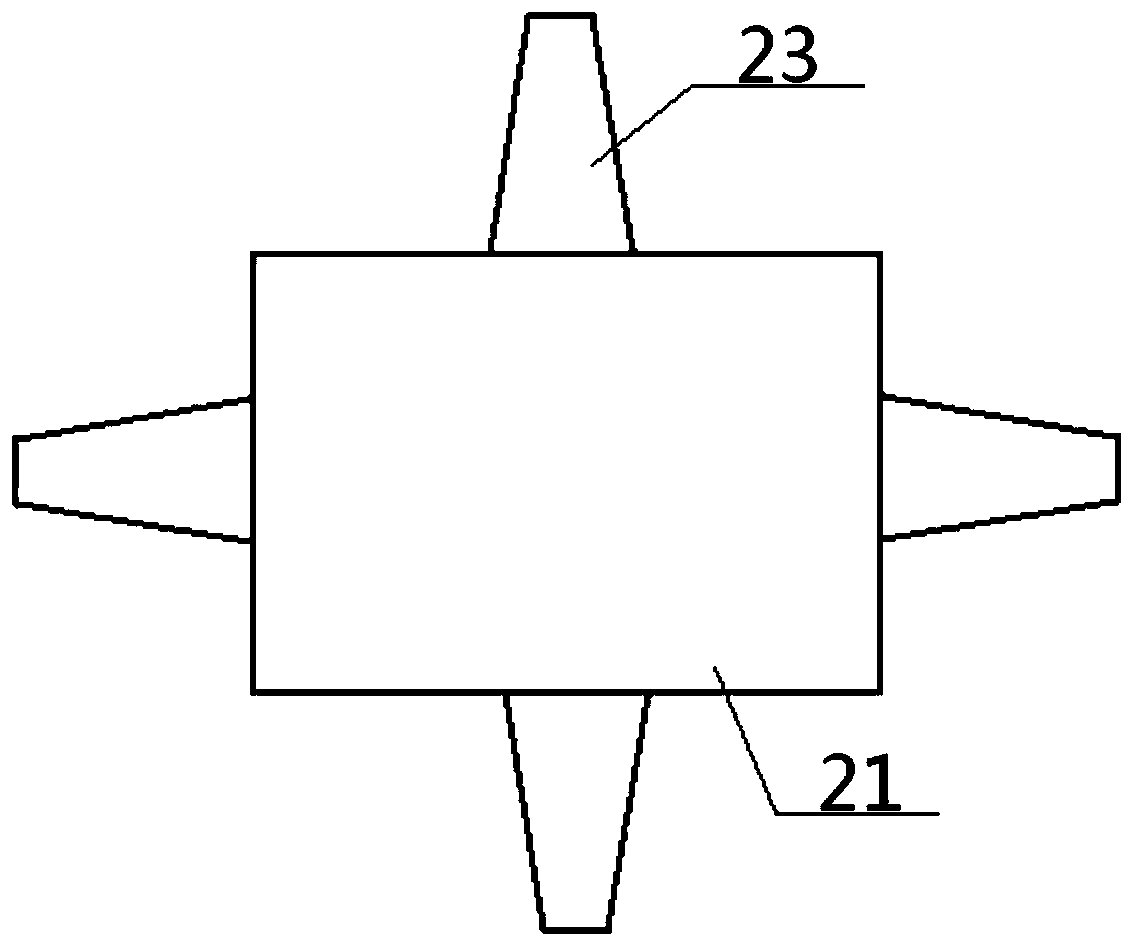

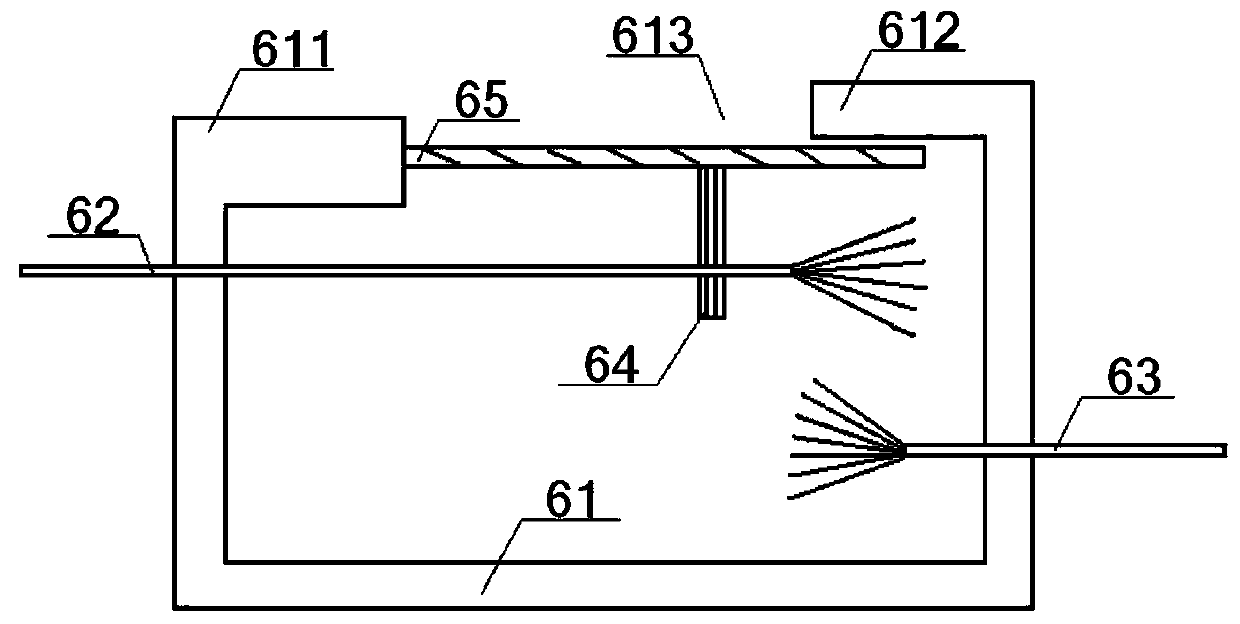

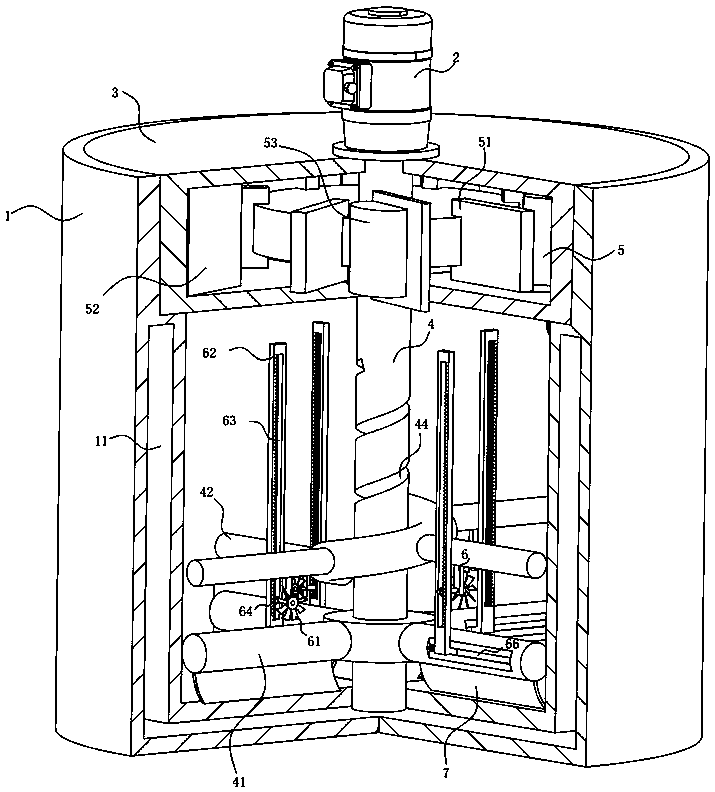

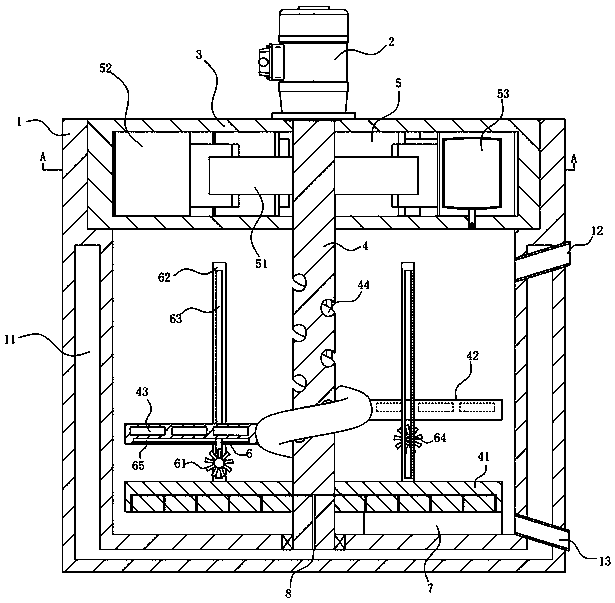

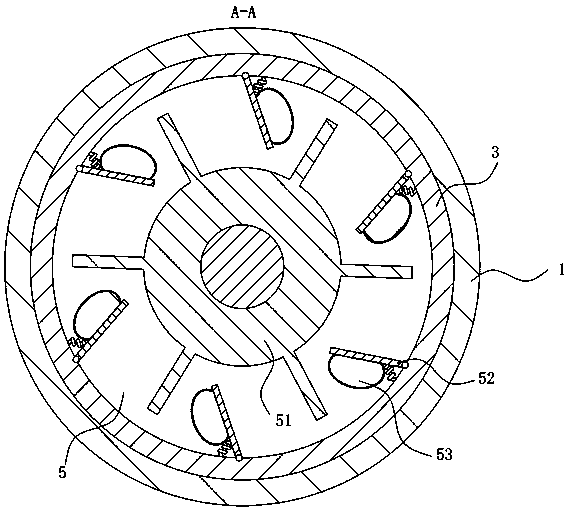

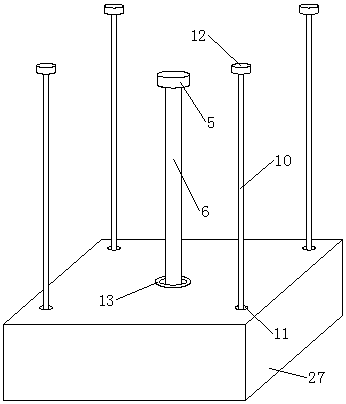

Rotary nanofiber preparation device

InactiveCN110923833AIncrease productivityEasy to collectSpinnerette packsFilament forming substance formingHeat conductingNanofiber

The invention discloses a rotary nanofiber preparation device. A charging vessel in the rotary nanofiber preparation device includes nozzles, an upper rectangular shell and a lower rectangular shell,wherein the upper rectangular shell and the lower rectangular shell are of hollow structures, the upper rectangular shell and the lower rectangular shell are connected up-down into a whole structure,a junction position of the upper rectangular shell and the lower rectangular shell are connected with the nozzles, and the inner parts of the upper rectangular shell and the lower rectangular shell together form an in-device cavity in communication with the nozzles. The in-device cavity is internally provided with a fiber source, an upper heater is arranged above the top of the upper rectangular shell, a lower heater is arranged below the bottom of the lower rectangular shell, the bottom of the lower rectangular shell is connected to a rotary shaft through a bottom bearing, a heat conducting chamber is formed in the position, close to the lower heater, on the rotary shaft, and buffer layers are arranged at the top and the side part of the heat conducting chamber correspondingly. The designdoes not need to apply a high-voltage electric field and is not subject to conductivity constraints, the heating effect is good, the production efficiency is high, and the adjustability is high.

Owner:吴江市欧鑫纺织品有限公司

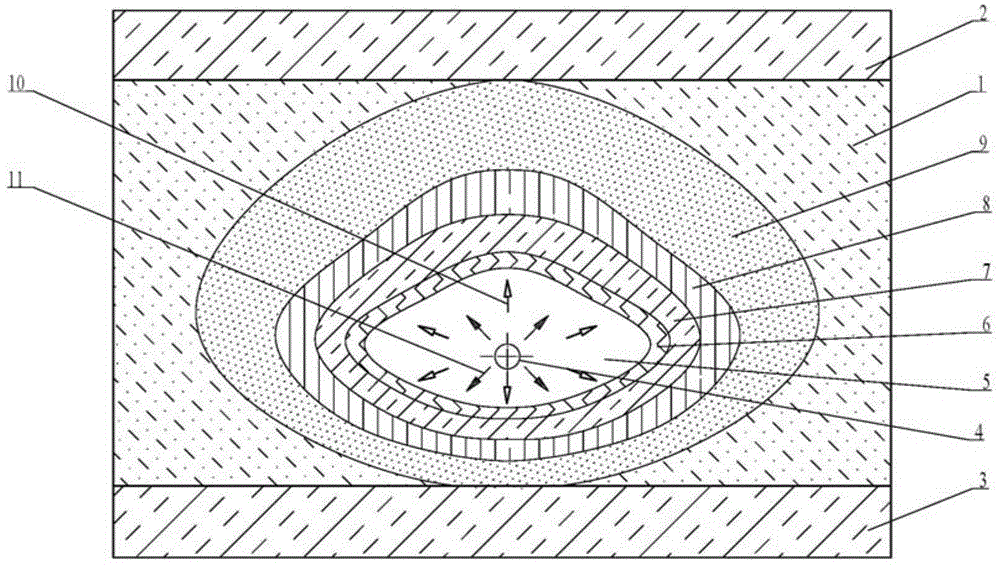

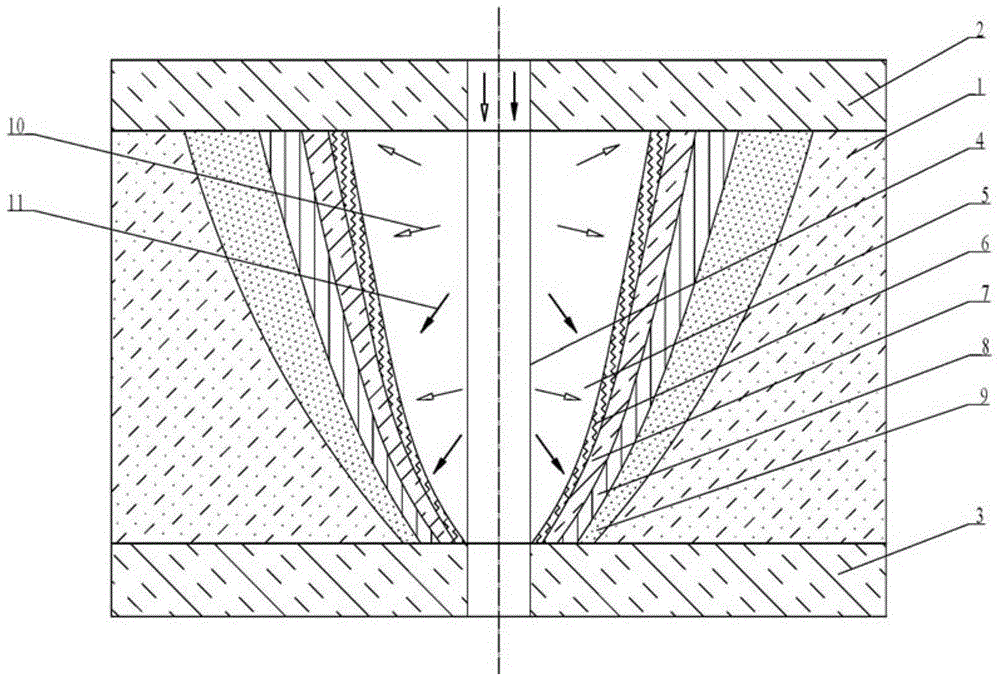

Fracture-assisted combustion of oil in-situ stimulation thickened oil exploiting method

