Patents

Literature

59results about How to "Achieve preheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

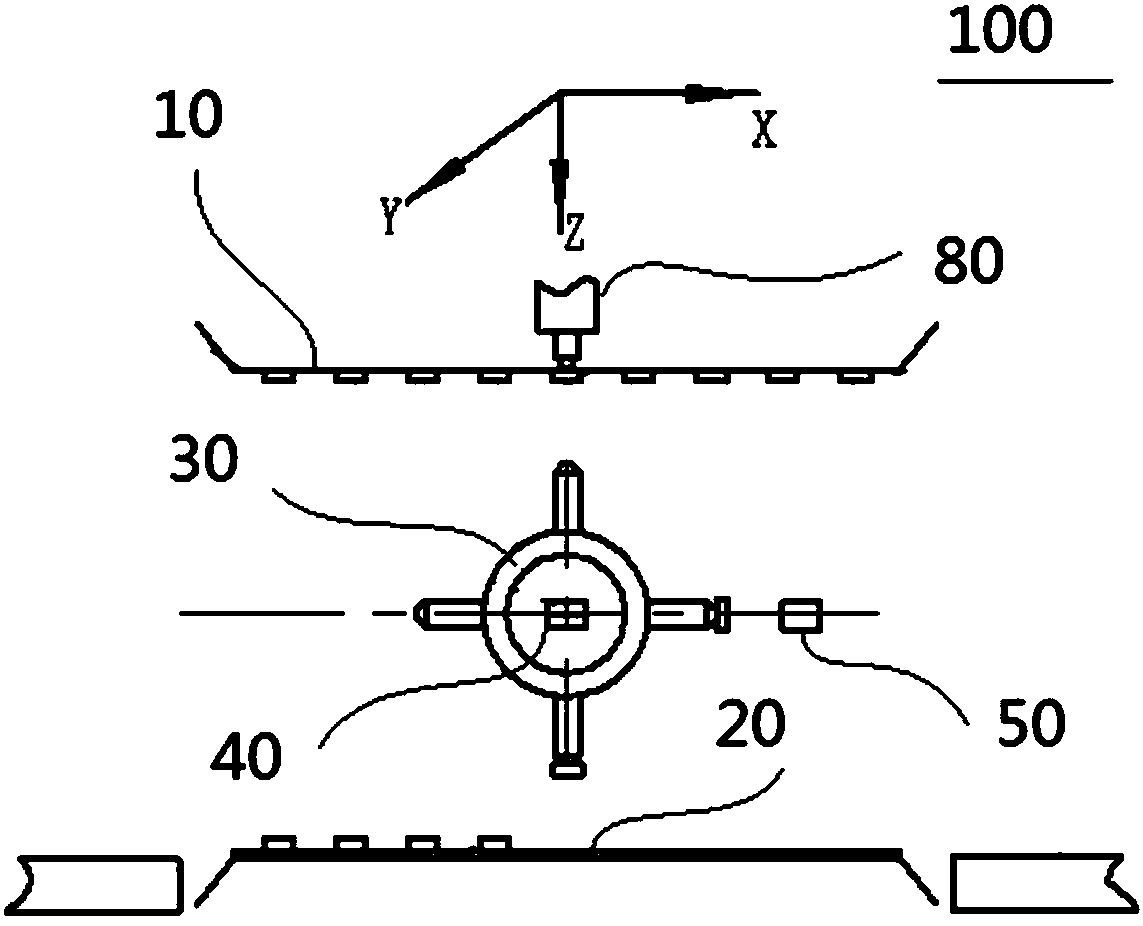

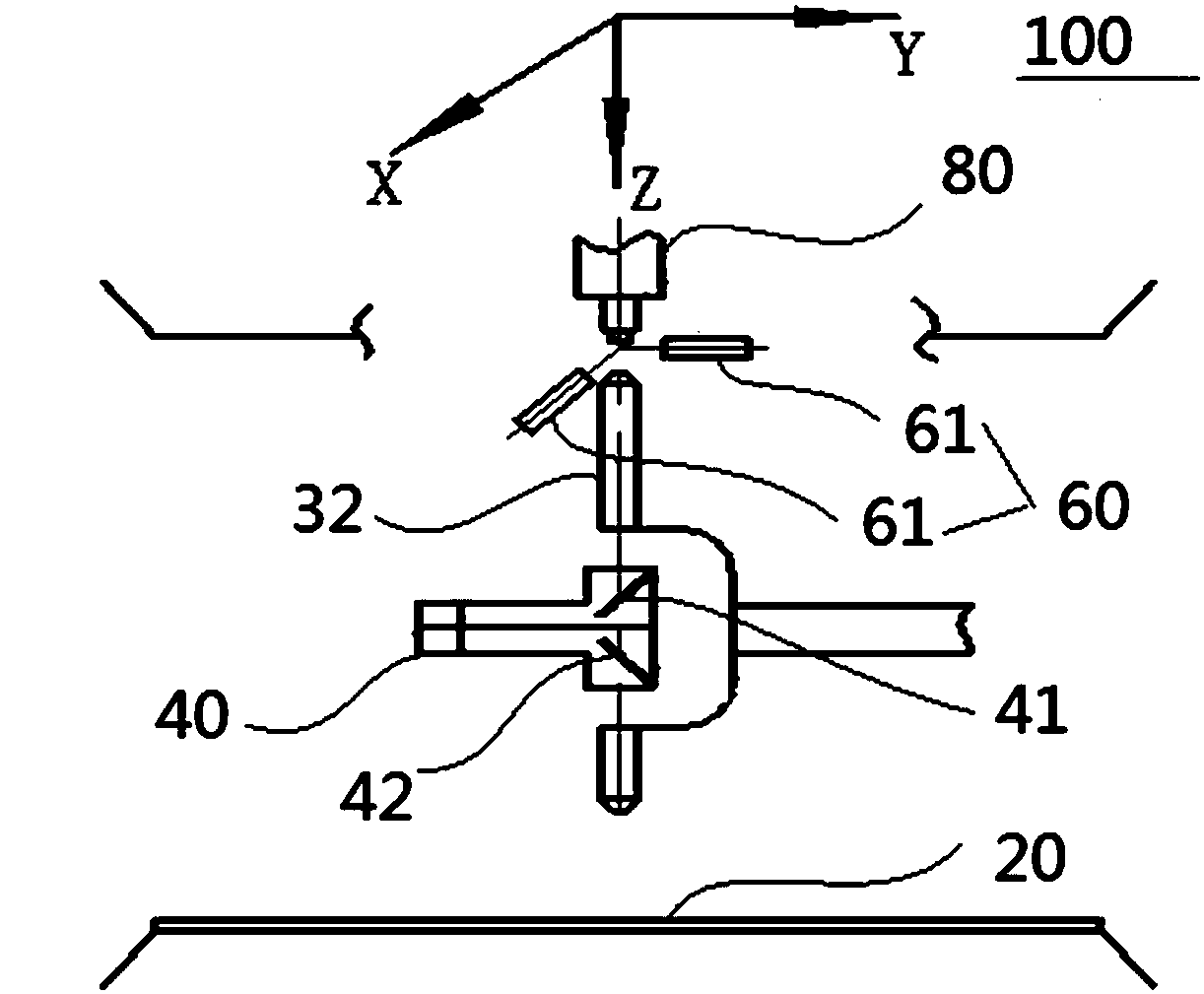

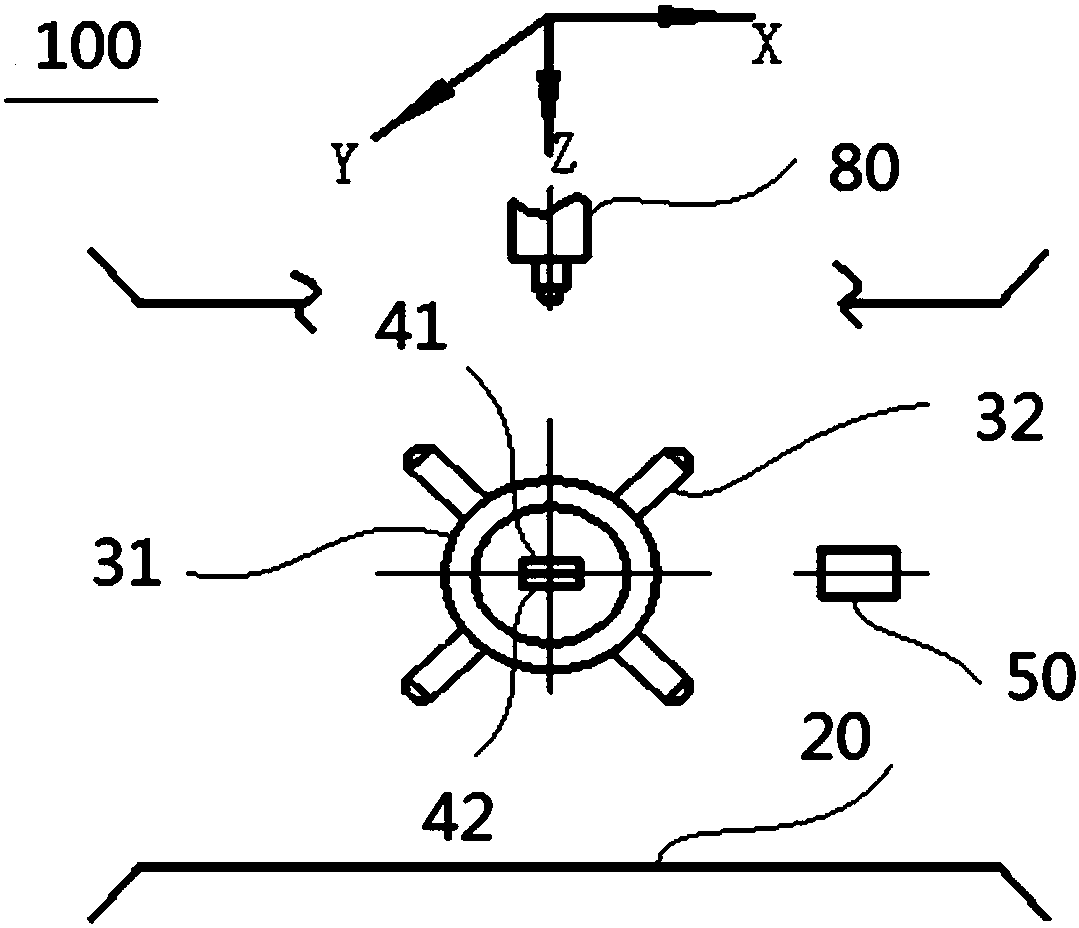

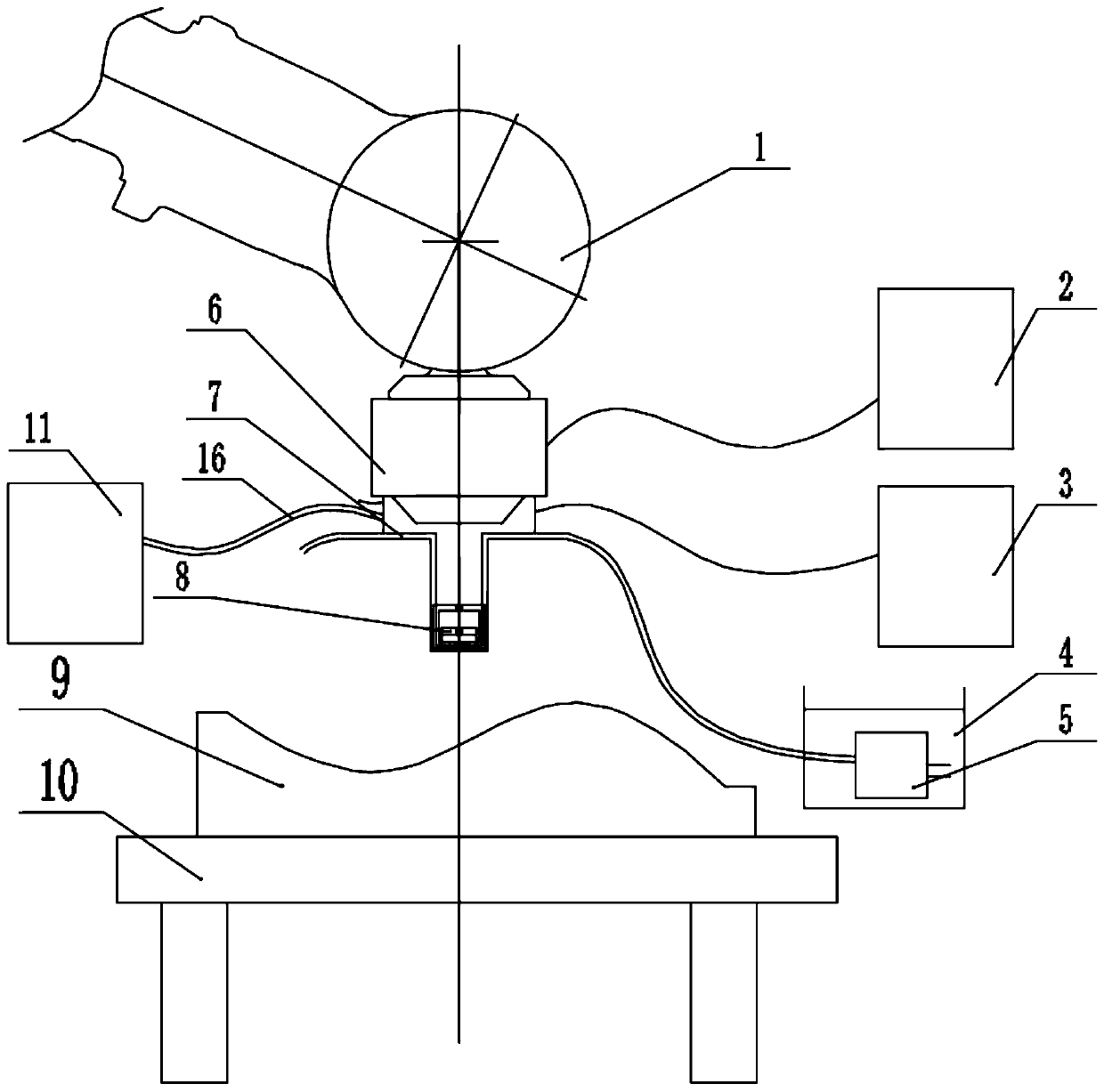

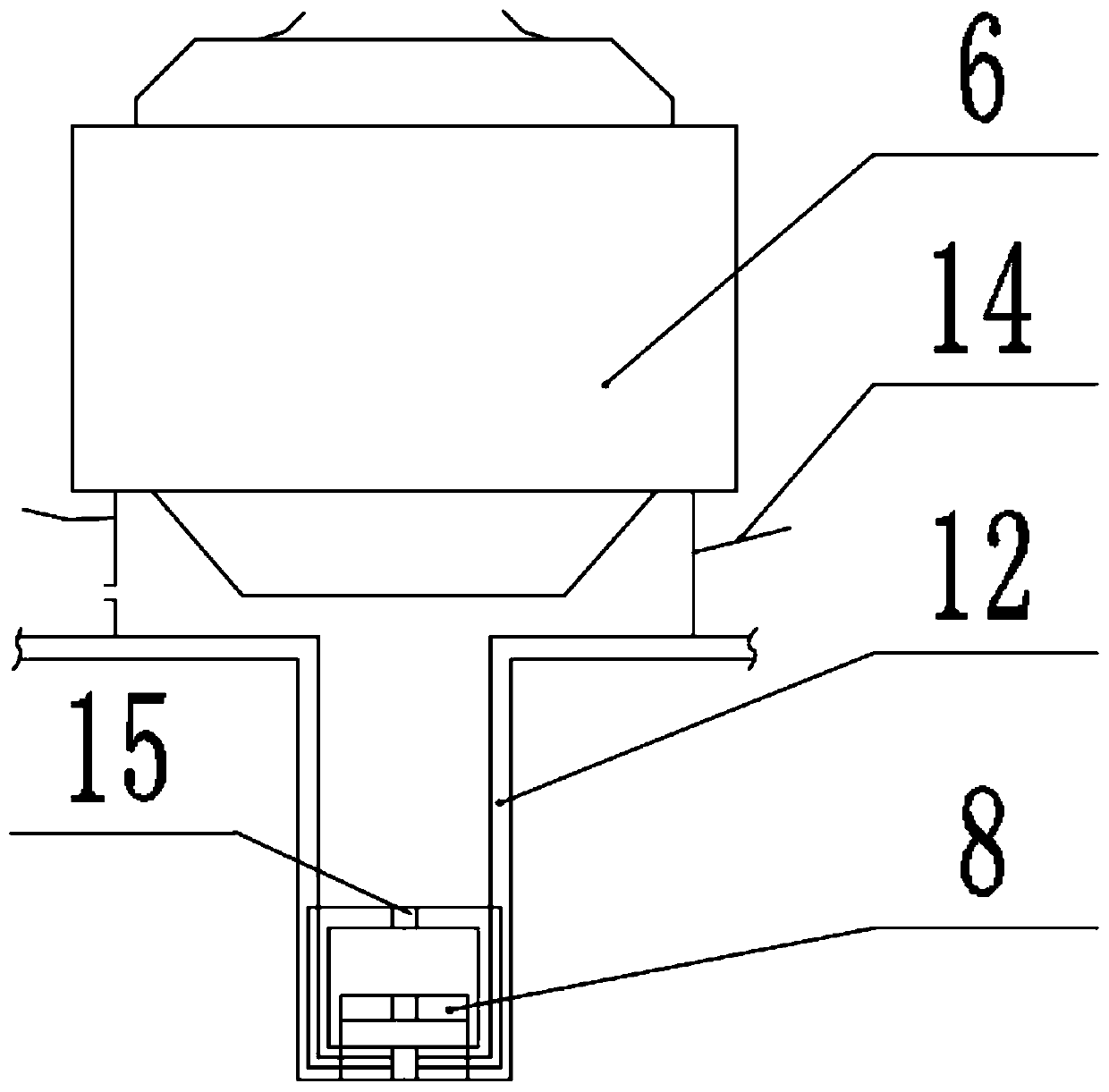

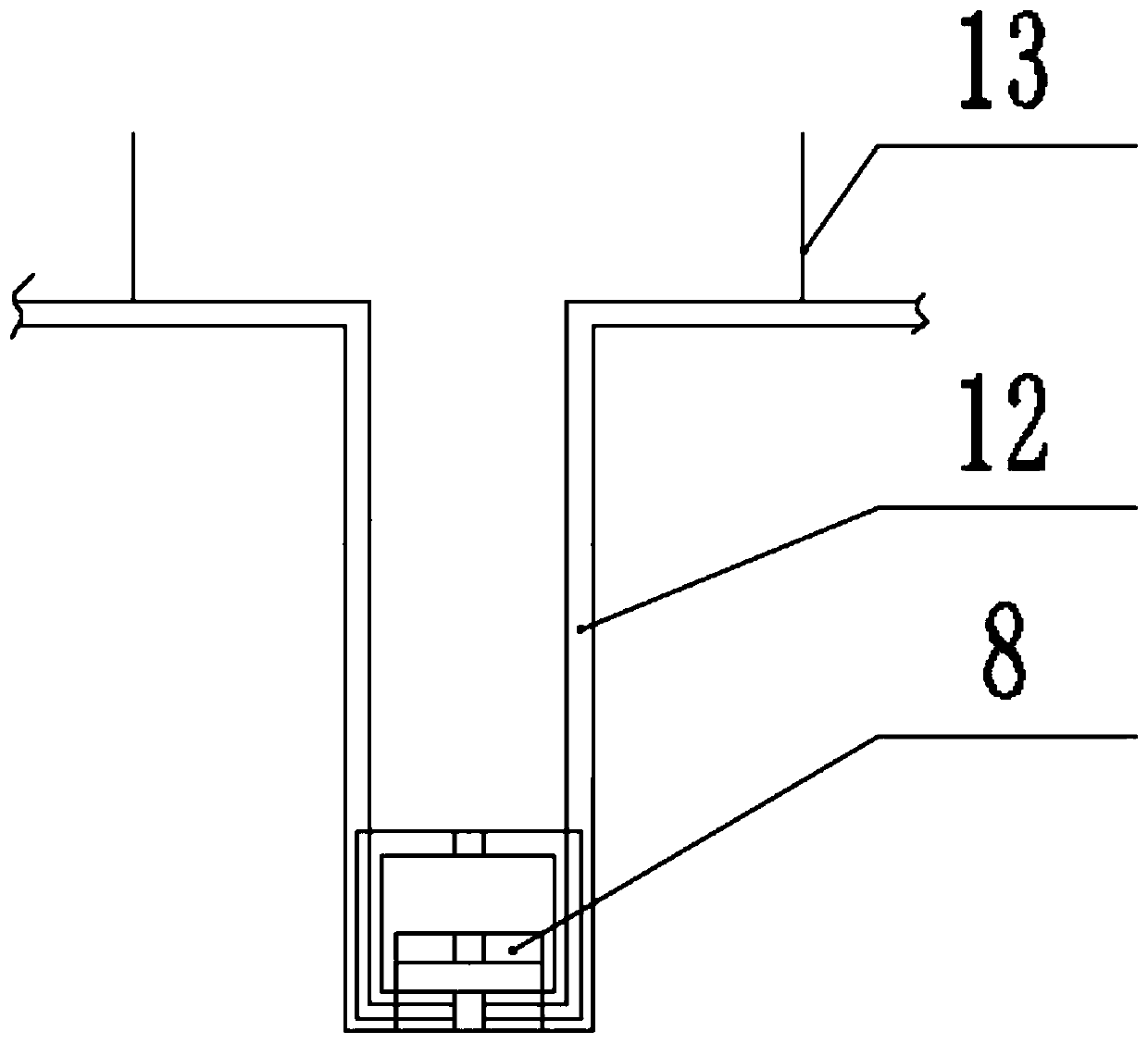

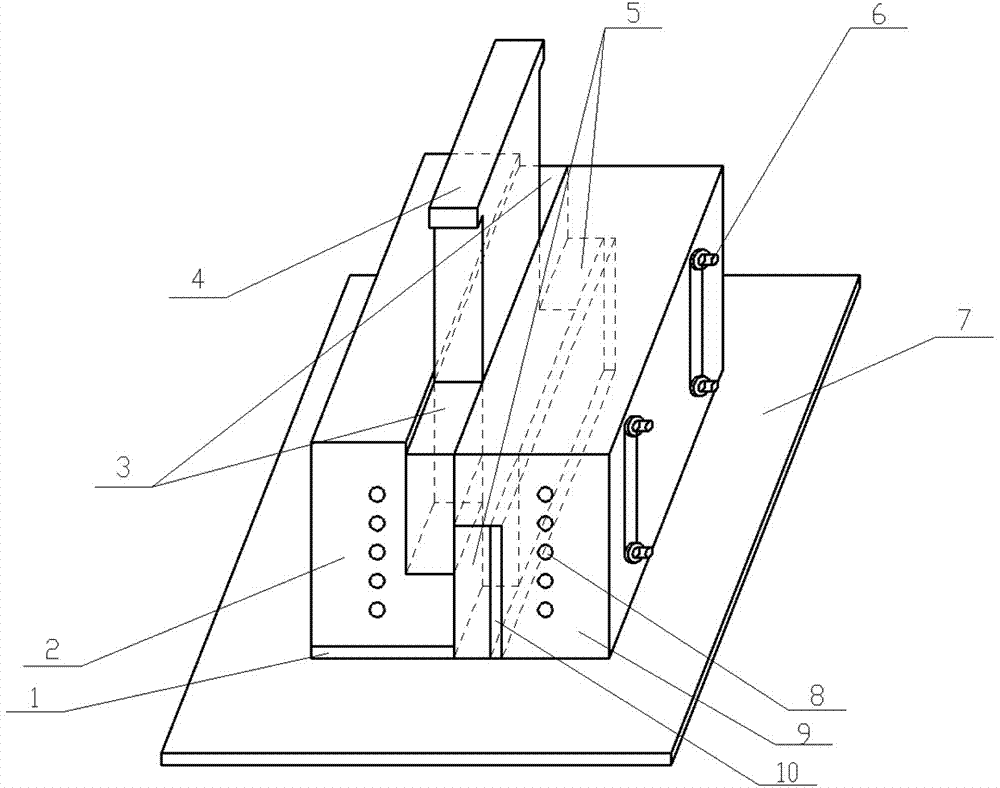

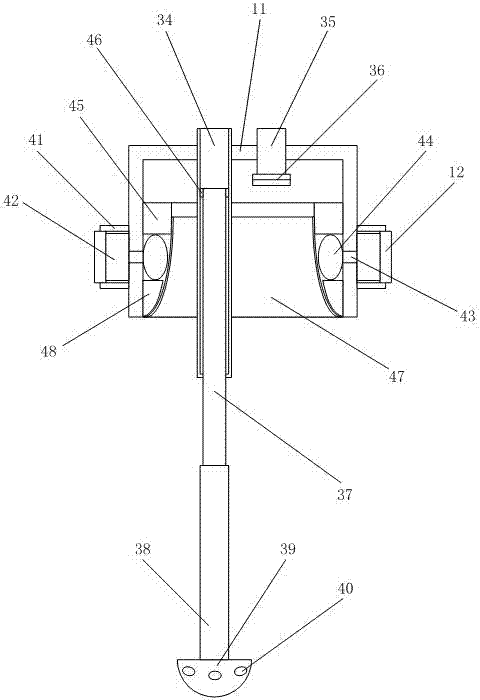

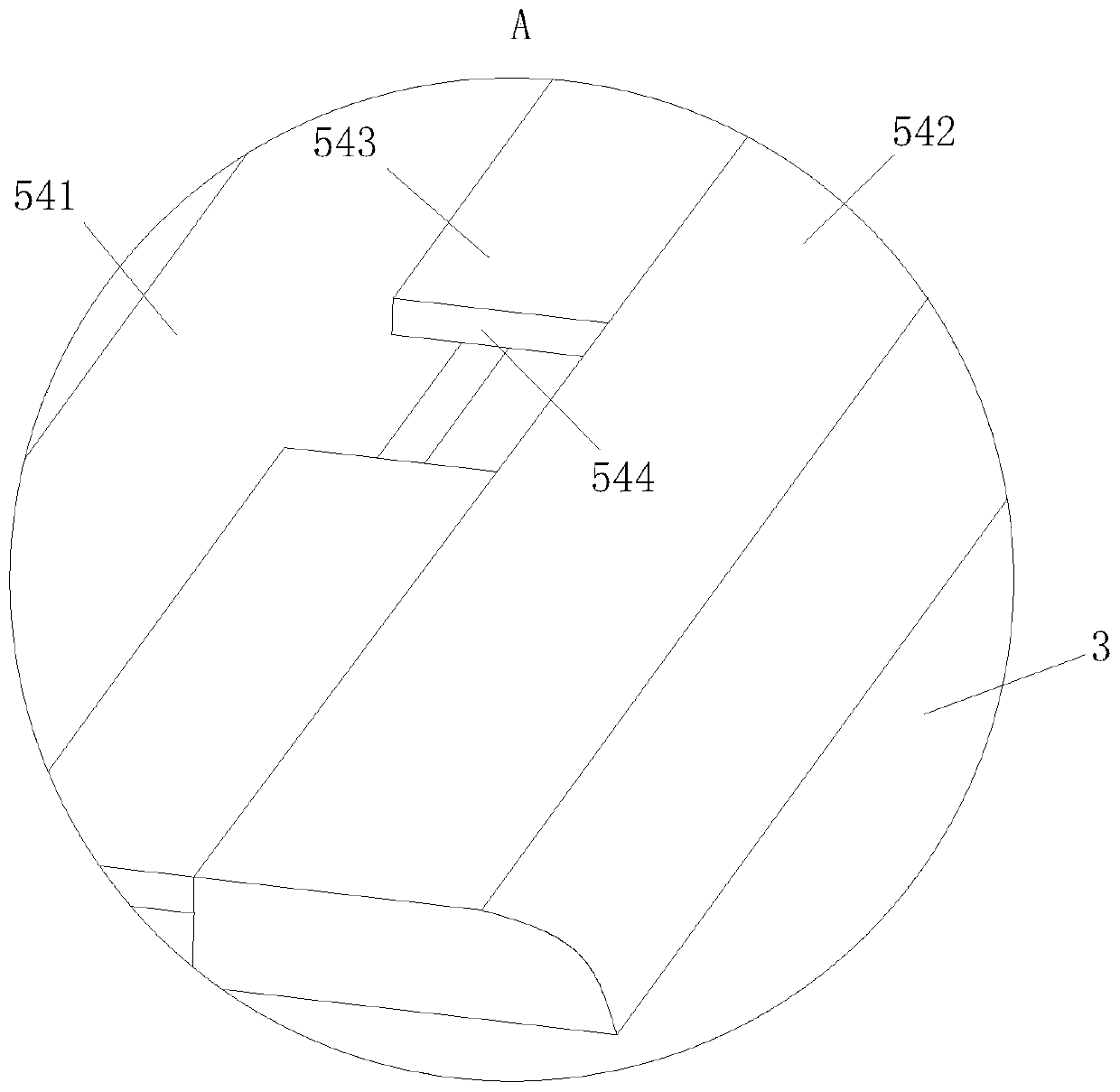

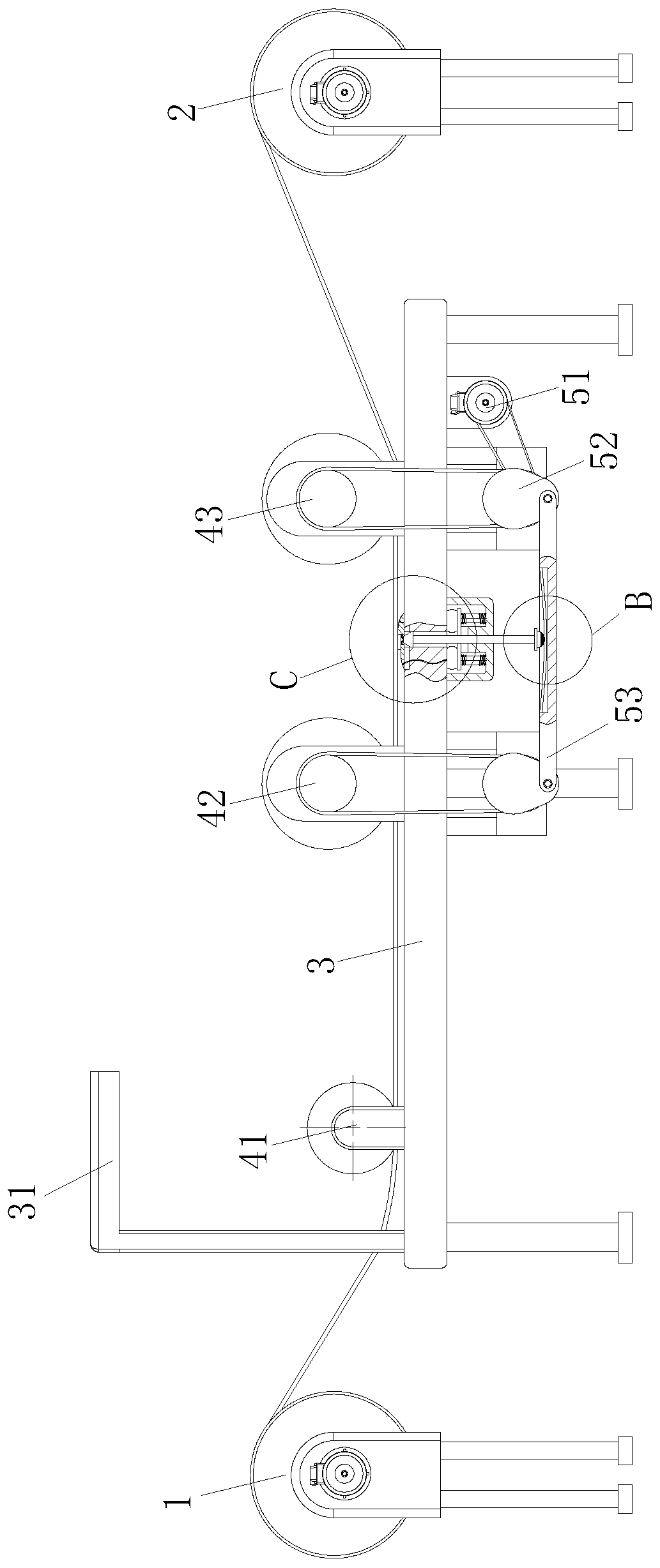

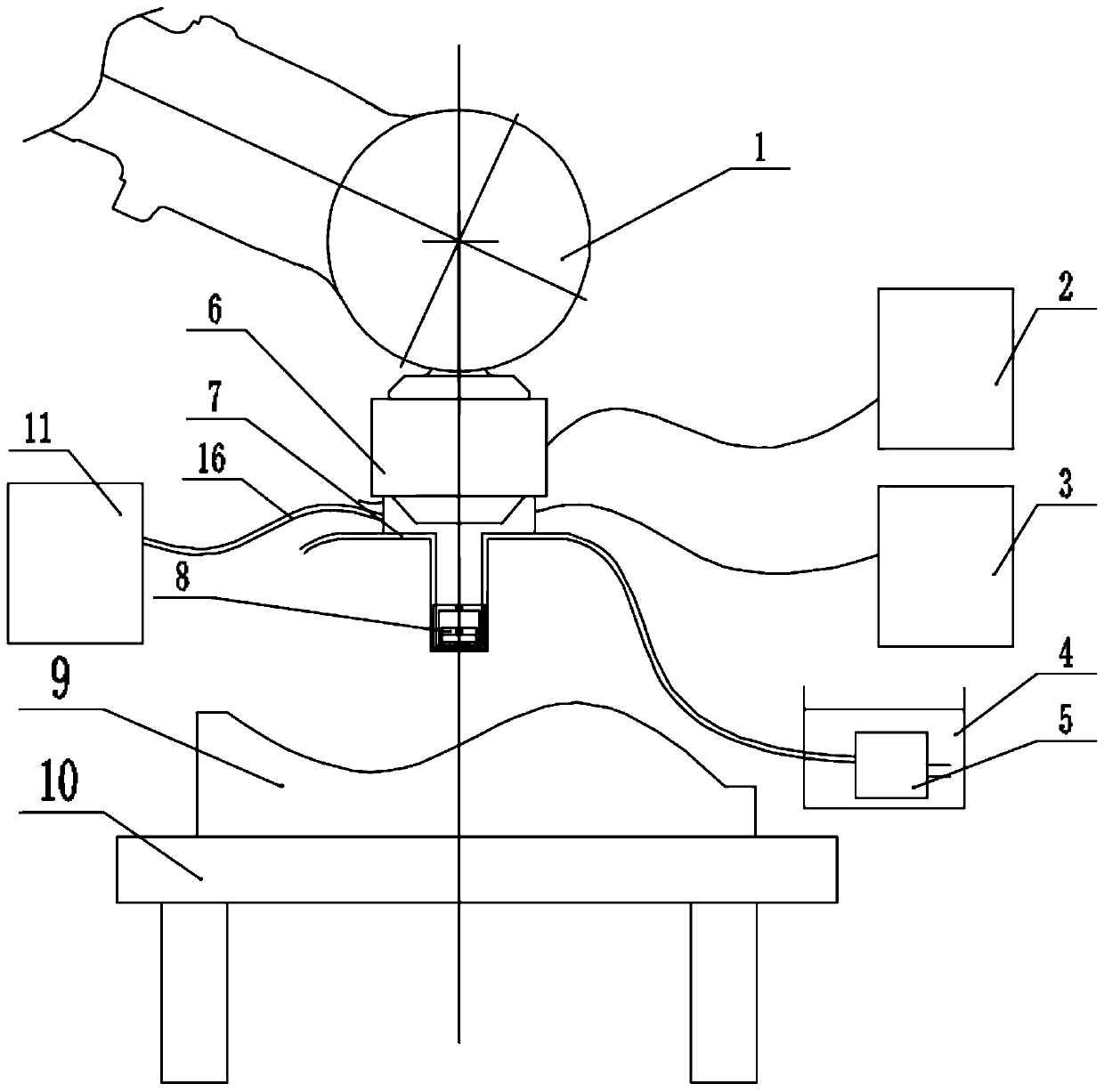

Chip attaching device and method

InactiveCN108155124AShorten the transfer strokeAchieve preheatingSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention provides a chip attaching device and method. The device comprises a wafer table, a basic material table, a rotary picking and placing mechanism and a vision mechanism. The wafer table can move in the plane where the wafer table is located; the basic material table is parallel to the wafer table and opposite to the wafer table, and can move in the plane where the basic material tableis located; the rotary picking and placing mechanism is arranged between the wafer table and the basic material table, and provided with a movable bonding portion, wherein the bonding portion can pickup a chip and attach the chip to an attaching position; the vision mechanism is arranged between the wafer table and the basic material table and matched with the rotary picking and placing mechanismto recognize the position of the chip and the attaching position. The method includes the steps that the positions of corresponding parts and components of the chip attaching device are calibrated; the chip is placed at the corresponding position of the attaching device, and position data of the chip is obtained and corrected; the chip is picked up, and the position and the angle data of the picked chip are obtained; the position, for