Oxygen-enriched combustion poly-generation process and equipment for steam injection boiler in oil field

A technology of steam injection boiler and oxygen-enriched combustion, which is applied in the direction of inorganic chemistry, chemical instruments and methods, nitrogen compounds, etc., can solve the problems of unseen large-scale demonstration projects or engineering applications, reduced economic benefits, high energy consumption, etc., and achieve saving The effect of long-distance transportation costs, increased benefits, and large profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

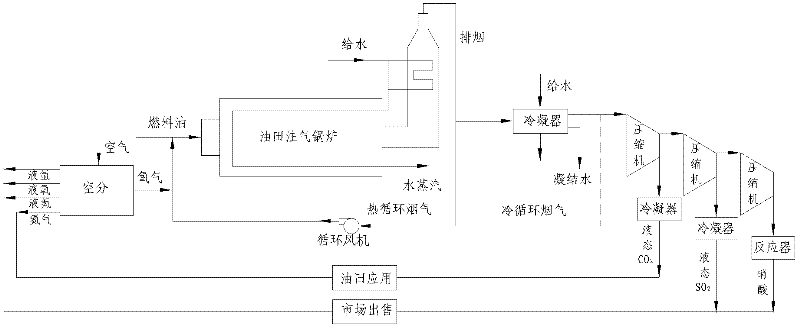

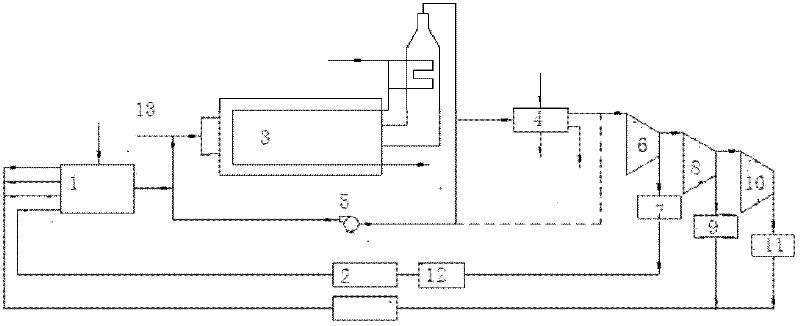

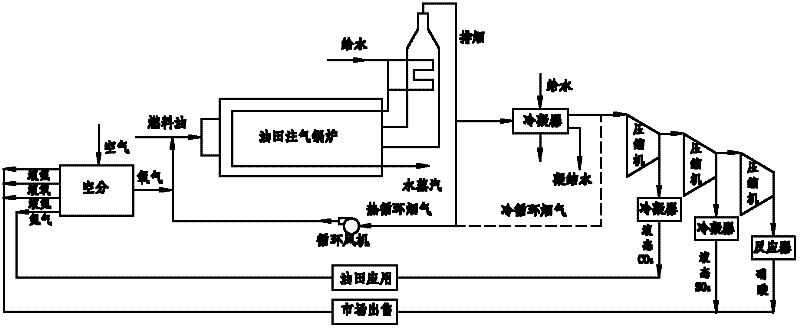

[0038] Oilfield steam injection boiler oxygen-enriched combustion polygeneration process such as figure 1 shown. Cryogenically separate the air to obtain nitrogen and pure oxygen. The nitrogen is sent to the oil recovery system for secondary oil recovery, tertiary oil recovery, oil and gas well protection or transportation protection. Pure oxygen is introduced into the oilfield steam injection boiler and mixed with fuel oil for combustion. Exhausted CO rich 2 The flue gas is divided into two parts, the first part is the circulating gas, which is pressurized by the circulating fan and circulated to the burner of the steam injection boiler in the oil field, and the high-purity oxygen produced by the cryogenic air separation oxygen generator before entering the burner It is mixed through a three-way pipeline and used as an oxidant for heavy oil combustion, in which oxygen accounts for 27-30%. The flow rate can be adjusted by the recirculation fan, which is adjustable and accoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com