Method for titanizing inner wall of new reactor in production of titanium sponge

A technology of reactor and titanium sponge, which is applied in the field of titanium plating on the inner wall of the new reactor, can solve the problems of poor anti-iron pollution effect of the titanium infiltration layer, high iron content of the new reactor product, and high cost, and achieve low cost and easy operation , solve the effect of high iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After the 1.3m-diameter sponge titanium reduction-distillation new reactor passed the leak test, it was repeatedly soaked and rinsed with 5% industrial hydrochloric acid to remove oxides and oil stains on the surface of the new reactor. After pickling, the reactor is rinsed with clean water, and after the outflow of washing water is neutral, it is dried with pure compressed air.

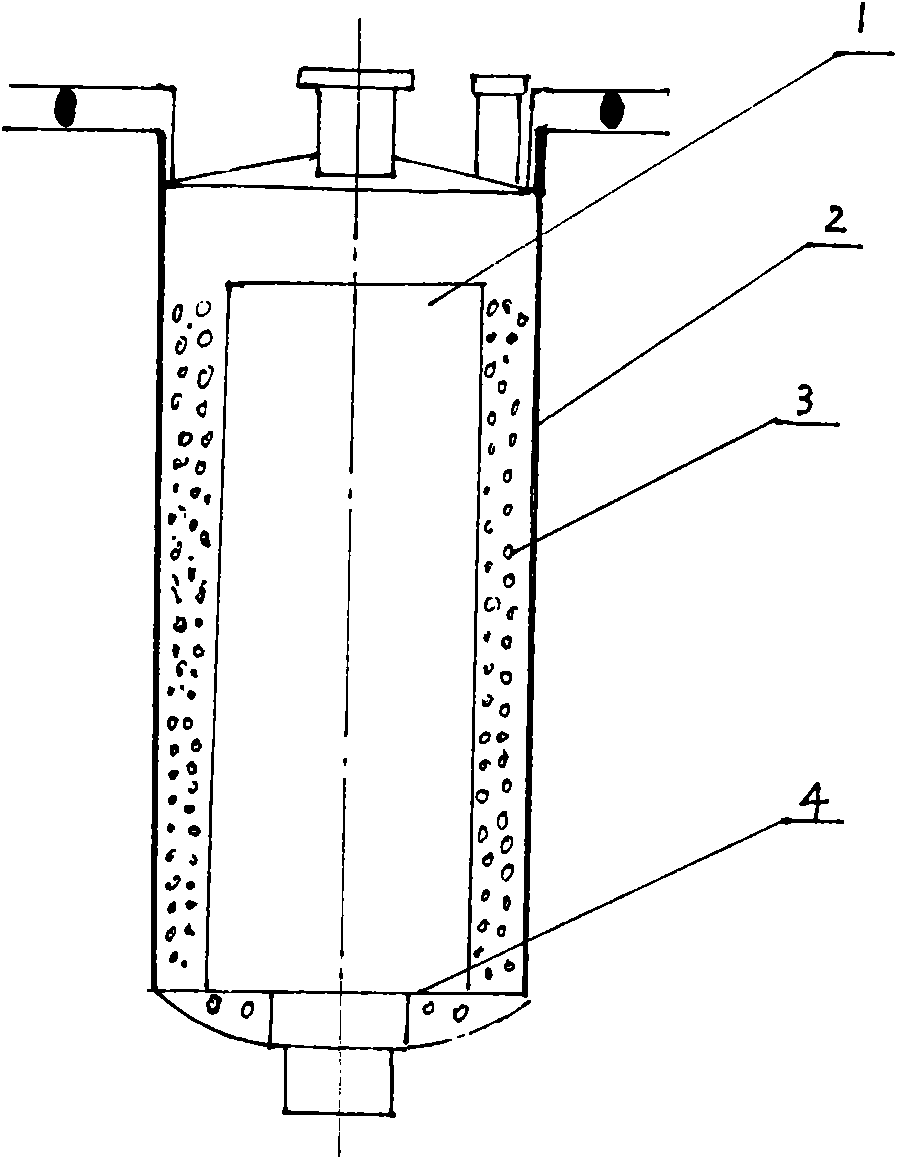

[0022] The new reactor after drying has a built-in sleeve, the height of the sleeve is 30cm lower than the reactor flange, and the circumference is 5cm away from the reactor wall. Crush titanium sponge or waste titanium to 0<particle size≤50mm, fill it into the gap between the reactor wall and the sleeve, and install the reactor and condenser. After installation, start the vacuum system in the furnace, heat to 200°C when the pressure is less than 100Pa, keep the temperature constant for 5 hours and degas, raise the temperature to 350°C, keep the temperature constant for 3 hours and degas, and ...

Embodiment 2

[0024] After the 1.5m-diameter sponge titanium reduction-distillation new reactor passed the leak test, it was repeatedly soaked and rinsed with 5% industrial hydrochloric acid to remove oxides and oil stains on the surface of the new reactor. After pickling, the reactor is rinsed with clean water, and after the outflow of washing water is neutral, it is dried with pure compressed air.

[0025] The new reactor after drying has a built-in sleeve, the height of the sleeve is 50cm lower than the reactor flange, and the circumference is 10cm away from the reactor wall. Crush titanium sponge or waste titanium to 0<particle size≤50mm, fill it into the gap between the reactor wall and the sleeve, and install the reactor and condenser. After installation, start the vacuum system in the furnace, heat to 150°C when the pressure is less than 100Pa, keep the temperature for 5 hours and degas, raise the temperature to 400°C, keep the temperature for 5 hours and degas, and finally raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com