Hydrogen-injection oil extraction method

A technology for hydrogen and gas injection wells, applied in the direction of production fluid, earth drilling, isolation devices, etc., can solve the problems of high air cost, high cost, unfavorable reservoir development, etc., and achieve the effect of improving oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a block of an oilfield, the depth of the oil layer is 1800 meters, the temperature of the oil layer is 65°C, and the thickness of the oil layer is 10 meters. The depletion production has been carried out. Reservoir pressure is 10 MPa after depleted production. As the temperature of long-term water injection reservoirs decreased, wax began to precipitate in the oil layer, affecting crude oil recovery, so it was decided to carry out hydrogen injection oil recovery.

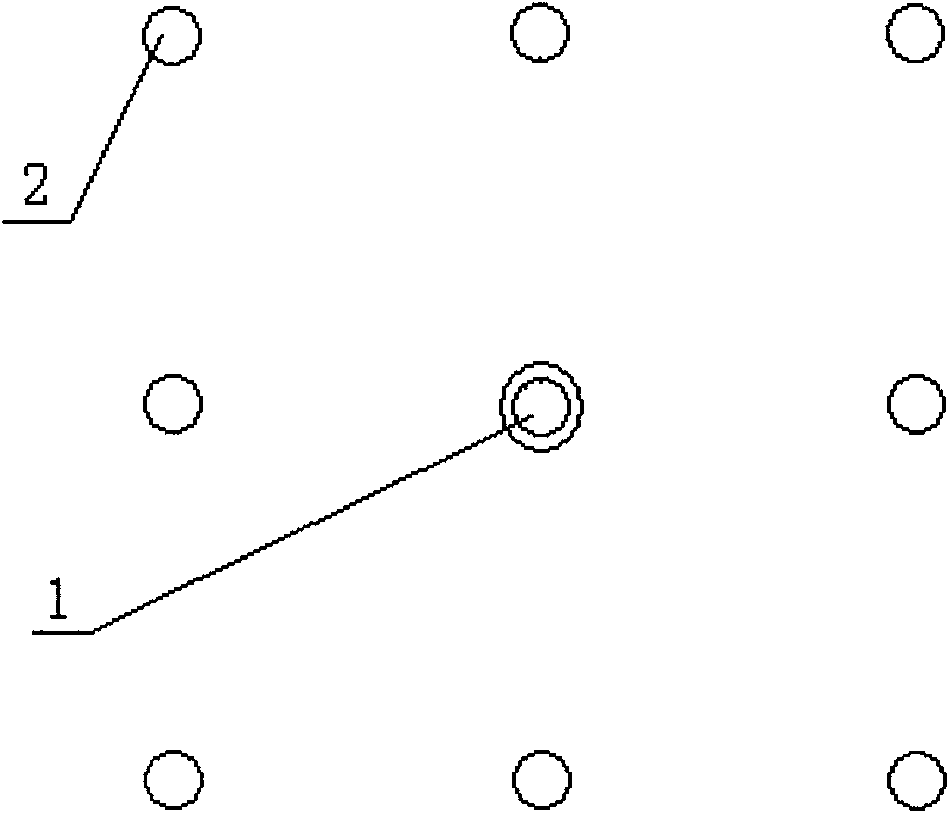

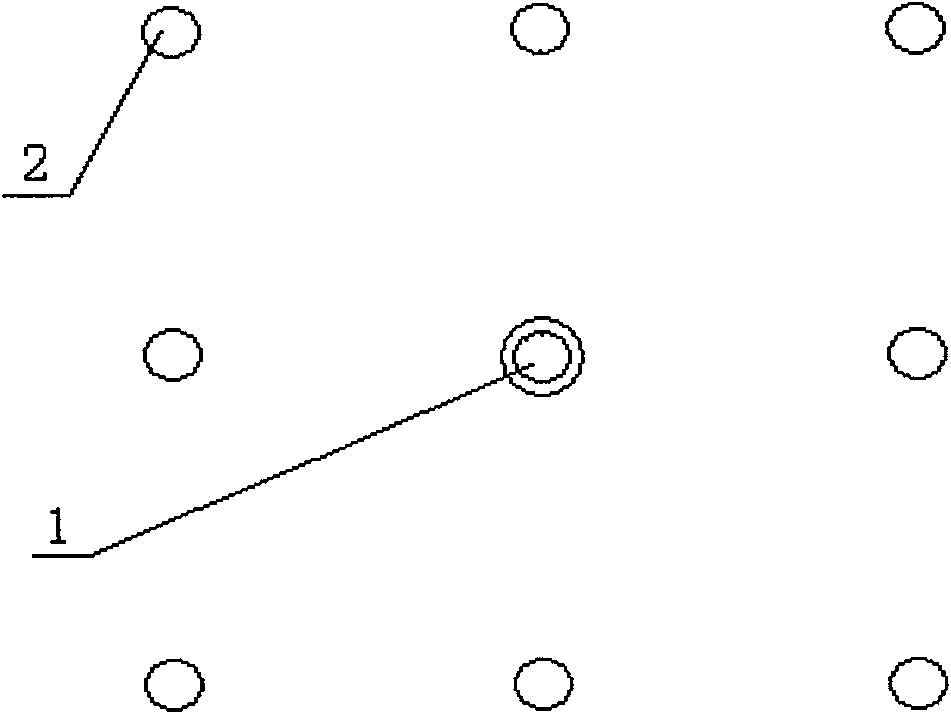

[0021] refer to figure 1 . The first step: improve the well pattern in the hydrogen injection oil production area, adopt a nine-point well pattern, the gas injection well 1 is in the middle, and there are 8 production wells 2 around it, and the 8 production wells 2 are arranged in a rectangle. The gas injection well 1 is 100-200 meters away from the near production well 2, and 140-280 meters away from the far production well 2. In the present embodiment, there are 150 meters away from the nearer product...

Embodiment 2

[0026] In a block of an oilfield, the reservoir depth is 4,000 meters, the reservoir temperature is 132°C, the thickness of the reservoir is 20 meters, the reservoir pressure is 30 MPa, and the permeability is 1 millidarcy. It was decided to carry out hydrogen injection oil recovery.

[0027] refer to figure 1 . The first step: improve the well pattern in the hydrogen injection oil production area, adopt a nine-point well pattern, the gas injection well is in the middle, and there are 8 production wells around it. Meter. Gas injection wells are connected with hydrogen injection equipment, and production wells are connected with oil production equipment.

[0028] The second step: continuously inject hydrogen into the gas injection well 1, and the gas injection volume is 7000 cubic meters per day (volume under atmospheric pressure).

[0029] Step 3: Regularly detect the amount of hydrogen produced by the production well (test once a week). If the hydrogen production of a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com