Method for purifying and recycling benzoid hydrocarbon, ammonia and coal tar from coke-oven gas

A technology for coke oven gas and benzene hydrocarbons, applied in chemical instruments and methods, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of disordered process temperature changes, complex process flow, frequent gradient changes, etc. The effect of smooth gradient change, simplified process flow, and orderly temperature change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

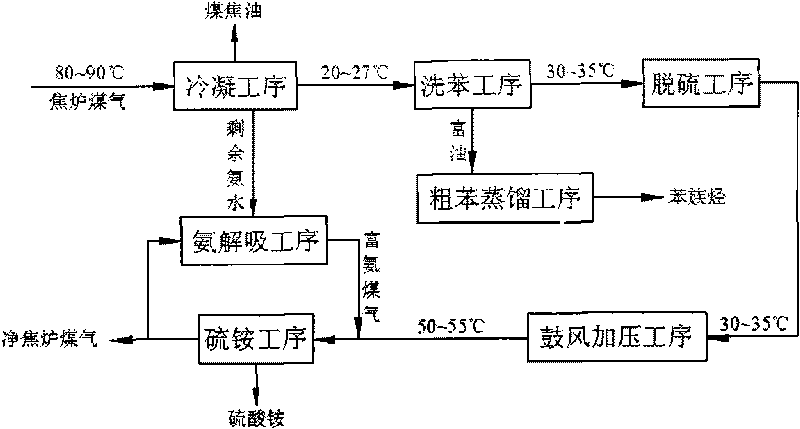

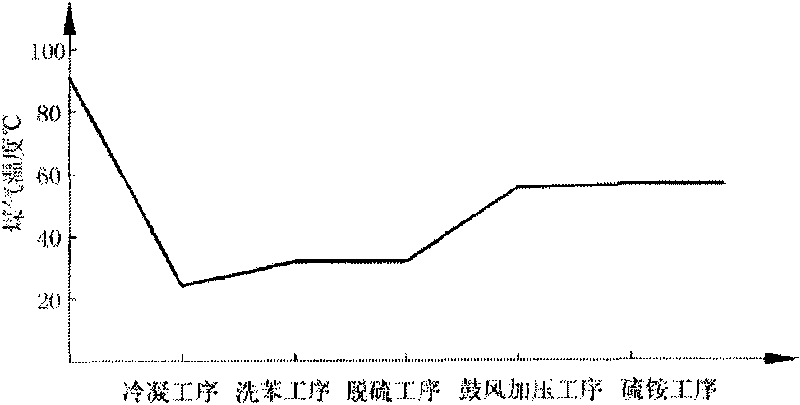

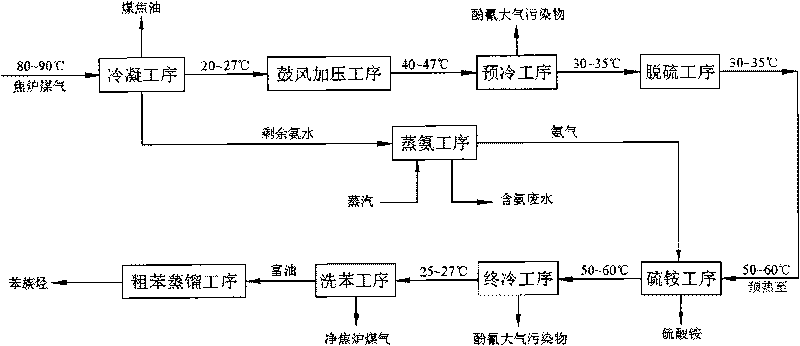

[0030] A method for purifying coke oven gas and recovering benzene group hydrocarbons, ammonia and coal tar. Its process is as figure 1Shown: Coke oven gas at 80-90°C is cooled to 20-27°C through the condensation process and then directly enters the benzene washing process. The final 30~35℃ coke oven gas enters the desulfurization process for desulfurization, and the desulfurized 30~35℃ coke oven gas enters the blast pressurization process for pressurization, and the coke oven gas is naturally heated to 50~55℃. The gas enters the ammonium sulfate process to recover ammonia, and the net coke oven gas after the ammonium sulfate process is used as high-quality fuel for external supply.

[0031] The remaining ammonia water produced in the condensation process enters the ammonia desorption process to desorb the ammonia, and enters the ammonium sulfate process to produce ammonium sulfate; the rich oil produced in the benzene washing process passes through the crude benzene distilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com