InactiveCN104265258AIncreased air injection capacityExtended heating rangeFluid removalCombustionFlue gas

The invention relates to a fracture-assisted combustion of oil in-situ stimulation thickened oil exploiting method. The method comprises the steps of conducting hydrofracture transformation on the oil reservoir on the perforating section of an oil well casing, forming vertical artificial fractures on both wings of a shaft, adding fracturing propping agents with which the fractures are filled, and conducting sieve tube gravel pack completion inside the casing; making the bottom hole temperature reach the ignition temperature of crude oil by means of the firing technique to ignite the oil layer of an oil well; injecting air into the oil well continuously by means of an air compressor; conducting soaking after air injection; opening the well for stoping. The method is mainly applied to low-permeation heavy oil reservoirs, thin-bedded heavy oil reservoirs and thin-interbed heavy oil reservoirs. Compared with the prior art, the method has the advantages that combustion of oil in-situ stimulation air injection speed and monocyclic cumulative injection rate can be increased by over three times, thermal front and flue gas front swept volume is increased by over three times, well yield is increased by over two times, and cyclic cumulative production is increased by over three times.

Owner:BEIJING PUXIN PETROLEUM TECH DEV

Crucible for manufacturing optical glass

InactiveCN111333305AExtended heating rangeEvenly heatedPot furnacesGlass furnace apparatusCrucibleElectric machine

The invention belongs to the technical field of optical glass smelting, and particularly relates to a crucible for manufacturing optical glass. The crucible comprises a crucible body, a motor and a sealing cover; a cavity is designed in the crucible body; a rotating shaft of the motor penetrates through the sealing cover and is fixedly connected to a stirring shaft in the cavity of the crucible body; the stirring shaft is rotatably connected to uniformly arranged stirring rods and heating rods; a first cavity is formed in the sealing cover; the rotating shaft of the motor is fixedly connectedto a rotating wheel in the first cavity; extrusion plates which are uniformly arranged are hinged to the wall of the first cavity; an inclined side of the extrusion plates are fixedly connected to extrusion bags; a second cavity is formed in the inner wall of the crucible body; the second cavity is arranged around the inner cavity of the crucible body; the extrusion bags are all communicated withthe inner cavity of the crucible body and the second cavity through one-way conduits; the motor rotates to drive the rotating wheel to extrude the extrusion bags, so that the extrusion bag pumps airflow in the inner cavity of the crucible body into the second cavity, the air pressure of the crucible body is reduced, and the melting point of raw materials is partially reduced.

