Wet type combustion huff-puff oil extraction method

A fire huff and puff, wet technology, applied in the field of oil extraction from wells, can solve the problems of affecting heavy oil production, high heat loss, low oil-steam ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

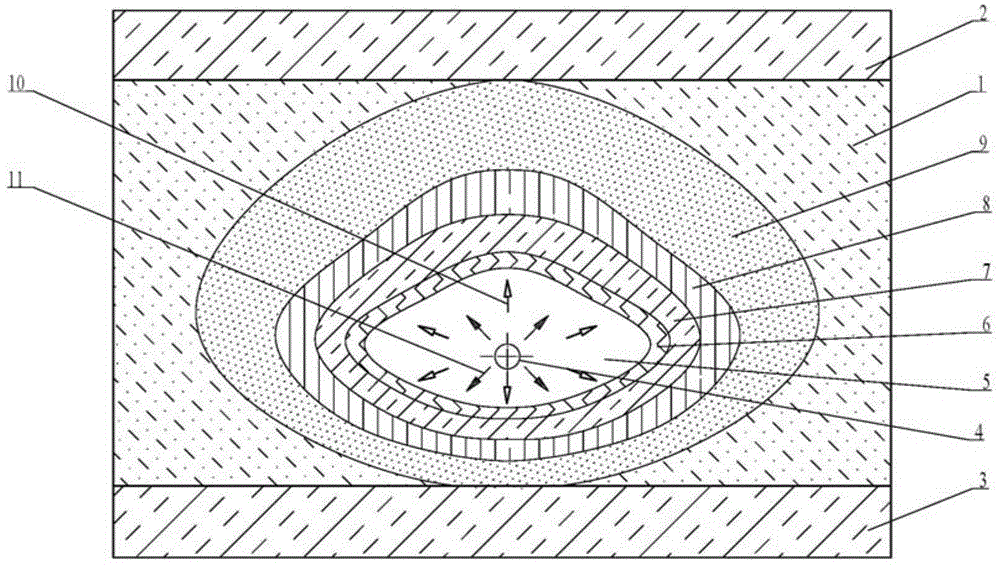

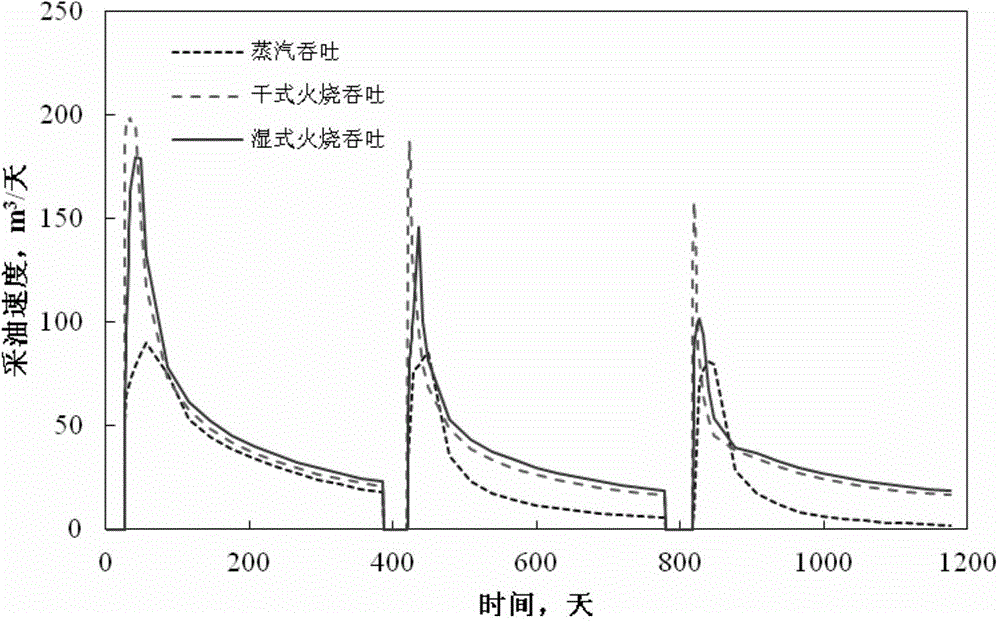

[0116] see figure 1 . This example is aimed at a single-layer heavy oil reservoir, a deep ordinary heavy oil reservoir with a size of 600m×200m×20m in the Nanpu reservoir of Bohai Sea, the top depth of the reservoir is 1000m, the thickness is 20m, and one horizontal well section is long For the 300m horizontal well, the specific reservoir parameters and well parameters are shown in Table 1. A homogeneous reservoir geological model with 20 × 40 × 20 grids was established, and the thermal recovery simulator of ECLIPSE was used to simulate and calculate the production effect of three rounds of wet combustion huff and puff recovery in horizontal wells. The production effect of 3 rounds of steam huff and puff in horizontal well and 3 rounds of dry fire huff and puff in horizontal well. Horizontal wells are completed with casing.