attaching the chip, of a basic material and the angle data of the chip are obtained, the deviation of the chip is calculated and corrected in combination with the position and the angle data of the picked chip, and the chip is attached to the attaching position. With the device and the method, attaching efficiency and accuracy are higher.

Owner:CETC BEIJING ELECTRONICS EQUIP

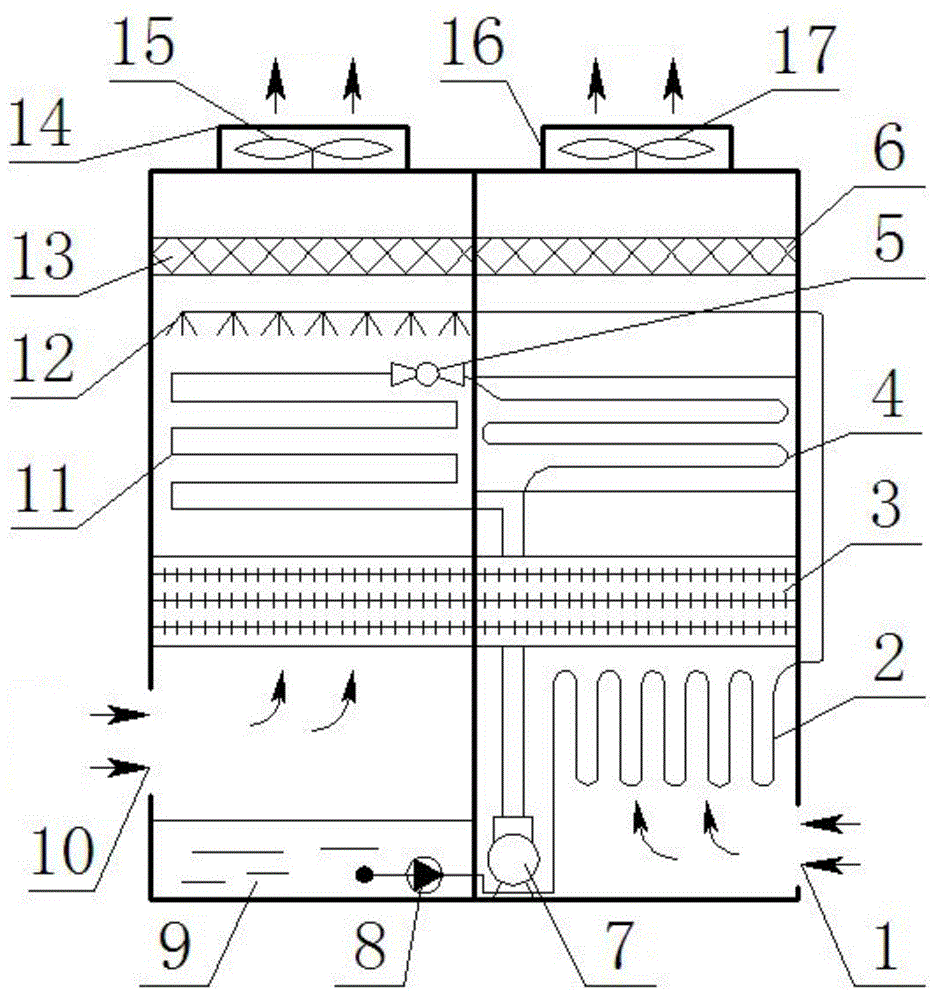

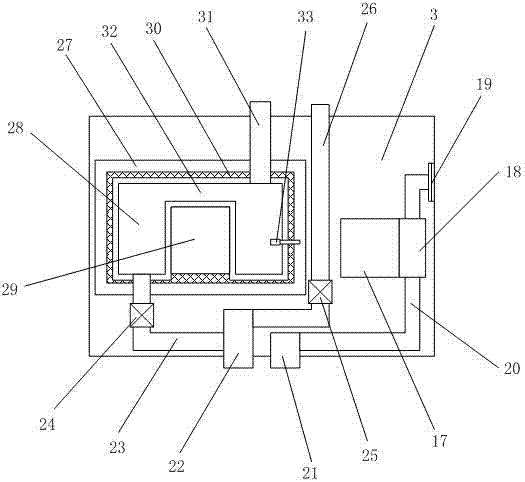

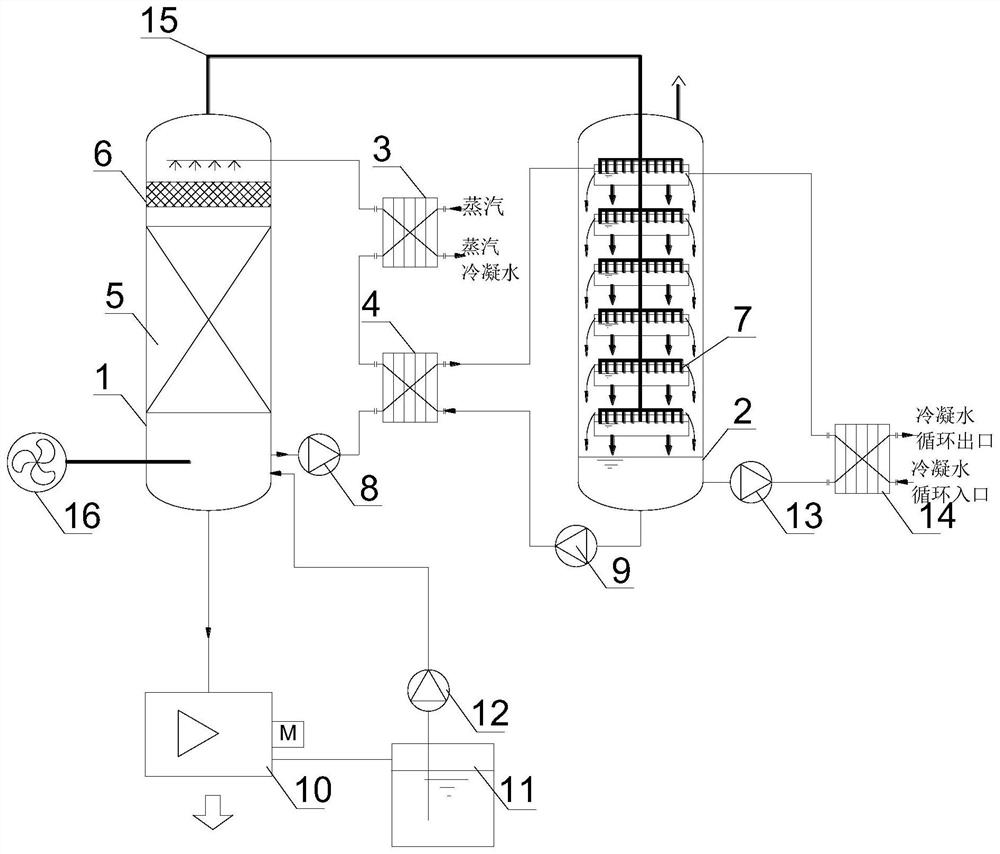

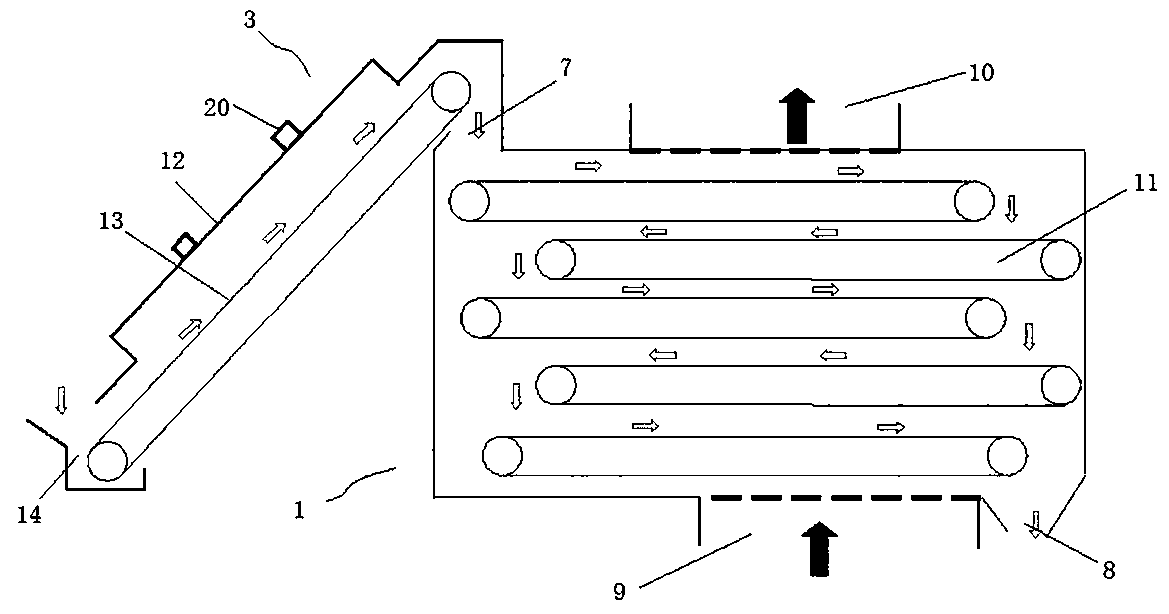

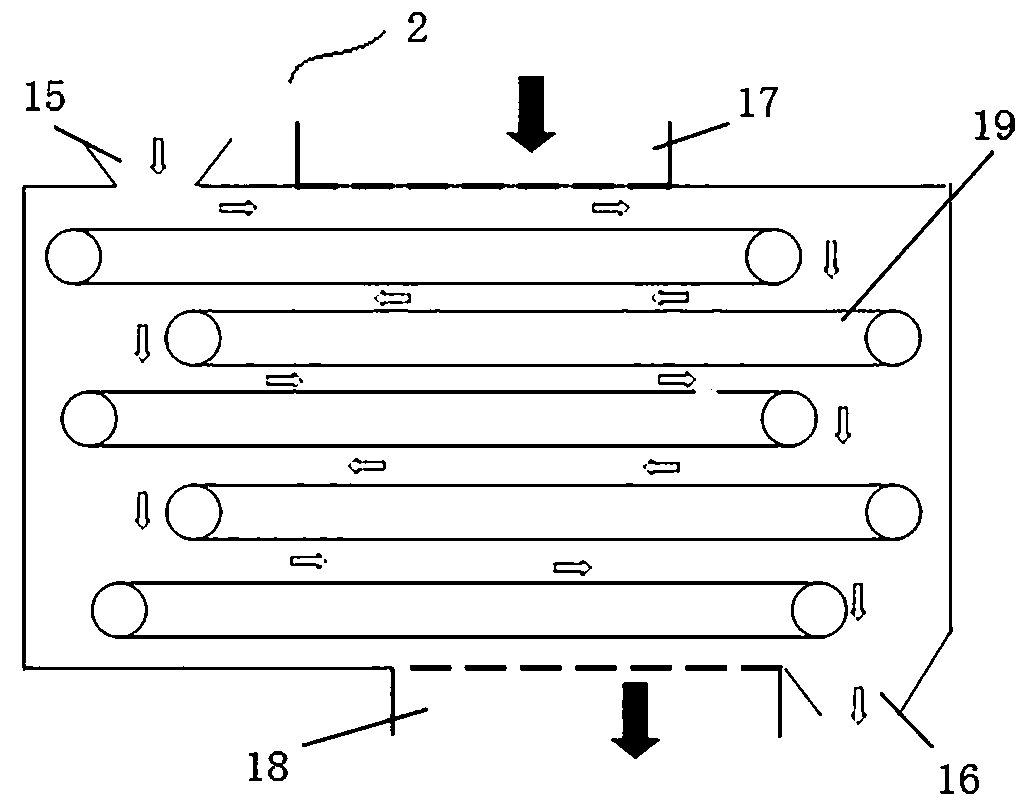

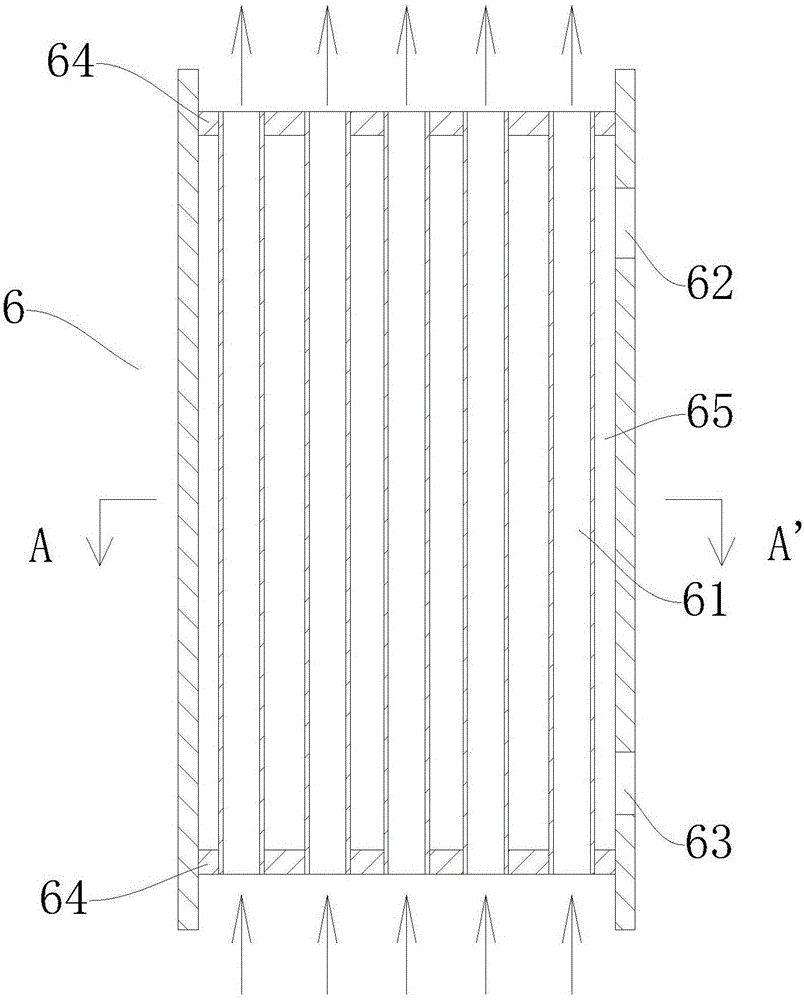

All-in-one evaporative cooling and mechanical refrigerating combined air conditioning unit usable in summers and winters

ActiveCN103604180AReduce water temperatureAvoid cross contaminationDucting arrangementsLighting and heating apparatusEvaporative coolerFresh air

The invention discloses an all-in-one evaporative cooling and mechanical refrigerating combined air conditioning unit usable in summers and winters. The all-in-one evaporative cooling and mechanical refrigerating combined air conditioning unit usable in summers and winters comprises an exhaust channel and an air supply channel which are independent and are formed by dividing the inside of a shell of the air conditioning unit; a mechanical refrigerating unit is arranged in the air supply channel; an evaporative cooling unit is arranged in the exhaust channel; and the mechanical refrigerating unit is connected with the evaporative cooling unit through a pipe network. The combined air conditioning unit recycles cold energy and heat energy of exhausted air by using heat pipes, and has a free cooling function and a pre-cooling effect on fresh air by using cold water; the leading role of evaporative cooling is sufficiently played; and the air conditioning unit has the advantages of environmental protection, high efficiency and energy conservation.

