Patents

Literature

166results about How to "Protect the atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

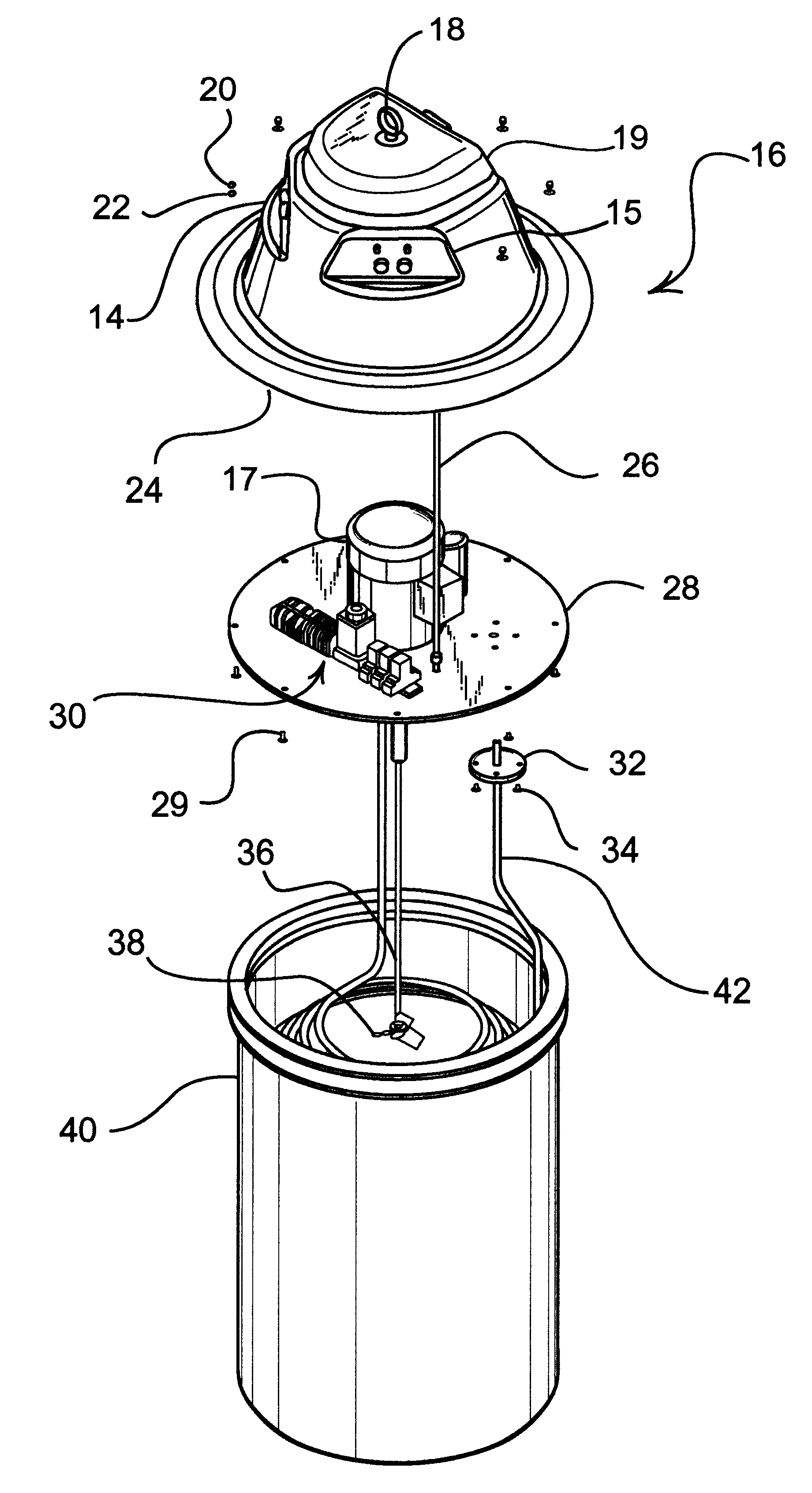

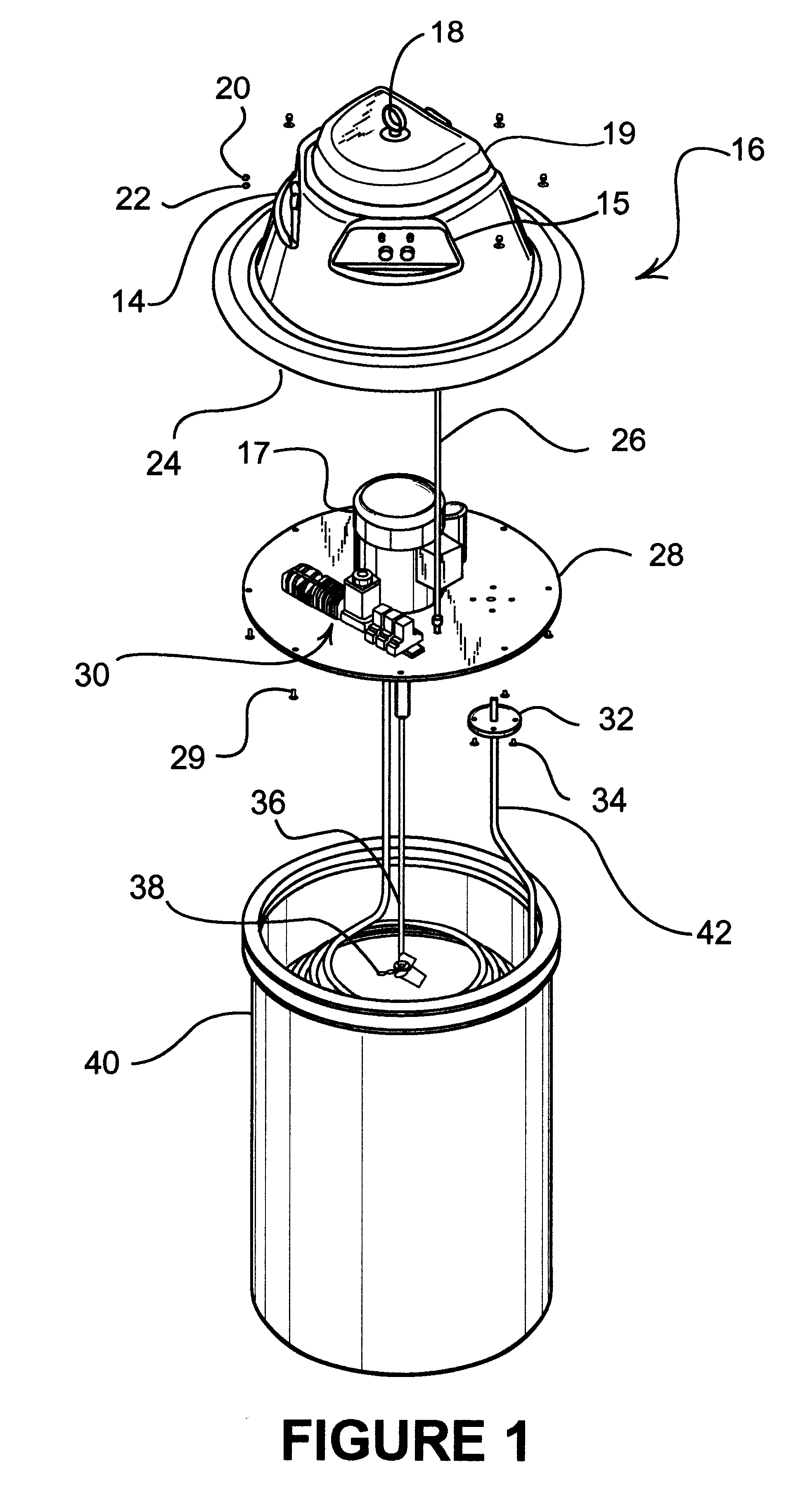

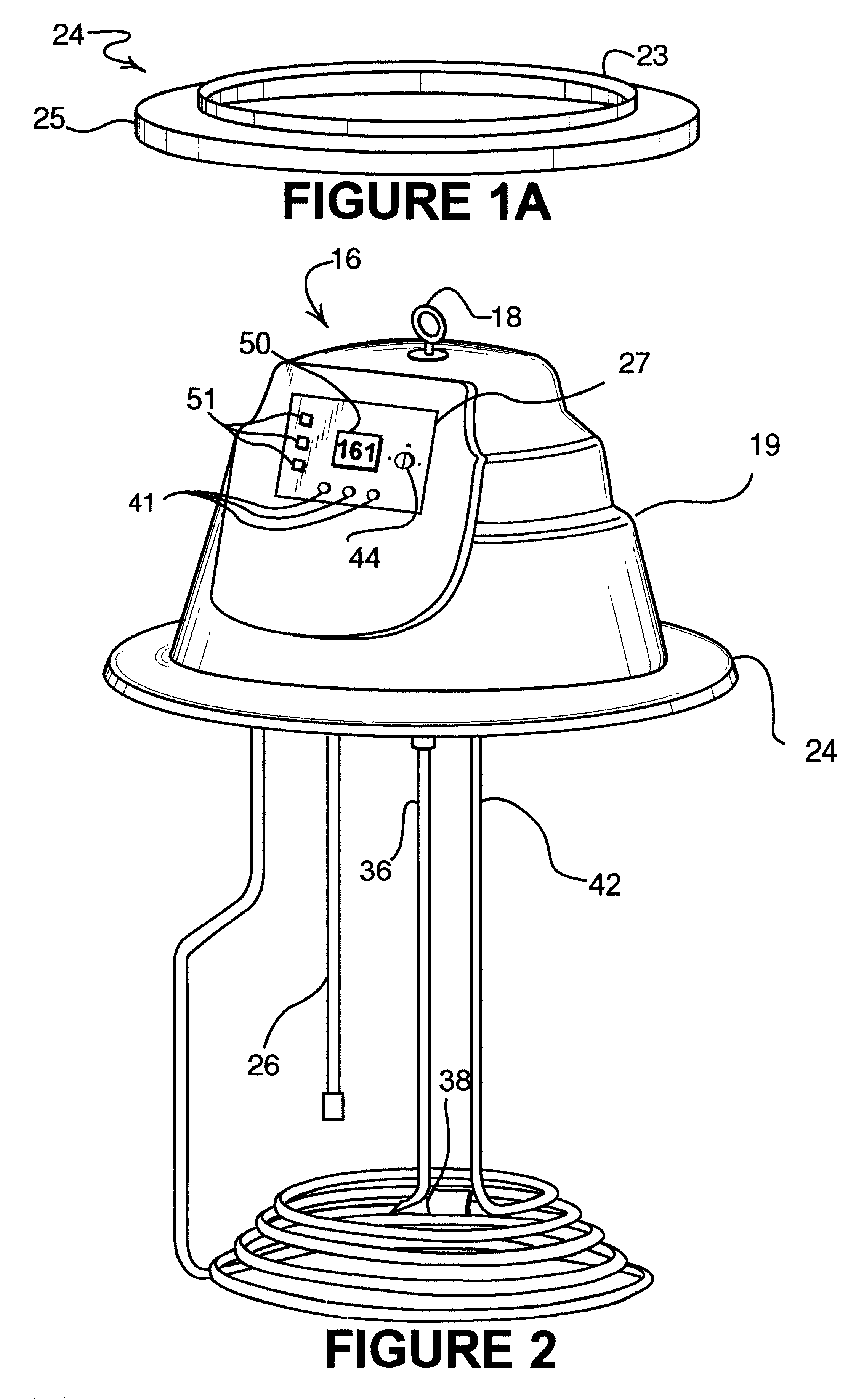

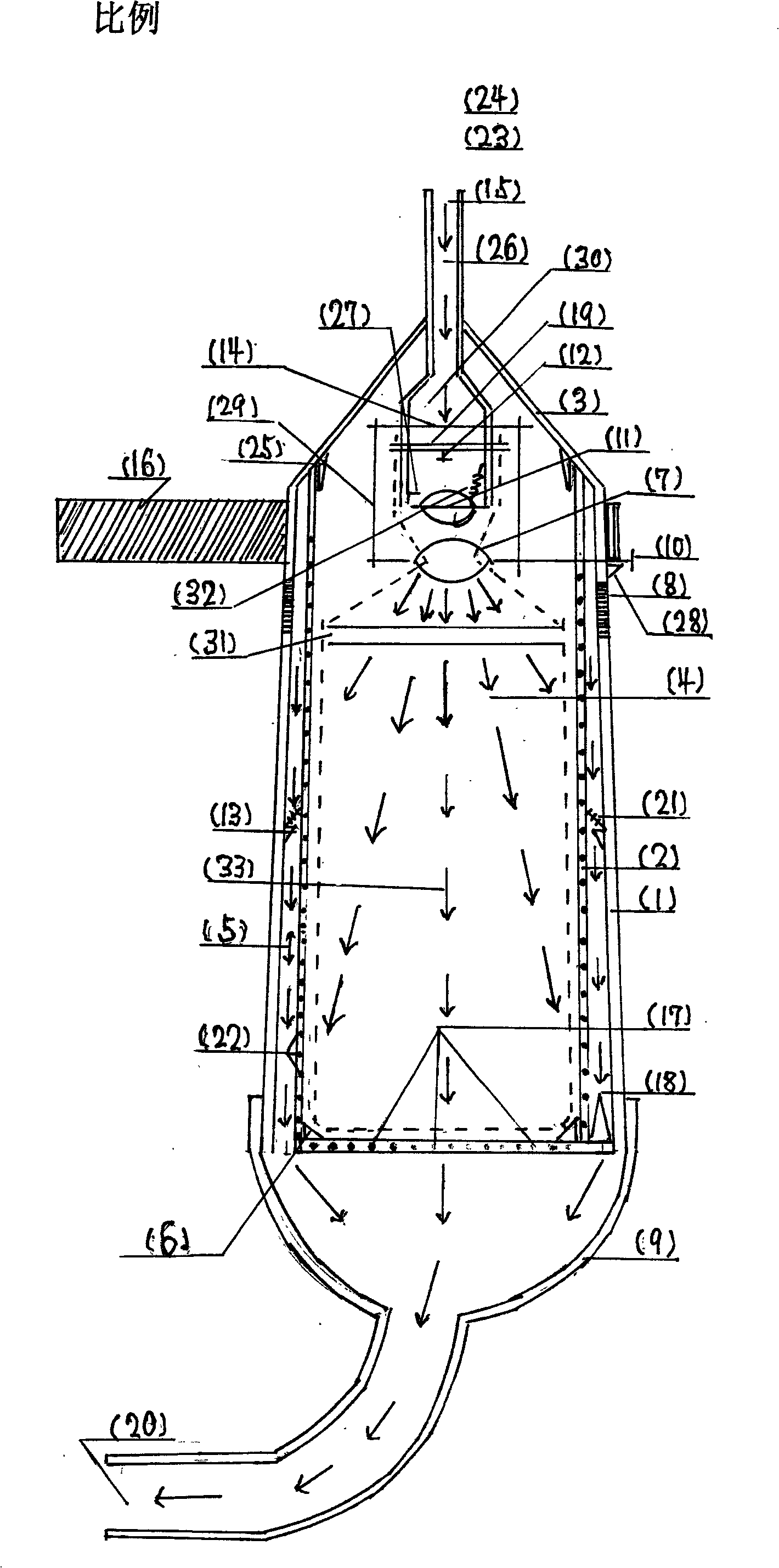

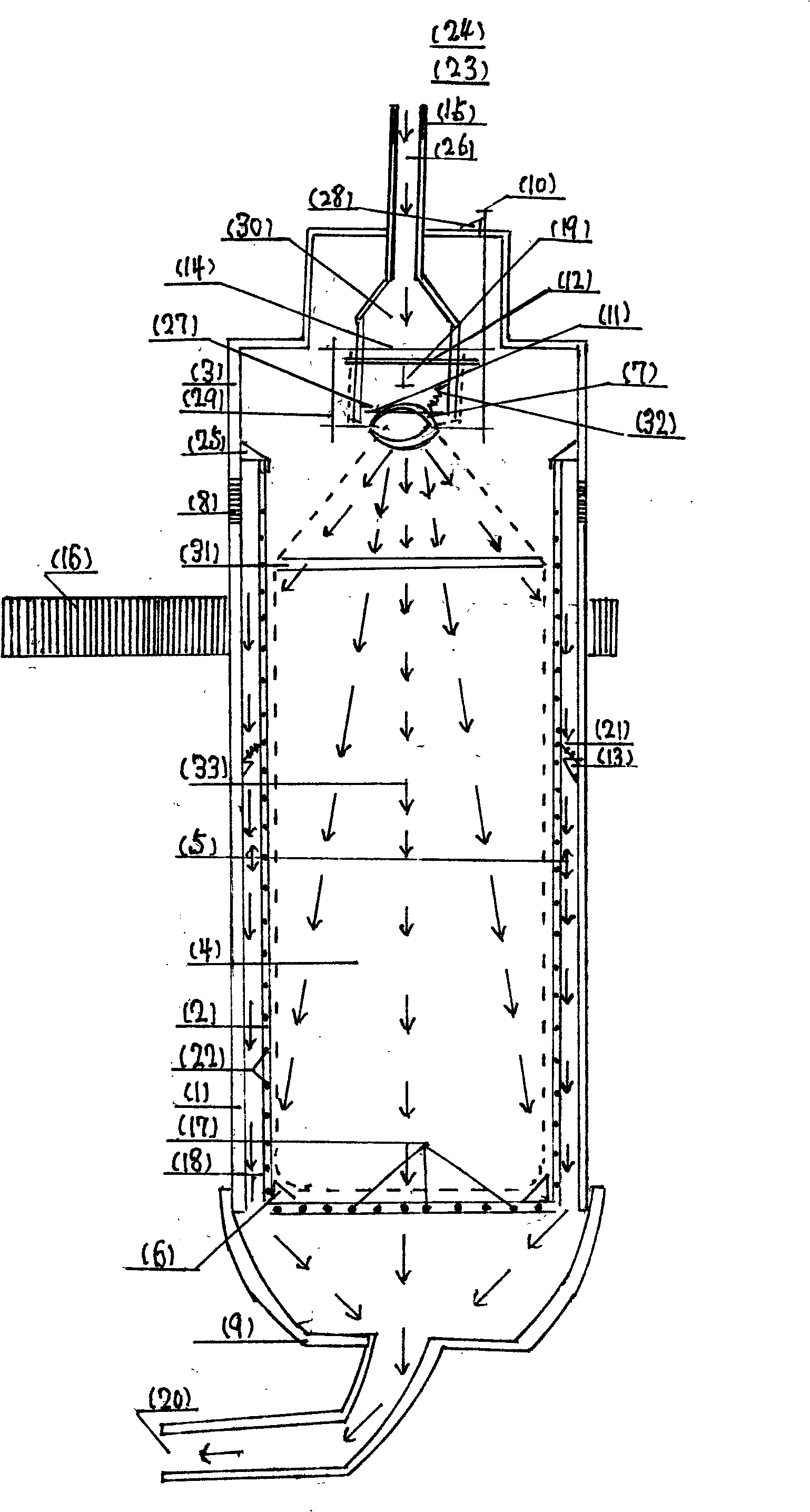

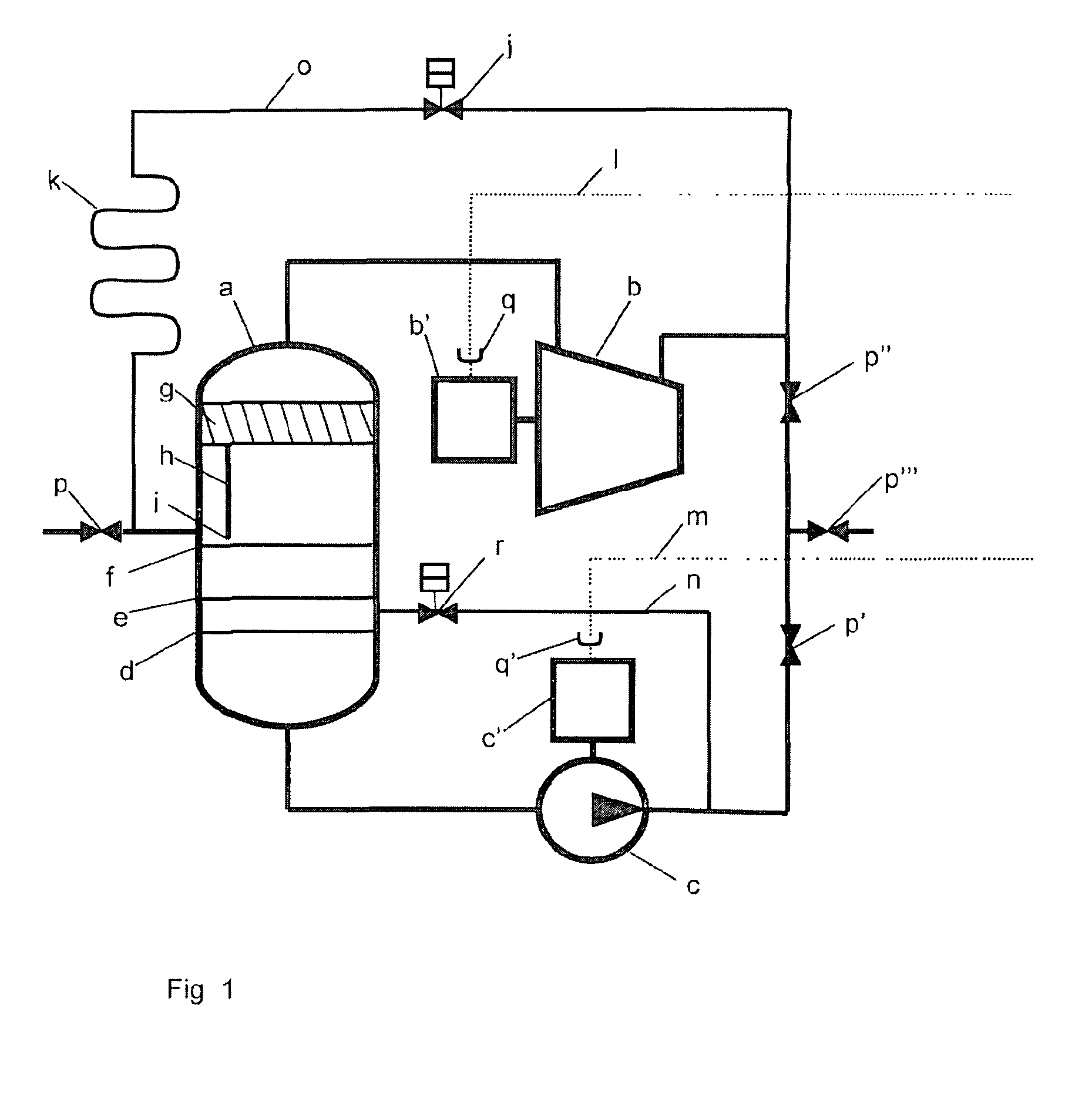

Portable batch pasteurizer

InactiveUS6276264B1Convenient overall hoistingEasy to cleanAutomatic control devicesMeat/fish preservationImpellerEngineering

A portable batch pasteurizer for pasteurization or other heat treatment of contained fluids for consumption by animals or humans provides a heat transfer coil through which hot or cold fluids are pumped to heat or cool the fluid in which it is immersed. An impeller circulates the fluid in which the fluid is contained to ensure even heating or cooling.

