Patents

Literature

60results about How to "Improve oil production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for developing deep-layer heavy crude reservoir by carbon dioxide auxiliary steam driving

ActiveCN101139923ASame recovery factorImprove oil production rateFluid removalCondensed waterCarbon dioxide

A method to excavate deep heavy oil reservoir with carbon dioxide auxiliary steam drives adapts to oil field exploitation. The method is characterized in that: Exploitate deep heavy oil reservoir with a composite rod drive for straight wells and horizontal wells. Meanwhile, the invention is designed to fill carbon dioxide gas at the same time of filling steam. The specific value of of underground volume in cold water valent weight between the carbon dioxide and steam is 8 to 10; total injection volume of the carbon dioxide is 0.2 to 0.5PV. The targets are as follows: Solve the problem that, the traditional method of only injecting steam into deep heavy oil reservoirs is difficult to meet steam drive requirements, so that oil-steam ratio and percent recovery are both too low. After meeting cold oil at the early stage of transcending condensed water, the carbon dioxide can solve some raw oil, lower viscosity, improve raw oil fluidity, shorten low-yield period in the preliminary stage of the steam drive, and improve oil recovery speed. On the basis of steam throughput, the method can improve yield extent by about 30 percent, and accumulated oil-steam ratio can be higher than 0.20; taking yield extent during the throughput stage into considerations, total percent recovery can reach about 50 percent.

Owner:PETROCHINA CO LTD

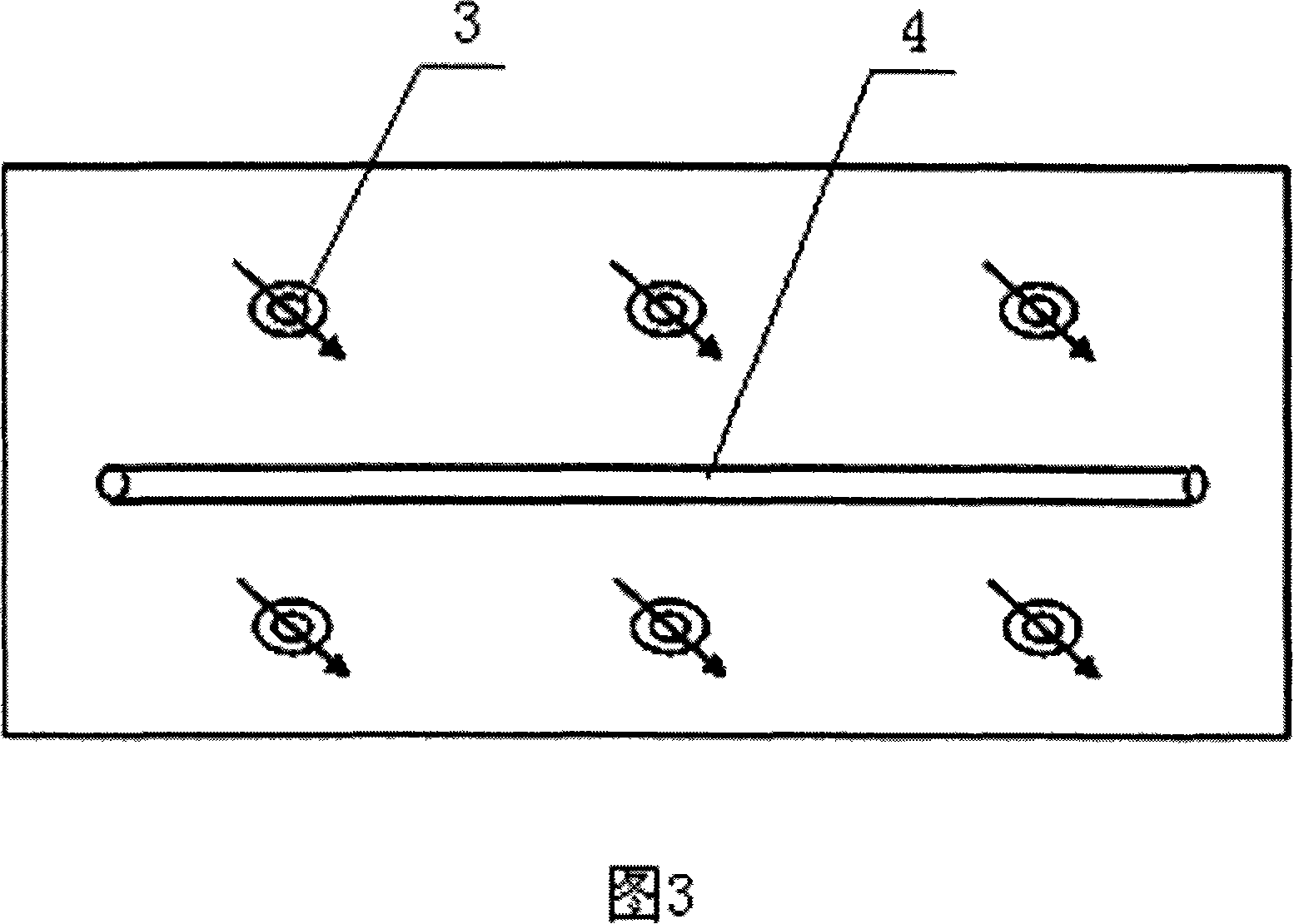

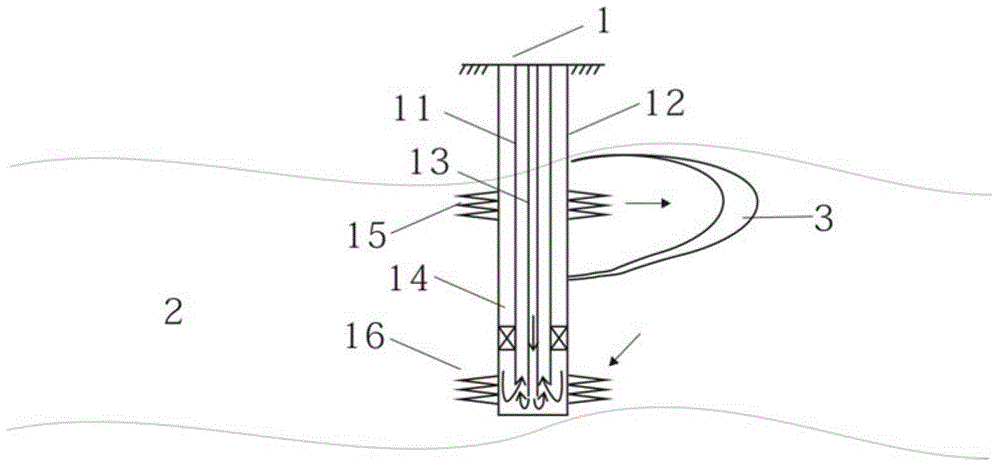

Method for developing heavy oil reservoir of horizontal well by combining staged volume fracturing and fracturing filling

ActiveCN105422068AReduce heat lossImprove seepage propertiesFluid removalSealing/packingPorosityGeomorphology

The invention provides a method for developing a heavy oil reservoir of a horizontal well by combining staged volume fracturing and fracturing filling. According to the method, firstly, a steam injection well is deployed at the bottom of the oil reservoir; a production well is deployed at the middle upper part of the oil reservoir; then, the volume fracturing or fracturing filling operation is performed according to the porosity degree and seepage rate distribution condition of the two horizontal wells; then, the two wells form heat communication in a steam throughput mode; next, the two wells transfer to continuous steam injection production; and the production is stopped when the oil-steam ratio is lowered to 0.1. According to the invention, a fracture net system is formed in a compact region by the volume fracturing, so that the seepage capability of the oil reservoir is improved; the fracturing filling process is used in a high-porosity and high-permeability region for performing compaction so as to reduce a formation sand production phenomenon; the seepage mode of a low-permeability region oil reservoir is converted from the single seepage to the sewage and fracture laminar flow; meanwhile, a high-permeability region is filled with small-grain-size sand for filling loose reservoir sandstone particle pores, so that the permeability near the production well is reduced,the oil reservoir anisotropy is reduced and the whole oil reservoir can be uniformly used and developed.

Owner:PETROCHINA CO LTD

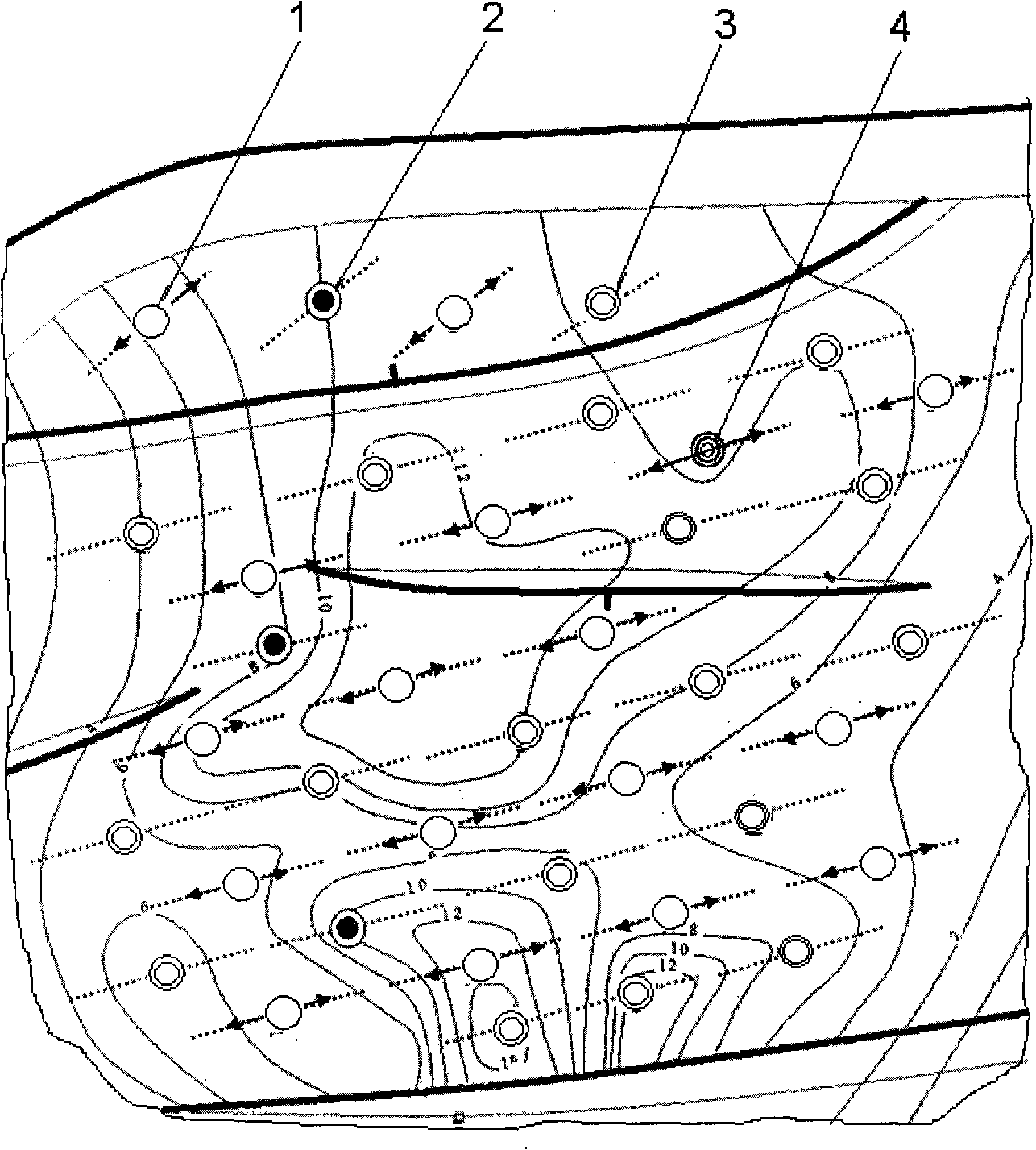

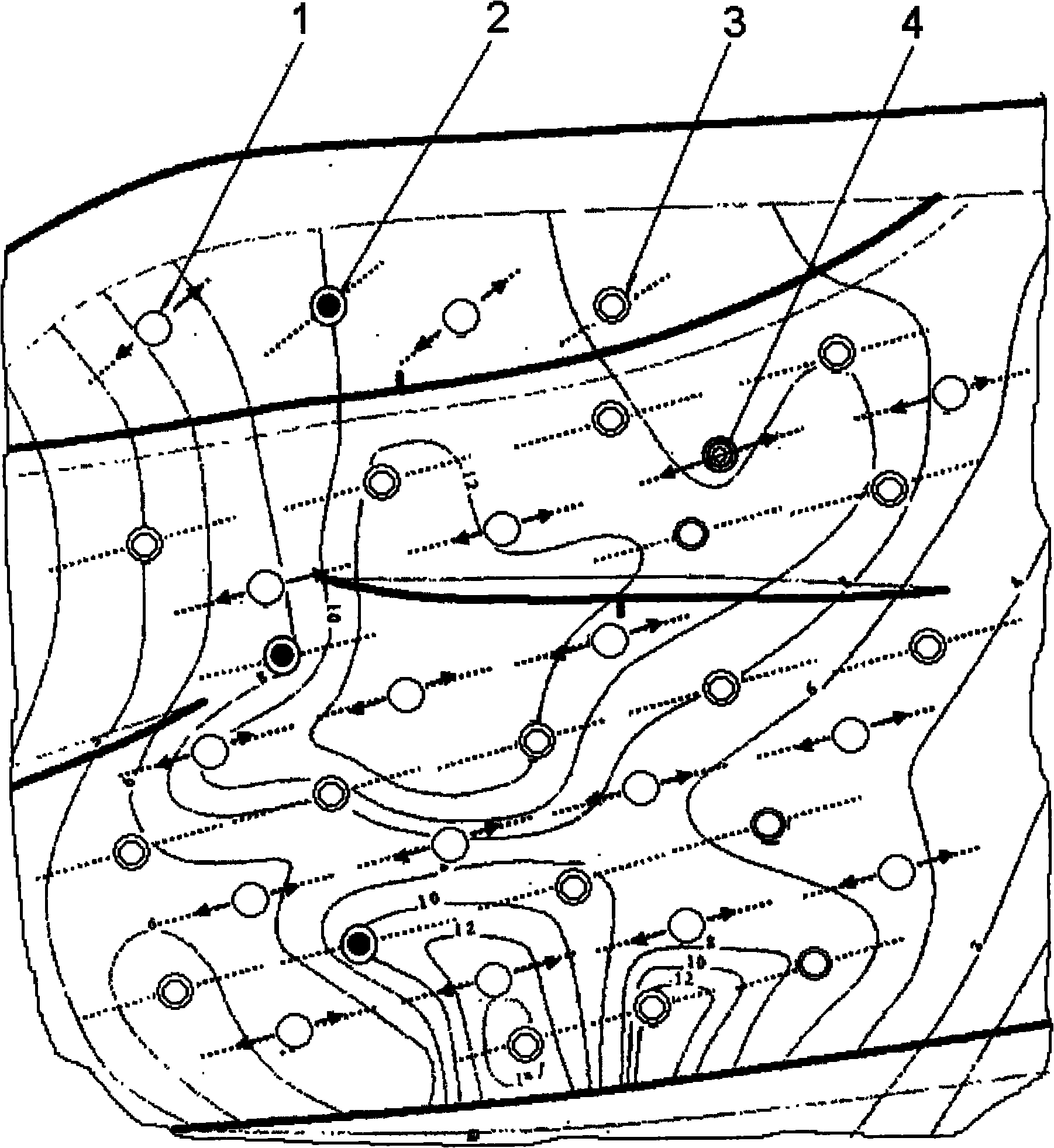

Low permeable oil deposit virtual horizontal well development method

The invention relates to a low permeable oil deposit virtual horizontal well development method, comprising the following process technologies: deploying a developed well pattern, early flooding under nearly high pressure condition, optimizing a perforation well section and a perforation way, designing and deploying the development technology and producing a long slot by ultra large scale fracturing. When the developed well pattern is deployed, the well pattern is designed and deployed in a region with the thickness of an oil layer being higher than a 4m line, the well pattern is a five-spot square one with the distance between an oil well row and a water well row being 490-520m and the distance between an injection well row and an extraction well row being 170-200m, wherein the directionof the oil well row and the water well row is consistent with the direction of the main geostatic stress; the early flooding is carried out under the nearly high pressure condition that the strata pressure coefficient is kept to be 0.9-1.0; at the middle part of the oil layer is perforated for only 2-4 meters, and the perforating is carried out by adopting a multiphase optimized perforation way; the development technology is designed and oil-water wells and capacities of the oil-water wells are deployed in a block; and the slot is produced by adopting the ultra large scale fracturing while monitoring is carried out, wherein average length of half slot is 190-250m, and high delivery volume construction at the speed of high quality fracturing fluid being 5-6m<3> / min is adopted in the whole course. The invention is applied to a low permeable oil deposit development process.