Owner:新疆华奕新能源科技有限公司

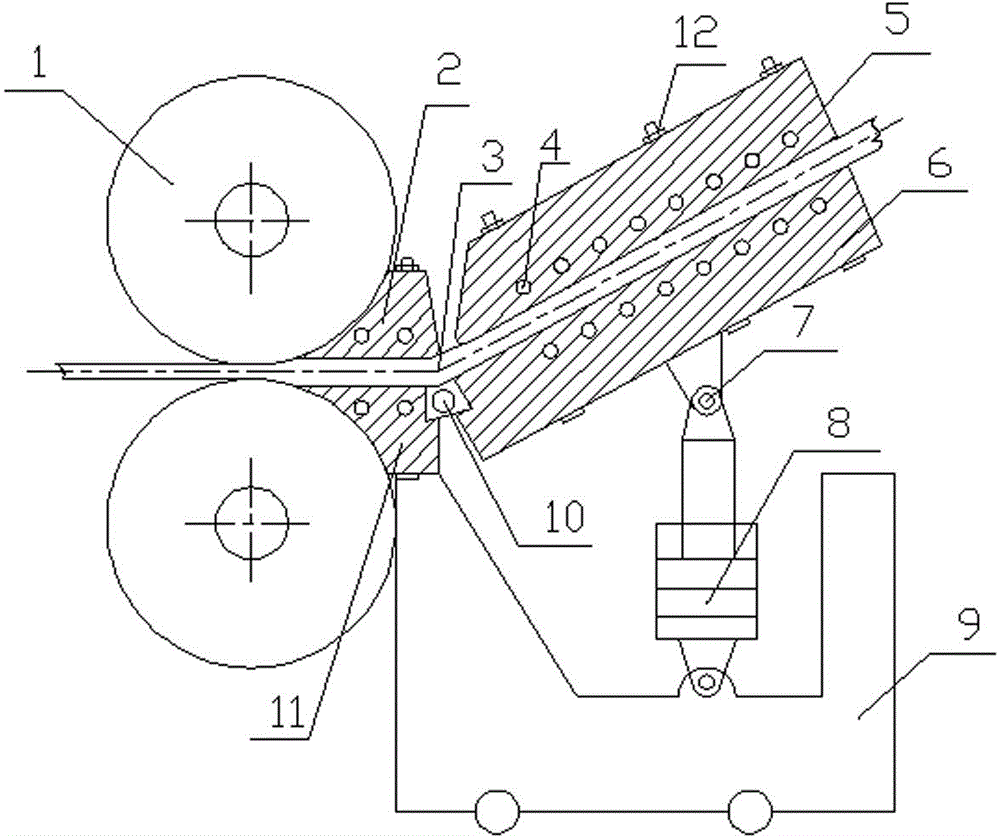

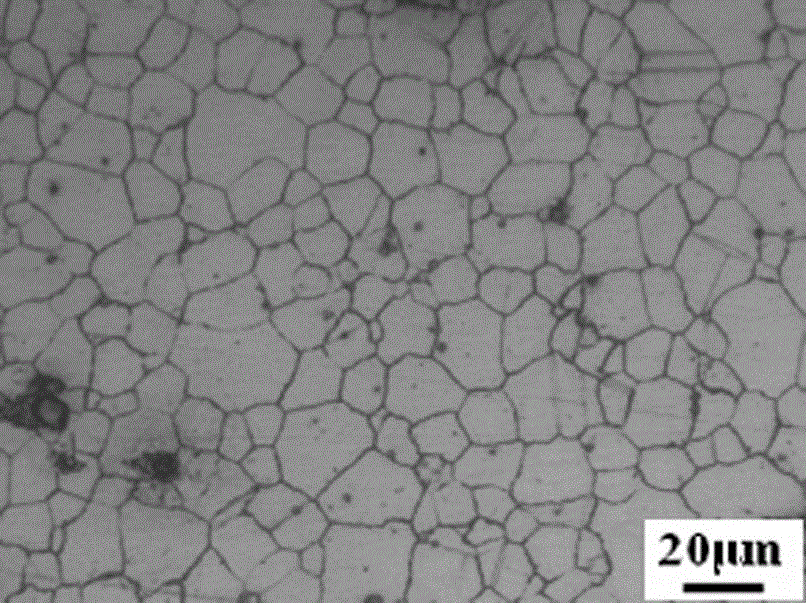

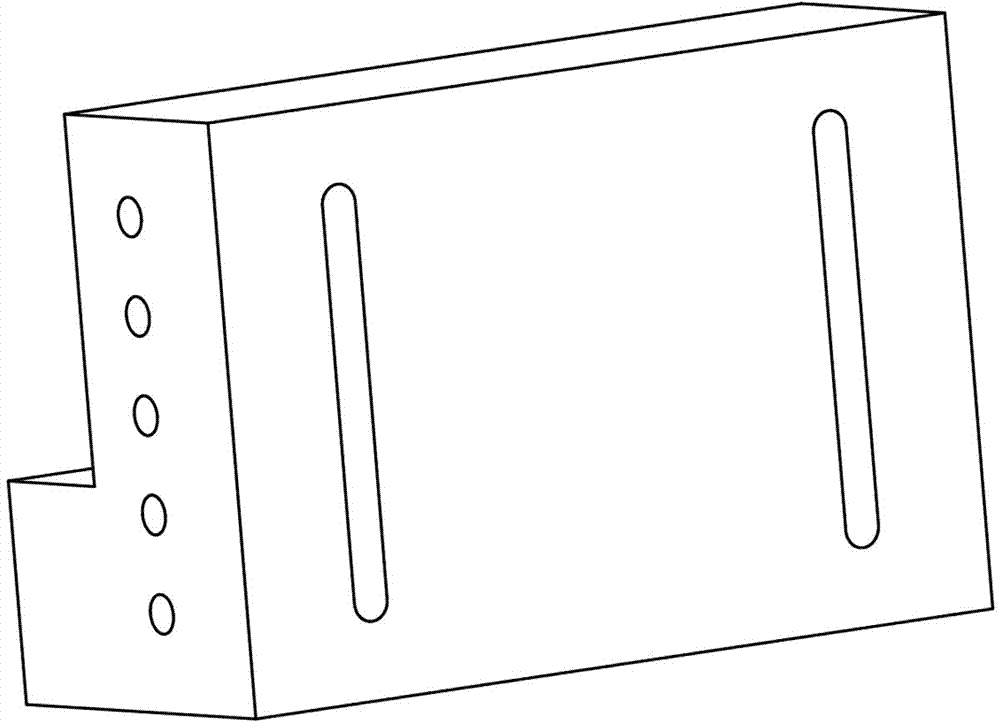

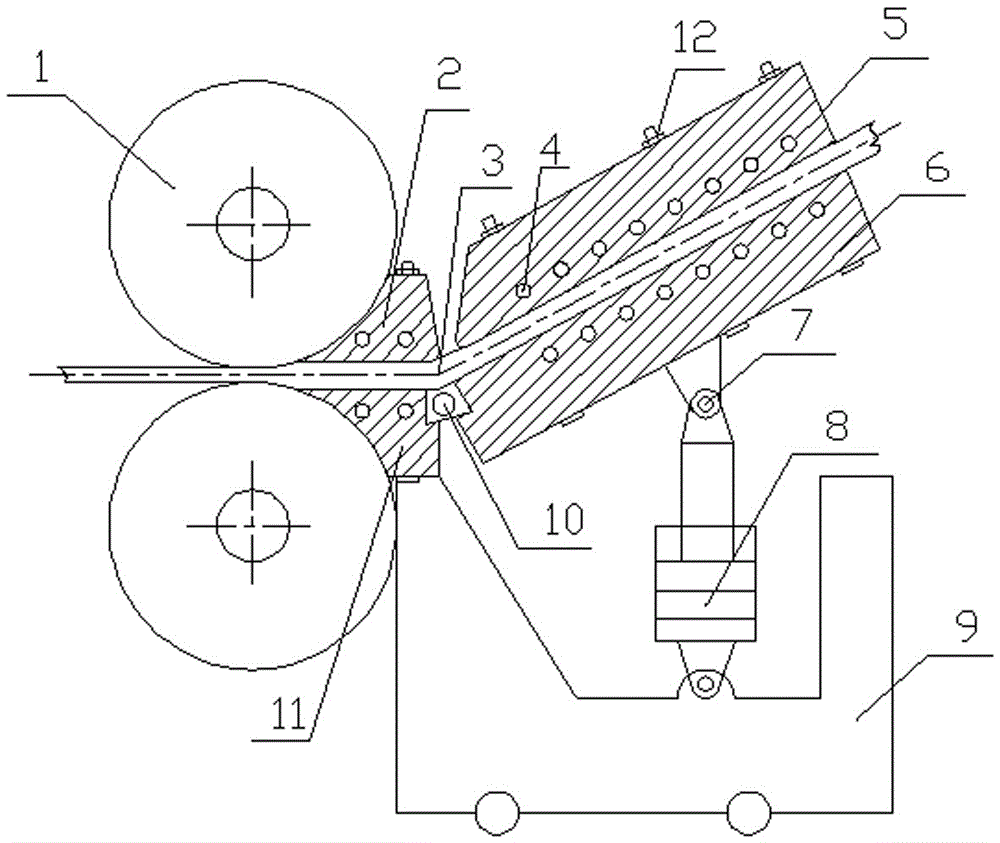

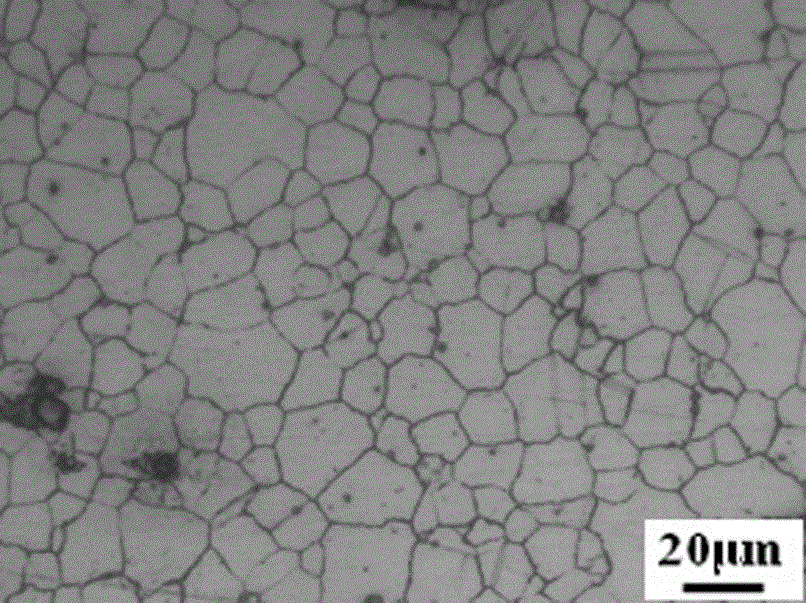

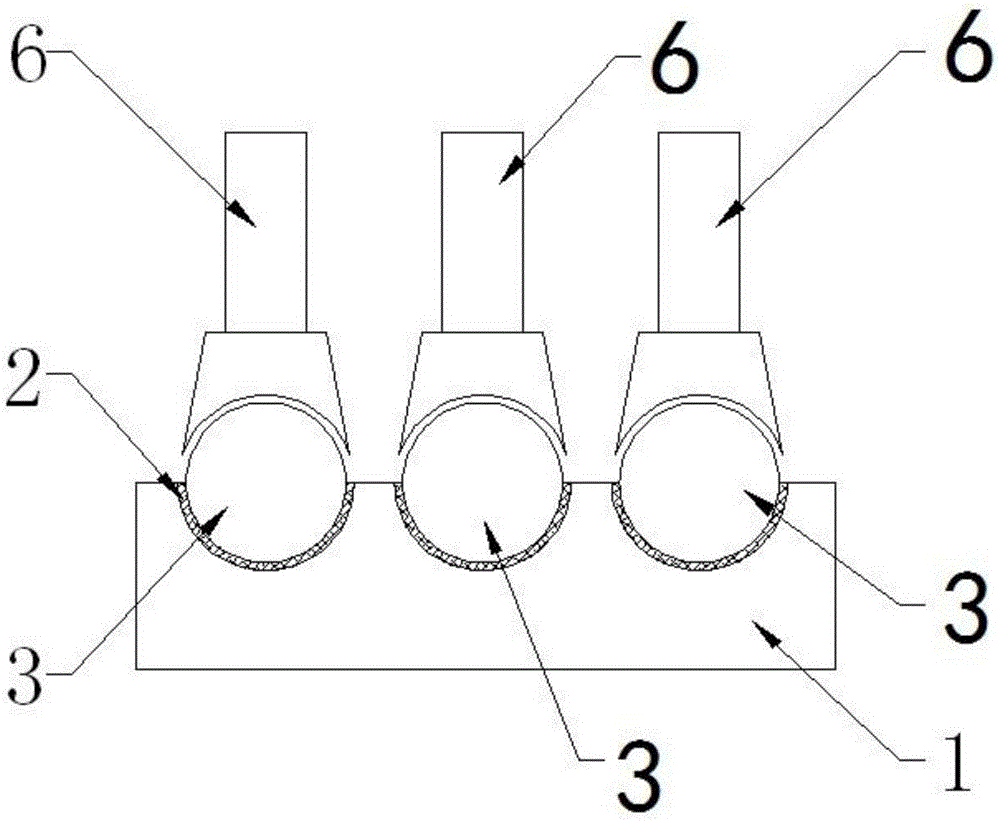

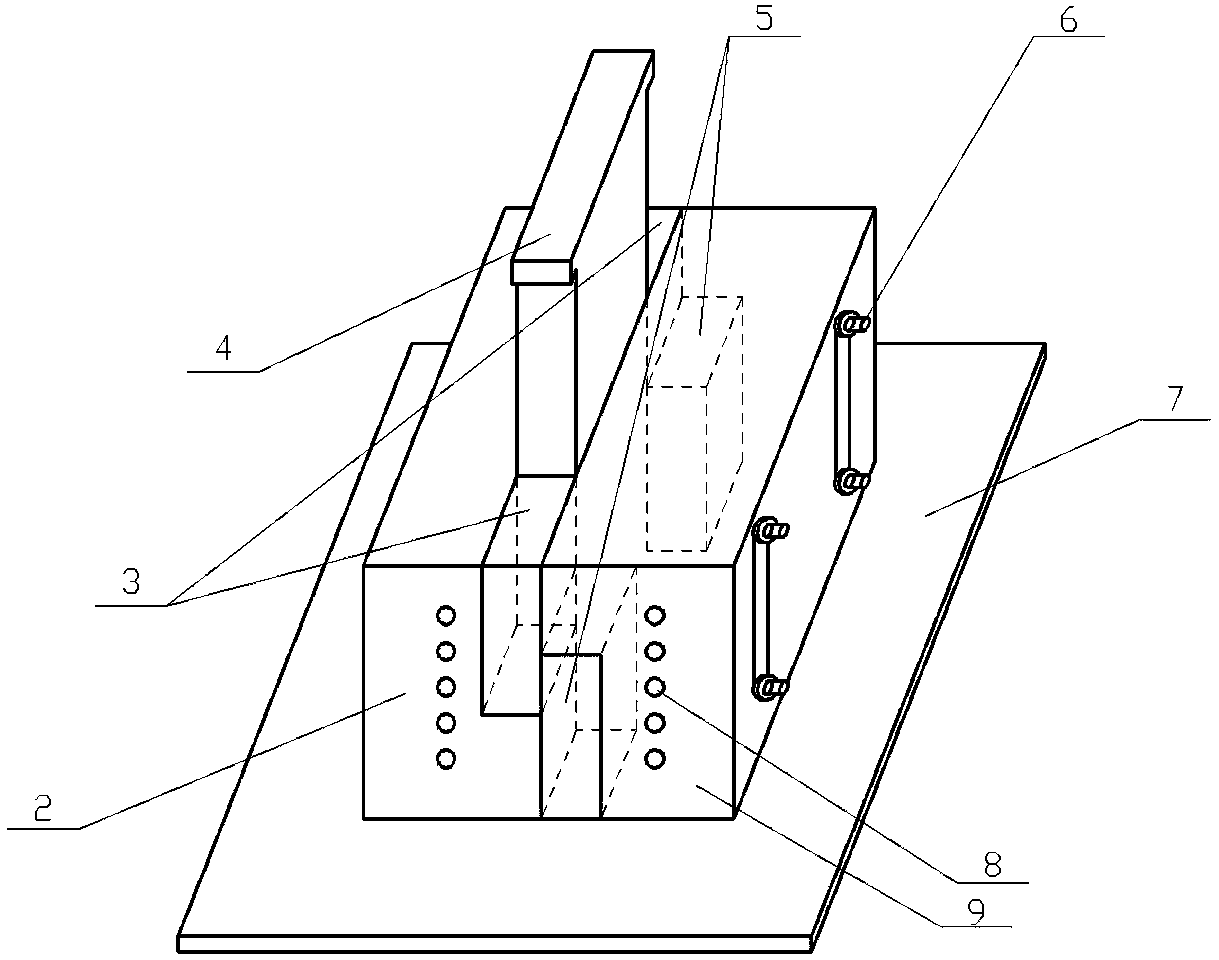

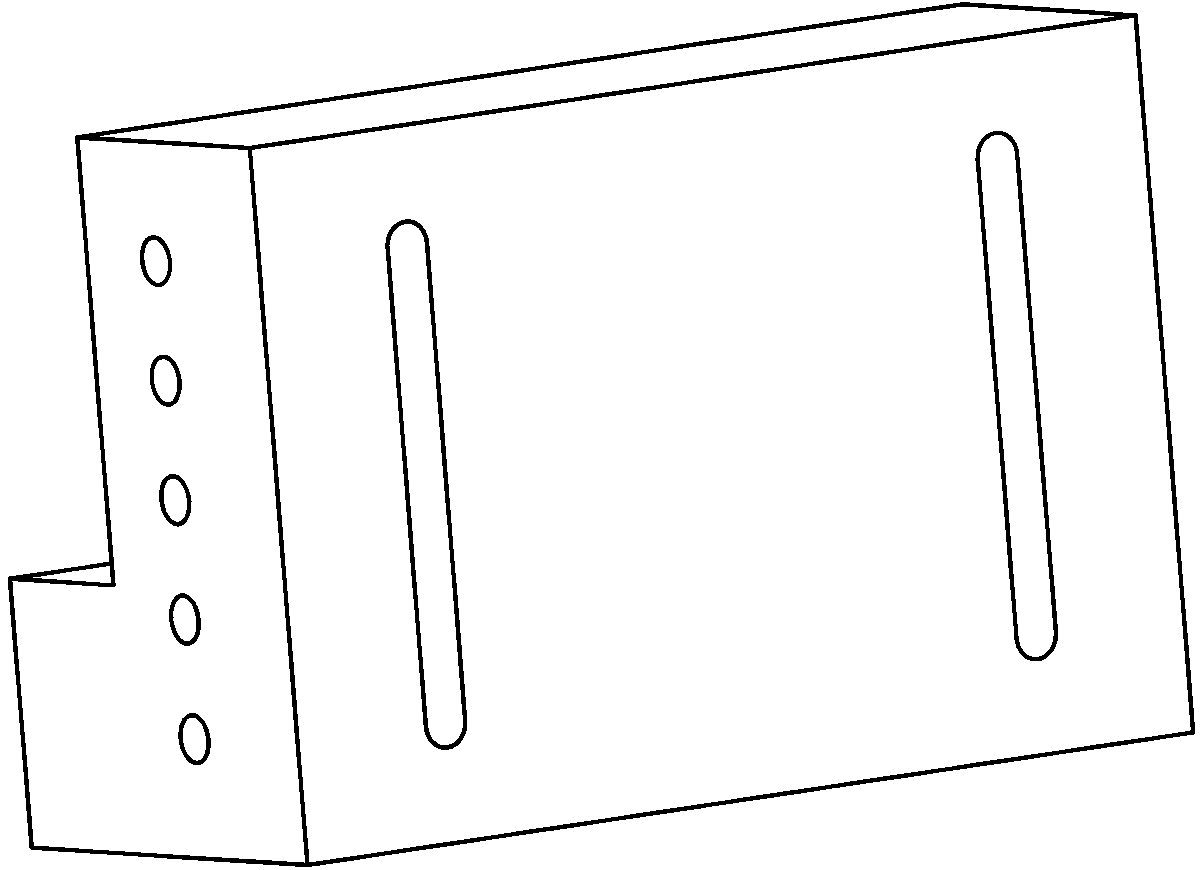

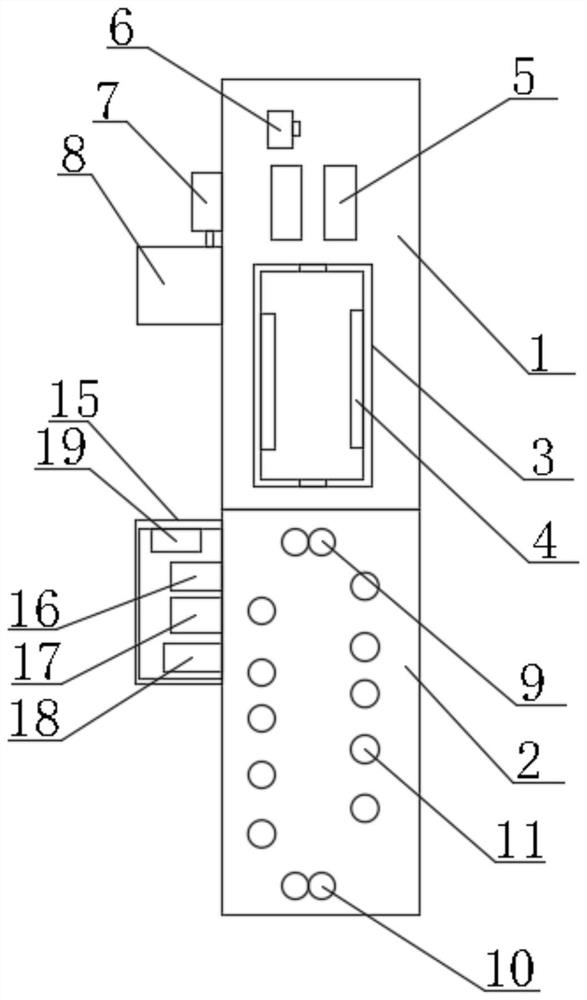

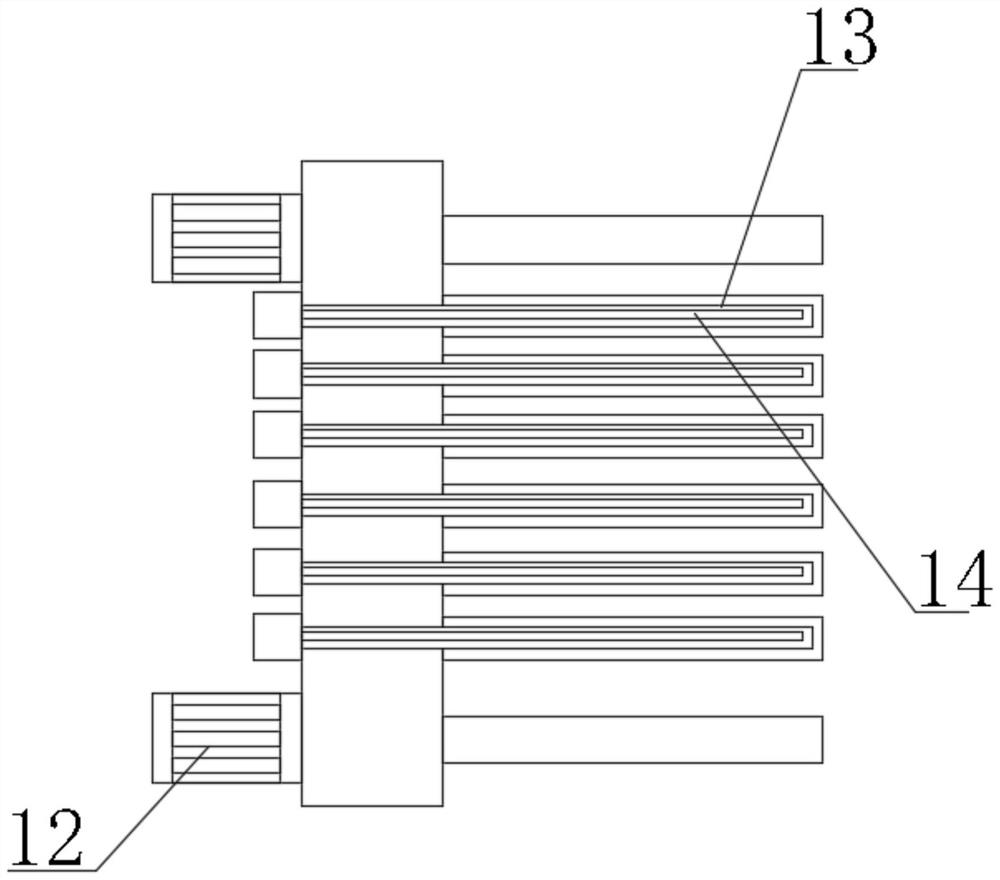

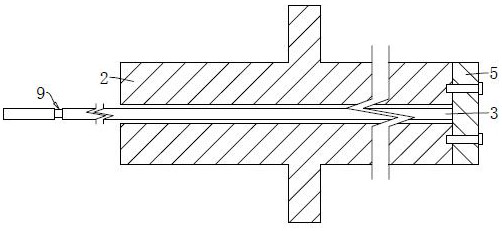

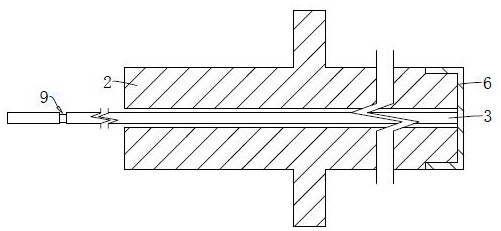

Strong-shear rolling forming method and device for metal plate

ActiveCN104646416AGrain refinementImprove microstructureForging/pressing devicesMetal rolling arrangementsRoll formingShearing deformation

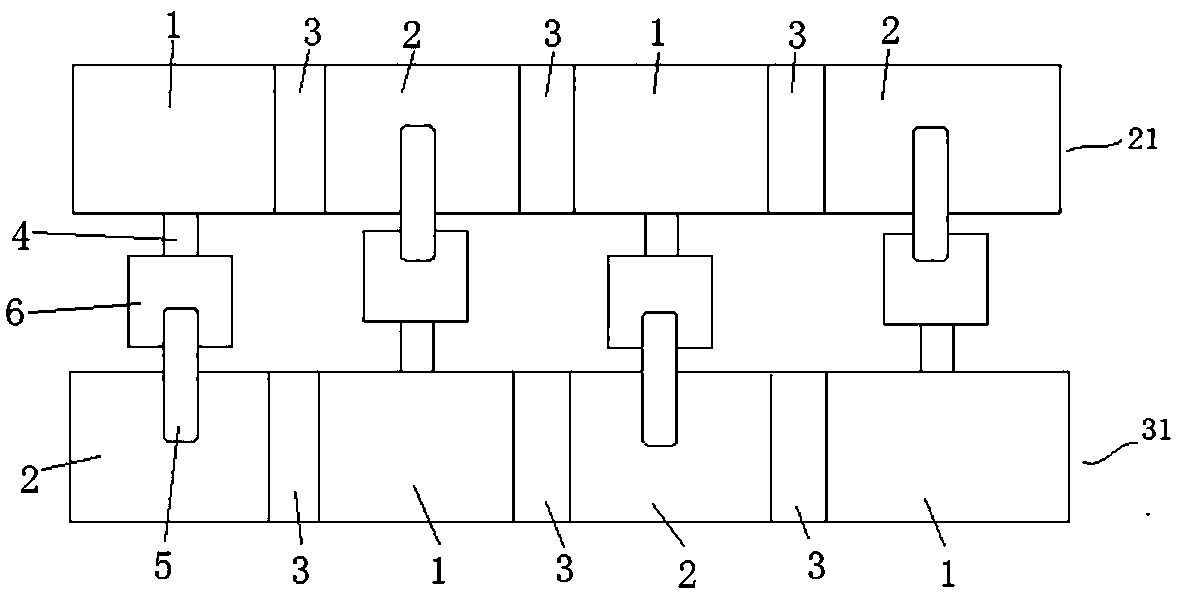

The invention discloses a strong-shear rolling forming method and a strong-shear rolling forming device for a metal plate. Power is provided by friction force between the plate and rollers during rolling deformation, and the plate is subjected to the strong-shear deformation of dies, and then enters a part between the rollers for plate rolling deformation. The device comprises a double-roller rolling mill, a movable die upper template, a movable die lower template, a stand, a fixed die lower template and a fixed die upper template, wherein the fixed die lower template is fixedly arranged on the stand; the movable die lower template is hinged to the fixed die lower template, and is arranged on the stand through an oil cylinder; the fixed die upper template and the movable die upper template are arranged on the fixed die lower template and the movable die lower template through bolts respectively; the double-roller rolling mill is arranged at an outlet of a metal plate passage. The method and the device are flexible in die equal channel angular adjustment and low in cost; the rolling deformation and the shear deformation of the metal plate such as a magnesium plate and an aluminum plate can be effectively combined, crystal grains of the plate can be refined, the texture evolution of the plate can be controlled, and the mechanical performance and the forming performance of the plate can be improved.

