Patents

Literature

90results about How to "Continuous release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

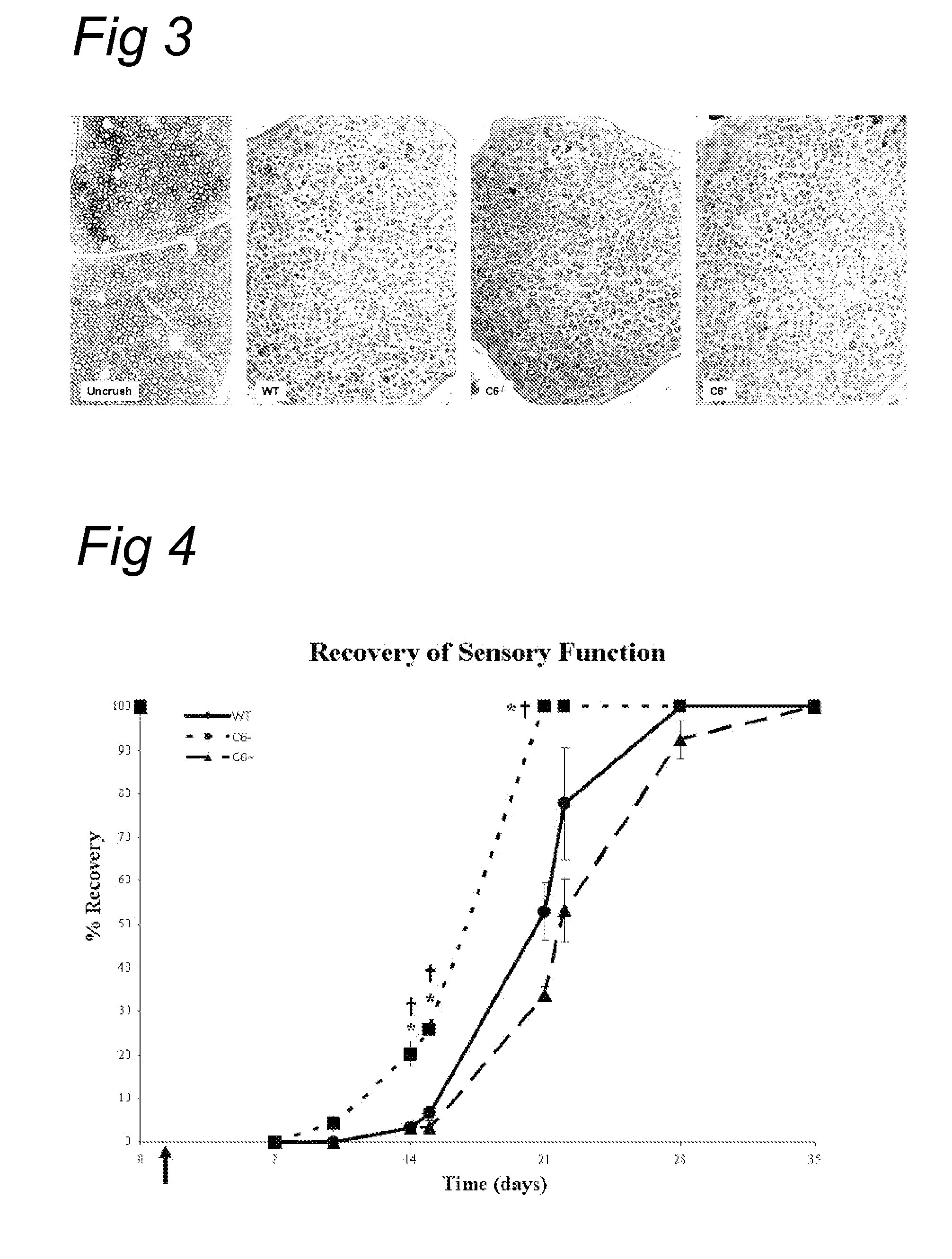

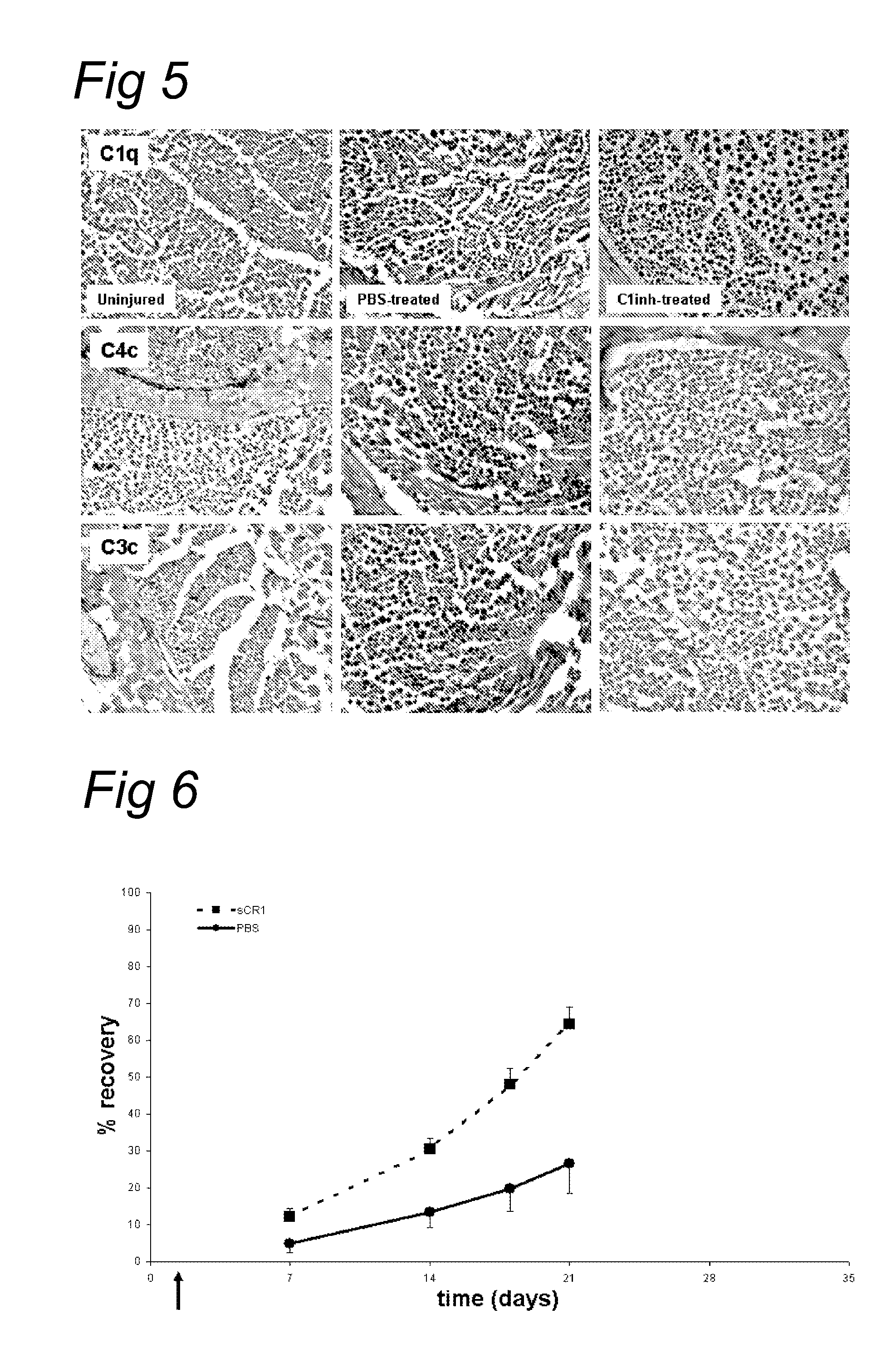

Complement inhibition for improved nerve regeneration

ActiveUS20100143344A1Improve regenerative abilityPromote regenerationBiocideNervous disorderDiseaseNervous system

The present invention relates to methods and medicaments used for treating conditions that require axonal regeneration, e.g. in mammals affected by injury or disease of the central or peripheral nervous system. The medicaments used in these methods facilitate axonal regeneration by inhibition of the complement system. Conditions requiring axonal regeneration that may be treated in accordance with the invention include physical injuries as well as neurodegenerative disorders of the peripheral or central nervous system.

Owner:REGENESANCE

Complement inhibition for improved nerve regeneration

ActiveUS8703136B2Improve regenerative abilityPromote regenerationNervous disorderPeptide/protein ingredientsDiseaseNervous system

The present invention relates to methods and medicaments used for treating conditions that require axonal regeneration, e.g. in mammals affected by injury or disease of the central or peripheral nervous system. The medicaments used in these methods facilitate axonal regeneration by inhibition of the complement system. Conditions requiring axonal regeneration that may be treated in accordance with the invention include physical injuries as well as neurodegenerative disorders of the peripheral or central nervous system.

