Oleic acid mixture based heavy oil modification and mixed-phase thermal fluid flooding combined oil extraction method

A technology of mixtures and thermal fluids, which is applied in the direction of production fluids, drilling compositions, chemical instruments and methods, etc., can solve the problems of slow oil recovery, poor fluidity, and low recovery, so as to increase oil recovery and reduce production cost, effect of enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

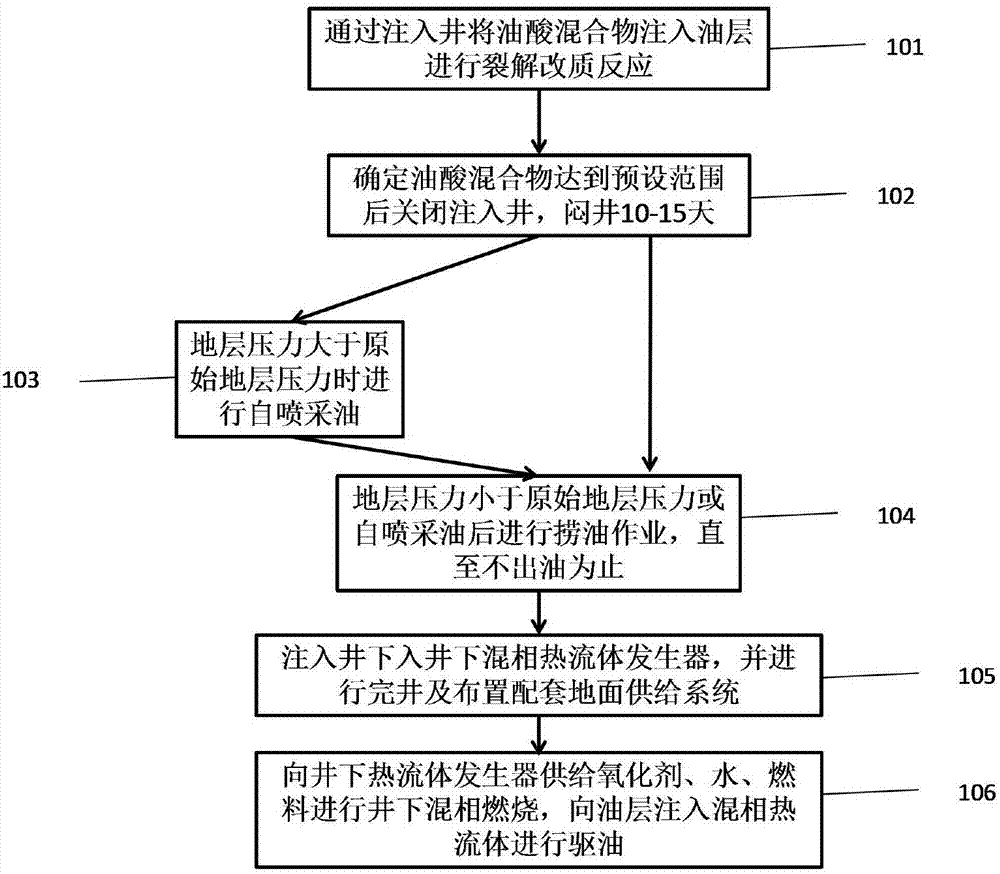

Method used

Image

Examples

Embodiment 1

[0044] A block in a certain oil field, the oil layer depth is 1700 meters, the oil layer temperature is 50 degrees Celsius, the oil layer thickness is 12 meters, the crude oil viscosity is 44000 mPas, and the original formation pressure is 17.5 MPa. Water flooding has been carried out, but the water injection pressure is high and the water injection volume is small. , The available reserves in the oil layer are relatively small. The current water injection pressure is 33 MPa, the water injection rate is 5 cubic meters per day, and the current recovery rate is 2%.