Owner:DAIRY TECH CO LTD

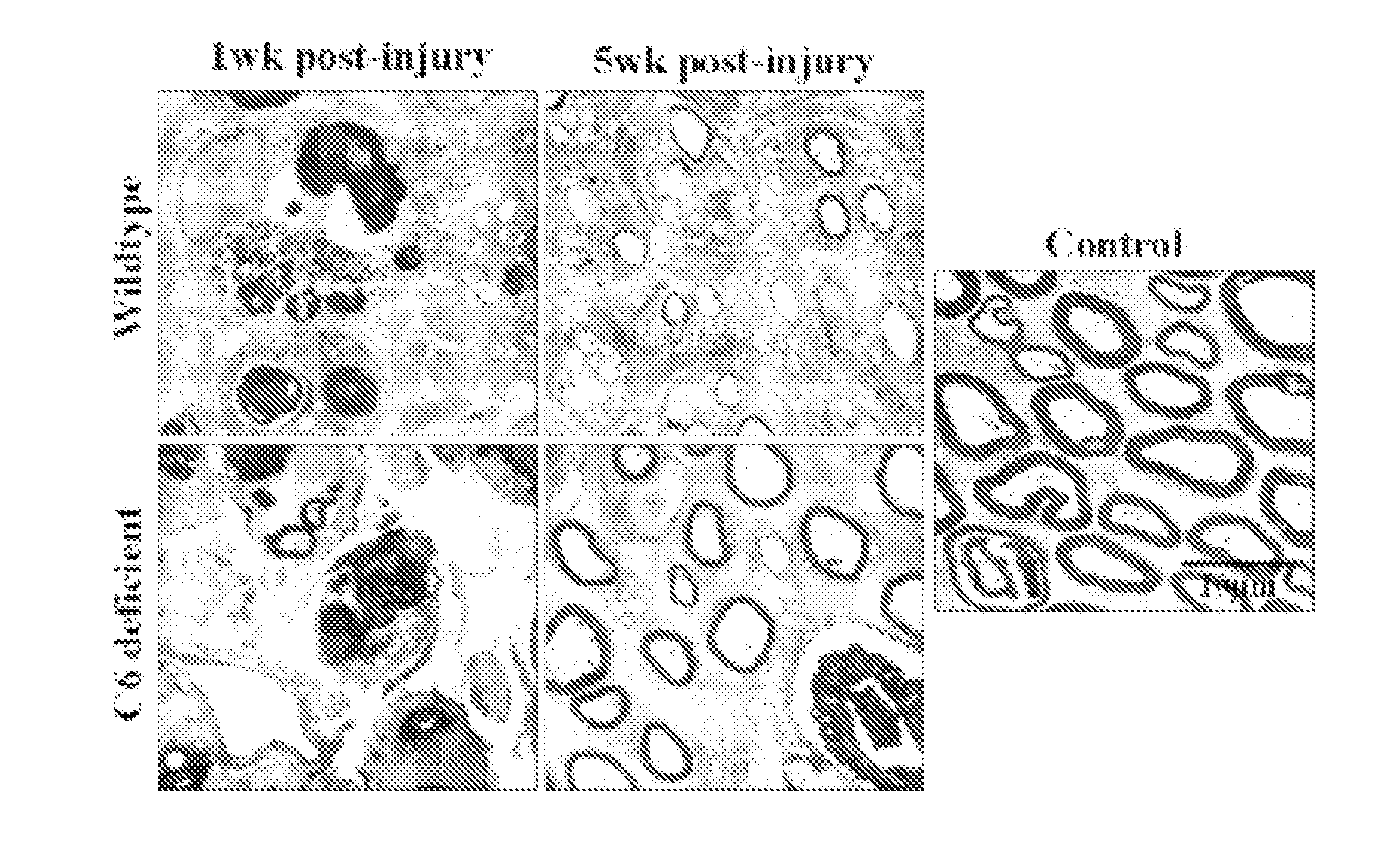

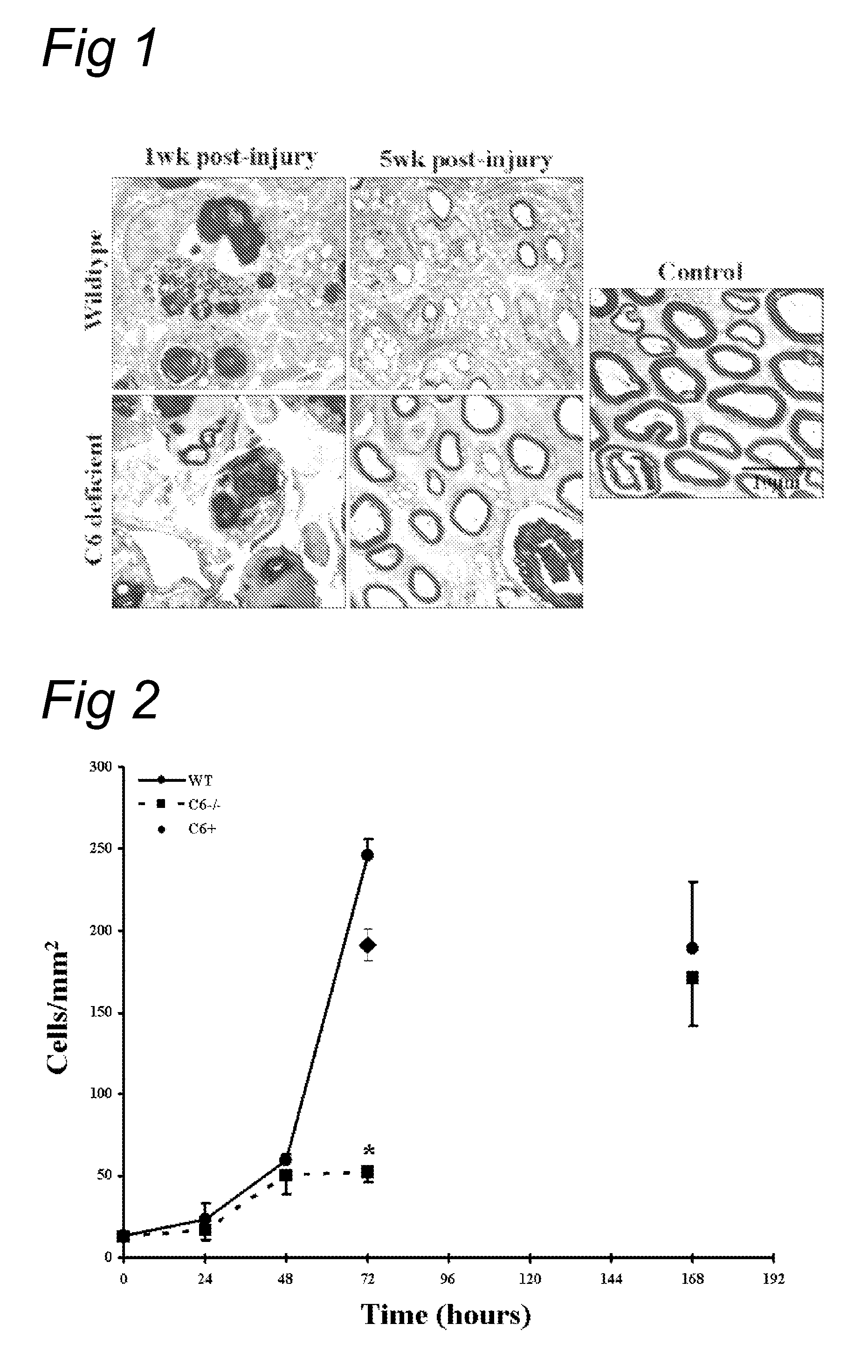

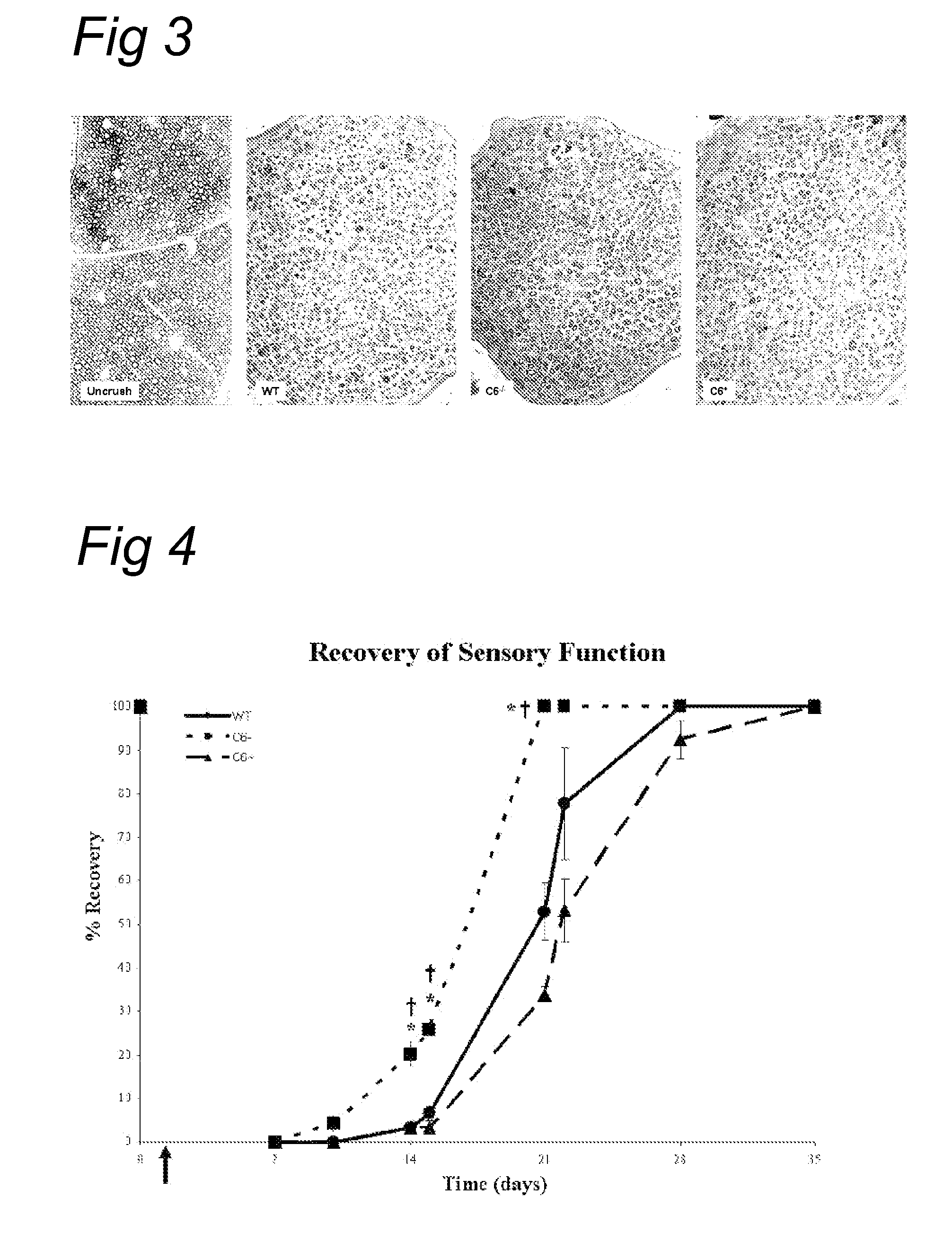

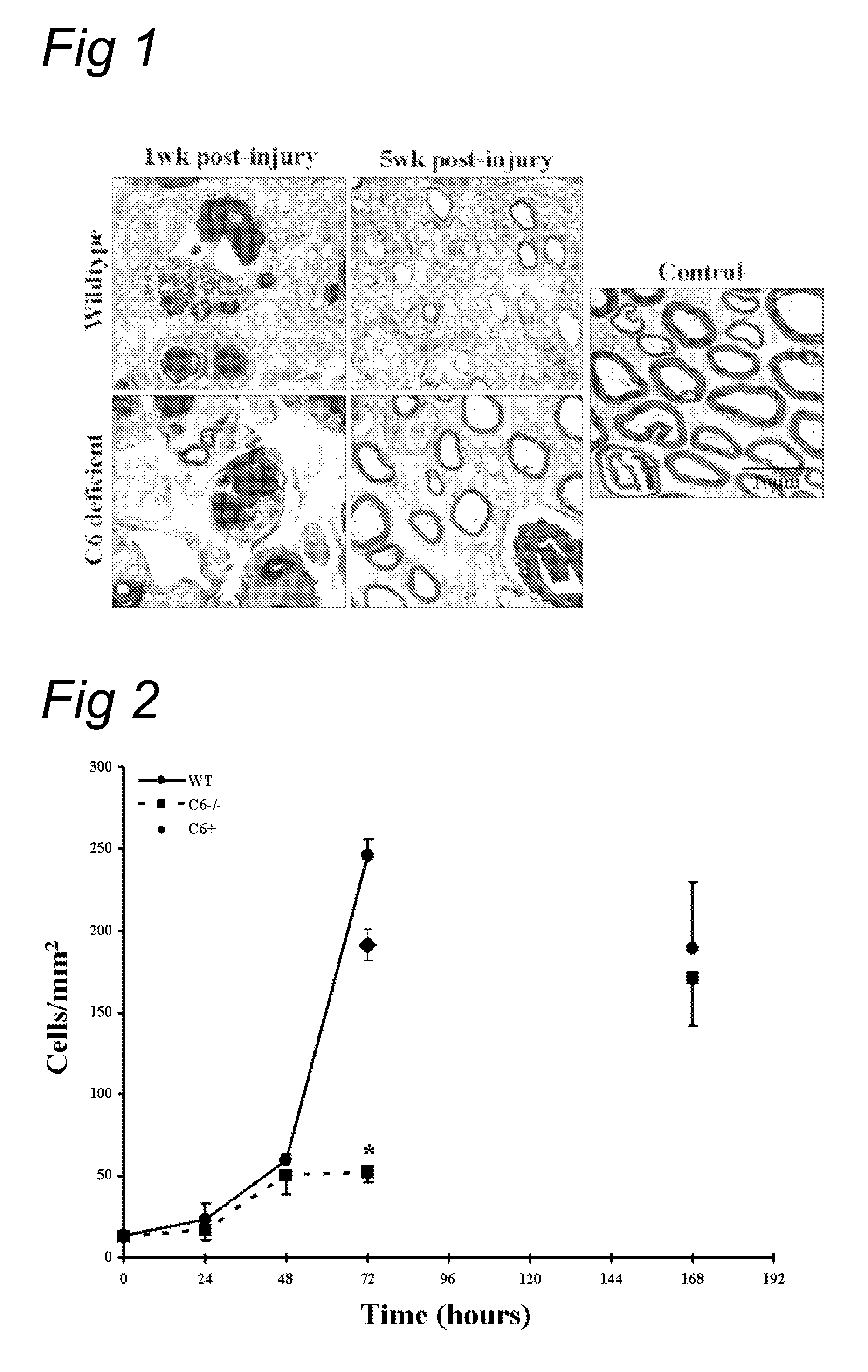

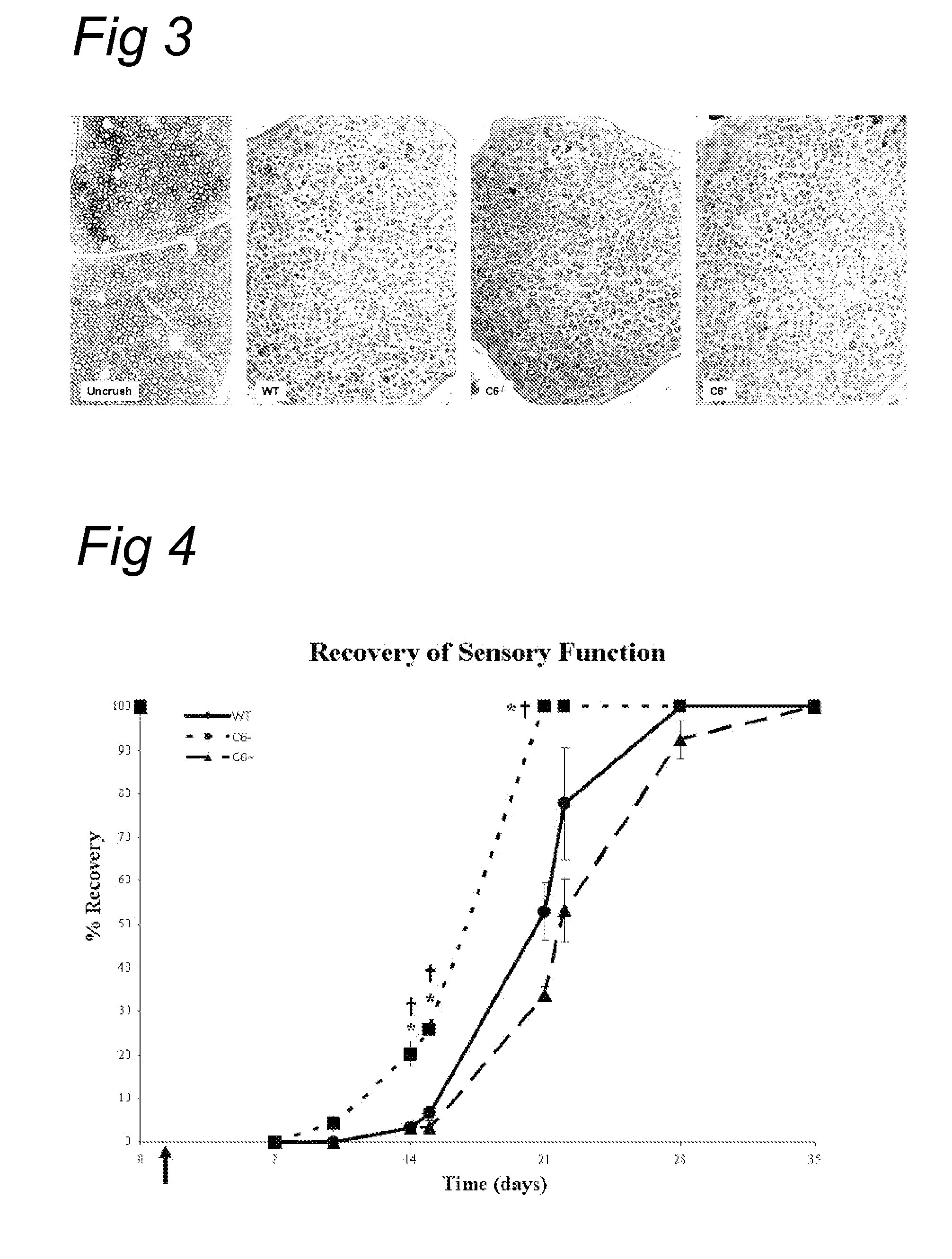

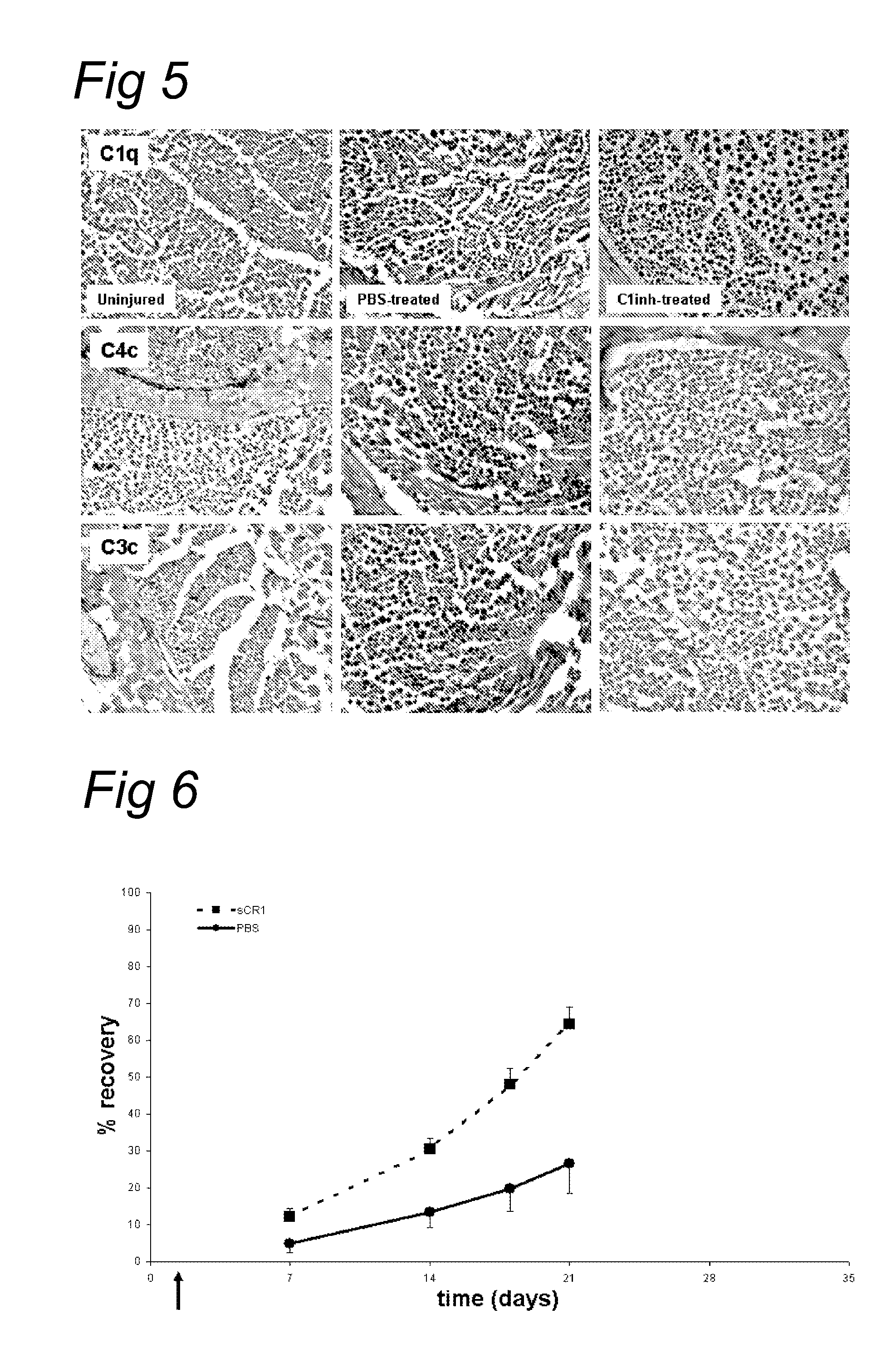

Complement inhibition for improved nerve regeneration

ActiveUS20100143344A1Improve regenerative abilityPromote regenerationBiocideNervous disorderDiseaseNervous system

The present invention relates to methods and medicaments used for treating conditions that require axonal regeneration, e.g. in mammals affected by injury or disease of the central or peripheral nervous system. The medicaments used in these methods facilitate axonal regeneration by inhibition of the complement system. Conditions requiring axonal regeneration that may be treated in accordance with the invention include physical injuries as well as neurodegenerative disorders of the peripheral or central nervous system.

Owner:REGENESANCE

Complement inhibition for improved nerve regeneration

ActiveUS8703136B2Improve regenerative abilityPromote regenerationNervous disorderPeptide/protein ingredientsDiseaseNervous system

The present invention relates to methods and medicaments used for treating conditions that require axonal regeneration, e.g. in mammals affected by injury or disease of the central or peripheral nervous system. The medicaments used in these methods facilitate axonal regeneration by inhibition of the complement system. Conditions requiring axonal regeneration that may be treated in accordance with the invention include physical injuries as well as neurodegenerative disorders of the peripheral or central nervous system.

Owner:REGENESANCE

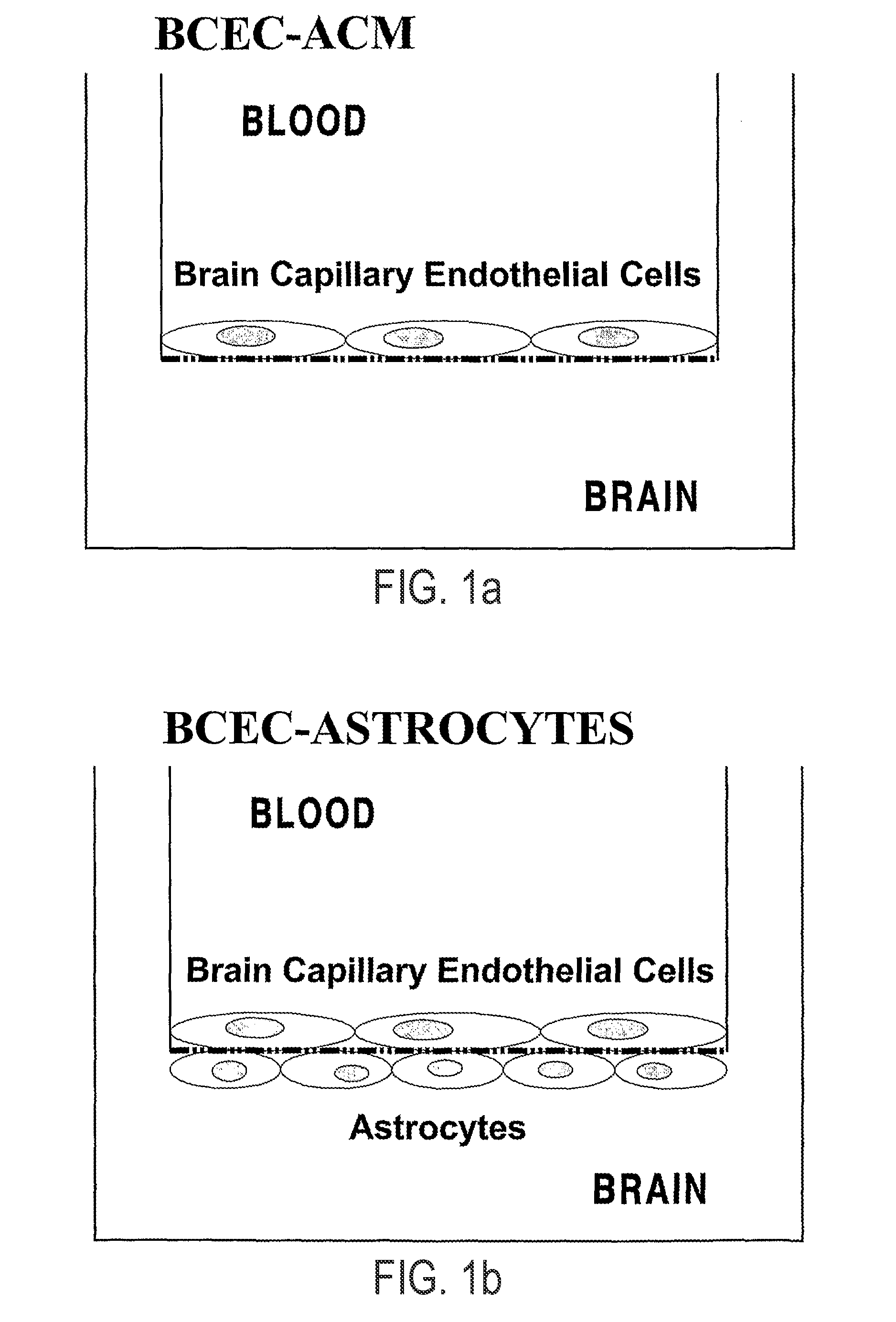

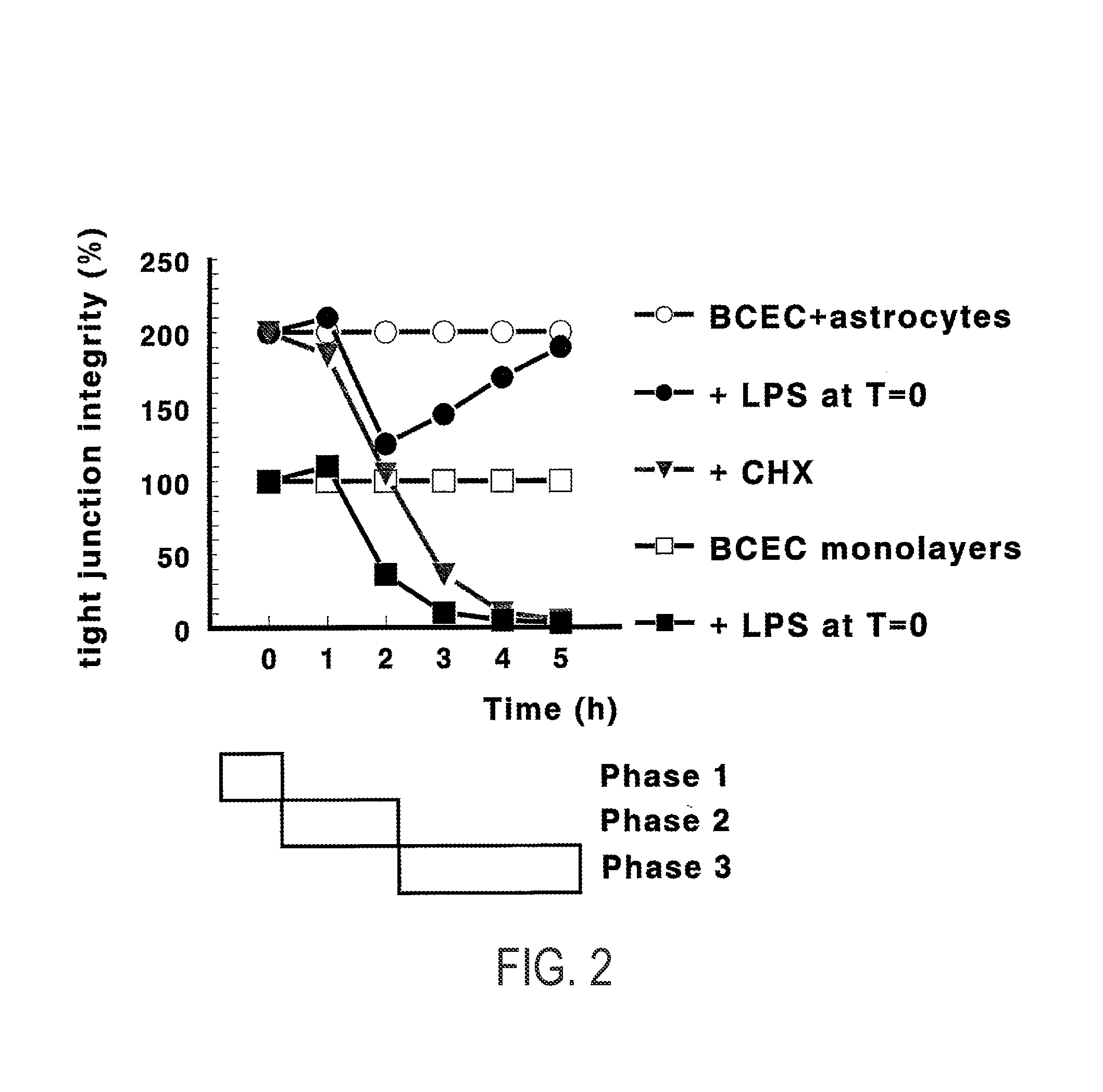

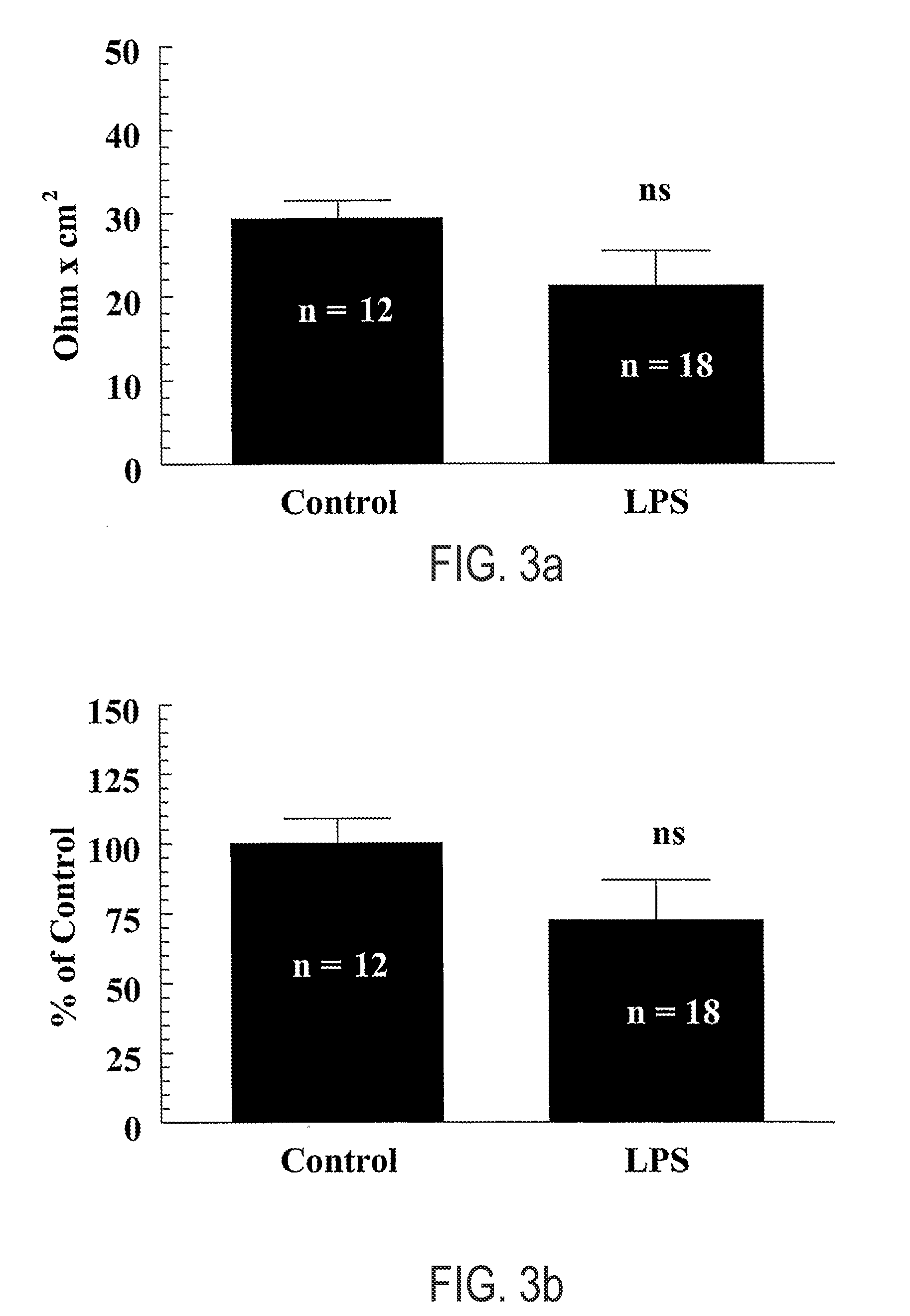

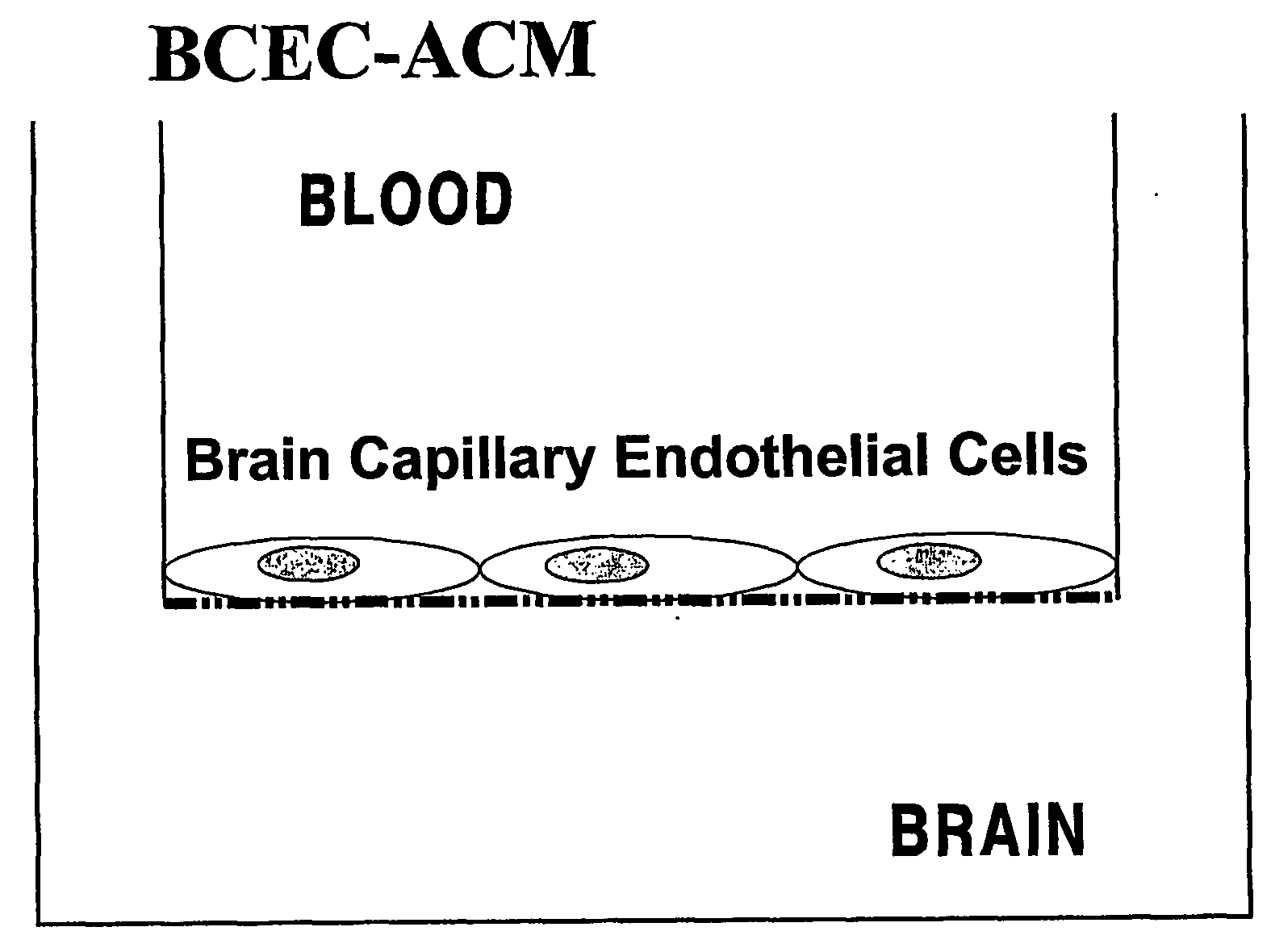

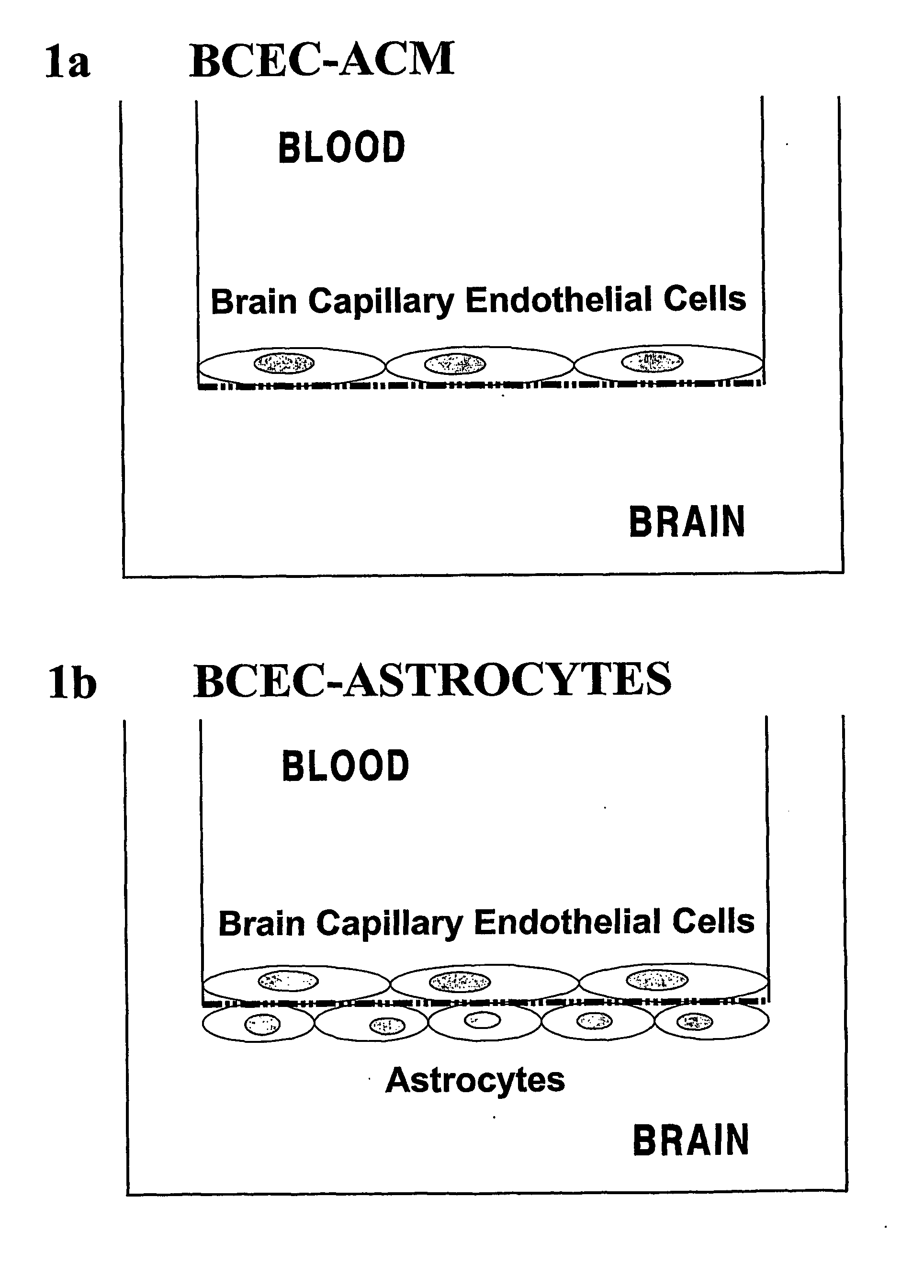

Methods and compositions for targeting agents into and across the blood-barrier and other endothelial cell microvascular barriers

InactiveUS8026209B2Improve permeabilityHigh activityOrganic active ingredientsPeptide/protein ingredientsMammalBiology

The present invention relates to nucleic acids and polypeptides encoded thereby, whose expression is modulated in brain microvascular endothelial cells undergoing early dynamic inflammation-induced changes in blood-brain barrier functionality. Such polypeptides are referred to as lipopolysaccharide-sensitive (LPSS) polypeptides herein. These nucleic acids and polypeptides may be useful in methods for controlling blood-brain barrier properties in mammals in need of such biological effects. This includes the diagnosis and treatment of disturbances in the blood-brain / retina barrier, brain (including the eye) disorders, as well as peripheral vascular disorders. Additionally, the invention relates to the use of anti-LPSS polypeptide antibodies or ligands as diagnostic probes, as blood-brain barrier targeting agents or as therapeutic agents as well as the use of ligands or modulators of expression, activation or bioactivity of LPSS polypeptides as diagnostic probes, therapeutic agents or drug delivery enhancers.

