Anti-counterfeiting printing press

A printing machine and printing unit technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of deformation and curling of the packaging bag surface, affect the printing effect of packaging bags, and low energy utilization rate, so as to enhance the overall use effect, Enhance the effect of printing and drying, and improve the overall use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

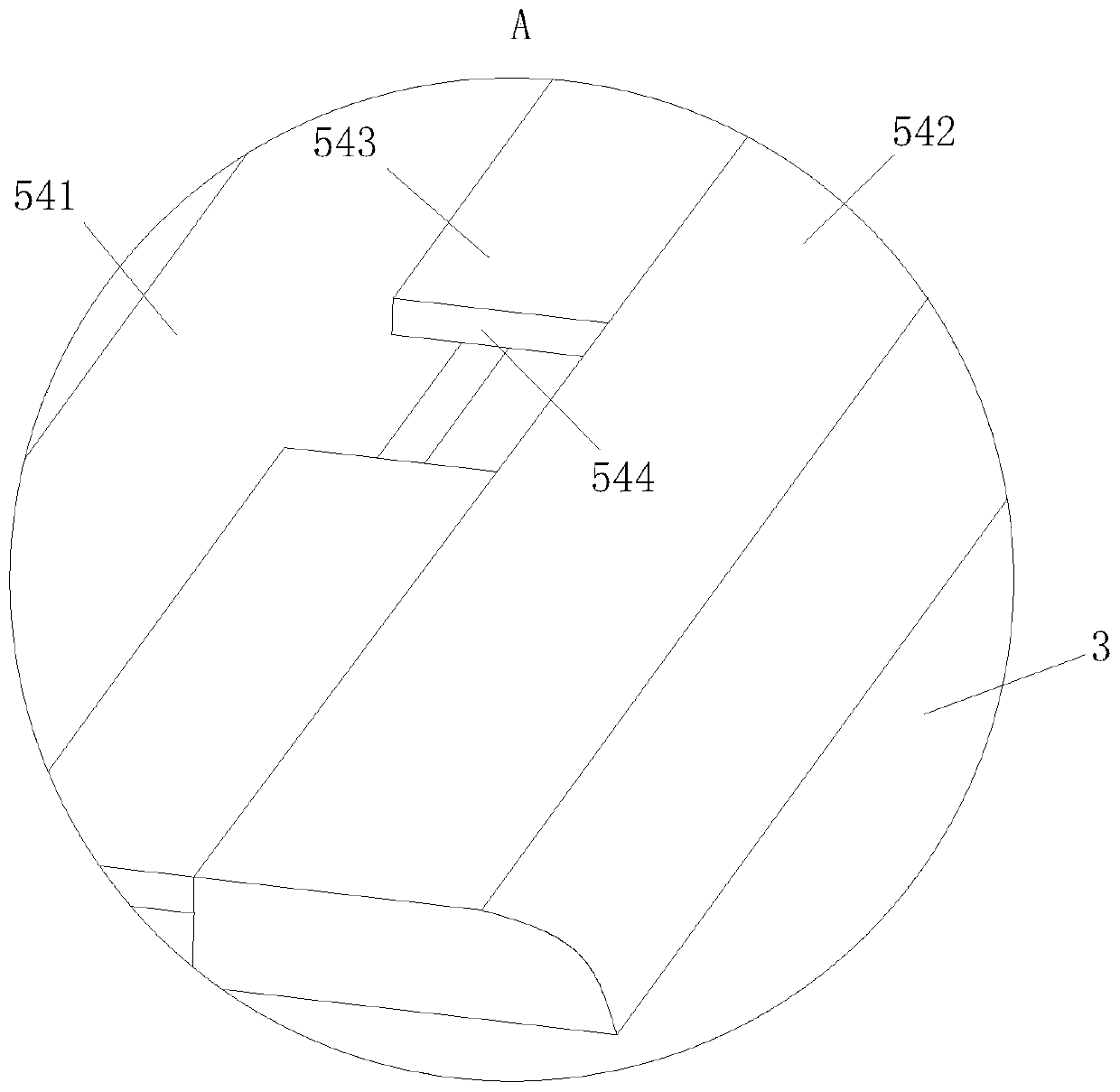

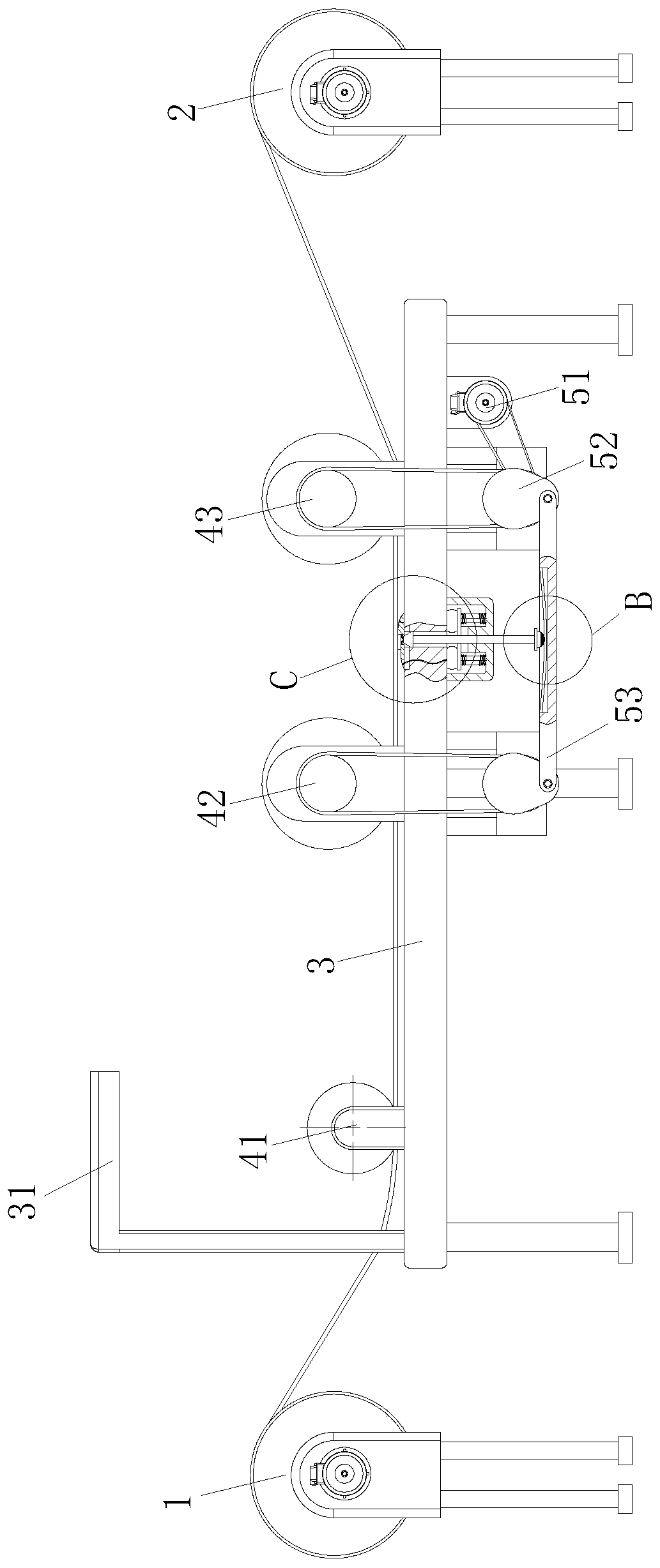

[0027]As an embodiment of the present invention, the side wall of the No. 1 block 541 away from the tapered block 554 and the side wall of the No. 2 block 542 away from the tapered block 554 are both provided with arc-shaped chamfers, thereby avoiding wrapping paper Creases appear on the surface after heating; during work, during the rotation of the printing wheel 42 and the drying wheel 43, the cam 52 is driven to rotate, and the cam 52 makes the hinge plate 53 move up and down along with the cam 52 when the cam 52 rotates. Since the bottom end of the ejector rod 55 is slidably connected in the No. 2 chute 531, the cam 52 drives the ejector rod 55 to reciprocate up and down. When the ejector rod 55 slides upwards in the fixed box 34, the heating block 54 is pushed out of the No. 1 chute first. chute 32, and as the push rod 55 continues to slide, the conical block 554 produces a pressing force on the No. 1 block 541 and the No. 2 block 542, thereby pushing the No. 1 block 541 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com