Automobile tail door made of composite material

A composite material and tailgate technology, used in doors, vehicle parts, household components, etc., can solve the problems of complex assembly process and large number of parts, protect the environment, reduce the number of parts and molds, specific strength and ratio. The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

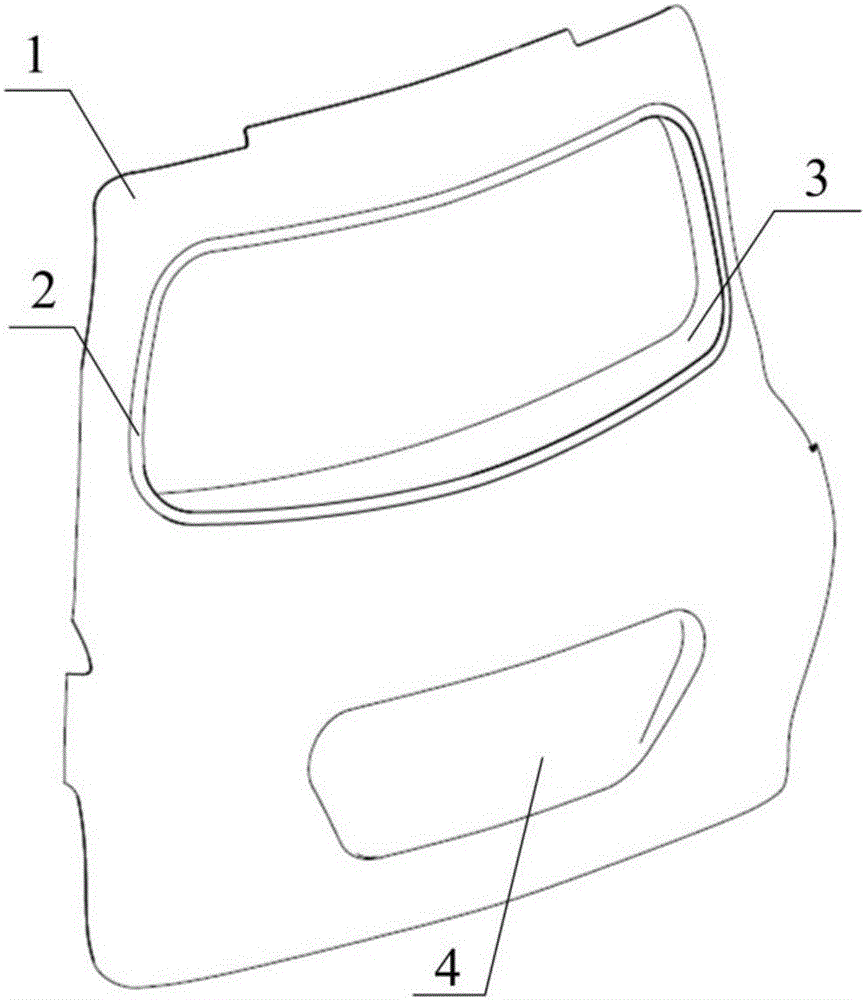

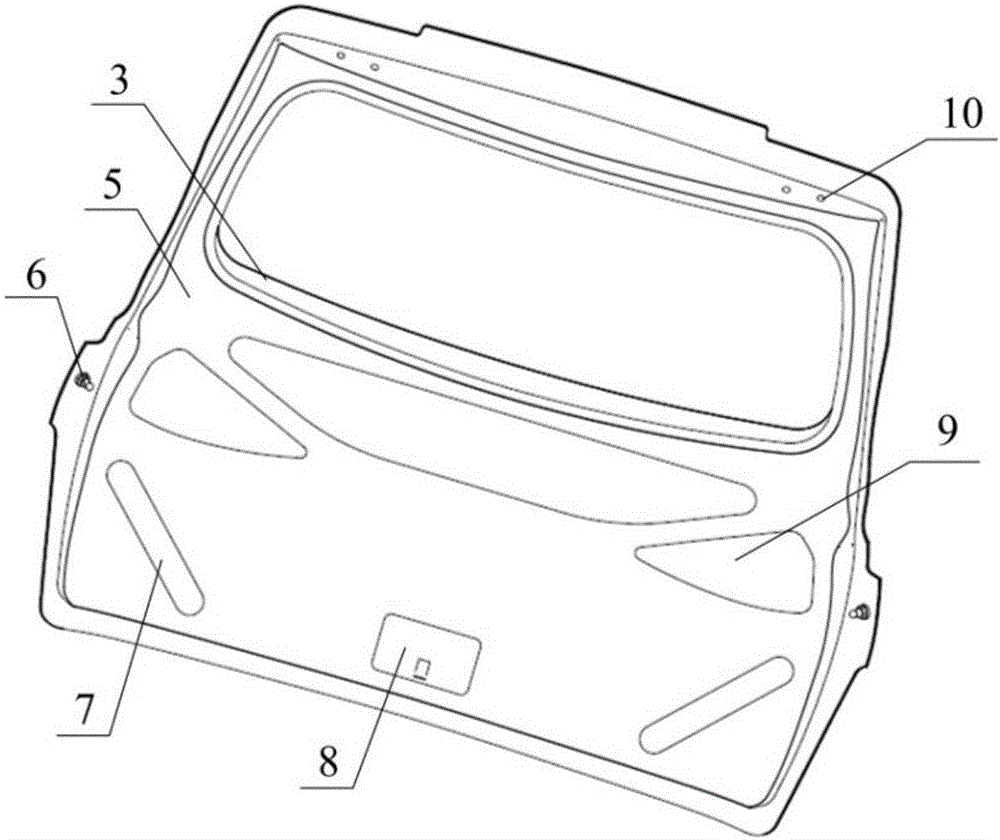

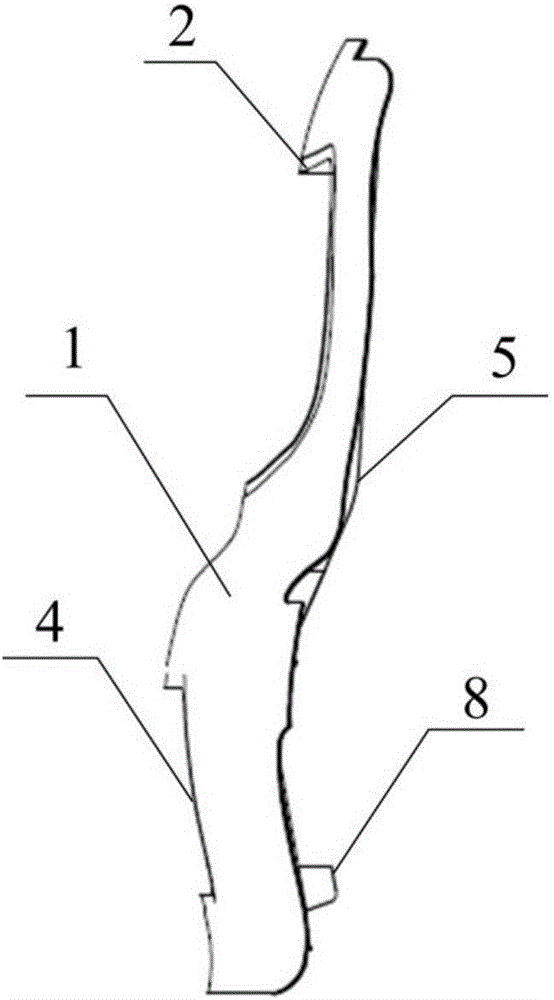

[0027] As shown in the accompanying drawing, a kind of automobile tailgate of composite material of the present invention comprises following parts: automobile tailgate outer panel 1, tailgate window edge 2, car window inner frame 3, tailgate license plate frame 4, automobile tailgate inner panel 5. Tailgate hydraulic cylinder mounting support 6, inner panel reinforcement rib 7, tailgate latch 8, inner panel weight reduction hole 9, tailgate hinge installation hole 10. The position connection relationship between them is: the outer panel 1 of the tailgate of the car is fixedly connected with the window edge 2 of the tailgate; the inner frame 3 of the car window is fixedly connected with the edge 2 of the window of the tailgate; The inside of the outer panel 1; the inner panel 5 of the tailgate of the automobile is fixedly connected with the outer pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com