Owner:2 BBB MEDICINES BV

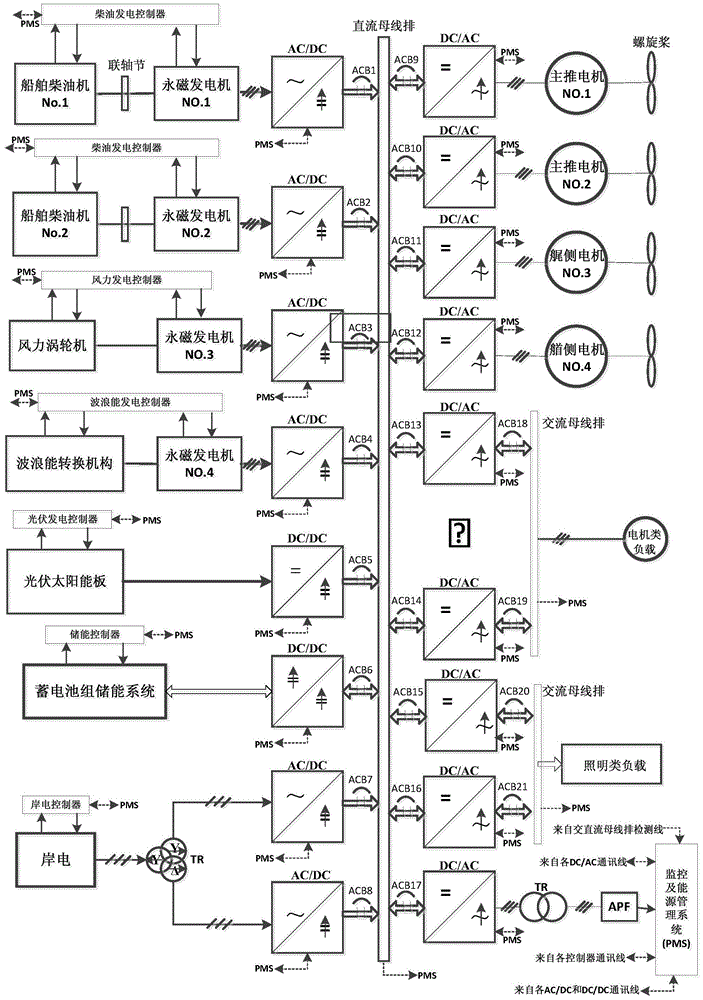

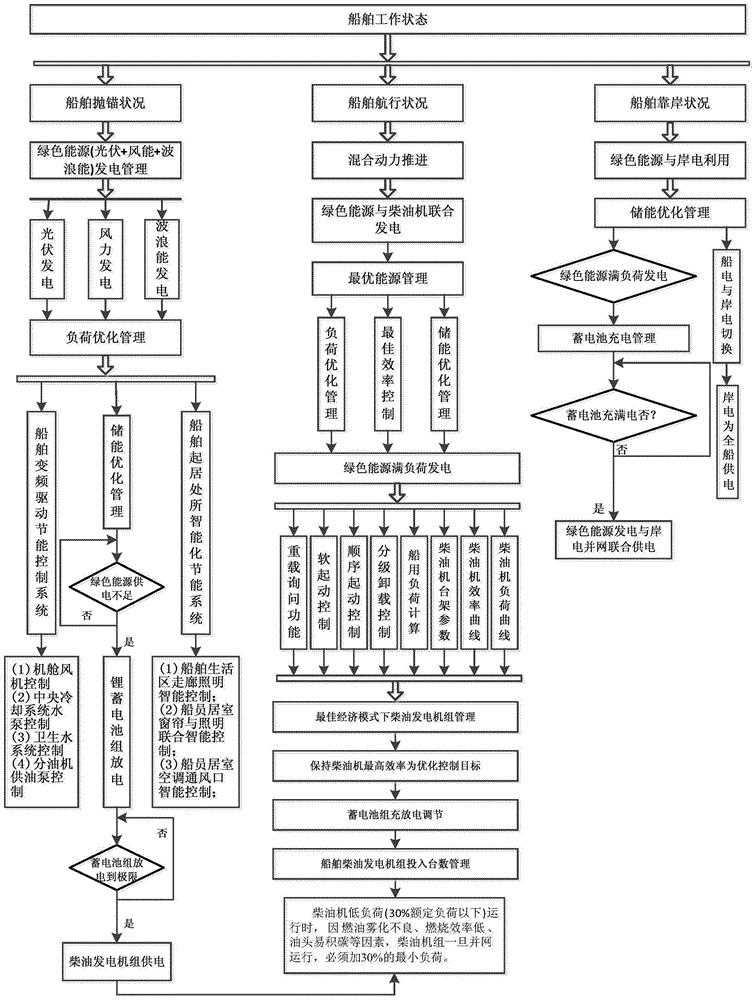

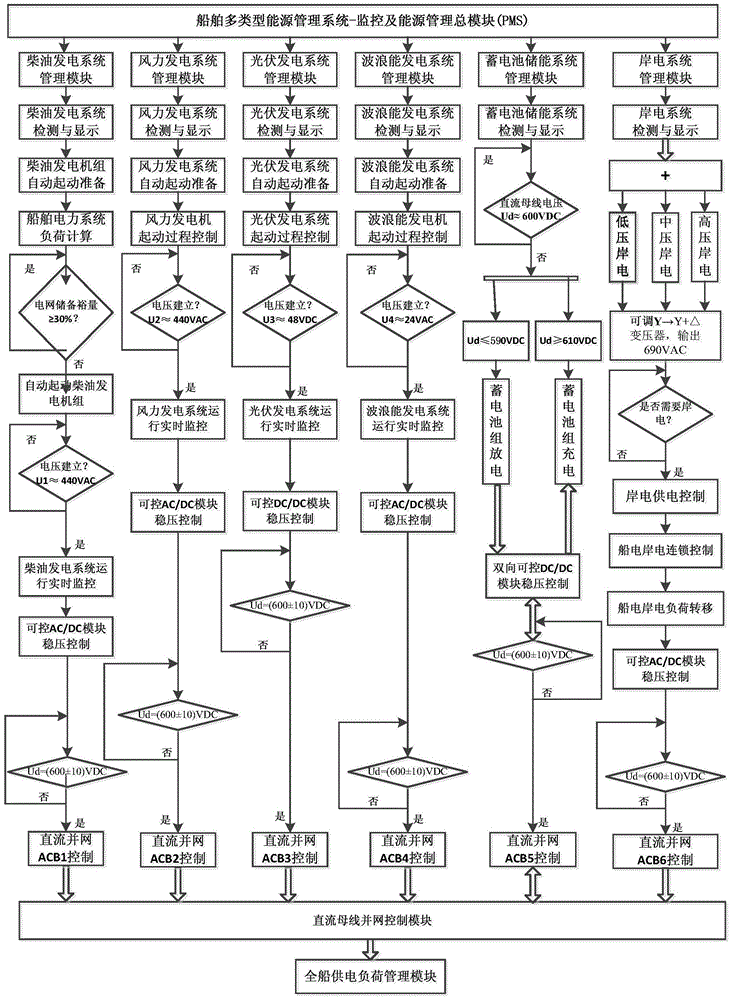

Ship multi-type energy source management system and energy source management method

InactiveCN106809363AControlled emissionsPromote sustainable developmentPropulsion based emission reductionAuxillariesThermal energyShore

The invention provides a ship multi-type energy source management system and an energy source management method. The ship multi-type energy source management system comprises a monitoring and energy source management master module, a diesel power generation system, a wind power generation system, a photovoltaic power generation system, a wave energy power generation system, a storage battery energy storage system, a shore power system, a direct current bus bar and a plurality of paths of power transmission systems. The ship multi-type energy source management system and the energy source management method have the advantages that the ship multi-type energy source management system provided by the invention fills the technological blank of integrating various types of green energy source power generation into ship heat energy power generation systems; the energy conservation and emission reduction are met; the global warming is responded; the greenhouse gas emission is controlled; the atmospheric environment is protected and the sustainable development of low-carbon economy is promoted.

Owner:SHANGHAI GUANTU ELECTRICAL TECH CO LTD

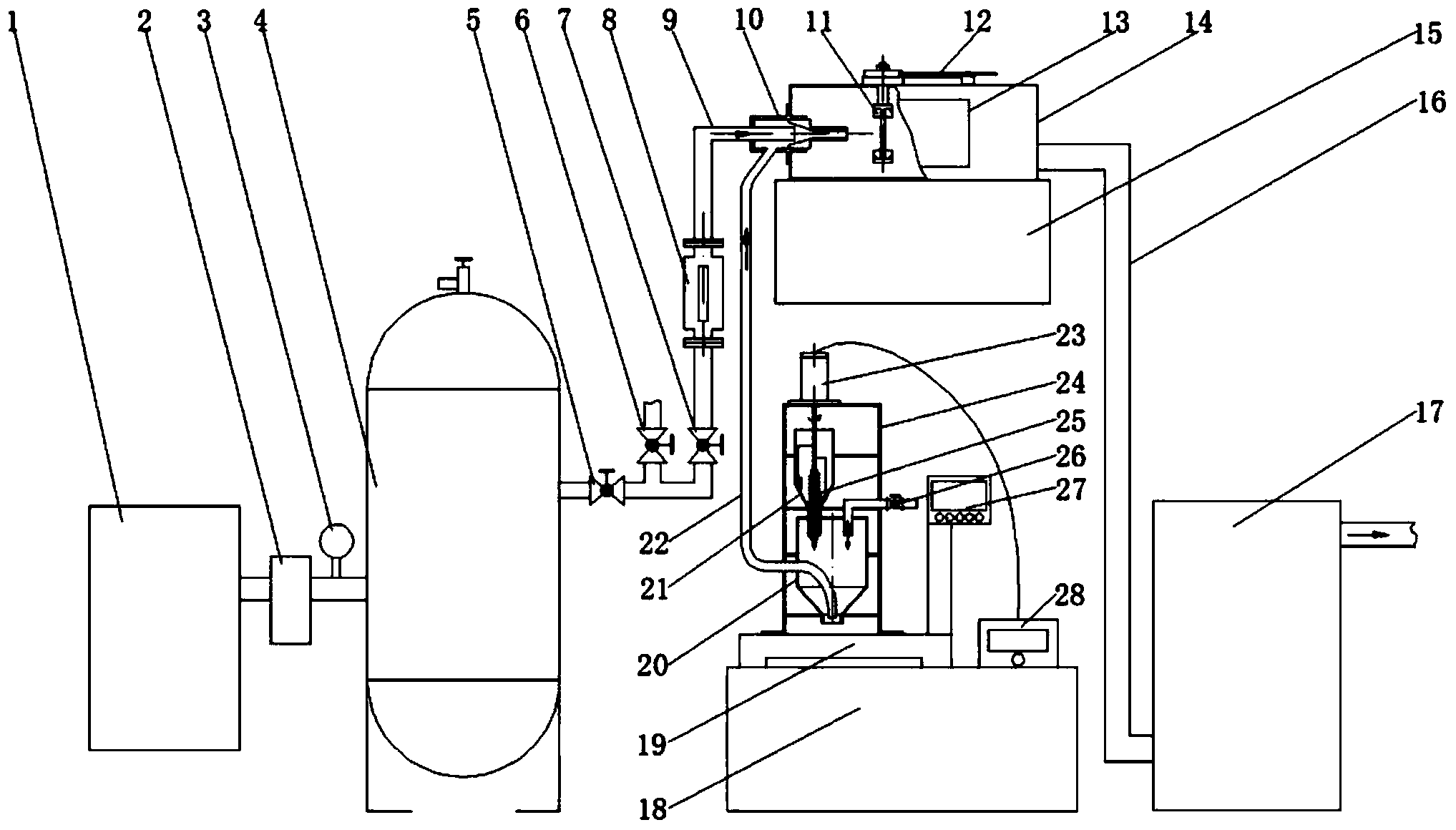

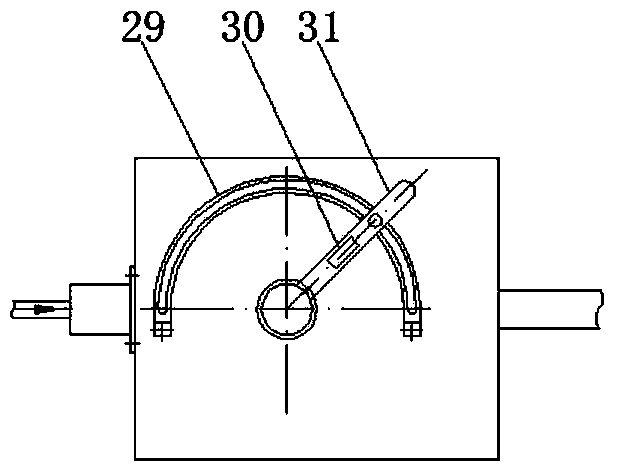

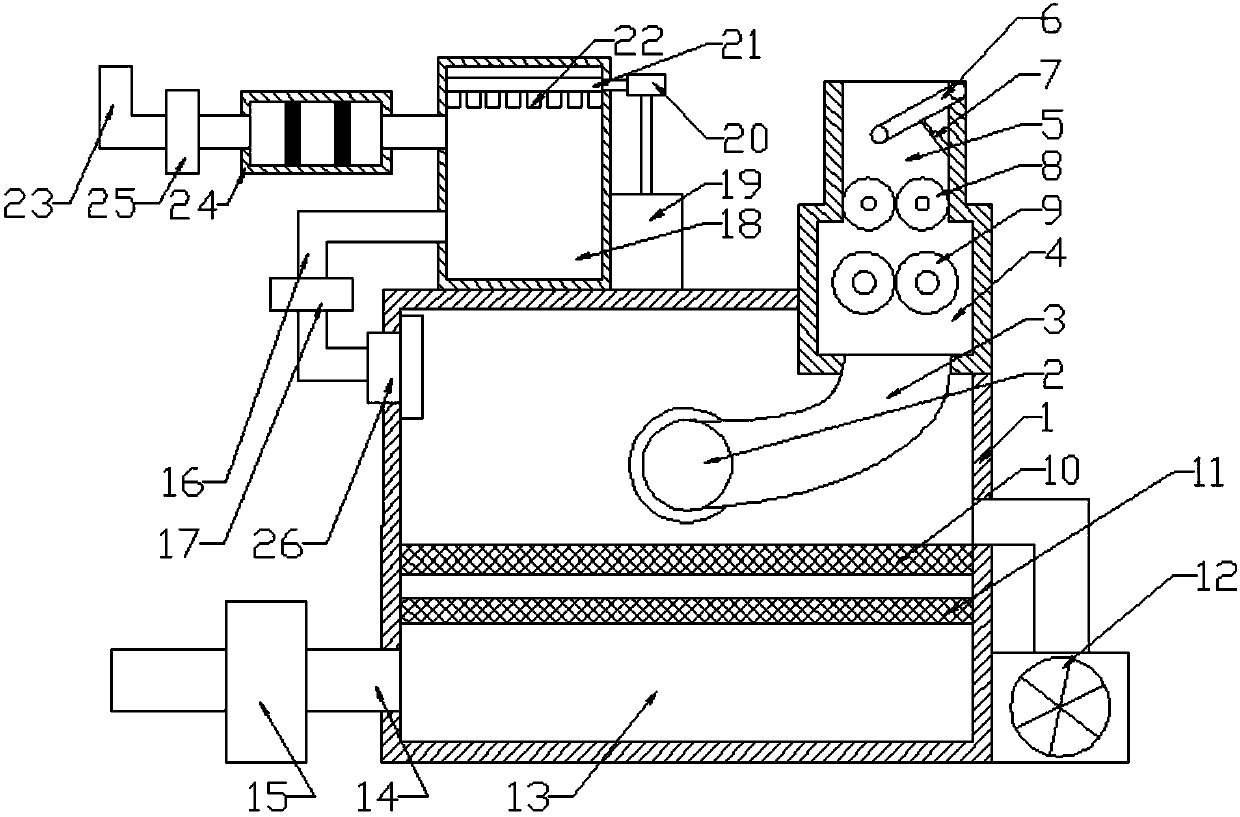

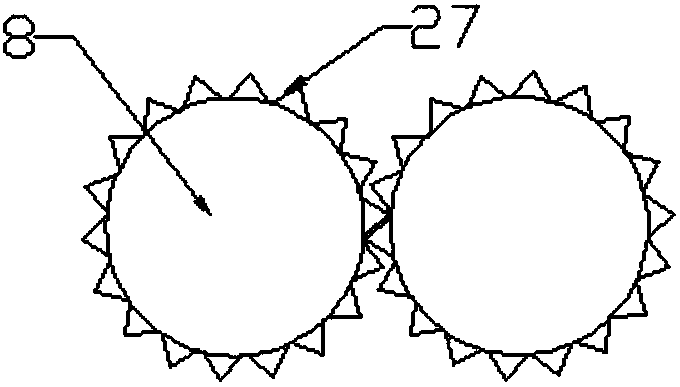

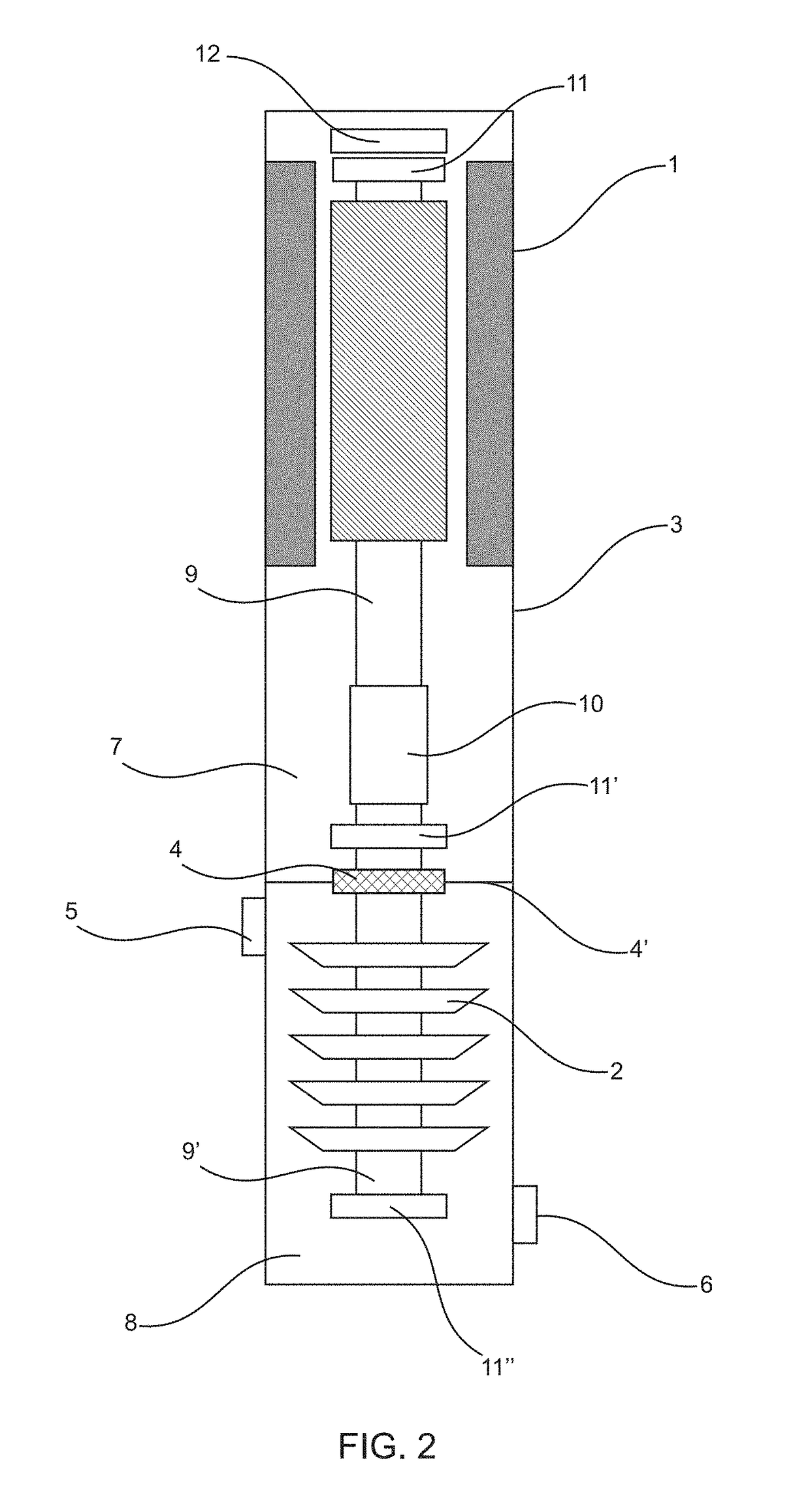

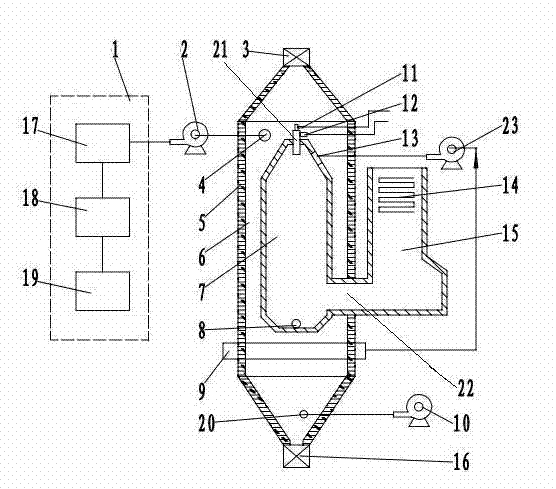

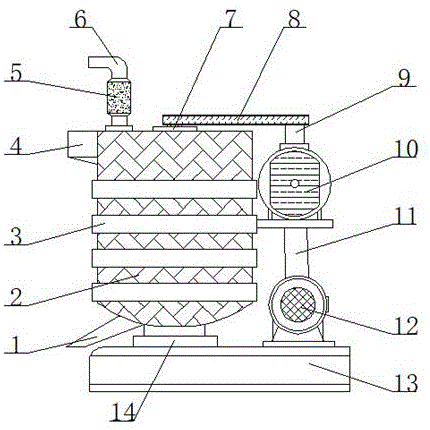

Air flow sand-blasting-type erosive wear testing machine

InactiveCN103760048AEasy to adjustSmooth feedingInvestigating abrasion/wear resistanceWear testingExhaust valve

The invention discloses an air flow sand-blasting-type erosive wear testing machine. The air flow sand-blasting-type erosive wear testing machine comprises a high-speed air flow unit, a screw rod charging unit, an erosive testing unit and a purifying and dedusting unit, wherein the high-speed air flow unit and the screw rod charging unit are both communicated with an inlet of the erosive testing unit; the dedusting unit is communicated with an outlet of the erosive testing unit; the screw rod charging unit comprises an electronic scale, a material storage chamber, a charging funnel, a charging screw rod and a screw rod electromotor, wherein the electronic scale is provided with the material storage chamber; the material storage chamber is provided with the charging funnel communicated with the material storage chamber; the charging funnel is provided with the charging screw rod driven by the screw rod electromotor, and the material storage chamber is communicated with a suction spray gun by a charging pipeline; the screw rod electromotor is controlled by a controller. According to the erosive wear testing machine, the air flow impact speed can be up to 0m / s-200m / s by regulating an air exhaust valve and a flow meter. The erosive angle is changed between 0 degree and 90 degrees by a specimen rotary table. The uniform charging can be ensured by means of a screw rod charger.

Owner:SHANDONG UNIV

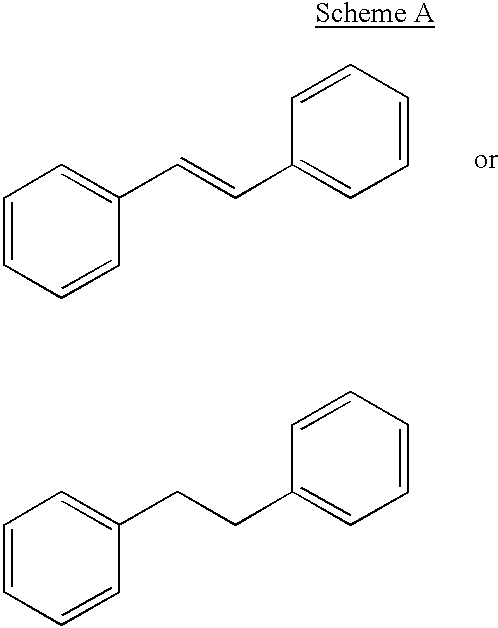

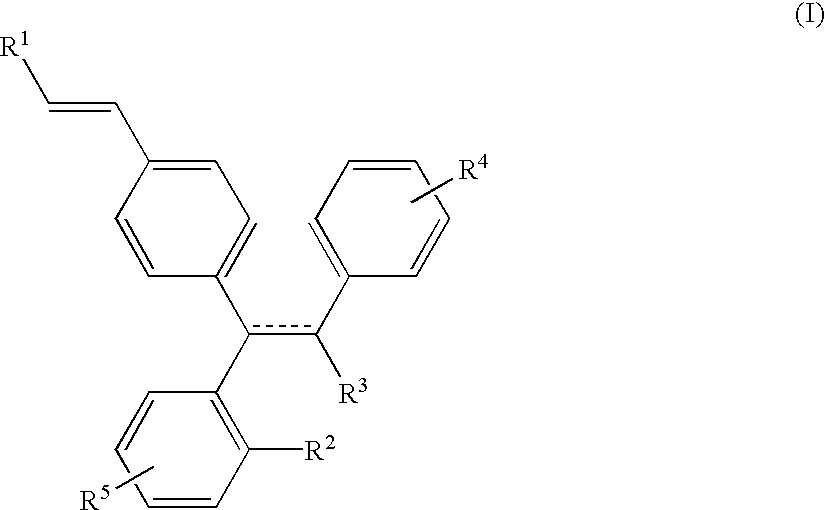

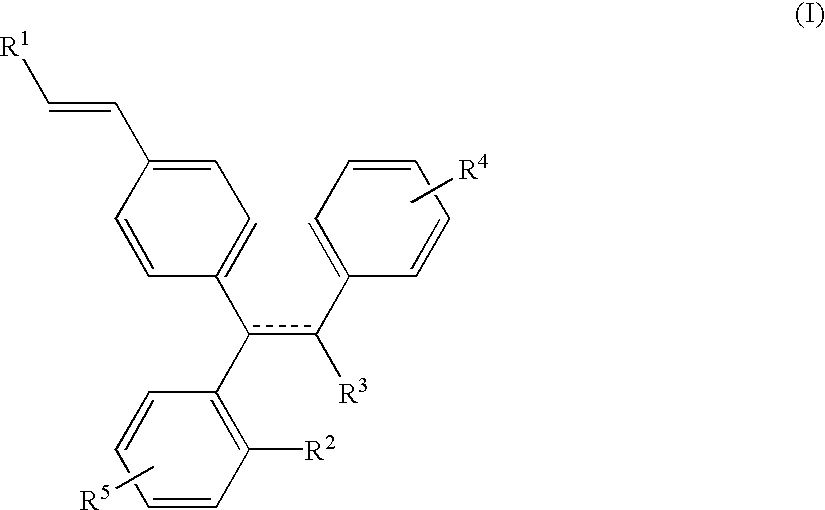

Selective estrogen receptor modulators

InactiveUS20030105148A1Improve patient acceptanceContinuous releaseBiocideNervous disorderSelective androgen receptor modulatorProstate cancer

The present invention provides, inter alia, triphenylethylene derivatives, such as, 3-{4-[6-(3-Methoxy-phenyl)-8,9-dihydro-7H-benzocyclohepten-5-yl]-phenyl}-acrylic acid, as selective estrogen receptor modulators. Also provided are methods for the treatment and / or prevention of estrogen stimulated diseases in mammals including breast, uterine, ovarian, prostrate and colon cancer, osteoporosis, cardiovascular disease, and benign proliferative disorders, as well as pharmaceutical compositions of the compounds of the present invention.

