Waste heat and electricity composite drive temperature increasing type heat pump circulation system

A heating-up heat pump and circulation system technology, applied in refrigeration and liquefaction, lighting and heating equipment, steam generation methods, etc., can solve the problems of limited temperature range and low energy efficiency, and achieve the goal of expanding the heating range and saving compression power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

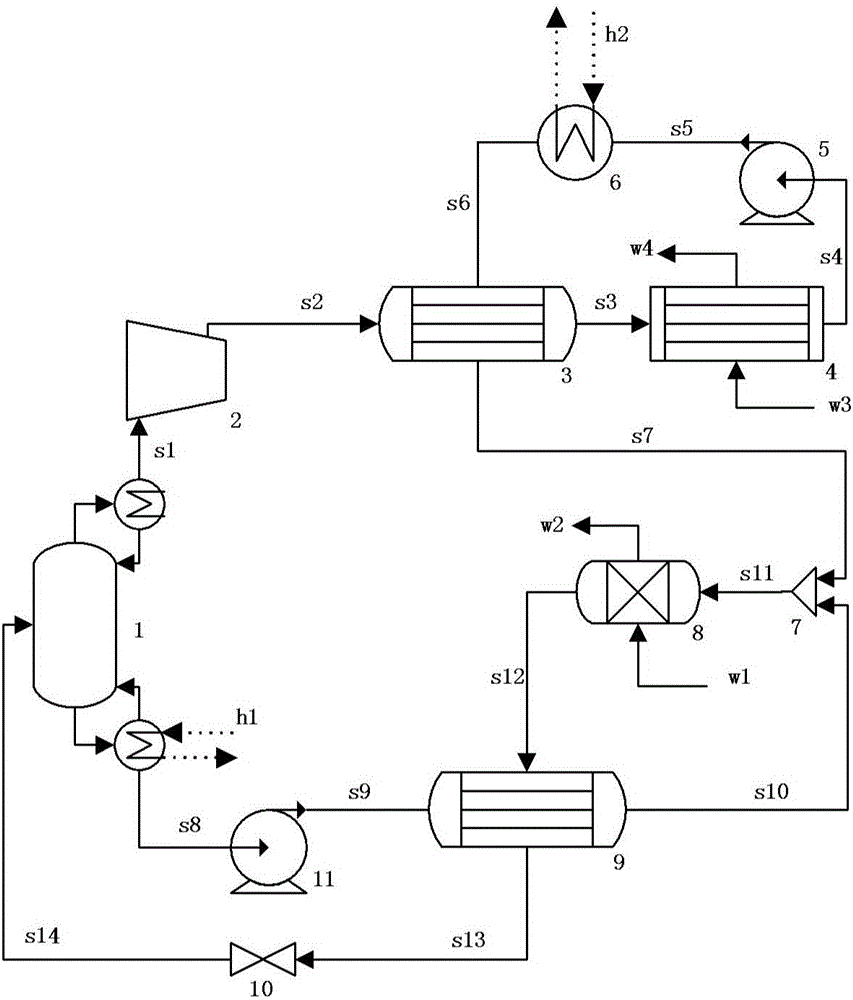

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0027] The heating-up type heat pump circulation system driven by waste heat and electric compound provided by the present invention adds steam regenerator, pump, evaporator and condenser on the basis of the original absorption compression heat pump. The low-pressure ammonia vapor is compressed to a higher pressure, cooled by the high-pressure ammonia liquid on the low-temperature side of the steam regenerator, completely condensed in the condenser, and then compressed to the absorption pressure by the pump. Among them, the heat source of the evaporator is the exhaust heat that cannot be utilized by the waste heat boiler, and the temperature rise can be as high as 50-100°C, and industrial steam above 0.5MPa can be produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com