Capillary liquid chromatographic column temperature control device

A technology of a liquid chromatography column and a temperature control device is applied in the field of a capillary liquid chromatography column temperature control device, and can solve the problems that the mobile phase cannot fully achieve temperature equilibrium, the column temperature box cannot be well used, and the separation reproducibility is affected. , to achieve the effect of uniform heating, precise control of operating temperature and solving heating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

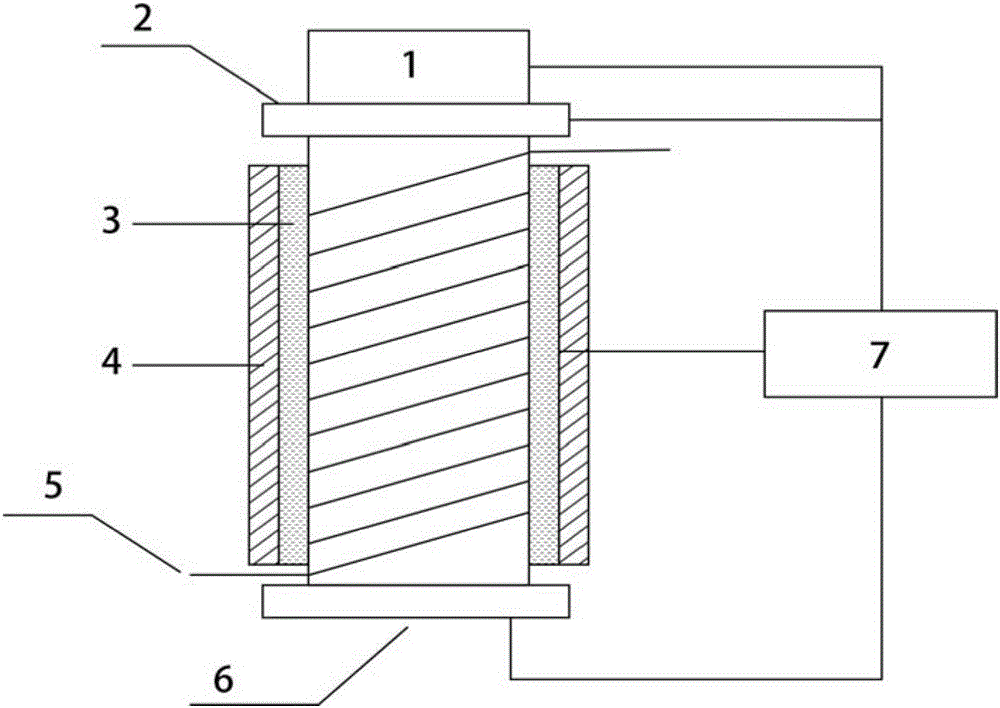

[0020] see figure 1 The embodiment of the present invention is provided with a cooling fan 1, a hollow capillary column support tube 2, a capillary liquid chromatography column 5, a temperature control device 7 and a base 6, and the cooling fan 1 is installed on the top of the hollow capillary column support tube 2. The outer periphery of the hollow capillary column support cylinder 2 is coated with an electric heating coating, and the hollow capillary column support cylinder 2 is engraved with thread grooves, and the thread grooves are used to fix the capillary liquid chromatography column 5, and the capillary liquid chromatography The column 5 is spirally wound on the surface of the hollow capillary column support tube 2; the outer periphery of the hollow capillary column support tube 2 wrapped with the capillary liquid chromatography column 5 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com