Owner:REGENESANCE

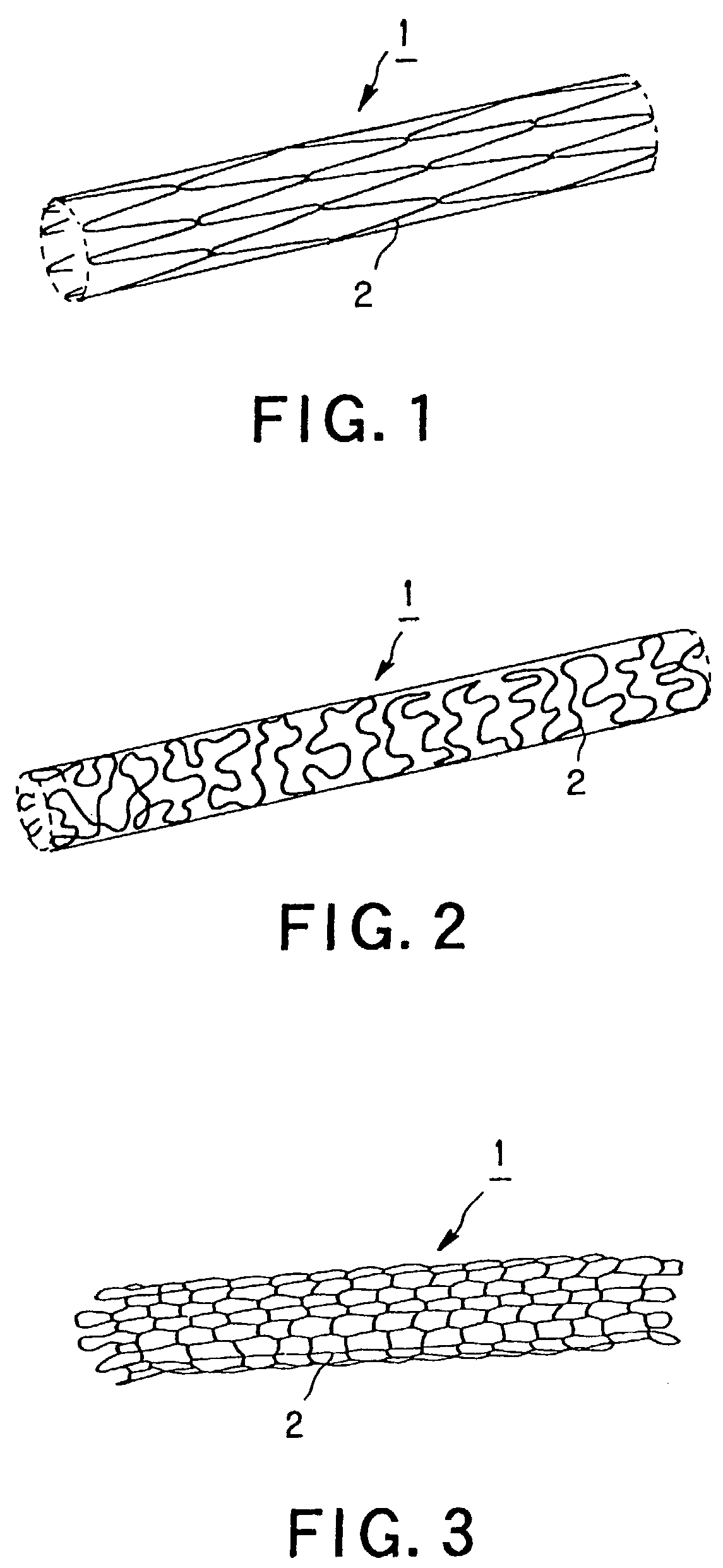

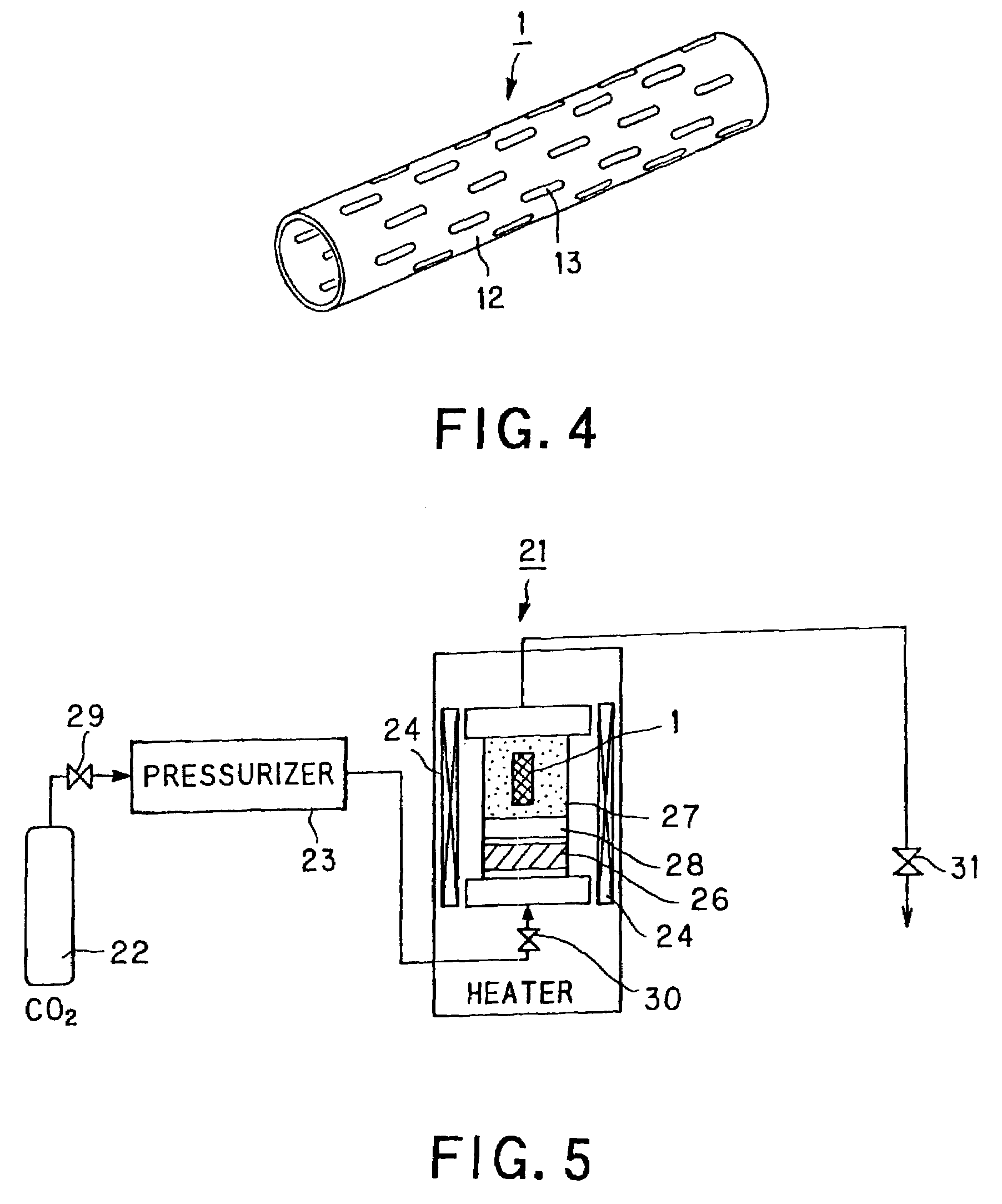

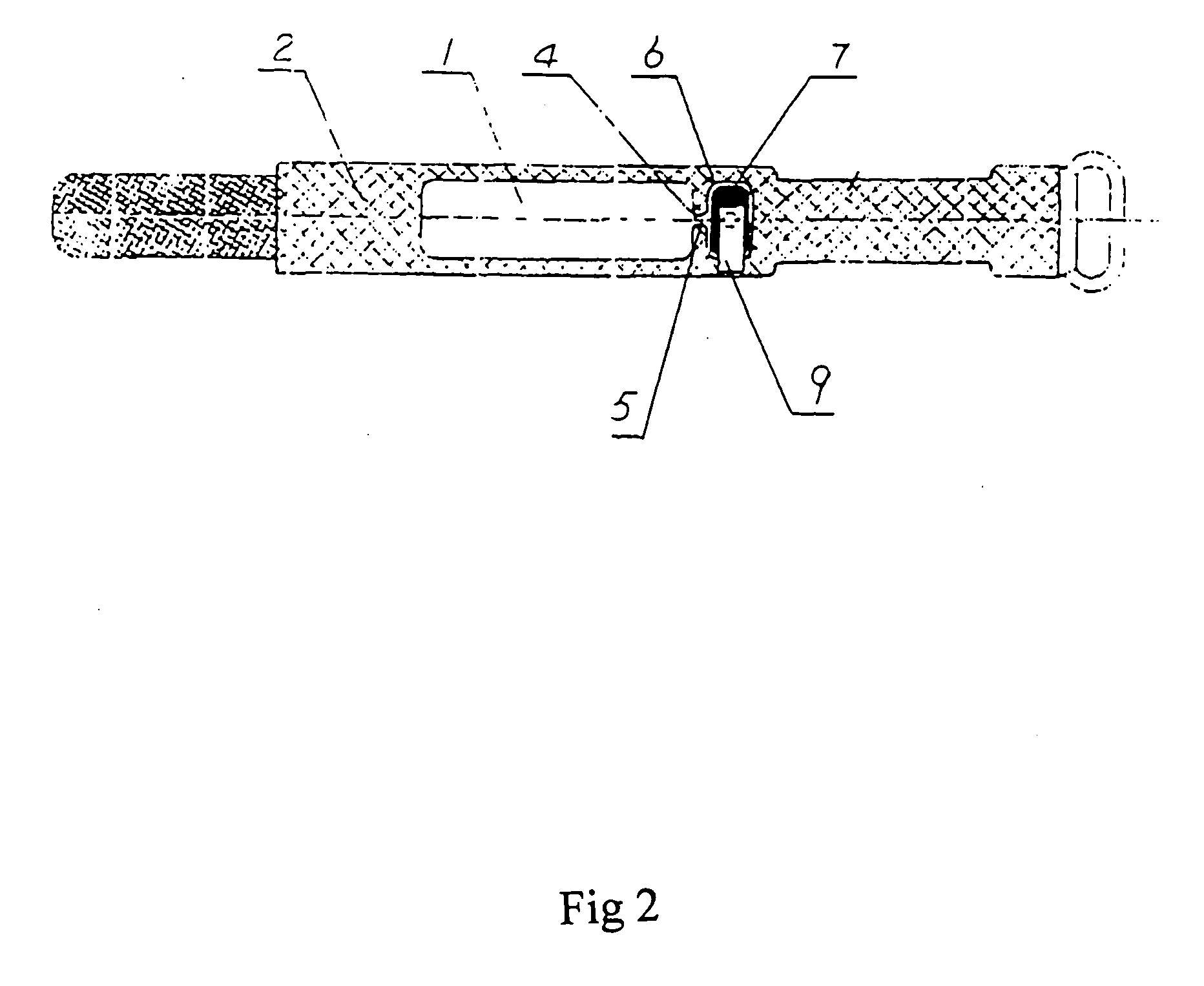

Stent for blood vessel and material for stent for blood vessel

A luminal stent, implanted and implanted and left in the blood vessel, is disclosed. By permitting a stent (1), formed of a biodegradable polymer material (2), to be swollen, and by impregnating the swollen stent (1) with a drug, a sufficient quantity of the drug is impregnated in the stent. This drug is continuously released into the blood vessel over a prolonged time. A biodegradable polymer layer is formed on the surface of the stent (1) impregnated with the drug, and the release rate of the drug impregnated in the stent is controlled.