Owner:BRISTOL MYERS SQUIBB PHARMA CO

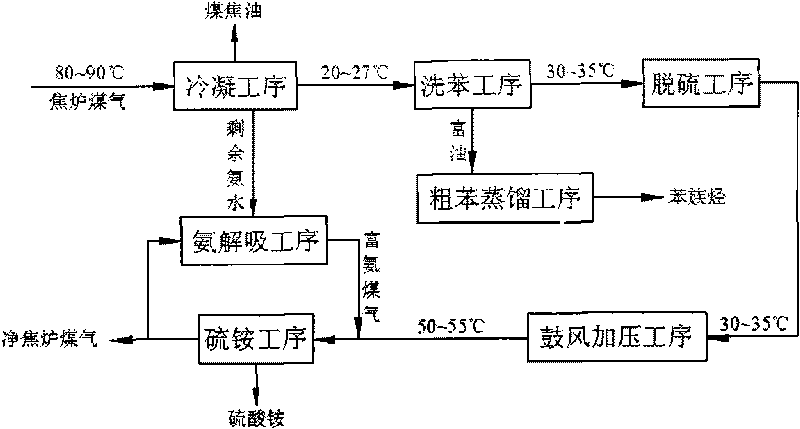

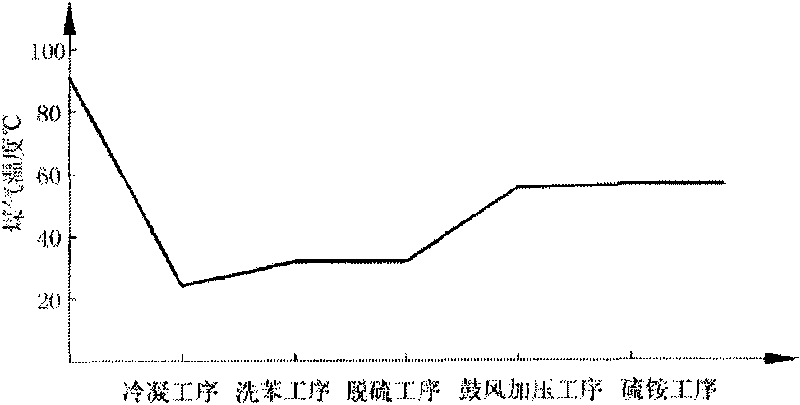

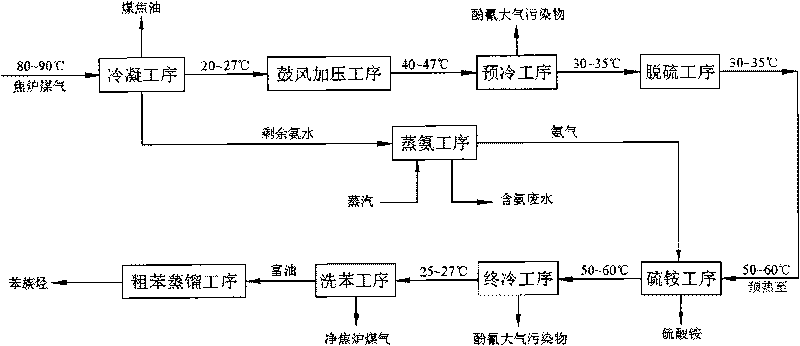

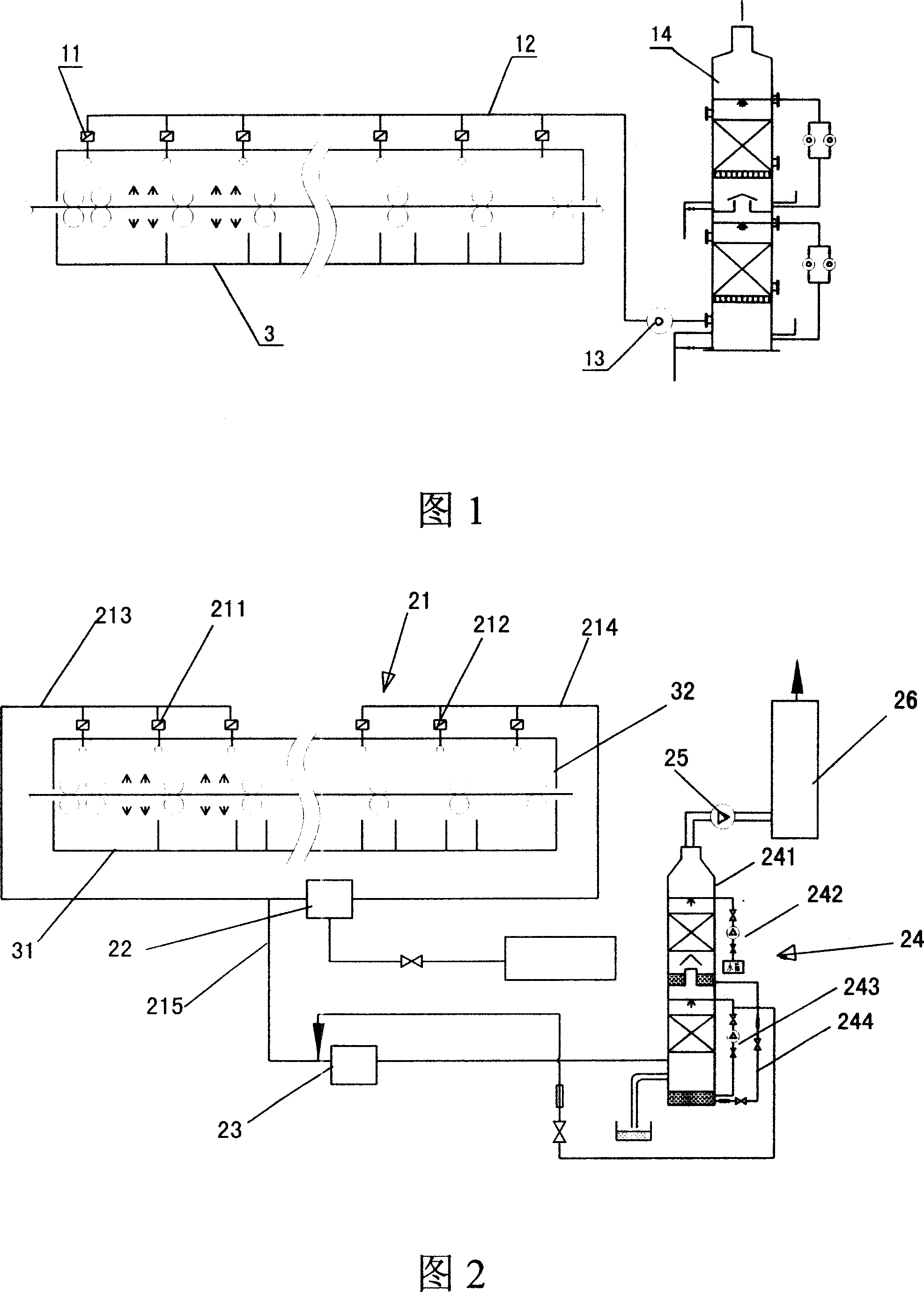

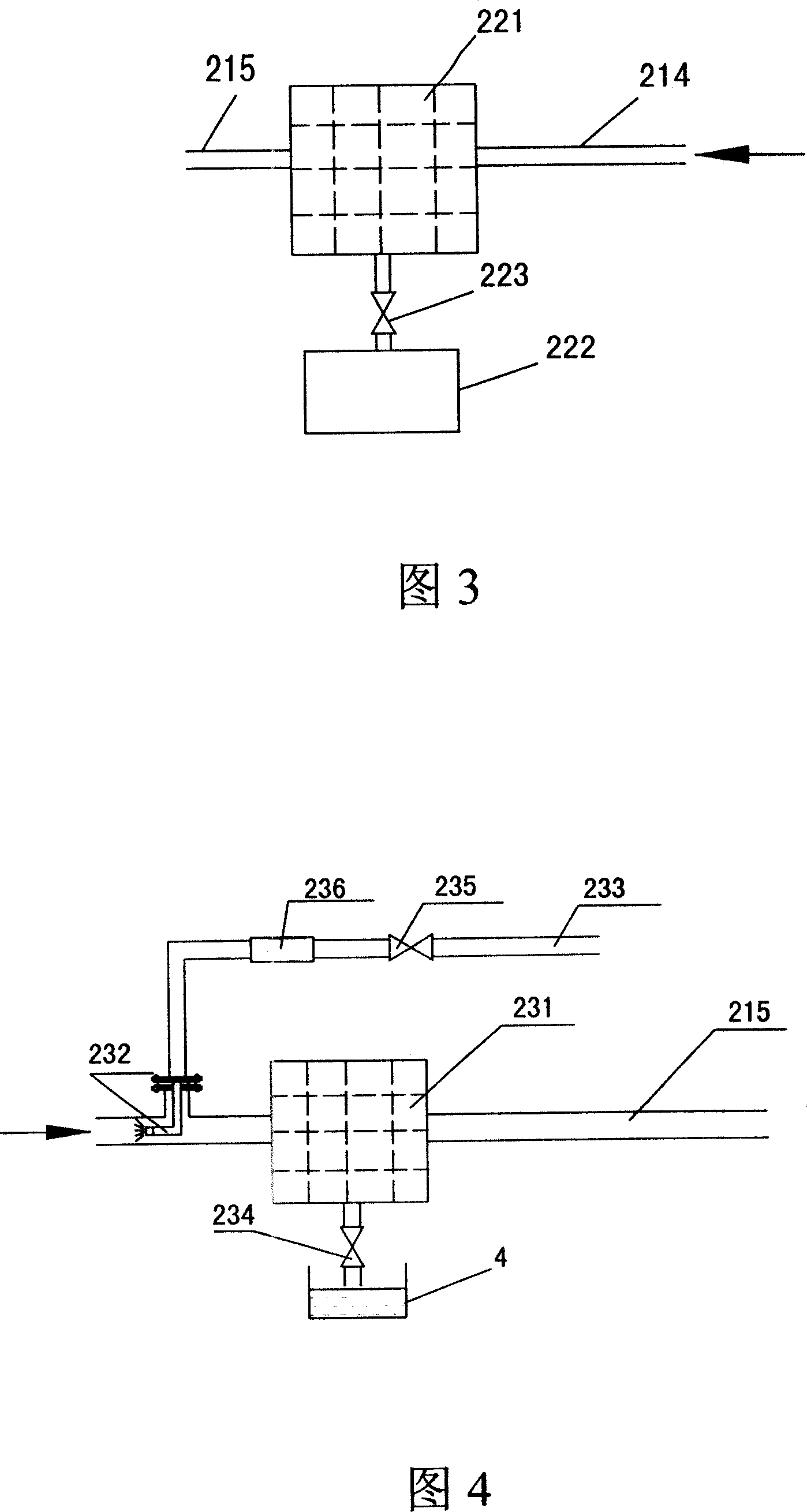

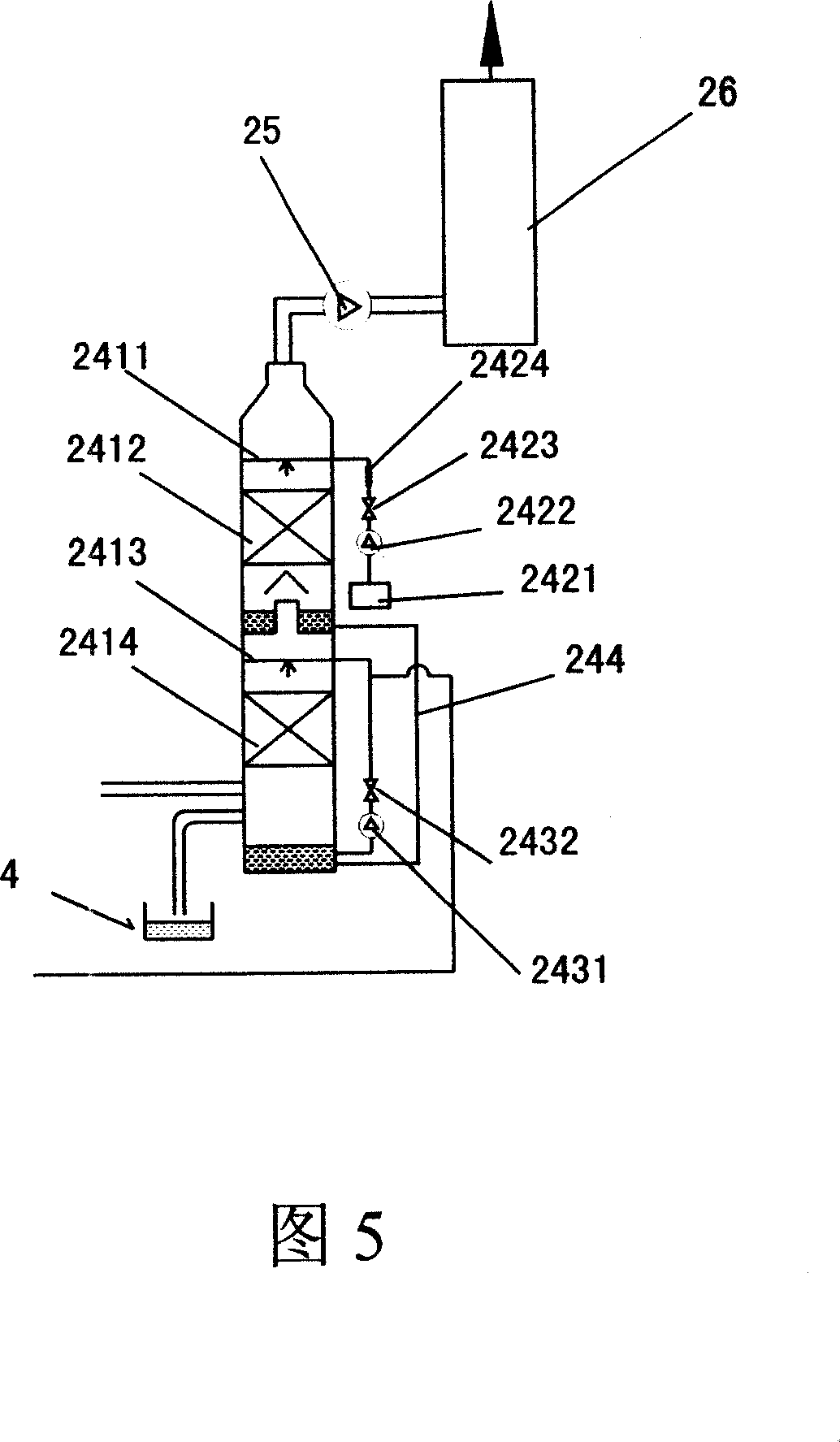

Method for purifying and recycling benzoid hydrocarbon, ammonia and coal tar from coke-oven gas

InactiveCN101724471AMeet temperature requirementsReduce energy consumptionLiquid hydrocarbon mixture recoveryGas purification by non-gaseous materials condensationBenzeneDesorption

The invention relates to a method for purifying and recycling benzoid hydrocarbon, ammonia and coal tar from coke-oven gas. The technical scheme of the method comprises the following steps of: cooling the 80-90 DEG C coke-oven gas through a condensation step to 20-27 DEG C, then directly carrying out a benzene washing step, absorbing benzoid hydrocarbon in the coke-oven gas to the wash oil to form rich oil, desulfurizing the coke-oven gas at 30-35 DEG C after the benzene washing step, air-blast pressurizing the desulfurized coke-oven gas at 30-35 DEG C, naturally raising the temperature of the coke-oven gas to 50-55 DEG C, carrying out an ammonium sulfate step on the coke-oven gas to recycle ammonia therein, and using the purified coke-oven gas after the ammonium sulfate step as high-grade fuel to be supplied to the outside. The remaining ammonia water generated in the condensation step goes into an ammonia desorption step so as to desorb ammonia and goes into the ammonium sulfate step to produce ammonium sulfate; and benzoid hydrocarbon is recycled from the rich oil produced in the benzene washing step through a crude benzene distilling step. The invention has the characteristics of orderly temperature change, smooth change of gradient, simple technical process, low energy consumption, low production cost, high purification efficiency and environmental friendliness.

Owner:WUHAN UNIV OF SCI & TECH

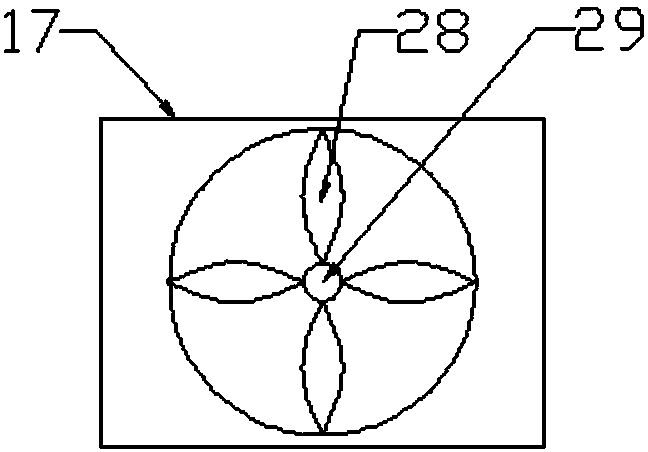

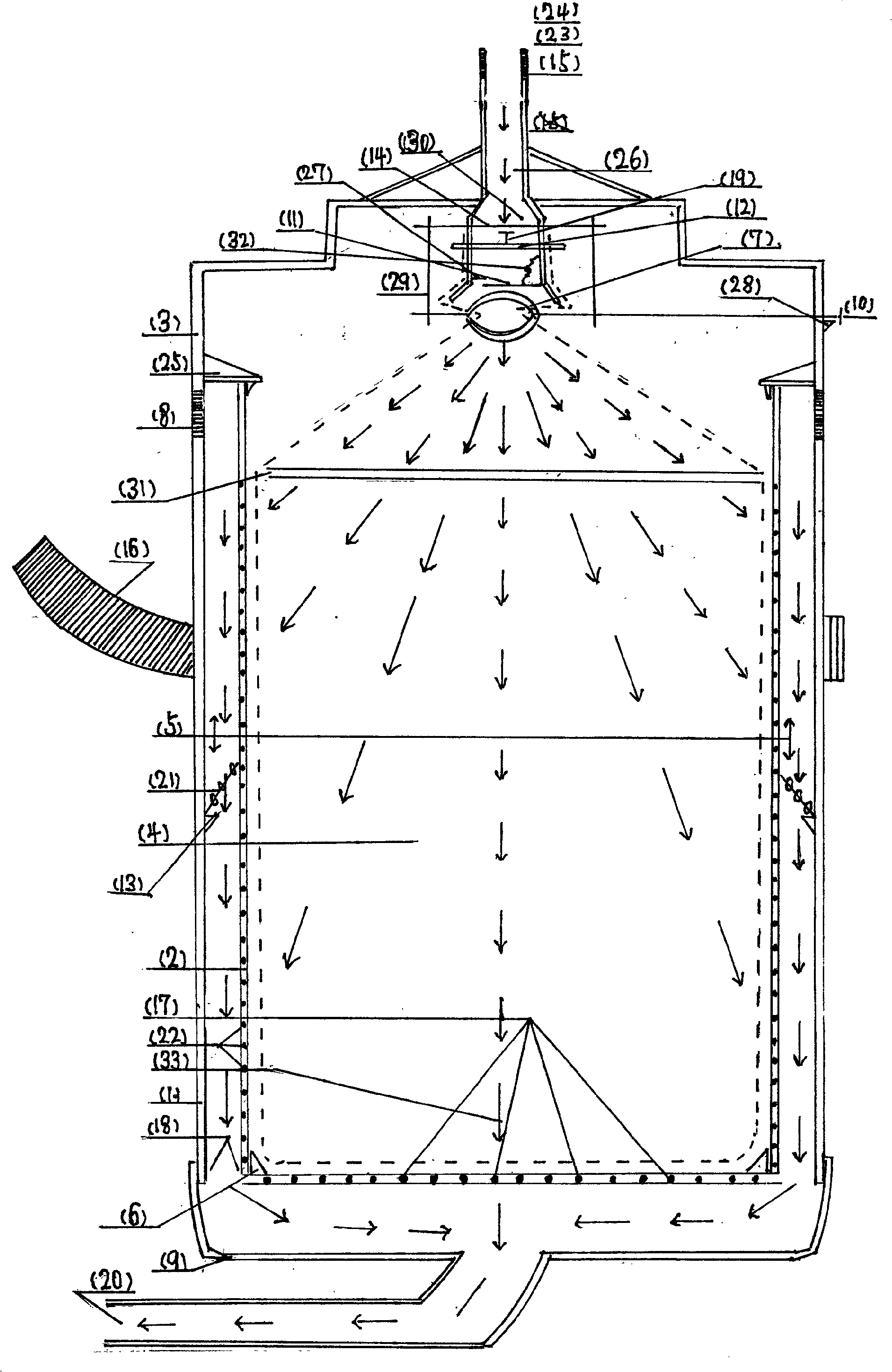

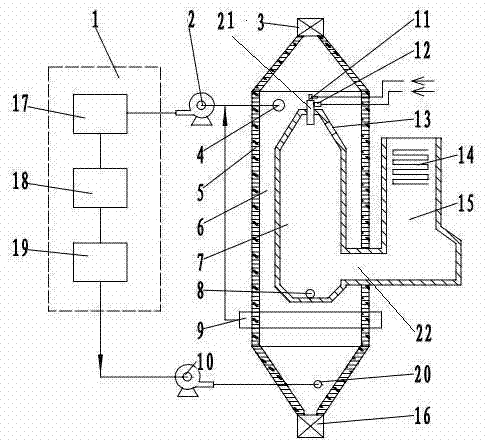

Harmless treatment environment-friendly device for crop straws

InactiveCN107816722ADelicate handlingSolve the blockageBlast-producing apparatusIncinerator apparatusSlagWater storage tank

The invention provides a harmless treatment environment-friendly device for crop straws, and belongs to the technical field of crop straw environment-friendly treatment. The harmless treatment environment-friendly device comprises a treatment machine body, a primary crushing chamber, a secondary crushing chamber, a waste gas treatment chamber, a waste gas purifying chamber and a water storage tank. According to the harmless treatment environment-friendly device, in the actual working process, after being put into the primary crushing chamber, the large number of crop straws can fall on a cutting blade of a cutting rotating roller for primary cutting crushing treatment, materials after primary treatment fall into the secondary crushing chamber for deep secondary crushing treatment under theaction of gravity, so that the large straws are treated more exquisitely, and favorable conditions are provided for subsequent incineration treatment; and in the treatment process, an electric telescopic rod is adjusted to make an opening and closing side baffle to conduct inlet plugging, not only can be the plugging problem caused by too fast falling of the large bulk materials solved, but alsosplashing broken slag materials in the treatment process can be blocked very well, so that the harm to surrounding people due to the fact that the broken slag materials splash to the exterior of the device is prevented.

Owner:周梅阳

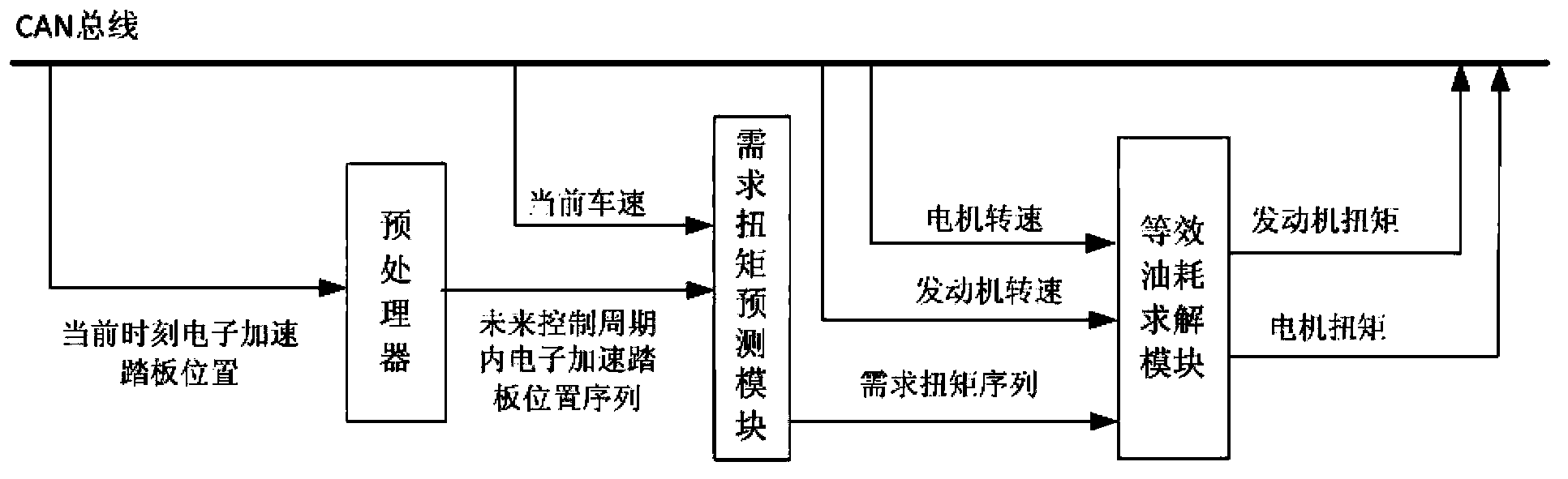

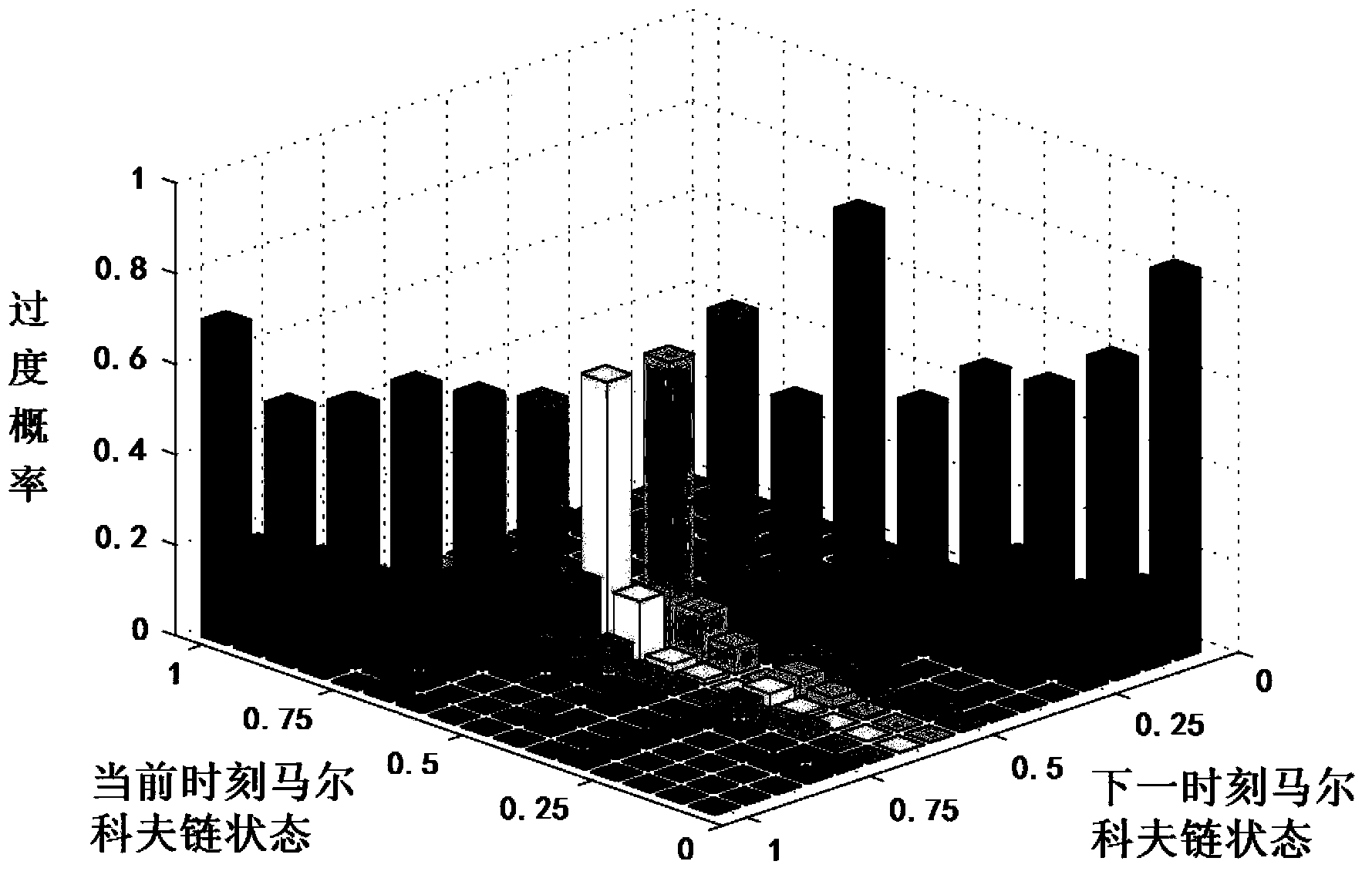

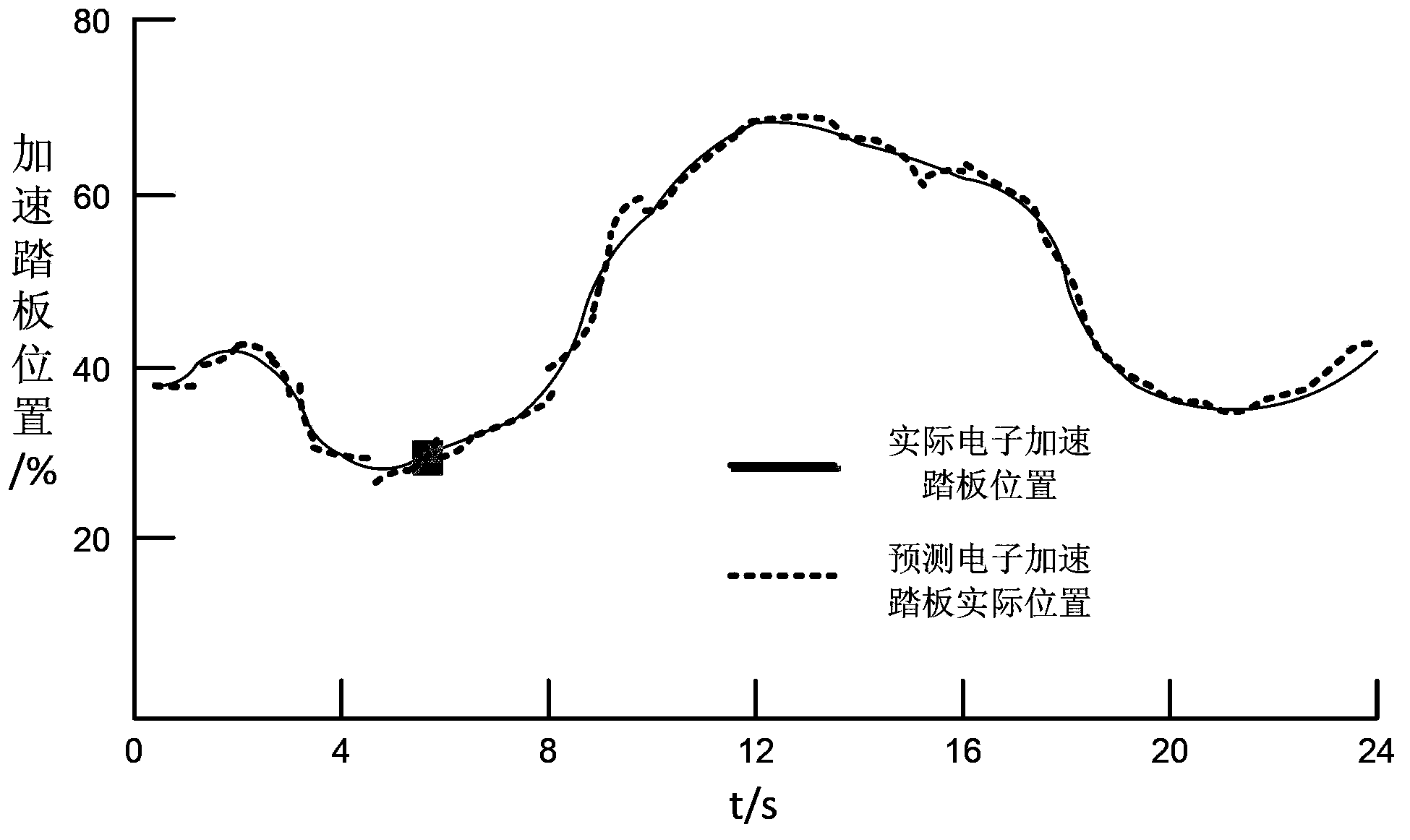

Device and method for controlling torque output of hybrid electric vehicle

InactiveCN103350696AReduce fuel consumptionLow emission potentialHybrid vehiclesAutomatic controlElectric machinery

The invention belongs to the technical field of automatic control and particularly relates to a device and method for controlling the torque output of a hybrid electric vehicle. The device for controlling the torque output of the hybrid electric vehicle is composed of a CAN bus, a preprocessor, a demand torque prediction module and an equivalent fuel consumption solving module, wherein the preprocessor, the demand torque prediction module and the equivalent fuel consumption solving module are sequentially connected, and the CAN bus is respectively connected with the preprocessor, the demand torque prediction module and the equivalent fuel consumption solving module. According to the device and method for controlling the torque output of the hybrid electric vehicle, by solving the minimum value of the equivalent fuel consumption objective function, the engine torque and the motor torque needing outputting at the moment in a future control cycle are obtained and sent to an engine and a motor respectively through the CAN bus. Control of the torque output of the hybrid electric vehicle is achieved, the potential of low fuel consumption and low emission of the hybrid electric vehicle is fully utilized, and the requirements for saving petroleum energy, protecting the atmospheric environment and reducing emission are achieved.

