Chromatographic liquid phase sampling valve

A sampling valve and liquid phase technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of frequent replacement of sampling needles, cumbersome steps of replacing sampling needles, heavy workload of sampling needle replacement, etc., to achieve convenient maintenance Effects of replacement, improvement of vaporization capacity, and reduction of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

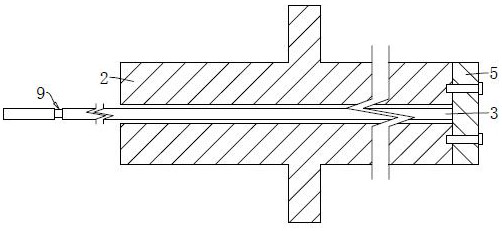

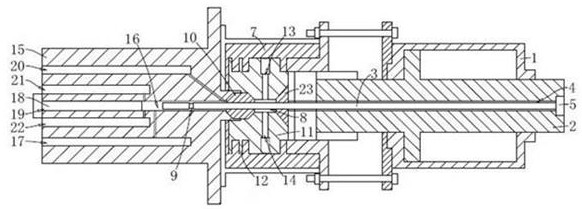

[0038] refer to figure 1 , the present application provides a chromatographic liquid sampling valve, comprising a cylinder 1, a piston rod 2 adapted to the cylinder 1, a sampling needle 3 fixed on the piston rod 2, a liquid The phase support 7, and the heating and gasification module arranged on the side of the liquid phase support 7 away from the cylinder 1, the liquid phase support 7 has a liquid phase chamber 8 for accommodating a liquid phase sample, and the heating and gasification module is There is a vaporization chamber 16 for vaporizing liquid-phase samples, the sampling needle 3 penetrates the liquid-phase chamber 8 and is inserted into the inside of the vaporization chamber 16, and pushes the piston rod 2 to make the sampling needle 3 continuously penetrate into the vaporization chamber 16 , the sampling needle 3 can then take a quantitative liquid phase sample into the gasification chamber 16 .

[0039]In order to facilitate the disassembly and replacement of the ...

Embodiment 2

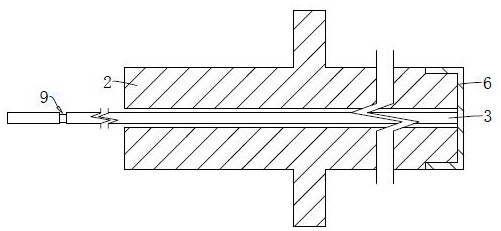

[0053] refer to figure 2 The difference between this embodiment and the first embodiment is that a connecting block 5 is fixed at the end of the sampling needle 3 , and the connecting block 5 is attached to the end surface of the piston rod 2 and is fixedly connected with the piston rod 2 by screws.

Embodiment 3

[0055] refer to image 3 , the difference between this embodiment and the first embodiment is that the connection mode between the sampling needle 3 and the piston rod 2 is different; in this embodiment, the connection mode between the sampling needle 3 and the piston rod 2 is different; In the embodiment, the end of the sampling needle 3 is fixed with a connection cover 6 that can be sleeved on the end of the piston rod 2 , and the connection cover 6 is threadedly connected with the piston rod 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com