Owner:刘明举

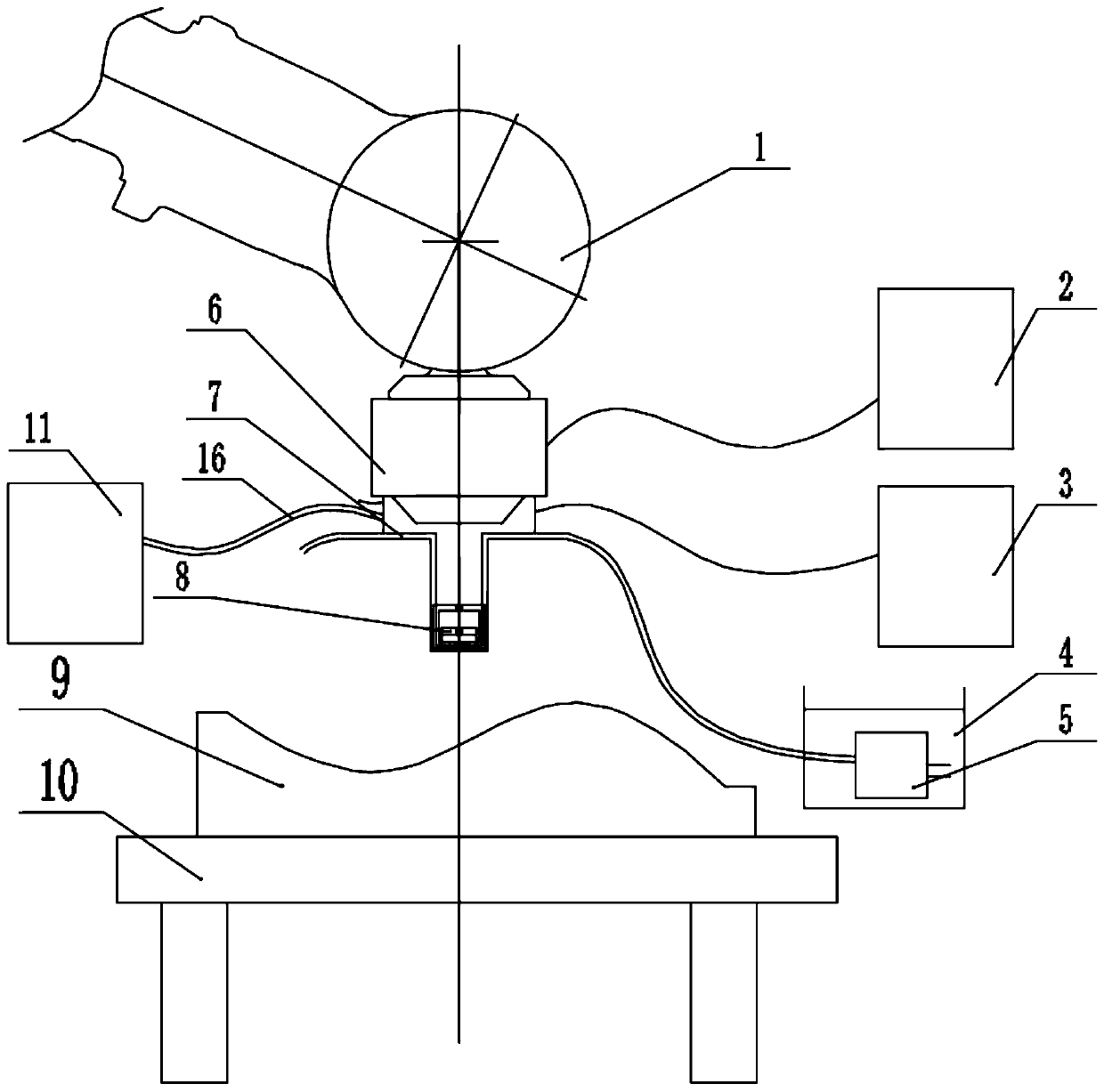

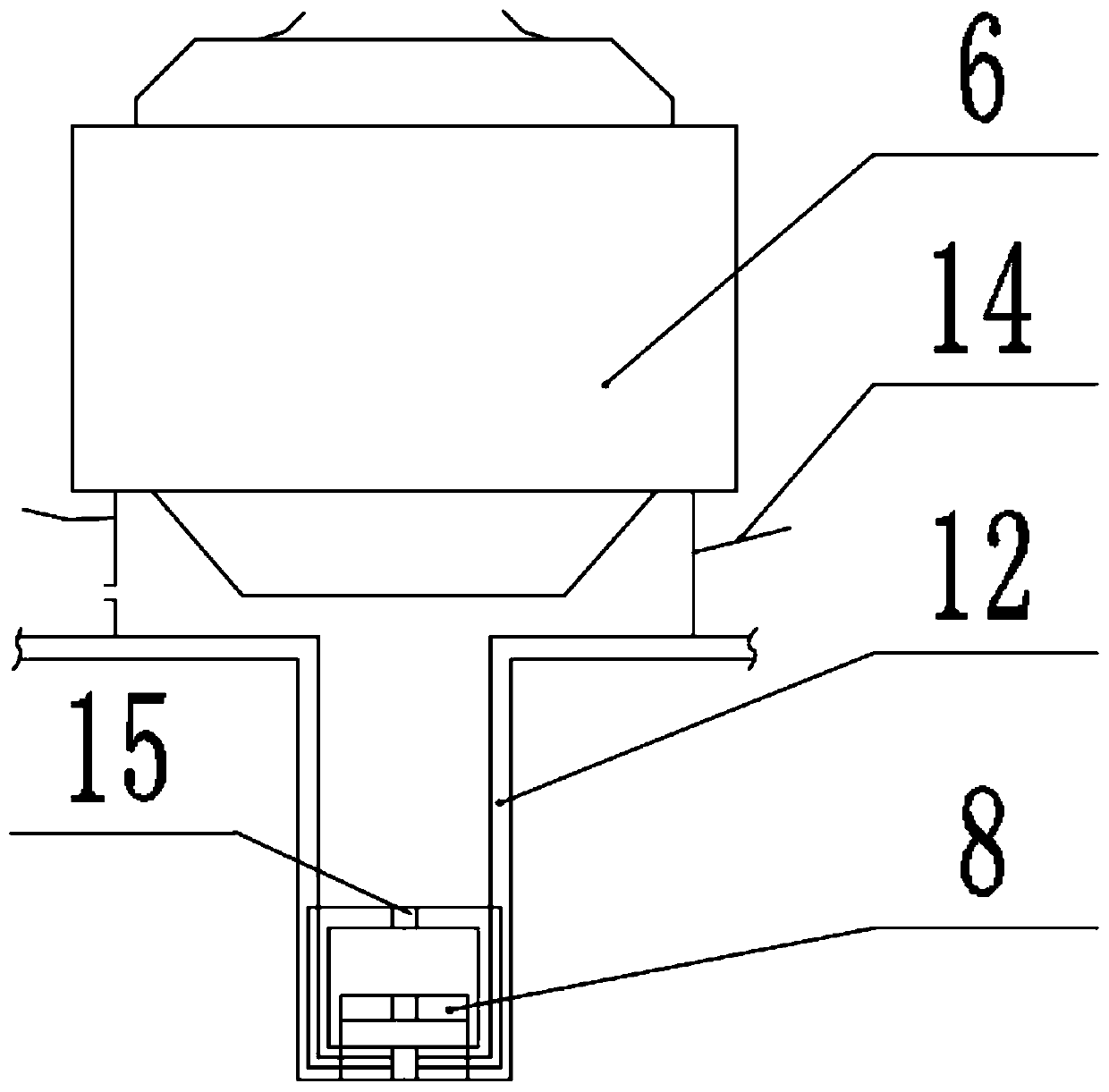

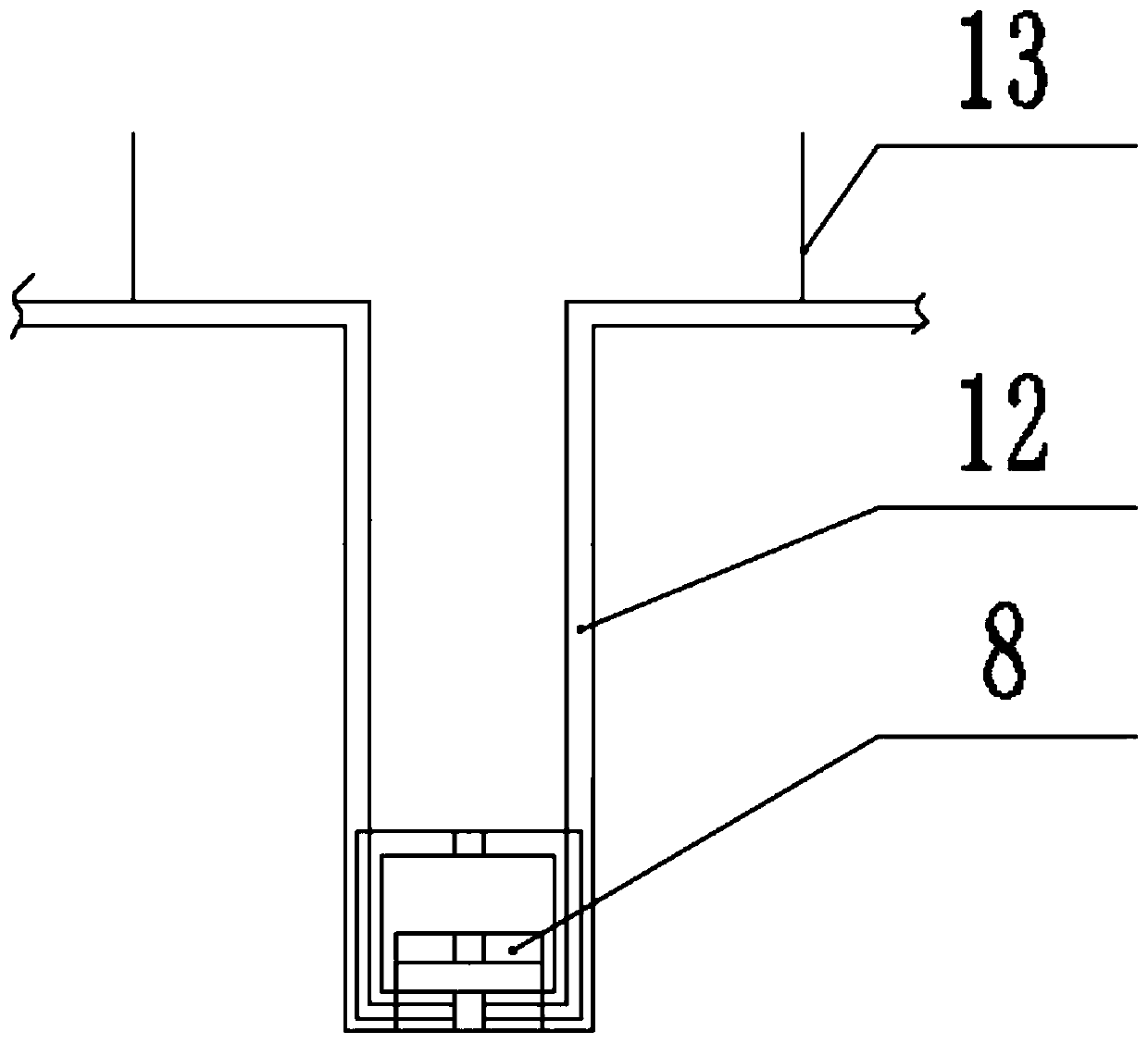

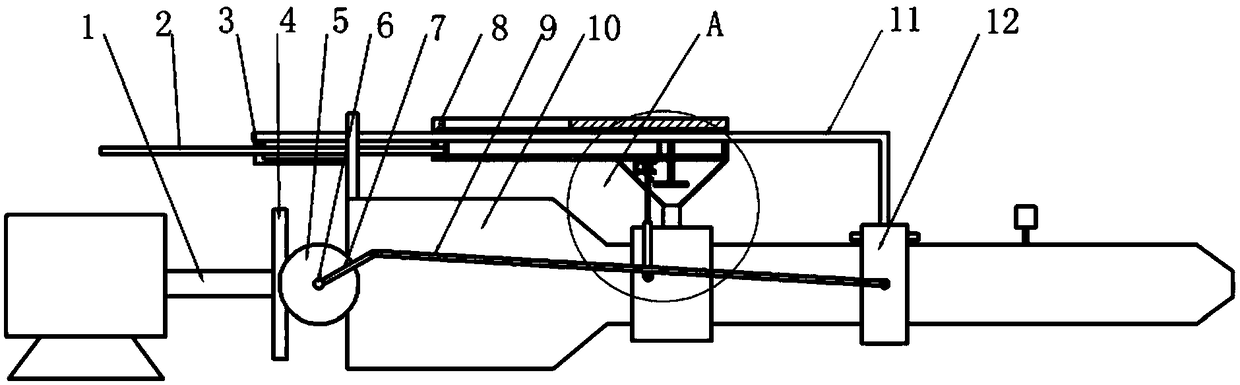

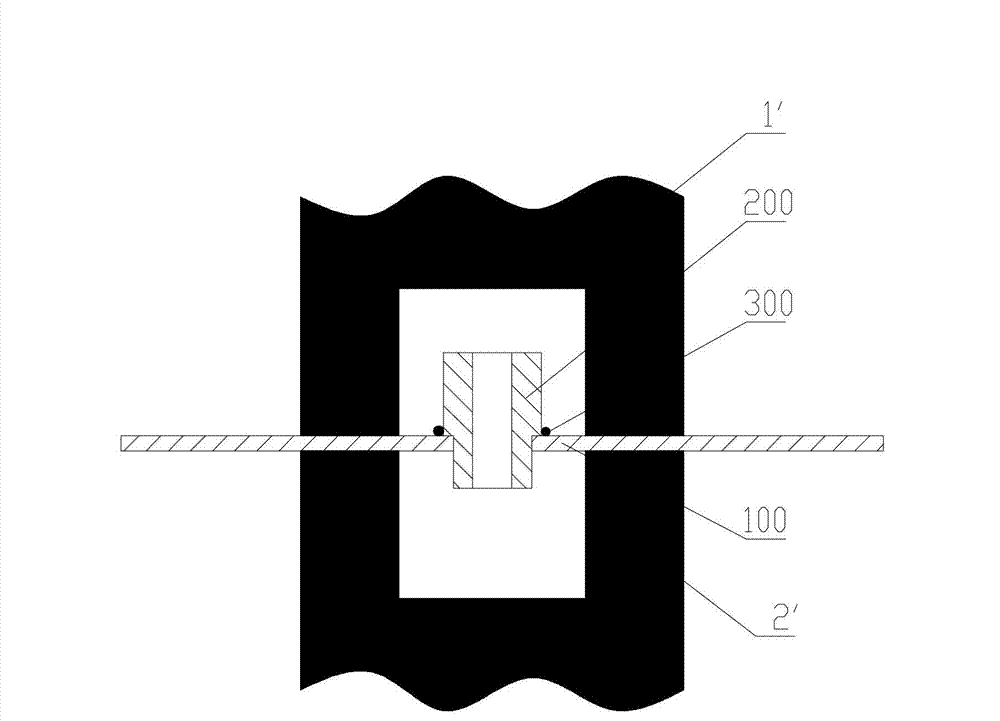

Electromagnetic assisted laser synchronous cladding device and method for remanufacturing metal parts

ActiveCN110373666AAchieve preheatingReduce cooling rateMetallic material coating processesHigh energyEddy current

The invention discloses an electromagnetic assisted laser synchronous cladding device and method for remanufacturing metal parts. The electromagnetic assisted laser synchronous cladding device comprises a six-degree-of-freedom actuator, a laser, an electromagnetic induction heater, a powder spraying device and a workbench, wherein the working table is used for containing a workpiece to be machined, and the powder spraying device is used for spraying metal powder to the surface of the workpiece to be machined; the laser is installed at the tail end of the six-degree-of-freedom actuator, and thelaser is used for generating high-energy lasers for achieving cladding of the metal powder on the surface of the workpiece arranged on the workbench; the electromagnetic induction heater comprises aninduction coil and an induction power supply for supplying power to the induction coil, and the induction coil is made of a hollow metal tube; and cooling water is fed into the hollow metal tube forcooling, and the induction coil is arranged below the laser device and used for carrying out auxiliary cladding on the metal powder on the surface of the workpiece to generate an eddy current. According to the electromagnetic assisted laser synchronous cladding device, the structure is simple, the cladding speed is high, the powder utilization rate is high, and the applicable cladding material range is wide.