Owner:KYOTO MEDICAL PLANNING

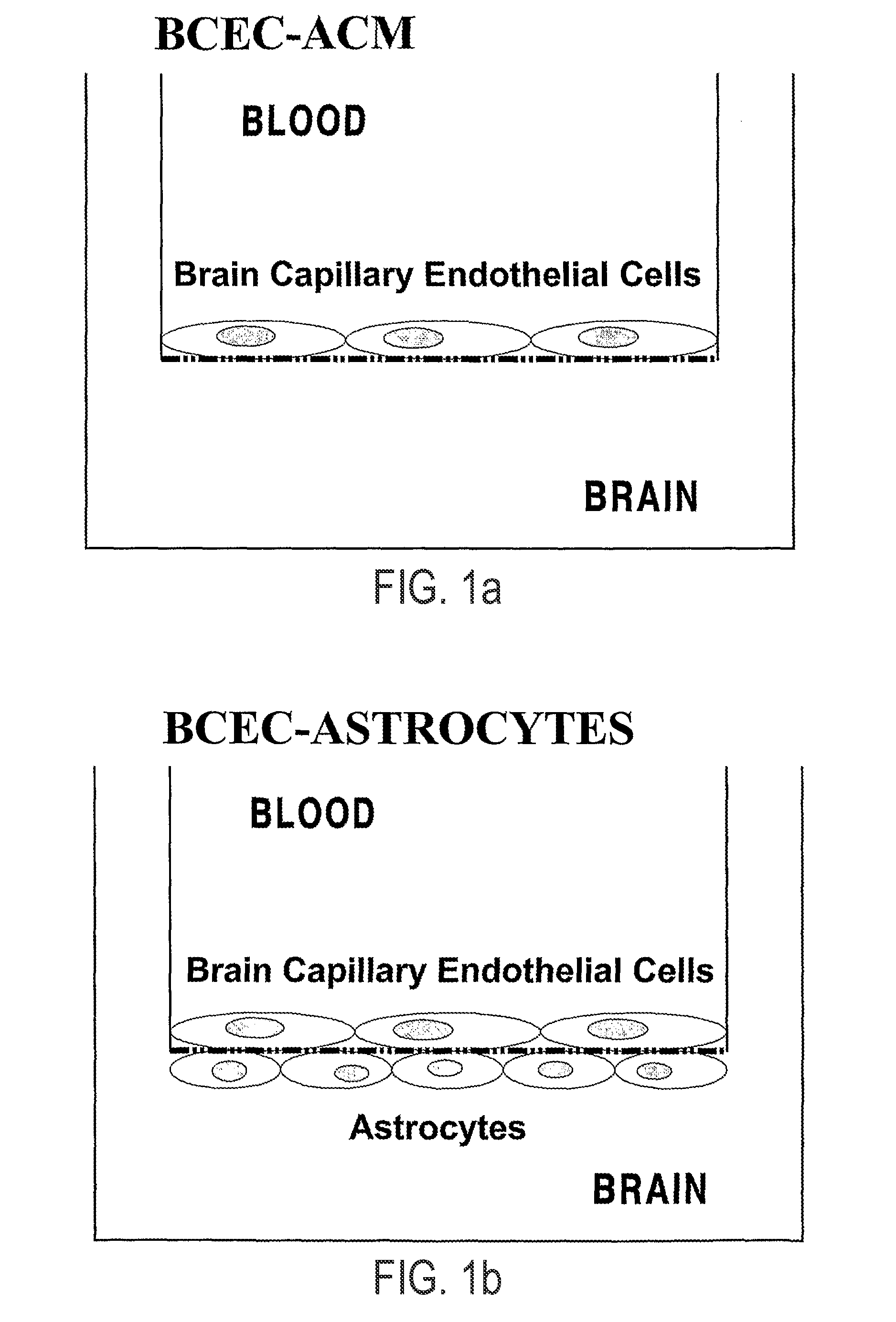