Owner:胜利油田鲁明油气勘探开发有限公司

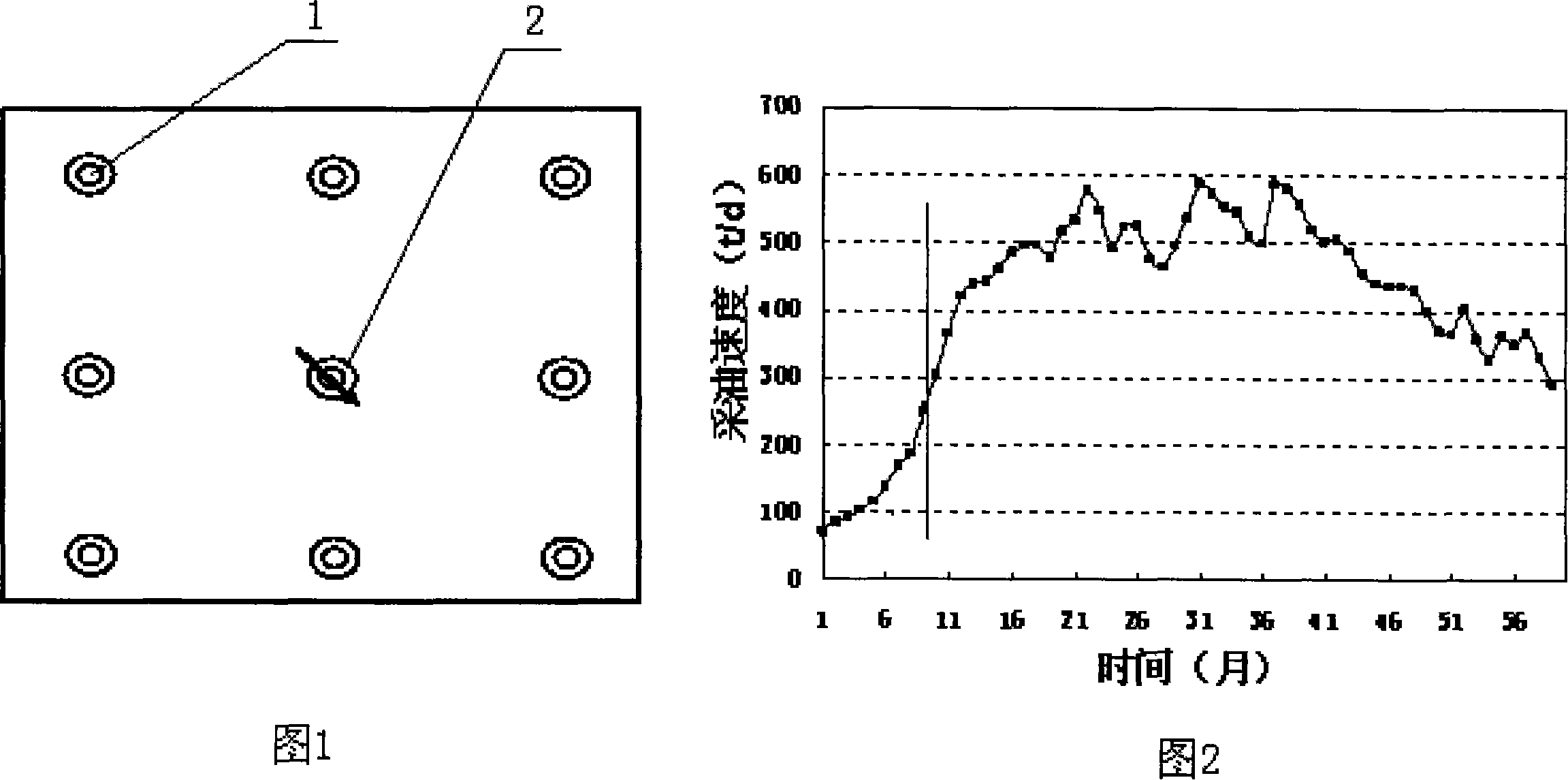

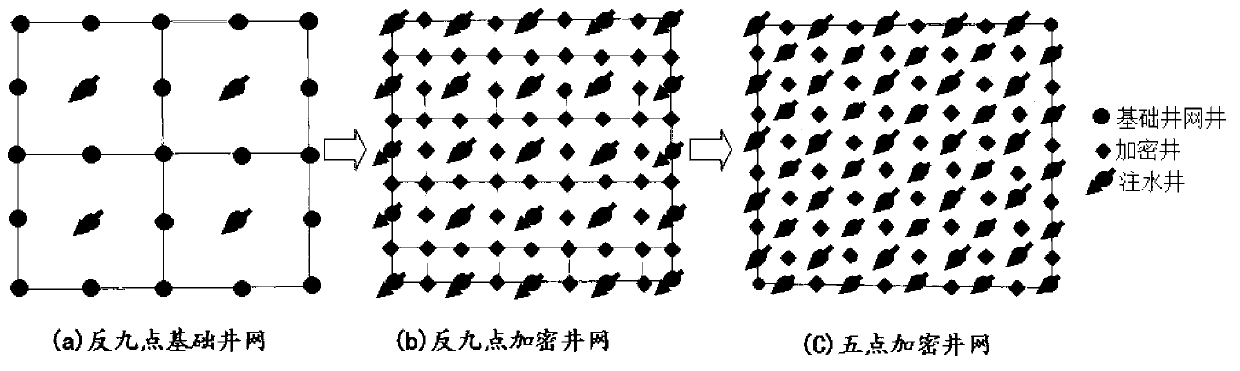

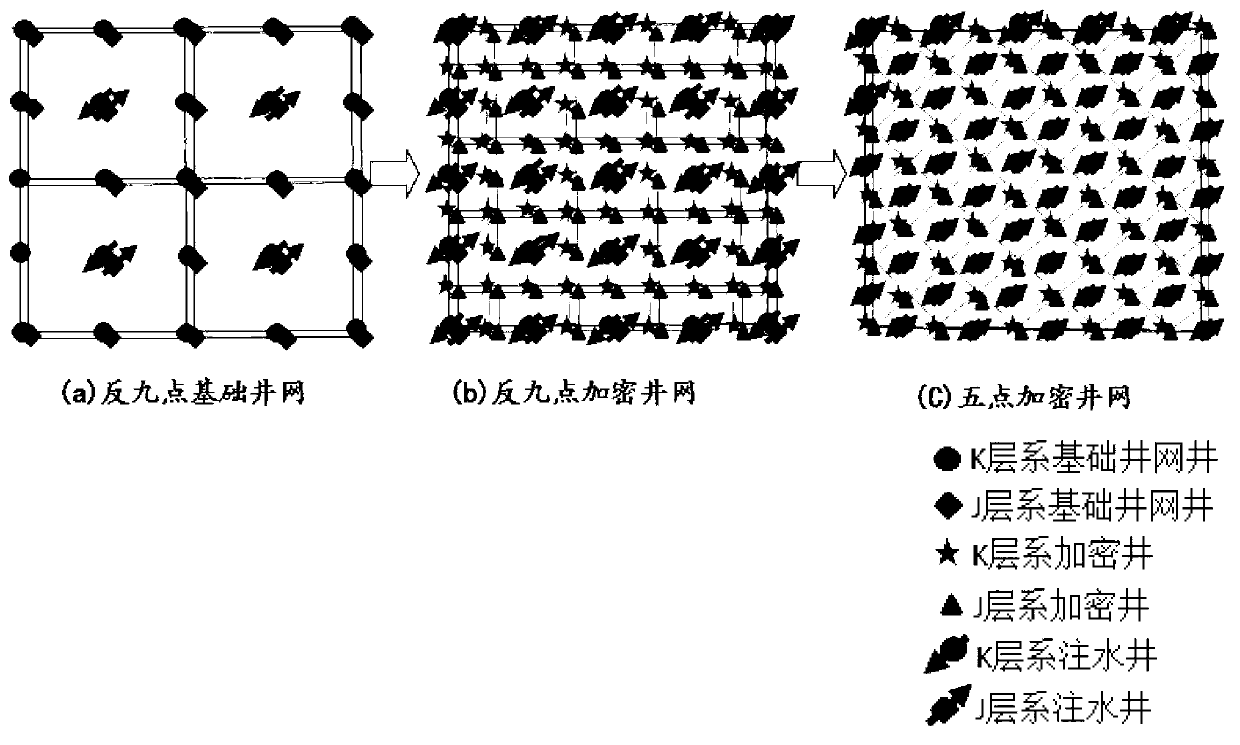

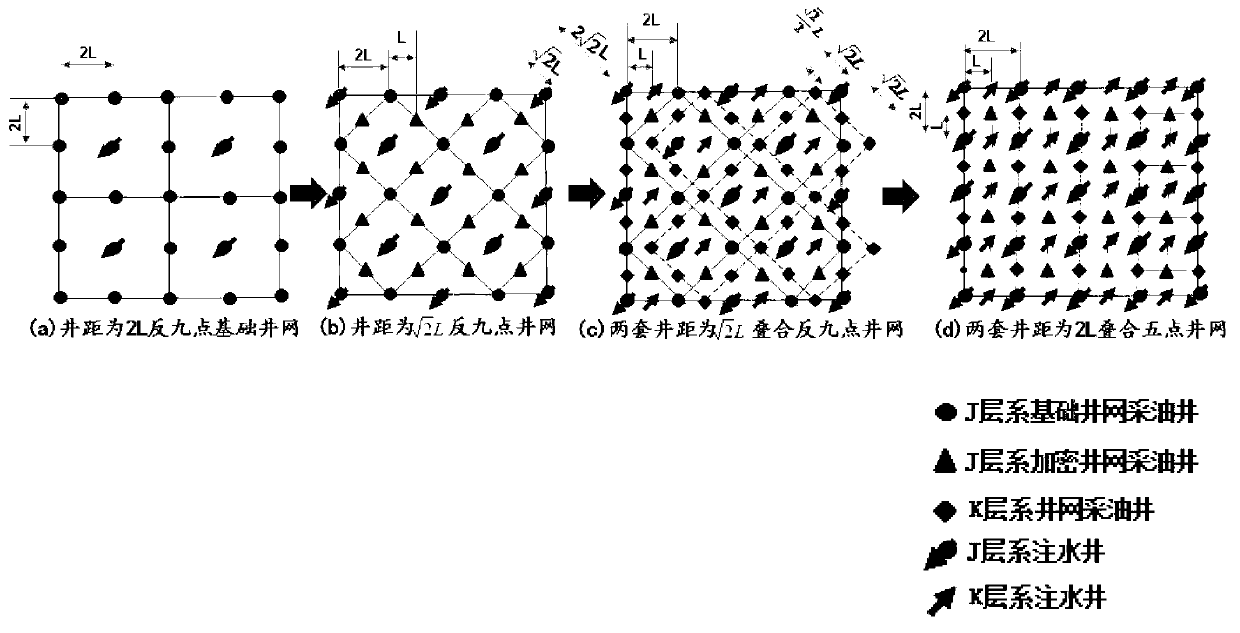

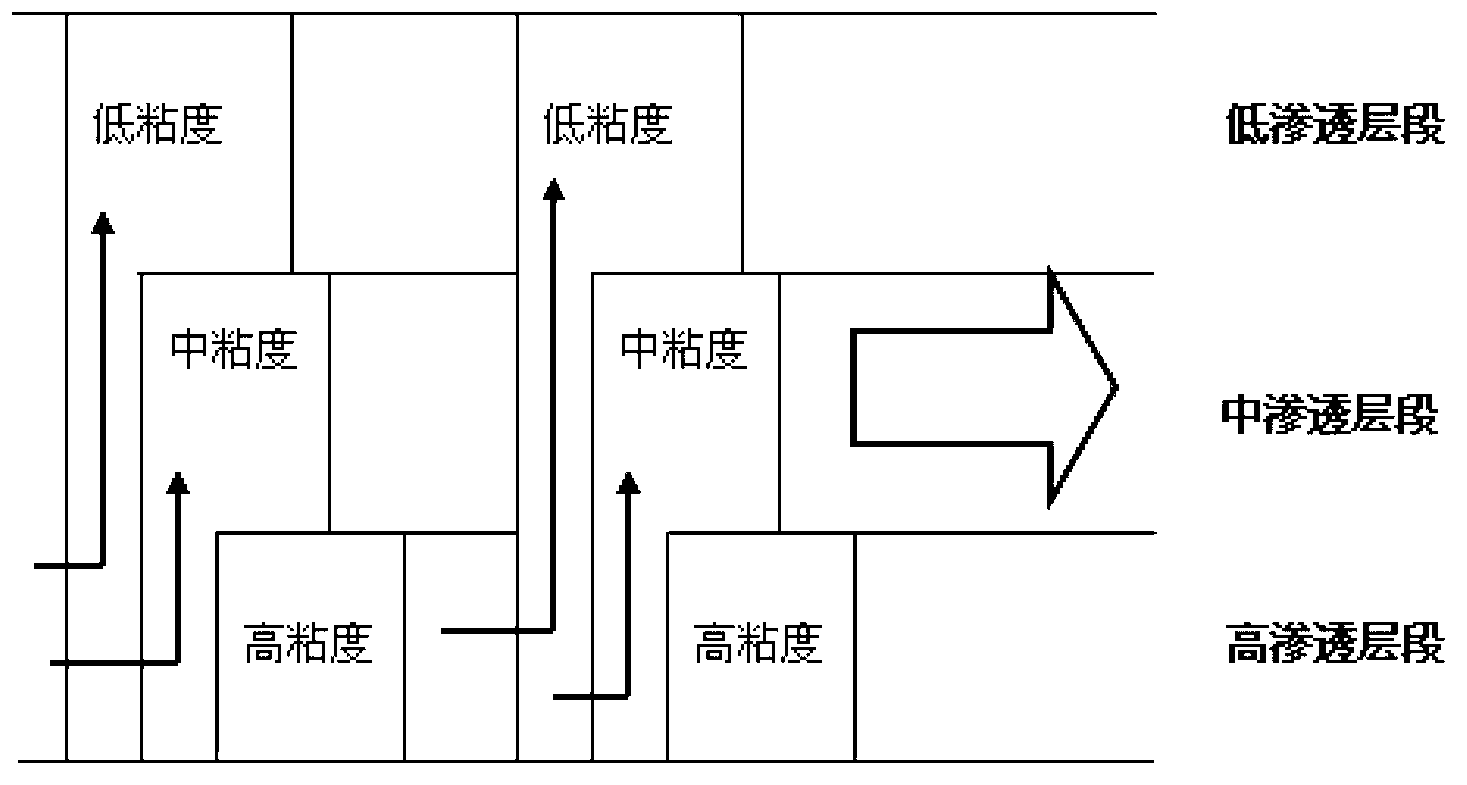

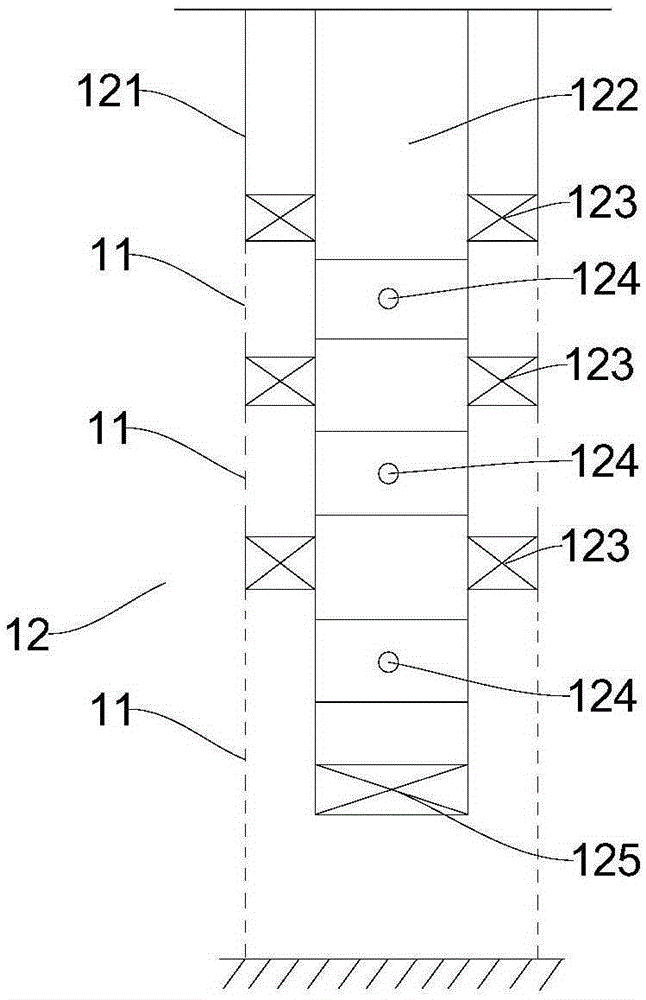

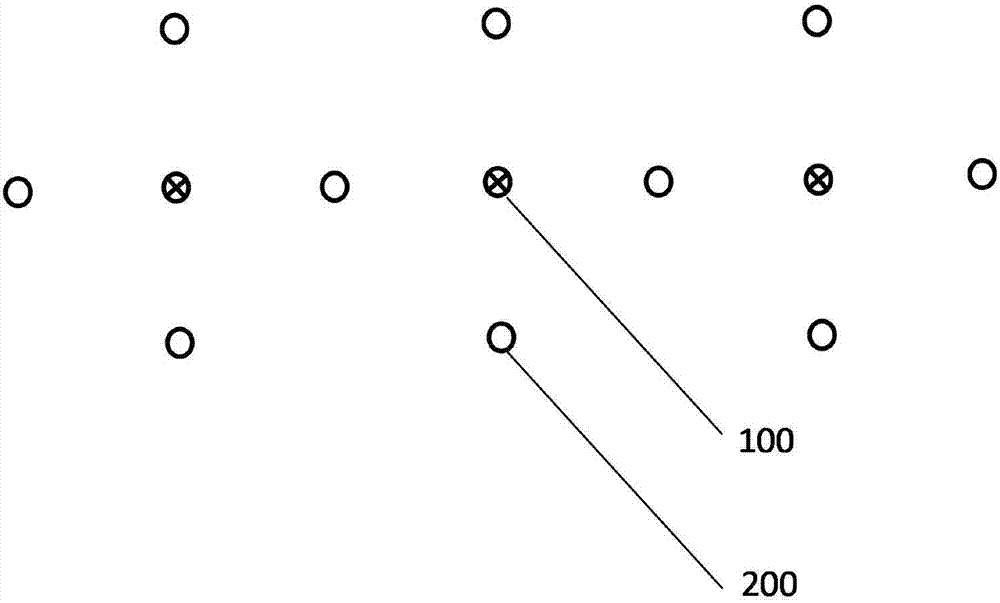

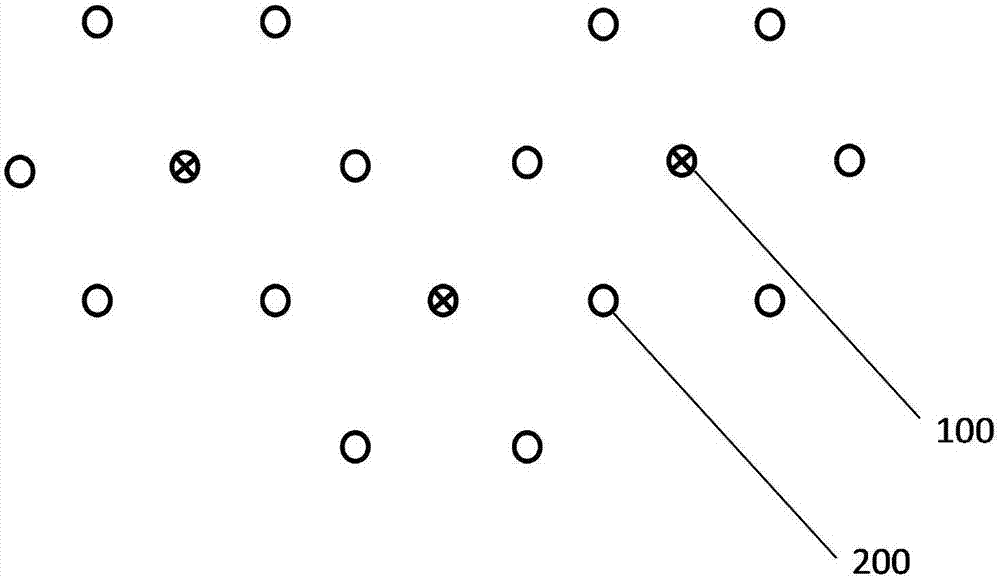

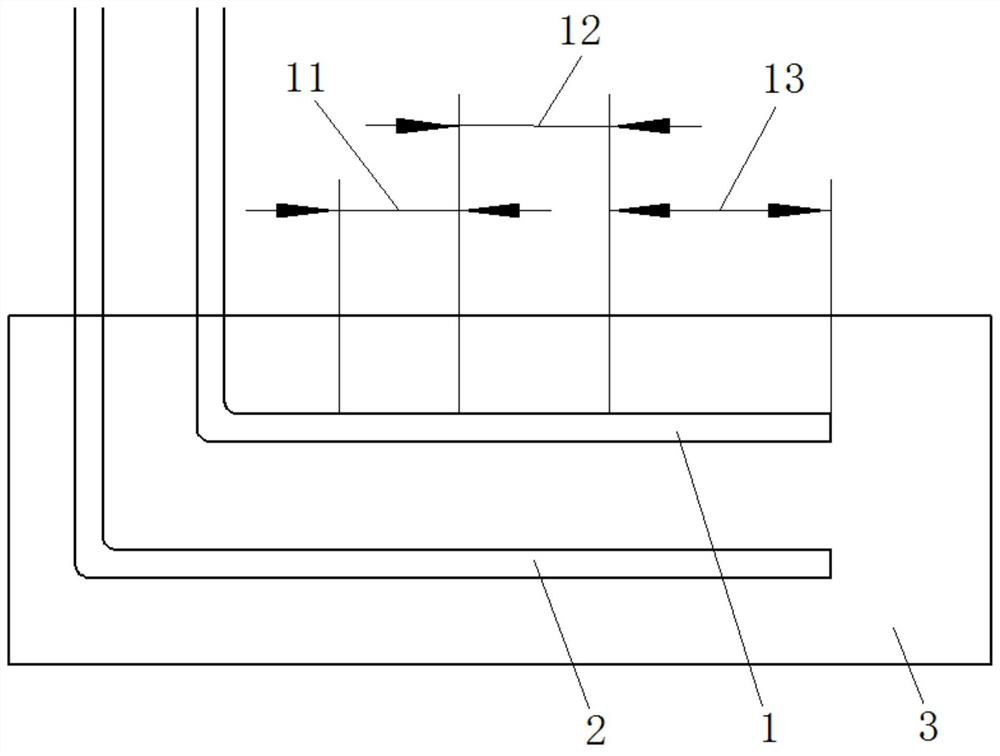

Longitudinally superposed developing two-strata oil reservoir well pattern, and arrangement method of two-strata oil reservoir well pattern

ActiveCN102839959AReduce developmentIncrease profitFluid removalWell drillingLongitudinal development

The embodiment of the invention discloses a longitudinally superposed developing two-strata oil reservoir well pattern, and an arrangement method of the two-strata oil reservoir well pattern. The method comprises the following steps: firstly determining the longitudinal development strata of the oil reservoir and the rational well distance, and determining the well spacing of a basic well pattern and the well spacing of a middle transitional well pattern according to the longitudinal development layer coefficient. According to the longitudinally superposed developing two-strata oil reservoir, the well spacing of the basic well pattern is 2L, after being encrypted once, the well spacing of a middle transitional well pattern is square root of 2 times L; after being encrypted twice, two superposed well patterns with a well spacing of square root of 2 times L are formed; the well spacing of the superposed well pattern after alternative strata development is L; the evolution process of the well spacing is as follows: 2L to 2 times square root of 2 L to L; the conversion middle process of a well pattern with a well spacing of square root of 2 times L; in the same drilling speed, well placement uniformity coefficient and reserve control speed are increased; the well spacing is encrypted in the alternation of well patterns; each well pattern can realize order development to each strata; the utilization ratio of the well patterns is improved; and meanwhile, the oil reservoir is uniformly used, so that the method is in favor of increasing accumulated oil production of an oil field and improving the recovery ratio; and interlayer interference generated by extracting oil in multiple oil layers of longitudinal series of strata is avoided.

