Method for preparing damping vibration attenuation composite coating on surface of rotary machine thin-shell component

A technology of composite coating and rotating machinery, applied in the field of materials, to achieve high stability, increased dynamic stiffness, and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

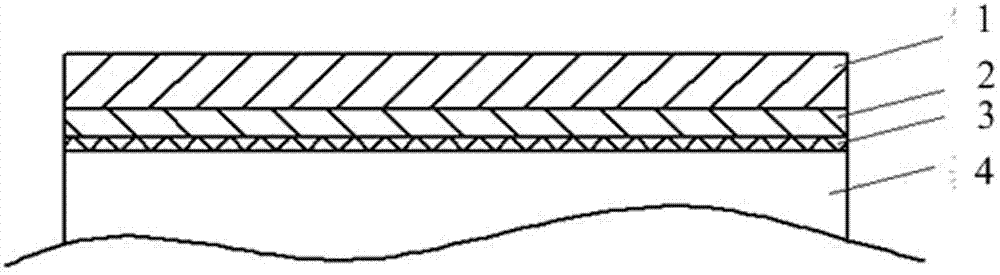

Image

Examples

Embodiment 1

[0030] Using the engine rotor blade as the substrate, the oil and impurities on the surface of the substrate are removed, and then placed in the vacuum chamber of the filtered arc ion coating machine;

[0031] Evacuate the vacuum chamber to a pressure of ≤1×10 -3 Pa, and then preheat the substrate to 200°C;

[0032] Introduce argon gas into the vacuum chamber until the pressure is 0.5 Pa, start the filtered arc ion coating machine, use metal titanium as the target material, deposit titanium coating on the substrate surface, control the negative bias voltage amplitude of the substrate to 200V, and the bias duty cycle 10~30%, the main arc current is 40~80A; the deposition time is 8min, and a titanium coating with a thickness of 1μm is formed on the surface of the substrate;

[0033] Using Ni 60 Cr 33.7 Al 4.5 Y 1.8 The alloy is used as the target material, and Ni is deposited on the surface of the titanium coating 60 Cr 33.7 Al 4.5 Y 1.8 Alloy coating, control substrate...

Embodiment 2

[0036] Using the rotating blade as the substrate, the oil and impurities on the surface of the substrate are removed, and then placed in the vacuum chamber of the filtered arc ion coating machine;

[0037] Evacuate the vacuum chamber to a pressure of ≤1×10 -3 Pa, then preheat the substrate to 100°C;

[0038] Introduce argon gas into the vacuum chamber until the pressure is 0.6 Pa, start the filtered arc ion coating machine, use metal titanium as the target material, deposit titanium coating on the substrate surface, control the negative bias voltage amplitude of the substrate to 200V, and the bias duty cycle 10~30%, the main arc current is 40A; the deposition time is 10min, and a titanium coating with a thickness of 1.5μm is formed on the surface of the substrate;

[0039] Using Ni 60 Cr 33.7 Al 4.5 Y 1.8 The alloy is used as the target material, and Ni is deposited on the surface of the titanium coating 60 Cr 33.7 Al 4.5 Y 1.8 Alloy coating, control substrate negativ...

Embodiment 3

[0042] Using the rotating blade as the substrate, the oil and impurities on the surface of the substrate are removed, and then placed in the vacuum chamber of the filtered arc ion coating machine;

[0043] Evacuate the vacuum chamber to a pressure of ≤1×10 -3 Pa, and then preheat the substrate to 300°C;

[0044] Introduce argon gas into the vacuum chamber until the pressure is 0.8 Pa, turn on the filtered arc ion coating machine, use metal titanium as the target material, deposit titanium coating on the surface of the substrate, control the negative bias voltage amplitude of the substrate to 300V, and the bias duty cycle 10~30%, the main arc current is 80A; the deposition time is 10min, and a titanium coating with a thickness of 0.5μm is formed on the surface of the substrate;

[0045] Using Ni 60 Cr 33.7 Al 4.5 Y 1.8 The alloy is used as the target material, and Ni is deposited on the surface of the titanium coating 60 Cr 33.7 Al 4.5 Y 1.8 Alloy coating, control subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com