Owner:WUHAN UNIV OF TECH

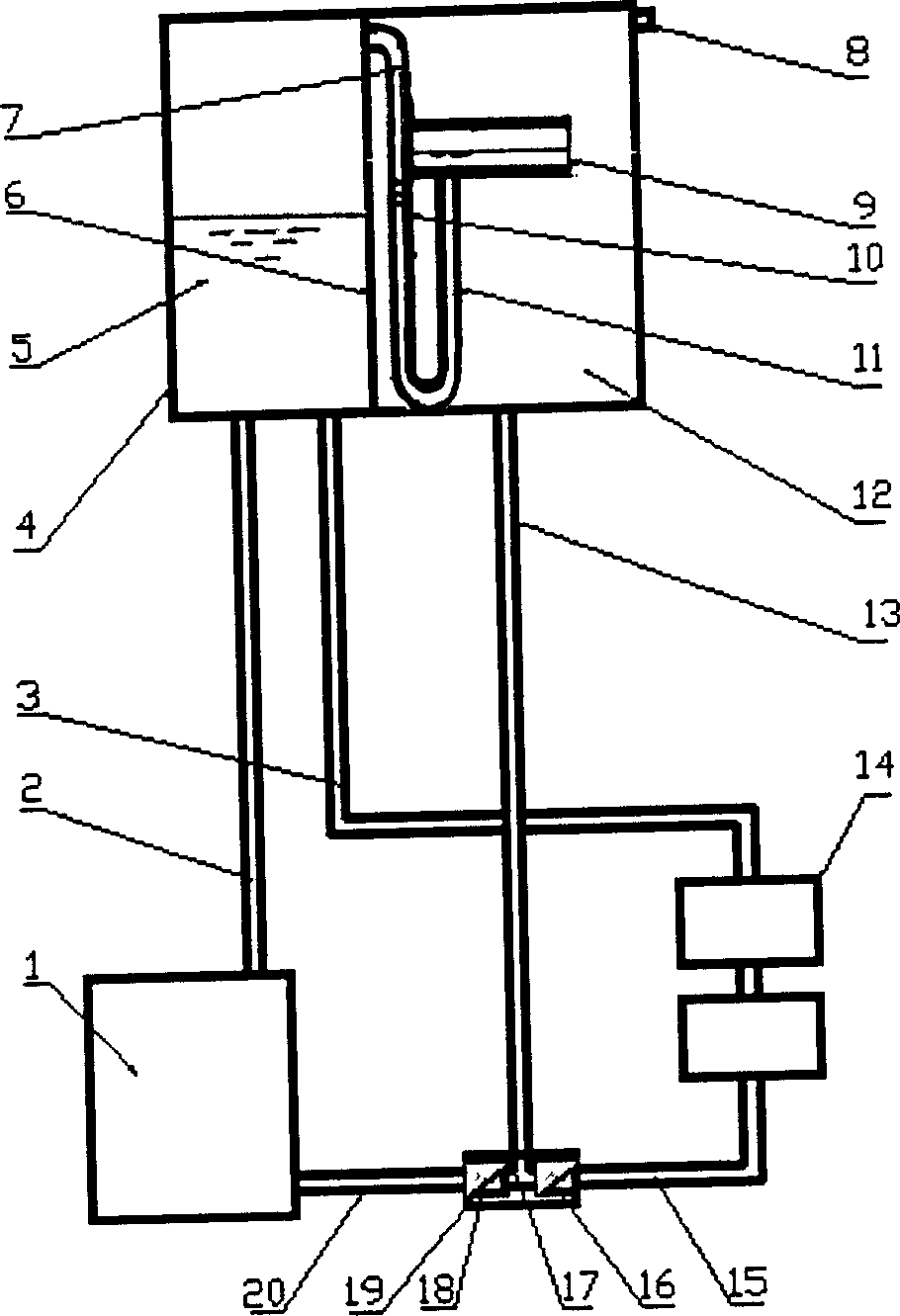

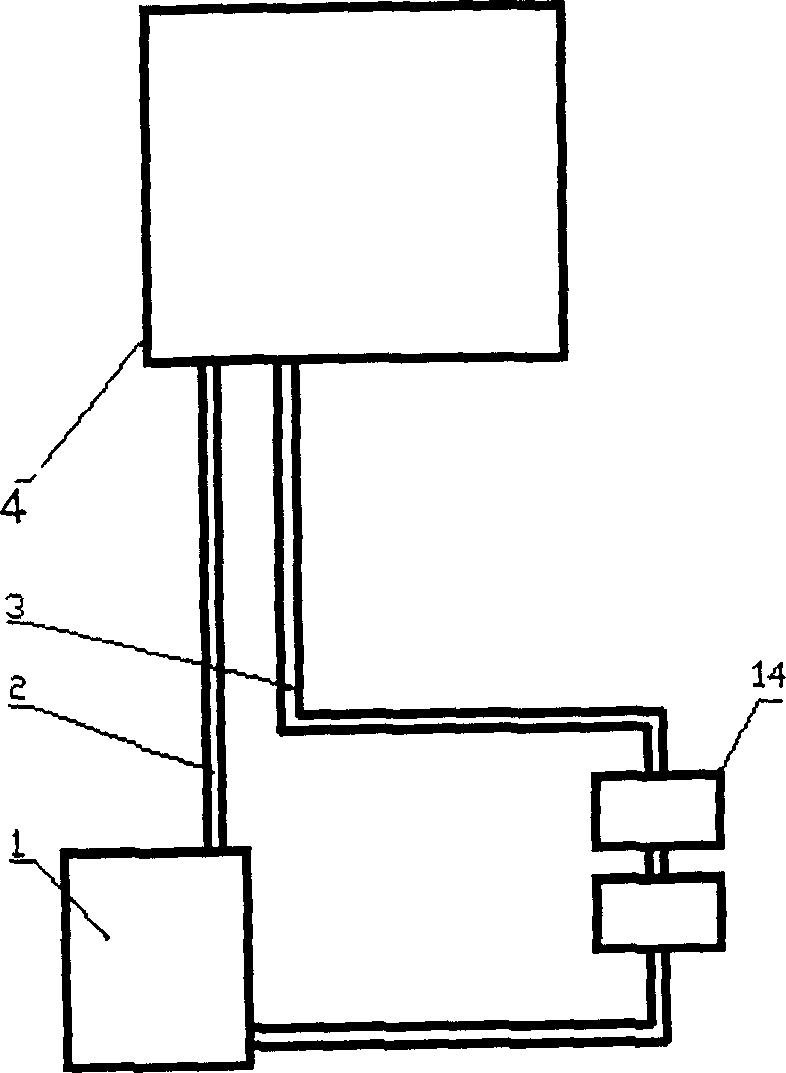

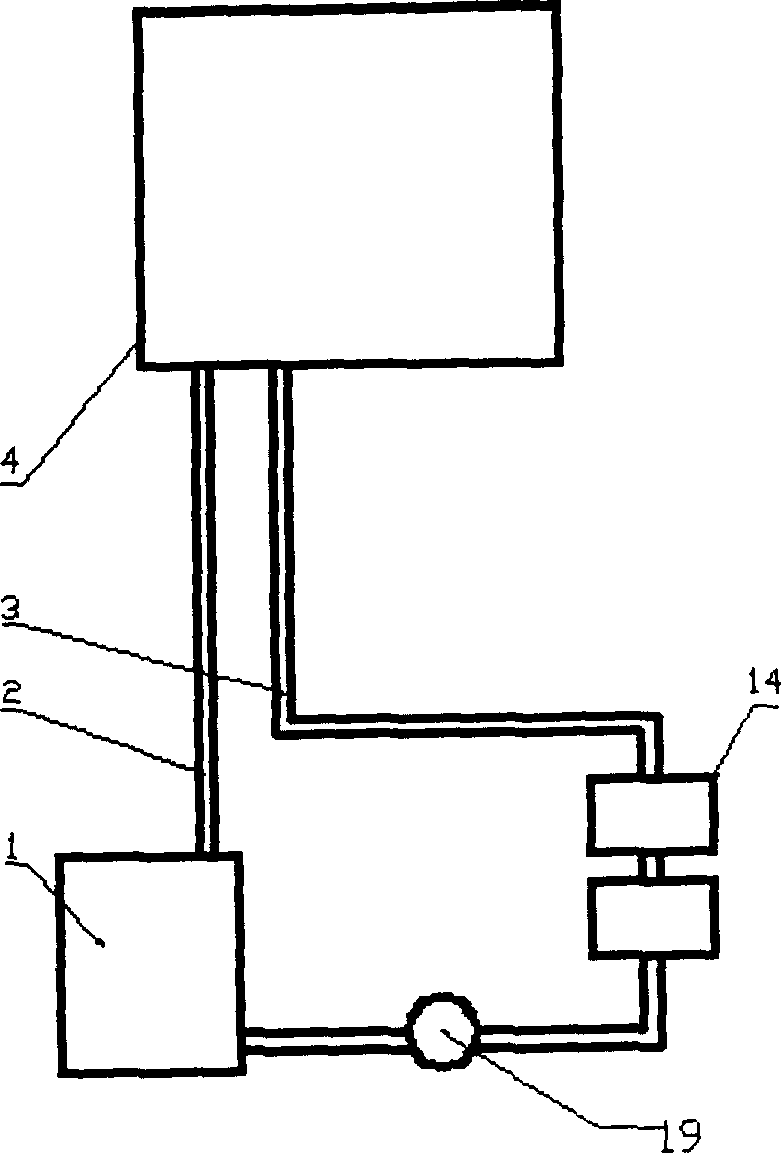

Initiative hot-water circulation heating system

InactiveCN1789826AImprove layout flexibilityExtended heating rangeLighting and heating apparatusSpace heating and ventilation detailsWater circulationHeating system

This invention relates to one positive hot water recycling supplying system, wherein, water box is located above hot turbine; the water box is located with vertical isolation board to divide the water box into hot and cool chambers and the cool chamber is connected to the hot one and control its water level with exhaust tube located on top; exchanger and hot turbine connection path are located with single valve components with three direction connection to the entrance single valve, and balance tube; the balance tube is connected to the down end of cool chamber; the hot turbine is connected to the water box down end; the exchanger one end is connected to the down end of the water box and the other end is connection to the hot turbine through recycle tube, single valve component and water-in tube.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Drying equipment for clothing processing

InactiveCN108589211AEasy to moveExtended heating rangeTextiles and paperLaundry driersBevel gearThreaded rod

The invention discloses drying equipment for clothing processing. The drying equipment includes a mounting base, columns are fixedly installed on both sides of the top of the mounting base respectively, a drying box of a hollow structure is fixedly installed on the tops of the two columns, first rotating grooves are formed in the inner walls of the two sides of the drying box respectively, a rotating rod is rotatably installed in each first rotating groove, and each first bevel gear fixedly sleeves the corresponding rotating rod; threaded grooves are formed in the ends, close to each other, ofthe two rotating rods respectively, each threaded rod is in threaded connection with the interior of the corresponding threaded groove, a sliding groove is formed in the inner wall of the top of thedrying box, a sliding block is fixedly installed on the top of each threaded rod and slidingly connected to the sliding groove, and a fixing rod is fixedly installed on the top of each threaded rod. The structure is simple, operation is convenient, heating lamps can be moved fast and conveniently, the heating range of the heating lamps is widened, the effect of drying clothing is improved, the demand for large-scale drying is met, and the people's needs are met.

Owner:湖州吴兴华溢服装厂

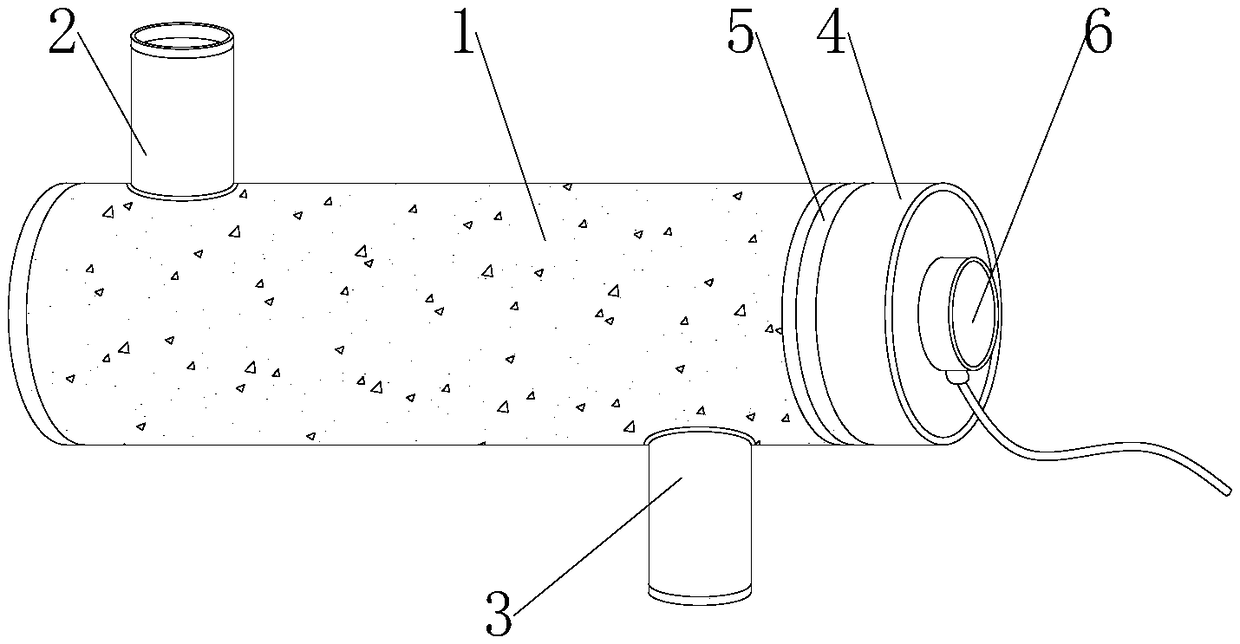

Pipeline heating device in environment-friendly equipment

The invention relates to the technical field of pipelines, in particular to a pipeline heating device in environment-friendly equipment. A liquid outlet pipe is arranged on the right side of the lowerend of a round pipe and is fixedly connected with the round pipe. A closing cover is arranged at the left end of the round pipe and is formed by a fixing block and a stop block. The fixing block is arranged at the left end of the stop block and is fixedly connected with the stop block. The stop block is rotatably connected with the round pipe through a spiral thread, and the closing cover is rotatably connected with the round pipe through the fixing block. A rubber ring is fixedly connected to the left end of the stop block and is located on the outer side of the fixing block. According to the pipeline heating device in the environment-friendly equipment, through the arrangement of a heating bar, a liquid inlet pipe and the liquid outlet pipe, liquid can be heated by the heating device more sufficiently, and the heating efficiency of the heating device is improved; and liquid heating range of the heating device can be greatly enlarged through heat conduction strips so that the liquidcan be heated more uniformly, and accordingly, the problems of narrow heating range and non-uniform heating of tubular electric heating elements are solved.

Owner:江苏中远环保科技有限公司

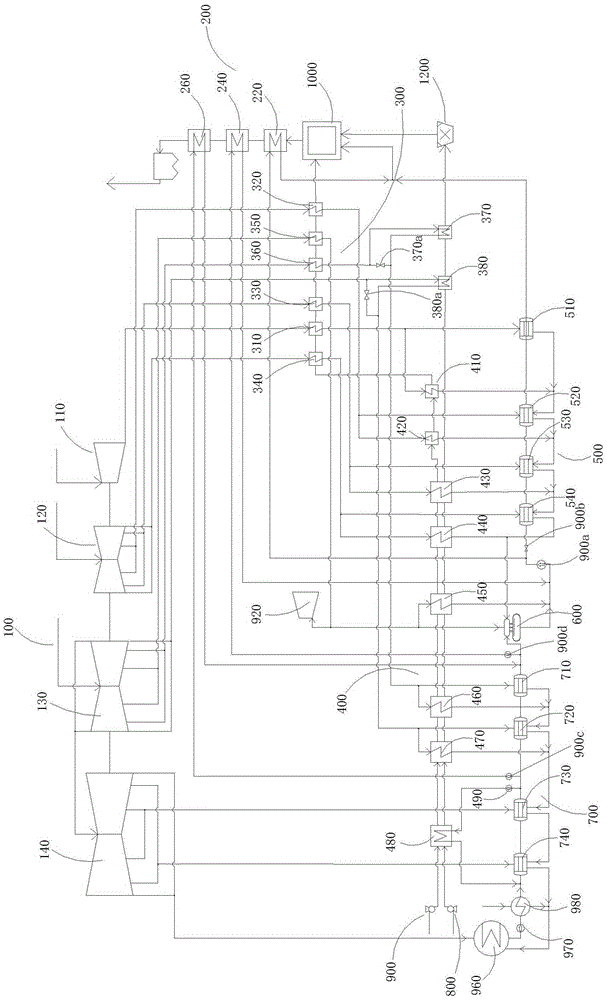

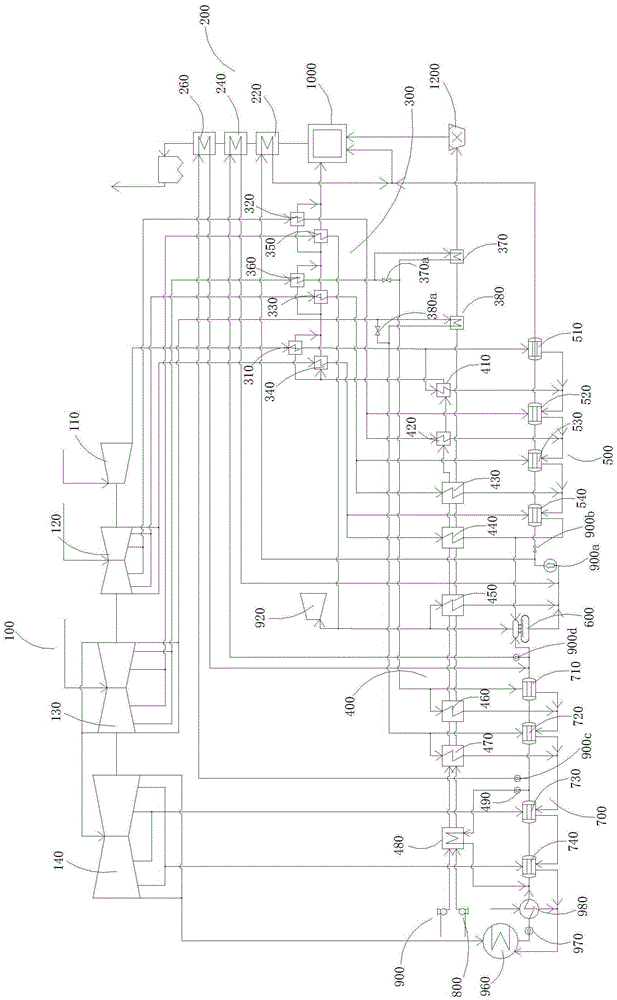

Double-reheat steam turbine heat regenerative energy utilizing system for primary air and secondary air of heating boiler

ActiveCN105371267AEliminate air leakage and dust blockingReduce power consumptionFeed-water heatersBoiler furnaceCoal