[0117] After washing and clearing the crude oil in the wellbore of horizontal well 4, inject oxidant 10 into oil layer 1 with air as oxidant, pass 1,0...

Embodiment 2

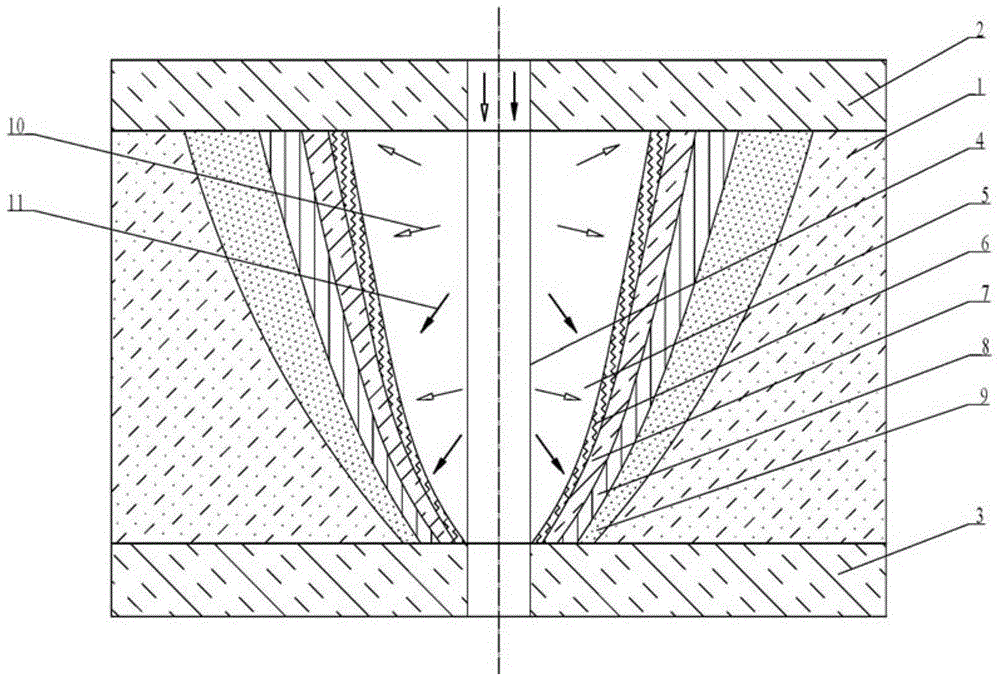

[0143] refer to figure 2 , figure 2 It is a schematic diagram of the vertical well wet combustion huff and puff recovery method. figure 2 Among them, 1 is oil reservoir, 2 is overburden, 3 is underburden, 4' is vertical well, 5 is burned area, 6 is combustion front, 7 is cracking and evaporation area, 8 is condensation heating area, and 9 is Gas-swept area, 10 is injected oxidant, 11 is injected water.

[0144] In this embodiment, after the crude oil in the vertical well 4 is cleaned out, the oxidant 10 is injected into the oil layer 1, and at the same time, the 30KW electric heater is heated to 400°C to ignite, so that part of the crude oil components are burned in the high-pressure oxidizer 10. As the oxidant 10 is continuously injected, the combustion front 6 propagates from the oil well 4 to the deep part of the oil reservoir 1 . When the high temperature of the combustion front 6 partially cracks the crude oil in the front cracking evaporation zone 7, and vaporizes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com