Owner:BEIJING JIAOTONG UNIV

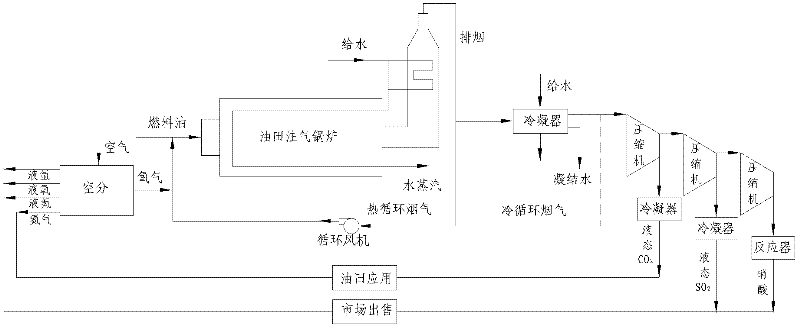

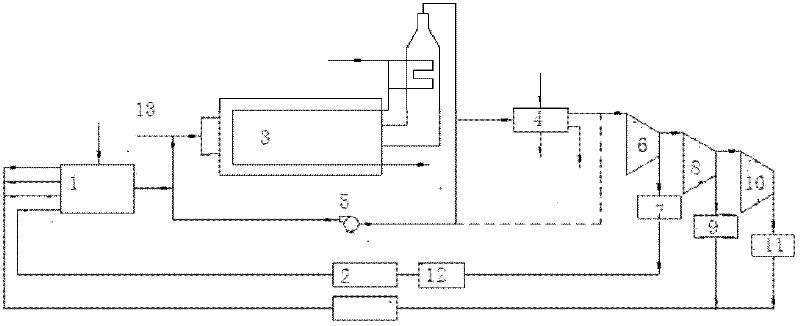

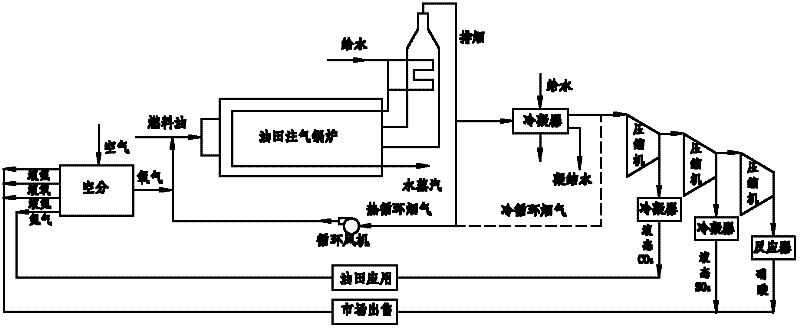

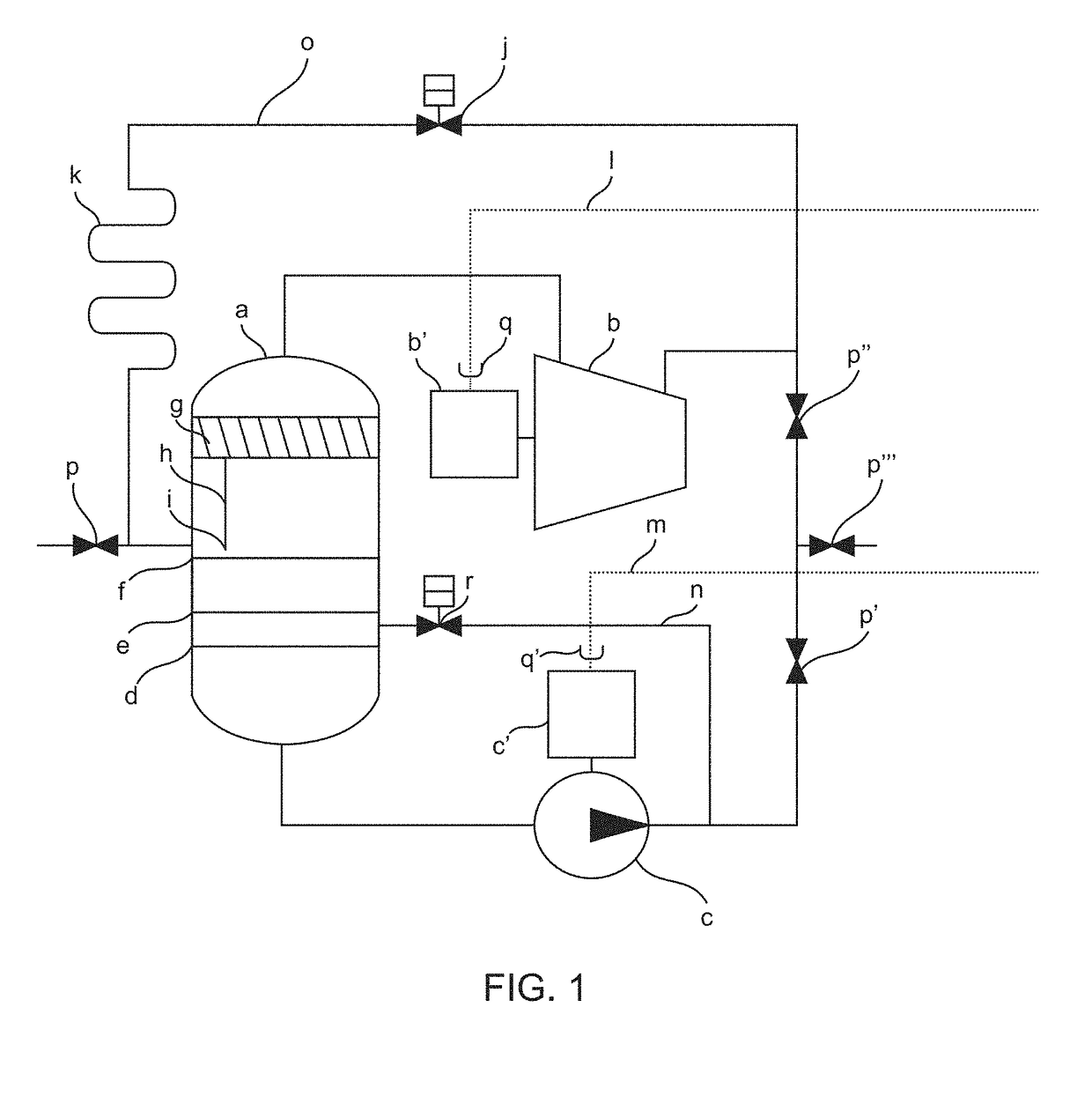

Oxygen-enriched combustion poly-generation process and equipment for steam injection boiler in oil field

InactiveCN102431974AFix storage issuesRealize integrated collaborative removalNitrogen compoundsSulfur compoundsAtmospheric airFuel oil

The invention relates to an oxygen-enriched combustion poly-generation process and equipment for a steam injection boiler in an oil field. According to the invention, air is subjected to deep cooling air separation so as to obtain nitrogen and pure oxygen; the pure oxygen is introduced into a steam injection boiler in an oil field and is mixed and burned with fuel oil so as to obtain CO2-rich flue gas; a part of the CO2-rich flue gas is used as circulation gas and is mixed with the pure oxygen, and mixed gas enters into the steam injection boiler; the rest part of the CO2-rich flue gas is compressed and condensed by using a CO2 liquefaction system so as to obtain high purity CO2, and the high purity CO2 is delivered to an oil displacement system of the oil field; flue gas which has undergone condensation and removal of CO2 enters into a SO2 and NOx recovery system so as to realize condensation and recovery of SO2 and NOx. According to the invention, the technology of oxygen-enriched combustion is introduced into the steam injection boiler, which enables the problem of storage of CO2 to be overcome and allows recovery and treatment of residual flue gas to be realized by using a simple method, thereby realizing integrated simultaneous removal of pollutants and protecting atmospheric environment; since a plurality of byproducts are obtained, considerable economic benefits can be achieved.

Owner:SHANDONG UNIV

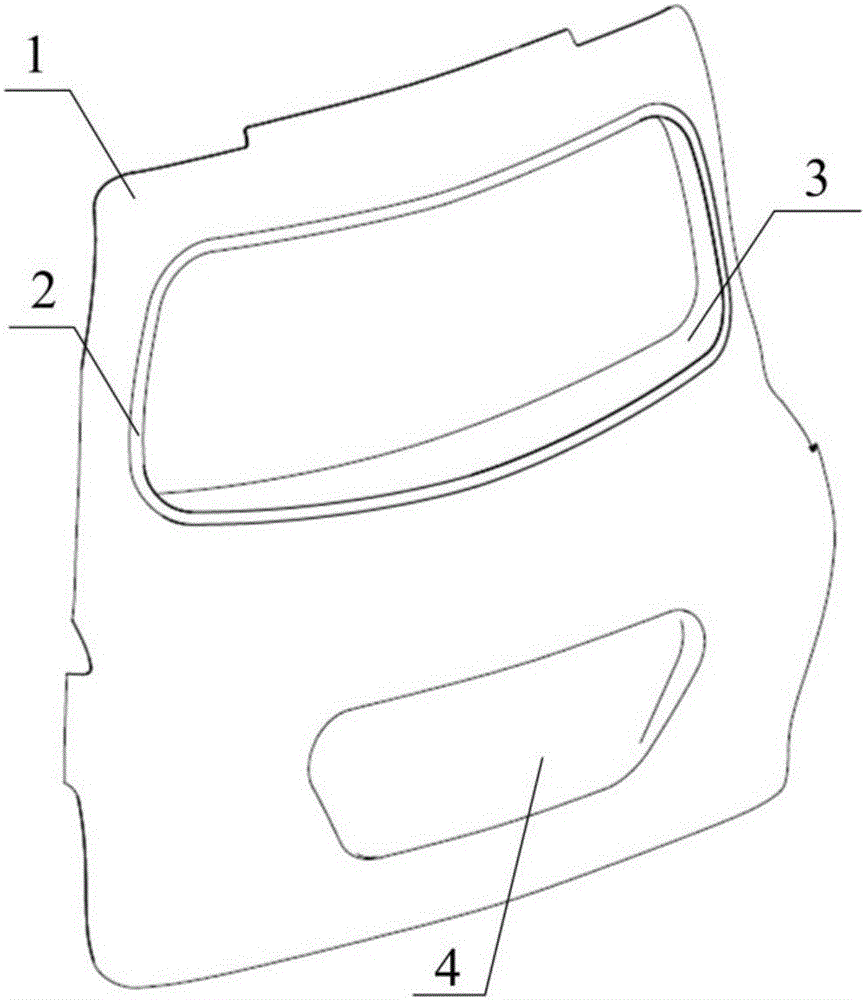

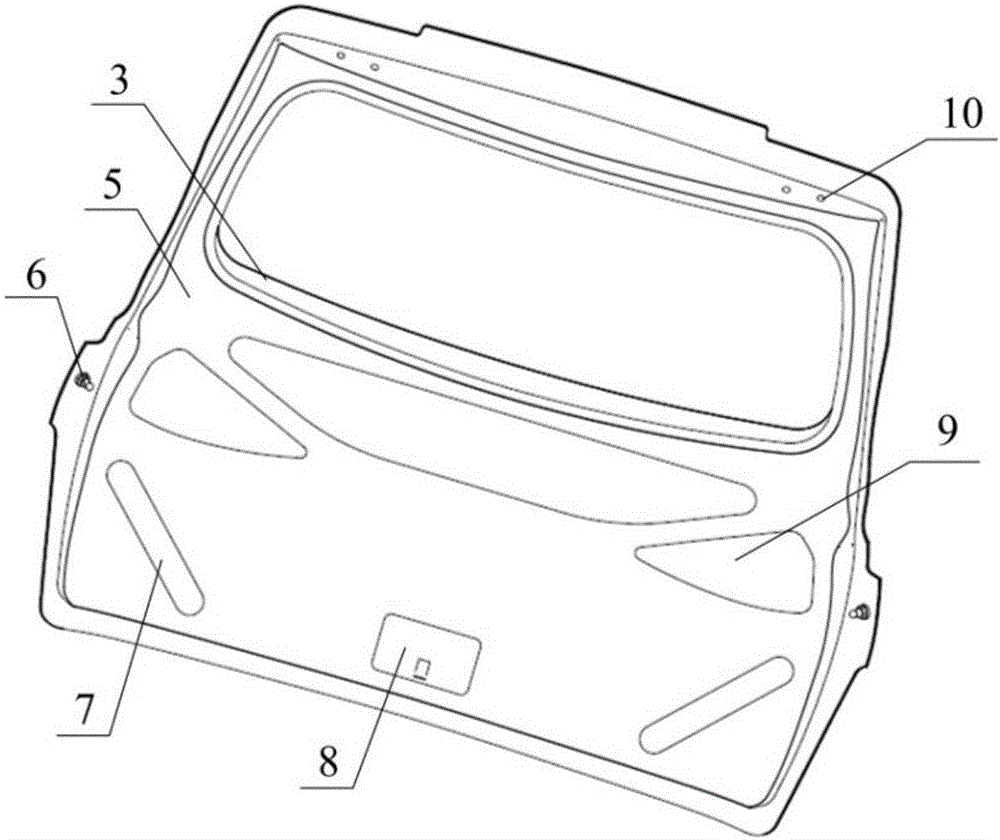

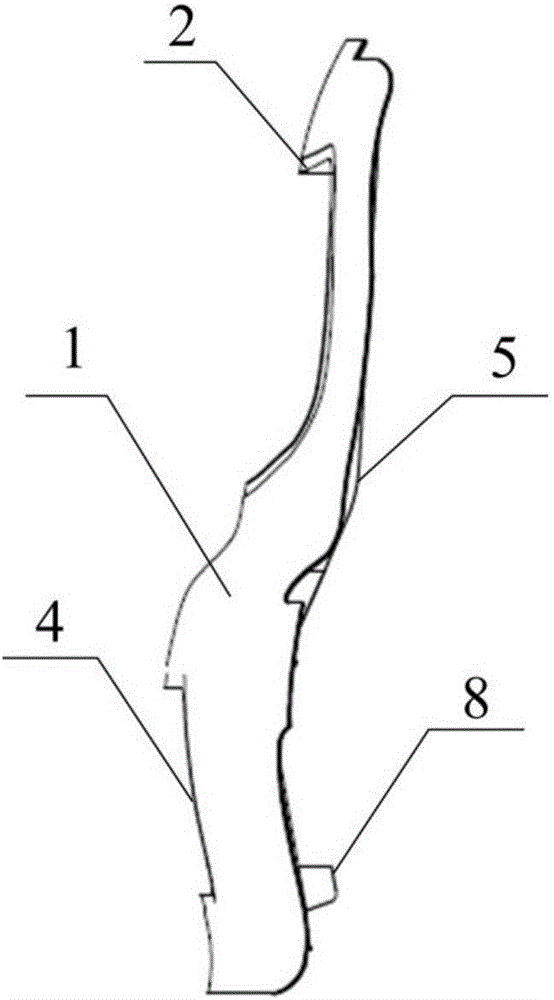

Automobile tail door made of composite material

InactiveCN105711106AReduce in quantityReduce the number of moldsDomestic articlesDoorsCarbon fibersResin matrix

An automobile tailgate made of resin-based composite material, which includes an automobile tailgate outer panel, a tailgate window edge, a vehicle window inner frame, a tailgate license plate frame, an automobile tailgate inner panel, a tailgate hydraulic cylinder mounting support, and an inner panel reinforcement Ribs, tailgate latches, inner panel weight-reducing holes, tailgate hinge mounting holes. It is made of large-tow carbon fiber or glass fiber material, combined with low-viscosity resin, using resin transfer molding (RTM) process. The weight of the tailgate is further reduced through the topologically optimized weight-reduction holes on the inner panel of the tailgate. The strength and rigidity of the inner panel are enhanced through the reinforcing rib at the bottom of the inner panel of the tailgate. Use the tailgate hydraulic cylinder mounting brackets, tailgate latch and tailgate hinge mounting holes to mount composite automotive tailgates to the vehicle body. Due to the use of fiber-reinforced composite materials with high specific strength and specific stiffness, combined with the modular and lightweight design concept, the weight of the vehicle is greatly reduced, the number of parts of the tailgate is reduced, and energy saving and emission reduction are realized.

Owner:BEIHANG UNIV

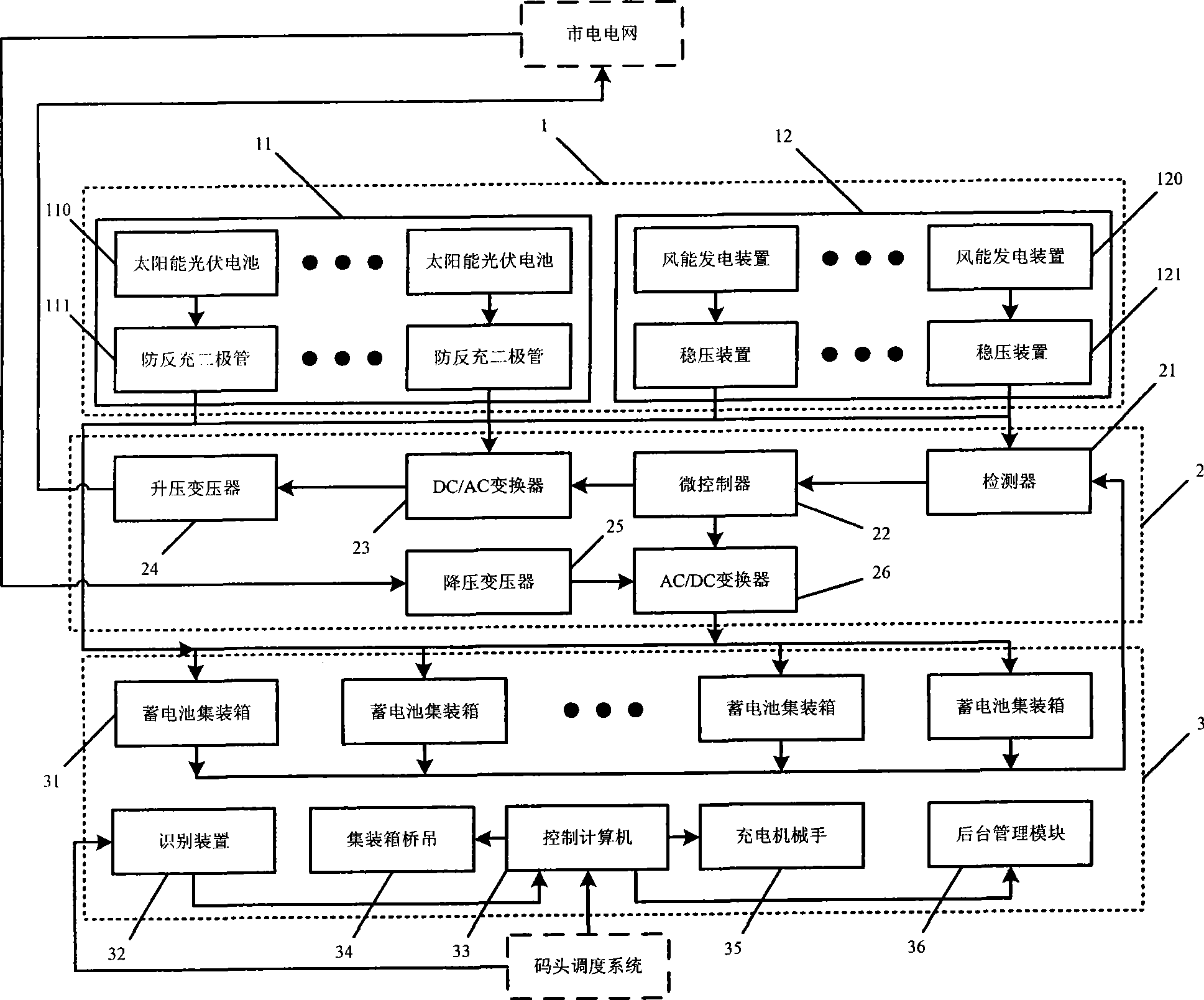

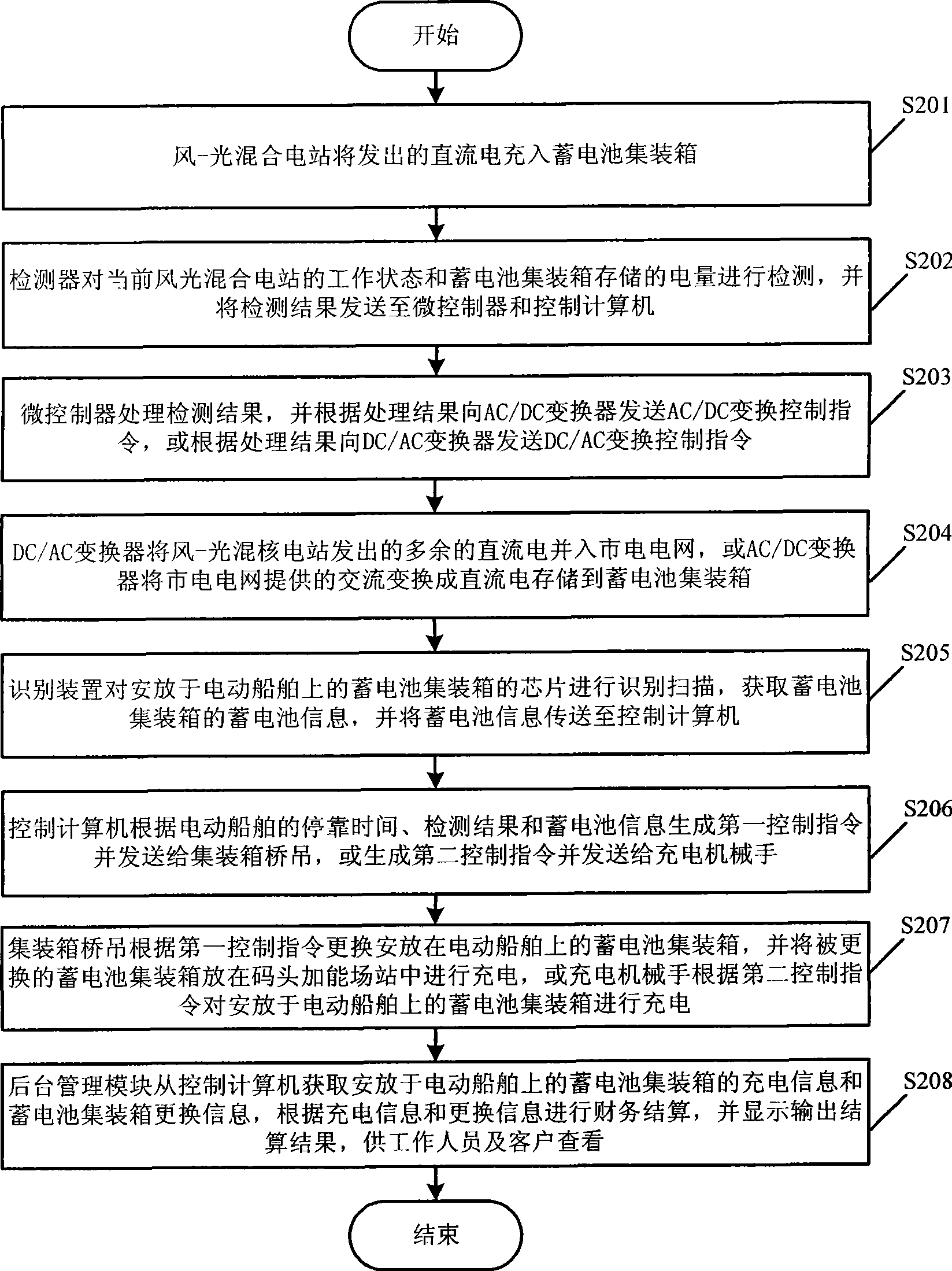

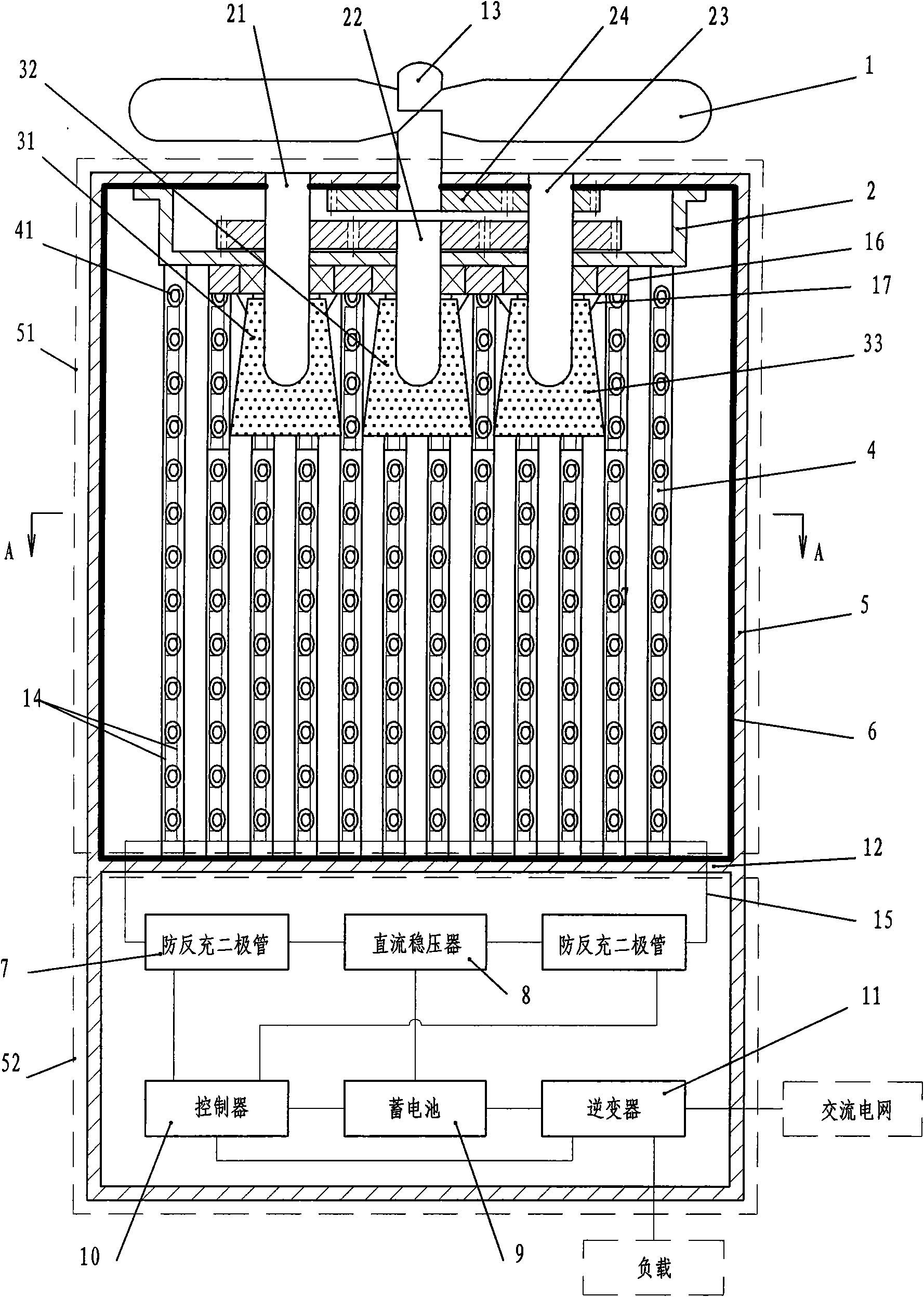

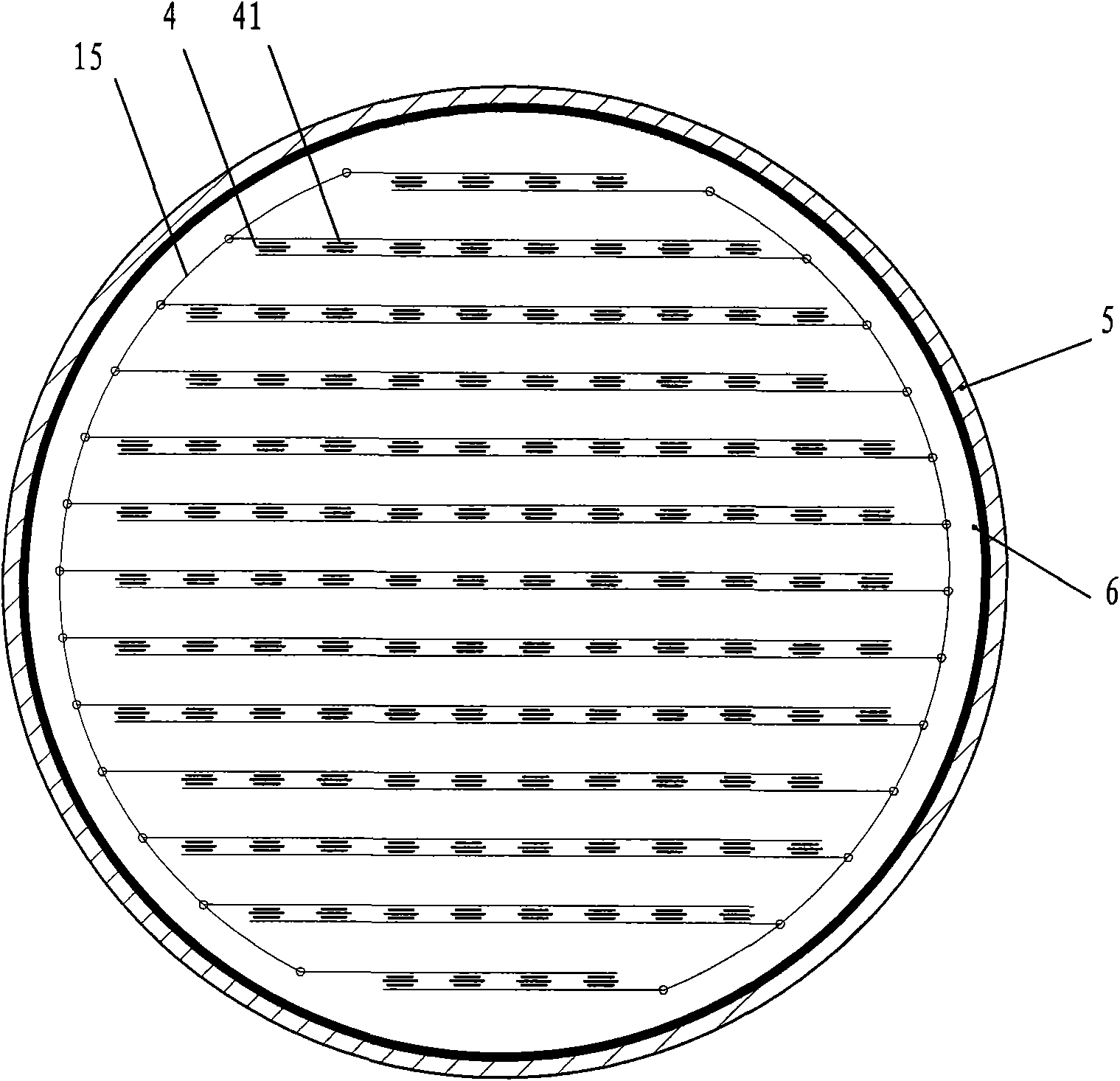

System and method for power supply to electric ship by natural energy

InactiveCN101478268AReduce noise pollutionReduce dependenceAc-dc conversion without reversalPV power plantsEngineeringAlternating current

The invention provides a system and a method for supplying natural energy as power to an electric ship. The embodiment of the invention transforms solar energy and wind energy into electrical energy through a wind-light mixed power station, and is used by a wharf energy-adding station and used for charging a storage battery container hold of the electric ship; at the same time, the system is also connected with a commercial-power electric-fence; when the weather is fine in the daytime and the wind is heavy, the generated energy of the wind-light mixed power station is sufficient, the excess electric quantity can be merged into the commercial-power electric-fence for the use of other loads; when the weather is wet at night or in the daytime and the wind is light, the alternating current of the commercial-power electric-fence can be transformed into direct current so as to be used by the wharf energy-adding station and also used for charging the storage battery container hold of the electric ship; the wind-light mixed power station and the commercial-power electric-fence complement each other, so the natural energy supplied as power to the electric ship stably and reliably, the dependence on non-renewable energy resources such as petroleum, coals, etc. as well as the ship noise pollution can be reduced, energy crisis is relieved, and the atmosphere and the marine environment are protected.