Owner:广州粤能电力科技开发有限公司

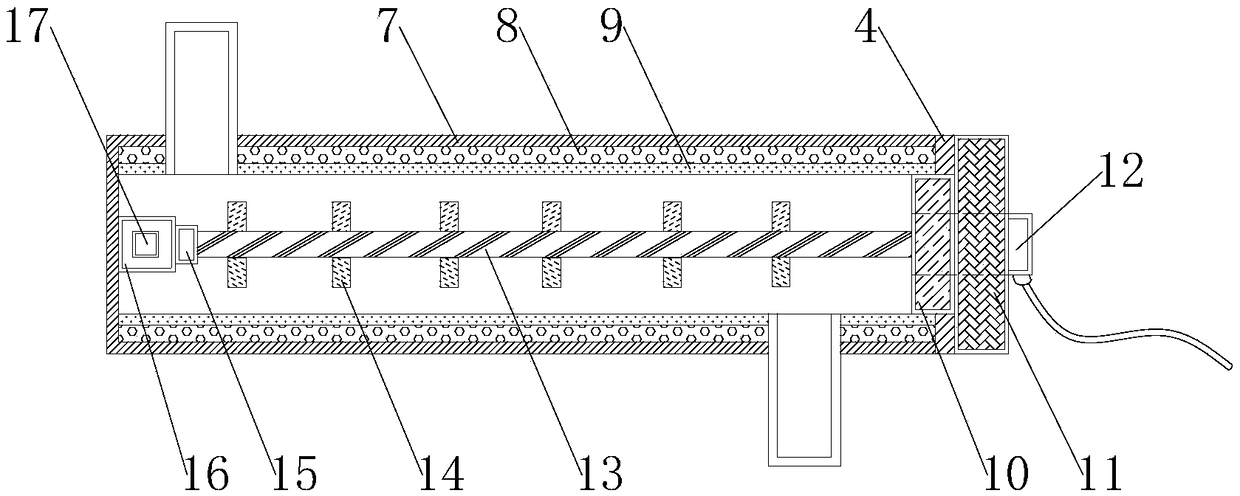

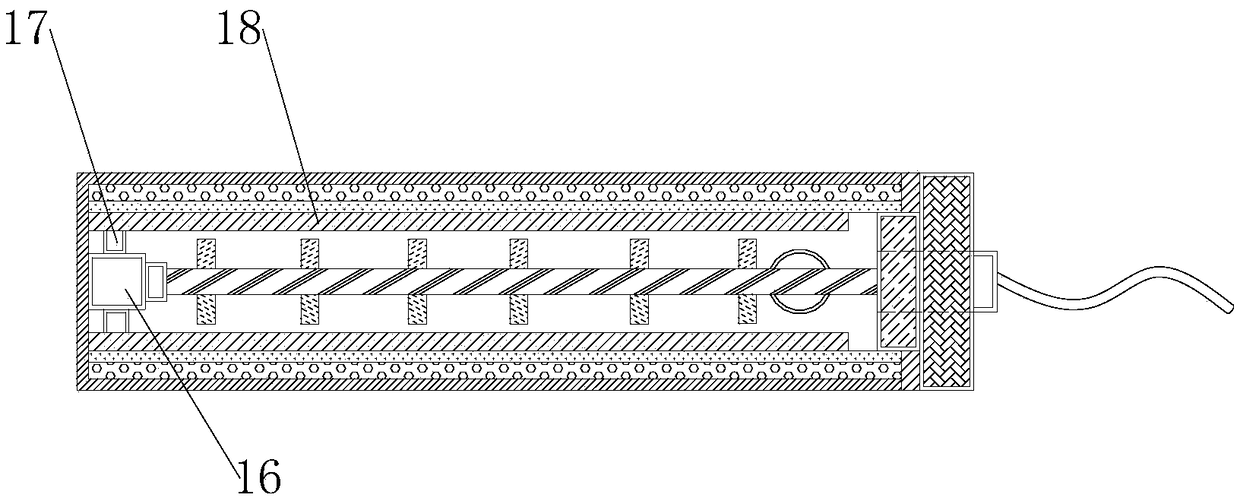

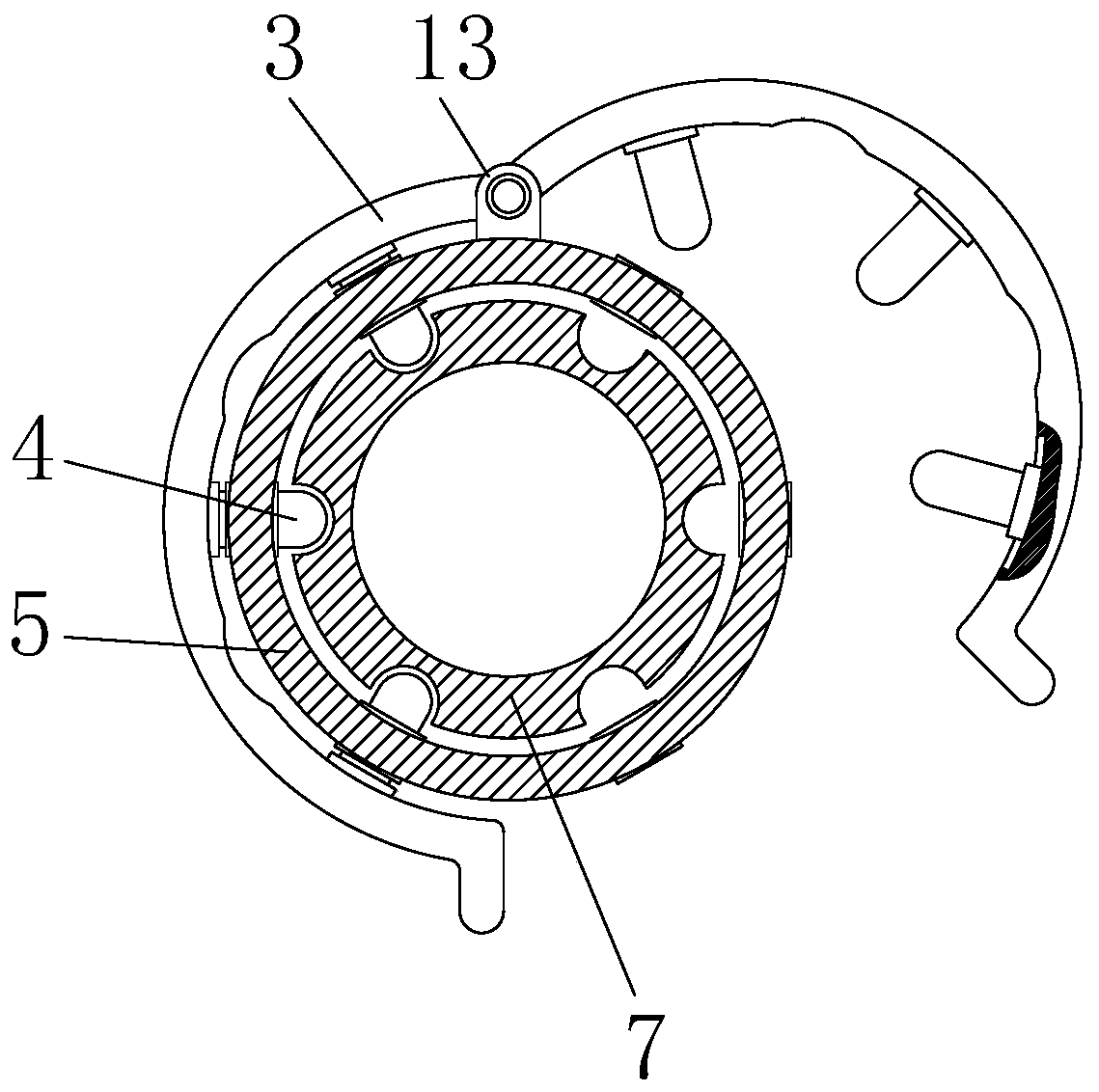

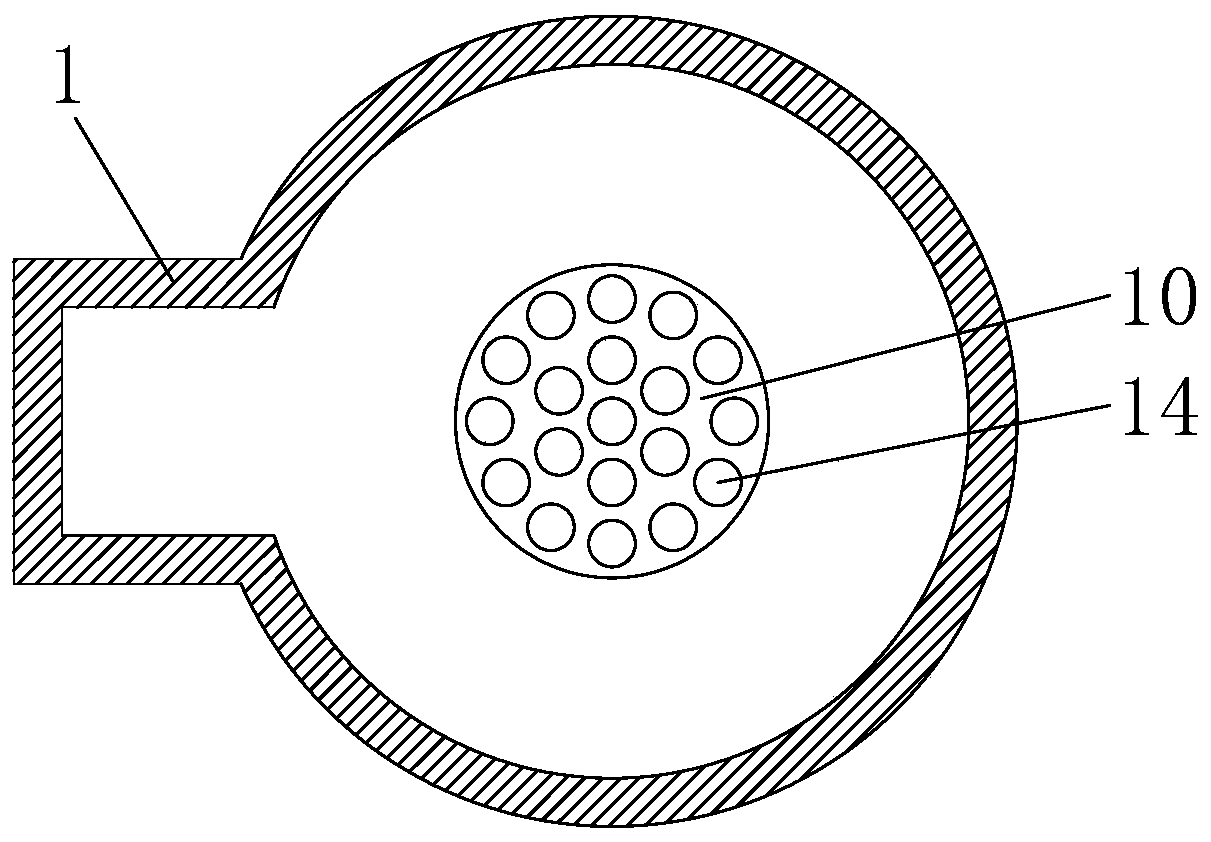

Capillary liquid chromatographic column temperature control device

InactiveCN106706817AFix Heating ProblemsSmall footprintComponent separationTemperature controlDisplay device

The invention relates to a capillary liquid chromatographic column temperature control device, and relates to a capillary liquid chromatographic column. The capillary liquid chromatographic column temperature control device comprises a cooling fan, a hollow capillary column supporting tube, a capillary liquid chromatographic column, a temperature control device and a base, wherein the cooling fan is arranged at the top of the hollow capillary column supporting tube, and the periphery of the hollow capillary column supporting tube is covered with an electric heating coating layer; a threaded groove is engraved in the outside of the hollow capillary column supporting tube and is used for fixing the capillary liquid chromatographic column, and the capillary liquid chromatographic column is spirally wound on the surface of the hollow capillary column supporting tube; the periphery of the hollow capillary column supporting tube wound with the capillary liquid chromatographic column is covered with a temperature sensitive resistance layer, and the temperature control device is provided with a temperature sensor and a display device; the temperature sensor is used for detecting the temperature of the temperature sensitive resistance layer, and the temperature signal output terminal of the temperature sensor is connected with the display device; and the temperature signals of the temperature sensor are displayed by the display device, and the hollow capillary column supporting tube is arranged on the base.

Owner:厦门宜柱科技有限公司

Novel household quartz pipe electric warmer

PendingCN108443947ALower the altitudeSmall footprintLighting and heating apparatusElectric heating systemEngineeringStructural stability

The invention discloses a novel household quartz pipe electric warmer. The novel household quartz pipe electric warmer comprises a first shell, and a threaded column fixing shell is fixedly connectedto the middle position of the lower end of the interior of the first shell through a plurality of studs. According to the novel household quartz pipe electric warmer, a lifting motor is arranged and is coordinated with positioning rods, so that a user does not need to be strenuous when a warming head is adjusted, in addition, when the electric warmer is stored, the lifting motor can be used for decreasing the height of the warming head, the occupied space is reduced, storage is convenient, a rotating motor is arranged and enables the warming head to rotate, so that the warming range is widened, the positioning rods are arranged, can fix the first shell and can further play a role in improving the overall structural stability of the electric warmer when the warming head is lifted, and a dust-proof window can play a role of an air inlet window and can further prevent the phenomenon that the heating efficiency of a quartz electric heating pipe is influenced due to the fact that external dust enters the interior.

Owner:龙岩丽荣电子科技有限公司

Extruder

The invention belongs to the field of plastic extrusion equipment and particularly discloses an extruder. The extruder is characterized in that a driving gear is fixedly connected to a driving screw rod; a driven gear is meshed with the driving gear; the driving gear and the driven gear are both bevel gears; a rotating shaft is fixedly connected to the driven gear; a driving connecting rod is fixedly connected to the shaft side of the rotating shaft; a driven connecting rod is hinged to the driving connecting rod; a heater is hinged to the driven connecting rod and is connected to a casing ina sliding manner; a feeding funnel is communicated to the casing; a discharge opening is formed in the feeding funnel; a sealing plate for abutting against and sealing the discharge opening is connected to the inner part of the feeding funnel in a sliding manner; the upper section of an elastic telescopic rod is fixedly connected to the lower part of the sealing plate; a baffle is fixedly connected to the lower section of the elastic telescopic rod and is positioned under the driven connecting rod; a stirring blade for stirring material particles in the feeding funnel is in driving connectionwith the heater. According to the device, the problems of higher labor intensity and easiness in mistakes in the prior art are solved.