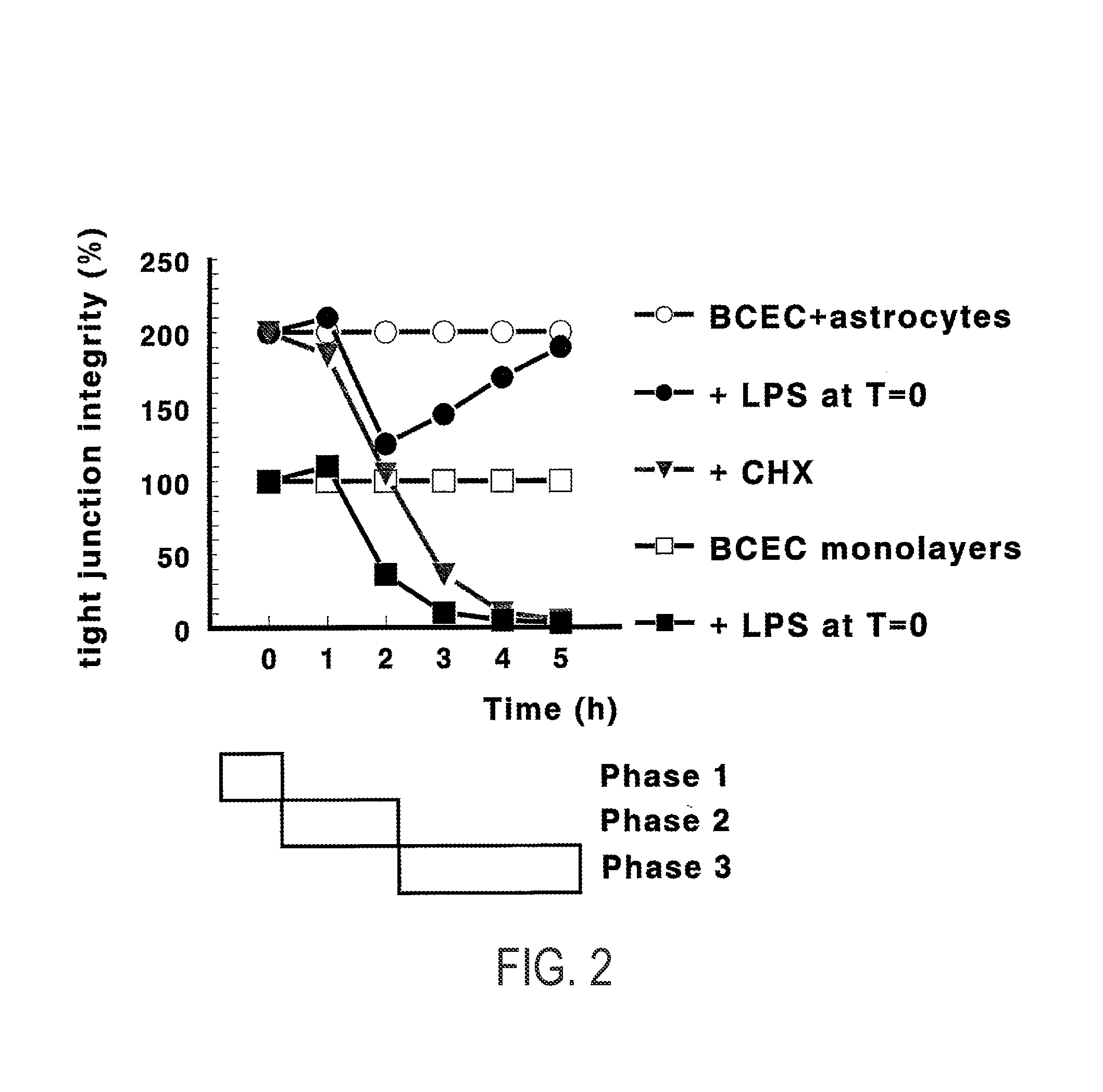