Owner:吴速

Differentially Expressed Nucleic Acids in the Blood-Brain Barrier Under Inflammatory Conditions

ActiveUS20080213179A1Improve permeabilityHigh activityOrganic active ingredientsPeptide/protein ingredientsMammalBiological activation

The present invention relates to nucleic acids and polypeptides encoded thereby, whose expression is modulated in brain microvascular endothelial cells undergoing early dynamic inflammation-induced changes in blood-brain barrier functionality. Such polypeptides are referred to as lipopolysaccharide-sensitive (LPSS) polypeptides herein. These nucleic acids and polypeptides may be useful in methods for controlling blood-brain barrier properties in mammals in need of such biological effects. This includes the diagnosis and treatment of disturbances in the blood-brain / retina barrier, brain (including the eye) disorders, as well as peripheral vascular disorders. Additionally, the invention relates to the use of anti-LPSS polypeptide antibodies or ligands as diagnostic probes, as blood-brain barrier targeting agents or as therapeutic agents as well as the use of ligands or modulators of expression, activation or bioactivity of LPSS polypeptides as diagnostic probes, therapeutic agents or drug delivery enhancers.

Owner:2 BBB MEDICINES BV

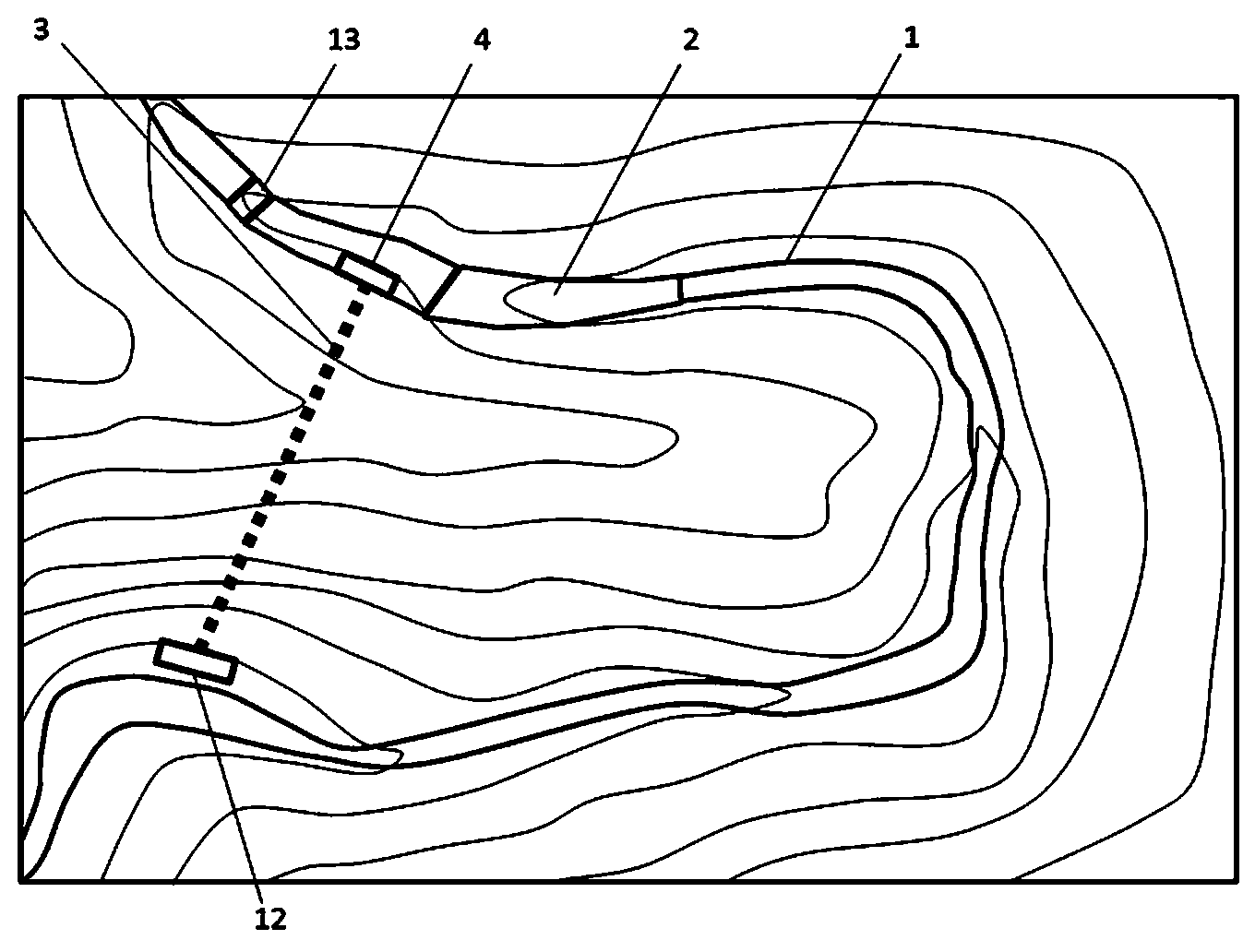

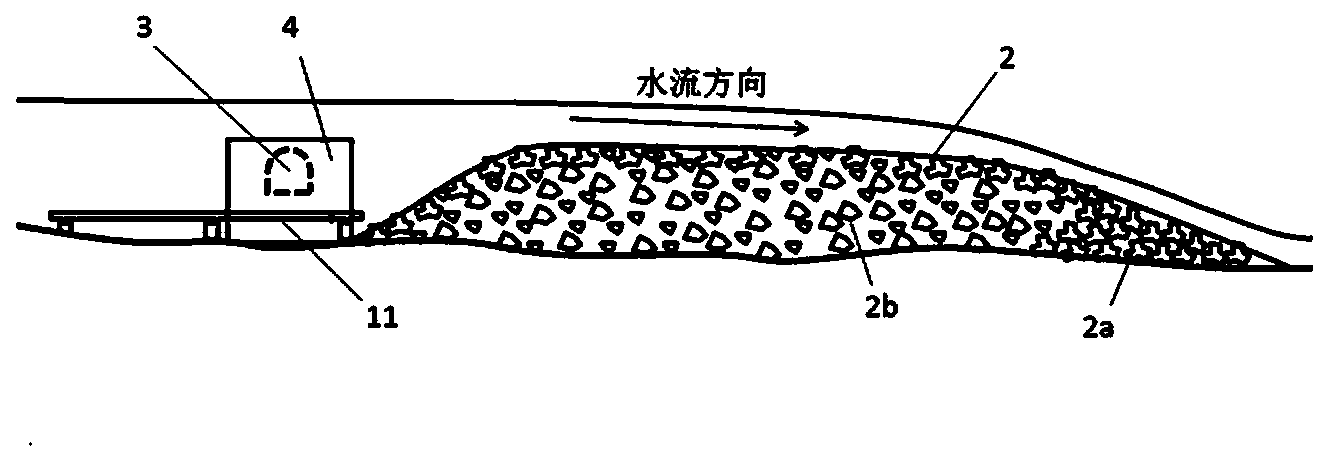

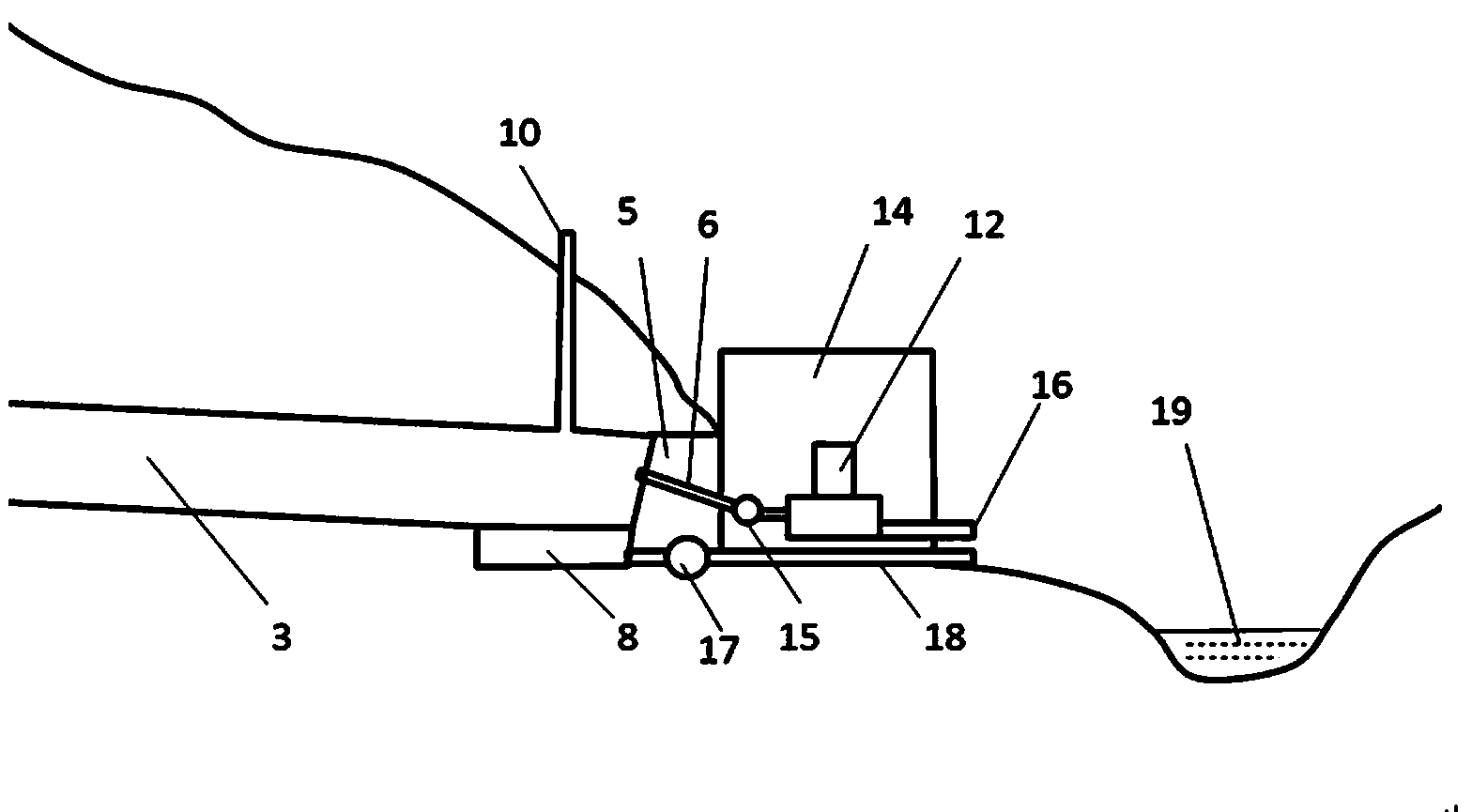

Low overflow dam cave depot type hydropower station

InactiveCN103510493AAvoid cut-offAvoid destructionWater-power plantsHydro energy generationWater turbineWater diversion

The invention relates to a low overflow dam cave depot type hydropower station. An low overflow dam is built at the upstream position of a river with an arc-shaped way; a water diversion tunnel cave depot of which the water diversion amount reaches or exceeds the annual average runoff of the river is built between the upstream position and the downstream position of the arc-shaped way of the river; the water inlet of the cave depot is positioned at the upstream position of the low overflow dam; a submerged front pool of which the top is lower than the body of the low overflow is built, or a channel of which the diameter is greater than that of the opening of the cave depot is built at the front end of the water inlet of the cave depot for water diversion from the cave depot, and a gate is built on the channel; a blocking wall body and a longitudinal water diversion pipeline are arranged at the water outlet tail end of the cave depot; the longitudinal water diversion pipeline is arranged in the blocking wall and used for connecting the cave depot with a water-turbine generator set outside the cave depot; the low overflow dam refers to that the dam body can be partially percolated by river water, part of the river water can overflow the top of the low overflow damp to flow downstreams in the high water period, and part of the river water seeps from the dam body and flows towards a dam body at the downstream position. The low overflow dam cave depot type hydropower station does not need to cut off the river, can be built on a river with a small or even very small head drop, further increases the utilization ratio of hydropower resources, and is low in construction difficulty.

Owner:贵州道轮水电科技开发有限公司

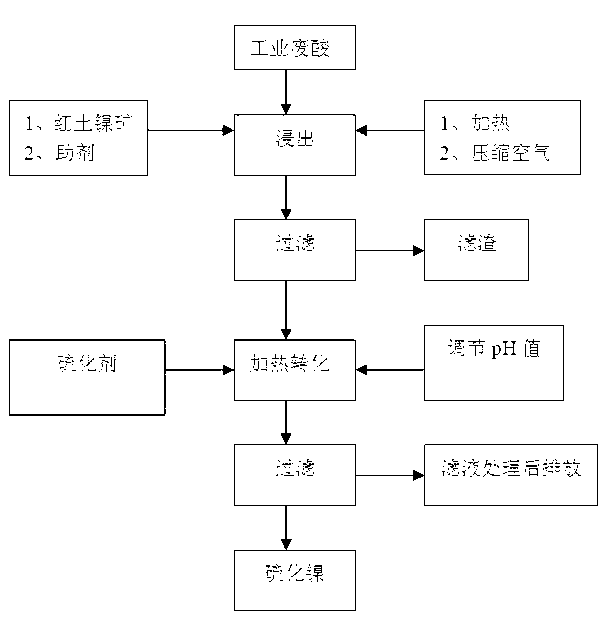

Method for producing nickel sulfide ore concentrate by use of industrial waste acid

ActiveCN102994746ASolve the problem of comprehensive utilizationReduce manufacturing costProcess efficiency improvementEconomic benefitsOxygen

The invention provides a method for producing nickel sulfide ore concentrate by the use of industrial waste acid. The specific technical scheme is as follows: adopting industrial waste acid to soak laterite-nickel ore, heating, stirring and extracting, and after a period of time, adding assistant, blowing in compression air or oxygen, reacting for a period of time, filtering, heating filtrate to a required temperature, and then adding vulcanizing agent, stirring, keeping the temperature for a period of time, and filtering to obtain the nickel sulfide ore concentrate. The method is an effective way for comprehensively utilizing the industrial waste acid to change waste into wealth, thereby reducing the cost for producing nickel sulfide ore by hydrometallurgical process, lowering air pollution and having a good economic benefit.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

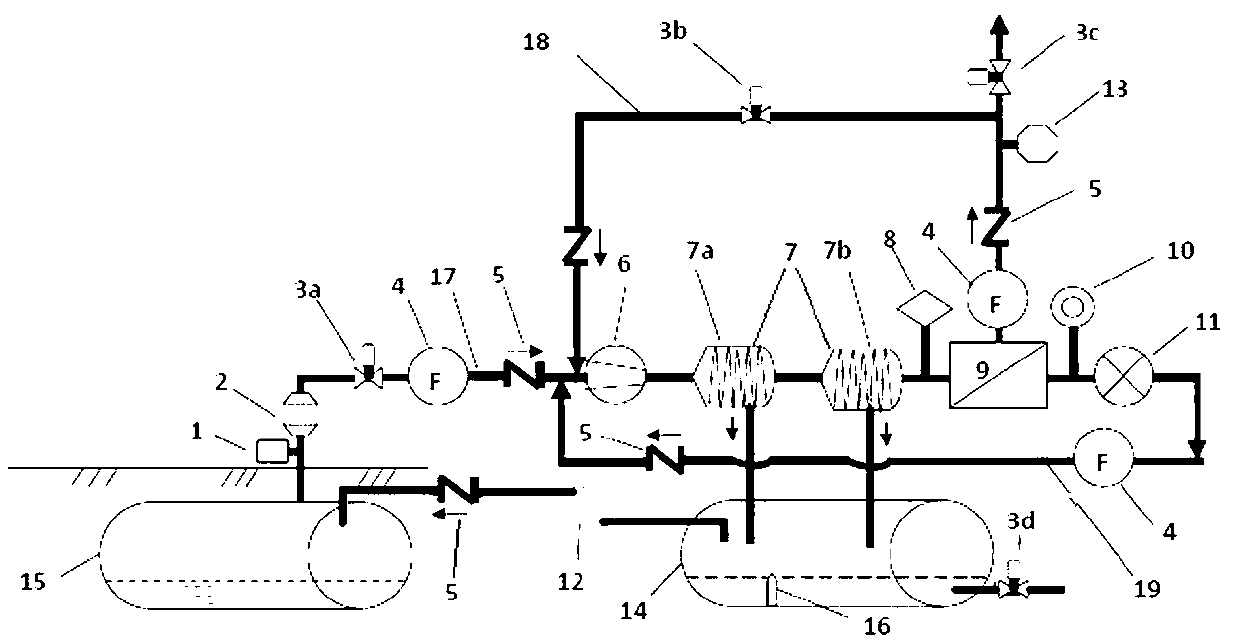

Membrane and condensation combined oil-gas recovery system

ActiveCN103272401ASolve emission pollutionProtect the atmosphereDispersed particle separationVapor condensationExhaust gasPressure sensor

The invention discloses a membrane and condensation combined oil-gas recovery system, comprising an oil storage tank (15) provided with a gas-liquid separator (2); a micro pressure sensor (1) is installed on a pipe between the oil storage tank (15) and the gas-liquid separator (2) , the gas-liquid separator (2) is connected with a liquid ring compressor (6) through an oil gas inlet pipe (17) provided with an air inlet solenoid (3a); the liquid ring compressor (6) is connected with a condenser group (7) through a pipe; the condenser group (7) is connected with a membrane assembly (9) through the pipe; the membrane assembly (9) is connected with the liquid ring compressor (6) through an oil gas exhaust gas return pipe (18) with a non-methane hydrocarbon detector (13); the oil gas exhaust gas return pipe (18) is provided with an exhaust pipe; and the permeation side of the membrane assembly (9) is connected with the liquid ring compressor (6) through an enrichment oil gas return pipe (19) with a vacuum pump (11). The membrane and condensation combined oil-gas recovery system has the characteristics of environment protection, high automatic degree, economy and efficiency.