Owner:HUNAN UNIV OF SCI & TECH

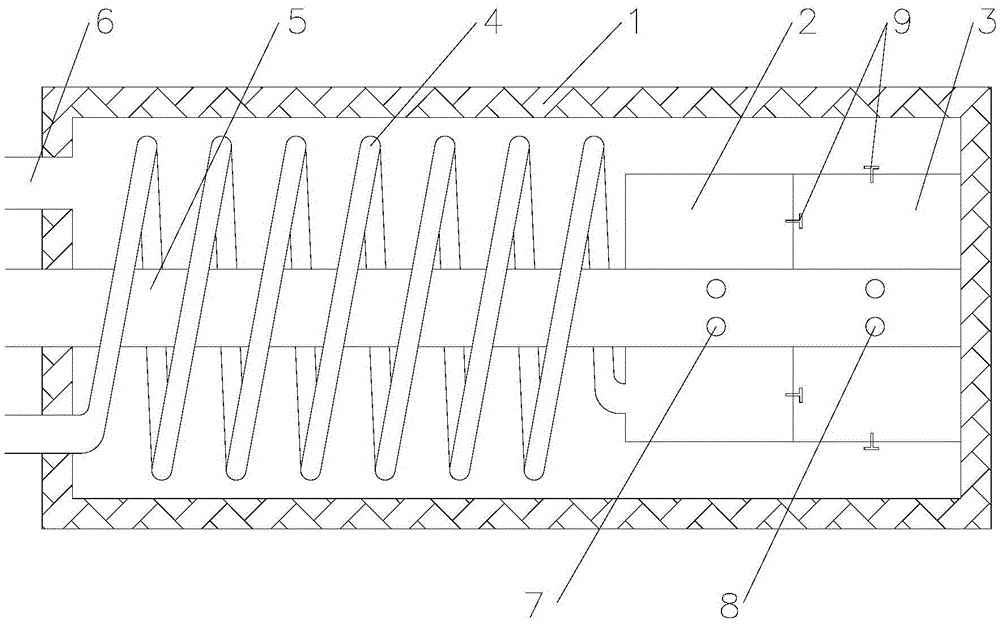

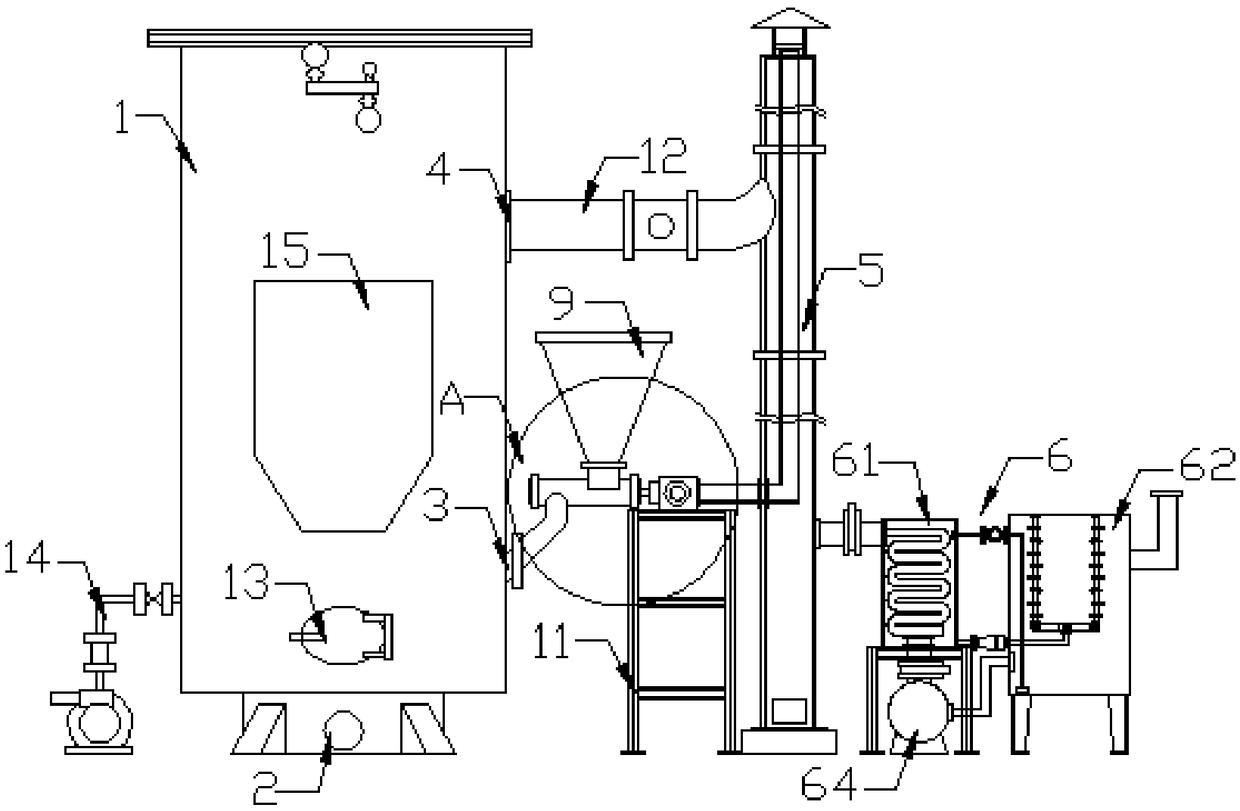

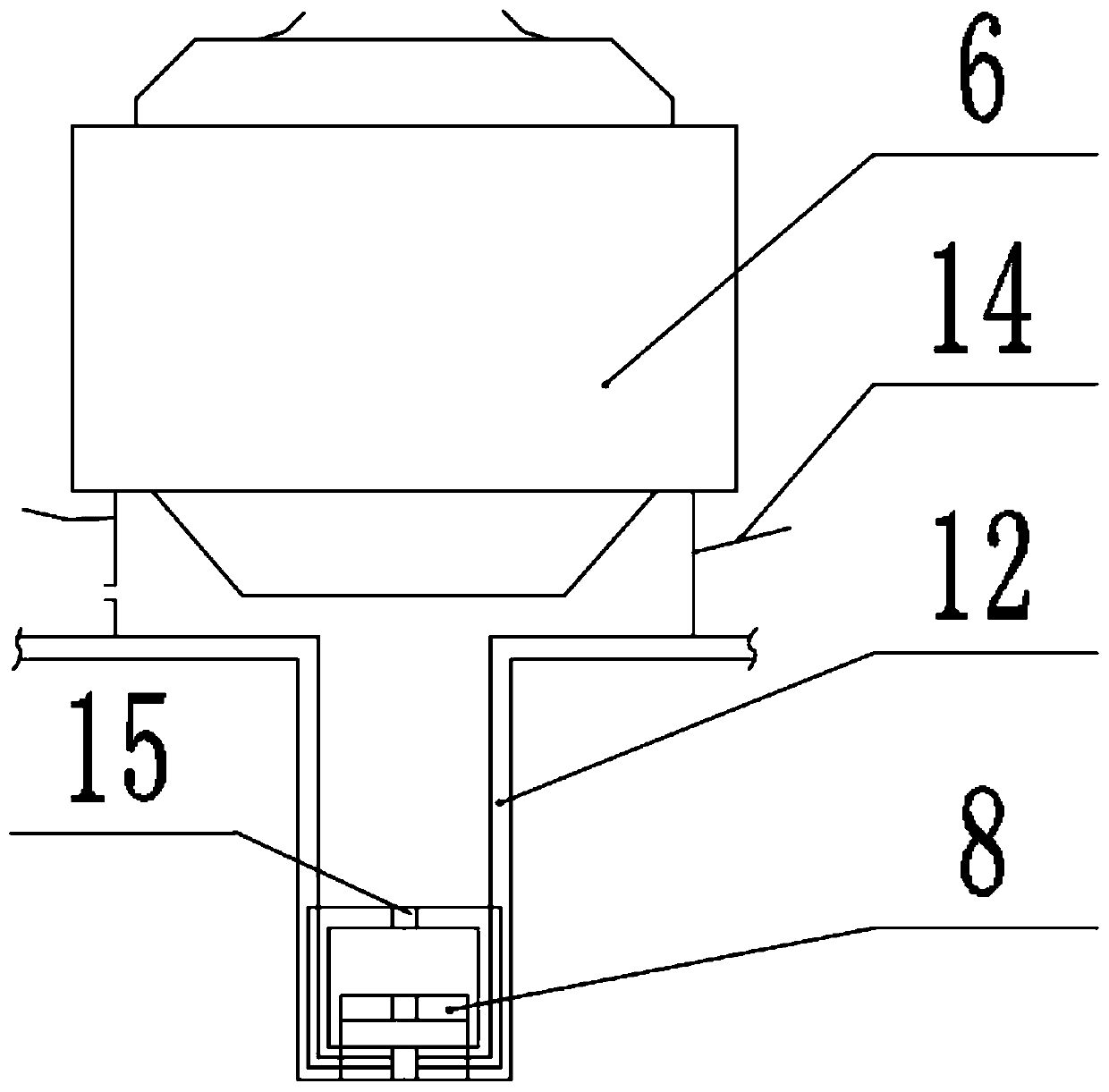

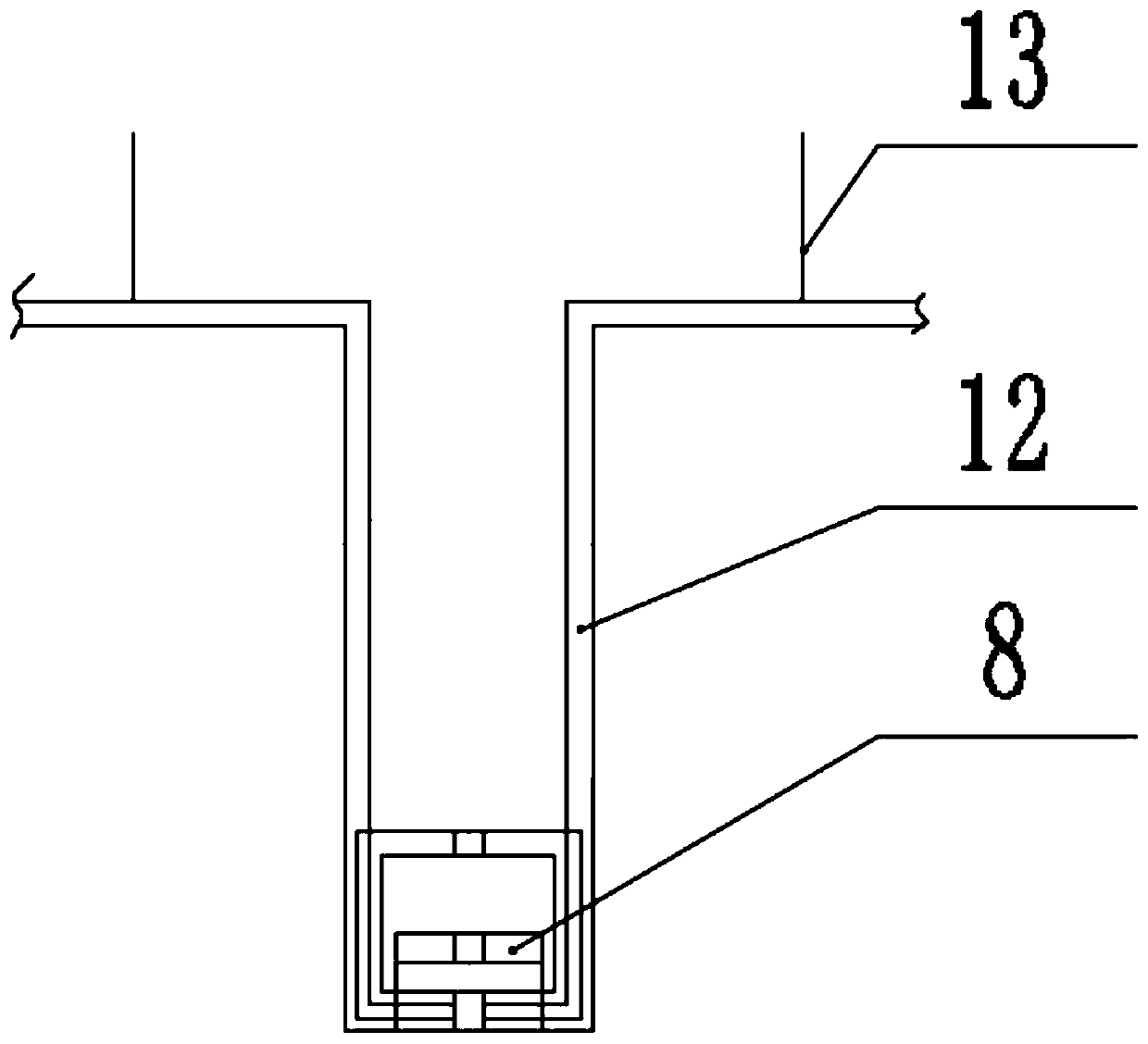

Efficient incinerator

InactiveCN105570909AAchieve preheatingIncreased preheating flow areaIncinerator apparatusCombustion chamberExhaust fumes

The invention relates to an efficient incinerator. A primary combustion chamber and a secondary combustion chamber are arranged at the back end of a furnace chamber; a check valve is arranged between the primary combustion chamber and the secondary combustion chamber; an air pipe is arranged in the center of an inner cavity of a furnace shell, enters the furnace chamber from the front end of the furnace shell and penetrates through the primary combustion chamber and the secondary combustion chamber; a first air inlet is formed in the pipe wall of the air pipe in the primary combustion chamber; a second air inlet is formed in the pipe wall of the air pipe in the secondary combustion chamber; the secondary combustion chamber is communicated with the furnace chamber through the check valve; a waste gas pipe enters the furnace chamber from the front end of the furnace shell, is communicated with the primary combustion chamber, is in a spiral shape and is arranged outsides the air pipe; and an exhaust hole is formed in the front end of the furnace shell. According to the efficient incinerator disclosed by the invention, with the arrangement of two combustion chambers, waste gas is fully combusted, so that content of harmful substances in the exhausted gas is lowered, and environmental pollution is reduced; and gas after being combusted flows through the exterior of the air pipe and the waste gas pipe, so that the waste gas and the air are preheated, the waste is avoided, and the cost is saved.

Owner:CHANGZHOU JINTAN HANGUANG TECH CO LTD

Electromagnetic assisted laser synchronous cladding device and method for remanufacturing metal parts

ActiveCN110373666AAchieve preheatingReduce cooling rateMetallic material coating processesHigh energyEddy current

The invention discloses an electromagnetic assisted laser synchronous cladding device and method for remanufacturing metal parts. The electromagnetic assisted laser synchronous cladding device comprises a six-degree-of-freedom actuator, a laser, an electromagnetic induction heater, a powder spraying device and a workbench, wherein the working table is used for containing a workpiece to be machined, and the powder spraying device is used for spraying metal powder to the surface of the workpiece to be machined; the laser is installed at the tail end of the six-degree-of-freedom actuator, and thelaser is used for generating high-energy lasers for achieving cladding of the metal powder on the surface of the workpiece arranged on the workbench; the electromagnetic induction heater comprises aninduction coil and an induction power supply for supplying power to the induction coil, and the induction coil is made of a hollow metal tube; and cooling water is fed into the hollow metal tube forcooling, and the induction coil is arranged below the laser device and used for carrying out auxiliary cladding on the metal powder on the surface of the workpiece to generate an eddy current. According to the electromagnetic assisted laser synchronous cladding device, the structure is simple, the cladding speed is high, the powder utilization rate is high, and the applicable cladding material range is wide.

Owner:WUHAN UNIV OF TECH

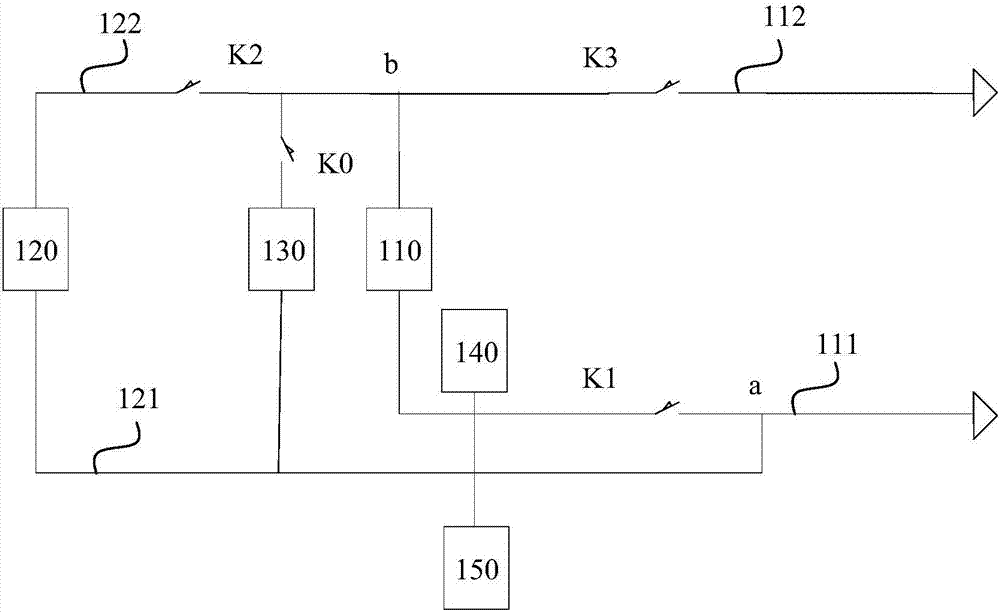

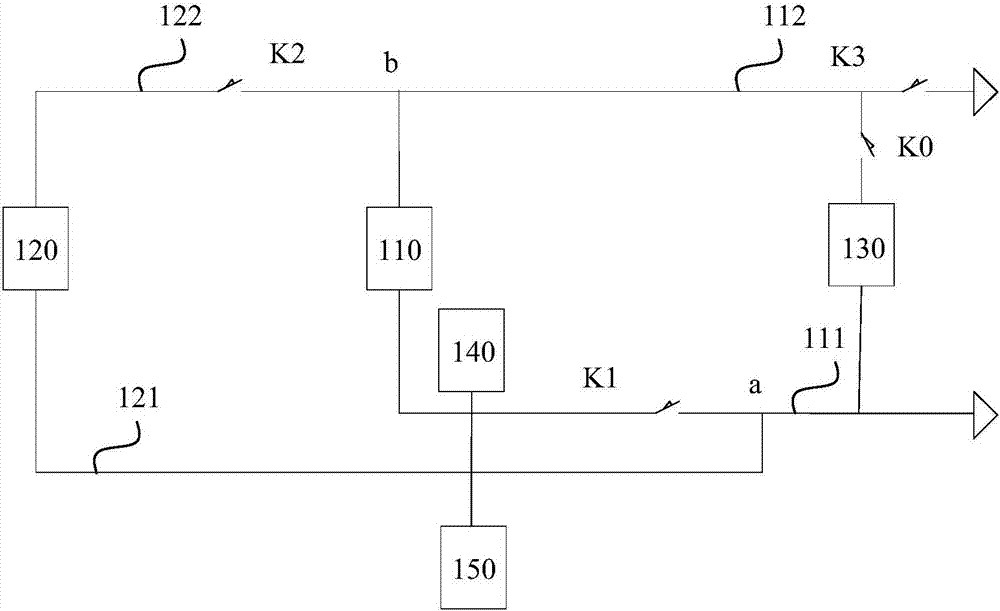

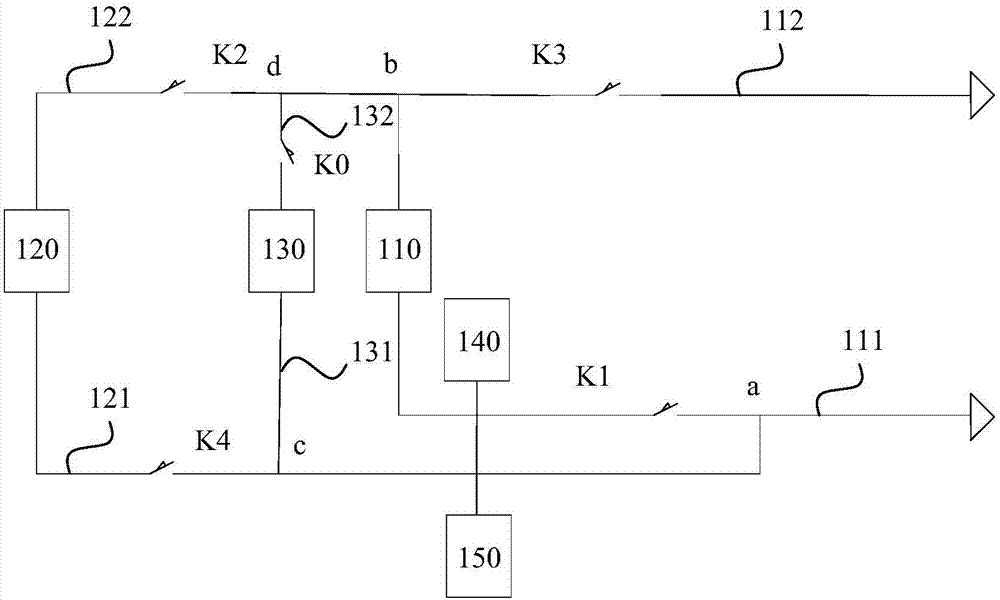

Power battery charging and heating system, control method, power battery pack and vehicle

InactiveCN107331922AFast chargingFast charging and heatingSecondary cellsPower batteryHeating system

The embodiment of the invention discloses a power battery charging and heating system, control method, power battery pack and vehicle. The power battery charging and heating system includes a battery, an anode and cathode of which are connected to two power supply buses, respectively. One power supply bus is provided with a first relay. A first charging interface is connected to a first connection point and a second connection point through two first charging wires and two power supply buses. The first relay is located between the battery and the first connection point. One first charging wire is provided with a second relay. A heater is connected between the two first charging wires or between two power supply buses. A connection wire of the heater and the first charging wires or power supply buses is provided with a heating relay. A detection unit is used for detecting the temperature of the battery. A control unit is connected to the relays and used for opening and closing each relay. According to the embodiment, the power battery can be preheated, and charging performance of the power battery is improved.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

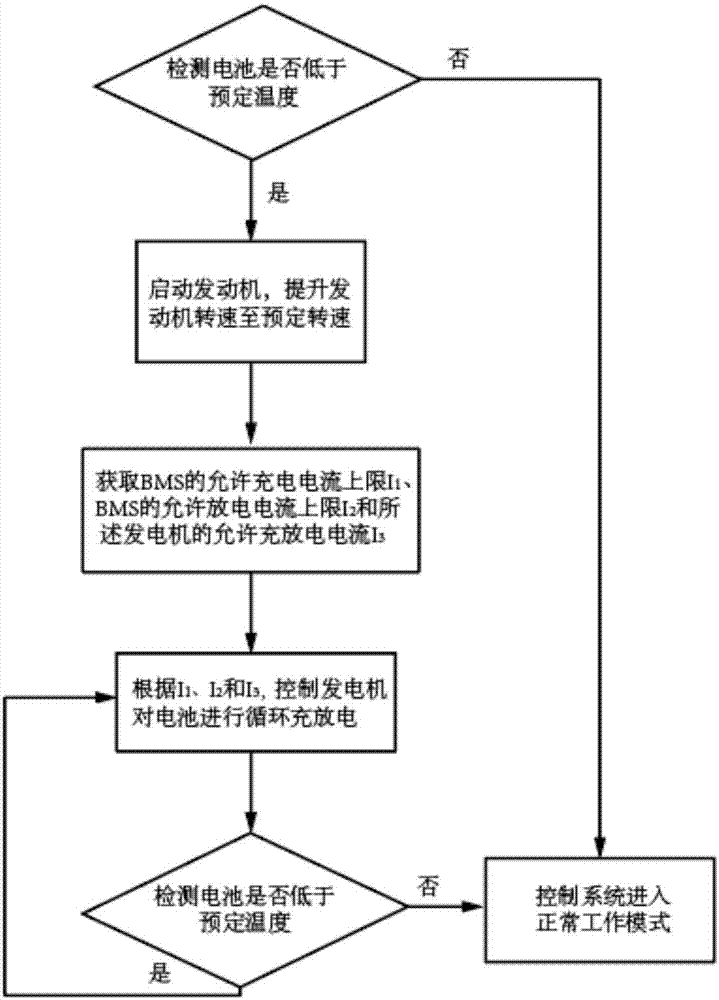

Power battery heating control method applied to hybrid electric vehicles

ActiveCN107317067AAchieve preheatingSimple structureSecondary cells charging/dischargingElectrical batteryCharged current

The invention discloses a power battery heating control method applied to hybrid electric vehicles. The power battery heating control method is characterized by comprising the following steps: S1, controlling electrification of a system, and detecting whether battery temperature is lower than a preset temperature, if yes, entering into step S2, and if not, entering into step S5; S2, starting an engine, and enabling engine speed to be a preset speed; S3, acquiring the allowable charging current upper limit I1 of BMS, the allowable discharging current upper limit I2 of BMS and the allowable charging and discharging current I3 of the engine; S4, controlling the engine to carry out cyclic charging and discharging on a battery according to I1, I2 and I3 so as to quickly heat the battery, so that the battery reaches the preset temperature; and S5, relieving an alarm, and controlling the system to be in a normal work mode. The power battery heating control method applied to the hybrid electric vehicles disclosed by the invention is simple and good in heating effect.

Owner:XIAMEN GOLDEN DRAGON BUS

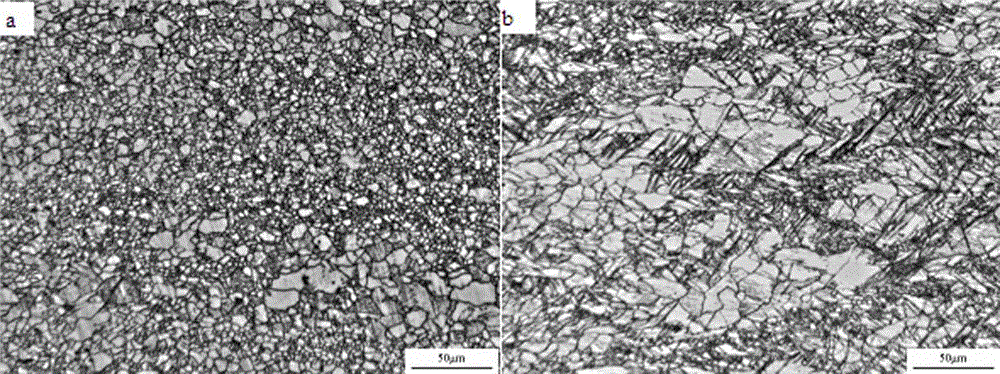

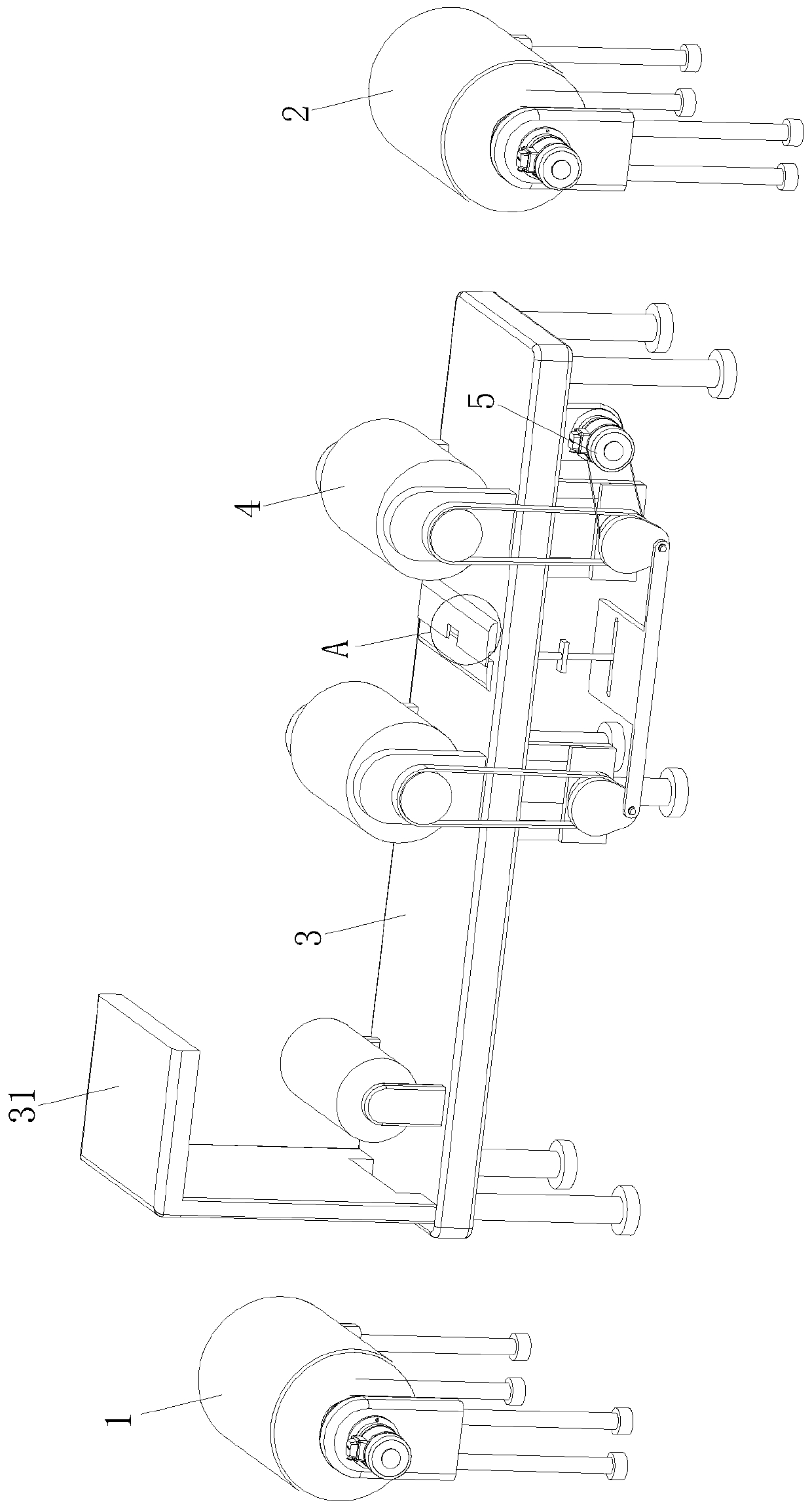

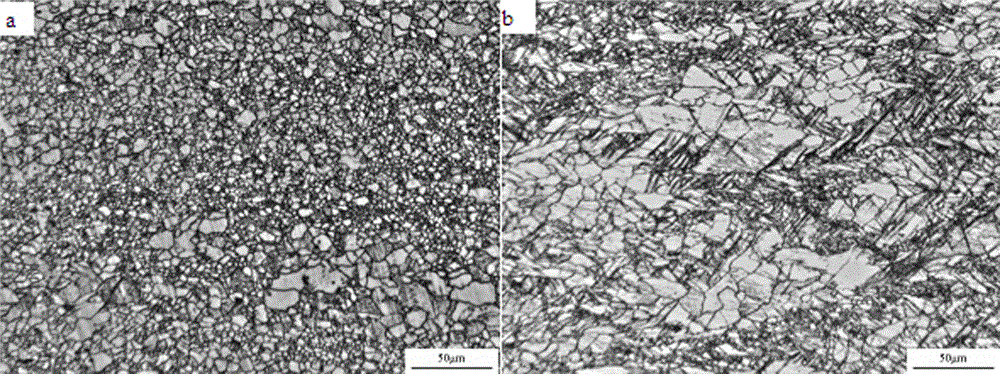

Shearing extrusion-rolling composite forming method and device for preparing high-performance panel

ActiveCN106984667AImprove surface qualityGood formabilityMetal working apparatusMetal rolling arrangementsShear formingMetal

The invention discloses a shearing extrusion-rolling composite forming method for preparing a high-performance panel. The method comprises the following steps that a shearing extrusion forming device is firstly utilized for repeated shearing forming, and blank grains are refined; then thinning shearing forming is conducted, and a metal panel with a strong shearing texture is prepared; and finally, the surface quality of the panel is improved through rolling deformation, meanwhile, the texture is balanced, and the metal panel forming performance is improved. A die is simple in structure, convenient to operate and low in cost, panel equal-thickness repeated shearing forming and thinning shearing extrusion forming functions can be achieved, a heating device on the device can be adopted for preheat treatment to improve the plastic deformation capability of the panel, a fine grain panel with a strong shearing texture is prepared through the shearing extrusion forming device, finally, panel surface quality improving and texture balancing are achieved through rolling, and the high-performance metal panel with the excellent mechanical performance is prepared. The invention further discloses a shearing extrusion-rolling composite forming device for preparing the high-performance panel.

