Preparing method and device for aluminum-magnesium-aluminum composite plate

A technology of aluminum cladding and sheet metal, which is used in metal extrusion control equipment, manufacturing tools, metal rolling, etc., can solve the problems of poor corrosion resistance, hinder the application of magnesium alloys, etc., to improve the plastic deformation ability and reduce the composite interface. Defects, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

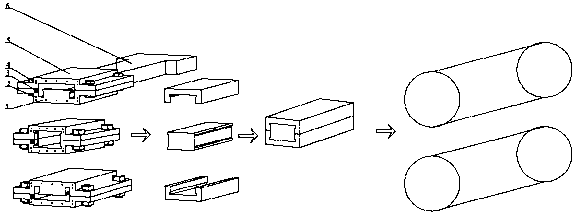

[0028] One piece of AZ31 magnesium alloy with an initial thickness of 10 mm and two pieces of 7050 aluminum alloy billet with an initial thickness of 8 mm were combined by extrusion-rolling to prepare a 3 mm thick aluminum-clad magnesium composite plate.

[0029] (1) Homogenize the 7050 aluminum alloy at 470°C / 24h, and homogenize the AZ31 magnesium alloy at 415°C / 15h;

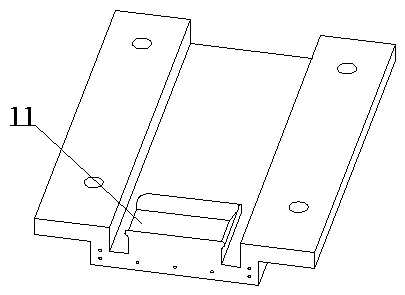

[0030] (2) Start the heating device 2, raise the temperature of the concave billet extrusion die to 420°C, and use the concave billet extrusion die with a height of 5 mm of the "T" forming block 11 to extrude to prepare two concave 7050 aluminum alloy billets of composite billets ;

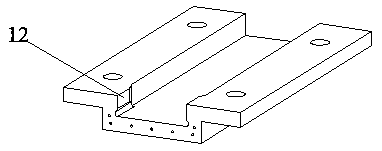

[0031] (3) Start the heating device 2, raise the temperature of the convex extrusion die to 400°C, and use the convex extrusion die with a height of 10 mm in the "I" cavity 12 to extrude to prepare a composite billet of an outwardly convex AZ31 magnesium alloy billet ;

[0032] (4) Stack two pieces of 7050 aluminum alloy to form ...

Embodiment 2

[0035] One piece of AZ31 magnesium alloy with an initial thickness of 8 mm and two pieces of 2519 aluminum alloy billets with an initial thickness of 8 mm were combined by extrusion-rolling to prepare a 3 mm thick aluminum-clad magnesium composite plate.

[0036] (1) Homogenize the 2519 aluminum alloy at 530°C / 12h, and homogenize the AZ31 magnesium alloy at 415°C / 15h;

[0037] (2) Start the heating device 2, raise the temperature of the concave billet extrusion die to 420°C, and use the concave billet extrusion die with a height of 4 mm of the "T" forming block 11 to extrude to prepare two concave 2519 aluminum alloy billets of composite billets ;

[0038] (3) Start the heating device 2, raise the temperature of the convex extrusion die to 400°C, and use the convex extrusion die with a height of 8 mm in the "I" cavity 12 to extrude to prepare a composite billet of an outwardly convex AZ31 magnesium alloy billet ;

[0039] (4) Stack two pieces of 2519 aluminum alloy to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com