Heat dissipating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The above objectives and structural and functional features of the present invention will be described with reference to the accompanying drawings.

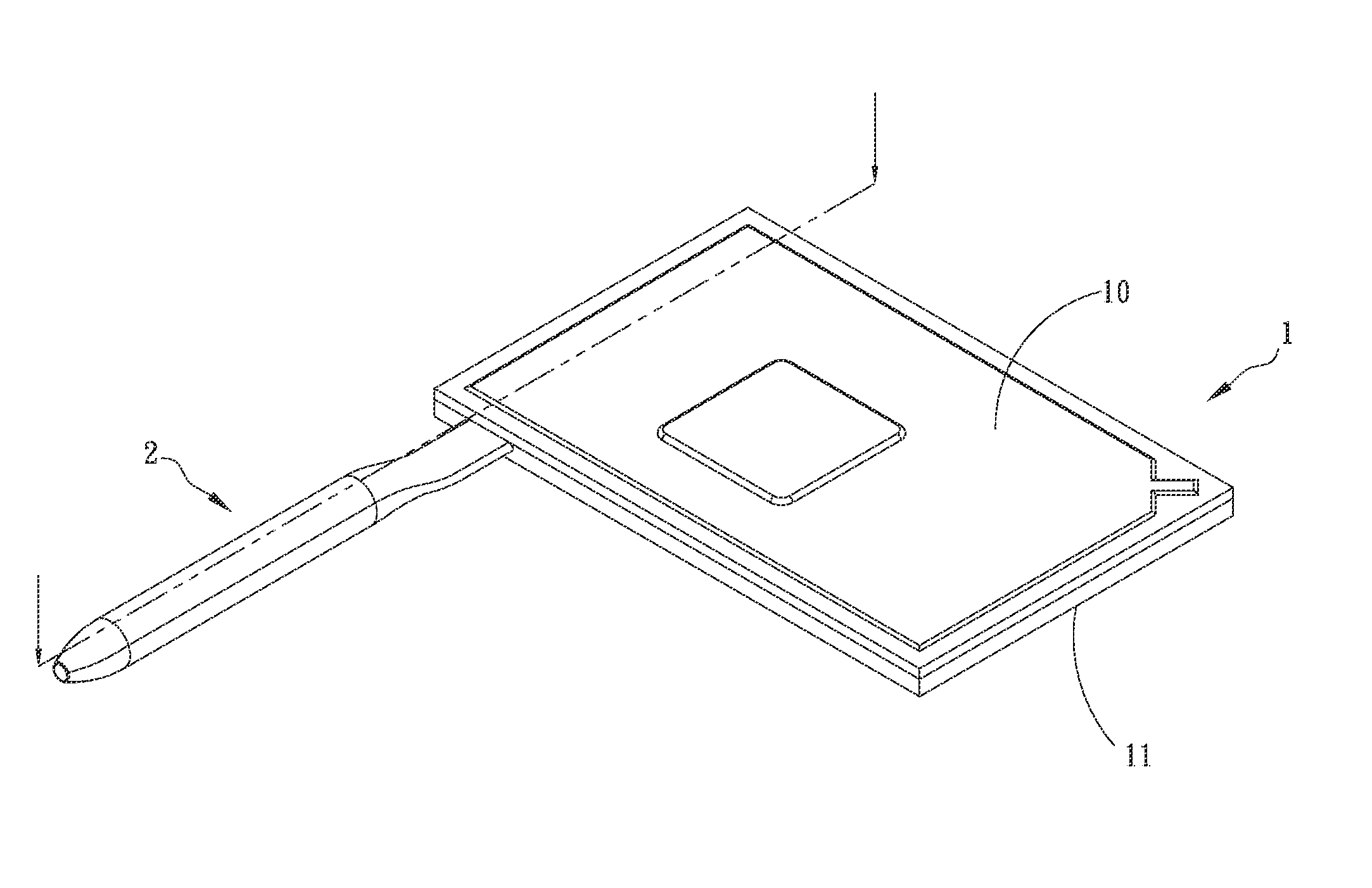

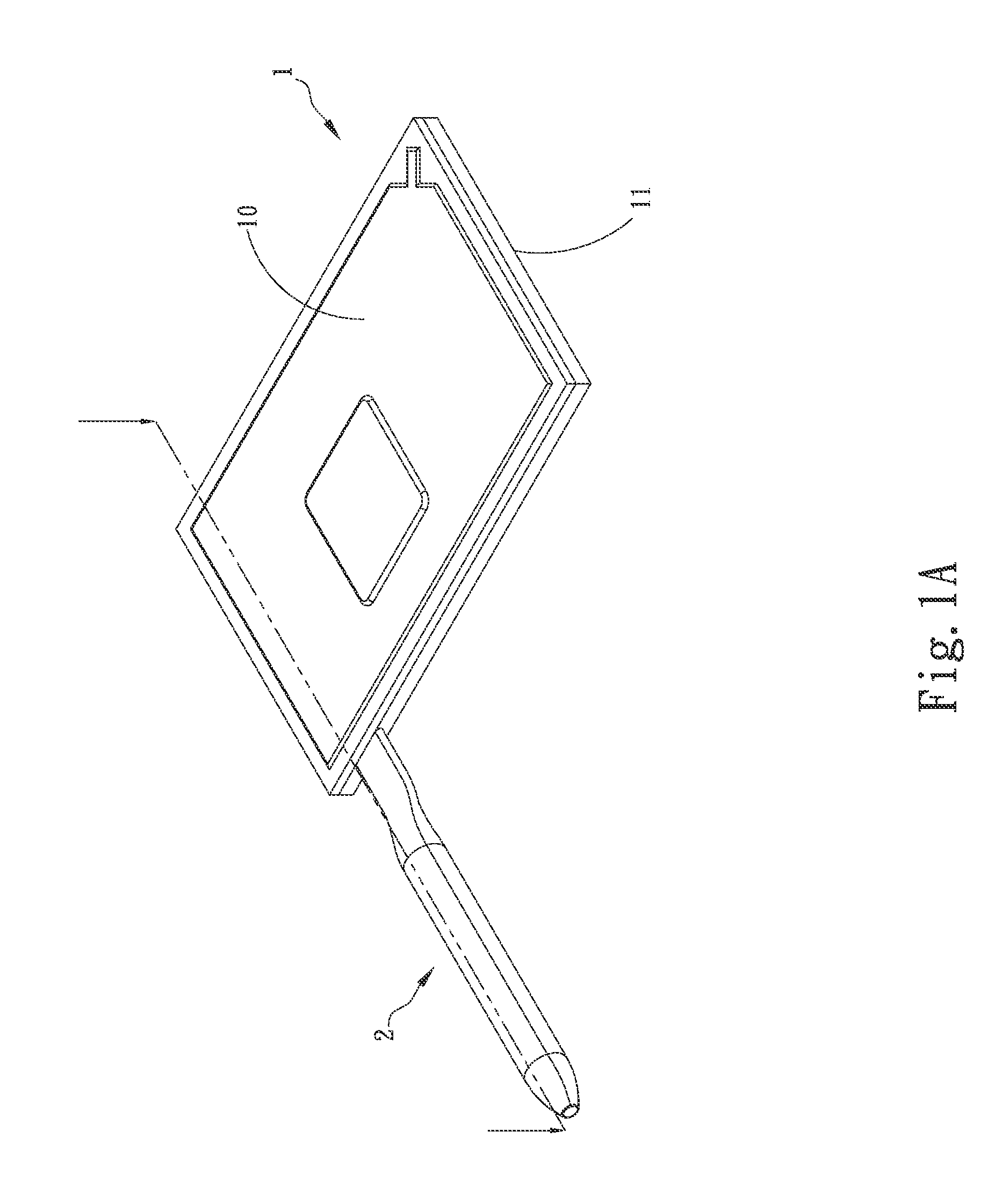

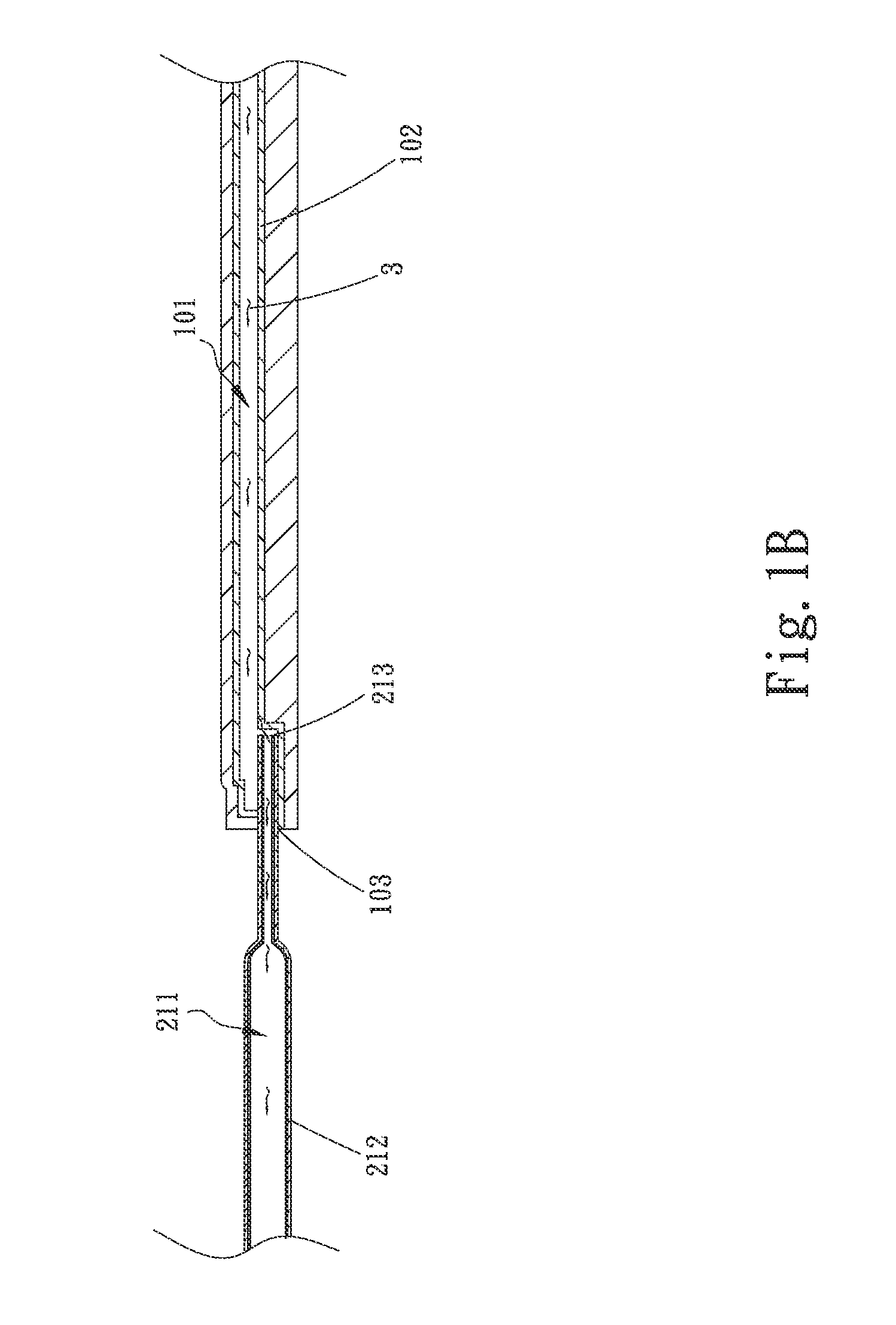

[0027]Please refer to FIGS. 1A and 1B, which are the assembled perspective view and cross-sectional view of the heat dissipating device according to the first embodiment of the present invention, respectively. The heat dissipating device comprises a first body 1, a second body 2, and a working fluid 3. The first body 1 has a first plate 10 and a second plate 11 disposed opposite to the first plate 10, the first plate 10 and the second plate 11 combined with each other to together define a first chamber 101, a first wick structure 102 being formed on the inner wall of the first chamber 101. The first wick structure 102 can be one of sintered powder, mesh, fiber, foam and porous material. The first body 1 further has a hole 103.

[0028]The above-mentioned second body 2 connects the first body 1 and extends opposite to the first body 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com