Owner:HUNAN UNIV OF SCI & TECH

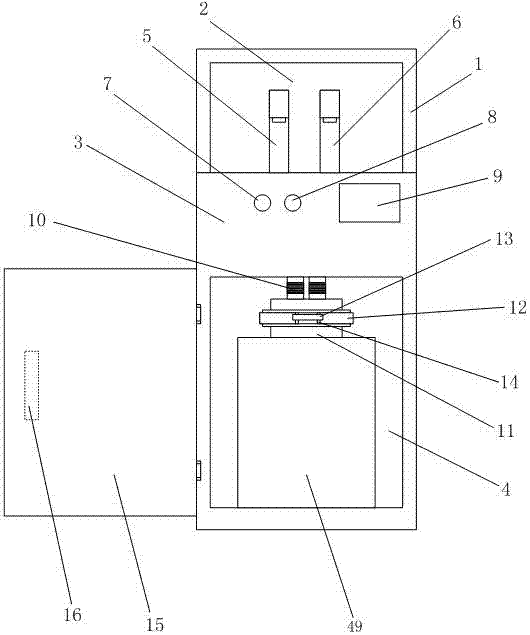

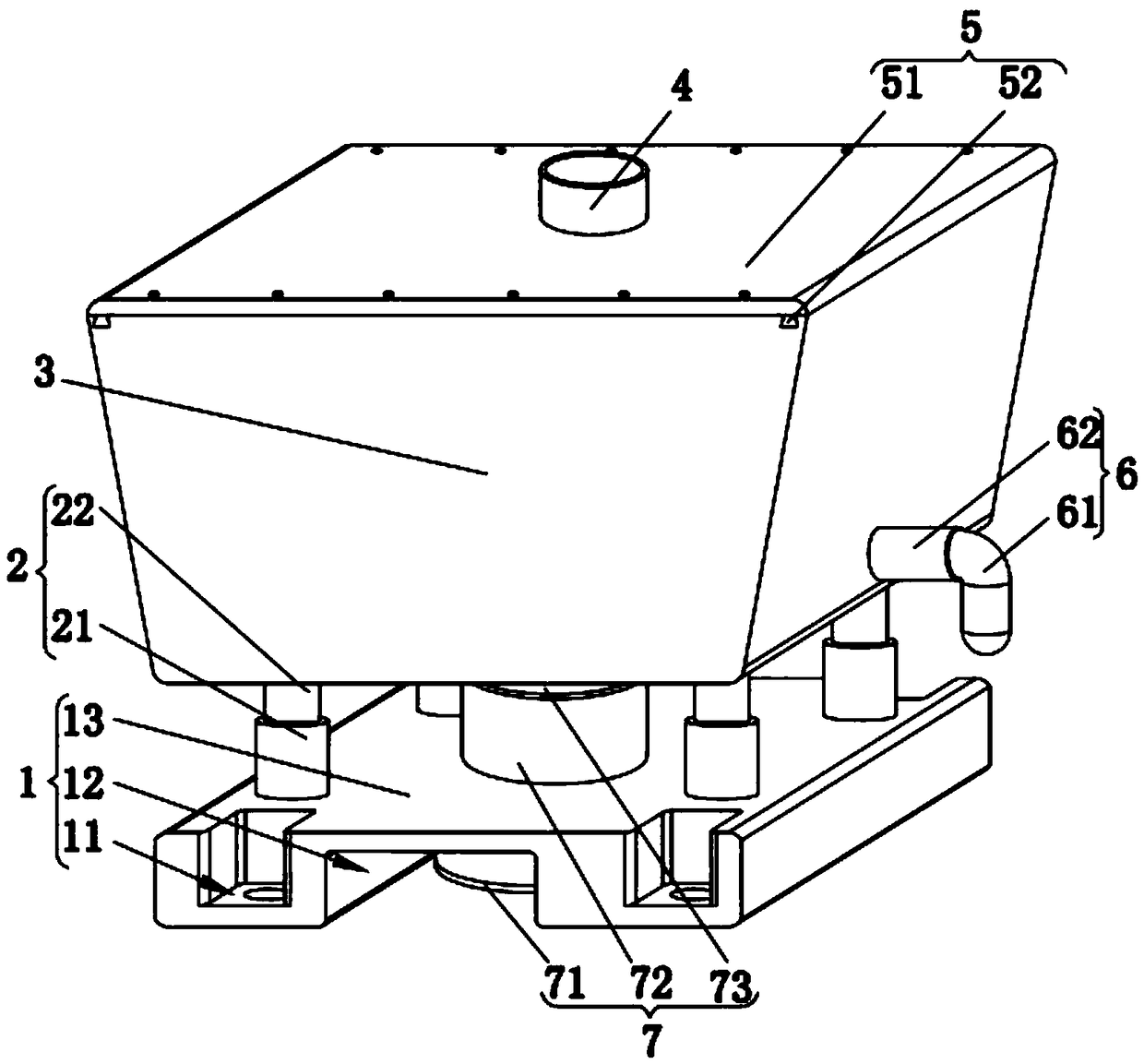

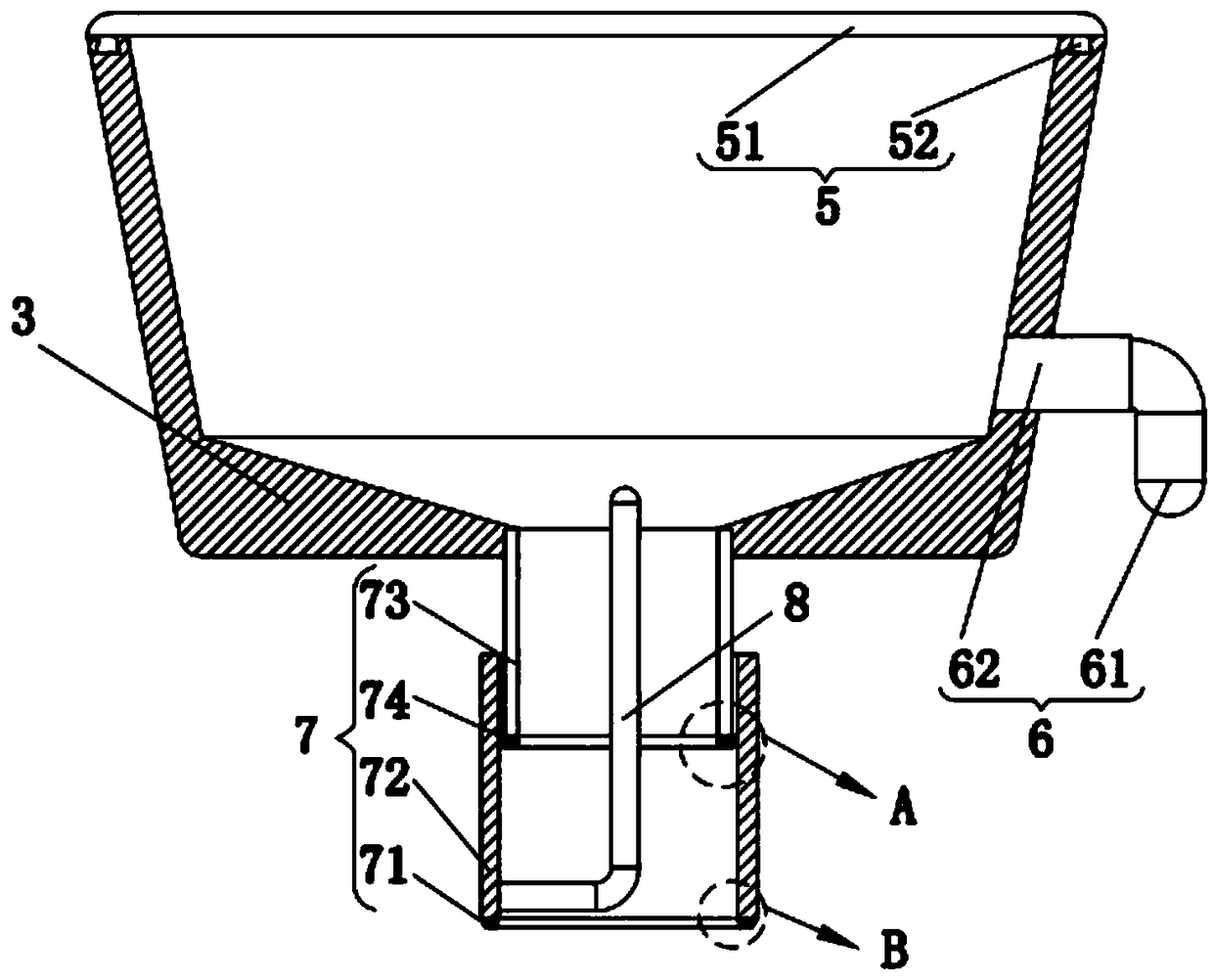

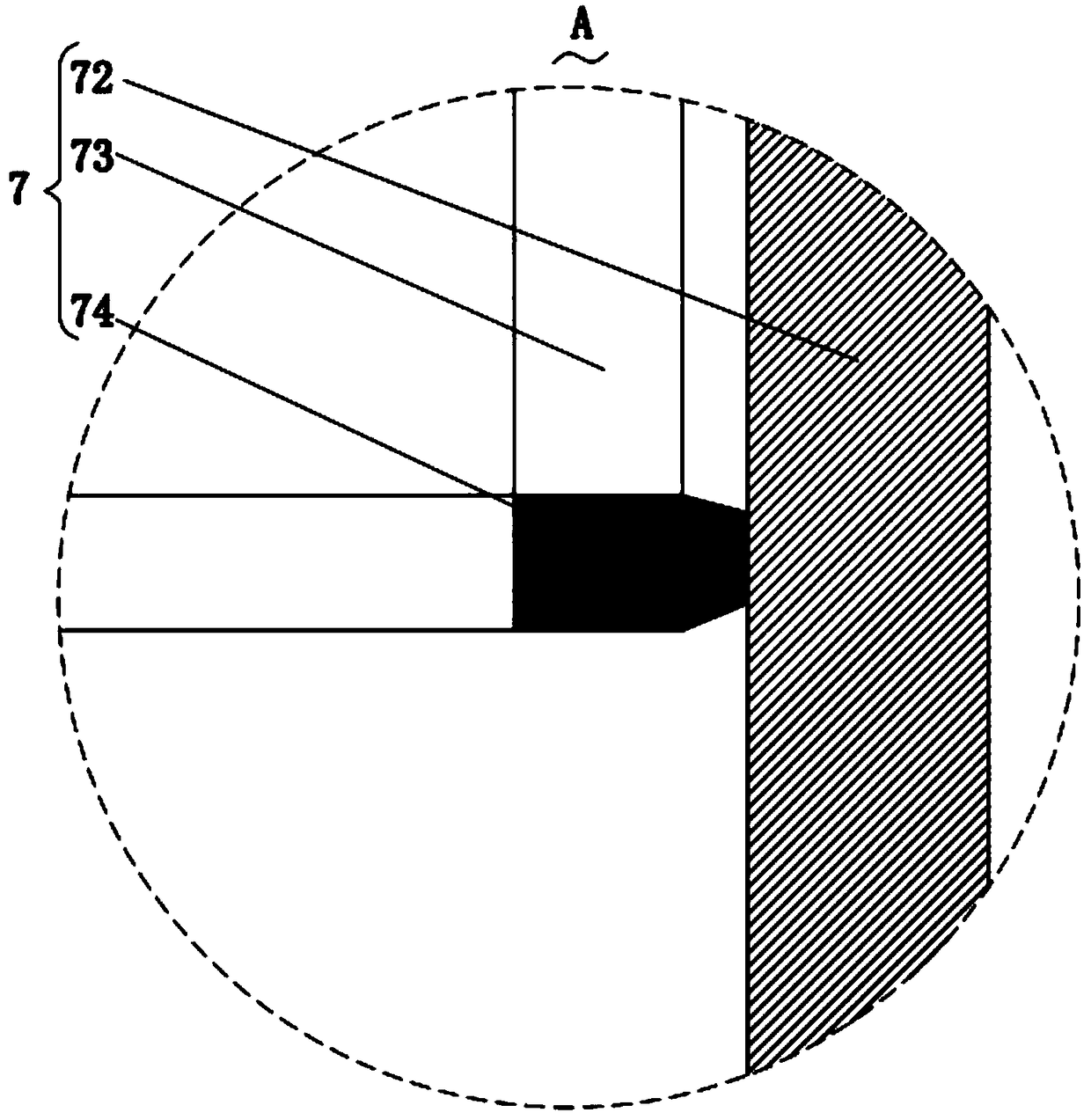

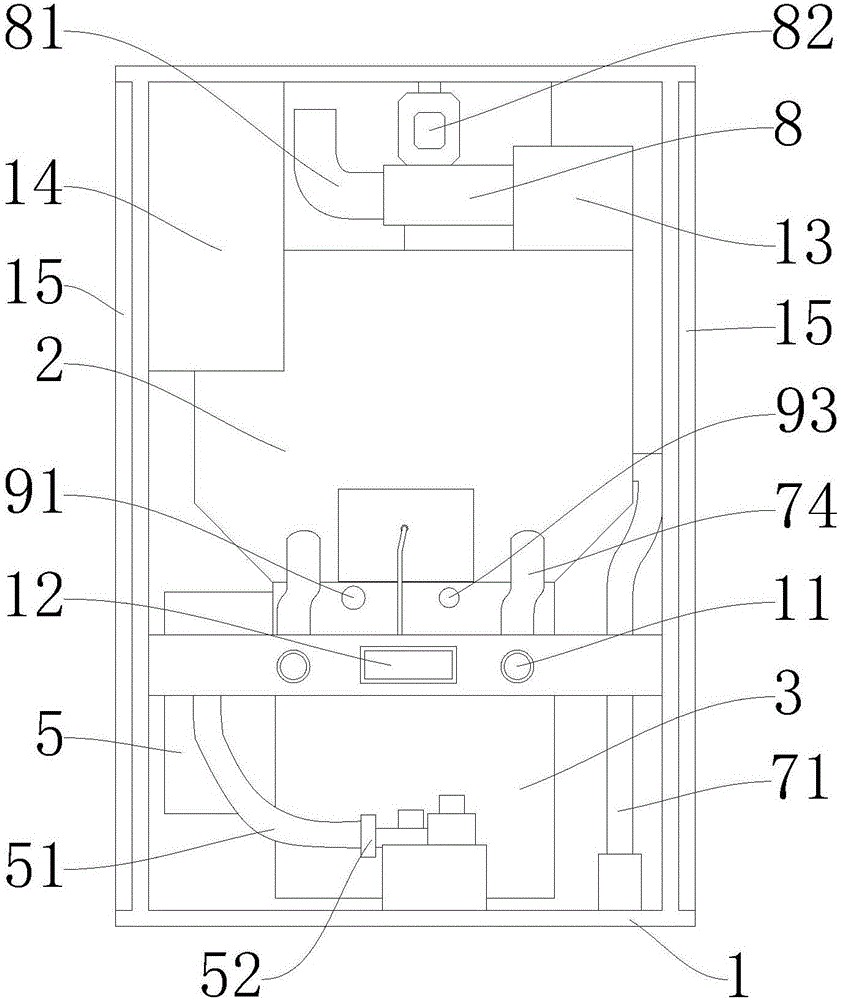

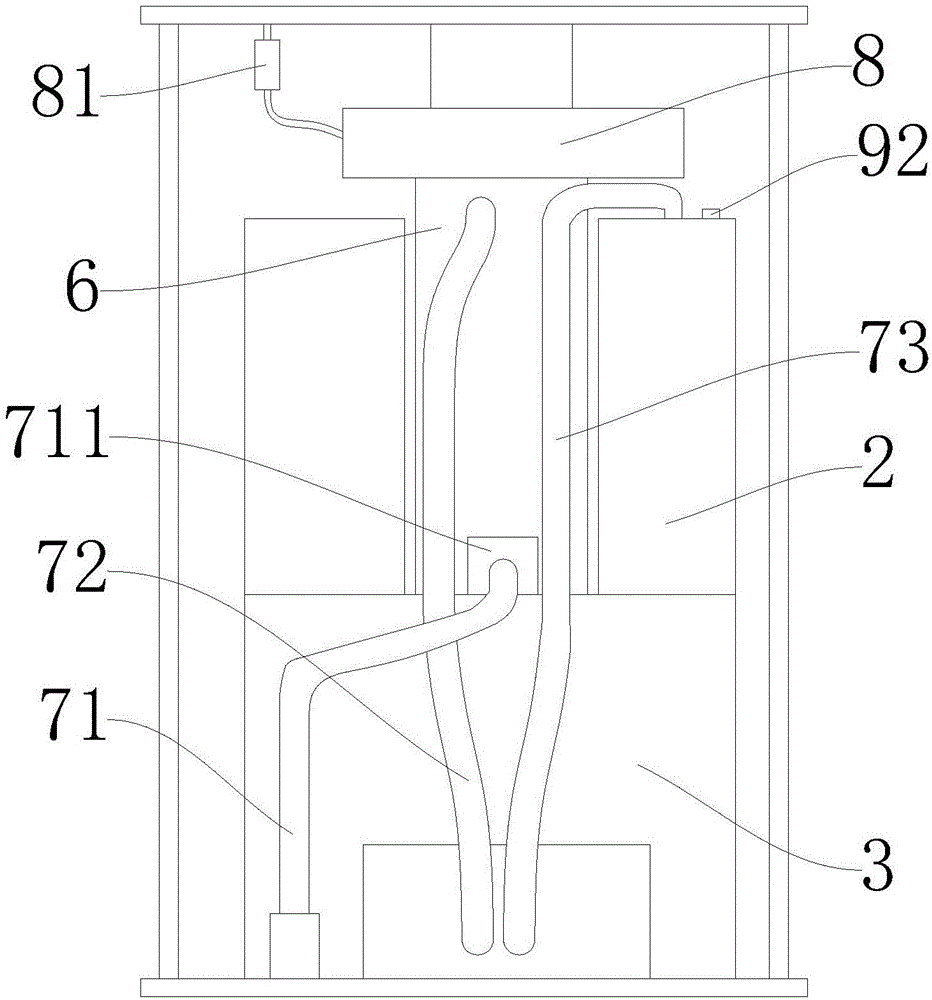

Water dispenser

PendingCN107874616ARealize the insulation effectAchieve preheatingBeverage vesselsWater flowEngineering

The invention provides a water dispenser. The water dispenser includes a cabinet body and a water barrel connector; the upper portion of the front side of the cabinet body is provided with a water receiving chamber, the middle of the front side of the cabinet body is provided with heating control chamber, and the lower portion of the front side of the cabinet body is provided with a water barrel placement chamber; a hot water faucet and a cold water faucet are installed in the water receiving chamber; a panel on the front side of the heating control chamber is provided with a cold water buttonand a hot water button; a heater, an aeration mechanism, a control module and a power supply module are arranged in the heating control chamber. The water dispenser applies pressure to the inside ofa water barrel through the cooperation of the water barrel connector and an air pump, water flow is made to be pressed into a water inlet pipe along a water receiving pipe so as to be supplied to a hot water inlet pipe and a cold water outlet pipe, the water barrel does not need to be carried to the upper portion for installation, time and labor are saved, and the water dispenser is convenient touse.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

High-temperature flue gas purification treatment device for biomass boiler

InactiveCN109210558AReduce energy consumptionLow costCombustion technology mitigationStationary tubular conduit assembliesThermal energyAir blower

The invention discloses a high-temperature flue gas purification treatment device for a biomass boiler. The high-temperature flue gas purification treatment device comprises a biomass combustion boiler, a biomass fuel inlet, a flue gas outlet, a first waste heat utilization device, a flue gas treatment device, a guiding pipe, a feeding channel, a feeding hopper, an air blower, a rack, a high-temperature flue gas pipeline and a combustor; and a base is fixedly mounted at the bottom of the biomass combustion boiler, the combustor is mounted in the biomass combustion boiler, and the biomass fuelinlet is formed in the position, on one side of the combustor, of the biomass combustion boiler. The high-temperature flue gas purification treatment device is simple in structure, convenient to use,and capable of achieving energy saving and environment protection ; and preheating treatment of biomass fuel and air required by combustion is achieved, energy consumption and the cost of boiler combustion are lowered, the absorption efficiency of harmful substances can be improved through heated water, the flue gas purification effect is ensured, pollution of the biomass combustion boiler on theenvironment is lowered, the utilization rate of boiler flue gas thermal energy is increased, and practicality is higher.

Owner:曾金玉

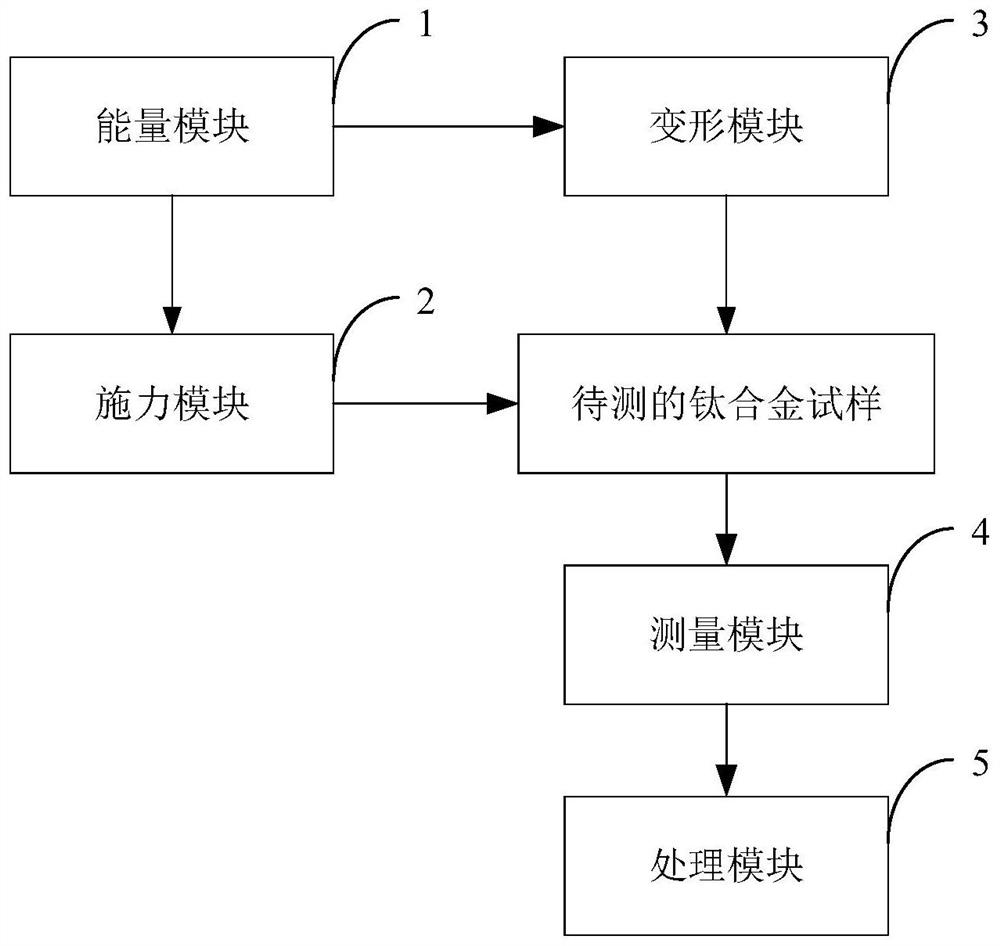

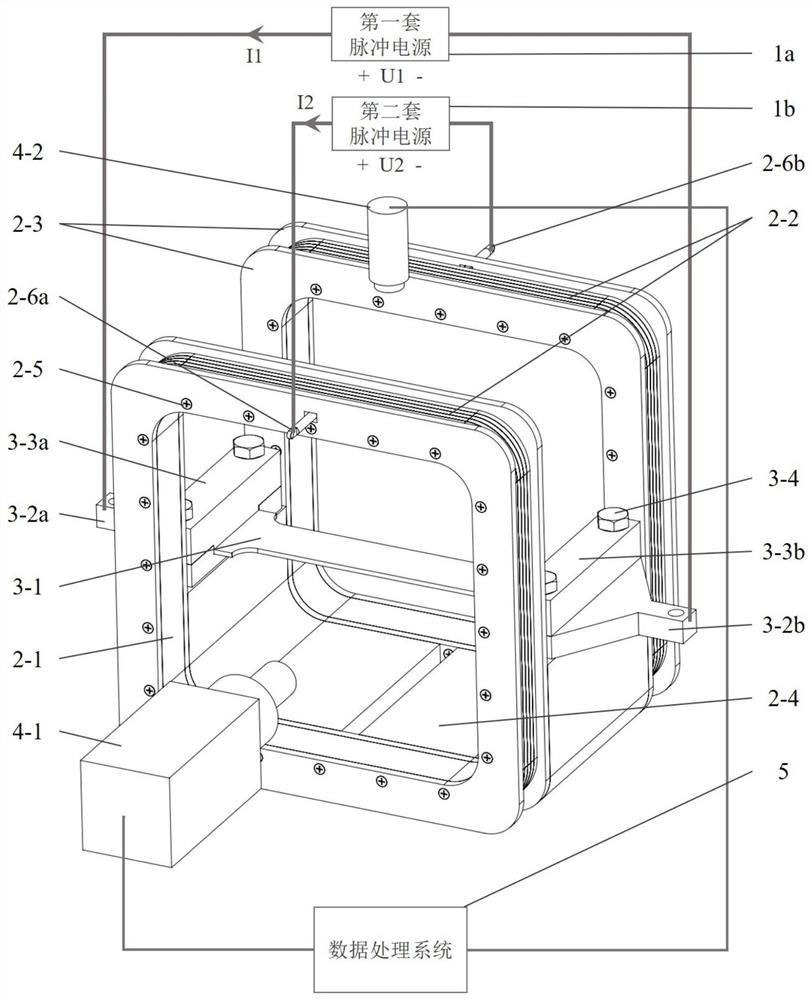

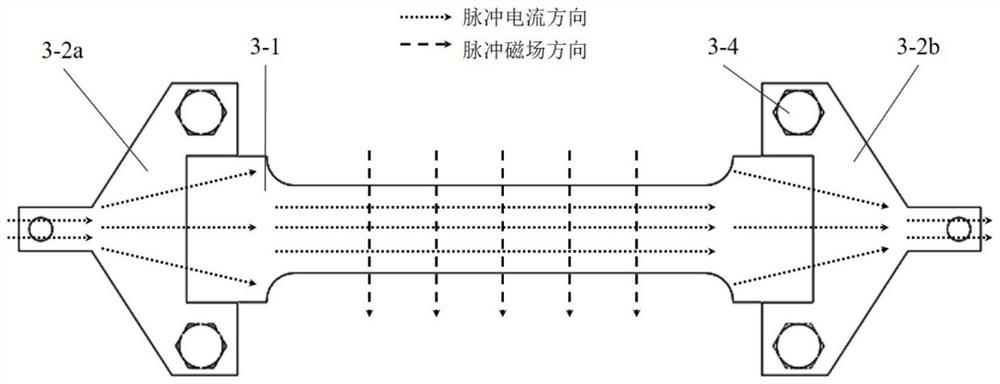

Titanium alloy material stress-strain curve testing device and method under high temperature and high strain rate

ActiveCN111855432AImprove test accuracyStrain rate trueMaterial strength using tensile/compressive forcesTitanium alloyMechanical property

The invention belongs to the field of material mechanical property testing, and discloses a titanium alloy material stress-strain curve testing device and method under high temperature and high strainrate. The testing device comprises an energy module, a force application module, a deformation module, a measurement module and a processing module, wherein the energy module is used for providing afirst pulse current and a second pulse current; the force application module is used for generating pulse electromagnetic force; the deformation module is used for preheating the to-be-measured titanium alloy sample to reach a target temperature after the first pulse current is introduced, and enabling the to-be-measured titanium alloy sample to generate high-speed tensile deformation under the action of the pulse electromagnetic force; the measurement module is used for collecting strain and speed data and temperature data; and the processing module is used for obtaining a stress-strain curveof the titanium alloy material at high temperature and high strain rate according to the strain and speed data and the temperature data. Real temperature, strain rate, strain and stress data can be directly obtained, and the test accuracy is very high.

