Moving device for oxygen lance and industrial furnace with moving device

A technology of mobile devices and oxygen lances, which is applied in hoisting devices, hoisting devices, furnaces, etc., can solve the problems of narrow heating range, difficulty in ensuring accuracy, and small speed regulation range, and achieve the effect of expanding the heating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

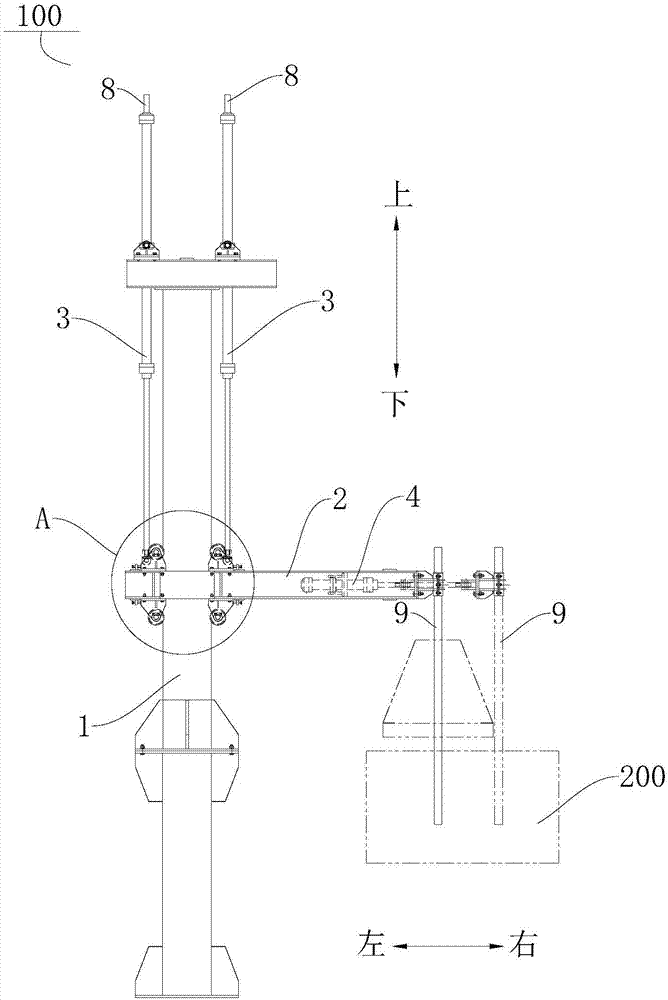

[0056] Such as figure 1 As shown, the moving device 100 for the oxygen lance 9 according to the embodiment of the present invention includes: a column 1 , a beam 2 , a vertical drive mechanism, a horizontal drive mechanism and a guide wheel set 5 .

