An electromagnetic-assisted laser synchronous cladding device and method for metal parts remanufacturing

A technology for assisting laser and metal parts, applied in the direction of metal material coating process, coating, etc., can solve the problem of reducing the probability of pores and cracks in the cladding layer, improve the intermittent phenomenon, promote the formation of carbides, The effect of improving the surface corrugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

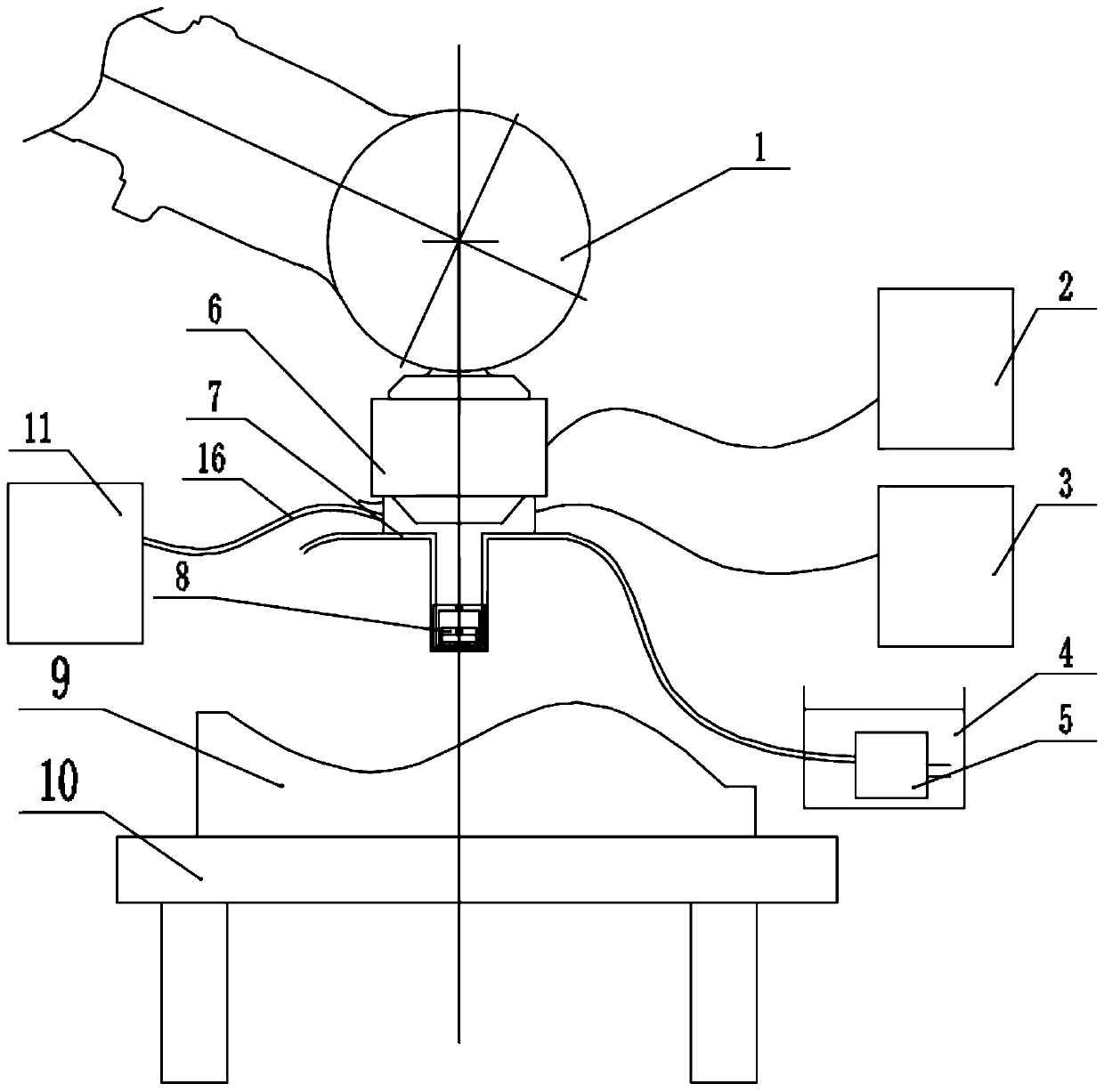

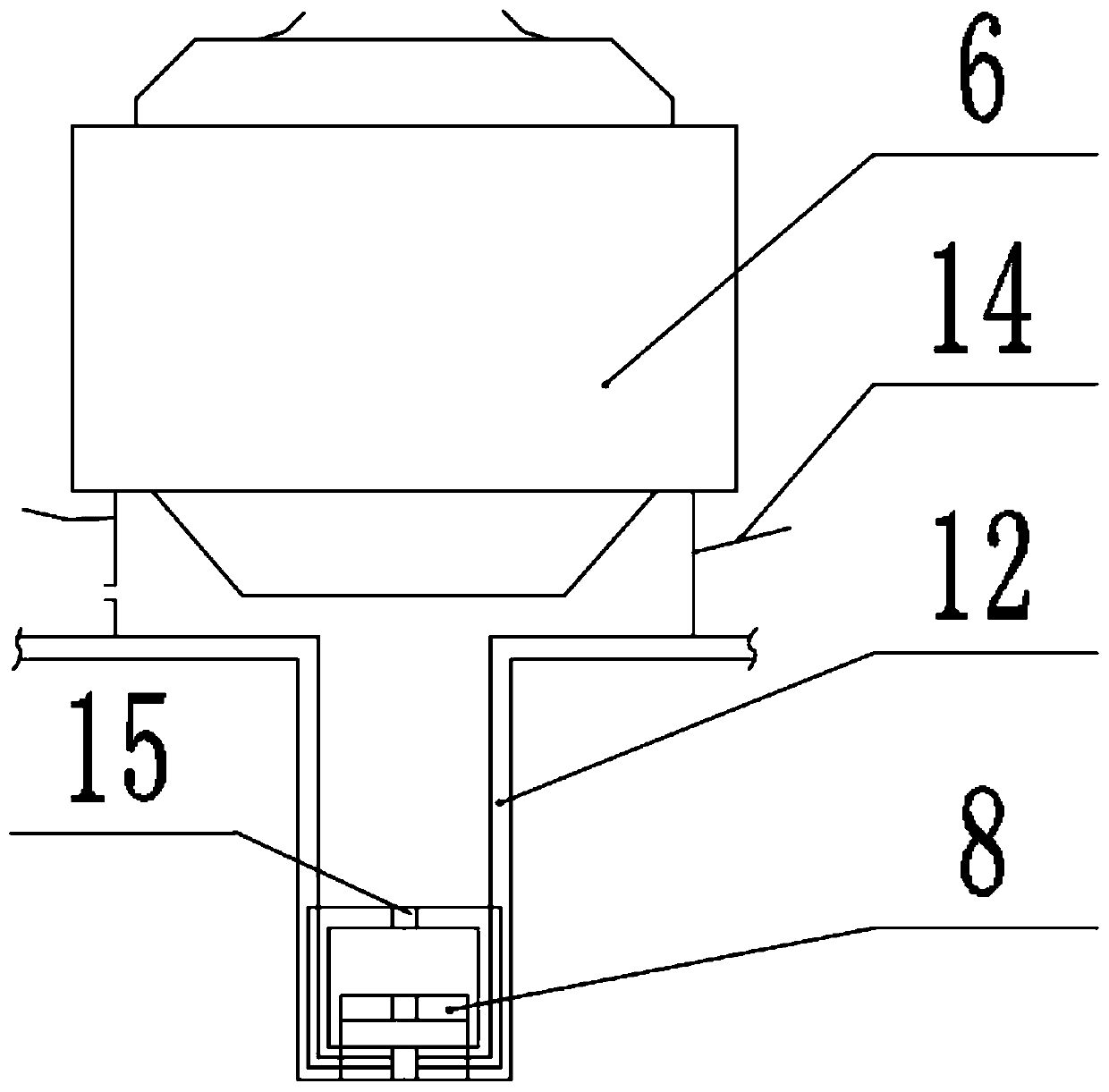

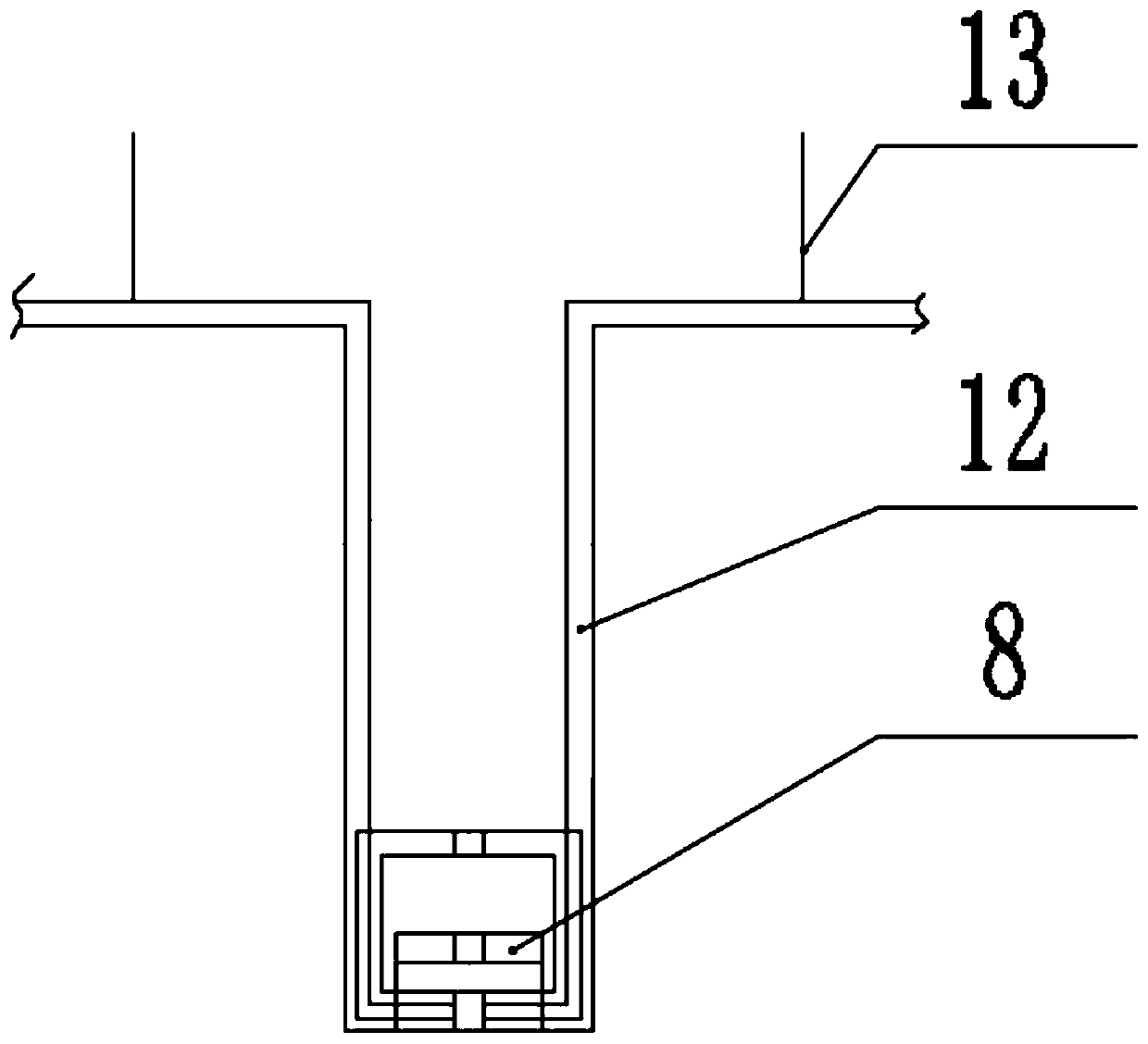

[0032] Such as Figure 1 to Figure 4 As shown, an electromagnetic-assisted laser synchronous cladding device for remanufacturing of metal parts is mainly composed of a six-degree-of-freedom actuator 1, a laser 6, a laser power supply 2, an induction coil 7, an induction power supply 3, a powder sprayer, a numerical control It consists of an automatic turning table 10, a workpiece fixture, a water tank 4, a water pump 5 and a shielding gas pump 11. The six-degree-of-freedom actuator 1 can be a robot, a robot arm or a six-degree-of-freedom machine tool, and its end can move arbitrarily within a certain range of three-dimensional space. A specific embodiment can use a six-axis robot; the laser 6 is fixed At the end of the six-degree-of-freedom actuator 1, the laser 6 is connected to the laser power supply 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com