Owner:HUAZHONG UNIV OF SCI & TECH

Anti-counterfeiting printing press

InactiveCN111532022AEasy to useAchieve preheatingRotary pressesPrinting press partsProcess engineeringPrinting press

The invention belongs to the technical field of printing press equipment, and particularly relates to an anti-counterfeiting printing press which includes a feed roller, a discharge roller, a work table, a printing unit and a heating unit. The printing unit includes a rolling wheel, a printing wheel and a drying wheel; the heating unit includes a motor, a cam, a hinge plate, a heating block and anejector rod; the ejector rod is slidably connected in a through hole, the bottom end of the ejector rod is slidably connected in a second slide groove, and the top end of the ejector rod is in contact with the heating block; the anti-counterfeiting printing of packaging paper is realized by the cooperation of the feed roller, the discharge roller, the work table, the printing unit and the heatingunit; and the situation of shrinking and curling of the packaging paper due to a large temperature difference of the packaging paper in the process of direct contact with the drying wheel is avoided,the printing processing quality of the packaging paper is ensured, and therefore the packaging paper can still ensure a relatively flat surface after printing processing.

Owner:滁州三界外工业设计有限公司

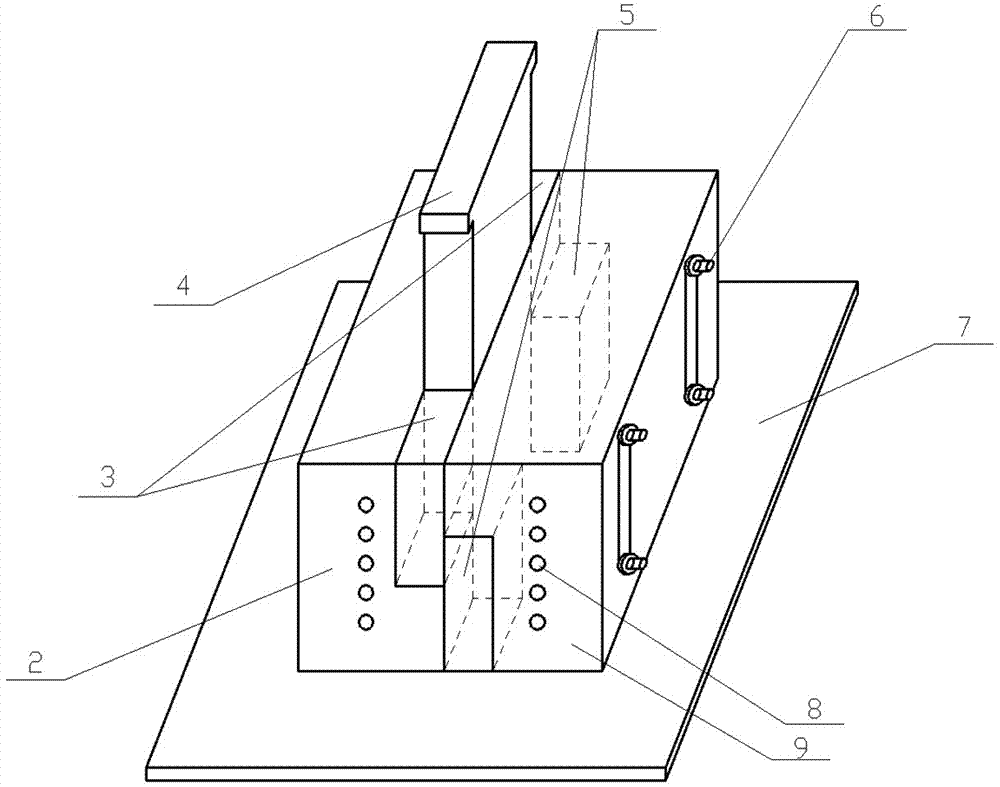

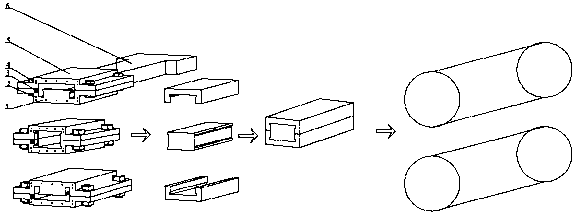

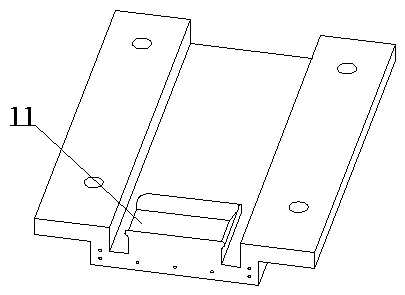

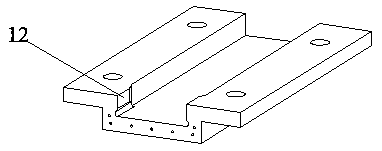

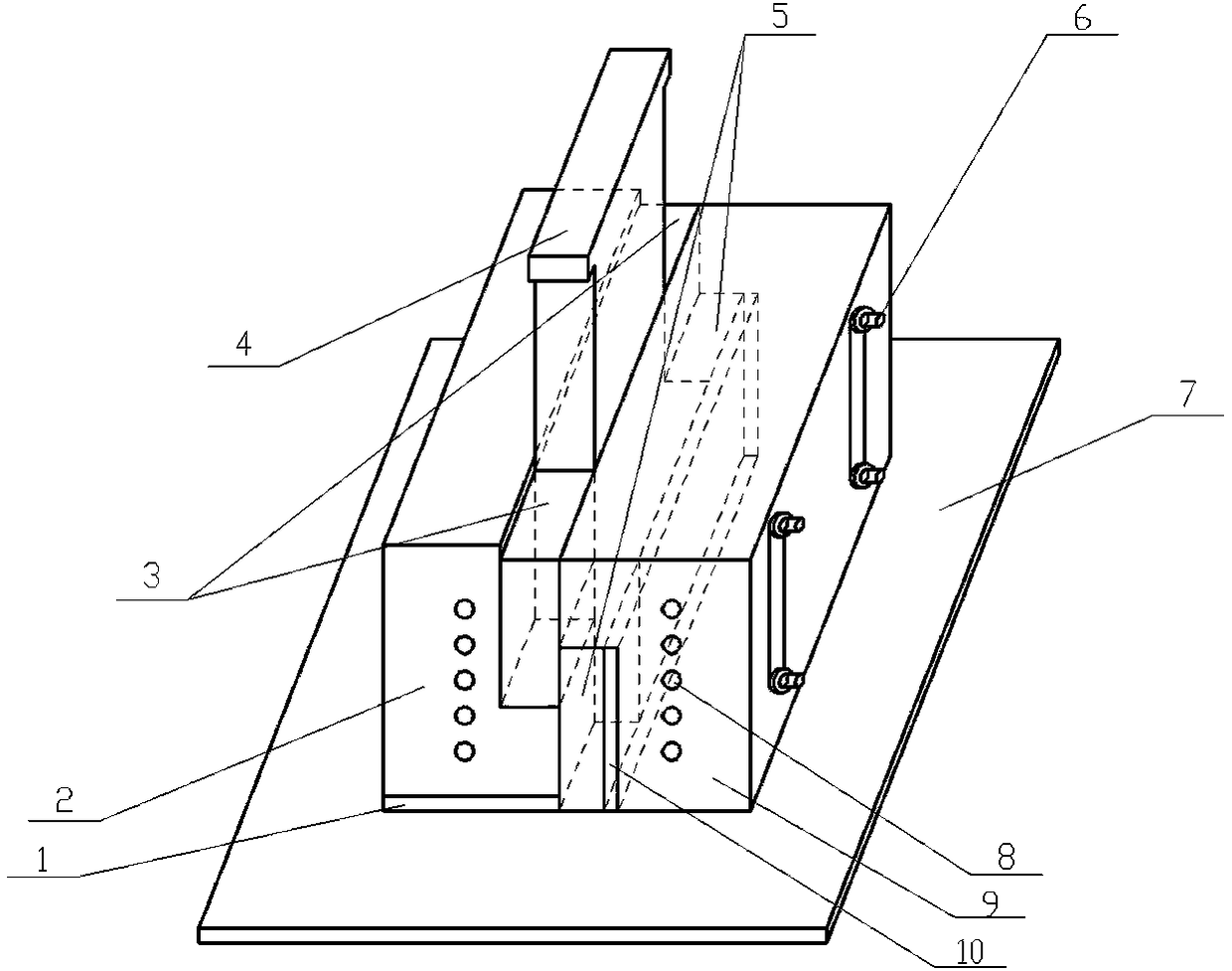

Preparing method and device for aluminum-magnesium-aluminum composite plate

PendingCN110842045AGood bindingReduction of Composite Interface DefectsExtrusion diesExtrusion control devicesAluminum compositesAluminium alloy

The invention discloses a preparing method and device for an aluminum-magnesium-aluminum composite plate. The preparation method includes the steps of homogenizing treatment of aluminum alloys and magnesium alloys, preparation of an I-shaped magnesium alloy blank, preparation of aluminum alloy blanks of a T-shaped cavity, stacking of the two aluminum alloy blanks to form the I-shaped cavity, extrusion of the I-shaped magnesium alloy blank into the two aluminum alloy blanks to obtain a composite blank and rolling treatment. The device is composed of a concave blank extrusion die and a convex blank extrusion die. The two sets of dies are each composed of an extrusion head, an upper die block, a lower die block, a heating device, a temperature measuring device and a fastening device; the lower die block of the concave blank extrusion die is provided with one T-shaped forming block, the convex blank extrusion die is provided with one I-shaped cavity, and the size of the I-shaped magnesiumalloy blank is slightly larger than that of the I-shaped cavity. The device is simple in structure, convenient to operate, capable of achieving three-dimensional compounding of composite materials through the aluminum alloy blanks and the magnesium alloy blank and capable of obtaining high-performance aluminum-clad magnesium composite materials.

Owner:HUNAN UNIV OF SCI & TECH

Method and device for strong shear rolling forming of metal sheet

ActiveCN104646416BGrain refinementImprove microstructureForging/pressing devicesMetal rolling arrangementsShearing deformationEngineering

The invention discloses a strong-shear rolling forming method and a strong-shear rolling forming device for a metal plate. Power is provided by friction force between the plate and rollers during rolling deformation, and the plate is subjected to the strong-shear deformation of dies, and then enters a part between the rollers for plate rolling deformation. The device comprises a double-roller rolling mill, a movable die upper template, a movable die lower template, a stand, a fixed die lower template and a fixed die upper template, wherein the fixed die lower template is fixedly arranged on the stand; the movable die lower template is hinged to the fixed die lower template, and is arranged on the stand through an oil cylinder; the fixed die upper template and the movable die upper template are arranged on the fixed die lower template and the movable die lower template through bolts respectively; the double-roller rolling mill is arranged at an outlet of a metal plate passage. The method and the device are flexible in die equal channel angular adjustment and low in cost; the rolling deformation and the shear deformation of the metal plate such as a magnesium plate and an aluminum plate can be effectively combined, crystal grains of the plate can be refined, the texture evolution of the plate can be controlled, and the mechanical performance and the forming performance of the plate can be improved.

Owner:HUNAN UNIV OF SCI & TECH

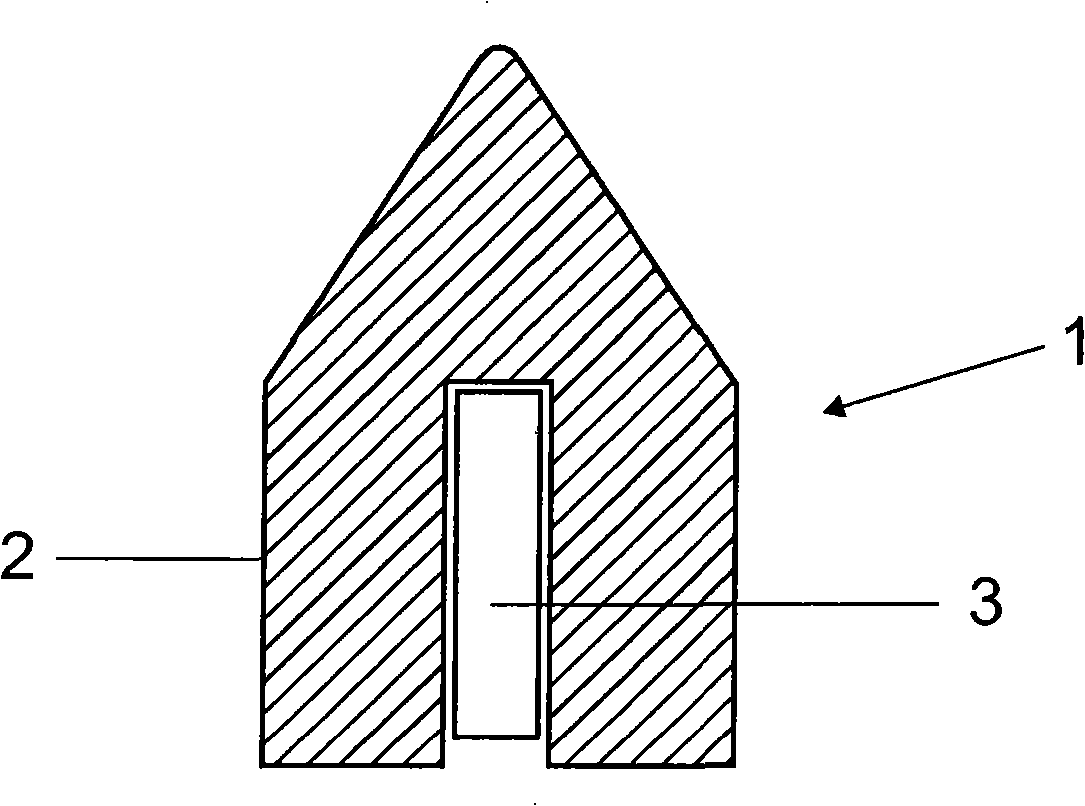

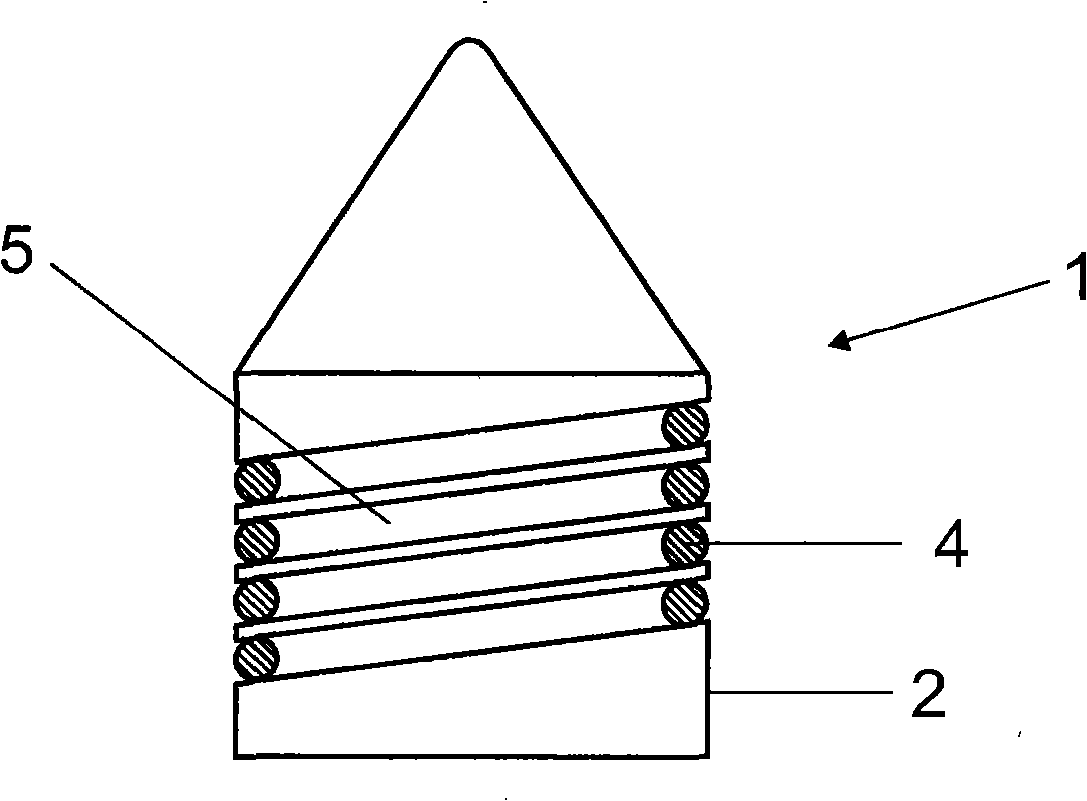

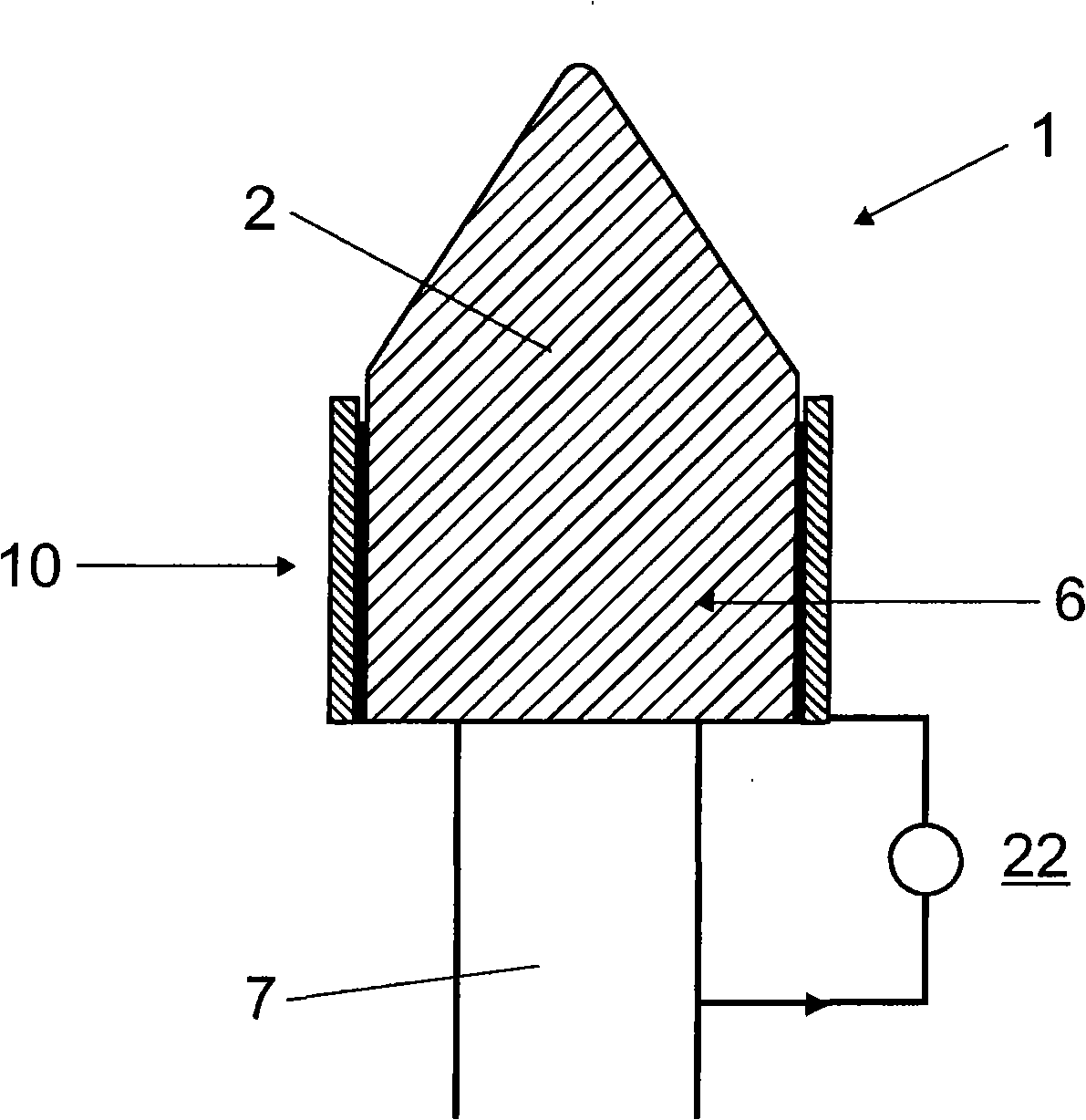

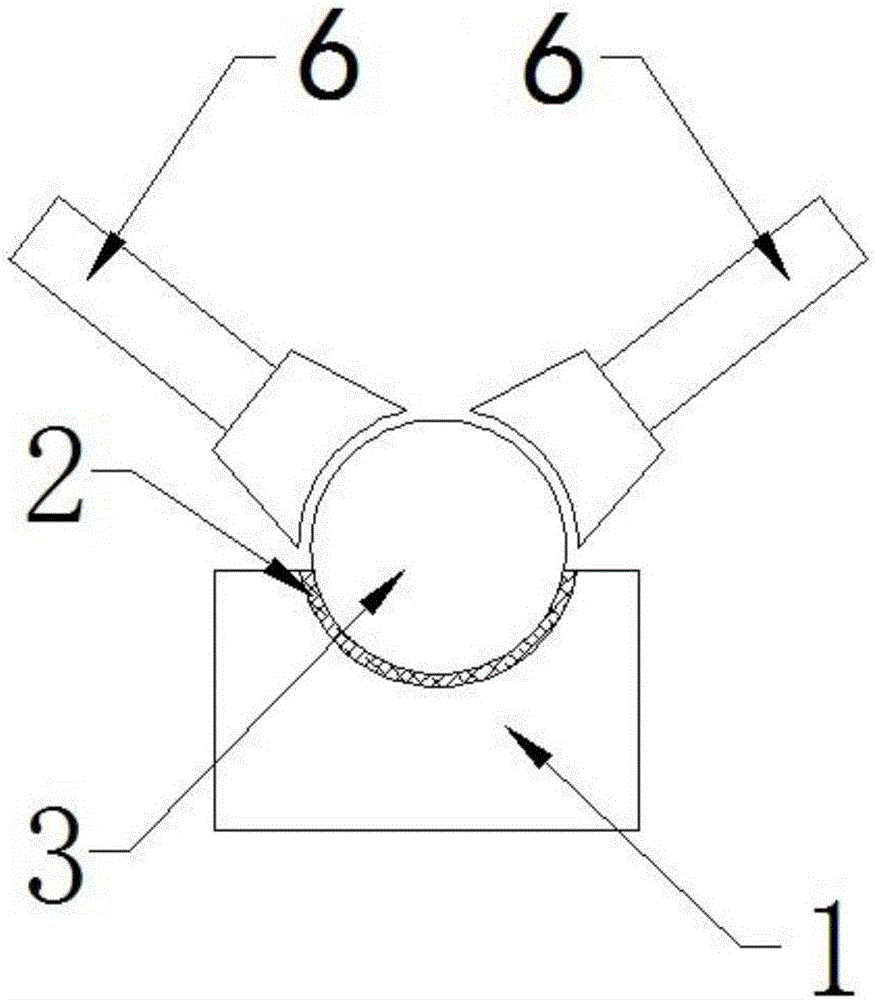

High pressure discharge lamp with discharge chamber

InactiveCN101263578AIncrease temperatureSupport dim featureHigh-pressure discharge lampsGas discharge lamp detailsHigh pressureElectrical and Electronics engineering

The invention relates to an electrode (1) of a high pressure discharge lamp with a heating device (3) housed in the head (2) in order to compensate for problems in dimmed operation.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

Tin-lead soldering method for base station antenna

The invention provides a tin-lead soldering method for a base station antenna. The method includes the following steps that firstly, a first structural part and a second structural part are fixed so that to-be-welded faces of the first structural part and the second structural part can be in contact with each other or be spaced by a preset distance; secondly, multiple welding heads on an automatic welding device are used for heating the first structural part and / or the second structural part at the same time to achieve preheating treatment; and thirdly, the multiple welding heads on the automatic welding device are used for heating the first structural part and / or the second structural part at the same time, and welding flux is put into the first structural part and / or the second structural part at the same time till the preset heating time is reached. According to the tin-lead soldering method, the consistency of the strength of the face of weld is improved, the welding stability is improved, and the welding work efficiency is improved.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