Owner:PETROCHINA CO LTD

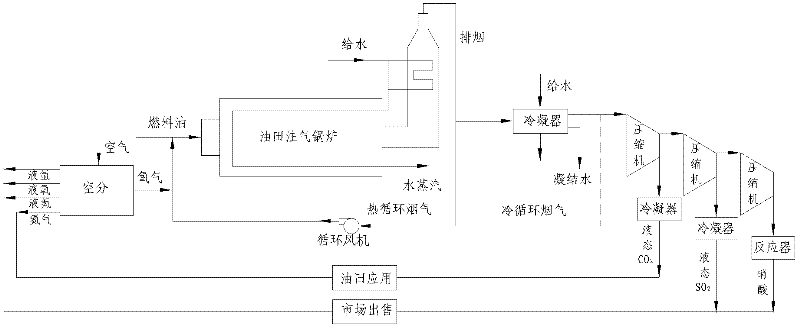

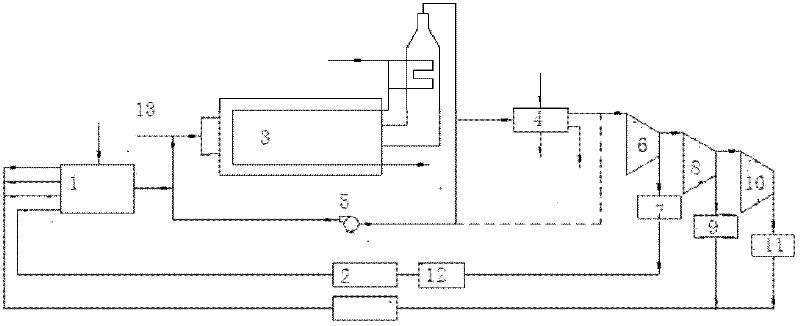

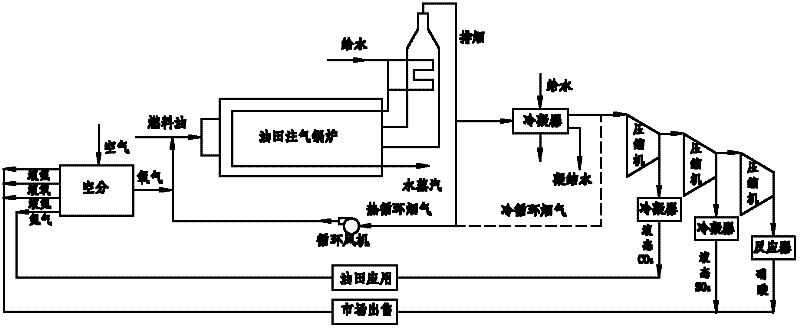

Oxygen-enriched combustion poly-generation process and equipment for steam injection boiler in oil field

InactiveCN102431974AFix storage issuesRealize integrated collaborative removalNitrogen compoundsSulfur compoundsAtmospheric airFuel oil

The invention relates to an oxygen-enriched combustion poly-generation process and equipment for a steam injection boiler in an oil field. According to the invention, air is subjected to deep cooling air separation so as to obtain nitrogen and pure oxygen; the pure oxygen is introduced into a steam injection boiler in an oil field and is mixed and burned with fuel oil so as to obtain CO2-rich flue gas; a part of the CO2-rich flue gas is used as circulation gas and is mixed with the pure oxygen, and mixed gas enters into the steam injection boiler; the rest part of the CO2-rich flue gas is compressed and condensed by using a CO2 liquefaction system so as to obtain high purity CO2, and the high purity CO2 is delivered to an oil displacement system of the oil field; flue gas which has undergone condensation and removal of CO2 enters into a SO2 and NOx recovery system so as to realize condensation and recovery of SO2 and NOx. According to the invention, the technology of oxygen-enriched combustion is introduced into the steam injection boiler, which enables the problem of storage of CO2 to be overcome and allows recovery and treatment of residual flue gas to be realized by using a simple method, thereby realizing integrated simultaneous removal of pollutants and protecting atmospheric environment; since a plurality of byproducts are obtained, considerable economic benefits can be achieved.

Owner:SHANDONG UNIV

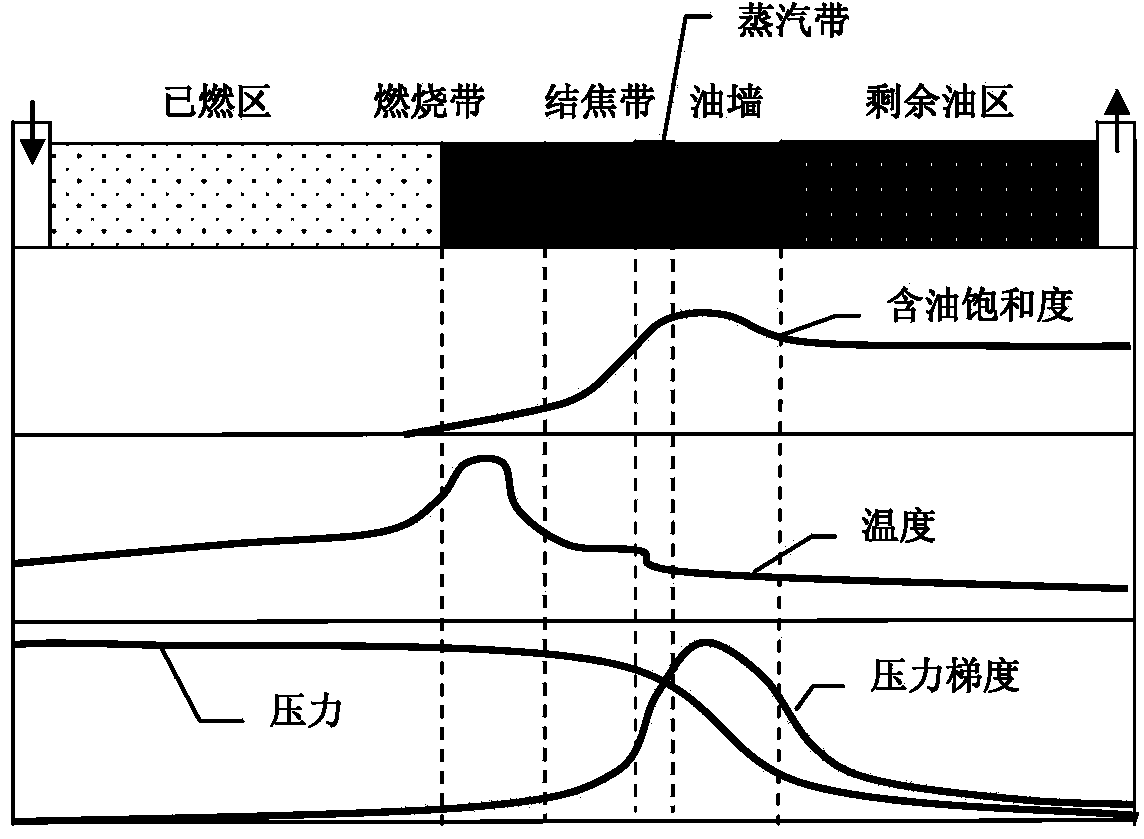

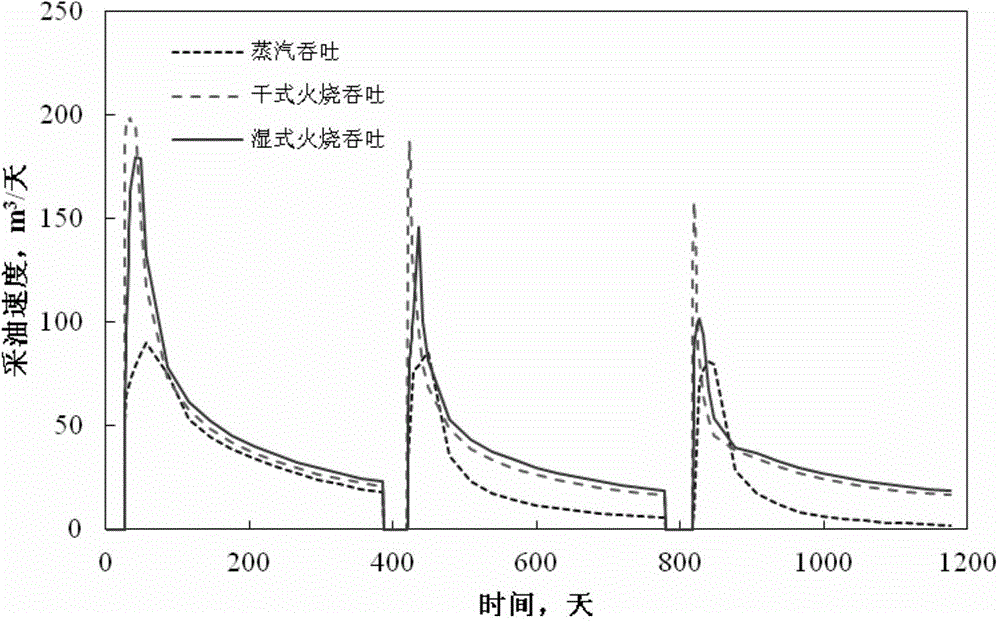

Fireflooding huff and puff and fireflooding linkage thickened oil exploitation method

InactiveCN104196507AReduce seepage resistanceThe fire drive process continuesFluid removalInjection airInjection well

The invention provides a fireflooding huff and puff and fireflooding linkage thickened oil exploitation method. The method comprises the steps of conducting well spacing in an area well pattern mode, wherein the distance between a deployment central well and the nearest producing well around the central well is smaller than or equal to 100 m; conducting fireflooding huff and puff on all wells of a deployment well pattern synchronously or sequentially; conducting area fireflooding with the central well of the area well pattern serving as a continuous gas-injection well and surrounding wells serving as producing wells after fireflooding huff and puff is conducted on all the wells for three to five periods averagely. According to the method, by means of fireflooding huff and puff and fireflooding linkage, air injection fireflooding exploitation of extra-heavy oil reservoirs and super-heavy oil reservoirs with viscosity over 10000 mPa.s under the formation condition is made possible.

Owner:BEIJING PUXIN PETROLEUM TECH DEV

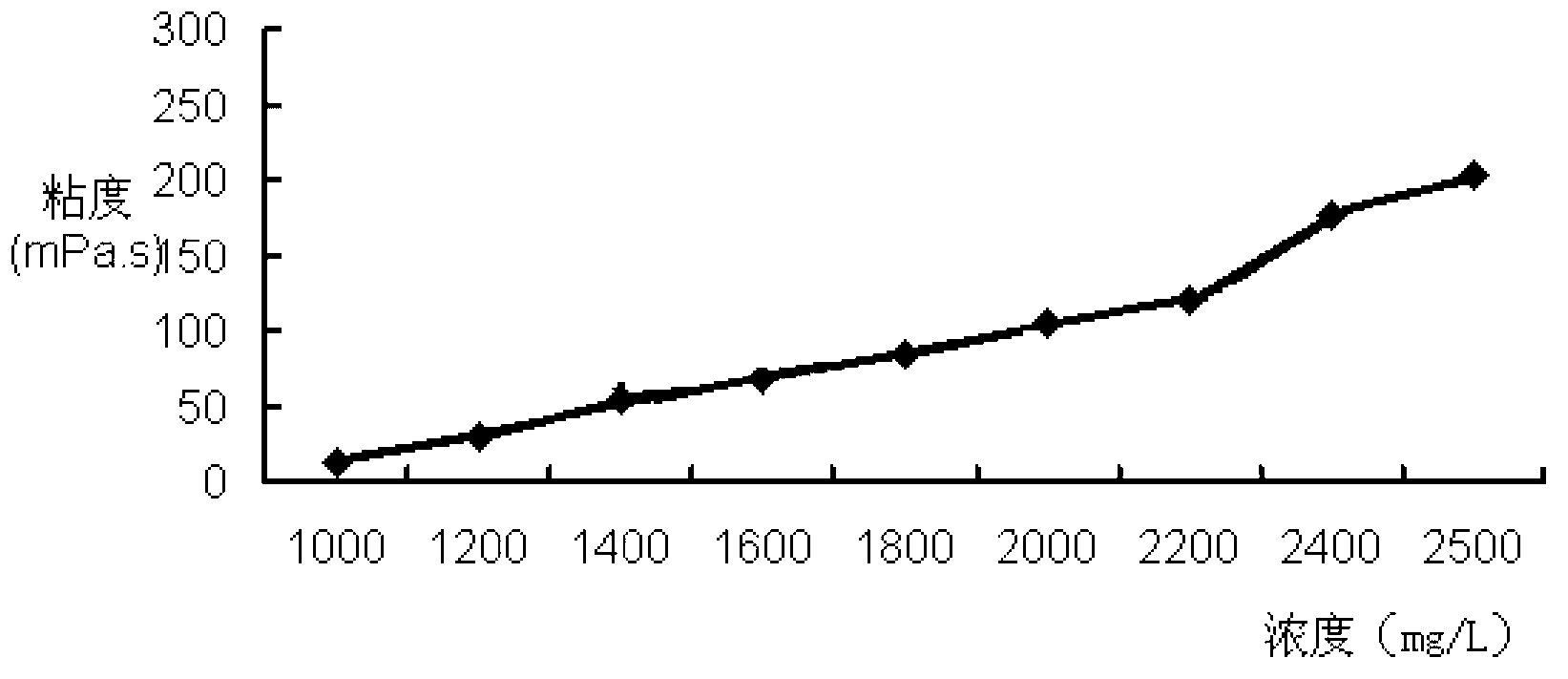

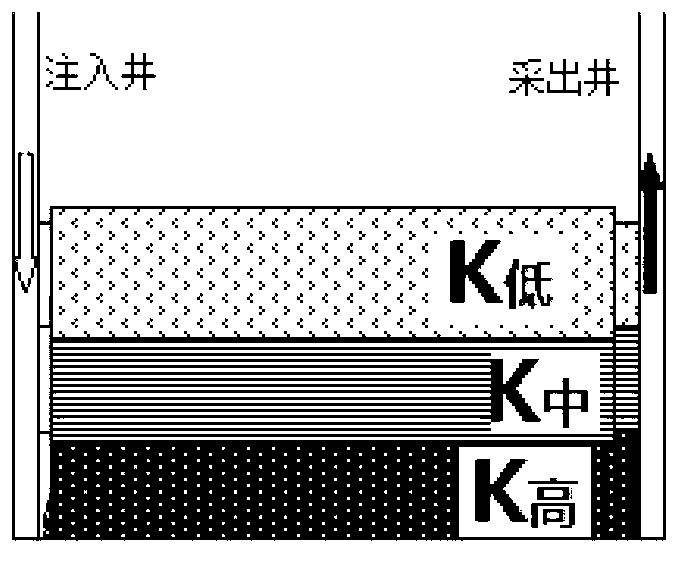

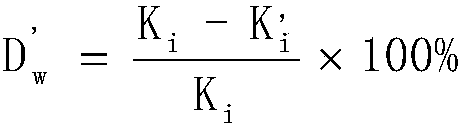

Heavy oil displacement method using wedged vicious slug

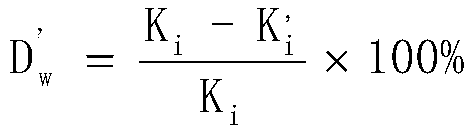

The invention relates to a heavy oil displacement method using a wedged vicious slug. The method includes the steps of 1, dividing a nonhomogeneous reservoir into a plurality of layers according to water absorbing capacities, and acquiring permeability Ki of each reservoir; 2, designing three slugs, namely a pre-slug, a main wedged slug and a trailed slug, according to the permeabilities Ki and the physical properties in heavy oil and reservoirs; 3, alternately injecting the heavy oil reservoir with the pre-slug which is prepared with low-concentration B III-type poly-surfactant and which enters a high permeability layer to emulsify crude oil; 4, injecting the reservoirs with the main wedged slug for multiple rounds; and 5, injecting the trailed slug with low-concentration B III-type poly-surfactant or fresh water generally. In each round, the main wedged slug is divided into three small slugs; the small slugs in each round are combined by regulating the corresponding concentrations by the B III-type poly-surfactant according to formation permeability. According to the method, the nonhomogeneous heavy oil reservoirs are emulsified to reduce viscosity, the wedged equivalent vicious slug is used for equi-fluidity displacement, and swept volume is increased; accordingly, recovery efficiency of heavy oil can be further increased, investment can be reduced and operation can be simplified.