Owner:NANJING UNIV OF TECH

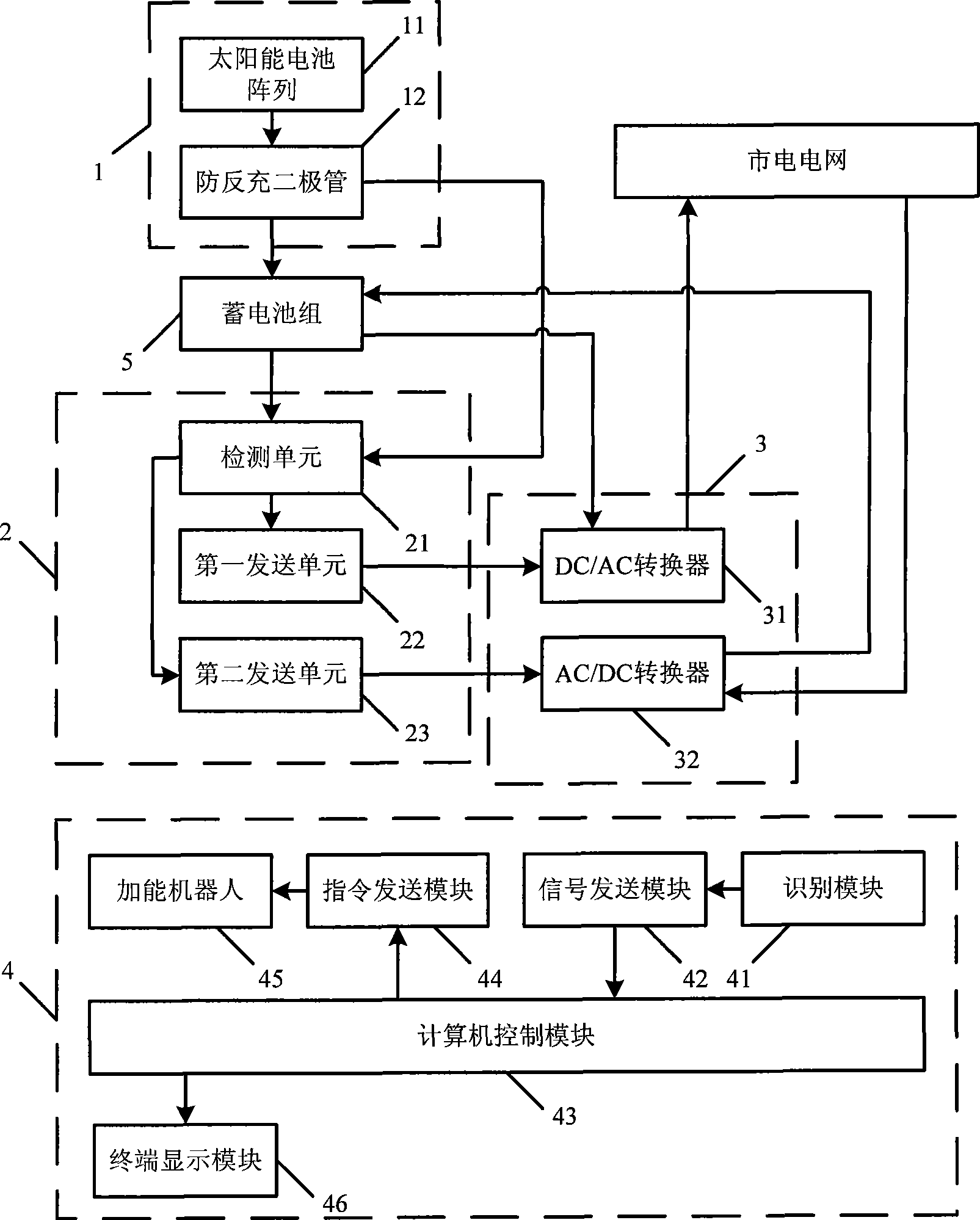

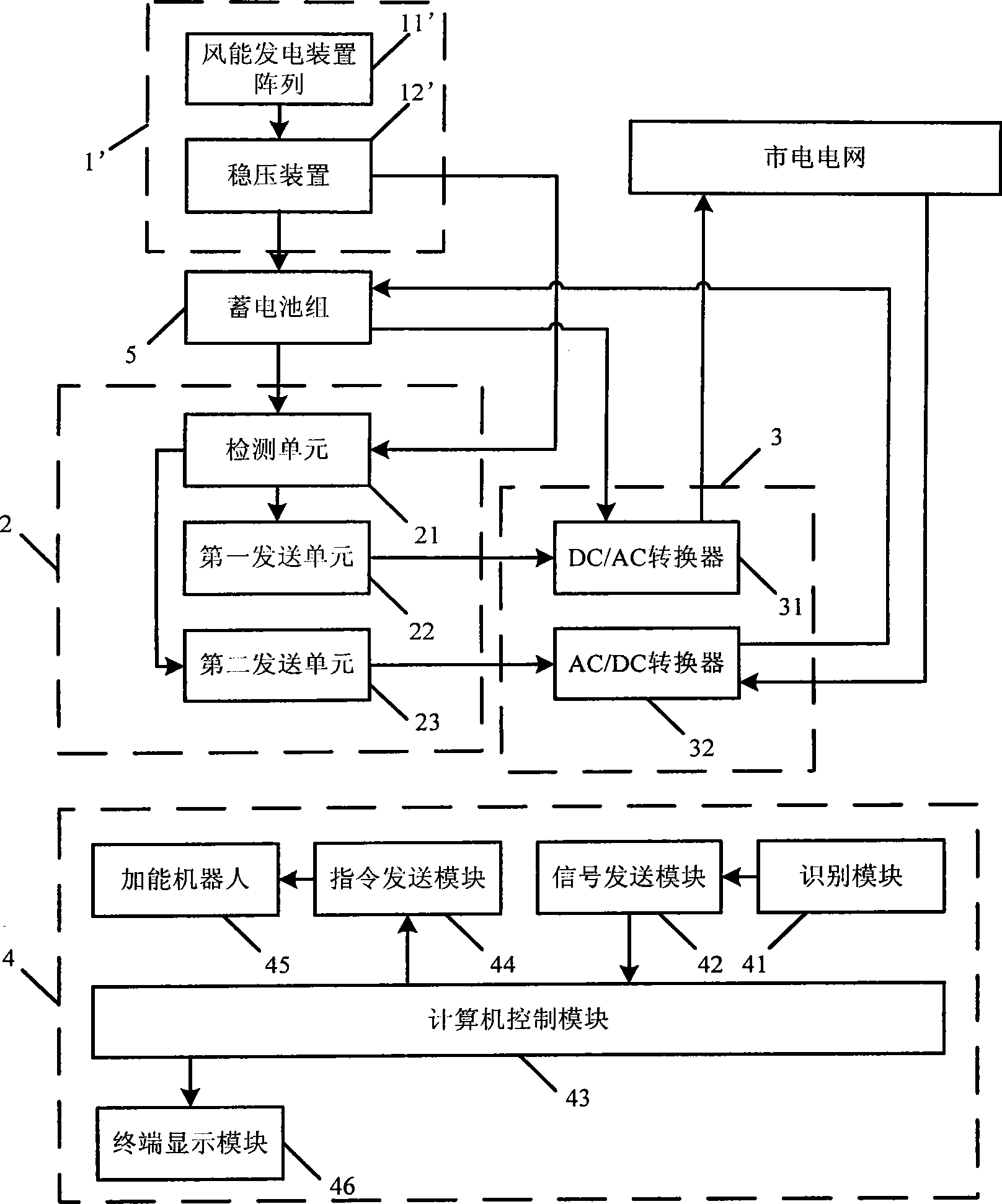

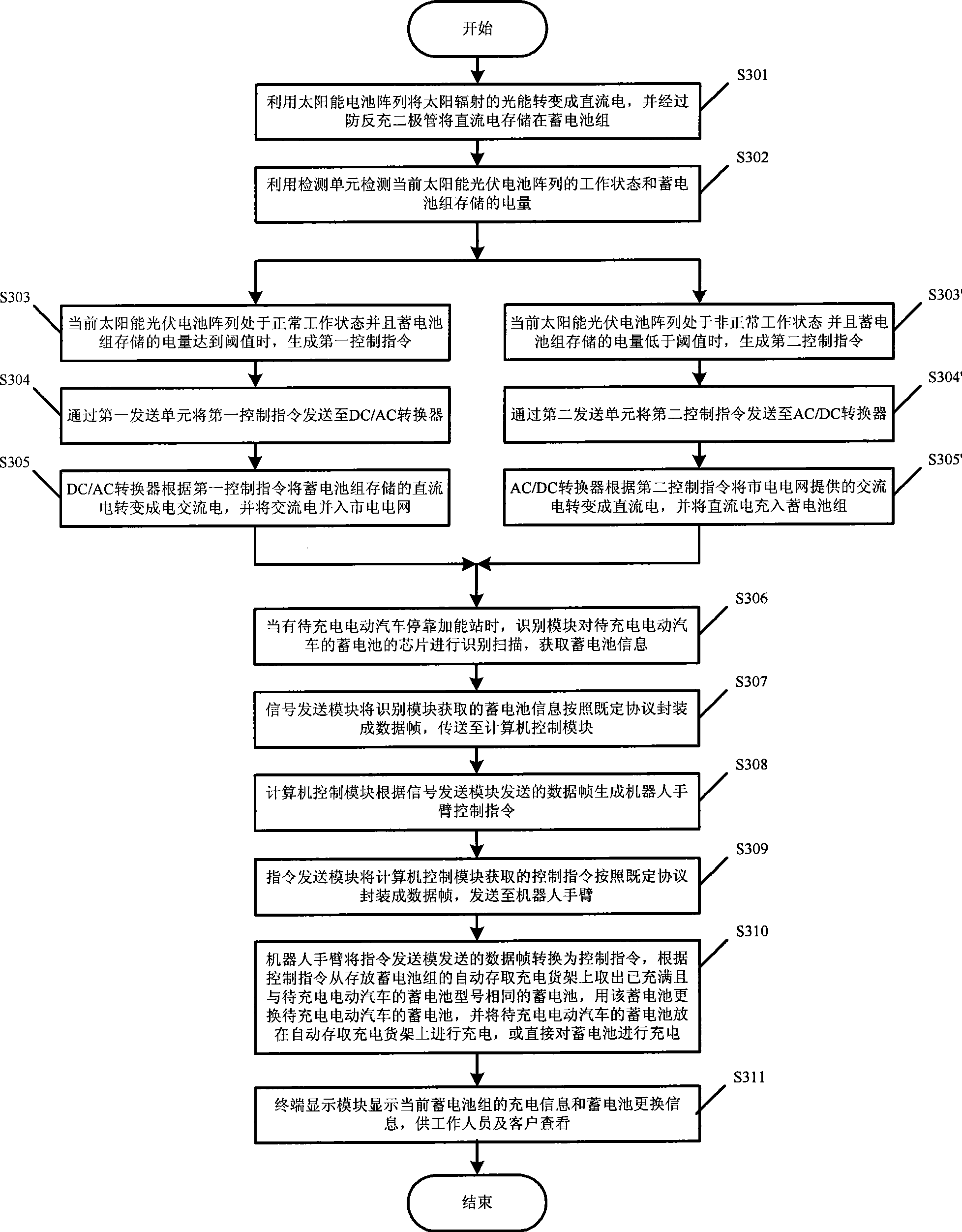

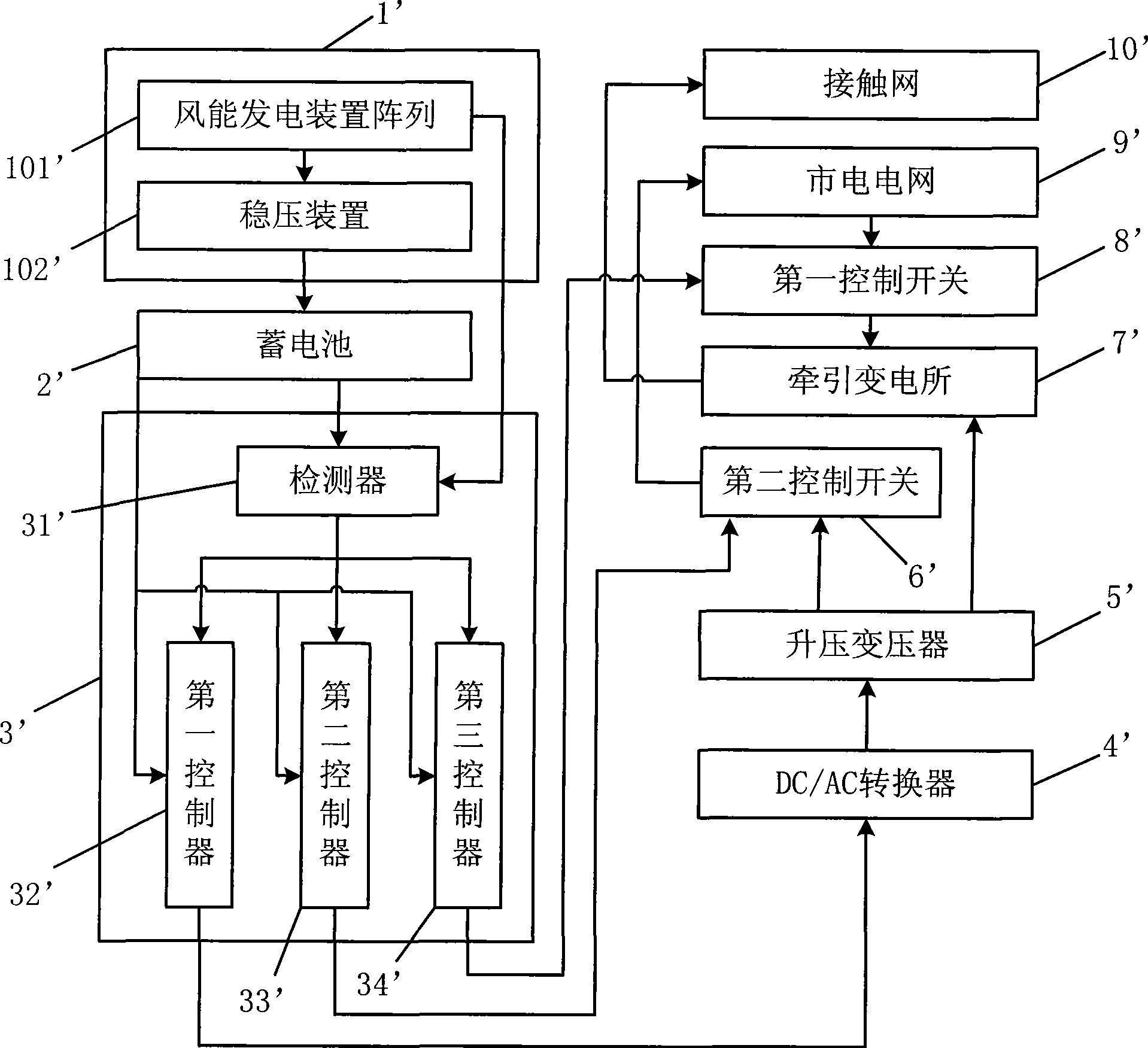

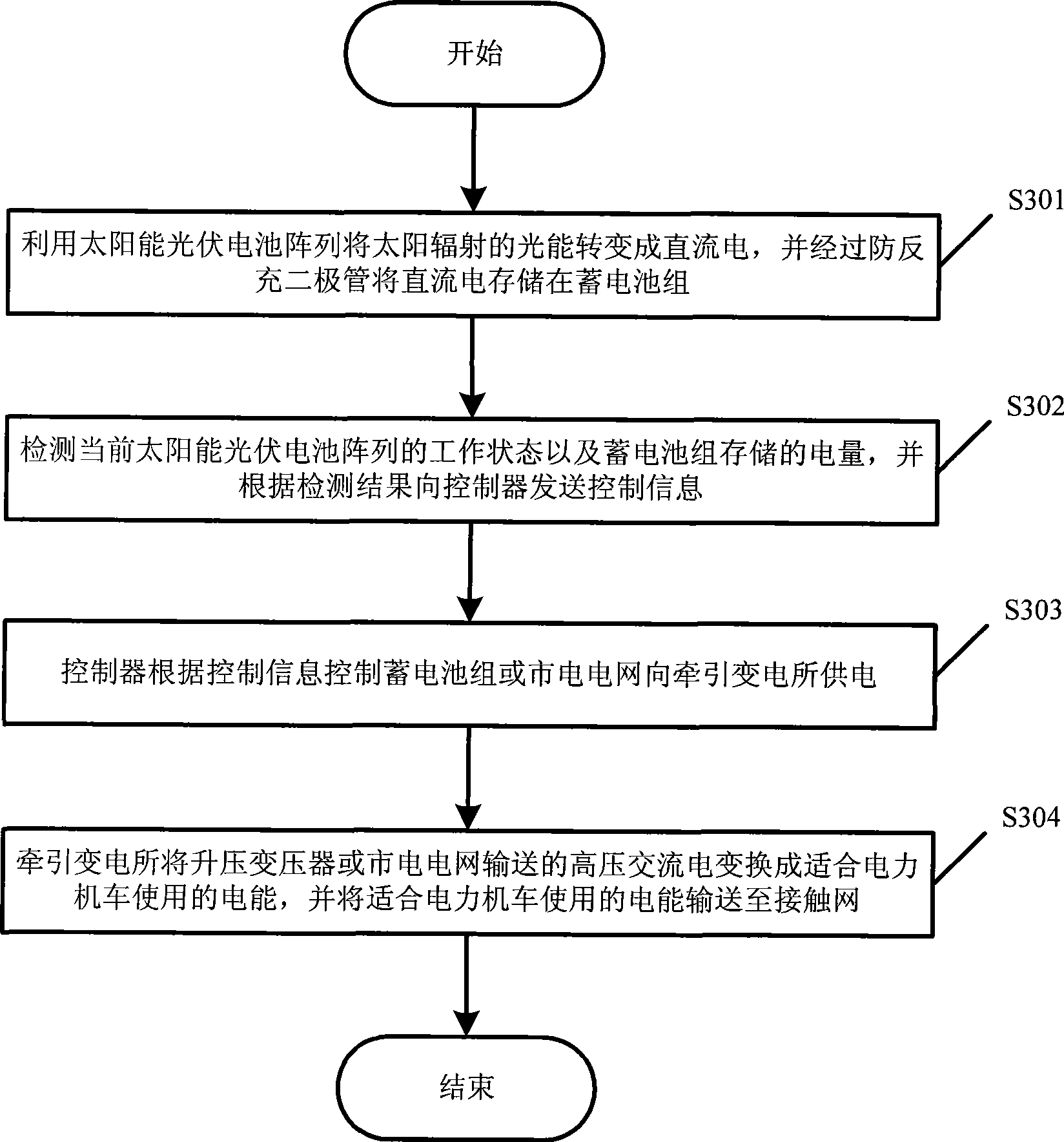

System and method for supplying energy for electric automobile by using natural energy

InactiveCN101412376AEfficient use ofReduce dependenceVehicular energy storageElectric propulsionAlternating currentPetroleum

The invention provides a system and a method for using natural energy to supply power to electric automobile. The method converts solar energy into electric energy for storage through a solar photovoltaic power generation array or through a wind-powdered generator array to supply power filling station with power for charging storage batteries of electric automobiles. Meanwhile, the system is connected with a commercial power grid, so that redundant power generated by the solar photovoltaic power generation array in sunny days or the wind-powered generator array in heavy wind days can be injected into the commercial power grid for use by other loads; and at night or in cloudy and rainy day, or in small wind days, alternating current of the commercial gird is converted into direct current to be stored for the power filling stations to charge the storage batteries of the electric automobiles. The commercial power and power generated by the solar photovoltaic power generation array or the wind-powered generator array are used complementarily. Therefore, the system and the method can use natural energy stably and reliably to supply power to the electric automobiles, reduce the dependence of the electric automobiles on petroleum, coal and other non-renewable energy resource, relieve energy crisis and protect the atmospheric environment.

Owner:吴速

Equipment for collecting and processing acidity mist

ActiveCN101130191AReduce total HCL (acid)Promote absorptionDispersed particle separationDirt cleaningWastewaterPollution

The invention discloses an acid mist collecting disposing device, which comprises the following parts: acid mist collecting mechanism, gas-liquid separated acid mist recycling mechanism, acid mist predisposing mechanism, acid mist disposing mechanism, fan, vent chimney and corresponding connecting duct line, wherein the duct line collecting mechanism, potcher and pickling bath are used to collect the acid mist generated from potcher and pickling bath; the gas-liquid separated acid liquid recycling mechanism connects acid mist collecting mechanism to separate and recycle acid liquid; the acid mist predisposing mechanism is set between the acid mist predisposed mechanism to predispose the acid mist in the acid mist disposing mechanism; the acid mist disposing mechanism washes and adsorbs the acid mist; the fan is connected between the acid mist disposing mechanism and smoke chimney generated by acid mist disposing mechanism to drain the waste gas out of drainage chimney. The invention can be applied in the waste disposing system in the steel surface disposing domain, which saves water and reduces the pollution of waste gas and waste water to improve economic and environmental benefit.

Owner:BAOSHAN IRON & STEEL CO LTD

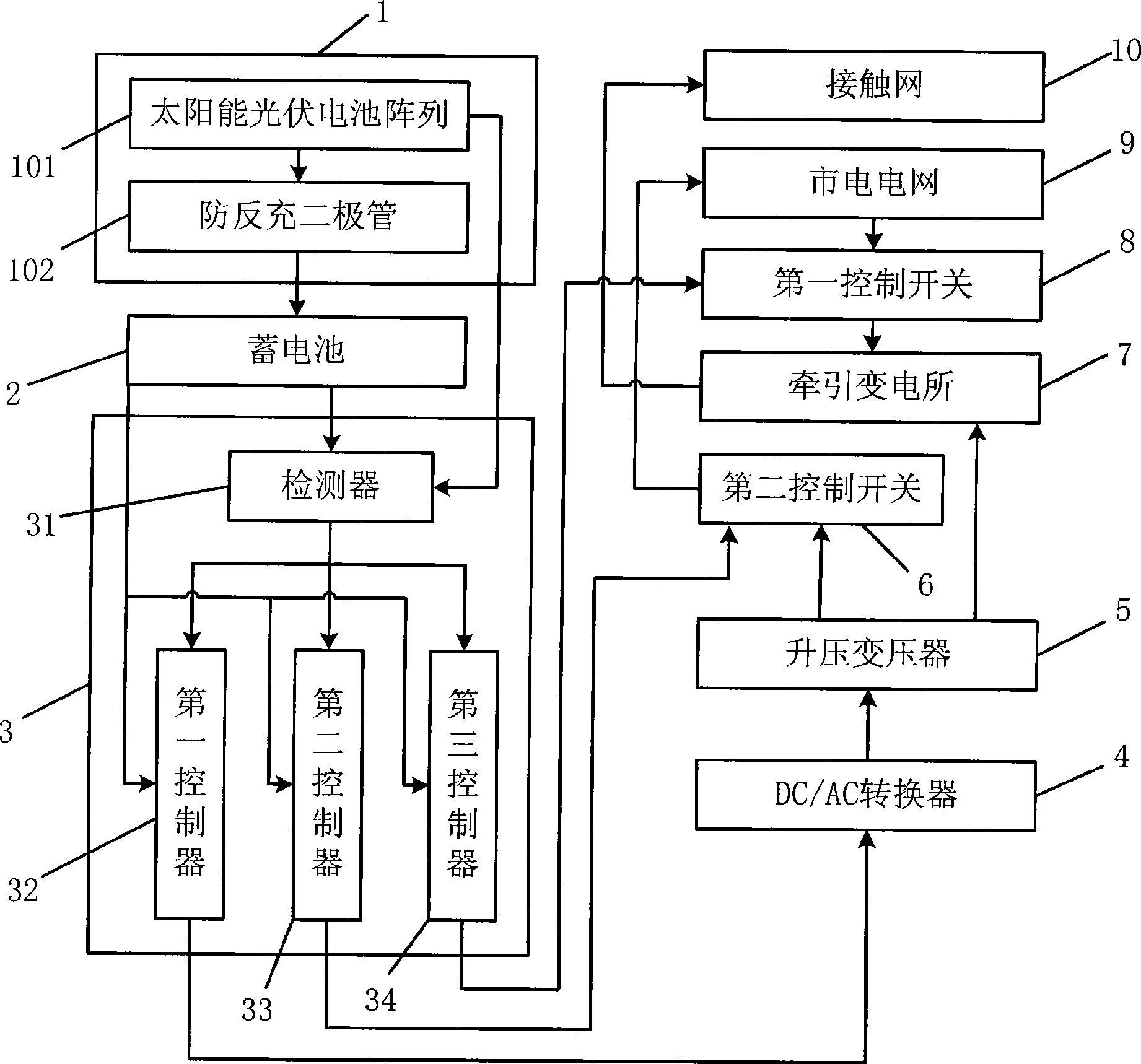

System and method for supplying power to electric locomotive with nature energy

InactiveCN101428565AReduce dependenceEfficient use ofElectric locomotivesRailway transportDaylightAlternating current

The invention provides a system for supplying energy to an electric locomotive by utilizing natural energy and the method thereof. Solar energy is converted to be electric energy for accumulation through a solar photovoltaic array, or wind energy is converted to be electric energy for accumulation through a wind power generation device array in the invention, so as to be used for charging a storage battery of the electric locomotive in an energy filling station, and meanwhile, the system is also connected with a commercial power network. When the electric quantity generated by the solar photovoltaic array is sufficient in a sunny daylight, or electric quantity generated by wind power generation device array is sufficient because of larger wind, the redundant electric quantity can be incorporated into the commercial power network for other loads; in an overcast weather in a daylight or a night, or when the wind is smaller, the alternate current from the commercial power network can be converted into direct current for accumulation, so as to be used for charging the storage battery of the electric locomotive in the energy filling station; and the storage battery and the electric locomotive can be complemented one another. Therefore, the reliable and stable energy supply for the electric locomotive by utilizing the natural energy can be realized, the dependence on the non-renewable energy resources, such as petroleum, coal and the like, can be reduced, the energy crisis is relieved, and the atmospheric environment is protected.

Owner:吴速

Series equipments for catching pest and manufacturing method thereof

InactiveCN101258845AReduce volumeGuaranteed to surviveInsect catchers and killersJet aeroplanePesticide residue

The invention relates to a pest capturing device, in particular to a portable pest capturing device which is combined with a main working cabin and a pest-storing net cabin, etc., which are made from materials such as PVC and arranged with matching negative pressure suction. The device is used for capturing flies, mosquitoes, deerflies and cabbage caterpillars. The device can replace toxic chemical spraying agent such as dichlorvos and dimethoate for killing pests and is applicable to families in urban or suburban areas, guesthouses, restaurants, hotels, hostels, eateries, offices, airplanes, trains, vehicles, ships, dormitories, farms, urban and suburban refuse dumps, environmental hygiene organizations and farmlands all over the world for protecting vegetables, fruits and foodstuff from being contaminated by pesticide residues; the device can effectively capture the pests that harm human beings by spreading cholera, typhoid and destroy farm plants with a speed of capturing 80 to 300 pests per minute, and then distributes the living pests without the chemical contamination of the pesticides to livestock farms for breeding chickens, ducks and fishes as high protein feedstuff so as to realize the aim of stopping general environment pollution, turning harm to benefit and protecting the health of human beings.

Owner:张小勇

System for driving piezoelectric material to generate electricity by using wind energy

InactiveCN101594073AIncrease profitSave energyBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesElectricityHigh energy

The invention provides a system for driving a piezoelectric material to generate electricity by using wind energy, which comprises a wind-powered rotating device and a box body, wherein a transmission device, an alarm, spring pieces of which a plurality of surfaces are provided with piezoelectric patches, a DC regulator, an anti-charge diode, a storage battery, a controller and an inverter are arranged in the box body. The system drives the alarm to generate the voice with a certain sound intensity by using reproducible, clean and pollution-free wind energy, the piezoelectric patches with high energy density and high power generation efficiency are driven through the sound to carry out vibration power generation, thus the system improves the energy efficiency, saves energy and protects atmospheric environment.

Owner:吴速

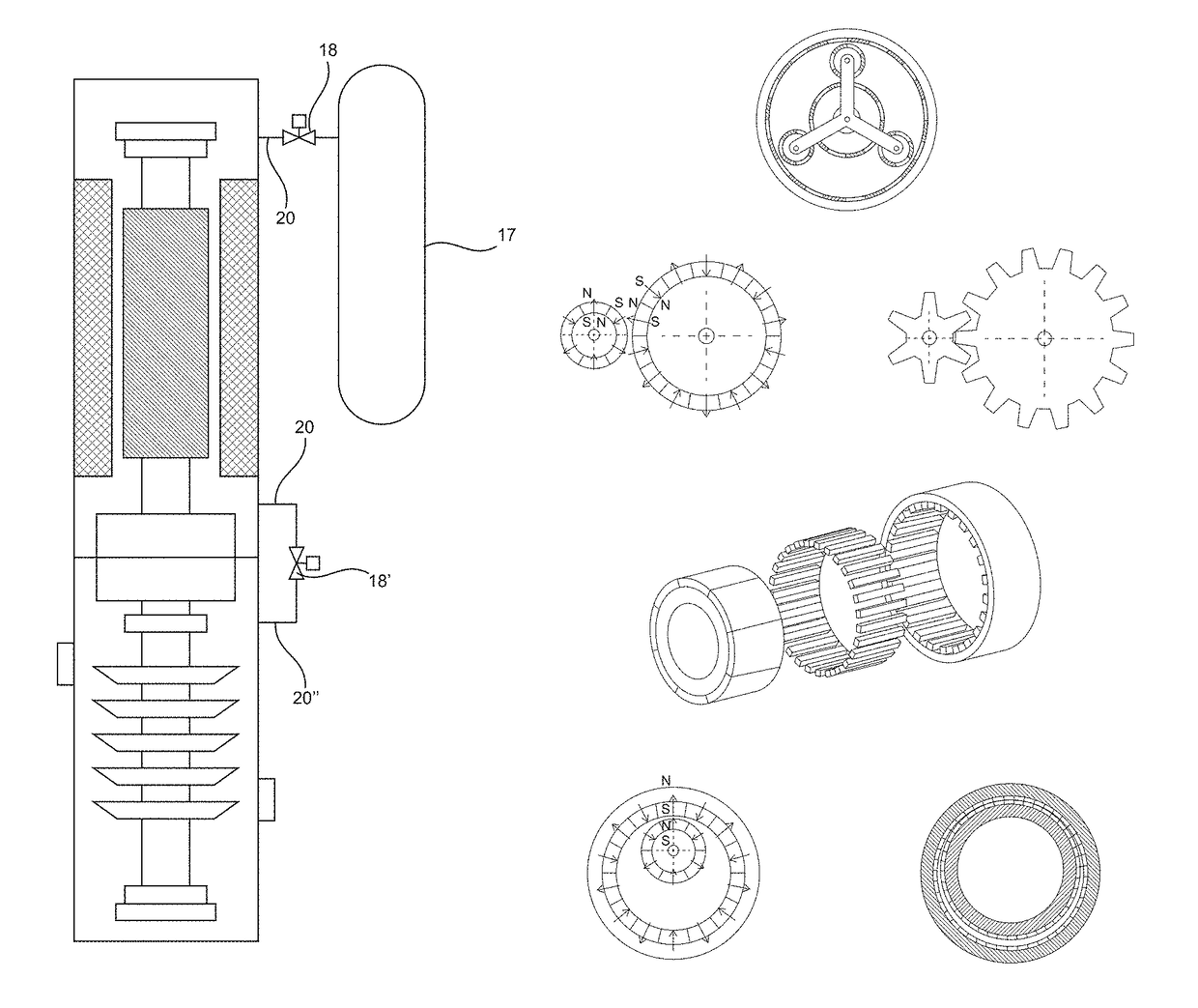

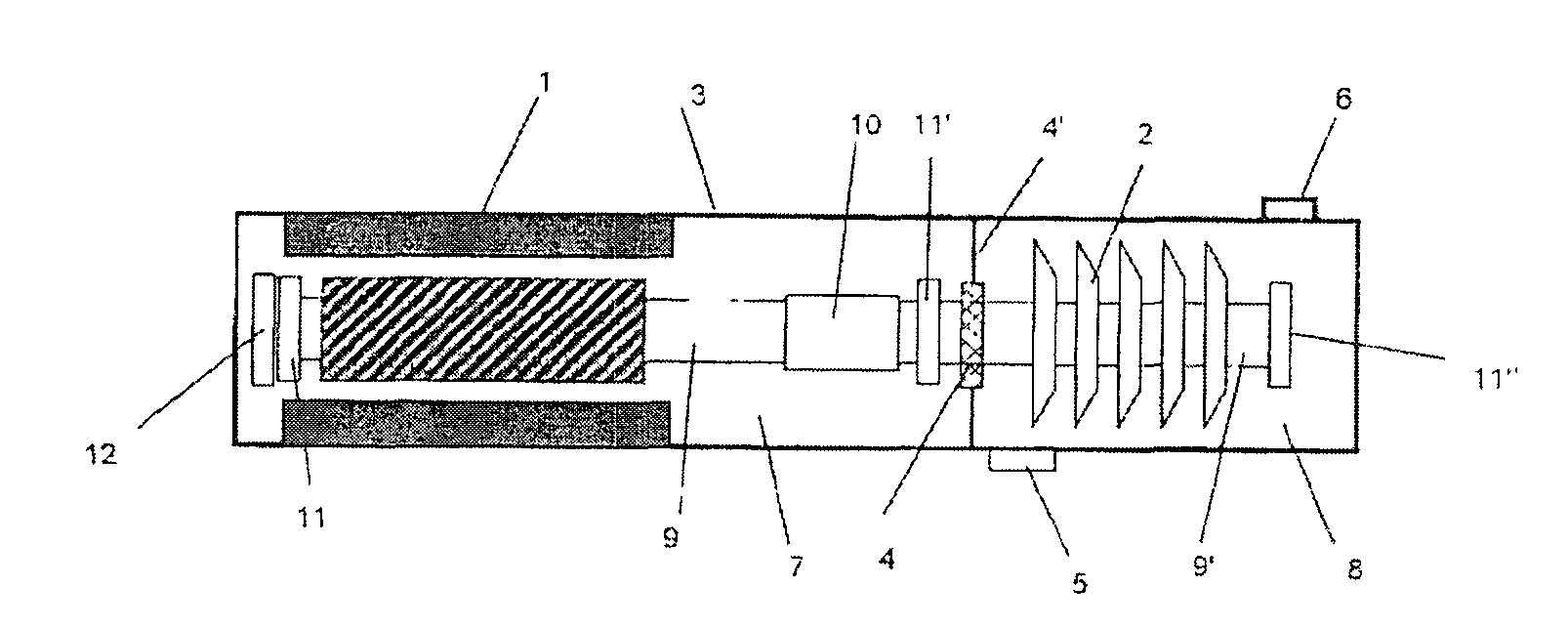

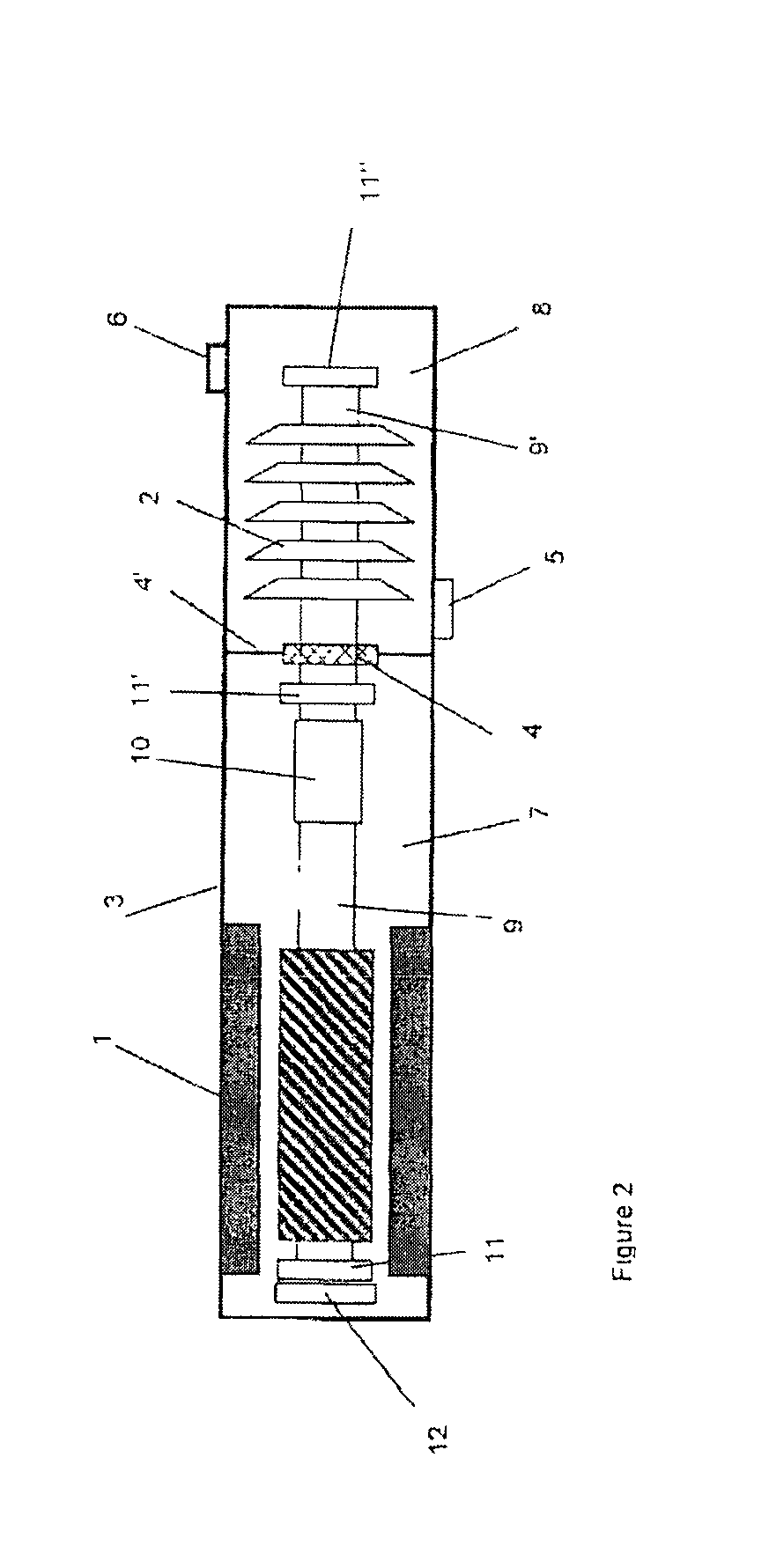

Subsea pressure booster

ActiveUS9841026B2Increase speedSmooth power transmissionPump componentsPump installationsMagnetic gearElectric motor

Subsea turbomachine for boosting the pressure of petroleum fluid flow from subsea petroleum productions wells or systems, comprising an electric motor and a compressor or pump driven by the electric motor, a fluid inlet and a fluid outlet, distinctive that the turbomachine comprises a pressure housing common for the electric motor or stator, and compressor, pump or rotor; a magnetic gear inside the common pressure housing for operative connection between the motor or stator and compressor, pump or rotor; and a partition inside the common pressure housing, arranged so as to separate a motor or stator compartment from a compressor, pump or rotor compartment.

