Oil extraction method adopting cold and heat pulse alternate water injection

A pulse, cold and hot technology, applied in the direction of production fluid, earthwork drilling, instruments, etc., can solve the problems of high cost, inability to achieve obvious effects, tight and low permeability reservoirs that cannot recover the cost of development, etc., to achieve cost Low, improve physical properties, improve the effect of reservoir physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

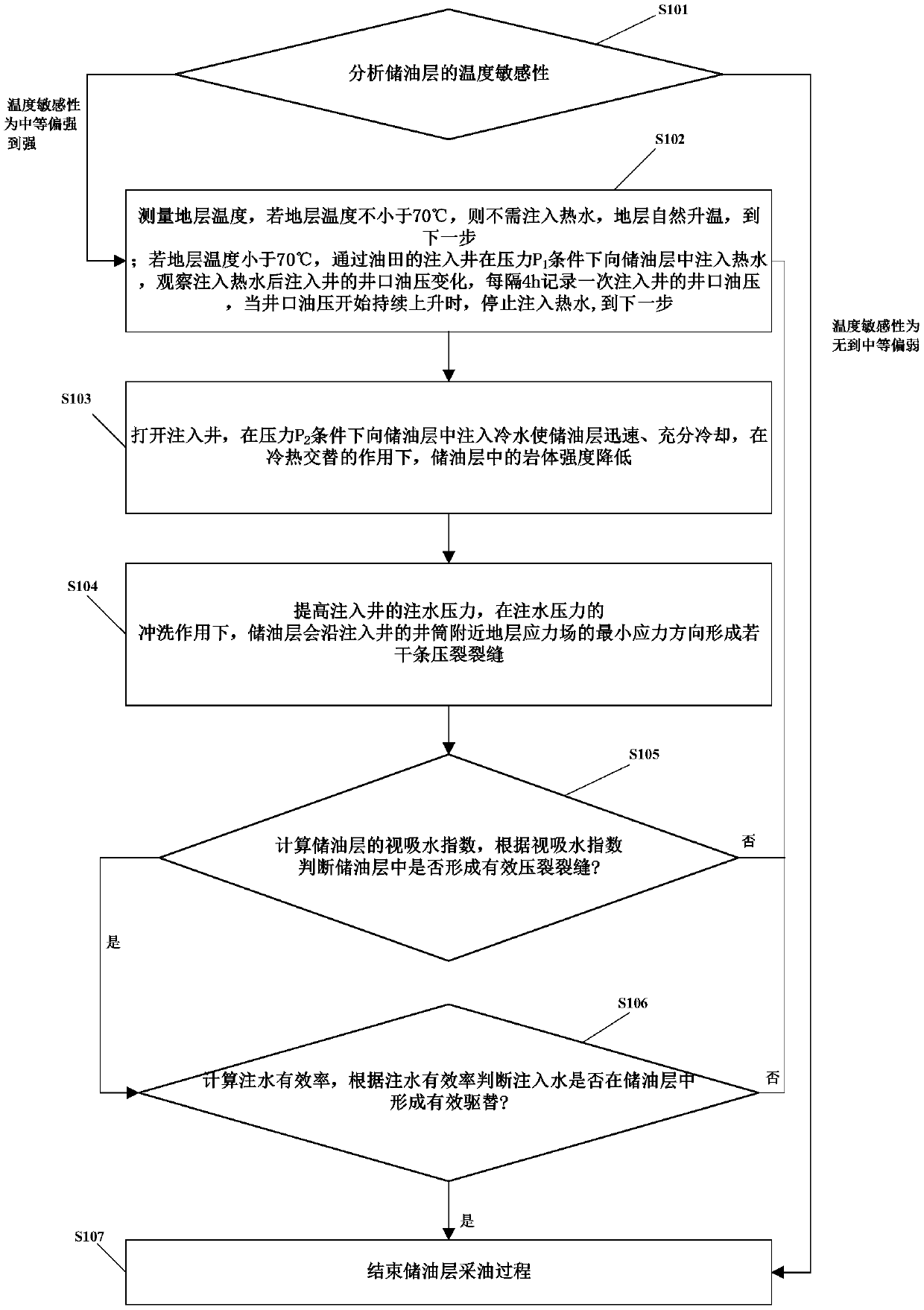

[0034] Please refer to figure 1 , the embodiment of the present invention provides a kind of oil production method of alternating hot and cold pulse water injection, comprising the following steps:

[0035] Step S101, analyzing the temperature sensitivity of the oil reservoir, if the temperature sensitivity of the oil reservoir is moderately strong to strong, go to step S102; if the temperature sensitivity of the oil reservoir is none to moderately weak, then go to step S107;

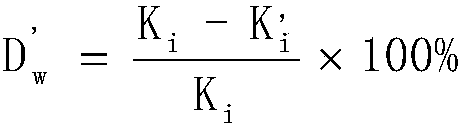

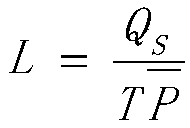

[0036] The analysis process of the temperature sensitivity of the reservoir is as follows: conduct the temperature sensitivity experiment of the reservoir lithology, and calculate the irreversible temperature sensitivity damage rate D’ of the reservoir w , the irreversible temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com