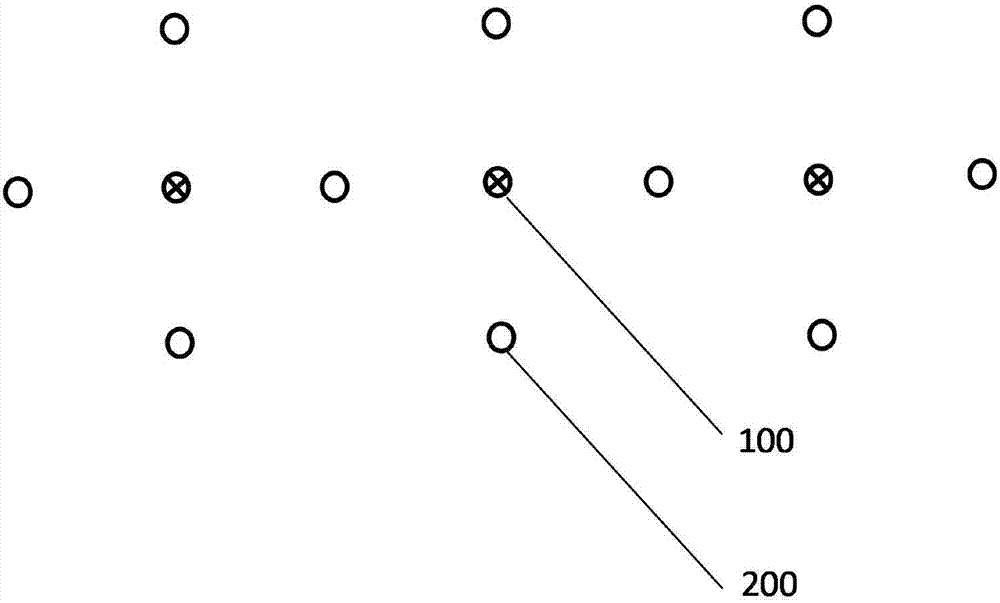

[0045] The first step: see figure 2 , Improve the well pattern of the oil production area, adopt a five-point well pattern, with injection well 100 in the middle, 4 production wells 200 around, and 4 production wells in a rectangular arrangement. The injection well 100 is 100-150 meters away from the more advanced production well 200 and 140-212 meters away from the farther production well 200. In this embodiment, the...

Embodiment 2

[0052] A block in a certain oil field, the oil layer depth is 2200 meters, the oil layer temperature is 70 degrees Celsius, the oil layer thickness is 20 meters, the crude oil viscosity is 75000 mPas, and the original formation pressure is 19 MPa. Because the formation crude oil viscosity is too high, the crude oil does not have fluidity in the formation. , The current mining is one-time oil extraction.

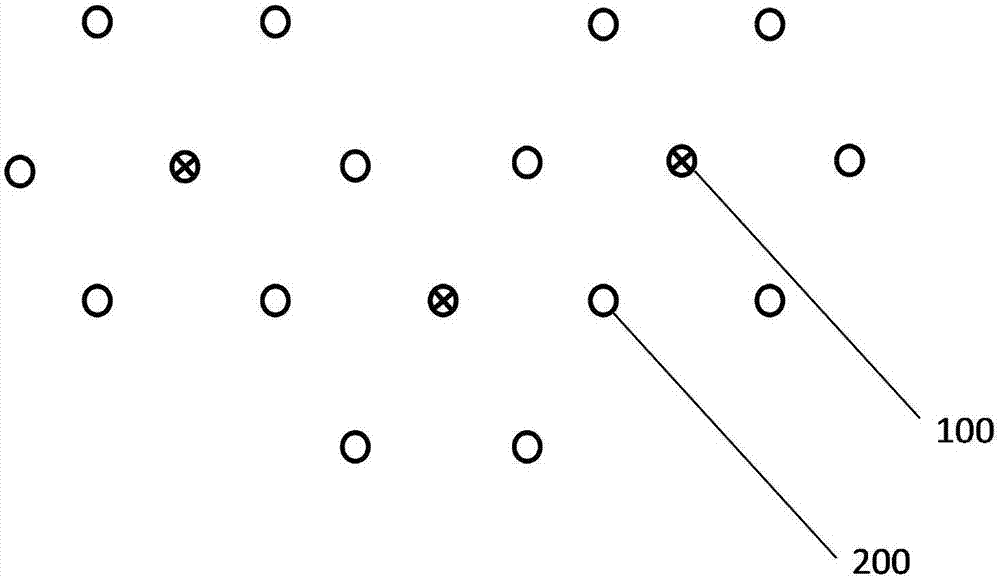

[0053] The first step: see image 3 , Improve the well pattern of the oil production area, adopt a seven-point well pattern, with injection well 100 in the middle, 6 production wells 200 around, and 6 production wells arranged in a hexagon. The injection well 100 is 100-150 meters away from the more advanced production well 200, and 140-212 meters away from the more distant production well 200. In this example, it is 120 meters away from the closer production well 200 and the farther production well. 200 is 170 meters.

[0054] The second step: inject a cracking catalyst oleic ac...

Embodiment 3

[0061] A block in a certain oil field, the oil layer depth is 1400 meters, the oil layer temperature is 55 degrees Celsius, the oil layer thickness is 13, the crude oil viscosity is 23000 mPas, and the original formation pressure is 12 MPa. Water flooding has been carried out. The current water injection pressure is 11 MPa and the water injection volume It is 100 cubic meters / day, and the current recovery rate is 34.5%.

[0062] The first step: see figure 2 , Improve the well pattern of the oil production area, adopt a five-point well pattern, with injection well 100 in the middle, 4 production wells 200 around, and 4 production wells in a rectangular arrangement. The injection well 100 is 100-150 meters away from the more advanced production well 200 and 140-212 meters away from the farther production well 200. In this embodiment, the distance to the production well 200 is 100 meters away, and the distance to the production well 200 is 140 meters away.

[0063] The second step: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com