Method for producing nickel sulfide ore concentrate by use of industrial waste acid

A technology of industrial waste acid and nickel sulfide refined, applied in the direction of improving process efficiency, can solve the problems of reducing the utilization rate of sulfur ions, increasing labor intensity, large equipment investment, etc., to protect the workshop and atmospheric environment, and low production costs , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

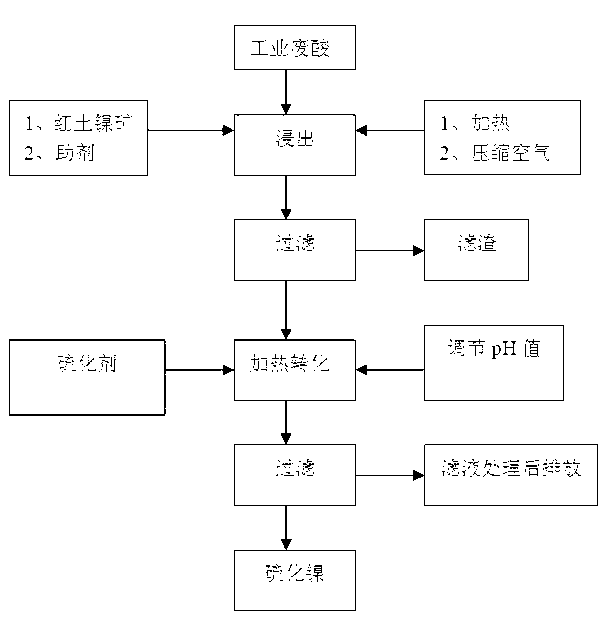

Image

Examples

Embodiment 1

[0023] Embodiment 1 (the content of all acid and nickel in the embodiment is weight content)

[0024] 1000Kg of laterite nickel, add 3300Kg of titanium white waste acid containing 21% acid, turn on the stirring to make a slurry, raise the temperature to 80°C, stir and extract at normal pressure for 45 minutes, add 150Kg of sodium sulfate solid, and add sodium hydroxide to adjust pH=4.2 , blow in compressed air, continue to react for 1.5 hours, cool down to 40°C and filter, put the filtrate into the reactor, heat to 80°C under stirring, add 200Kg powdered ferrous sulfide, keep the temperature for 3 hours, cool down to 50°C, filter , the filter residue is nickel sulfide concentrate with a nickel content of 11.0%.

Embodiment 2

[0026] 1000Kg laterite nickel, add 4000Kg electrolytic copper industrial waste acid containing 18% sulfuric acid, start stirring to make a slurry, heat up to 80°C, stir and extract at normal pressure for 60 minutes, add 100Kg potassium chloride solid, add sodium hydroxide to adjust pH =3.0, blow in compressed air, continue to react for 2 hours, filter, put the filtrate into the reactor, heat to 90°C under stirring, add 160Kg powdered calcium sulfide, keep warm for 3 hours, cool down to 50°C, filter, and the filter residue is Nickel sulphide concentrate with a nickel content of 12.1%.

Embodiment 3

[0028] 1000Kg of laterite nickel, add 6300Kg of waste acid produced by cleaning iron and steel products with a concentration of 15%, start stirring to make a slurry, heat up to 80°C, stir and extract at normal pressure for 60 minutes, add 100Kg of ammonium sulfate solid, add sodium hydroxide to adjust pH = 3.0, blow in compressed air, continue to react for 2 hours, filter, put the filtrate into the reactor, heat to 90°C under stirring, add 150Kg powdered 1:1 ammonium sulfide and ammonium polysulfide, keep warm for 4 hours and then cool down to 50°C, filter, and the filter residue is nickel sulfide concentrate, with a nickel content of 10.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com