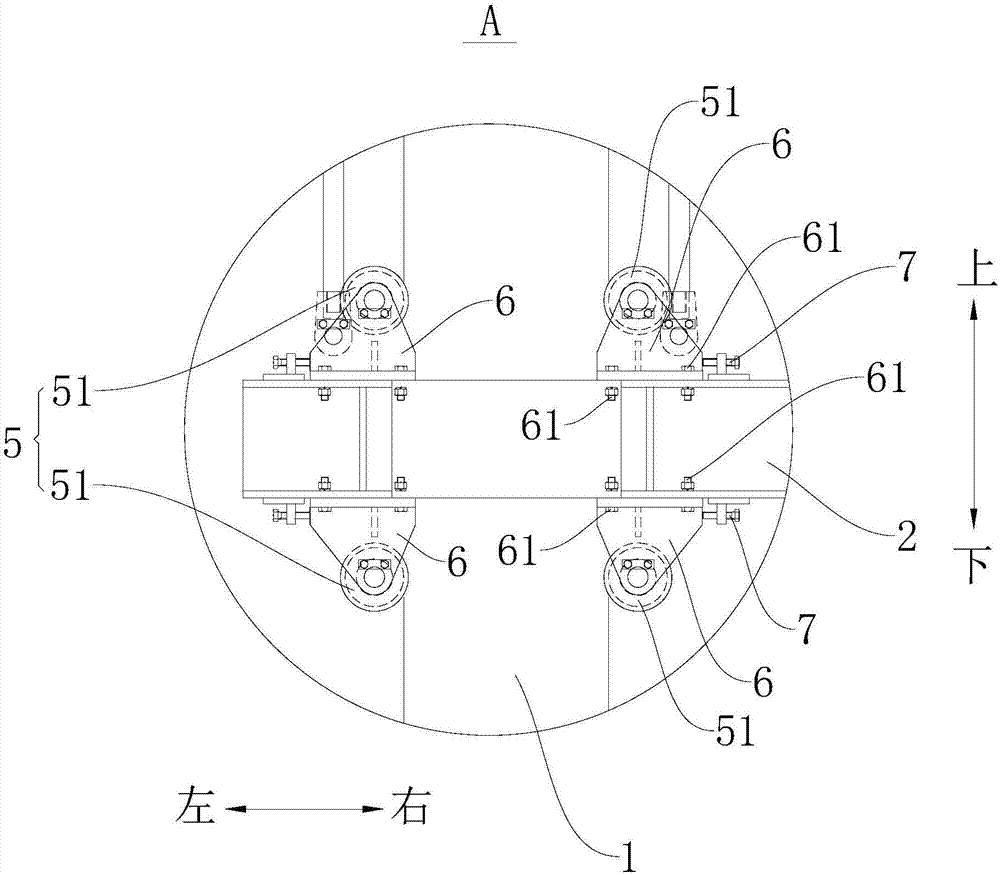

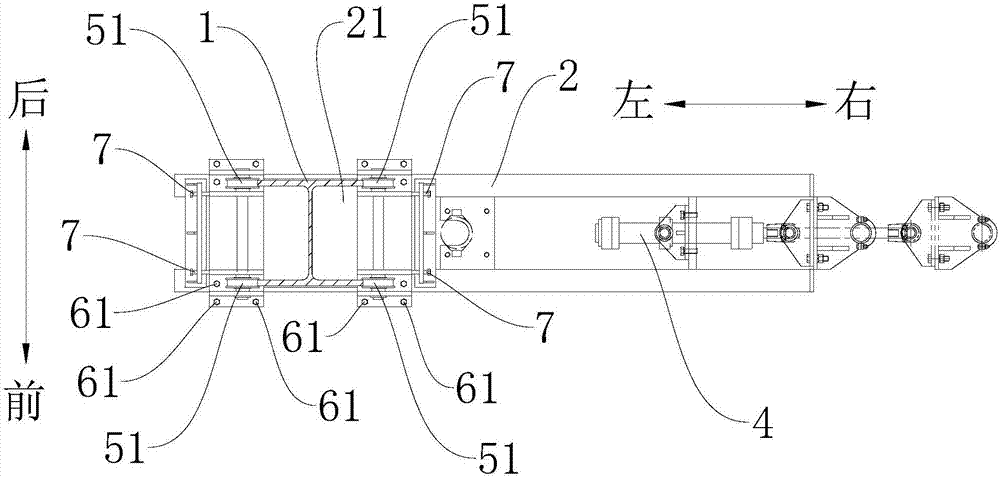

[0057] Specifically, as figure 1 and image 3 As shown, the column 1 is I-shaped steel, the flange of the column 1 is formed as a slideway, the slideway extends along the vertical direction of the column 1, the left end of the beam 2 is provided with a through hole 21 that penetrates up and down, and the column 1 is penetrated through the through hole 21 Inside, the right end of the crossbeam 2 is located on the right side of the slideway, which is close to the industrial furnace 200 and directly above the furnace mouth of the industrial furnace 200 . The vertical driving mechanism is arranged on the column 1, the vertical driving mechanism is connected with the beam 2 to drive the beam 2 to move along the slideway, the horizont...

Embodiment 2

[0065] Such as Figure 5 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the only difference is that there is one vertical hydraulic cylinder 3, and the mobile device 100 also includes a counterweight 12, The upper end of column 1 is provided with guide pulley 11, and the upper end of counterweight 12 is connected with steel wire rope, and steel wire rope walks around guide pulley 11 and is connected with beam 2. Thereby, the driving force of the vertical driving mechanism can be reduced.

[0066] The industrial furnace 200 according to the embodiment of the present invention includes the above-mentioned moving device 100 for the oxygen lance 9 . The beam 2 is located on one side of the column 1 which is close to the industrial furnace 200 . The beam 2 is directly above the furnace mouth of the industrial furnace 200 .

[0067] According to the industrial furnace 200 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com