Owner:CHONGQING RUITING PLASTIC

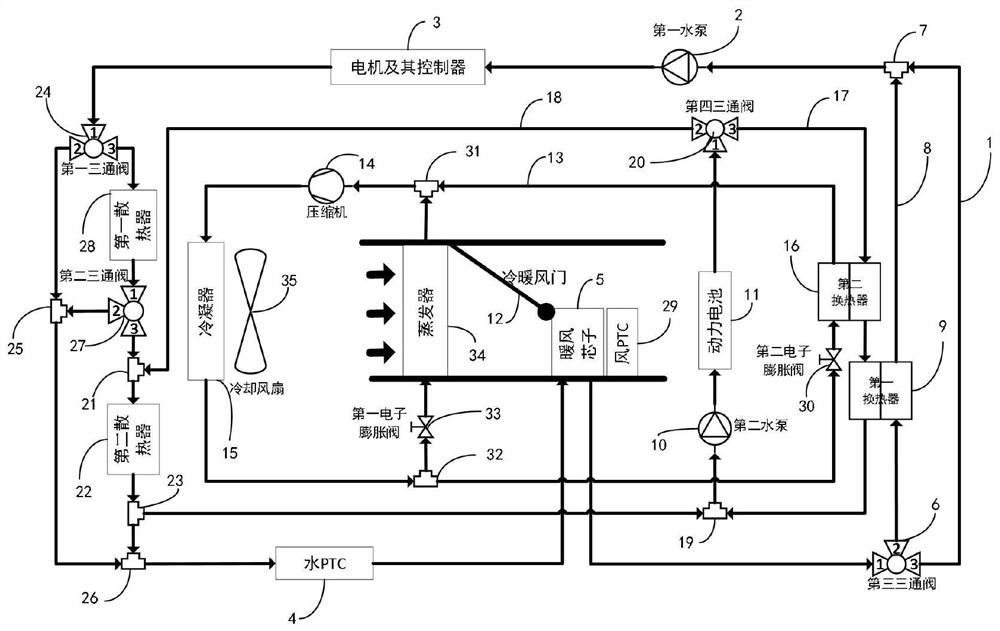

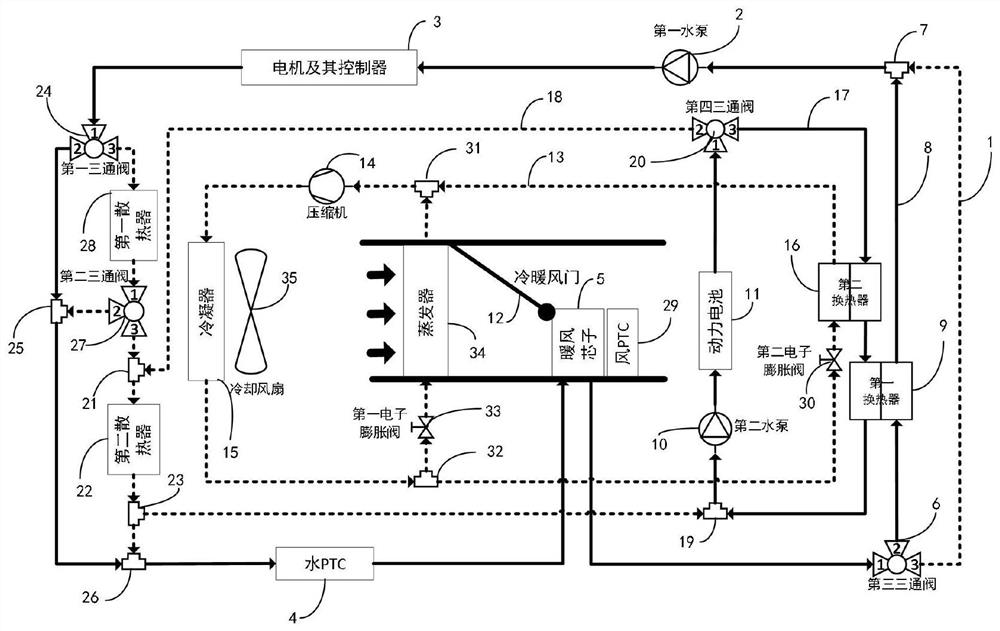

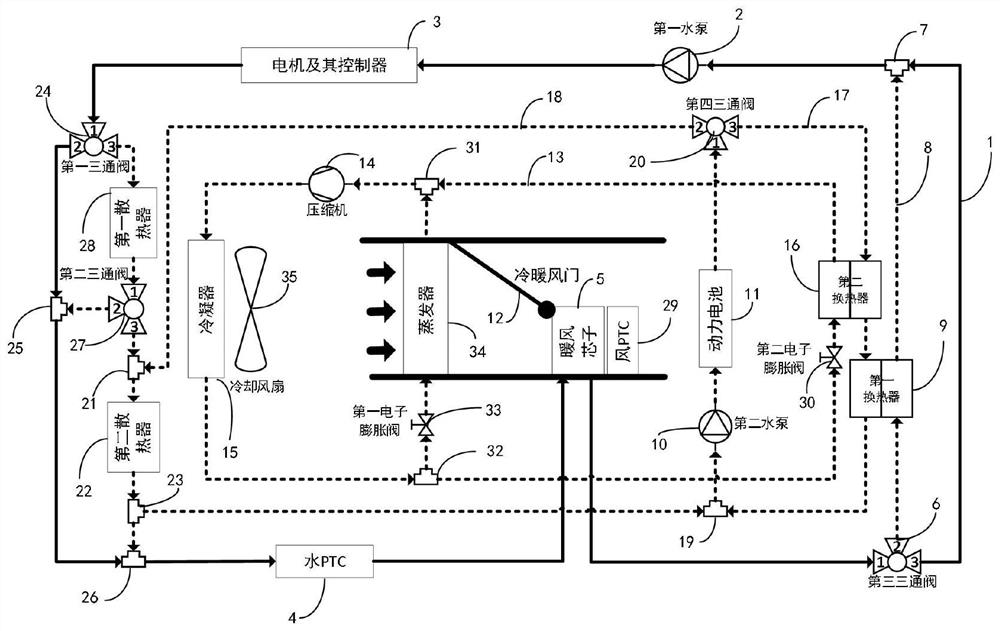

Whole vehicle thermal management system and vehicle

ActiveCN113276631ASimplify complexityReduce manufacturing costAir-treating devicesVehicle heating/cooling devicesPower batteryMotor loop

The invention relates to a whole vehicle thermal management system and a vehicle, which comprises a battery loop and a motor loop. The battery loop comprises a second water pump and a power battery which are connected with each other; the motor loop comprises a second pipeline, and a first water pump, a motor and a controller thereof, a water PTC (Positive Temperature Coefficient) of the air conditioning system, a warm air core of the air conditioning system, a third three-way valve and a first three-way pipe which are sequentially connected through the first pipeline, and two ends of the second pipeline are respectively connected with the third three-way valve and the first three-way pipe; and the second pipeline is provided with a first heat exchanger which is used for coupling the motor loop and the battery loop so as to heat the power battery. According to the whole vehicle thermal management system provided by the invention, the warm air core and the water PTC of the air conditioning system are connected in series in the motor loop, so that the motor loop and the heating module of the air conditioning system are completely coupled together, only one circulating water pump is needed, the complexity of the whole vehicle thermal management system is greatly simplified, and the cost is reduced. The manufacturing cost is reduced.

Owner:DONGFENG MOTOR GRP

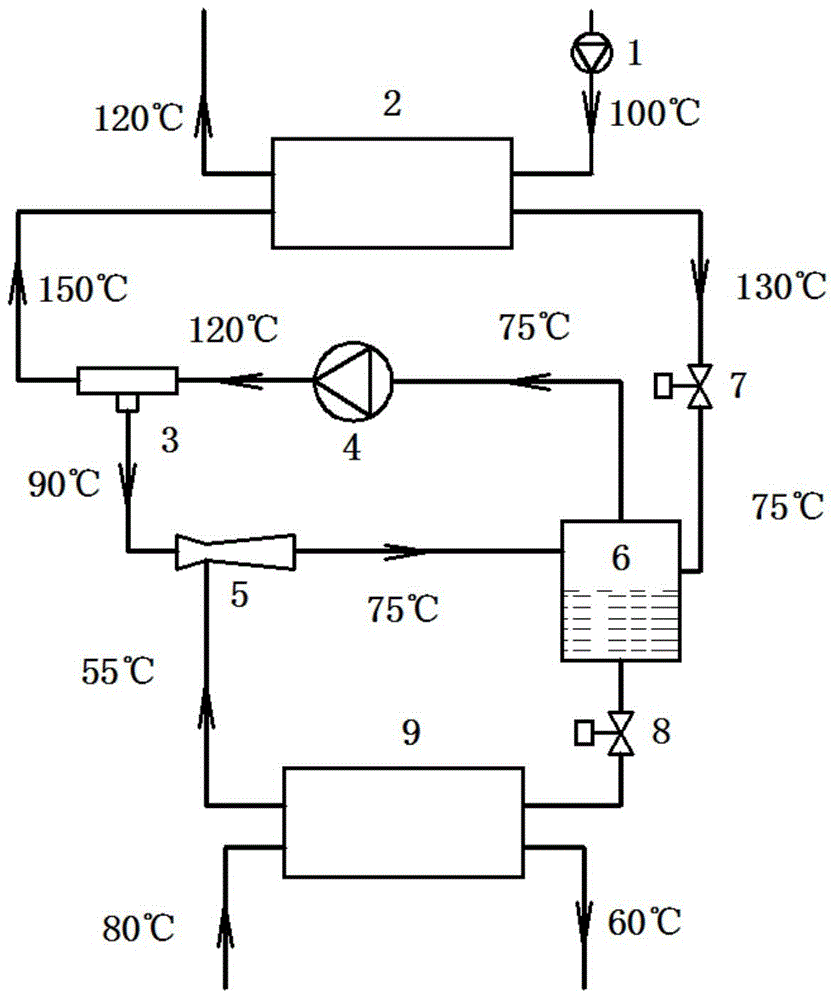

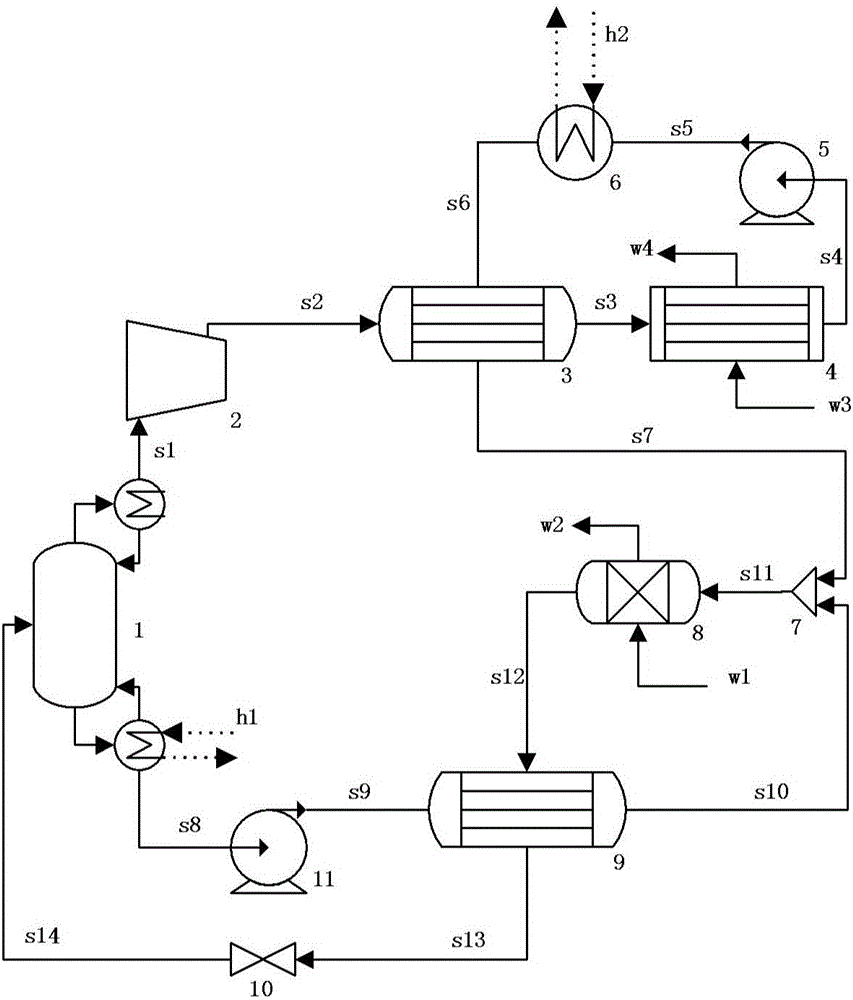

Waste heat and electricity composite drive temperature increasing type heat pump circulation system

ActiveCN106016822AExtended heating rangeReduced Compression Power ConsumptionSteam generation heating methodsRefrigeration machinesAbsorption compressionEvaporation

The invention discloses a waste heat and electricity compound drive temperature increasing type heat pump system and relates to the technical field of low-temperature industrial waste heat utilization. An ammonia water mixture serves as a working medium of the system, low-temperature smoke serves as a heat source, and waste heat and electricity are used for preparing industrial vapor. Low-temperature industrial waste heat is used for driving a rectifying tower to produce low-pressure ammonia vapor, meanwhile, high-pressure ammonia liquid evaporation is completed, electricity input externally is used for increasing the pressure of the low-pressure vapor and an ammonia water dilute solution, finally, the high-pressure ammonia vapor and the dilute solution complete the absorption process in an absorber, and released heat is used for preparing the industrial vapor. By means of the waste heat and electricity composite drive temperature increasing type heat pump circulation system, discharge smoke waste heat which cannot be utilized by a waste heat boiler is utilized, the beneficial effects that the wastes heat utilization efficiency is high and the temperature increasing amplitude is large are achieved, industrial vapor with the pressure being 0.5 MPa or above can be prepared, and the low-temperature waste heat utilization range is enlarged. Meanwhile, compared with an existing absorption compression type heat pump, a compressor and pump composite compression manner is adopted, compression power consumption is reduced, and the temperature increasing range of the temperature increasing type heat pump is enlarged.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Sample stage for measuring liquid sample by X-ray diffractometer

ActiveCN107966463AEasy accessCompact structureMaterial analysis using radiation diffractionTemperature controlWater baths

The invention discloses a sample stage for measuring a liquid sample by an X-ray diffractometer, wherein the sample stage includes a crucible furnace with adjustable temperature, a quartz crucible forholding a sample and a temperature control thermocouple; the upper surface of the crucible furnace is sunken inwards to form a groove, the quartz crucible is placed in the groove, and the temperaturecontrol thermocouple is inserted in the crucible furnace for adjusting the temperature of the crucible furnace. According to the sample stage for measuring the liquid sample by the X-ray diffractometer, the temperature control thermocouple inserted in the crucible furnace is used for controlling the temperature of the crucible furnace, so the quartz crucible placed in the crucible furnace is heated and has the temperature controlled, the problem that a water bath pot is needed to be externally connected for heating when a liquid is tested by a diffractometer at present is solved, and at the same time, the heating range is broadened.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