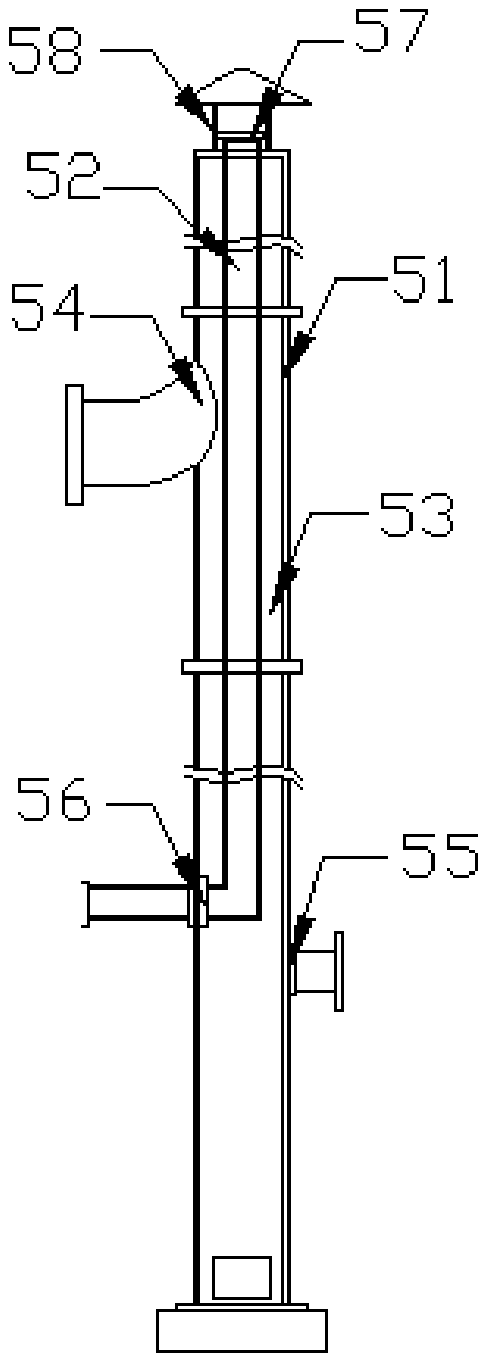

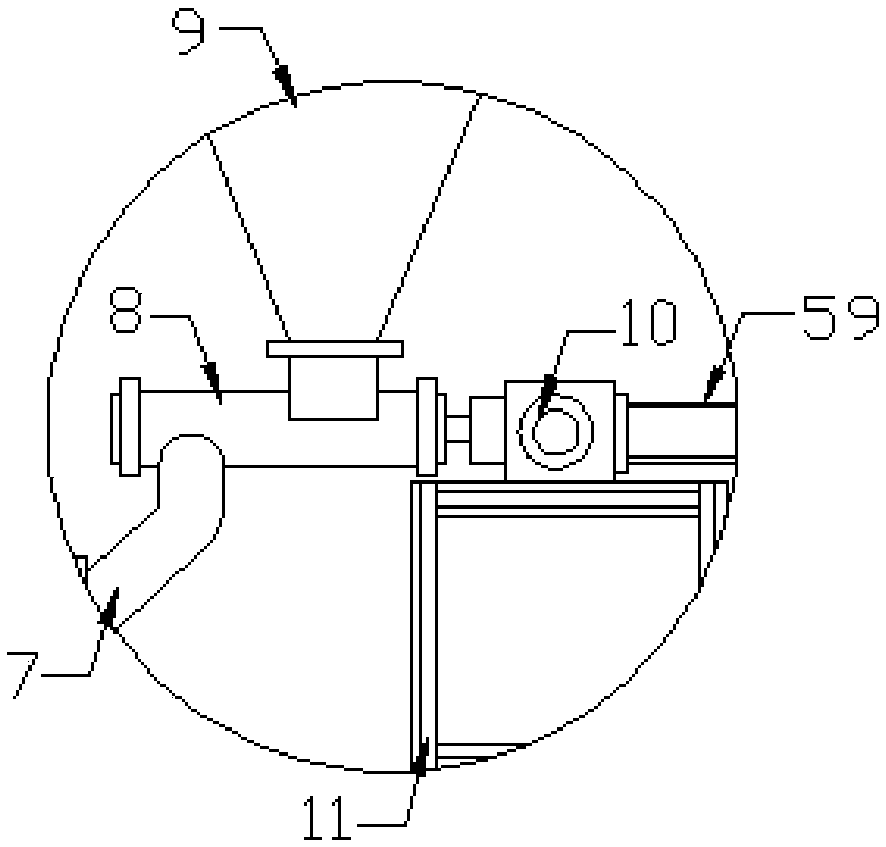

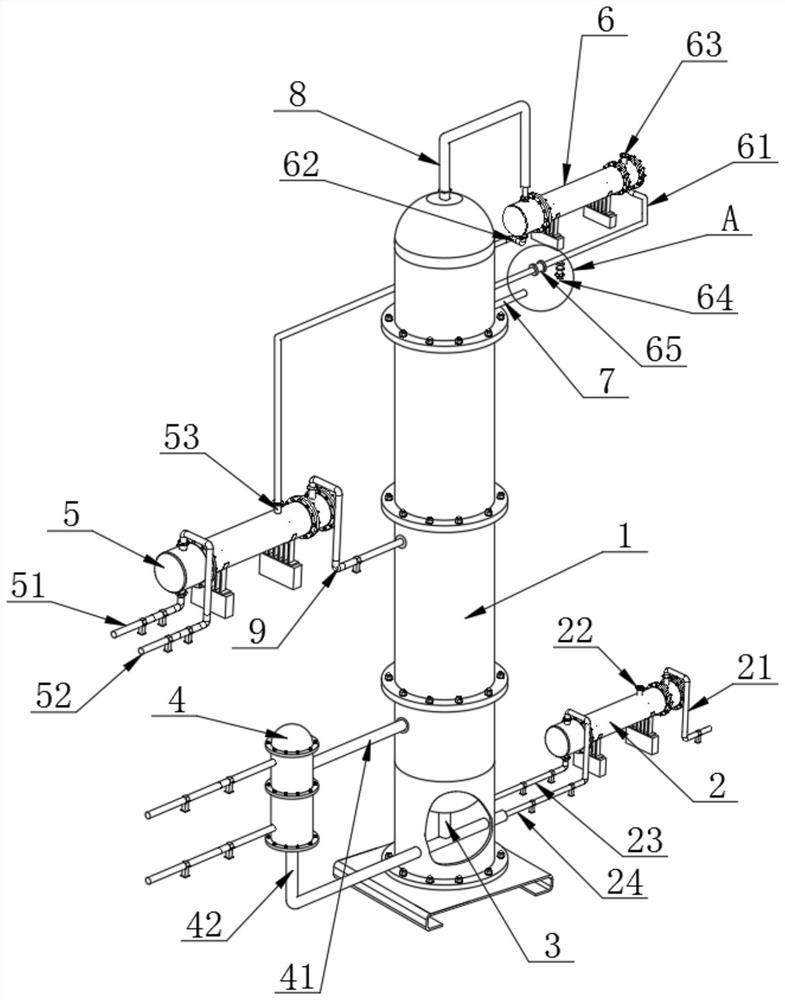

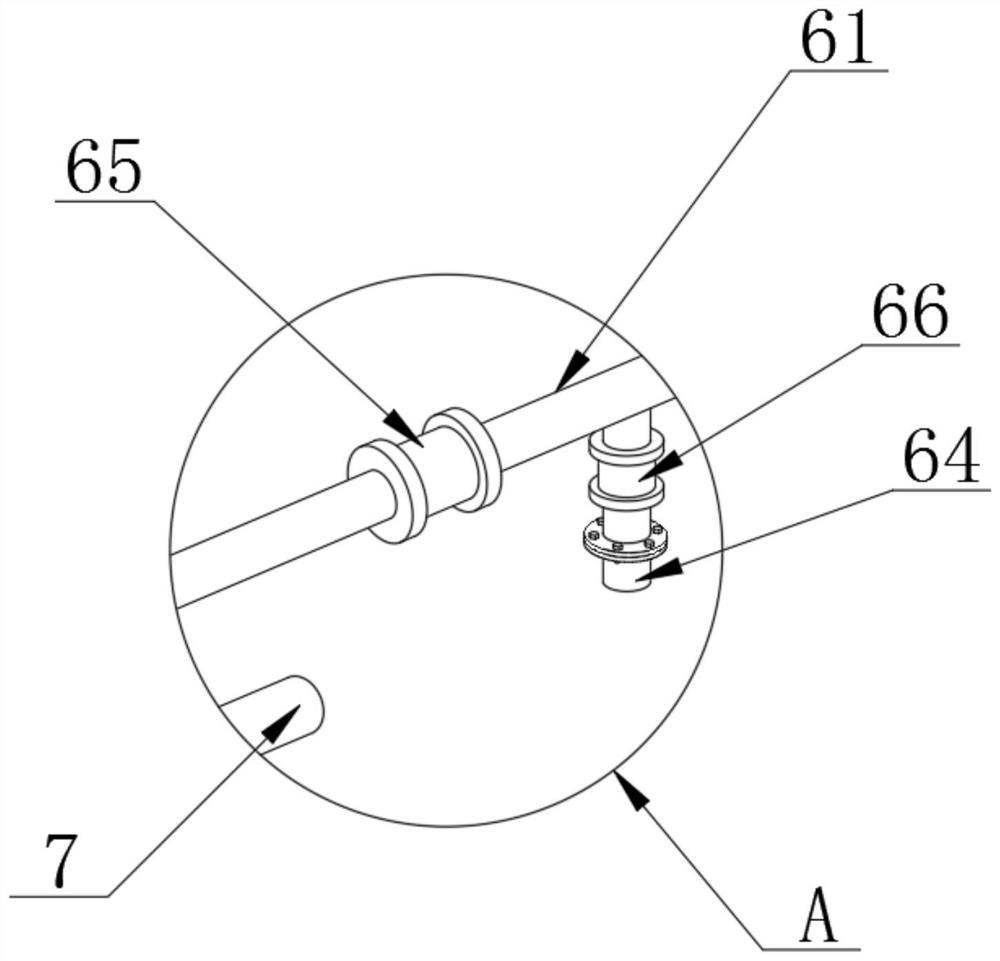

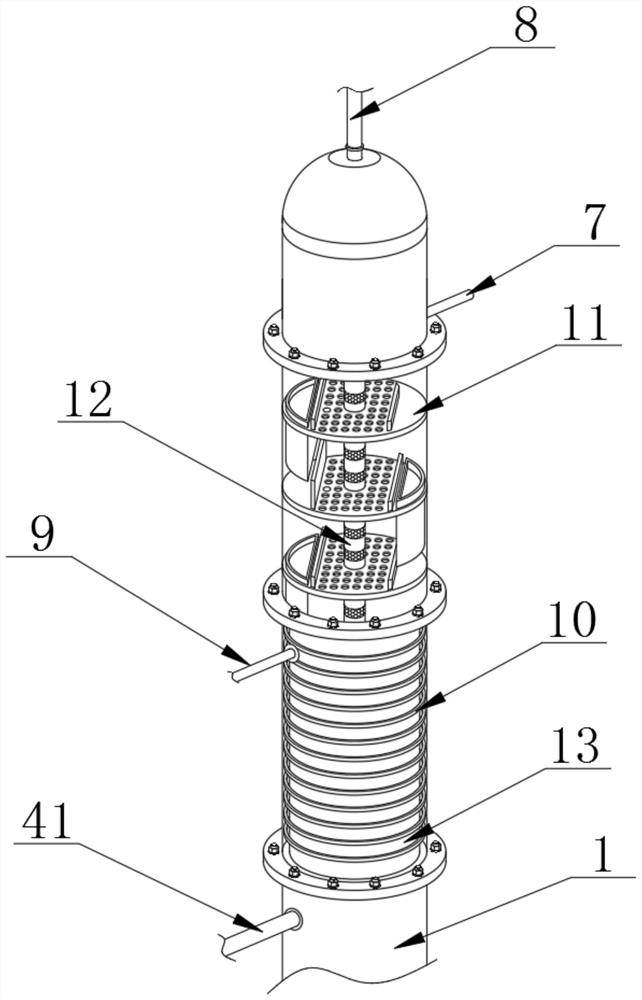

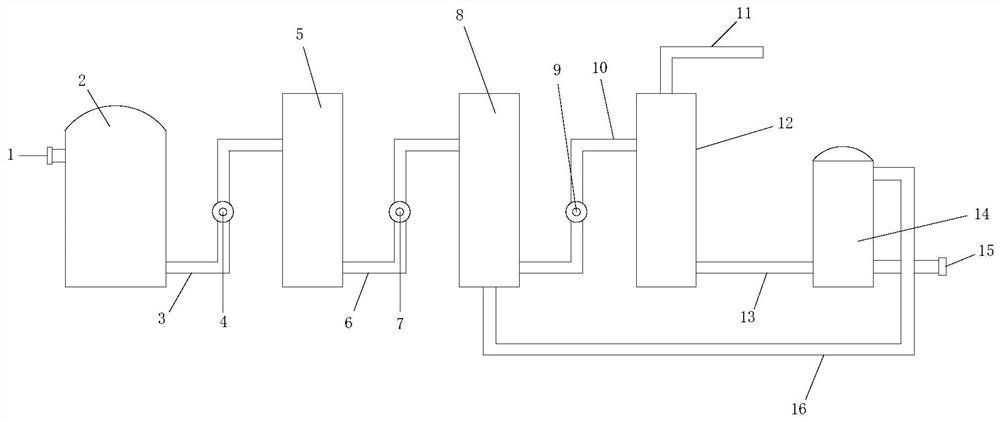

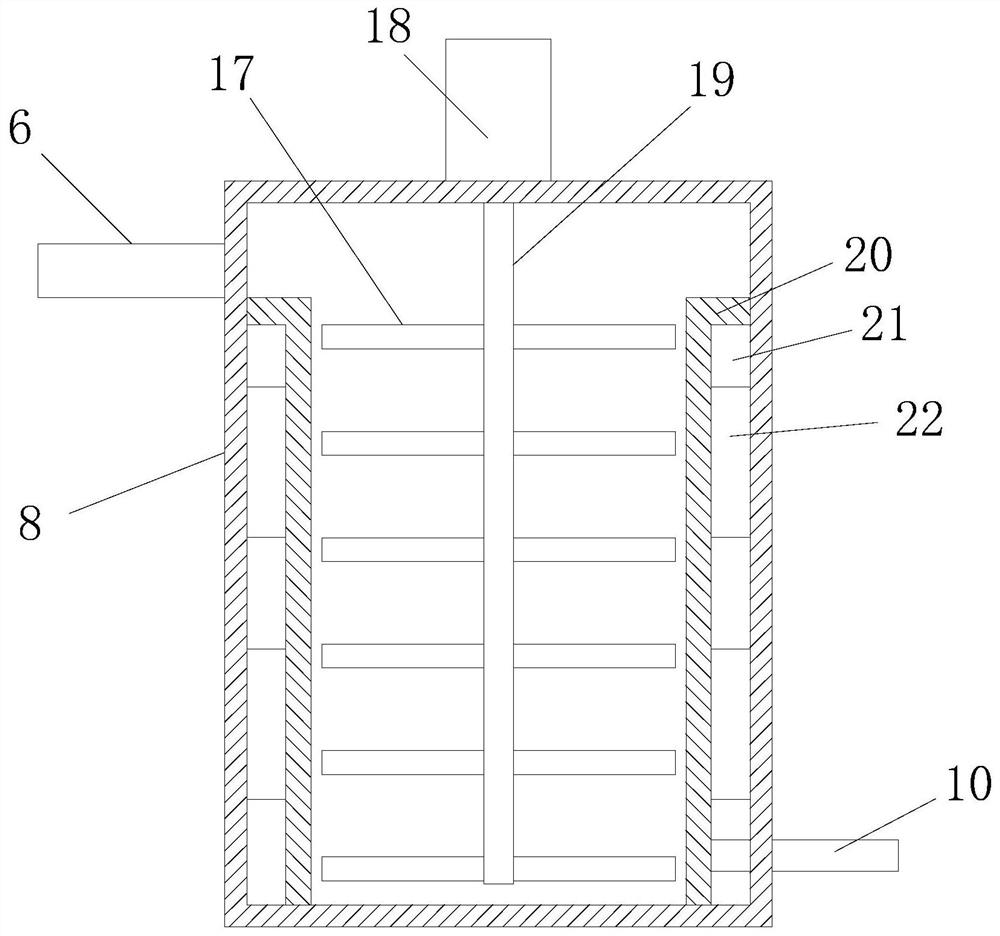

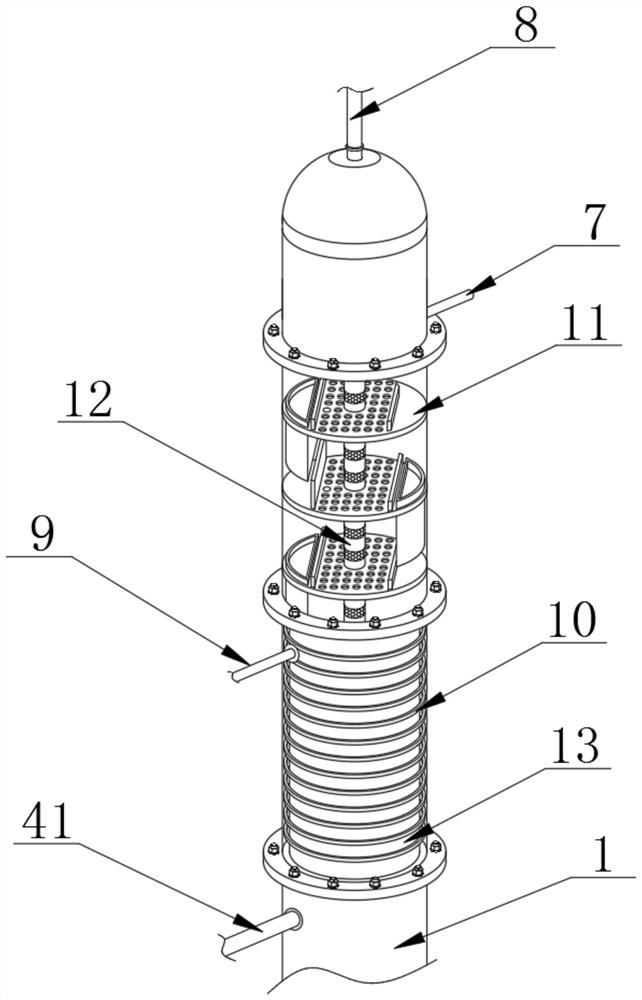

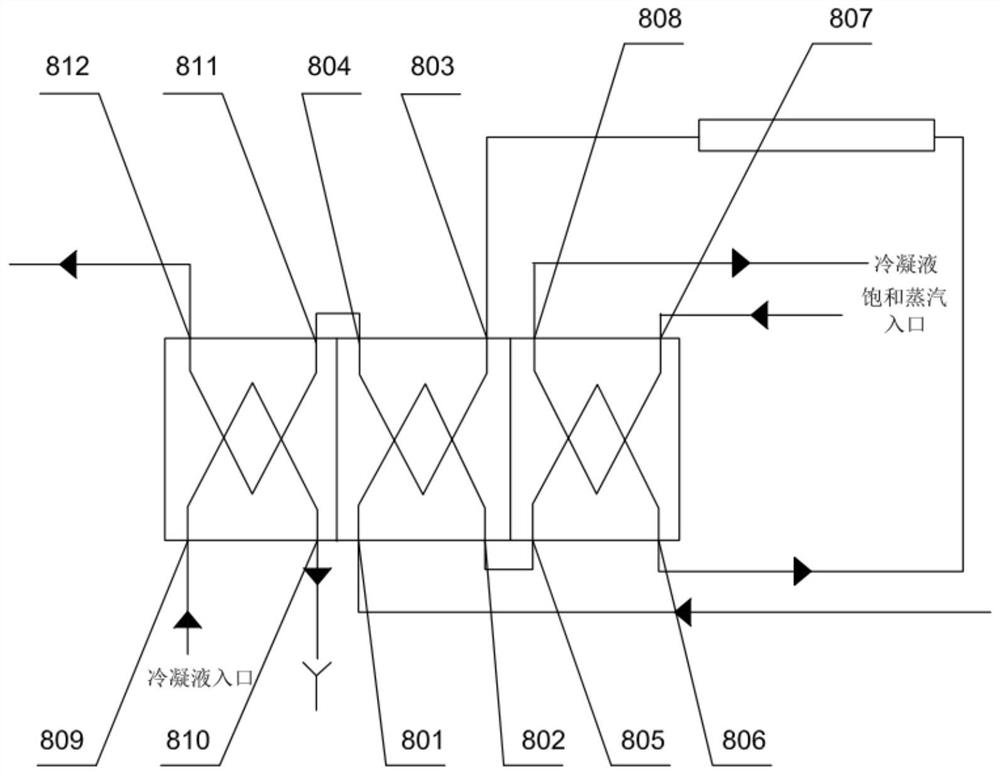

Improved column tray packing type rectifying column for molecular distillation

ActiveCN111803986AEnsuring Distillation EfficiencyImprove distillation efficiencyFractional distillationReboilerGas phase

The invention relates to the technical field of molecular distillation, and discloses an improved column tray packing type rectifying column for molecular distillation. The column comprises a column body, wherein a discharged material heat exchanger is arranged on one side of the bottom end of the column body; a reboiler is arranged on the other side of the bottom end of the column body; a fed material heat exchanger is arranged on the outer side of the middle of the column body; the middle part of the top end of the column body is communicated with a gas-phase matter discharge pipe, the otherend of the gas-phase matter discharge pipe is connected with a column top heat exchanger, an inner cavity is formed in the column body, a first circulating pipe is arranged in the inner cavity in a surrounding manner, a plurality of column plates are distributed in the column body from bottom to top, and a central pipe is arranged in the column body and penetrates through the centers of the column trays. According to the rectifying column, heat recycling is achieved, heat preservation of the column body is facilitated, heat loss of the column body is avoided, materials can be preheated, a plurality of steam layers are conveniently formed in the column body through cooperation of the center pipe and the gas ring, it is guaranteed that steam makes better contact with the materials, and therectifying efficiency of the materials is improved.

Owner:宿迁市盈科新材料有限公司

Device for evaporation by utilizing gas moisture content difference

The invention provides a device for evaporation by utilizing gas moisture content difference, and relates to the technical field of chemical wastewater. The device comprises a heating tower, a coolingtower, a centrifugal machine, a centrifugal mother liquor tank and a centrifugal fan, the lower part of the heating tower is communicated with the centrifugal fan, the bottom of the heating tower iscommunicated with the centrifuge, the other end of the centrifuge is connected with the centrifugal mother liquor tank, and the centrifugal mother liquor tank is communicated with the lower part of the heating tower; the lower part of the heating tower is further communicated with the top of the heating tower through the heat exchange assembly, special filler is arranged in the heating tower, thetop of the heating tower is connected with a flow guide pipe, the other end of the flow guide pipe is communicated with the cooling tower and extends to the bottom in the cooling tower, a tower tray is arranged in the cooling tower, and the bottom of the cooling tower is further communicated with the heat exchange assembly; the device further comprises a water cooling circulation assembly which communicates with the cooling tower, and the top of the cooling tower is further connected with the heat exchange assembly. The device has the advantages of low energy consumption, simplicity and convenience in maintenance, high comprehensive utilization rate and low manufacturing cost.

Owner:安徽聚云环保设备制造有限责任公司

Shear extrusion-rolling compound forming method and device for preparing high-performance plate

ActiveCN106984667BImprove surface qualityGood formabilityMetal working apparatusMetal rolling arrangementsShear formingMetal

The invention discloses a shearing extrusion-rolling composite forming method for preparing a high-performance panel. The method comprises the following steps that a shearing extrusion forming device is firstly utilized for repeated shearing forming, and blank grains are refined; then thinning shearing forming is conducted, and a metal panel with a strong shearing texture is prepared; and finally, the surface quality of the panel is improved through rolling deformation, meanwhile, the texture is balanced, and the metal panel forming performance is improved. A die is simple in structure, convenient to operate and low in cost, panel equal-thickness repeated shearing forming and thinning shearing extrusion forming functions can be achieved, a heating device on the device can be adopted for preheat treatment to improve the plastic deformation capability of the panel, a fine grain panel with a strong shearing texture is prepared through the shearing extrusion forming device, finally, panel surface quality improving and texture balancing are achieved through rolling, and the high-performance metal panel with the excellent mechanical performance is prepared. The invention further discloses a shearing extrusion-rolling composite forming device for preparing the high-performance panel.