Owner:DAQING DAHUA HONGYE PETROLEUM ENG TECH

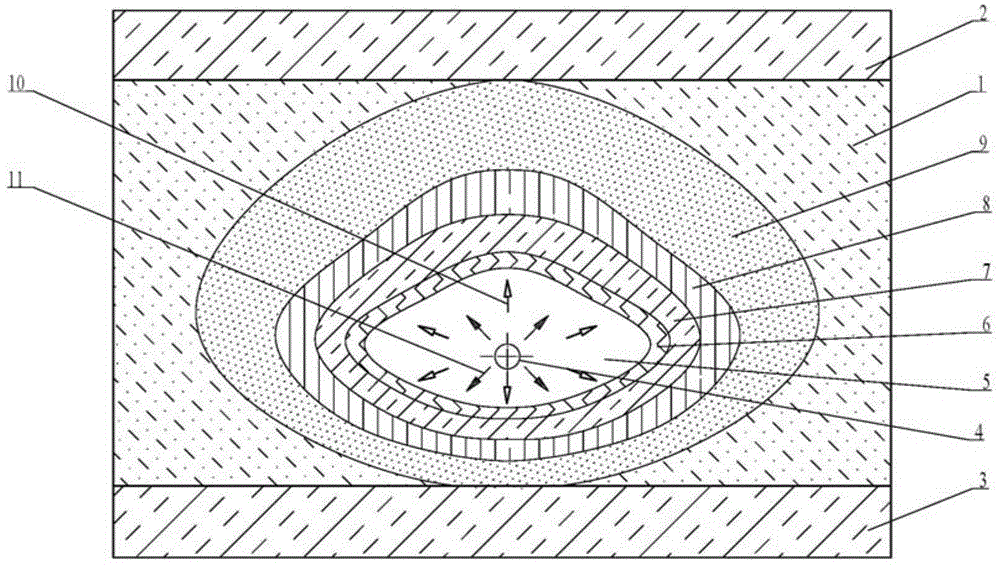

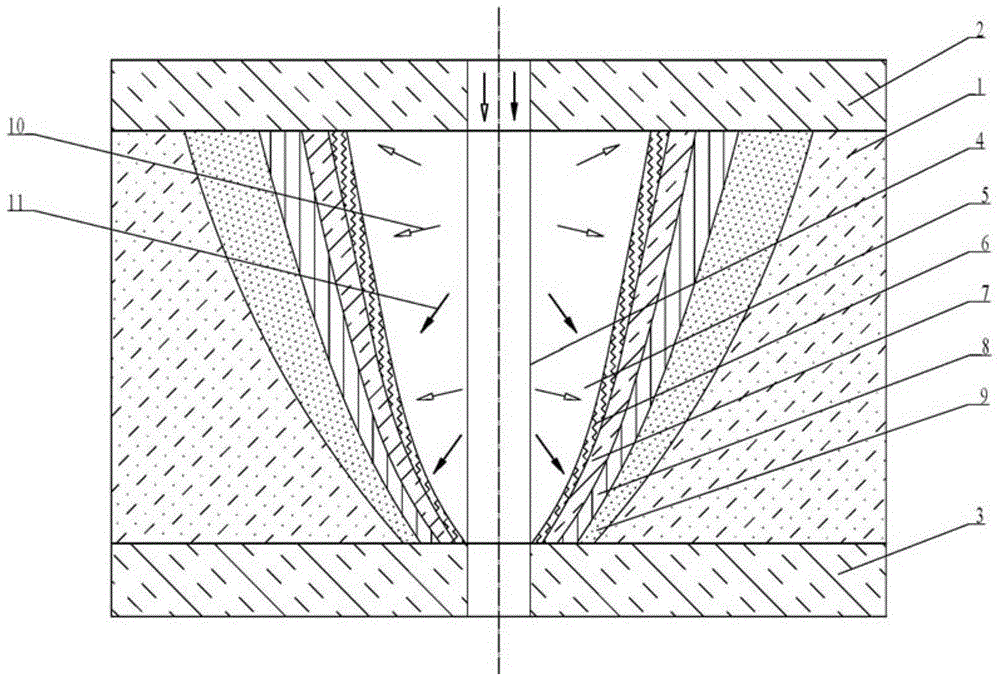

Wet type combustion huff-puff oil extraction method

The invention provides a wet type combustion huff-puff oil extraction method, comprising the steps of: 1, flushing an oil well, then injecting an oxidizing agent into an oil deposit, igniting to burn coke-like components generated by the oxidization and splitting decomposition of crude oil in the oil deposit to heat an oil layer; 2, while the oxidizing agent is completed injected or is injecting, injecting water to reduce the high temperature of a near wellbore formation, and extracting oil after soaking the well for 3-10 days; 3, after extracting oil for 100-700 days, performing a next round of processes of injecting the oxidizing agent, igniting, injecting water, soaking and extracting oil. According to the method provided by the invention, the water is injected into the oil deposit after the oxidizing agent is injected, and water flow flows through a combusted area and carries heat to the deep part of the oil deposit, so that the heating range of the oil deposit is enlarged, and the peripheral temperature of the oil well is prevented from being too high. According to the wet type combustion huff-puff oil extraction method, formation water and the injected water are vaporized to generate steam, heat, smoke and steam generated by combustion are comprehensively utilized to recover in a combined manner, the output and the recovery efficiency of the crude oil are improved, and the recovery efficiency is up to more than 70%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method of improving deep super-thick oil reservoir recovery efficiency

The invention relates to a novel method capable of improving deep super-thick oil reservoir recovery efficiency. According to the method, in the steam huff and puff and steam flooding processes, a water-soluble nano-catalyst is injected to make the viscosity of super-thick oil under the condition of an oil reservoir be reduced substantially, as a result, the fluidity of the super-thick oil under the condition of the oil reservoir is improved, the shortcomings that a deep super-thick oil reservoir is high in steam injection pressure and low in well bottom steam dryness are effectively overcome, steam injection quantity also can be reduced, and the purpose of economical and efficient development of the deep super-thick oil reservoir is achieved. On the basis of steam huff and puff and steam flooding, the method of improving deep super-thick oil reservoir recovery efficiency can reduce the velocity of crude oil by more than 80%, increase the recovery percent by about 15%, and increase the gas-oil ratio in a huff and puff well period by 0.15.

Owner:CHINA PETROLEUM & CHEM CORP +1

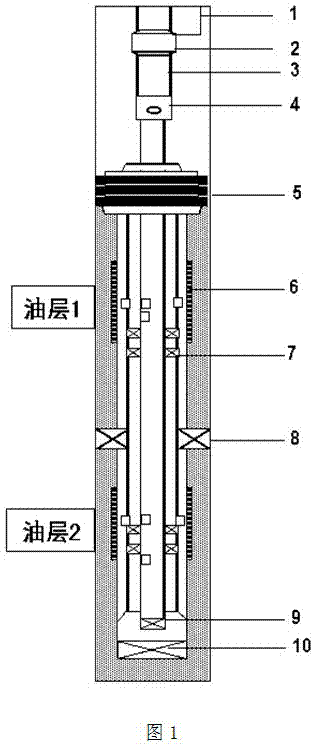

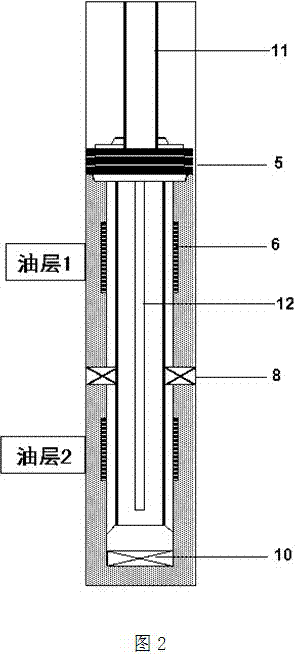

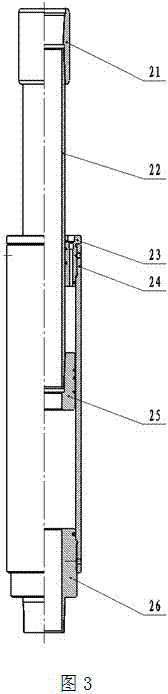

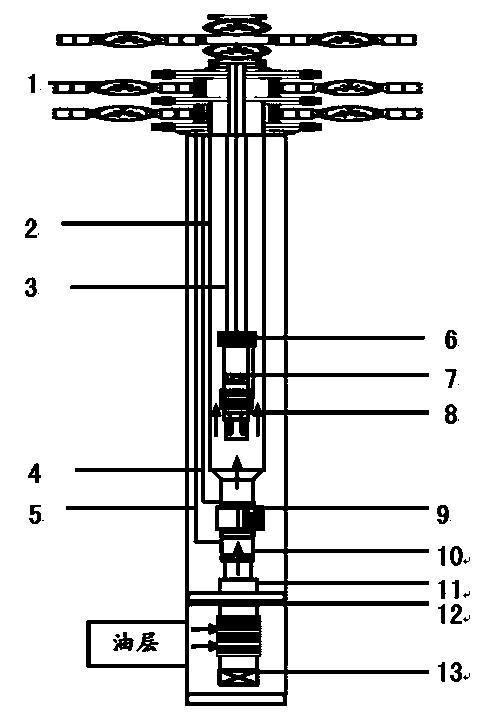

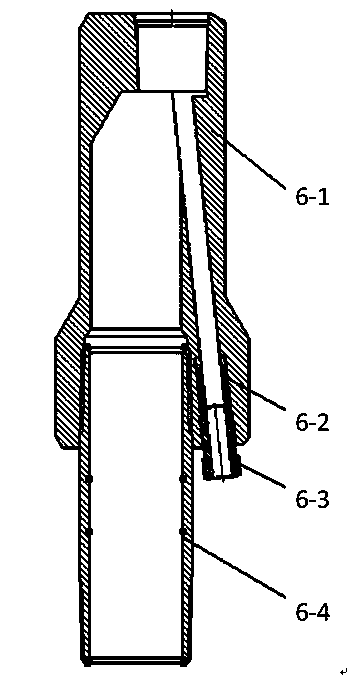

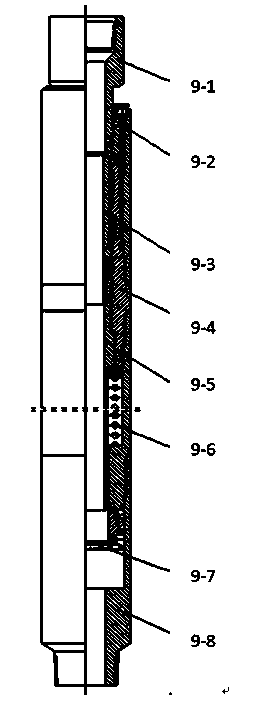

Lifting type layered oil production tubular column

InactiveCN103161432AGood technical effect and economic benefitImprove oil production rateDrilling rodsFluid removalOil productionOil well

The invention relates to a lifting type layered oil production tubular column which comprises a production tubular column and a hand-releasing tubular column which are mutually connected. The production tubular column includes a liquid control pipe line, a hydraulic hoisting device, a production oil pipe, an oil-well pump and a seal plug which are connected together from top to bottom. The hand-releasing tubular column comprises a hanging packer, a bi-layer sand-filtering pipe, and a layered packer. The bi-layer sand-filtering pipe is arranged on the outer side of the seal plug, the hanging packer is arranged on the upper end portion of the seal plug which is below the oil-well pump, and the layered packer is arranged at the middle position of the seal plug and between two oil layers. The lifting type layered oil production tubular column is capable of changing a technical tubular column of the layered oil production in a combination layer section, controlling the opening and closing of a multi-layer section switch in the pit through an extending and shortening mode of the tubular column and carrying out a combined oil production over oil production wells in different layer sections.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for exploiting thick-layer oil deposit in combustion of oil in situ

InactiveCN104594864AReduce operating costsEconomical and efficient developmentFluid removalElectricityCombustion

The invention provides a method for exploiting a thick-layer oil deposit in the combustion of oil in situ. The method includes the following steps that at least one vertical well or inclined straight well is arranged in a natural perpendicular crack area or a non-natural-perpendicular-crack area, and run casing completion is conducted; a high-temperature resistance packer is arranged and located above the bottom boundary of a target oil layer by 2-3 meters; when the non-natural-perpendicular-crack area is selected for arranging the well, a perpendicular crack penetrating through the whole target oil layer is arranged and generated in the target oil layer in the non-natural-perpendicular-crack area; a propping agent is injected in the perpendicular crack; an electric ignition or chemical ignition manner is used for igniting a fuel layer; oxygen-containing gas or matter generating oxygen through pyrolysis is injected into the target oil layer; an electric submersible pump is used for production or a coiled tube is used for gas injection for production, and when the front edge of a fire wire moves downwards to the packer, production is over. According to the method for exploiting the thick-layer oil deposit in the combustion of oil in situ, a large amount of operation cost can be saved, and economical and efficient combustion of oil in situ development of the thick-layer oil deposit is achieved.

Owner:PETROCHINA CO LTD

Polymer displaced steam injecting hot oil deposit exploiting method

The polymer displaced steam injecting hot oil deposit exploiting method is used for further exploitation of polymer displaced oil deposit to raise the exploiting rate. The polymer displaced oil deposit is converted into hot steam soak and hot steam displacement through the step of: selecting oil deposit with oil layer depth smaller than 3000 m, residual oil saturation degree greater than 0.30. oil depth thickness greater than 5.0 m, net total thickness ratio greater than 0.3, oil layer porosity greater than 0.15 and permeability variation coefficient smaller than 0.8; selecting reversed nine-point well network and drilling new steam injecting well apart from production well by 150-300 m for steam injecting hot exploitation; and converting into steam displacement of simultaneous steam injection and continuous production with single well steam injection speed of 1.0-3.0 cu m / d. ha m, well bottom steam quality greater than 30 % and injection-production ratio manufactured over 1.0. The present invention raises recovery ratio by over 10 %.

Owner:PETROCHINA CO LTD

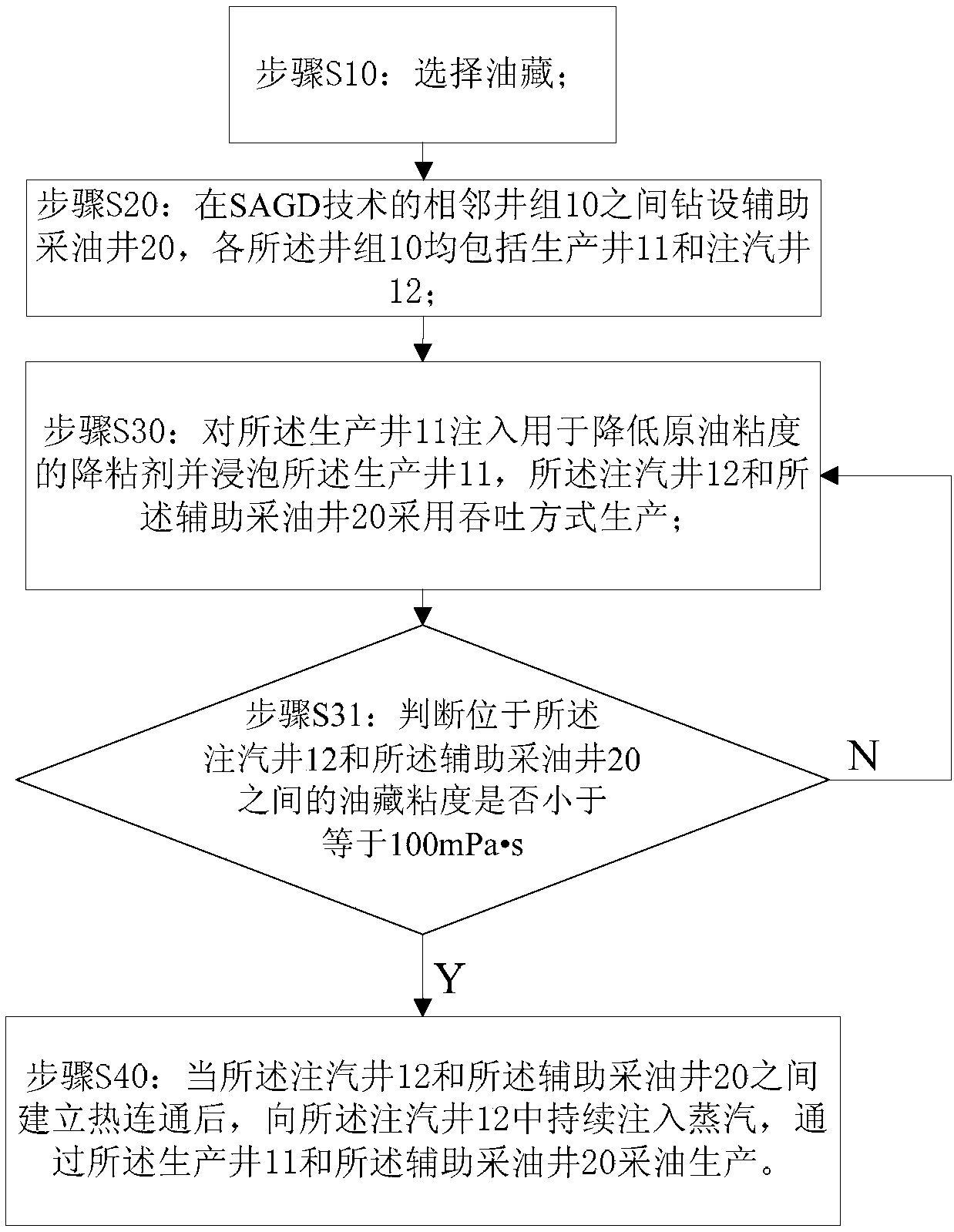

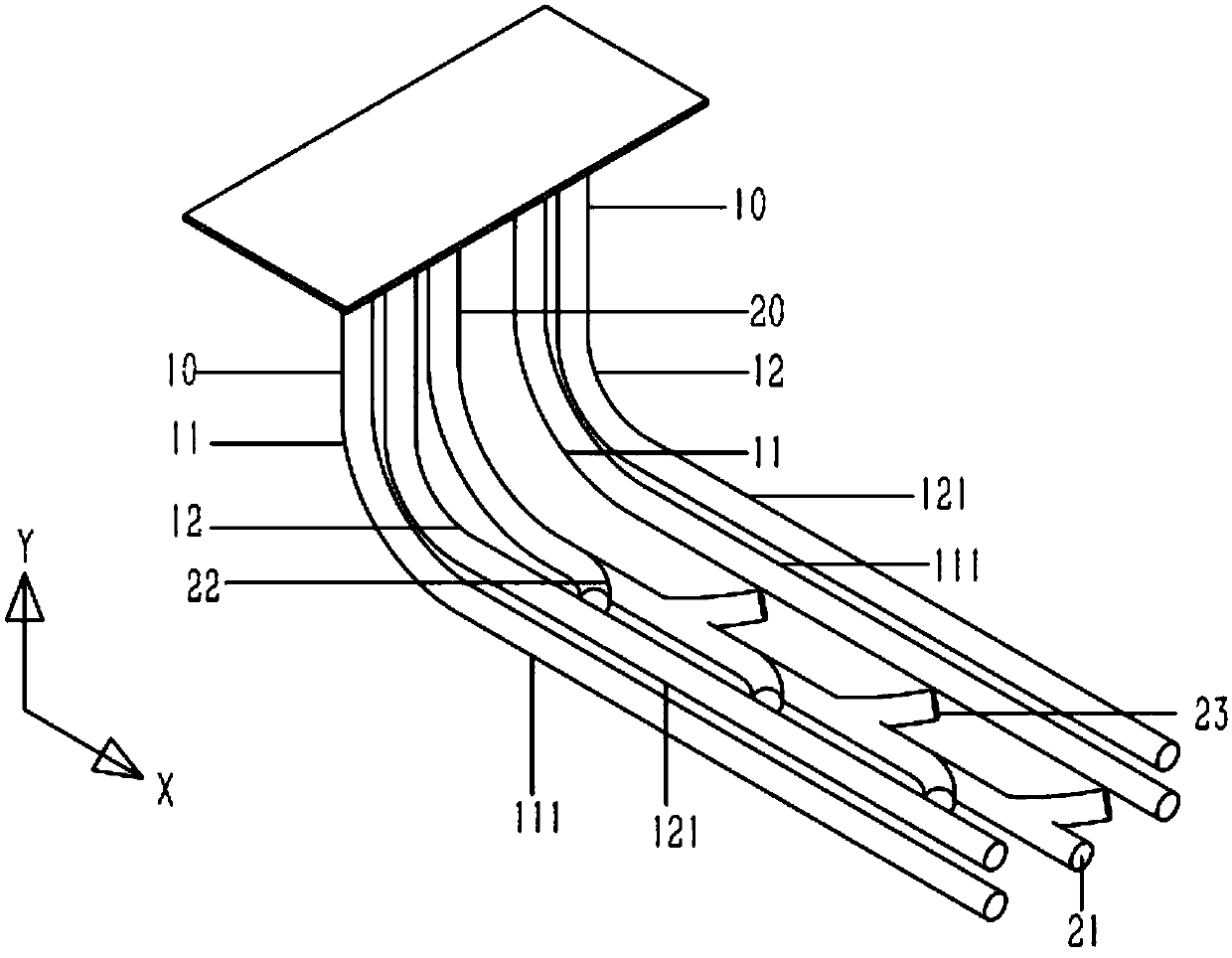

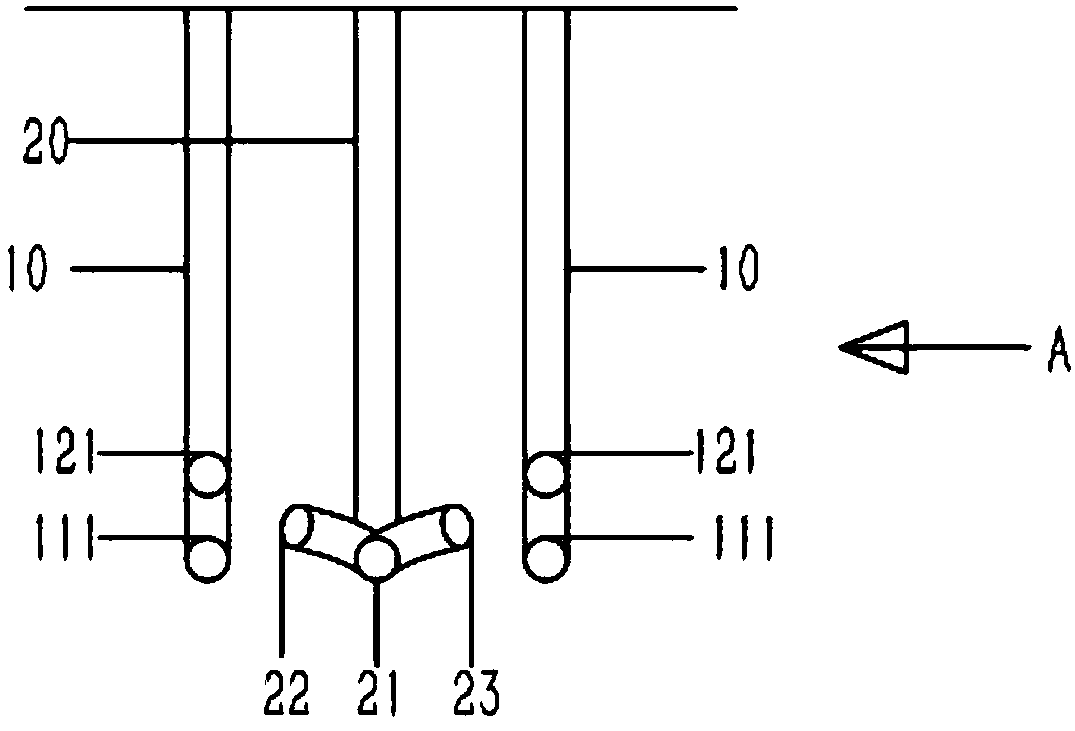

Method for exploiting super heavy oil through combination of auxiliary oil exploiting wells and steam assisted gravity drainage (SAGD)

The invention provides a method for exploiting super heavy oil through combination of auxiliary oil exploiting wells and steam assisted gravity drainage (SAGD). The method for exploiting the super heavy oil comprises the steps: S10, an oil reservoir is selected; S20, the auxiliary oil exploiting wells are drilled between adjacent well sets, and each well set comprises a production well and a gas injection well; S30, a viscosity reducing agent used for reducing the viscosity of crude oil is injected into the production wells and soaks the production wells, and the gas injection wells and the auxiliary oil exploiting wells adopt a huff and puff mode for production; and S40, after hot communication is established between the gas injection wells and the auxiliary oil exploiting wells, steam iscontinuously injected into the gas injection wells, and oil exploiting production is conducted through the production wells and the auxiliary oil exploiting wells. According to the method for exploiting the super heavy oil, the problem that in the prior art, the crude oil in a triangular area is very difficult to exploit in the later stage of SAGD production is solved.