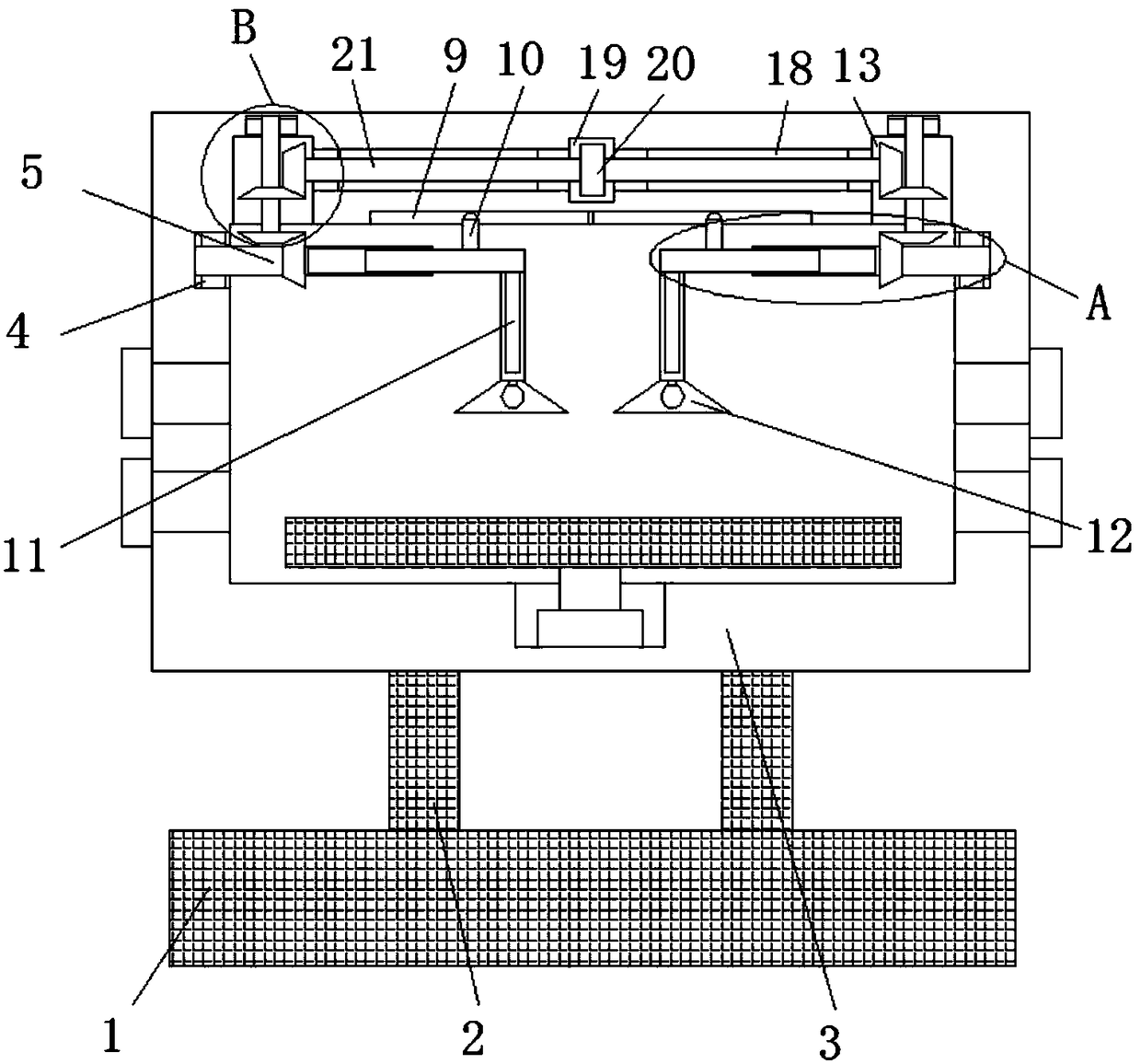

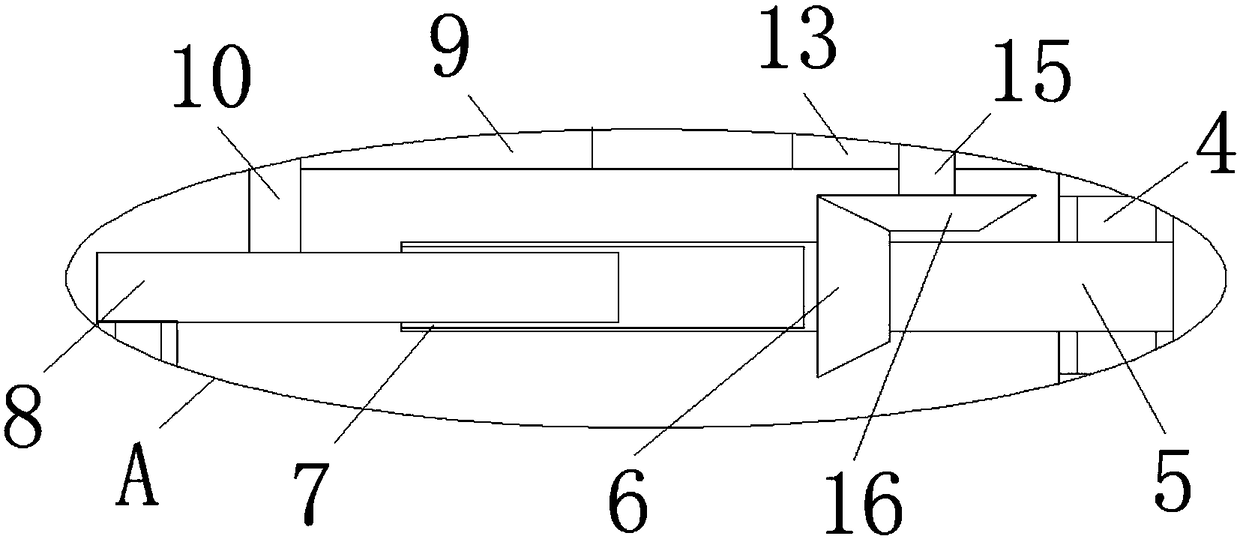

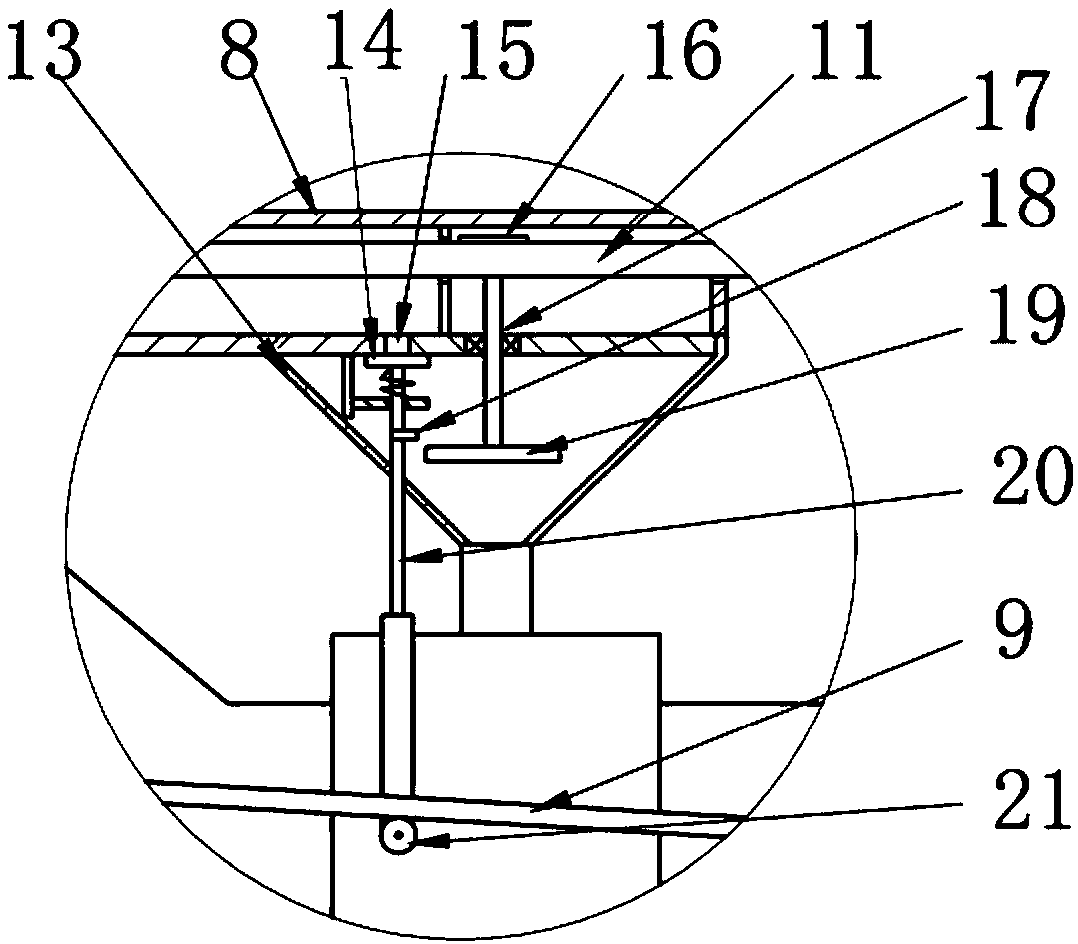

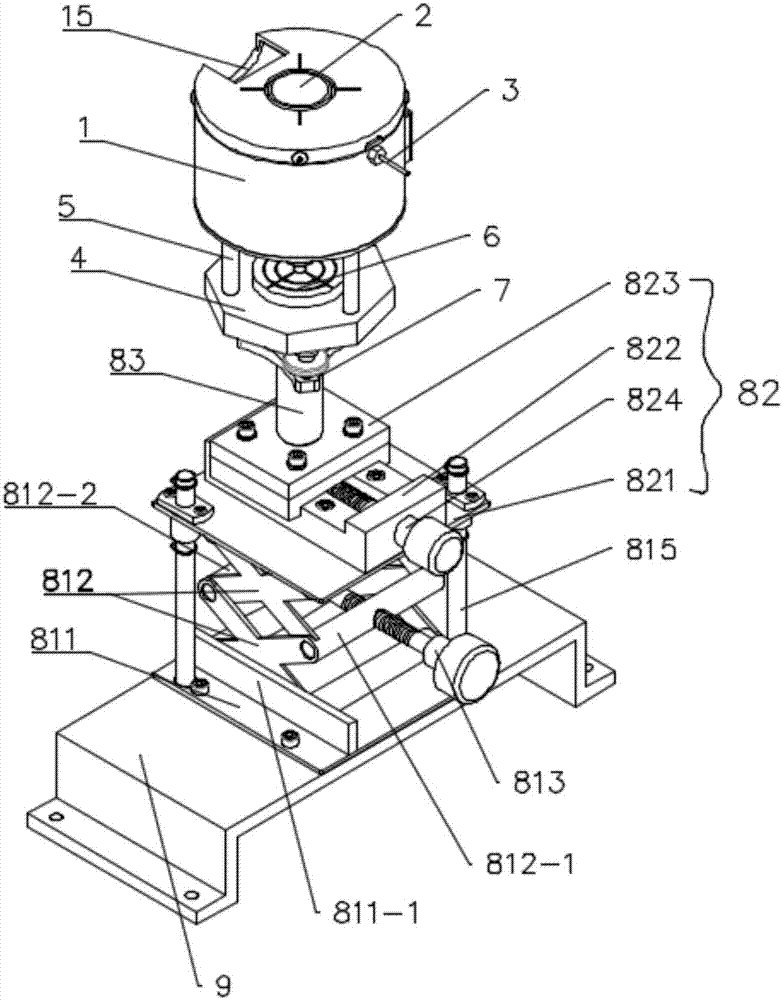

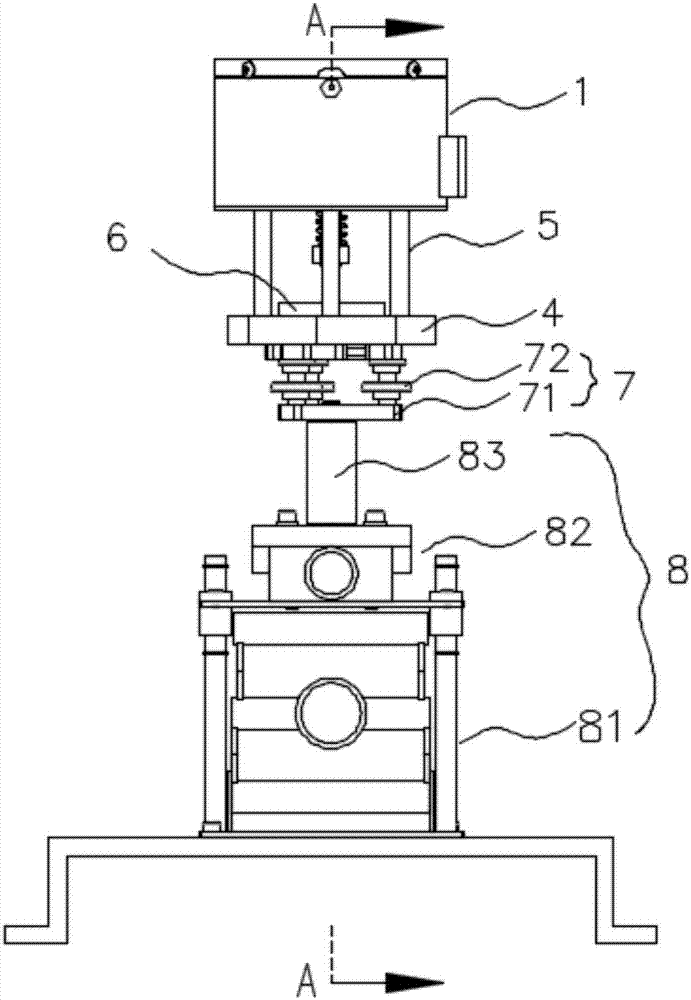

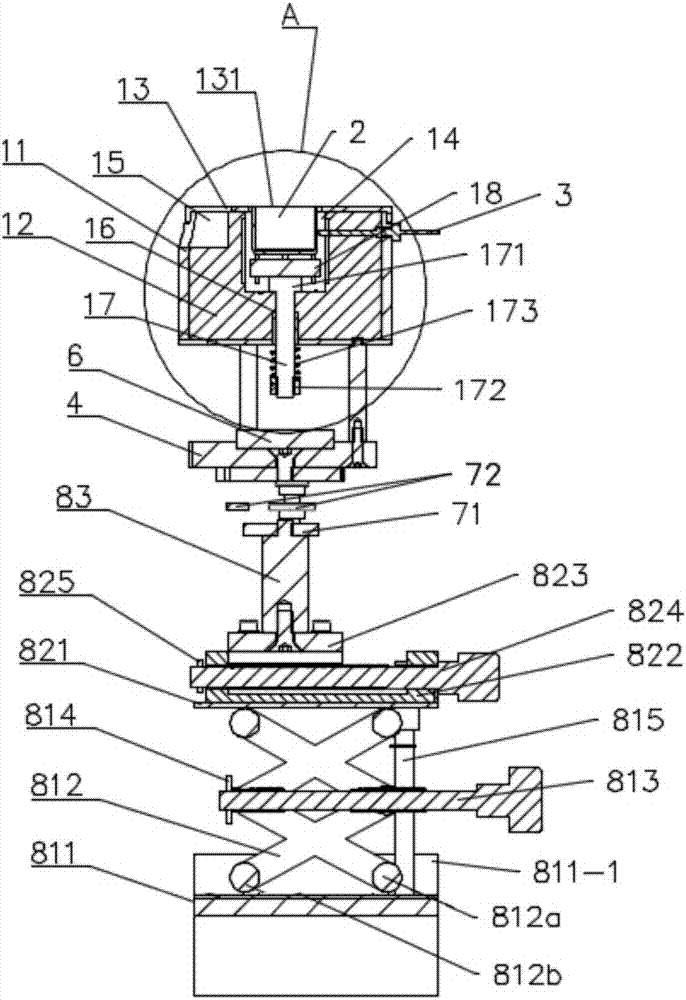

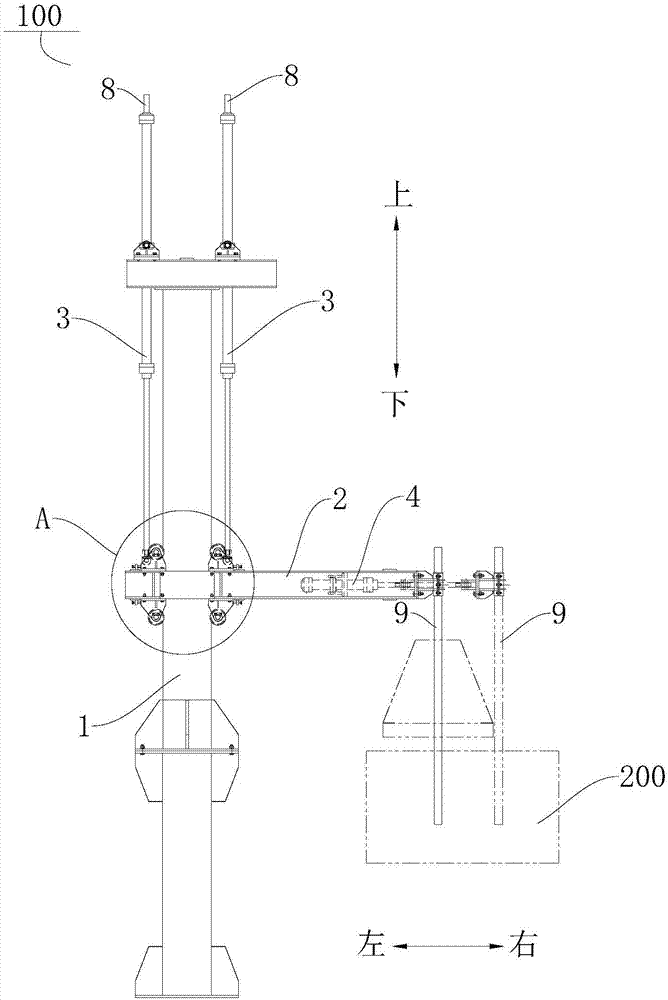

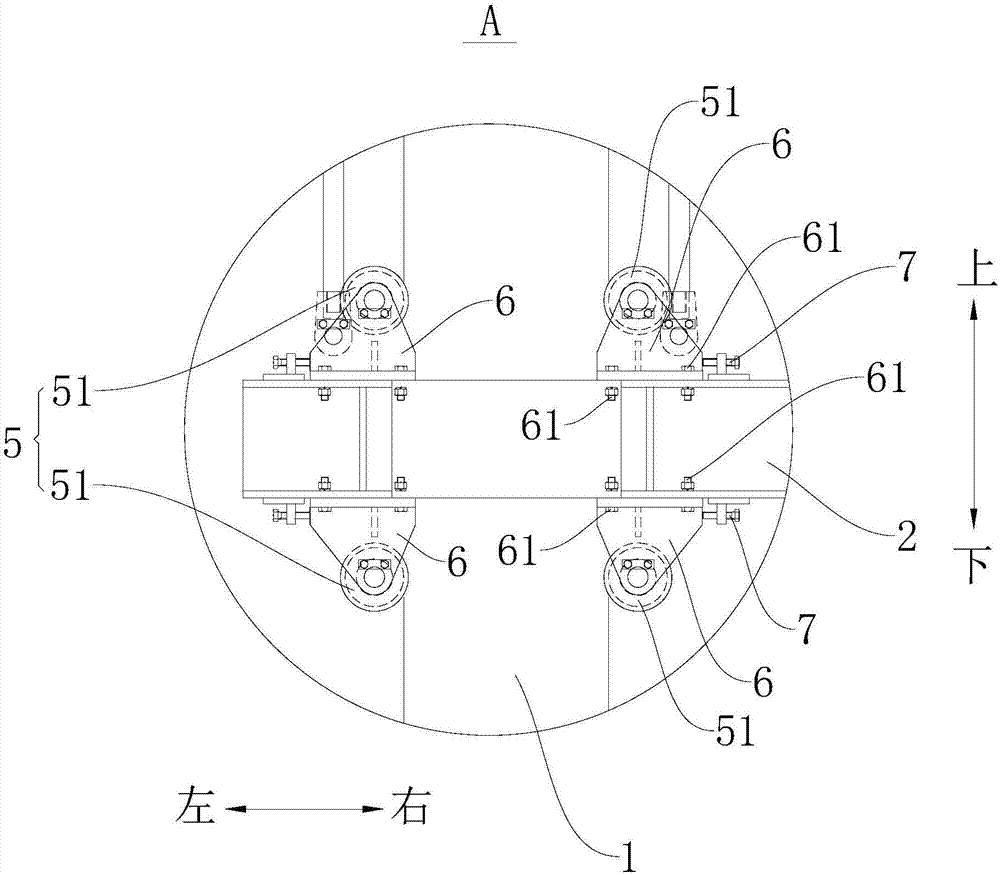

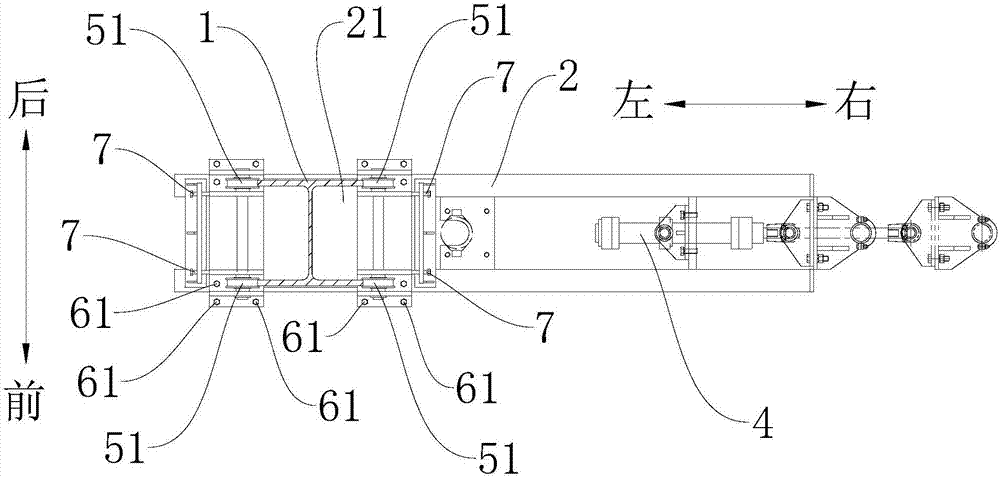

Moving device for oxygen lance and industrial furnace with moving device

PendingCN107062915AExtended heating rangeAchieve lateral movementLifting devicesCharge manipulationEngineeringIndustrial furnace

The invention discloses a moving device for an oxygen lance and an industrial furnace with the same, wherein the moving device includes: a column, the flange of which is formed as a slideway, and the slideway extends along the length direction of the column; On the column, the beam is perpendicular to the column, and the beam is located on one side of the column; the vertical drive mechanism, the vertical drive mechanism is arranged on the column, and the vertical drive mechanism is connected with the beam to drive the beam to move along the slideway; and the horizontal drive mechanism, the horizontal drive mechanism is set On the beam, the horizontal drive mechanism is connected with the oxygen lance to drive the oxygen lance to move. According to the moving device of the present invention, by setting the vertical drive mechanism to drive the crossbeam to move up and down, and setting the horizontal drive mechanism to drive the oxygen lance to move horizontally and horizontally, both the up and down movement of the oxygen lance and the lateral movement of the oxygen lance can be realized, so that the oxygen lance can be moved The heating of multiple areas expands the heating range of the oxygen lance.

Owner:SHENWU TECH GRP CO LTD

Aluminum profile smelting furnace

ActiveCN110274468AHeating fastExtended heating rangeCrucible furnacesElectromagnetic heatingMachining

The invention discloses an aluminum profile smelting furnace. The aluminum profile smelting furnace comprises a box body and a furnace body; the furnace body is arranged in an inner cavity of the box body; a heating resistance wire is in winding connection to a vertical surface on the outer surface wall of the furnace body; a fixed plate is welded at the bottom of the heating resistance wire; a rotating plate is arranged at the bottom of the fixed plate, and is movably connected with the fixed plate through an engagement convex block; a cover cap is sleeved at the top of the furnace body; a connecting hoop is sleeved at the external of the cover cap; and the connecting hoop and the cover cap are rotationally connected through a connecting base. In the aluminum profile smelting furnace, the heating resistance wire is heated through commercial power, and a magnetic field is formed on the inner side of the heating resistance wire, so that the quick heating of aluminum profiles is realized; and compared with a traditional flame heating mode, the electromagnetic heating mode is high in energy utilization rate and heating speed, reduces the machining cost, and meanwhile, improves the heating efficiency.

Owner:东阳市乔老爷铝业有限公司

Brazing machine

ActiveCN102886581AEvenly heatedReduce distortionHeating appliancesMetal working apparatusStress concentrationProduct gas