Owner:HUNAN UNIV OF SCI & TECH

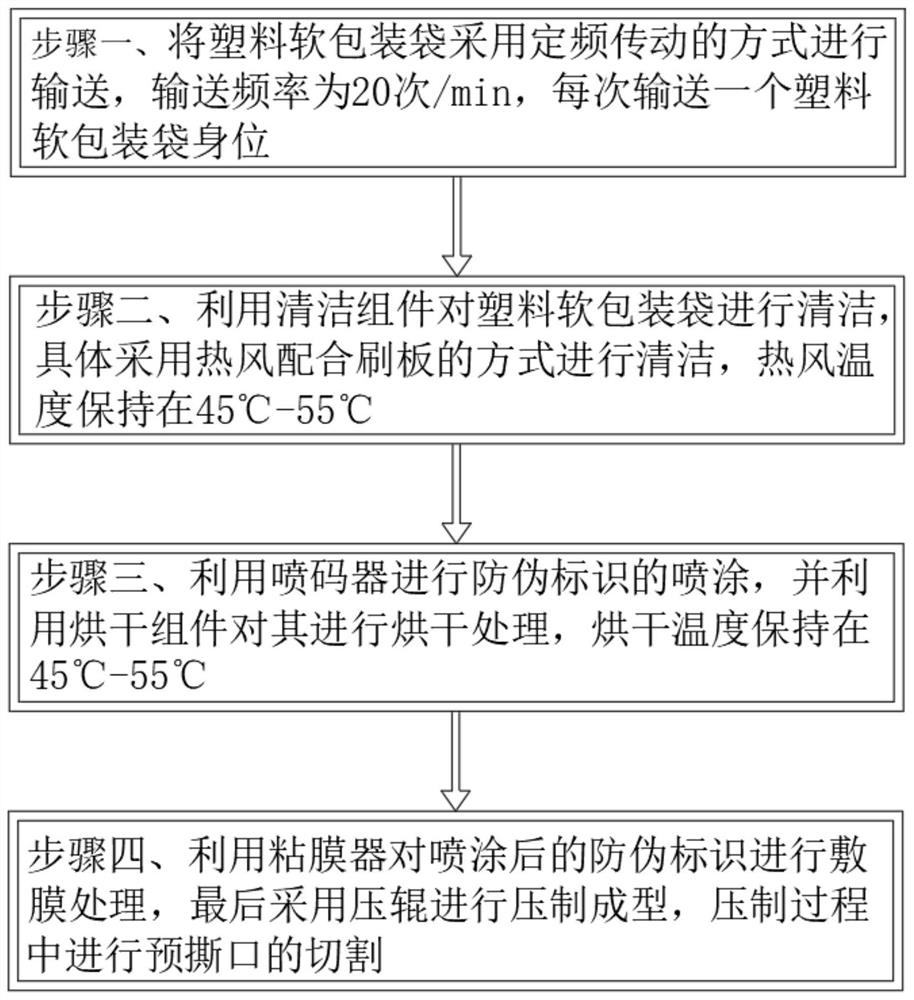

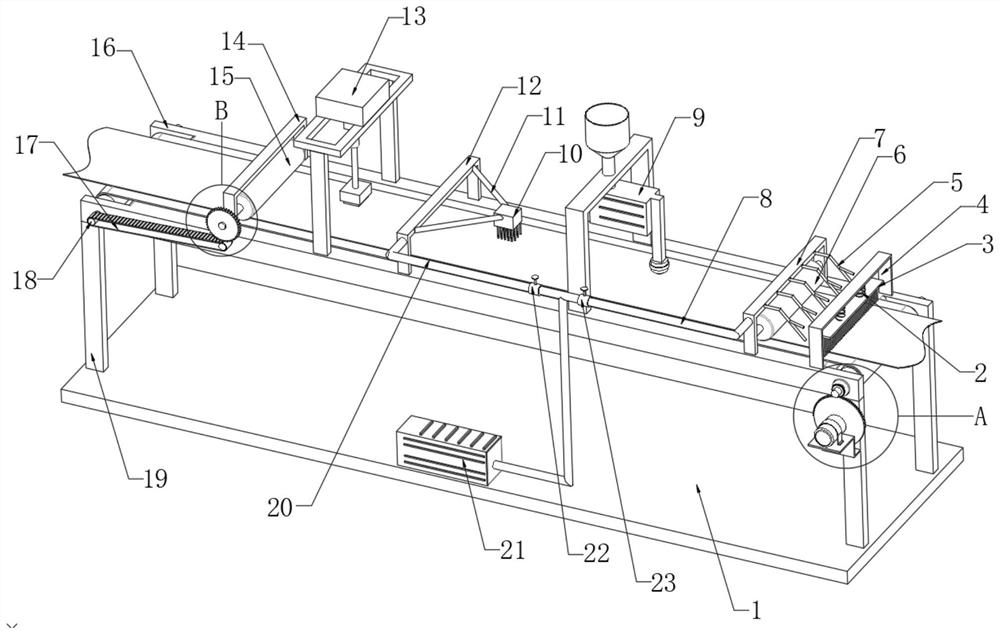

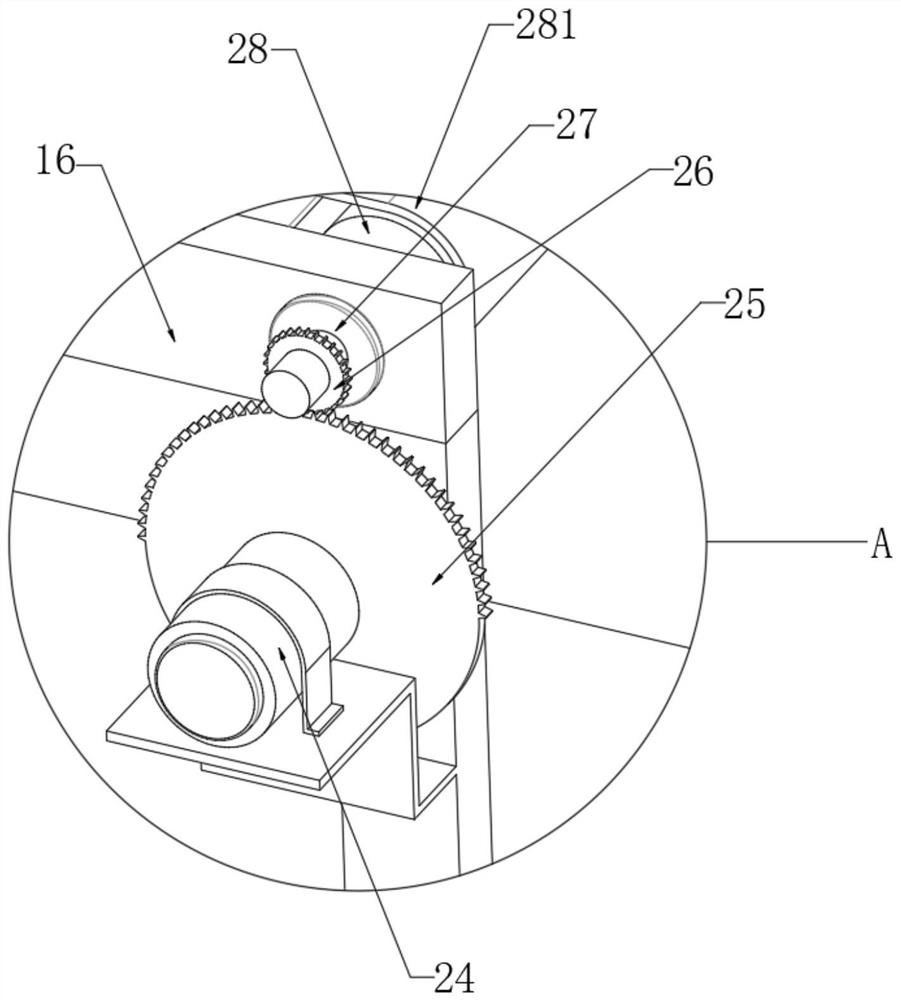

Production process of plastic flexible packaging bag with anti-counterfeiting mark

The invention discloses a production process of a plastic flexible packaging bag with an anti-counterfeiting mark, and relates to the technical field of plastic flexible packaging bag production, the production process of the plastic flexible packaging bag is based on a processing device, and the production process of the plastic flexible packaging bag comprises the following steps: step 1, conveying the plastic flexible packaging bag in a fixed-frequency transmission mode, the conveying frequency is 20 times / min, and one plastic flexible packaging bag body position is conveyed each time; secondly, the plastic flexible packaging bag is cleaned through a cleaning assembly, specifically, cleaning is conducted in the mode that hot air is matched with a brush plate, and the temperature of the hot air is kept at 45-55 DEG C; step 3, spraying an anti-counterfeiting mark by using a code spraying device; hot air sprayed out of the y-head air outlet pipe can be blown to a plastic belt on the frame plate and the brush plate, the brush plate is connected with the first bracket through the connecting spring, and the brush plate can shake under the action force, so that the brushing effect of the brush plate on the surface of a plastic bag is improved.

Owner:李冒林

Material drying unit

InactiveCN111023778AAvoid breakingGuaranteed qualityDrying solid materials with heatDrying gas arrangementsEngineeringAtmospheric sciences

The invention relates to a material drying unit, which comprises a hot air drying region and a cold air drying region. The hot air drying region is used for drying the materials by means of hot air; the cold air drying region is used for drying the materials by means of cold air; and a tempering region is arranged between the hot air drying region and the cold air drying region, and is used for buffering the temperature change from the hot air drying region to the cold air drying region or from the cold air drying region to the hot air drying region. Through setting the hot air drying region and the cold air drying region for drying materials by means of hot air and cold air correspondingly, and setting the tempering region between the hot air drying region and the cold air drying region,the materials pass through the tempering region firstly and then enter the hot air drying region after coming out of the cold air drying region, the temperature of the materials can be buffered in thetempering region to adapt to temperature changes, the materials are prevented from being overheated in the hot air drying region, and the quality of agricultural products is guaranteed.

Owner:河南省农业科学院农副产品加工研究中心

Intelligent fiber stretching mechanism for composite ES short fiber production

ActiveCN113265734AAchieve preheatingAchieve lubricationTextile treatment by spraying/projectingFiberPolymer science

The invention relates to the technical field of fiber stretching equipment, in particular to an intelligent fiber stretching mechanism for composite ES short fiber production. According to the device, an upper mounting frame and a lower mounting frame are sequentially arranged from top to bottom, wherein a preheating box is arranged on the upper mounting frame so that fiber silk threads can be preheated; a spraying cover is arranged above the preheating box so that the fiber silk threads can be lubricated, static electricity of the fiber silk threads can be reduced, the fiber silk threads can be kept soft and smooth, and the stretching quality of the fiber silk threads is improved; a feeding traction roller and a discharging traction roller are arranged on the lower mounting frame; when the running power of a driving motor of the feeding traction roller is lower than that of the discharging traction roller, the fiber silk threads can be stretched, and an arranged tension roller can heat and stretch the fiber silk threads; and when a feeding sensor detects that the fiber silk threads enter, the feeding sensor is matched with a PLC for use, automatic operation of the stretching mechanism can be achieved, operation is convenient, and the stretching mechanism is suitable for application and popularization.

Owner:福建闽瑞新合纤股份有限公司

Rubber banburying process optimization method

ActiveCN109483754AUniform temperature controlIncrease productivityTemperature controlProcess optimization

The invention relates to the field of rubber production process, in particular to a rubber banburying process optimization method. The method comprises the following steps that a plurality of temperature sensing modules are installed on an inner wall of an internal mixer, the temperature sensing modules are provided with temperature sensors, wireless transceivers and storage batteries, and the temperature sensing modules are used for wirelessly transferring the temperature in the internal mixer to a controller located outside the internal mixer; a temperature adjusting pipeline arranged in a tortuous mode is arranged inside the internal mixer, and cooling water or heat-conducting oil is introduced into the temperature adjusting pipeline; when the temperature sensing modules detect that theinternal temperature of the internal mixer is abnormal, the temperature of rubber is adjusted through the temperature adjusting pipeline; and a preheating pipe is spirally arranged in a storage box of the internal mixer, the preheating pipe communicates with a constant temperature pipeline, and rubber raw materials in the storage box are preheated by the preheating pipe. The rubber banburying process optimization method improves the production efficiency of rubber products and the quality of rubber products by improving the temperature control precision of rubber plastic and in the mixing process.

Owner:HUNAN MASTER SEALING

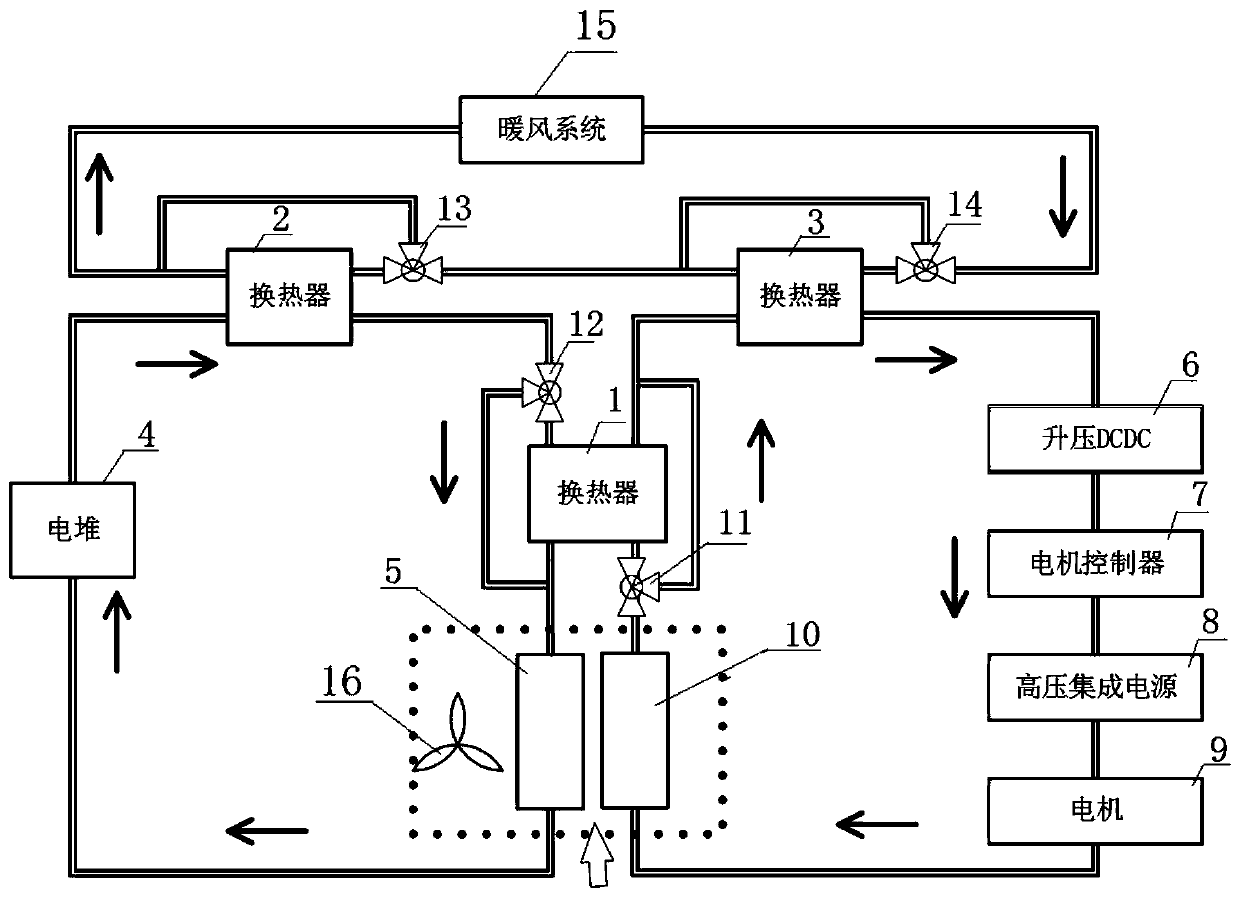

Fuel cell vehicle low-power-consumption multi-factor coupling heat radiation system and method

InactiveCN110450599AMaximize energy utilizationAchieve preheatingAir-treating devicesFuel cell heat exchangeFuel cellsEngineering

The invention discloses a fuel cell vehicle low-power-consumption multi-factor coupling heat radiation system and method. Problems of complicated structure, energy loss and the like, caused by singleheat radiation, of an existing heat radiation system are solved; and balanced effective utilization of energy is realized. The fuel cell vehicle low-power-consumption multi-factor coupling heat radiation system comprises an electric pile heat radiation system, a high voltage part heat radiation system, a first heat exchanger, a second heat exchanger and a third heat exchanger, wherein the first heat exchanger is correspondingly connected with the electric pile heat radiation system and the high voltage part heat radiation system, the second heat exchanger is connected between the electric pileheat radiation system and a heating system, and the third heat exchanger is connected between the high voltage part heat radiation system and the heating system.

Owner:ZHONGTONG BUS HLDG

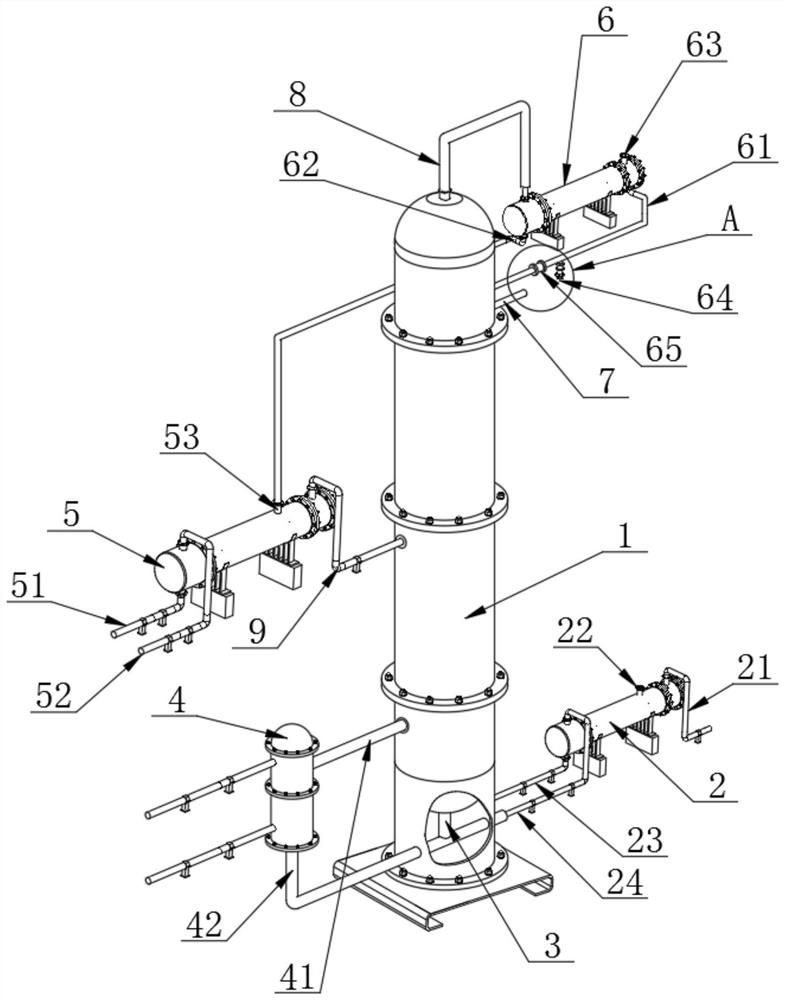

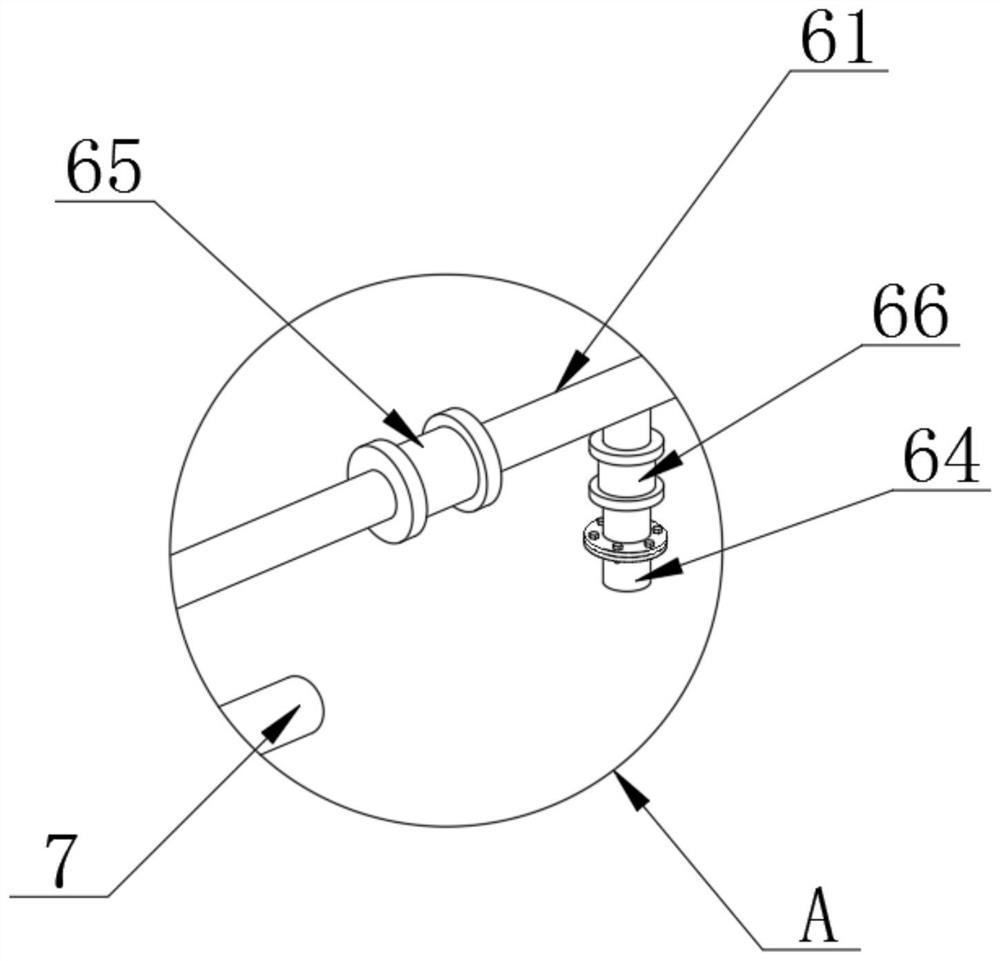

Livestock and poultry excrement resource regeneration treatment and municipal sludge pyrohydrolysis device and process

PendingCN111875209AAchieve preheatingAchieve heat recoverySludge treatment by pyrolysisWaste water treatment from animal husbandrySludgeLivestock

The present invention discloses a livestock and poultry excrement resource regeneration treatment and municipal sludge pyrohydrolysis device, which comprises a livestock and poultry excrement sludge storage tank, a feeding port is connected to the upper portion of the left end face of the livestock and poultry excrement sludge storage tank, and a centrifugal dehydrator, a stirring tank, a main reaction tank and a flash tank are sequentially installed on the right side of the livestock and poultry excrement sludge storage tank; stirring is conducted through a rotating rod and a stirring rod onthe outer surface of the rotating rod, preheating of the livestock excrement sludge is achieved through heating of a heater; after stirring and preheating, the livestock excrement sludge is pumped outthrough a third material pump and pumped into the main reaction tank through a third connecting pipe, and hot steam enters the main reaction tank through a steam inlet pipe to heat and pressurize thelivestock excrement sludge; and finally, the sludge is conveyed into the flash tank for flash evaporation by utilizing the pressure difference in the main reaction tank and the flash tank, wherein steam generated in the flash tank is returned into the stirring tank to be uniformly mixed with new livestock excrement sludge for heating, so that heat recovery is realized and the sludge subjected topyrohydrolysis is discharged from the discharge pipe. The device is simple to operate, high in treatment efficiency, low in cost and worthy of popularization.

Owner:亚循绿色产业科技有限公司

An improved tray-packed rectification column for molecular distillation

ActiveCN111803986BEnsuring Distillation EfficiencyImprove distillation efficiencyFractional distillationReboilerThermal insulation

The invention relates to the technical field of molecular distillation, and discloses an improved tray-packed rectification tower for molecular distillation, which includes a tower body, a discharge heat exchanger is arranged on one side of the bottom end of the tower body, and the bottom of the tower body There is a reboiler on the other side of the end, and a feed heat exchanger is installed outside the middle of the tower body, and the middle part of the top of the tower body is connected with a gas phase discharge pipe, and the other end of the gas phase discharge pipe is connected to a top heat exchanger. , the inside of the tower body is provided with an inner chamber, the inside of the inner chamber is surrounded by a first circulation pipe, the inside of the tower body is distributed from bottom to top with several trays, and the inside of the tower body runs through the center of the trays. central tube. The invention realizes the recovery and utilization of heat, facilitates the heat preservation of the tower body, avoids the heat loss of the tower body, and can preheat the materials, and utilizes the cooperation of the central tube and the gas ring to facilitate the formation of several steam layers in the tower body , to ensure better contact between the steam and the material, and improve the rectification efficiency of the material.

Owner:宿迁市盈科新材料有限公司

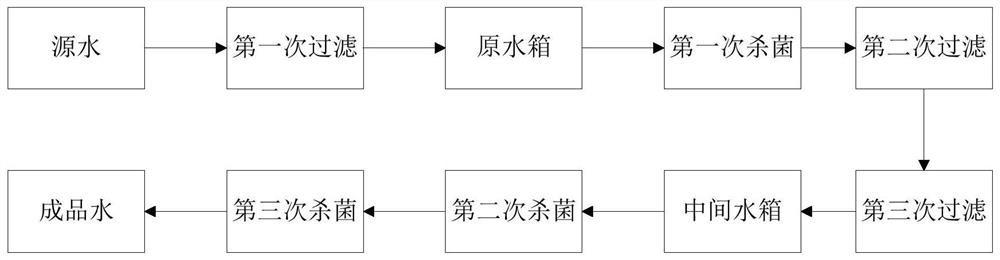

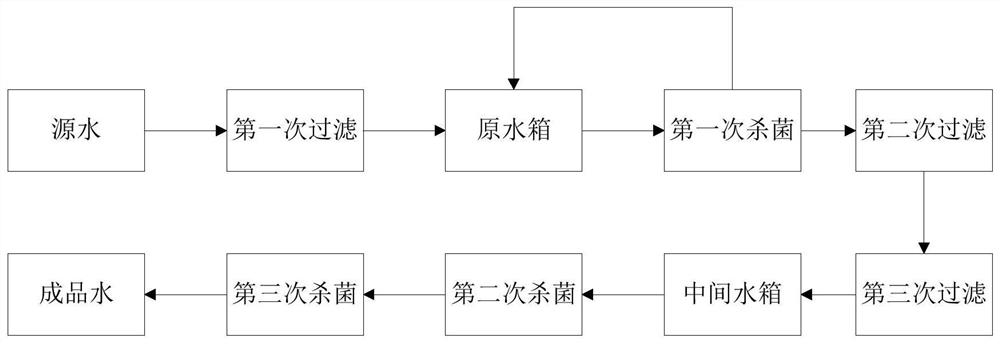

A kind of production method of fresh healthy drinking water

ActiveCN112723637BEfficient removalFresh and healthy waterWater/sewage treatment by irradiationSpecific water treatment objectivesParticulatesFiltration

The present invention relates to the technical field of drinking water, more specifically, to a method for producing fresh and healthy drinking water, comprising: delivering the source water to a water treatment workshop; Water tank; ultraviolet rays are used for the first sterilization; the effluent after the first sterilized treatment is filtered for the second time to remove the second solid particles; it flows into the antibacterial membrane system for the third filtration; the effluent treated by the third filtration flows into the middle Water tank; the second sterilization is carried out by ultraviolet light; the effluent after the second sterilizing treatment is sterilized for the third time by means of cold and hot exchange; the effluent water after the third sterilization treatment flows into the finished water tank and waits for filling. The source water of the present invention is transported to the workshop through a closed pipeline without aeration process and ozone sterilization process, effectively removes particles and microorganisms in the source water, strictly controls bromate and nitrite in the effluent, and obtains fresh and healthy product effluent.

Owner:鹿啄泉矿泉水有限公司

Fuel gas energy-saving water boiler

PendingCN106595050AAchieve preheatingRealize the insulation effectAir heatersSustainable buildingsHeating timeCombustion chamber

The invention relates to a fuel gas energy-saving water boiler. The fuel gas energy-saving water boiler comprises an upper water tank, a lower water tank, a heat exchanger, a combustion chamber and a condenser pipe. A smoke outlet pipe is installed in the condenser pipe and communicates with the heat exchanger; and a first water outlet and a first water inlet are formed above and below the condenser pipe correspondingly. The fuel gas energy-saving water boiler further comprises a first water inlet pipe and a second water inlet pipe; one end of the first water inlet pipe is externally connected with a water source, and the other end of the first water inlet pipe is connected with the first water inlet; and one end of the second water inlet pipe is connected with the first water outlet, and the other end of the second water inlet pipe communicates with the lower water tank. The fuel gas energy-saving water boiler has the beneficial effects that by installing two water tanks, after the water in the lower water tank is boiled, water is injected into the lower water tank, the hot water enters into the upper water tank under the effect of pressure, separation of heat preservation and heating is achieved, repeatedly boiled water does not occur, and the water is safe and healthy; and in addition, the cold water guided into the lower tank water passes through the condenser pipe to absorb heat energy of discharged smoke and gas in a smoke outlet pipe, preheating of the cold water is achieved, the heating time is shortened, and the effects of energy saving and environment protecting are achieved.

Owner:武汉见金节能技术研发有限公司

An electromagnetic-assisted laser synchronous cladding device and method for metal parts remanufacturing

ActiveCN110373666BAchieve preheatingReduce cooling rateMetallic material coating processesErbium lasersHigh energy laser

Owner:WUHAN UNIV OF TECH

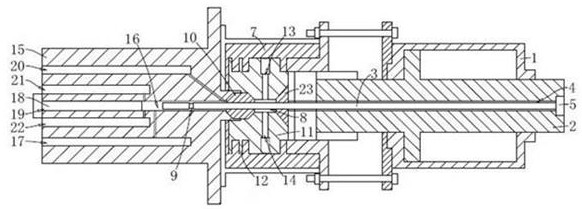

Chromatographic liquid phase sampling valve

PendingCN114814047ASimplify the replacement stepsEasy to repair and replaceComponent separationPhysicsFluid phase

The invention relates to the technical field of sample detection, in particular to a chromatographic liquid phase sampling valve which is characterized by comprising a cylinder body, a piston rod and a sampling needle, the piston rod penetrates through the two ends of the cylinder body and is in sliding connection with the cylinder body, and a needle hole allowing the sampling needle to be inserted is formed in the piston rod; one end of the sampling needle is detachably and fixedly connected with the corresponding end of the piston rod, and the other end of the sampling needle extends out of the piston rod; the purpose of reducing the workload of dismounting and replacing the sampling needle by conveniently dismounting and replacing the sampling needle is achieved.

Owner:BEIJING KALOON ANALYTICAL INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com