Oil mist recycling machine

A recovery machine and oil mist technology, applied in the direction of dispersed particle filtration, combined devices, transportation and packaging, etc., can solve the problems of reducing production efficiency, corrosion damage of mechanical equipment, etc., and achieve the goal of reducing damage, reducing corrosion damage, and protecting the atmospheric environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in conjunction with the following examples.

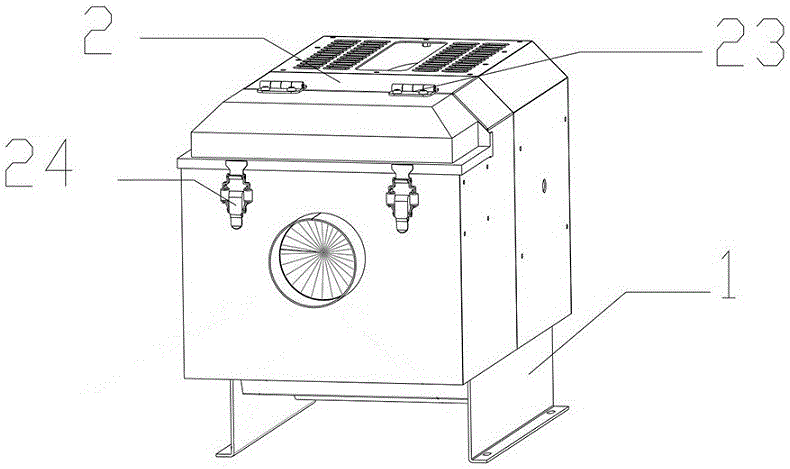

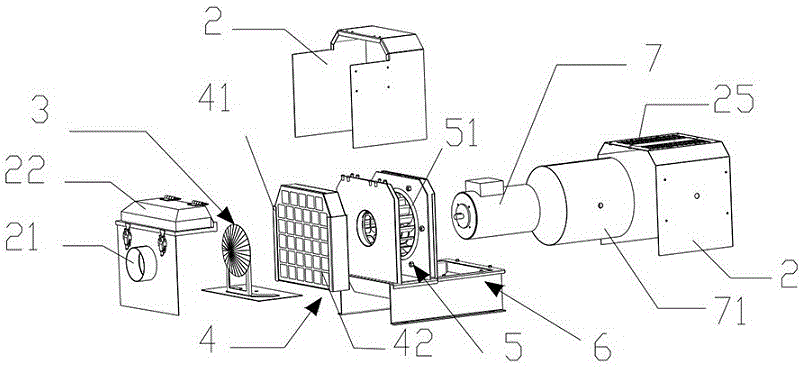

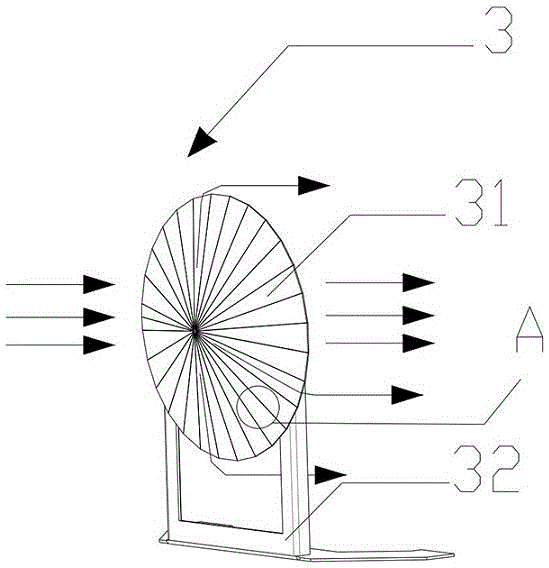

[0026] An oil mist recovery machine described in this embodiment includes a frame 1, the frame 1 is provided with a housing 2, and one side of the housing 2 is provided with an inlet 21, and the housing 2 is sequentially provided with The primary filtering device 3 for primary filtering of oil mist, the secondary filtering device 4 for secondary filtering of oil mist, the tertiary filtering device 5 for tertiary filtering of oil mist and the driving mechanism, all Said driving mechanism is driven and connected with the three-stage filter device 5; the lower end of said three-stage filter device 5 is provided with a collecting mechanism 6. Such as figure 1 , figure 2 As shown, the working principle is: under the driving action of the driving mechanism, a certain air pressure difference is formed between the inside and outside of the housing 2 , so that the oil mist floating around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com