The invention discloses a brazing machine which comprises a workbench and a hot air device, wherein the workbench is used for placing welded parts and a brazing material, and the hot air device is arranged in a manner of corresponding to and being separated from the welded parts and is used for generating and outputting hot air, so as to melt the brazing material to integrally weld the welded parts. In the process of welding, after the hot air device generates and outputs hot air, a thin plate and an end cap are heated to further melt solder wires attached to the welded parts, and the thin plate and the end cap are integrally welded by the molten solder wires. The brazing machine disclosed by the invention has the advantages that 1, the welded parts are heated by heating a gas with a certain temperature, thus contact between the hot air device and the welded parts is no longer needed, impressions on the welded parts by a clamping force in the prior art is avoided; and 2, the wide heating range of the hot air device results in more uniform heating for the welded parts, so deformation of the welded parts generated by centralization of heat stress after local heating is relieved and the quality of product is effectively improved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Coupling agent smearing device for ultrasonography department and using method of coupling agent smearing device

InactiveCN112386283AApply evenlyGood application effectUltrasonic/sonic/infrasonic diagnosticsMedical applicatorsEngineeringHeating effect

The invention discloses a coupling agent smearing device for ultrasonography department and a using method of the coupling agent smearing device. The coupling agent smearing device for ultrasonographydepartment comprises a cylinder body, wherein a material storage cavity and an air cavity are formed in the cylinder body, a vertical pipe and two air conveying pipes are arranged in the material storage cavity, the two air conveying pipes are symmetrically arranged on the two sides of the vertical pipe, an electric heating wire is fixedly mounted in the vertical pipe, the bottom end of the vertical pipe extends into the air cavity, the bottom ends of the two air conveying pipes extend into the air cavity, an outer cover is fixedly mounted at the bottom of the cylinder body, and the bottom ofthe outer cover is of an opening structure. The coupling agent smearing device is reasonable in design and good in practicability, discharged coupling agents can be evenly attached to the surface ofa smearing roller, the smearing roller is pushed to roll, the coupling agents can be evenly smeared on the skin, the smearing effect is good, the coupling agent heating effect is good, the coupling agents are evenly heated, and when the coupling agents are smeared on the skin of a patient, the discomfort of a patient caused by lower temperature of the coupling agents is not easy to occur.

Owner:苏州朝霞生物科技有限公司

Waste heat supply device

ActiveCN110332585AAvoid discomfortIngenious and reasonable structureLighting and heating apparatusElectric heating systemEngineeringFuselage

The invention discloses a waste heat supply device. The device comprises a heating machine body, a heating rotating table is rotatably arranged on the end wall of the top of the heating machine body,a heating system is arranged in the heating rotating table in an up and down swing manner, the heating system comprises a radiation lens and a heater fixedly arranged in front of the radiation lens, aswing connecting cavity is formed in the heating rotating table, a swing rod which extends left and right is rotatably arranged in the swing connecting cavity, the device is more reasonable and ingenious in whole structure, mounting, maintaining and overhauling are quite convenient, the device can adjust the height of the heating system according to the personal height, the practical degree of the device is improved, the device can slide left and right to increase the heat supply range of the device, the discomfort influence of the radiation on the person for a long time can be avoided, and in the use process, the device has the efficient automation degree, and higher use and popularization value.

Owner:临沂市欧科节能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com