Owner:PETROCHINA CO LTD

Fireflooding oil-extracting method for exploiting super heavy oil reservoir with bottom water

The invention provides a fireflooding oil-extracting method for exploiting a super heavy oil reservoir with bottom water. The method comprises the following steps of oil reservoir screening, well pattern arranging, steam stimulation, crude oil fireflooding and crude oil extracting. According to the fireflooding oil-extracting method for exploiting the super heavy oil reservoir with the bottom water, fireflooding oil extracting is conducted by adoption of different well pattern combination modes and different perforation modes, a bottom water layer is provided with flowing channels for the three phases of oil, gas and water in the fireflooding process, gas overlapping can be effectively controlled, fire line advancing is stable, and the purposes of uniform longitudinal producing, high oil flushing efficiency, high recovery efficiency, low production cost and good economic benefits are achieved.

Owner:PETROCHINA CO LTD

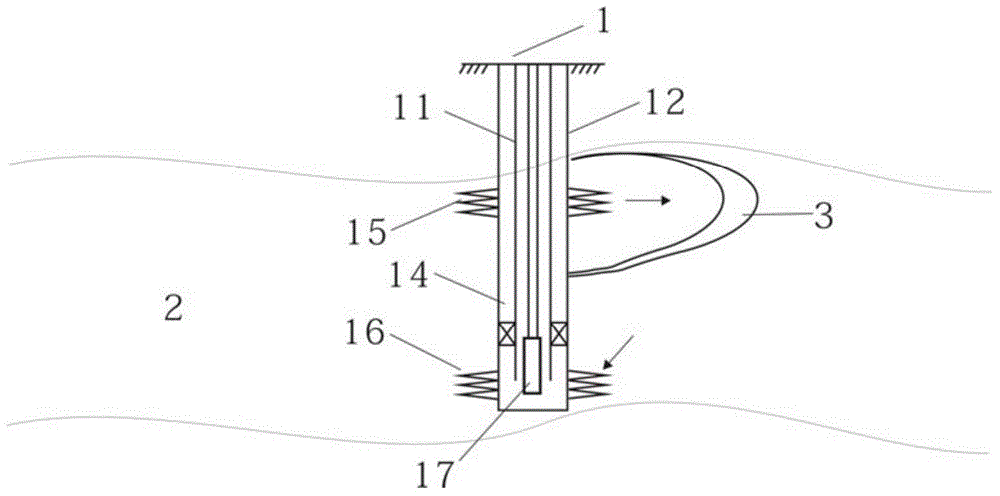

Oil recovery method combining steam flooding and fire flooding

ActiveCN105257269AEnhanced overall recoveryImprove oil production rateFluid removalExhaust gasSetting time

The invention provides an oil recovery method combining steam flooding and fire flooding. The method includes: arranging a vertical well and at least one horizontal well; injecting air into the vertical well to produce tail gas, and allowing the horizontal wells to discharge the tail gas; injecting high-temperature steam into a third oil layer through the vertical well, and stopping the high-temperature steam injection after the high-temperature steam is injected for first set time; performing ignition and gas injection on a second oil layer through the vertical well to allow the second oil layer to combust so as to form a fire line, and stopping air injection when the distance between the fire line and the tail ends of the horizontal wells reaches preset length; injecting high-temperature steam into a first oil layer and the third oil layer at the same time through the vertical well to produce flowing oil, allowing the horizontal wells to lift the flowing oil to the ground, and stopping the high-temperature steam injection when the high-temperature steam is injected for second preset time; injecting air into the first oil layer, the second oil layer and the third oil layer through the vertical well so as to perform oil layer reaction, and allowing the horizontal wells to lift the produced flowing oil to the ground. By the method, steam flooding oil recovery and fire flooding oil recovery can be performed in a layered manner after the air and / or high-temperature steam are injected in a layered manner through the vertical well.

Owner:PETROCHINA CO LTD

Offshore no-killing electric pump lifting process pipe string

ActiveCN103806878AThe impact of reduced capacitySignificant comprehensive benefitsSurveyFluid removalElectricityCoupling

The invention discloses an offshore no-killing electric pump lifting process pipe string. The pipe string comprises a control pipe string and a production pipe string which are mutually connected and matched, wherein the control pipe string comprises a sand preventing and filtering pipe, a pressure measuring and transferring cylinder and a no-coupling casing which are connected sequentially from bottom to top; the production pipe string is arranged in the no-coupling casing and comprises an electric pump unit, a check valve, a cable conversion device and a coiled tubing which are connected sequentially from bottom to top; a filling packer is connected between the sand preventing and filtering pipe and the pressure measuring and transferring cylinder, a densely inserting device is nested to the upper end part of the filling packer, and a guide step is arranged at the bottom of the densely inserting device; and a subsurface safety valve is connected between the pressure measuring and transferring cylinder and the no-coupling casing, and a variable-diameter guide step is arranged at the bottom of the no-coupling casing. According to the offshore no-killing electric pump lifting process pipe string, opening and closing of a flow path from the stratum to a wellhead of a down-hole are controlled through a mode that pressurization is performed by a ground hydraulic pump and pressure is transferred through a pilot-controlled pipeline, and operation such as no-killing pump inspection, pump change, downhole cable inspection and the like are performed on an offshore producing well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water displaced steam injecting hot masout exploiting method

The water displaced steam injecting hot masout exploiting method is used for further explitation of water displaced masout deposit to raise the exploiting rate. The water displaced masout deposit is converted into hot steam soak and hot steam displacement through the steps of: selecting masout deposit with oil layer depth smaller than 3000 m, residual oil saturation degree greater than 0.30, oil depth thickness greater than 5.0 m, net total thickness ratio greater than 0.3, oil layer porosity greater than 0.15 and permedbility variation coefficient smaller than 0.8; selecting reversed nine-point well network and drilling new steam injecting well apart from production well by 150-300 m for steam injecting hot exploitation; and converting into steam displacement of simultaneous steam injection and continuous production with single well steam injection speed of 1.0-3.0 cu m / d. ha m, well bottom steam quality greater than 30 % and injection-production ratio manufactured over 1.0. The present invention raises recovery ratio by over 10 %.

Owner:PETROCHINA CO LTD

Method for improving economic benefit of single well by exploiting oil and gas through bottom water vapor flooding

PendingCN113719261AIncrease Controlled ReservesGreat practicabilityFluid removalHorizontal wellsOil production

The invention discloses a method for improving the economic benefit of a single well by exploiting oil and gas through bottom water vapor flooding, namely heating the upper part of formation water of an oil and gas reservoir in a pressure control and stabilization mode, preheating the oil and gas reservoir, continuously boiling the formation water, and exploiting the oil and gas through the bottom water vapor flooding of the oil and gas reservoir; and the accumulated oil production of the single well of an oil reservoir is improved by increasing the single-well controlled reserves of a production well and reducing the number of heating horizontal wells, bottom water invasion is inhibited and delayed by replacing a single-branch horizontal production well with a multi-branch production well, increasing the preheating temperature of the oil reservoir and regulating and controlling one or more combination modes of the liquid discharge amount and the electric heating power of the production well, the horizontal radial flowing speed of crude oil is increased, the oil reservoir recovery efficiency and the oil extraction speed after the single-well controlled reserves are increased are further increased, the electric charge cost and the energy consumption of per ton of oil are reduced, and then the single-well economic benefits are increased. A digital-analog calculation result shows that the average cumulative oil production of a single well of a 80m * 200m * 600m multi-branch horizontal production well model is 180000-270000 tons, and the economic benefit is 3-5 times that of a 80m * 80m * 200m small well spacing model.

Owner:BEIJING RED BLUE BLACK ENERGY TECH CO LTD

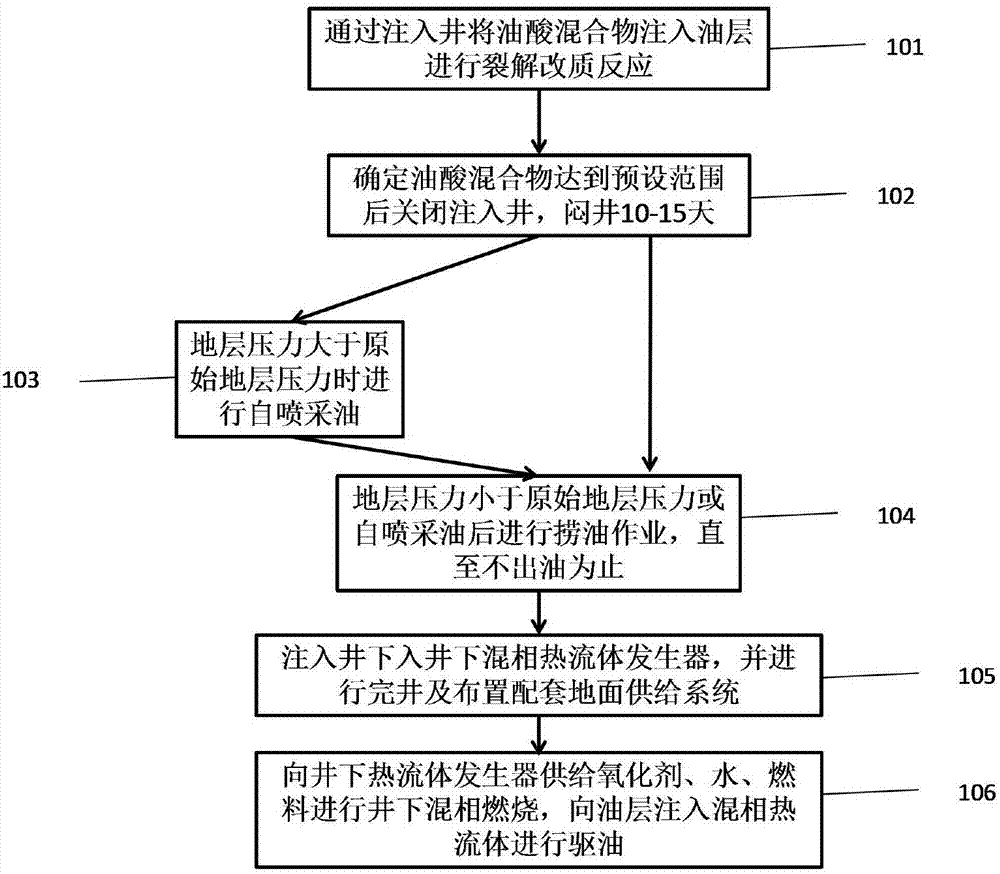

Oleic acid mixture based heavy oil modification and mixed-phase thermal fluid flooding combined oil extraction method

InactiveCN106996284AReduce heat lossReduce corrosionFluid removalDrilling compositionOil fieldInjection well

The invention relates to the technical field of oil field exploitation, in particular to an oleic acid mixture based heavy oil modification and mixed-phase thermal fluid flooding combined oil extraction method. The method includes: 1) injecting an oleic acid mixture into an oil reservoir through an injection well to enable underground cracking modification reaction between oleic acid and crude oil; 2) closing after determining that the injected oleic acid mixture reaches a preset range; 3) after closing time reaches a preset range, performing oil flow production; 4) pumping until oil discharging stops; 5) putting an underground mixed-phase thermal fluid generator in the injection well, arranging a matched ground supply system, starting underground generation of mixed-phase thermal fluid to carry out a flooding oil extraction step, and extracting the crude oil from a production well. The method can be applied to primary oil extraction of heavy oil and super-heavy oil reservoirs and is also available for tertiary oil extraction of the heavy oil and super-heavy oil reservoirs and capable of increasing heavy oil and super-heavy oil extraction ratio and reducing oil extraction cost.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Water displaced steam injecting hot masout exploiting method

The water displaced steam injecting hot masout exploiting method is used for further explitation of water displaced masout deposit to raise the exploiting rate. The water displaced masout deposit is converted into hot steam soak and hot steam displacement through the steps of: selecting masout deposit with oil layer depth smaller than 3000 m, residual oil saturation degree greater than 0.30, oil depth thickness greater than 5.0 m, net total thickness ratio greater than 0.3, oil layer porosity greater than 0.15 and permedbility variation coefficient smaller than 0.8; selecting reversed nine-point well network and drilling new steam injecting well apart from production well by 150-300 m for steam injecting hot exploitation; and converting into steam displacement of simultaneous steam injection and continuous production with single well steam injection speed of 1.0-3.0 cu m / d. ha m, well bottom steam quality greater than 30 % and injection-production ratio manufactured over 1.0. The present invention raises recovery ratio by over 10 %.

