A kind of production method of fresh healthy drinking water

A production method and drinking water technology, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve adverse effects, pathogenic bacteria and other microorganisms cannot be completely killed, and it is difficult to ensure natural drinking water drinking water Safety and other issues, to achieve good environmental protection, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

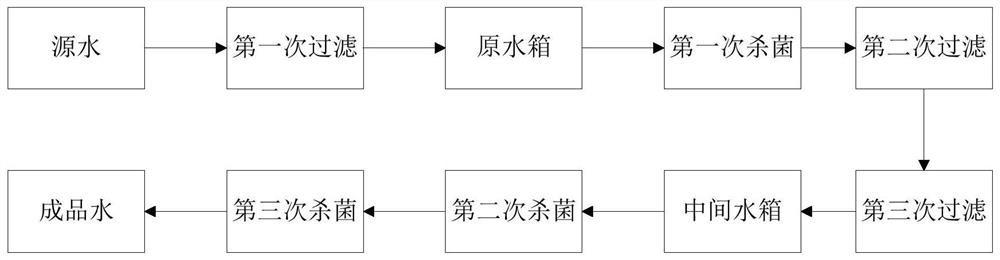

[0042] like figure 1 Shown is the first embodiment of the production method of fresh healthy drinking water of the present invention, comprises the following steps:

[0043] S10. Obtain the source water and transport the source water to the water treatment workshop; the source water in this embodiment can be natural mineral water gushed from underground drilling, mountain spring water formed by the self-purification of the mountain, and other naturally formed natural water. The water is transported by a fully enclosed pipeline, which is connected to the container to ensure that the natural water does not come into contact with the outside world during the transportation and treatment process, avoiding secondary pollution; in order to avoid the pollution of the natural water by the pipeline and the container, the The delivery pipeline can be SUS304 / 316L stainless steel pipeline, but it is not a restriction.

[0044] S20. In step S10, the source water flows into the raw water t...

Embodiment 2

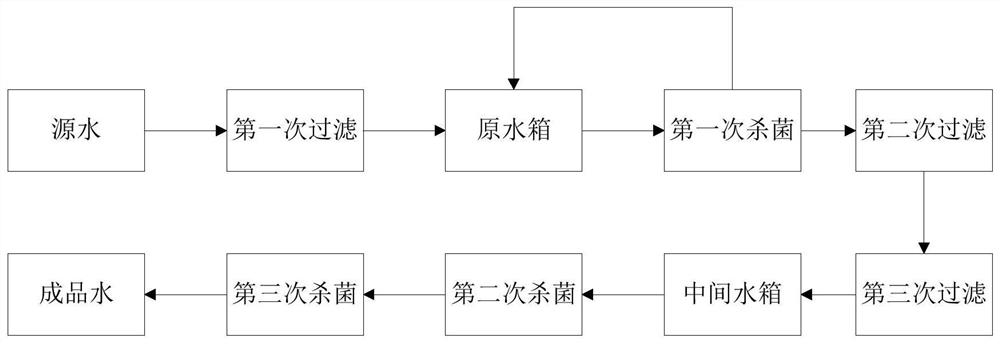

[0060] like figure 2 Shown is the second embodiment of the production method of fresh and healthy drinking water of the present invention, this embodiment is similar to embodiment one, the difference is:

[0061] In step S40, when the effluent treated with the first sterilization treatment is blocked from flowing to the second filtration process, the effluent treated with the first sterilization treatment flows back to the original water tank. In this embodiment, the first valve can be set between the first ultraviolet sterilizer and the security filter, and the second valve can be set between the first ultraviolet sterilizer and the raw water tank. By controlling the first valve to close and the second valve to open, that is The effluent of the first ultraviolet sterilizer can be realized to flow back into the raw water tank, and cycle sterilization can be realized, so as to effectively control the reproduction of microorganisms when the raw water stays in the raw water tank...

Embodiment 3

[0063] The present embodiment is the third embodiment of the production method of fresh and healthy drinking water, and the present embodiment is similar to the third embodiment, except that:

[0064] In step S70, the ultraviolet radiation intensity is monitored in real time when the low-pressure ultraviolet ray is used for sterilization and when the medium-pressure ultraviolet ray is used for sterilization. In this embodiment, a first light intensity detector can be installed in the cavity of the first ultraviolet sterilizer, and a second light intensity detector can be installed in the cavity of the second ultraviolet sterilizer for on-line monitoring of the ultraviolet intensity.

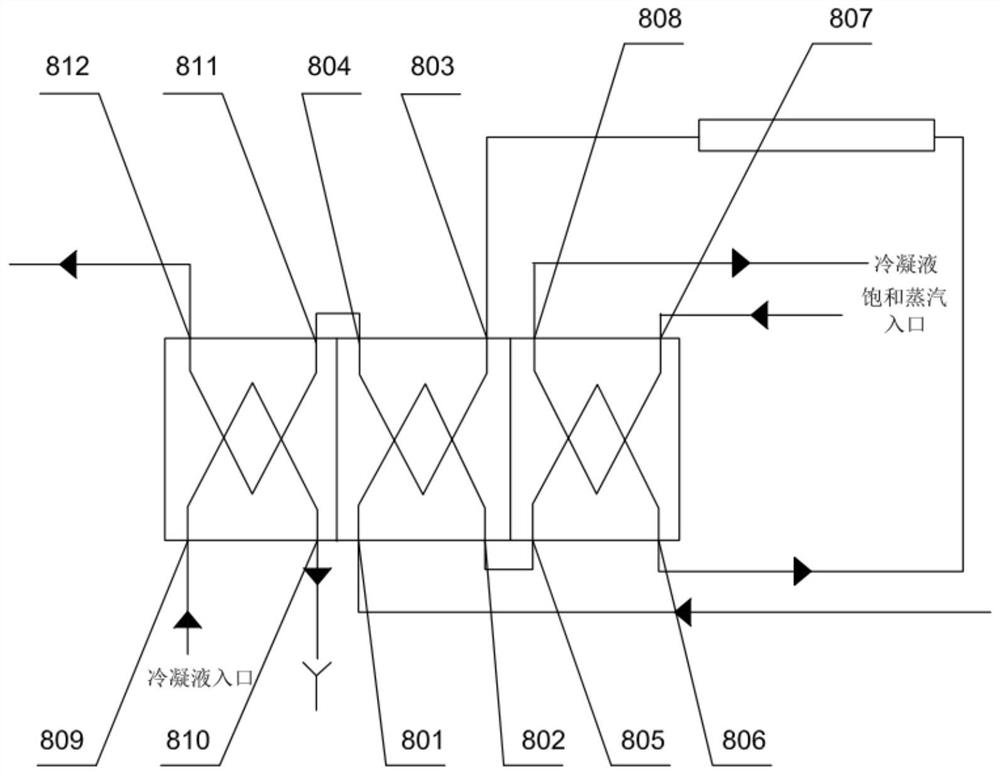

[0065] One end of the first ultraviolet sterilizer is provided with a first input pipeline, and one end of the second ultraviolet sterilizer is provided with a second pipeline for inputting treated water; in order to endow the treated water with flow power, a second pipeline is provided on the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com