Owner:AKER SOLUTIONS AS

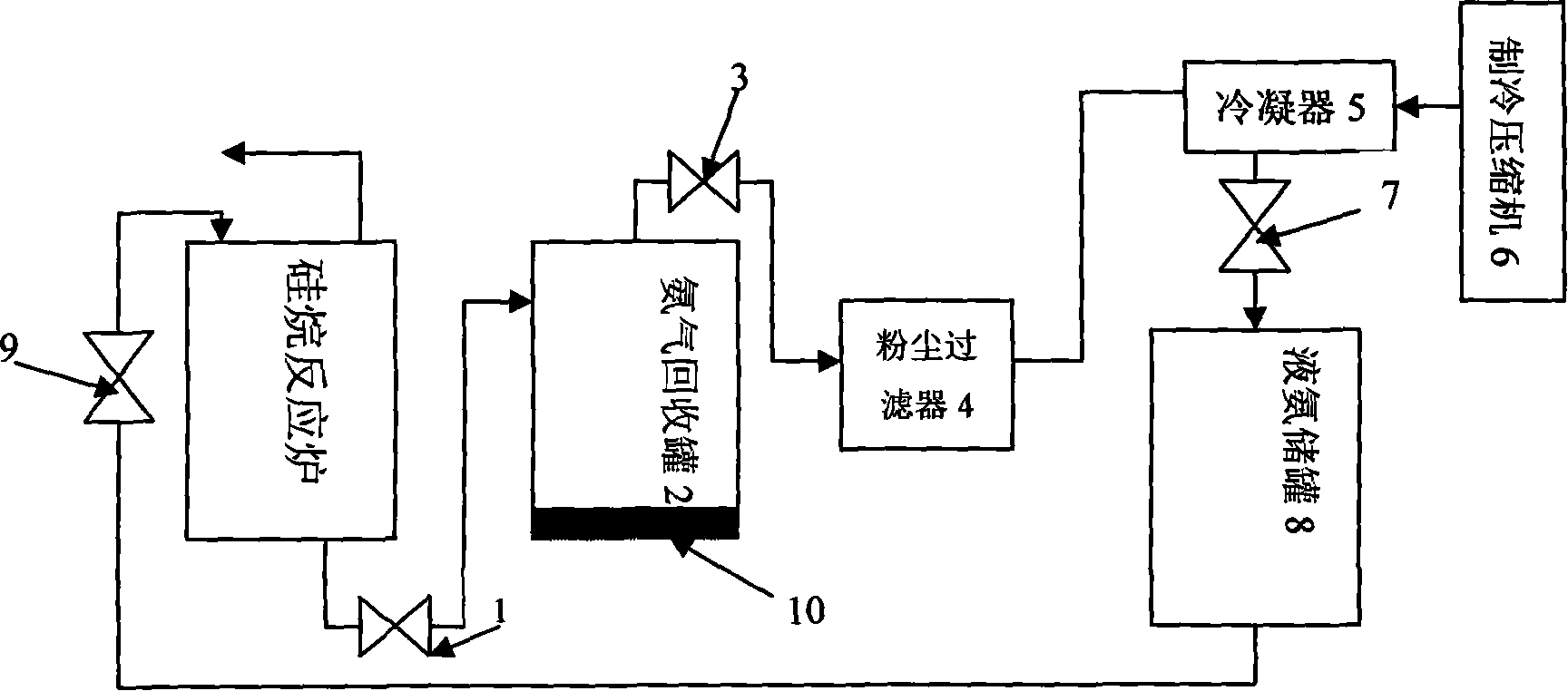

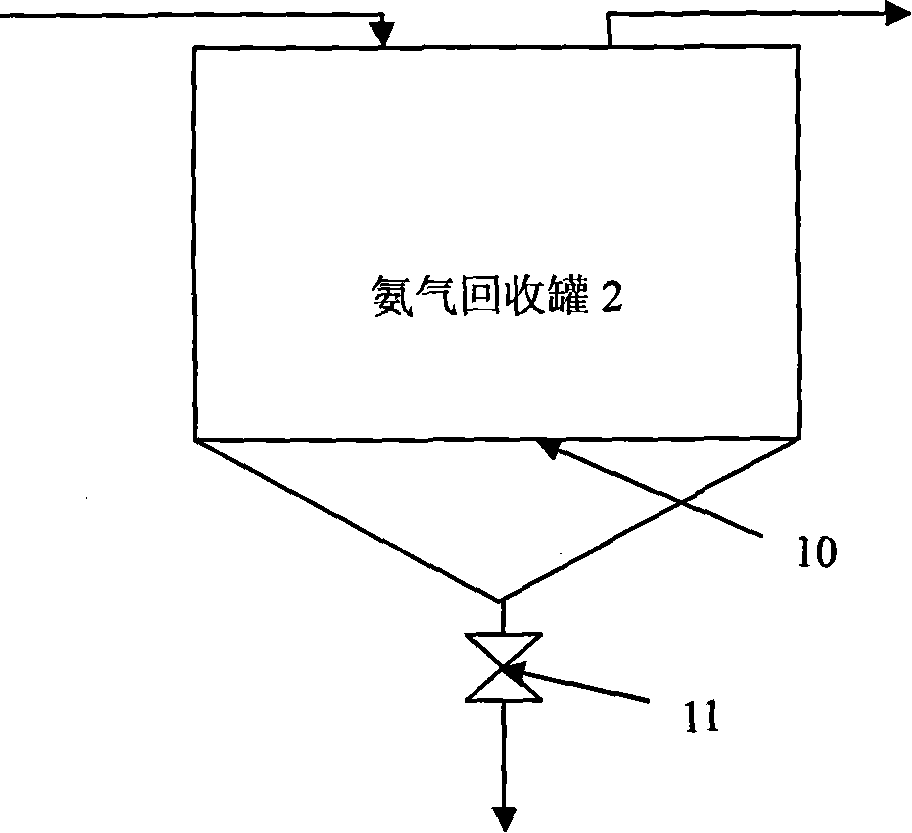

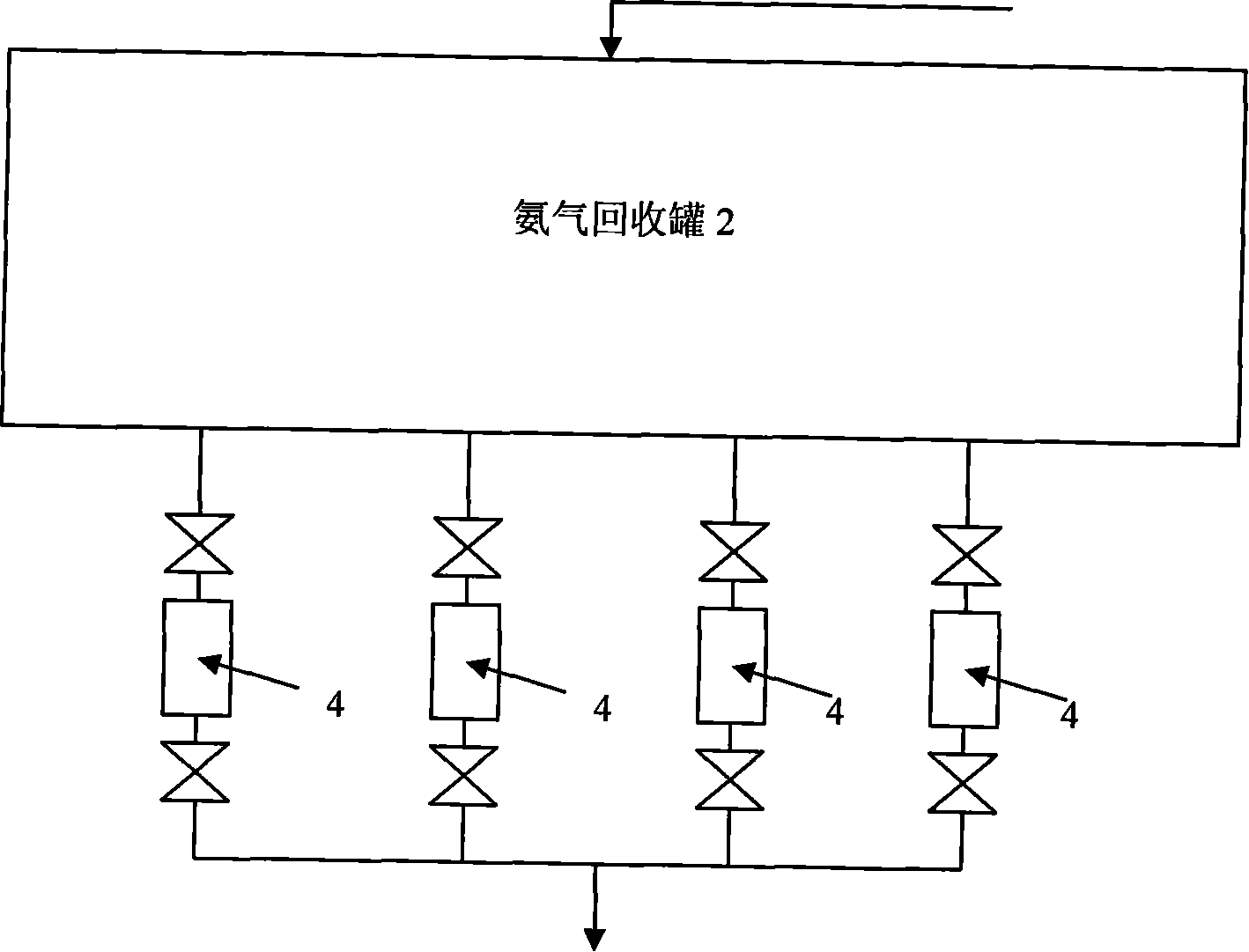

Recovery cyclic utilization method and apparatus for recovering discharged alkaline air in process of production of silicone hydride with magnesium silicide method

InactiveCN101249313AReduce dosageProtect the atmosphereDispersed particle filtrationVapor condensationChemistryLiquid ammonia

The invention discloses a recovery and recycling method of the discharged ammonia during the silane production process by the process of magnesium silicide method, the process includes the steps that: the generated residues during the silane production process by the process of magnesium silicide method are discharged into an ammonia recovery tank; when the temperature and the pressure of the residues in the ammonia recovery tank increase, the ammonia escapes from the residues to reach a pressure at 0.1MPa, the ammonia enters a condenser after the dust filtration and the silane removal; the condenser is refrigerated to liquefy the ammonia; and then the liquid ammonia is arranged in a liquid ammonia storage tank for recycling. At the same time, the invention also discloses a device to implement the method of the invention. The method of the invention adopts the low-temperature technology for recovering the gaseous ammonia to be converted into the liquid ammonia to carry out the recycling, which can not only save the consumption of the liquid ammonia, but can also protect the atmospheric environment. The device of the invention has simple structure, low manufacturing cost and convenient installation.

Owner:NANJING SPECIAL GAS FACTORY

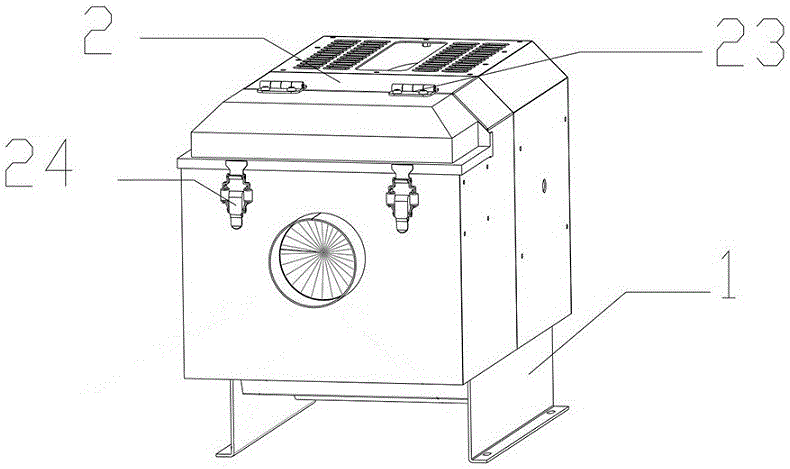

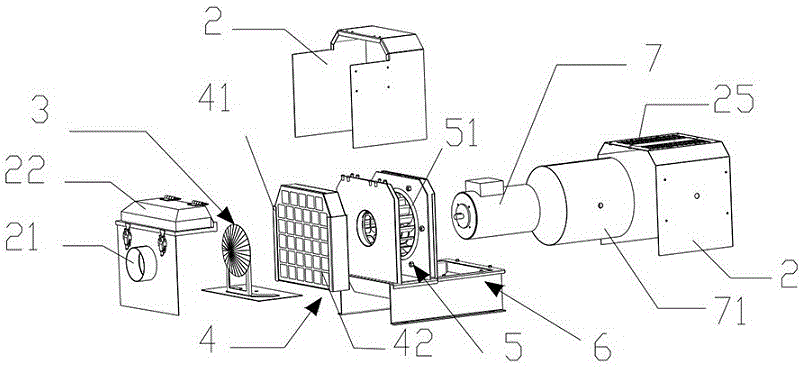

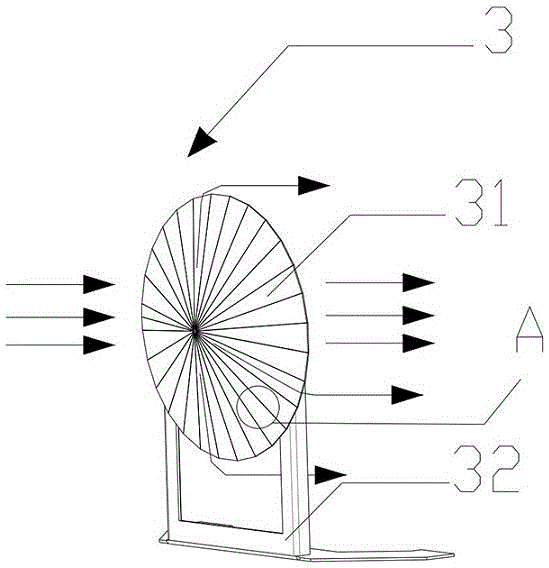

Oil mist recycling machine

PendingCN106823595AAvoid damagePurify the working environmentCombination devicesDispersed particle filtrationWorking environmentOil mist

The invention relates to the technical field of oil mist filtering equipment and in particular relates to an oil mist recycling machine. The oil mist recycling machine comprises a rack, wherein the rack is provided with a shell body; an inlet is formed in one side of the shell body; the shell body is internally provided with a first-grade filtering device for carrying out first-grade filtering on oil mist, a second-grade filtering device for carrying out second-grade filtering on the oil mist, a third-grade filtering device for carrying out third-grade filtering on the oil mist and a driving mechanism; the driving mechanism is in driving connection with the third-grade filtering device; a collection device is arranged at the lower end of the third-grade filtering device. According to the oil mist recycling machine provided by the invention, the effects of filtering the oil mist for a plurality of times, carrying out odor removal treatment and cooling, liquefying and recycling the oil mist can be realized through the first-grade filtering device, the second-grade filtering device and the third-grade filtering device. An external working environment is effectively purified and corrosion damages, caused by the oil mist, to the equipment are reduced; damages, caused by the oil mist, to human bodies are reduced; the atmospheric environment is protected.

Owner:TANGXIA BRANCH VISION TOOL & MOLD

Sleeve type shaft kiln with power generation device

ActiveCN104119007AQuality improvementIncrease temperatureCarbon compoundsEnergy inputCombustion chamberFlue gas

A sleeve type shaft kiln with a power generation device comprises a waste heat boiler, a carbon dioxide processing unit, the power generation device, a material supply device, an air supply system and a fuel supply system. A cooling zone of a kiln body is provided with a lower suction beam. The kiln body is internally provided with a combustion chamber, the combustion chamber has a cylinder structure, and the combustion chamber and the kiln body form an annular space. The upper part of the combustion chamber has a frustums structure, the top of the frustums is provided with a burn nozzle, and the side face of the frustums is provided with a secondary air inlet. The lower part of the combustion chamber is communicated with the waste heat boiler through a flue gas channel. A decomposition gas outlet is connected with the carbon dioxide processing unit through a draught fan, an outlet of the lower suction beam is connected to the secondary air inlet or an inlet of the draught fan, and an inlet of a cooling fan is connected with the carbon dioxide processing unit or is communicated with the atmosphere. A material in the kiln body is heated by heat conduction brick masonry in a flame isolation mode, so that the quality of the calcined product is improved, high-purity carbon dioxide is recycled, waste heat is used for power generation, thermal energy resources are fully utilized, and the comprehensive economic benefits of a lime kiln are increased.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Pavement and bricks of wall body made from domestic waste and producing method

InactiveCN1539783ASolve pollutionSave land for storageSolid waste managementSingle unit pavingsEcological environmentBrick

A brick for pavement or wall is prepared from life garbage, magnesium oxide, iron oxide, cement, hexahydrated magnesium chloride, magnesium sulfate and sodium chloride through proportionally mixing them with water, hydraulic vibration shaping, compacting, solidifying and curing. Its advantages are high performance and environmental protection.

Owner:王克通

Subsea pressure booster

ActiveUS20140086764A1Protect the atmosphereProtection from damagePump componentsPiston pumpsEngineeringMagnetic gear

Subsea turbomachine for boosting the pressure of petroleum fluid flow from subsea petroleum productions wells or systems, comprising an electric motor and a compressor or pump driven by the electric motor, a fluid inlet and a fluid outlet, distinctive that the turbomachine comprises a pressure housing common for the electric motor or stator, and compressor, pump or rotor; a magnetic gear inside the common pressure housing for operative connection between the motor or stator and compressor, pump or rotor; and a partition inside the common pressure housing, arranged so as to separate a motor or stator compartment from a compressor, pump or rotor compartment.

Owner:AKER SOLUTIONS AS

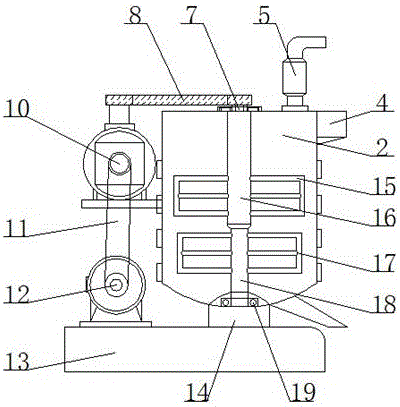

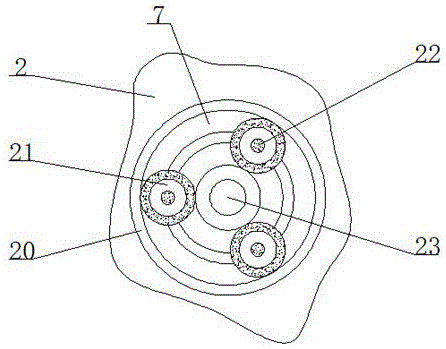

Asphalt mixing device

InactiveCN107519799ARelative movement tightKeep healthyRotary stirring mixersTransportation and packagingEngineeringRelative motion

The invention discloses an asphalt mixing device. The device comprises a mixing barrel, an ion purifier and a motor, wherein a bearing block is arranged in the middle of the lower side of the mixing barrel; a discharging port is formed in the lower side surface, close to the mixing barrel, of the left side of the bearing block; a heating ring is arranged on the outer side surface of the mixing barrel; a base is arranged on the lower side surface of the bearing block; a feeding port is formed above the left side of the mixing barrel; a planetary gear set is arranged at the top of the mixing barrel; a sun gear and a planetary carrier are correspondingly connected with a main mixing shaft and a shaft sleeve, so that the two shafts can gain rotating torque in opposite rotating direction and at different rotating speed; the mixing operation can be carried out at the upper layer and the lower layer at different rotating speed and in different rotating direction in the mixing barrel, relative motion between materials is closer, and as a result, the mixing effect is improved; in addition, the ion purifier is arranged at the top of the mixing barrel and can be used for ionizing and purifying harmful gas dispersed in a mixing process, the body health of workers can be ensured, and the atmosphere environment is protected.

Owner:南京极佳物联网科技有限公司

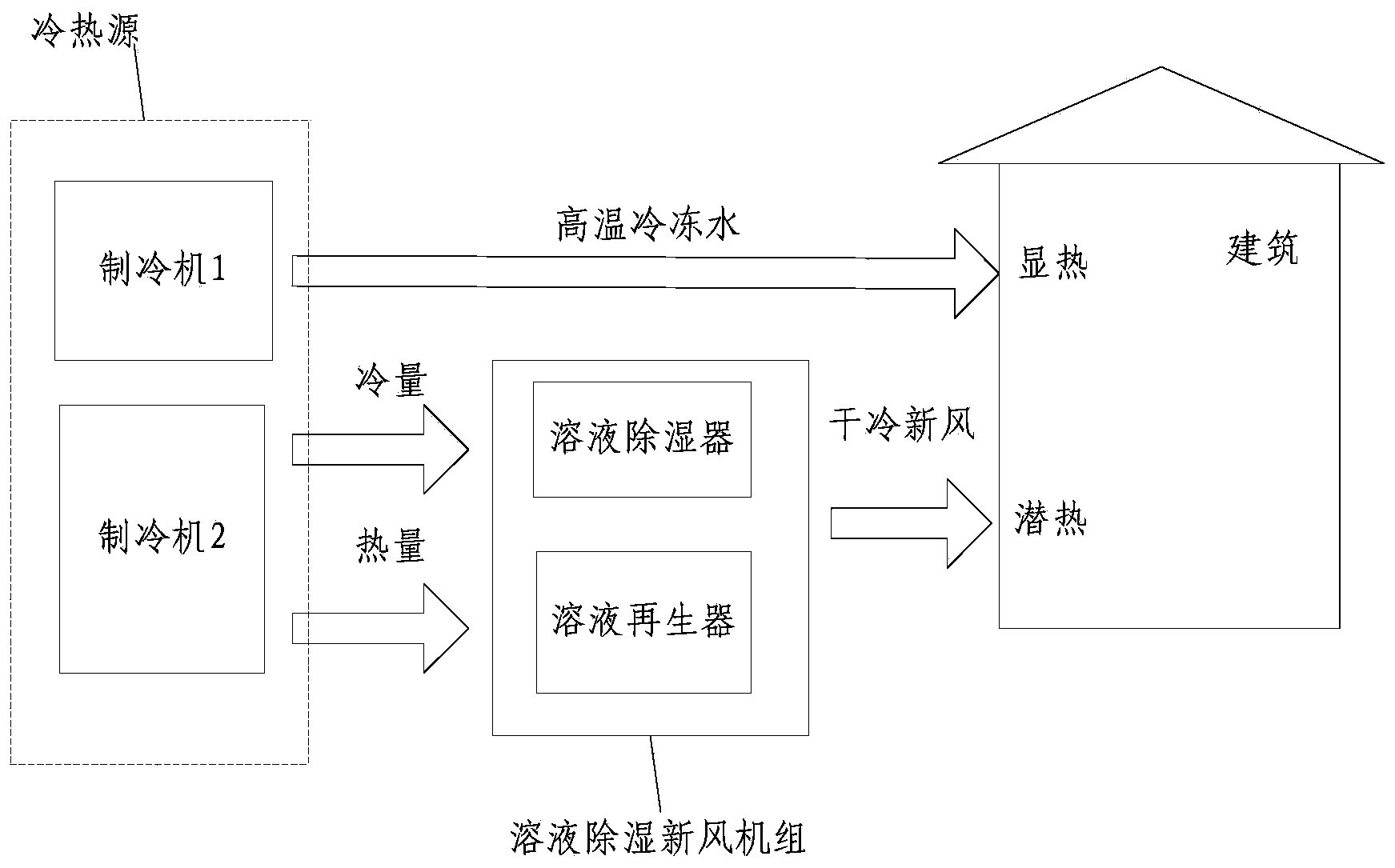

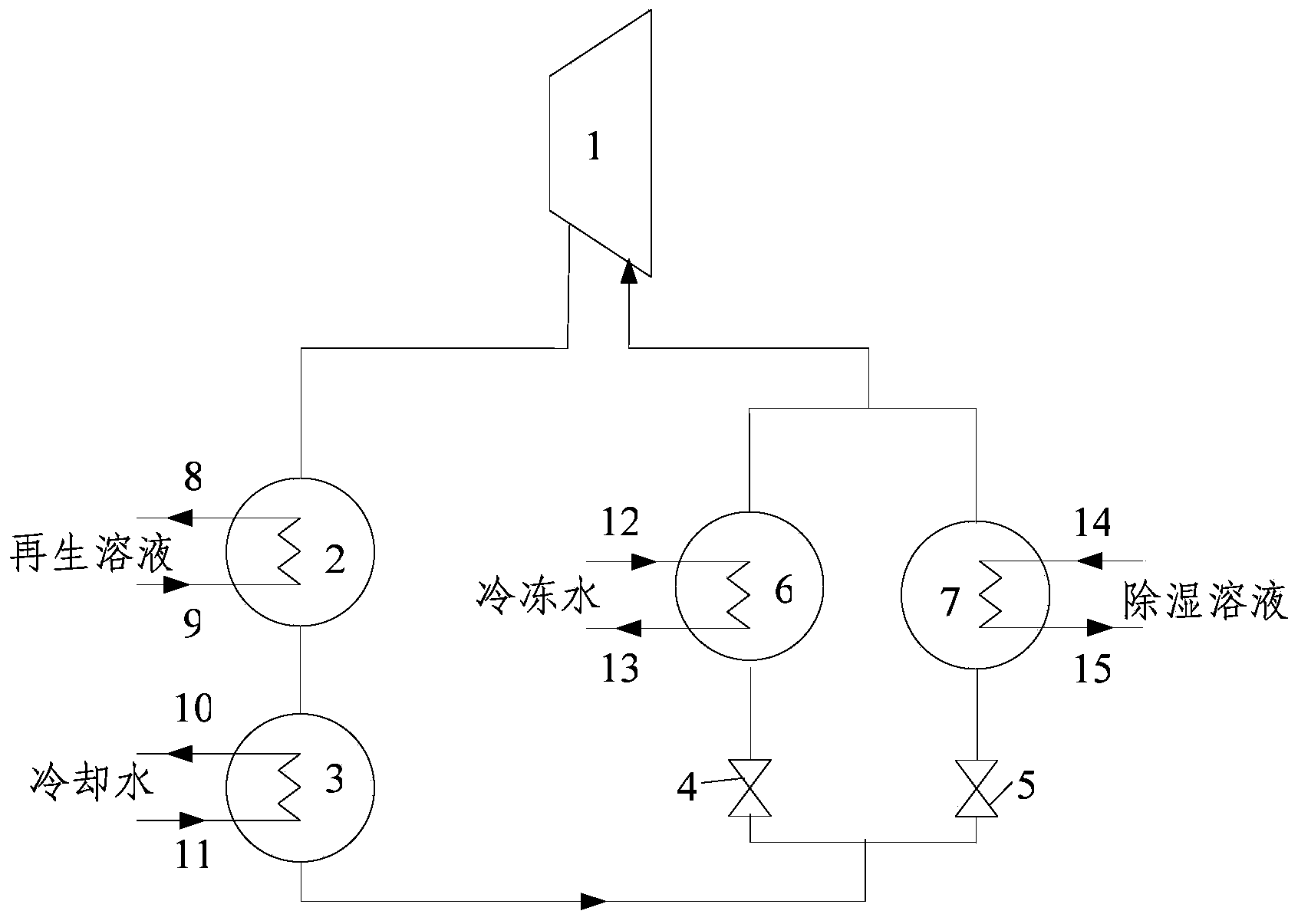

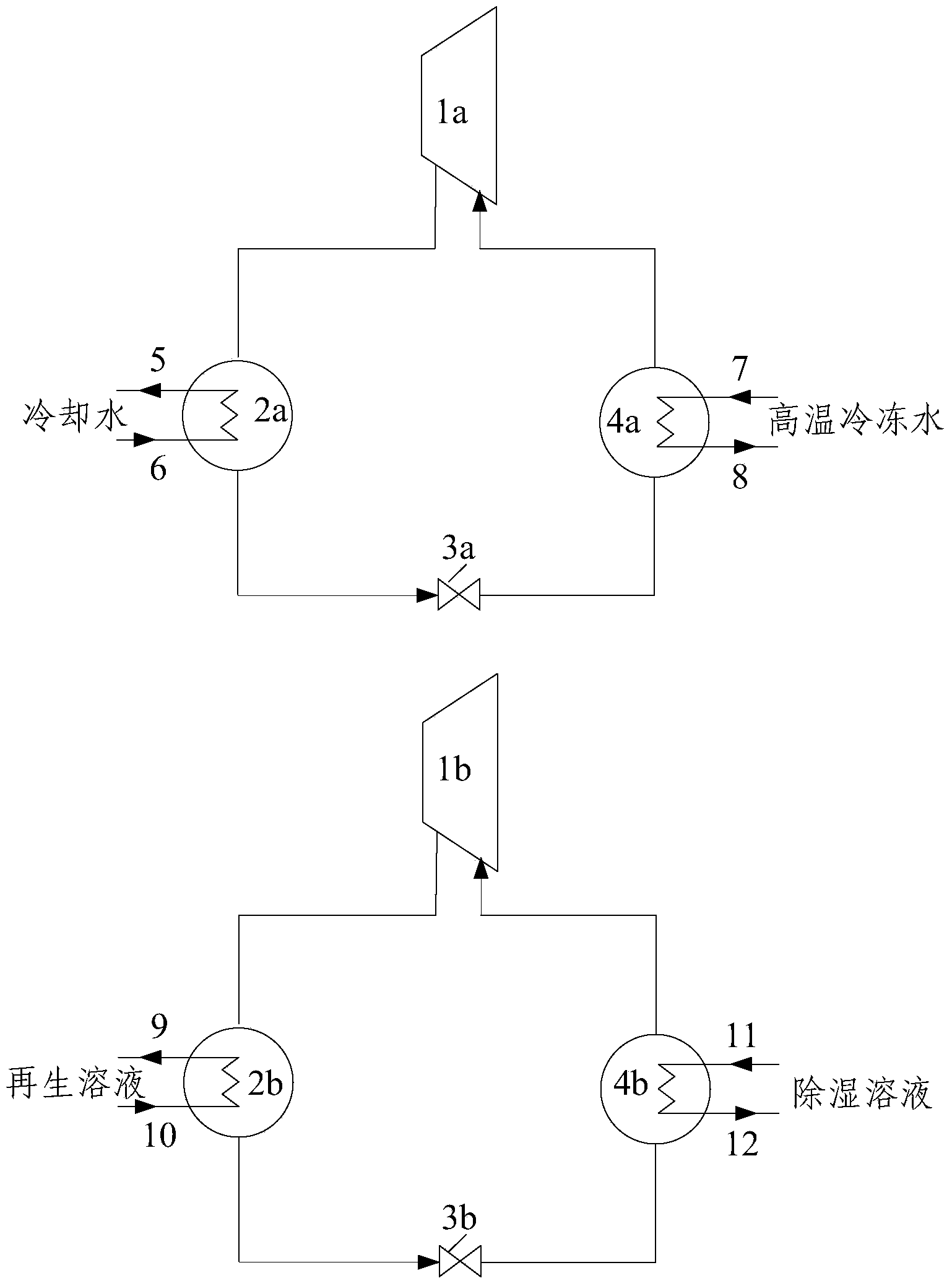

Heat and cold sources of temperature and humidity independent control air conditioning system

InactiveCN103562657AReduce consumptionImprove cooling efficiencyMechanical apparatusCompression machines with non-reversible cycleEngineeringAir conditioning

The present invention discloses heat and cold sources of a THIC air conditioning system, comprising: a compressor (1), a first condenser (2) and a second condenser (3), which are connected successively; a first expansion valve (4) and a second expansion valve (5) respectively connected to the second condenser (3); a first evaporator (6) and a second evaporator (7) respectively connected to the compressor (1); the first evaporator (6) is connected to the first expansion valve (4) to form a first cycle branch; the second evaporator (7) is connected to the second expansion valve (5) to form a second cycle branch; the first cycle branch and the second cycle branch which are connected in parallel connect the second condenser (3) and the compressor (1). The heat and cold sources of the THIC air conditioning system of the present invention have a relatively high refrigeration efficiency so as to significantly reduce energy consumption and protect atmospheric environment.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com