Owner:PETROCHINA CO LTD

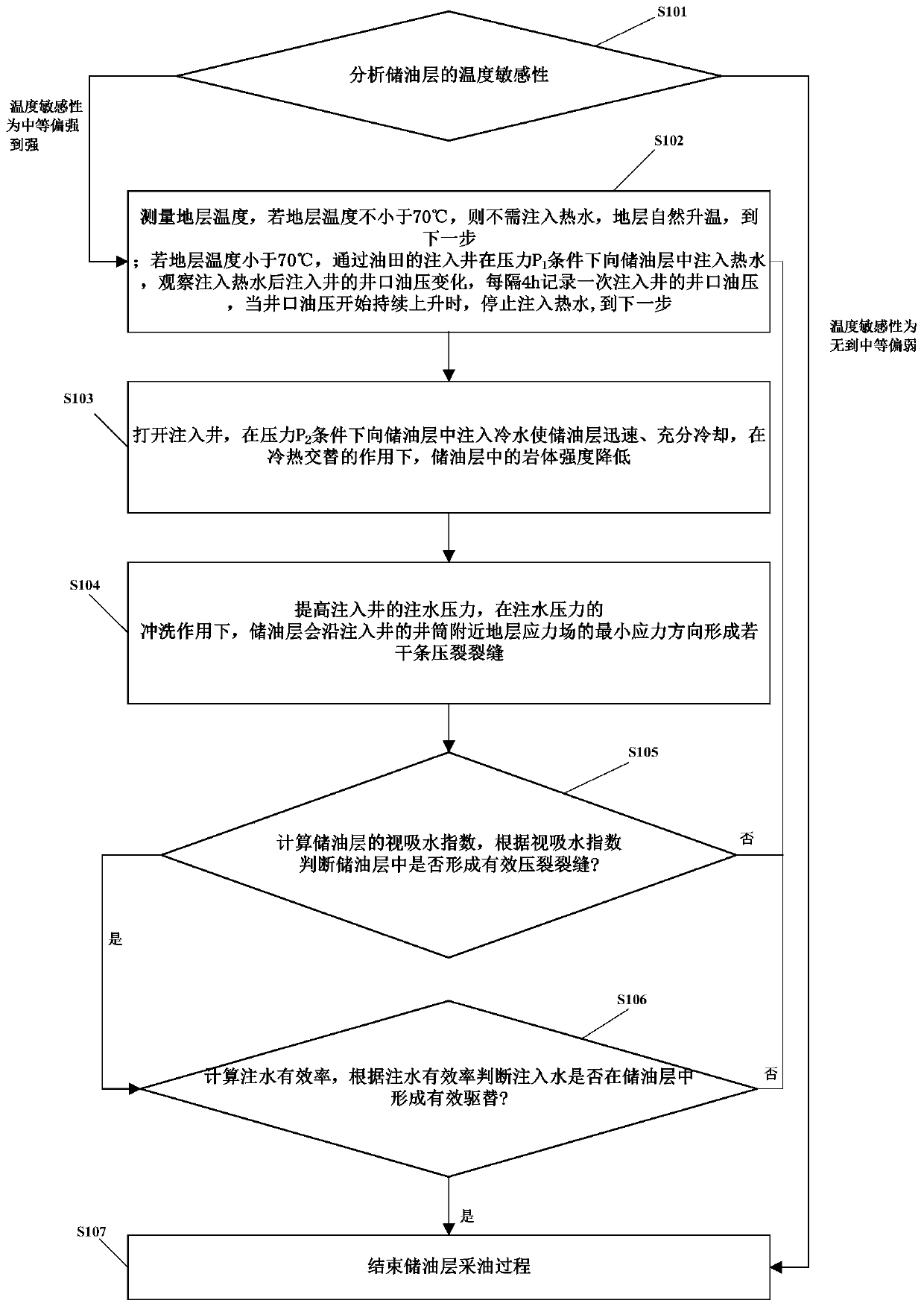

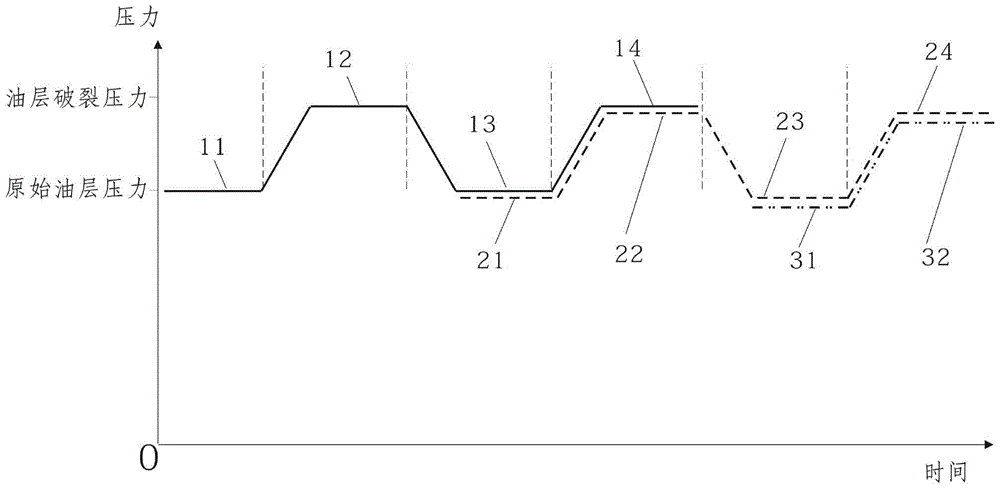

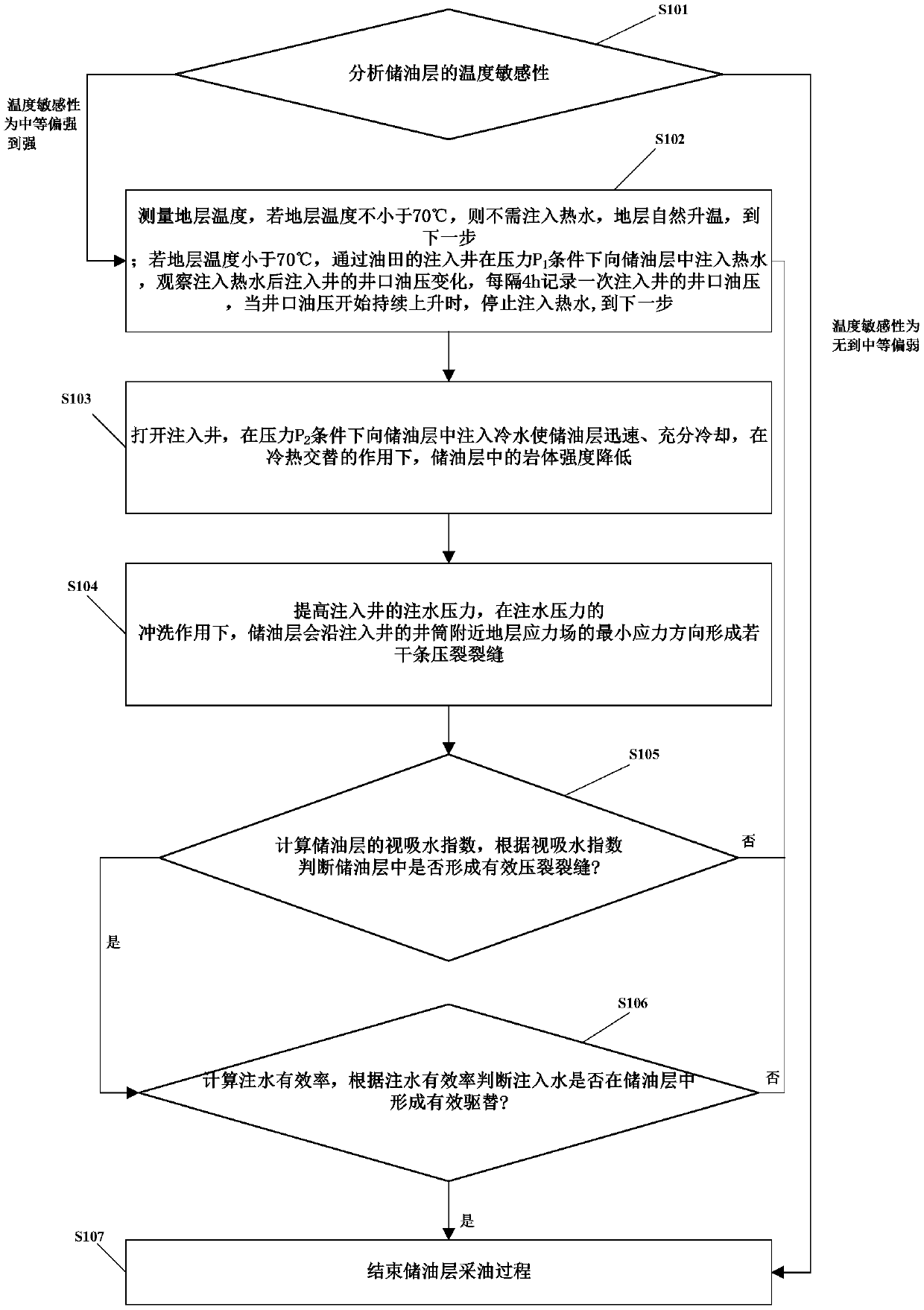

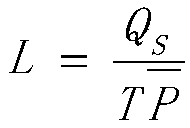

A kind of oil production method of alternate cold and hot pulse water injection

InactiveCN108643874BGood physical propertiesImprove oil production rateData processing applicationsFluid removalOil productionEvery Four Hours

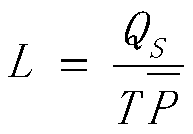

The invention provides an oil extraction method adopting cold and heat pulse alternate water injection. The oil extraction method comprises the following steps that the temperature sensitivity of an oil reservoir is analyzed, if the temperature sensitivity of the oil reservoir is medium to strong or strong, hot water is injected into the oil reservoir through an injection well of an oil field, thewellhead oil pressure of the injection well is recorded every four hours, and when the wellhead oil pressure begins to rise continuously, the hot water injection is stopped; the injection well is opened, and cold water is injected into the oil reservoir to enable the oil reservoir to be cooled; the water injection pressure of the injection well is increased, and under the flushing action of the water injection pressure, a plurality of fracturing cracks can be formed in the oil reservoir in the minimum stress direction of a stratum stress field near a shaft of the injection well; the apparentwater injectivity index of the oil reservoir is calculated, and according to the apparent water injectivity index, whether the effective fracturing cracks are formed in the oil reservoir or not is judged; and the water injection effective rate is calculated, and according to the water injection effective rate, whether the injected water forms effective displacement in the reservoir or not is judged.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Oil extraction method applied to oil exploration

InactiveCN110965975AIncrease Controlled ReservesExpand well spacingFluid removalThermodynamicsHorizontal wells

The invention discloses an oil extraction method applied to oil exploration. The oil extraction method comprises the following steps that (1) a horizontal well is arranged at the bottom of an oil layer, and a vertical well is arranged over the toe end of the horizontal well; (2) fracturing is conducted on the horizontal well; (3) a steam preheating stage, an ignition stage and a production stage are conducted sequentially, wherein at the steam preheating stage, a long pipe injection and short pipe extraction mode is adopted for the horizontal well, and low-pressure huff and puff production isadopted for the vertical well; and (4) horizontal well fireflooding auxiliary gravity oil drainage is conducted on the fractured horizontal well. Through the oil extraction method, the problems that the fireflooding transverse (the well spacing direction) spread range is small, and the yield is low are solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

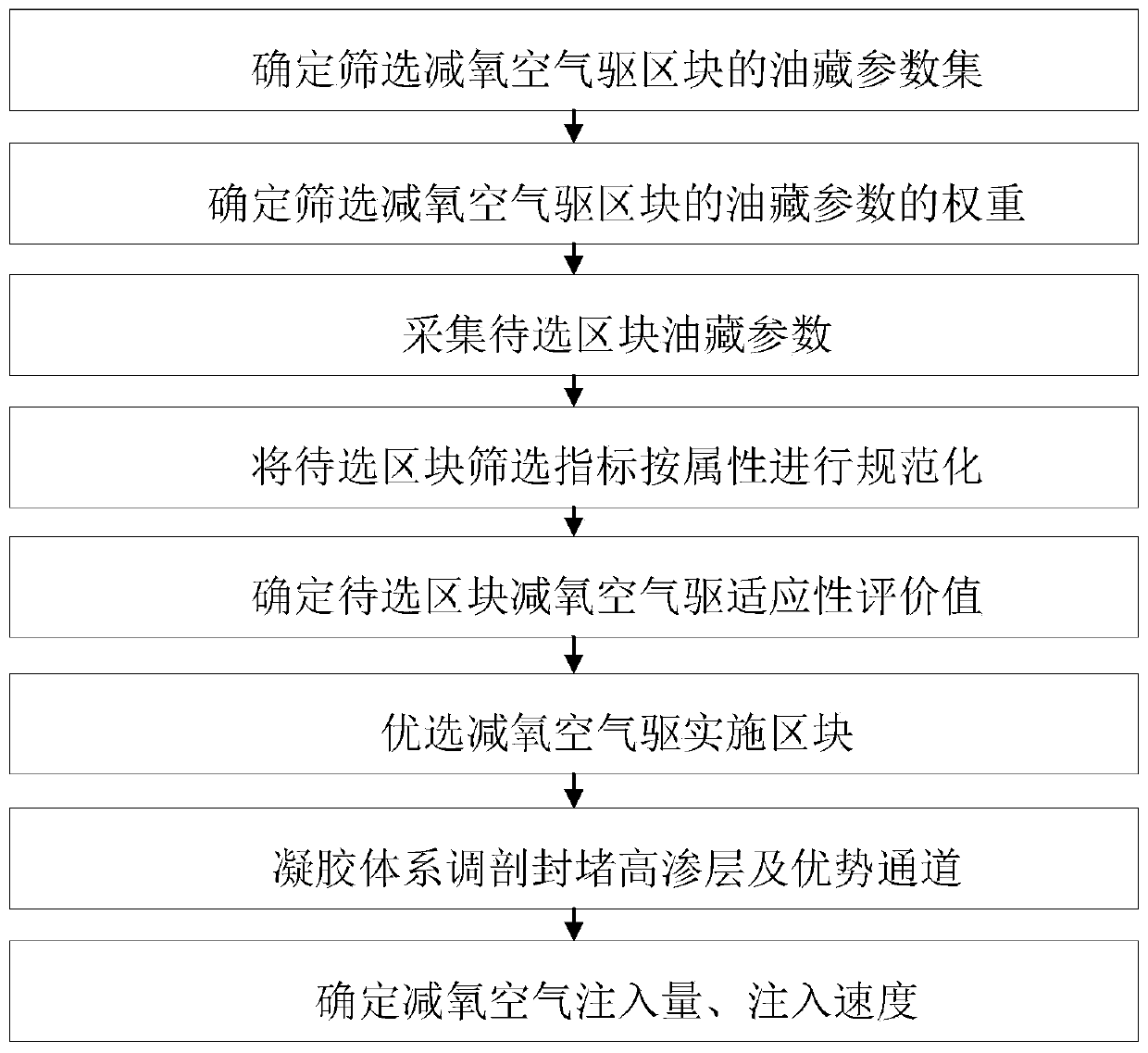

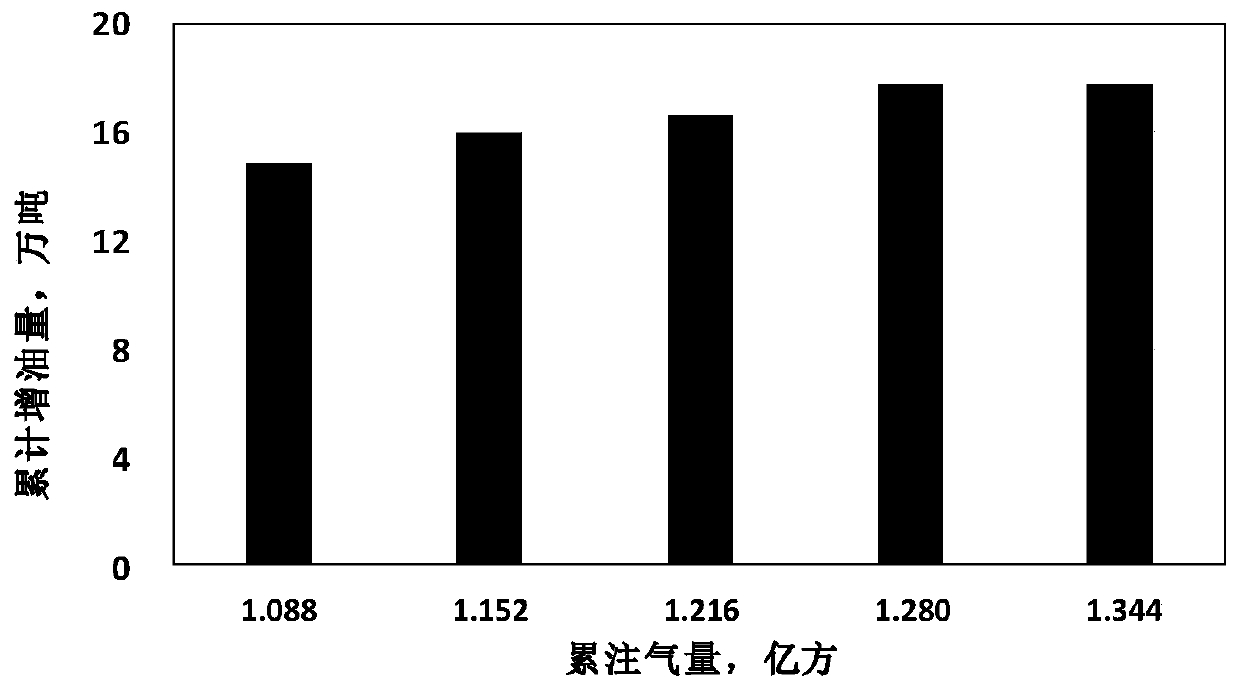

Method for improving recovery efficiency of oxygen-reduced air flooding of low-permeability oil reservoir

InactiveCN110778295AImprove oil production rateOil displacement effect is goodFluid removalEnvironmental engineeringResidual oil

The invention discloses a method for improving the recovery efficiency of oxygen-reduced air flooding of a low-permeability oil reservoir. The method comprises the steps of firstly determining a oil reservoir parameter set of a selected oxygen-reduced air flooding block, determining the adaptability evaluation value of the block to be selected for implementing the oxygen-reduced air flooding according to the weight of the oil reservoir parameters of the selected oxygen-reduced air flooding block and a relative membership degree matrix of candidate oil reservoir selecting indexes, determining the adaptability evaluation value of each block to be selected for implementing the oxygen-reduced air flooding, selecting the block with the highest evaluation value as the optimized implementation block of oxygen-reduced air flooding, and injecting oxygen-reduced air to the optimized oxygen-reduced air flooding oil reservoir. According to the method, after the oxygen-reduced air is dissolved in the oil, the volume of the crude oil is expanded, the oil extraction speed, the oil washing efficiency and the residual oil collection efficiency are favorably improved, the oil displacement effect isimproved, and therefore the oil recovery rate is further improved.

Owner:YANGTZE UNIVERSITY +2

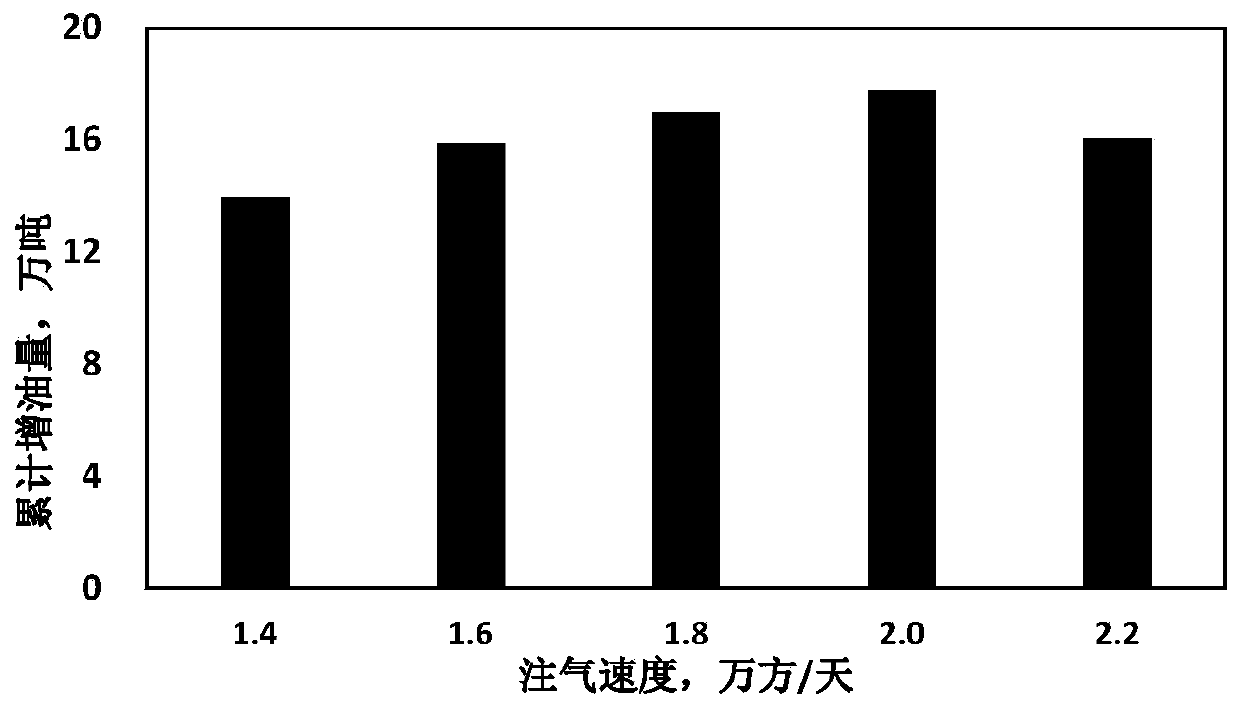

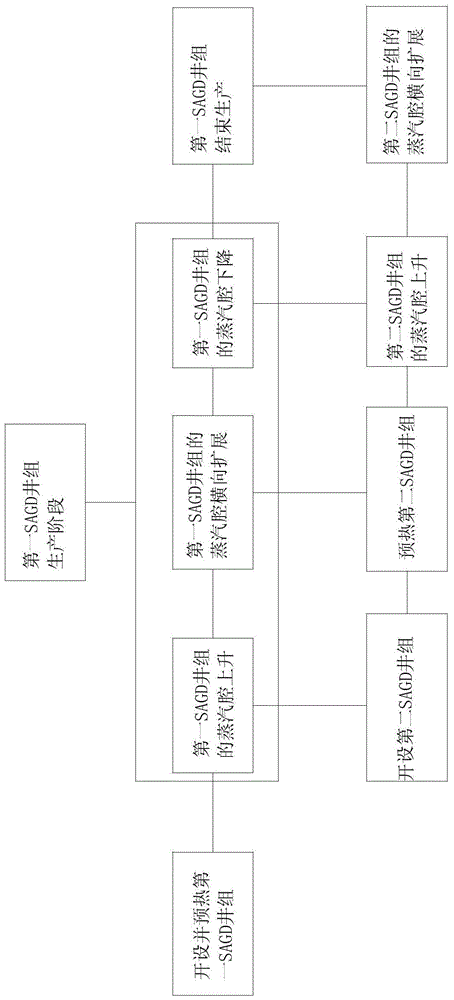

sagd production method of heavy oil reservoir

ActiveCN104265253BPrevent steam channelingReduce injection volumeFluid removalProduct gasHeavy oil reservoir

The invention relates to a method for exploiting a heavy oil reservoir by adopting an SAGD. The method comprises the following steps: a first SAGD well group is arranged on the heavy oil reservoir, the heavy oil reservoir is preheated, and pure steam or a steam composition is injected in the preheated first SAGD well group to form a steam cavity for production; when the steam cavity of the first SAGD well group ascends to the top of an oil layer, a second SAGD well group is arranged; when the steam cavity of the first SAGD well group is expanded to the interwall middle position, a pure non-condensation gas and a steam composition are injected in the first SAGD well group alternatively for plugging; when the steam cavity of the first SAGD well group descends, pure steam or a steam composition is injected in the second SAGD well group to form a steam cavity for production; when the production of the first SAGD well group is completed, the steam cavity of the second SAGD well group is expanded to the interwell middle position in the well, and a pure non-condensation gas and a steam composition are injected in the second SAGD well group alternatively for plugging to control the pressure in the steam cavity.

Owner:PETROCHINA CO LTD

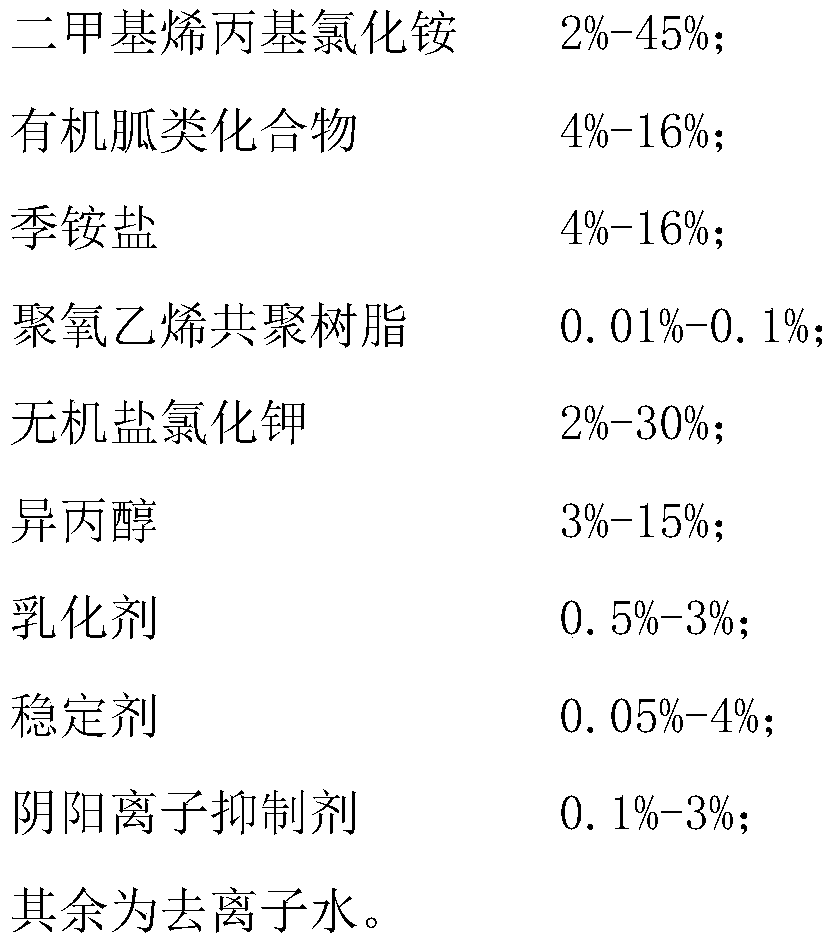

Decompressing injection-augmenting strengthening waterflooding anti-swelling swelling-reducing drag-reducing active agent

PendingCN110804430AReduce penetrationReduce water injection resistanceDrilling compositionClay mineralsActive agent

The invention discloses a decompressing injection-augmenting strengthening waterflooding anti-swelling swelling-reducing drag-reducing active agent, and mainly relates to the field of cationic surfactants. The decompressing injection-augmenting strengthening waterflooding anti-swelling drag-reducing active agent comprises the following components: dimethylallyl ammonium chloride 2%-45%, an organicguanidine compound 4%-16%, a quaternary ammonium salt 4%-16%, polyoxyethylene copolymer resin 0.01%-0.1%, an inorganic salt potassium chloride 2%-30%, isopropyl alcohol 3%-15%, an emulsifier 0.5%-3%,a stabilizer 0.05%-4%, an anion and cation inhibitor 0.1%-3% and the balance of deionized water. The active agent provided by the invention is injected into an ultra-low-permeability stratum, and after slug treatment, water-swellable clay in the stratum can become insensitive when contacting fresh water again, or a swelling phenomenon of low permeability can be reversed; and meanwhile, water injection resistance can be greatly reduced, and water-sensitive clay minerals become insensitive, so that permeability of the stratum is improved, a macroscopic swelling-reducing effect is exerted, and waterflooding development for oil and gas layers is further protected.

Owner:山东科兴化工有限责任公司

Oil extraction method adopting cold and heat pulse alternate water injection

InactiveCN108643874AGood physical propertiesImprove oil production rateData processing applicationsFluid removalOil fieldEvery Four Hours

The invention provides an oil extraction method adopting cold and heat pulse alternate water injection. The oil extraction method comprises the following steps that the temperature sensitivity of an oil reservoir is analyzed, if the temperature sensitivity of the oil reservoir is medium to strong or strong, hot water is injected into the oil reservoir through an injection well of an oil field, thewellhead oil pressure of the injection well is recorded every four hours, and when the wellhead oil pressure begins to rise continuously, the hot water injection is stopped; the injection well is opened, and cold water is injected into the oil reservoir to enable the oil reservoir to be cooled; the water injection pressure of the injection well is increased, and under the flushing action of the water injection pressure, a plurality of fracturing cracks can be formed in the oil reservoir in the minimum stress direction of a stratum stress field near a shaft of the injection well; the apparentwater injectivity index of the oil reservoir is calculated, and according to the apparent water injectivity index, whether the effective fracturing cracks are formed in the oil reservoir or not is judged; and the water injection effective rate is calculated, and according to the water injection effective rate, whether the injected water forms effective displacement in the reservoir or not is judged.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

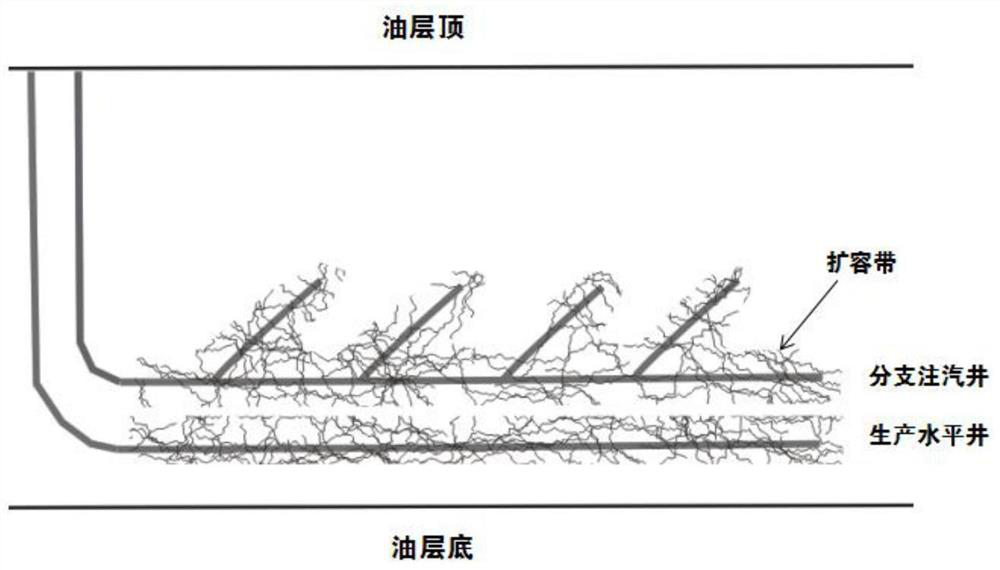

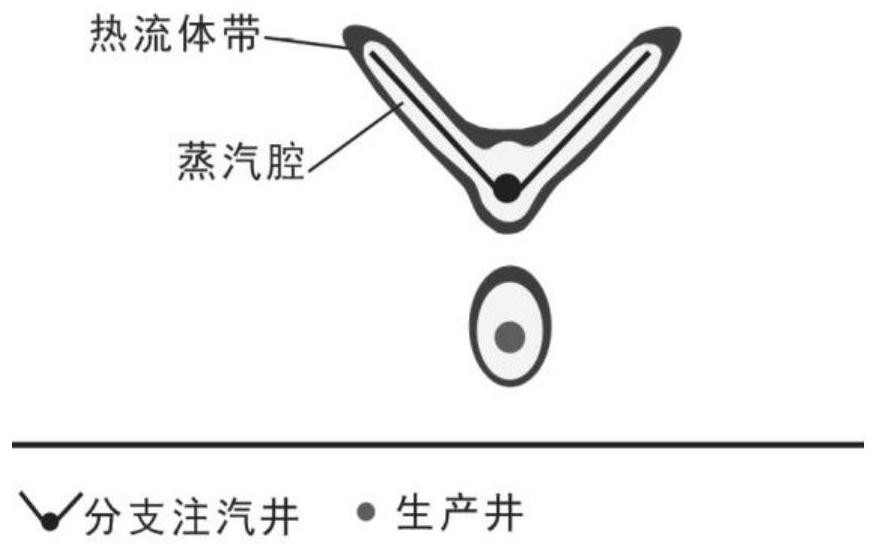

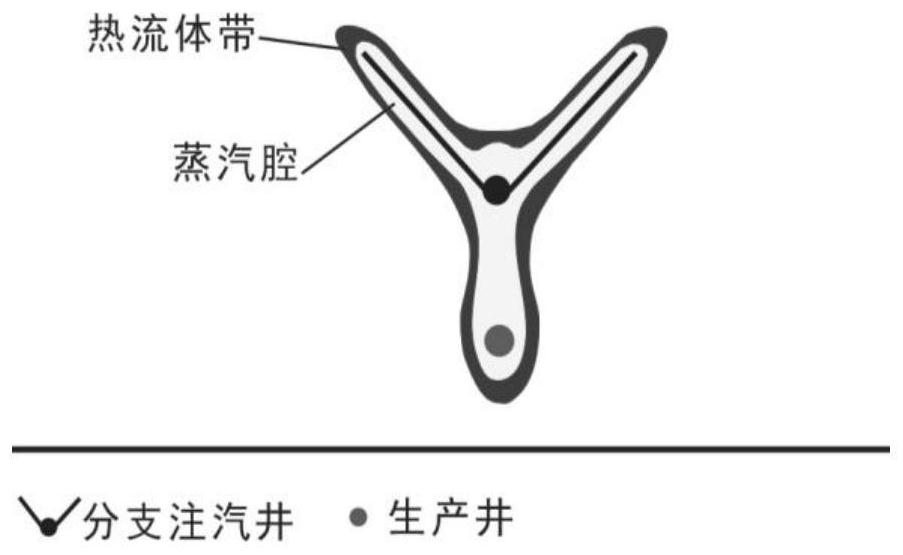

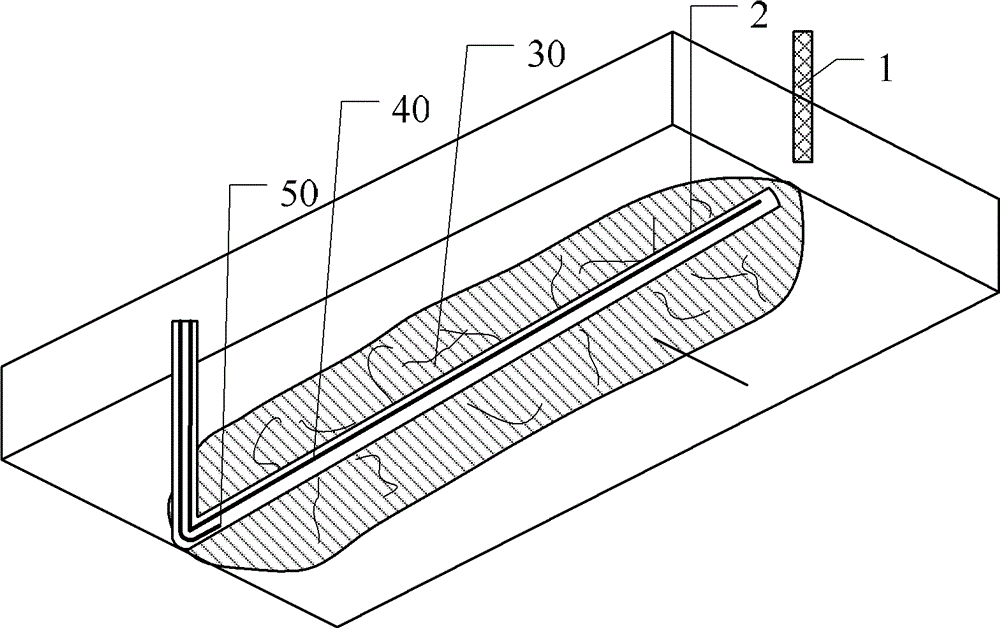

Super heavy oil reservoir multi-branch SAGD reservoir expansion oil extraction method

InactiveCN112901127AExpand the reachSolve the problem that the oil production rate is low and the remaining oil above the interlayer is difficult to useSurveyConstructionsThermodynamicsHorizontal wells

The invention provides a super heavy oil reservoir multi-branch SAGD reservoir expansion oil extraction method. The method comprises the following steps that S10, a super heavy oil reservoir area exploited through multi-branch SAGD is selected, and reservoir stratums around wellbores of a branch steam injection horizontal well and a production horizontal well are expanded and transformed; S20, constant-pressure steam injection circulation is conducted on the branch steam injection horizontal well and the production horizontal well at the same time, the steam circulation pressure is larger than the minimum principal stress of rock, and an oil drainage channel is formed between a surrounding expansion zone of the branch part of the branch steam injection horizontal well and a main well hole of the production horizontal well; and S30, micro pressure difference is established between the branch steam injection horizontal well and the production horizontal well, after an oil drainage channel is formed between the surrounding expansion zone of the branch part and the production horizontal well, SAGD production is conducted, and injection and production parameters of the multi-branch SAGD well group are adjusted till production is finished. The oil extraction efficiency is improved by the effect of increasing the oil extraction speed, and the problems that the oil extraction speed of a heterogeneous reservoir is low, and remaining oil above an interlayer is difficult to use are solved.

Owner:PETROCHINA CO LTD

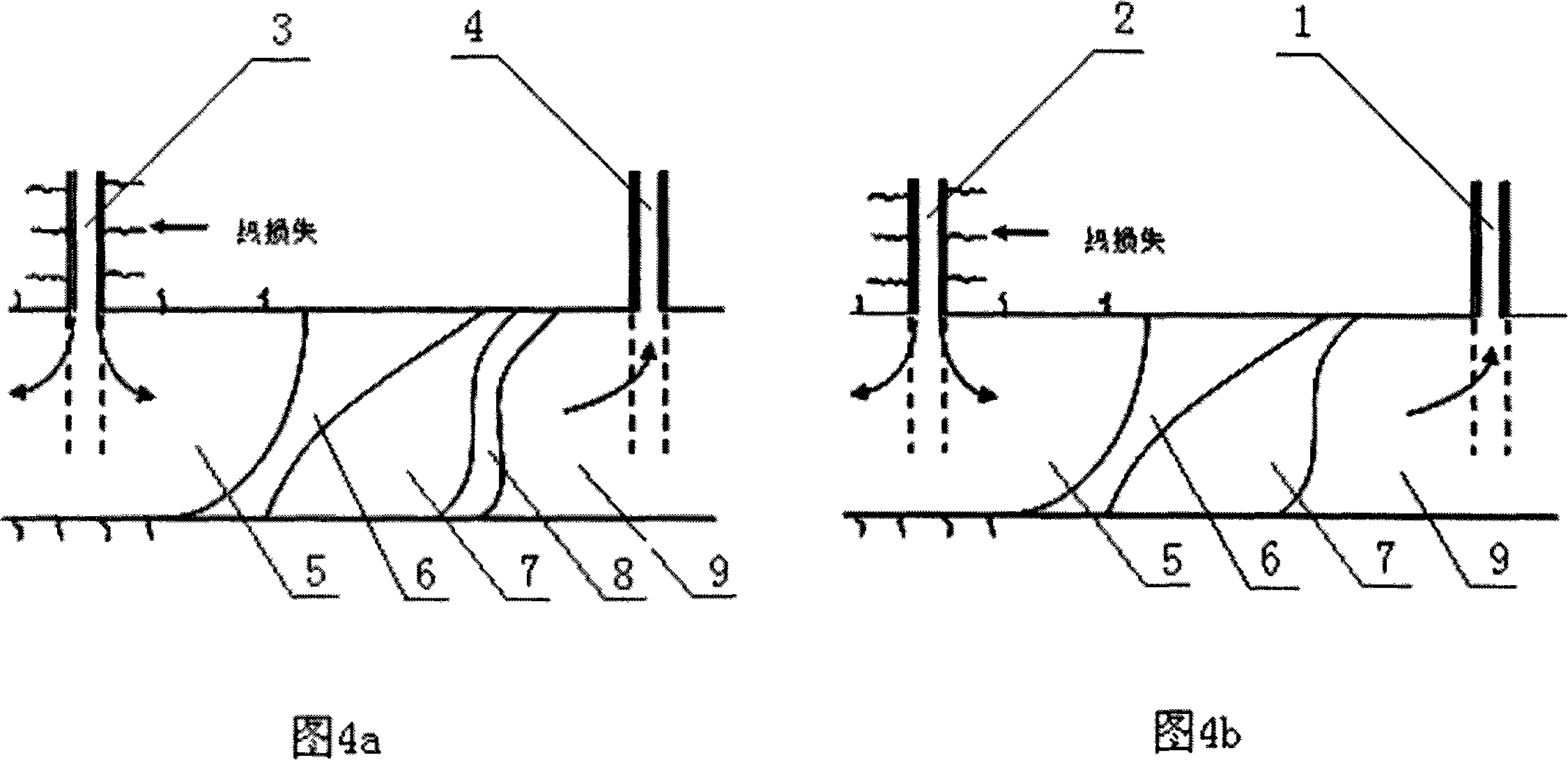

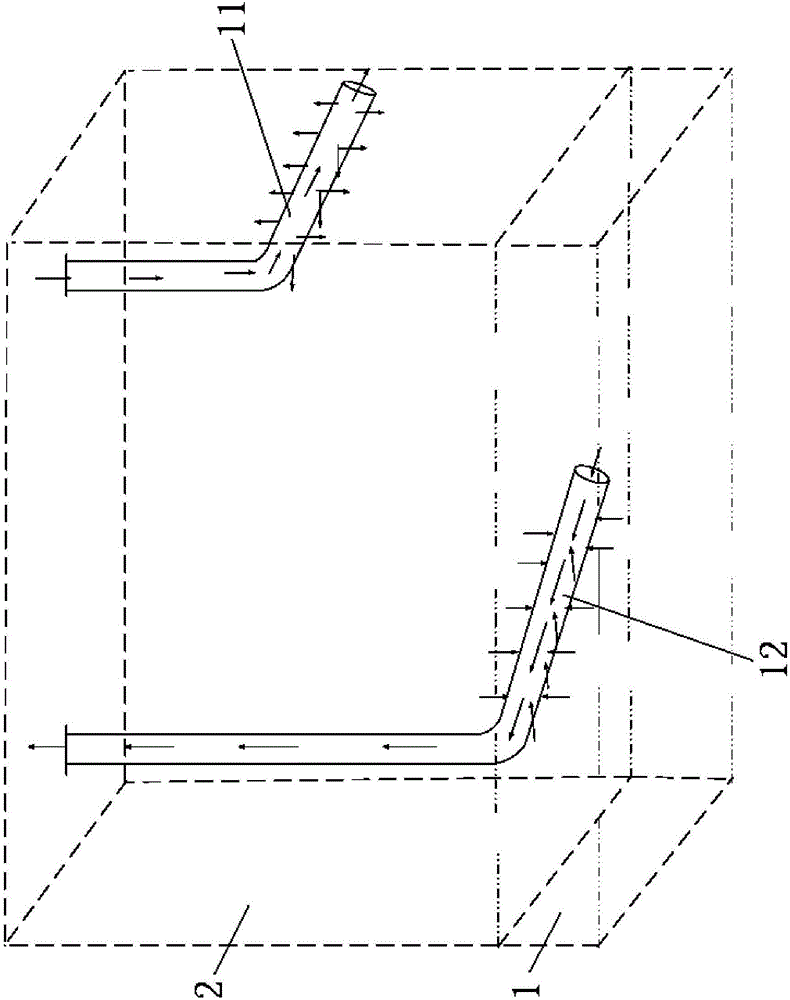

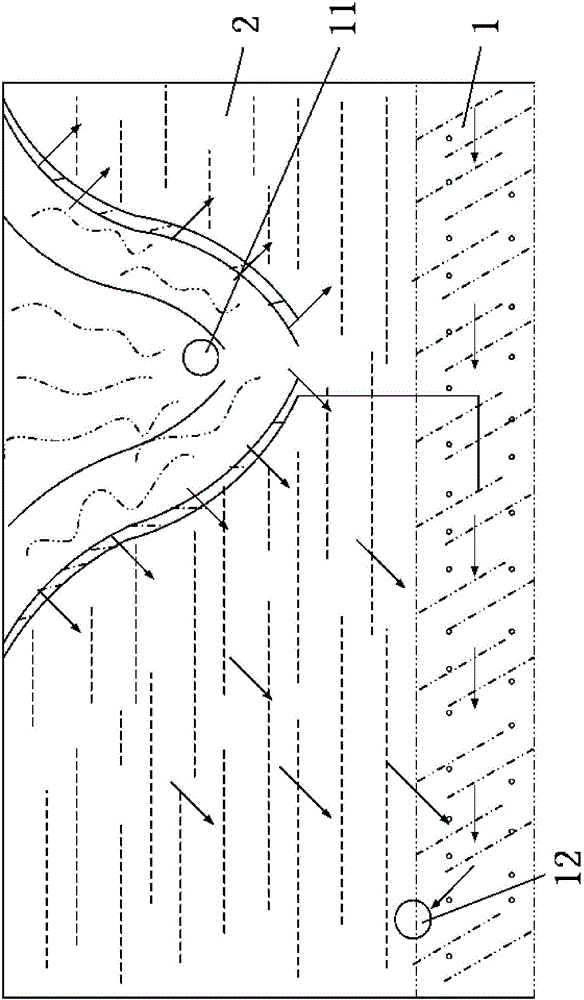

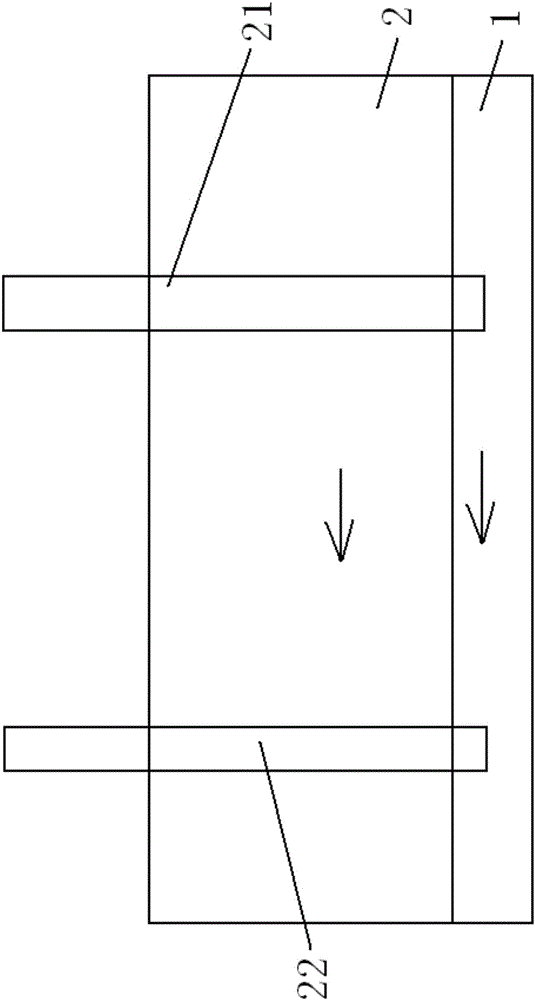

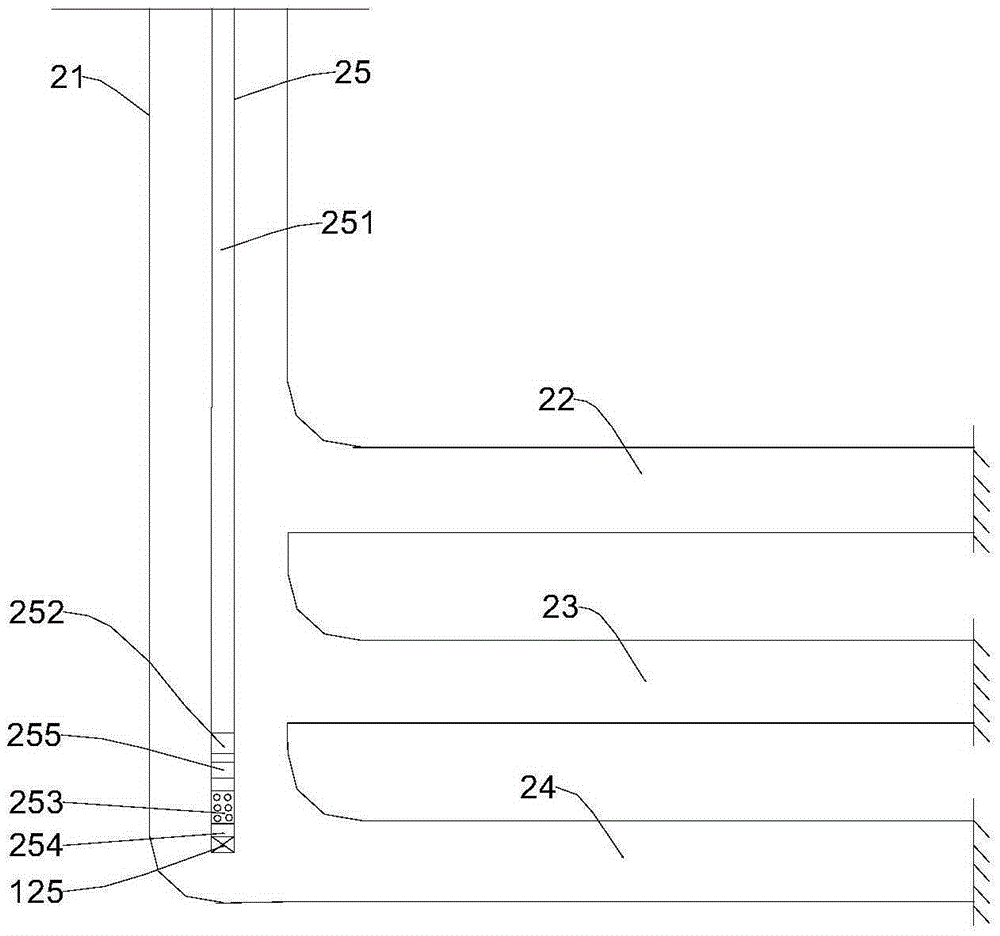

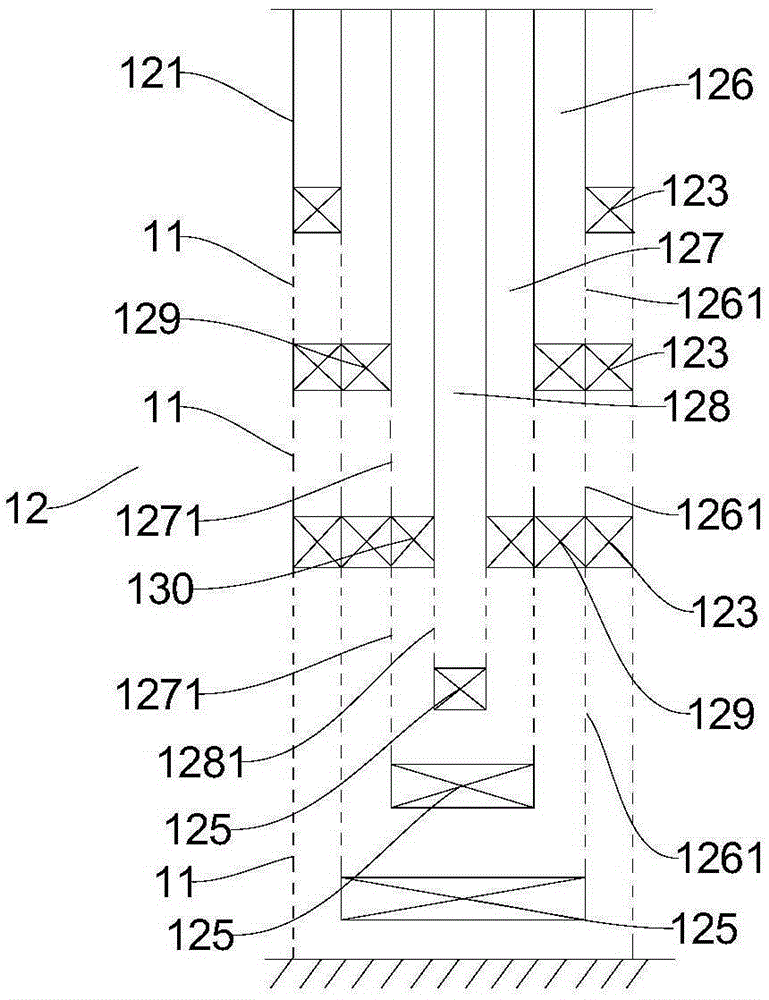

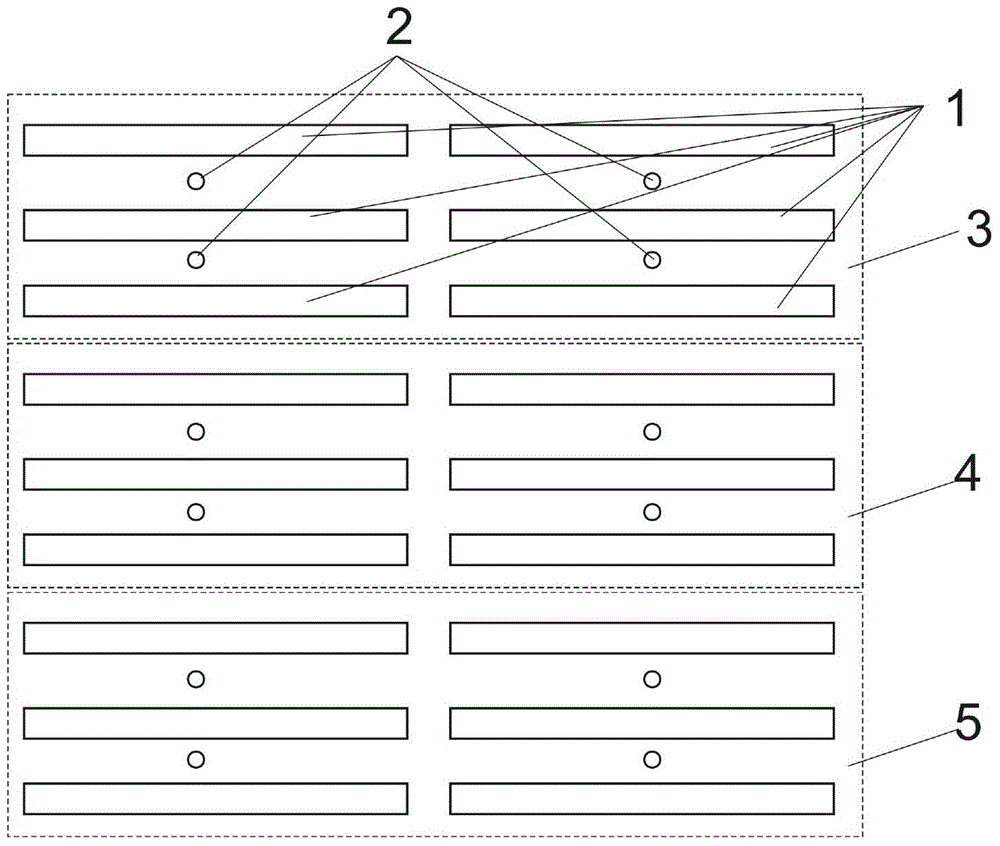

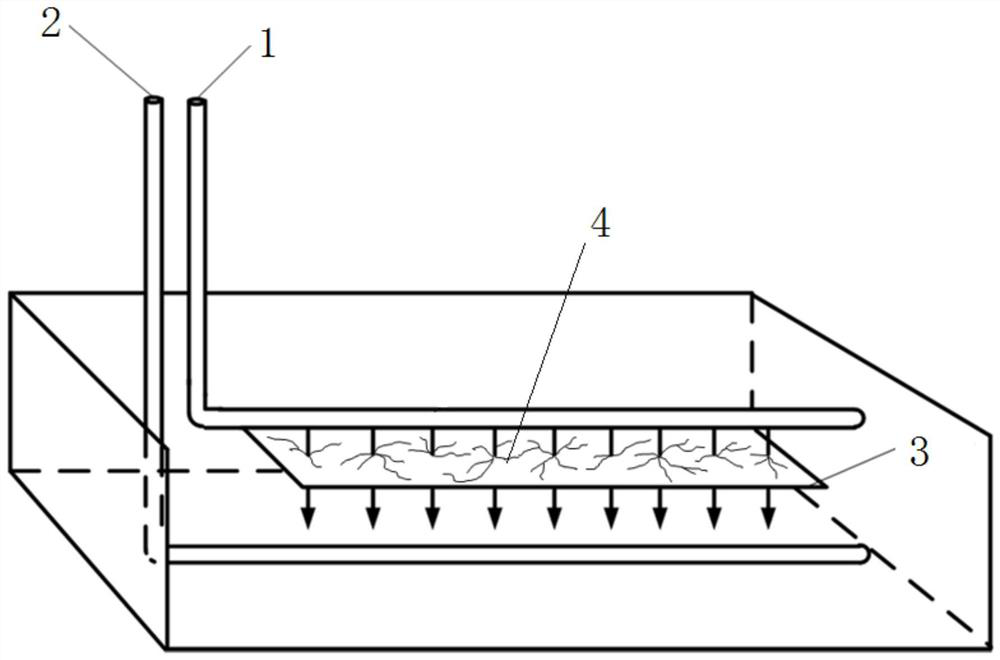

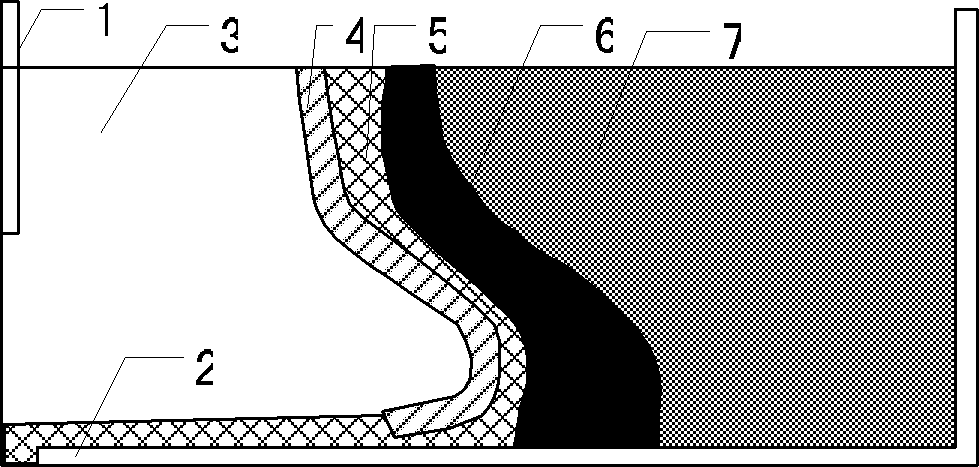

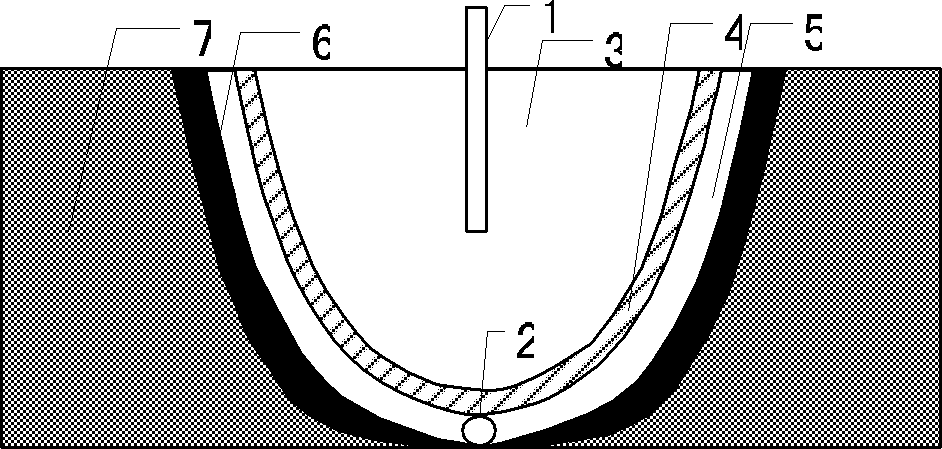

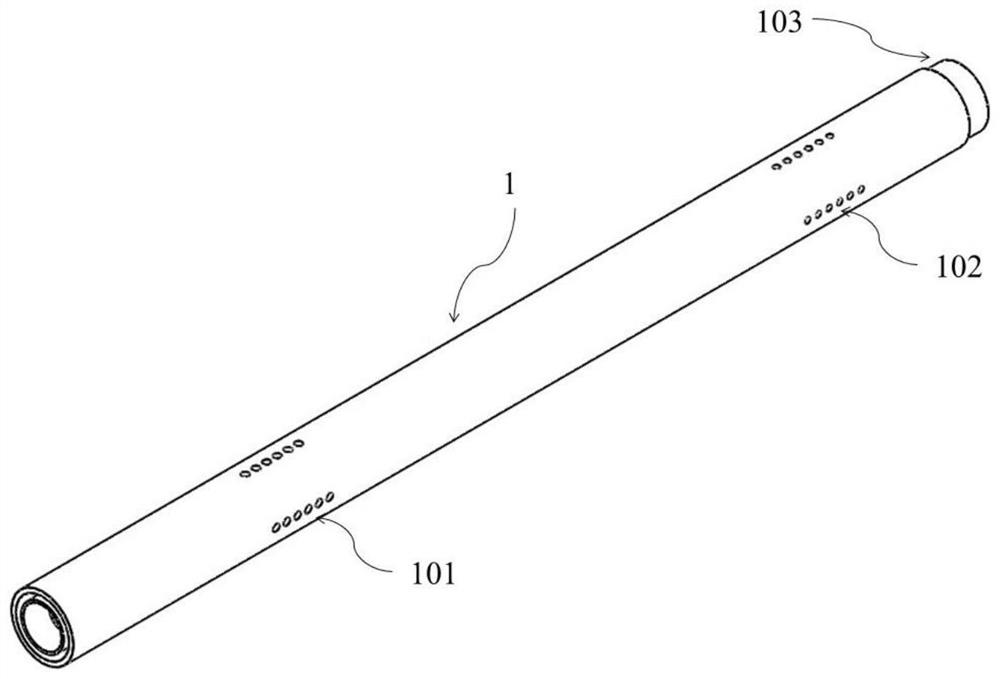

Method for increasing communication length of SAGD horizontal section of double horizontal wells

ActiveCN112727421AImprove seepage capacityExpand the use lengthFluid removalDrilling compositionHigh densityHorizontal wells

The invention discloses a method for increasing the communication length of an SAGD horizontal section of double horizontal wells. The method comprises the following steps that 1, through fine geological research and reservoir unit depiction, a low-permeability interlayer (3) of a well group control reservoir is recognized; 2, according to permeability range distribution of an oil layer between a steam injection well (1) and an oil production well (2), the steam injection well (1) is divided into a high-range difference section (11) and a middle-range difference section (12); 3, small-aperture high-density deep penetration perforation is conducted on the high-range difference section (11) of the steam injection well (1), and large-aperture deep penetration perforation and electric pulse artificial micro-crack operation are conducted on the middle-range difference section (12) of the steam injection well (1); and 4, viscosity reduction operation is conducted. According to the method for increasing the communication length of the SAGD horizontal section of the double horizontal wells, the flowing capacity of the horizontal section which is not used can be obviously improved, the production effect of a strong-heterogeneity super-heavy oil reservoir SAGD is guaranteed, and the oil production speed and the crude oil recovery ratio can be greatly increased.

Owner:PETROCHINA CO LTD

Oil extraction method

ActiveCN102587880BIncrease Controlled ReservesExpand well spacingFluid removalLayer thicknessFront edge

The invention discloses an oil extraction method for extracting raw oil in a horizontal well. The oil extraction method comprises the steps of: A, fracturing the horizontal well; and B, performing horizontal well fireflood assisted gravity drainage on the fractured horizontal well. According to the oil extraction method, the fracturing technology is combined with the single horizontal well fireflood assisted gravity drainage extraction technology, the double advantages of horizontal crack leading fireflood front edge expansion and gravity assisted drainage are made full use of, and a thick oil deposit with an oil layer thickness of more than 4m can be economically and effectively developed.

Owner:PETROCHINA CO LTD

Multi-stage oil-water separation and same-well injection-production device in horizontal well

ActiveCN112240193AEasy to harvestSolve the problem of low productionFluid removalHorizontal wellsOil water

The invention discloses a multi-stage oil-water separation and same-well injection-production device in a horizontal shaft. The device mainly solves the problems that in the horizontal well development process, the cost of water-containing produced liquid lifting and ground sewage treatment is high, and the perforation permeability of an oil-containing area is low. The device is characterized by comprising an oil pipe, an injection-production annulus packer and a coalescer; the injection-production annulus packer is used for improving an oil pipe space so as to achieve displacement of a high-oil-content area through same-well reinjection liquid obtained after separation of a low-oil-content area, and therefore the perforation permeability of the high-oil-content area is enhanced; and meanwhile, a coalescer is additionally arranged after a conventional cyclone is improved, so that small oil drops become large oil drops. According to the device, underground multi-stage oil-water separation of the horizontal well and same-well multi-section injection-production technology and equipment are applied, underground multi-stage oil-water separation can be achieved, and the underground oil-water separation efficiency and underground crude oil recovery rate are further improved.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com