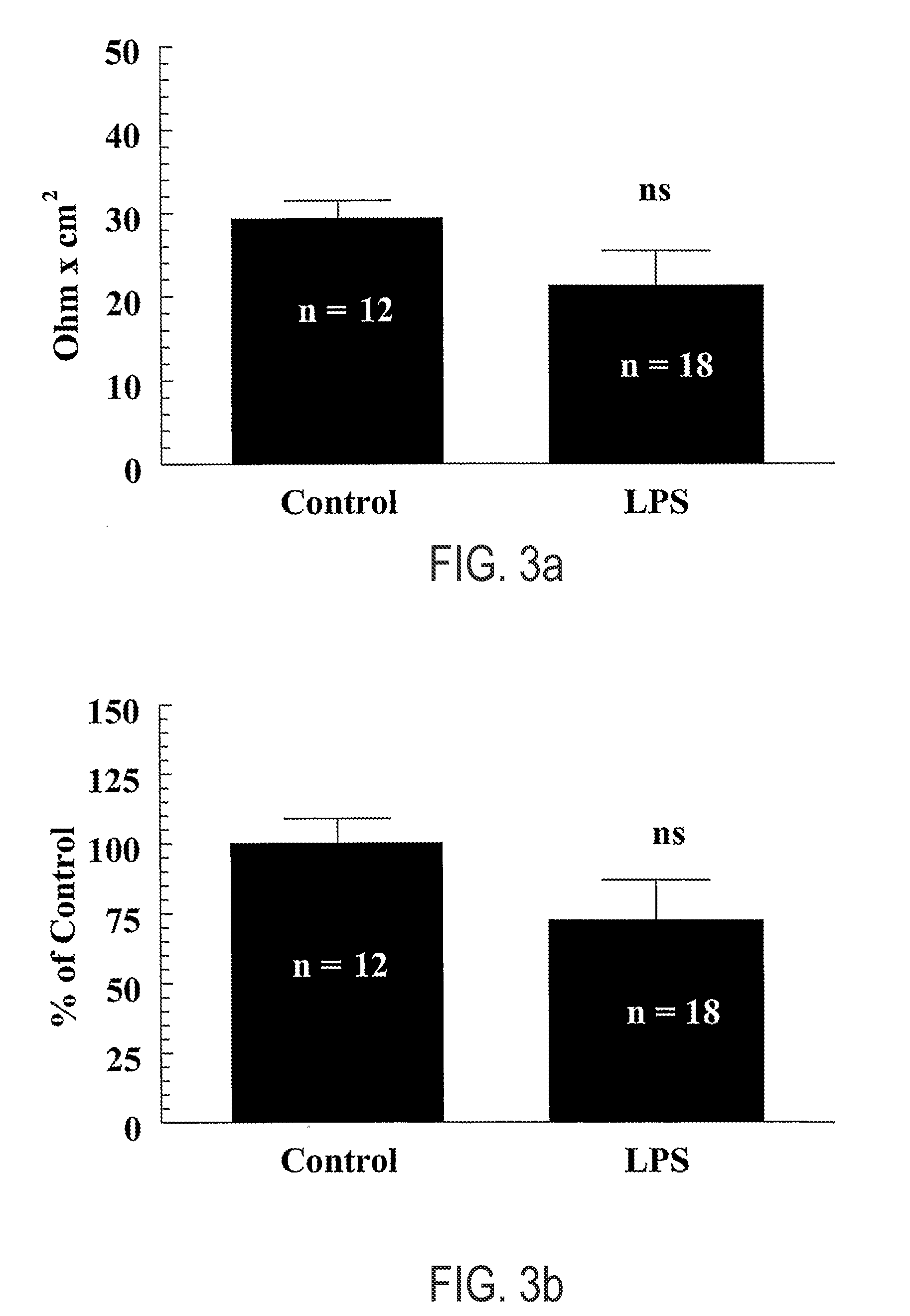

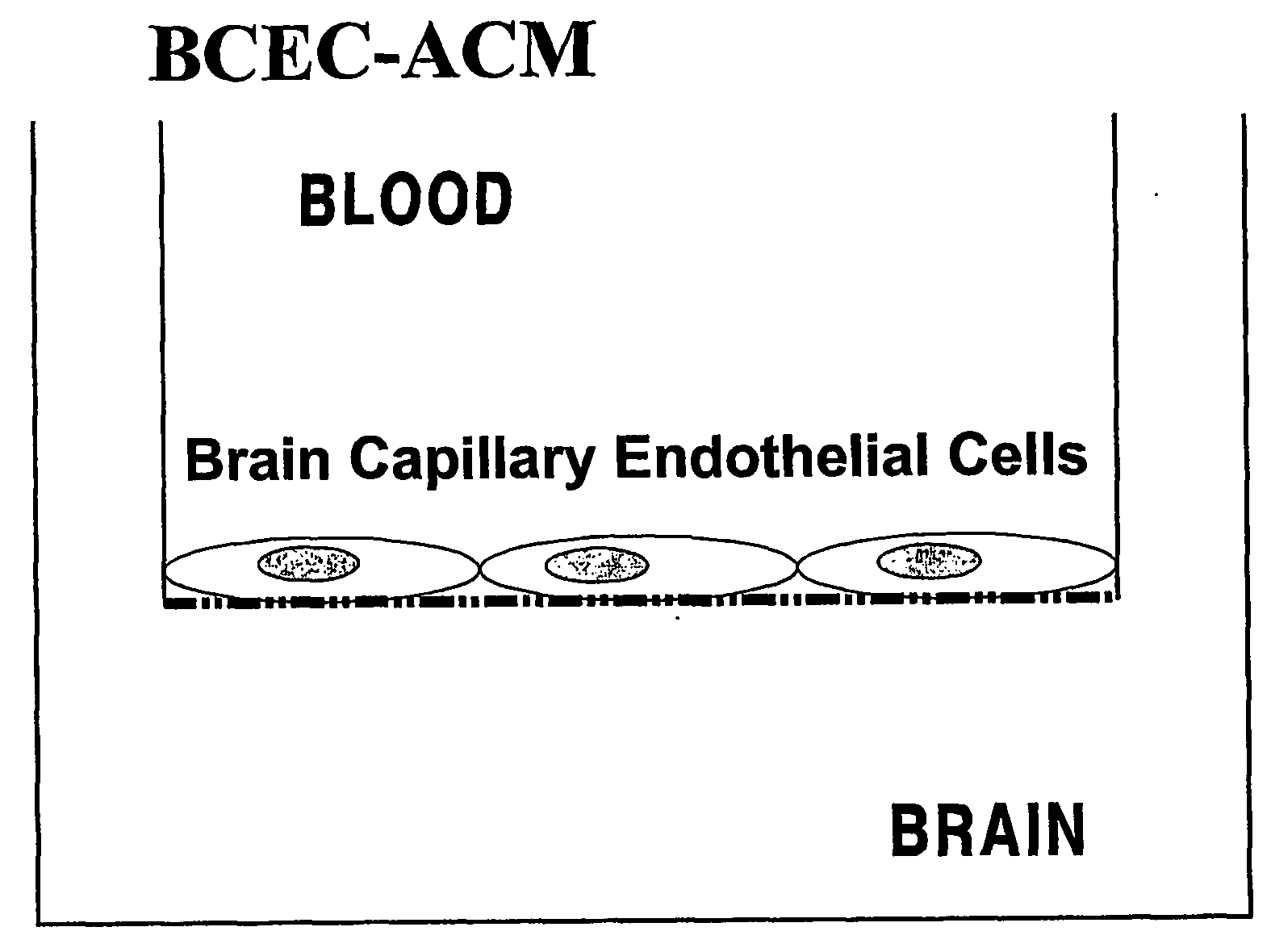

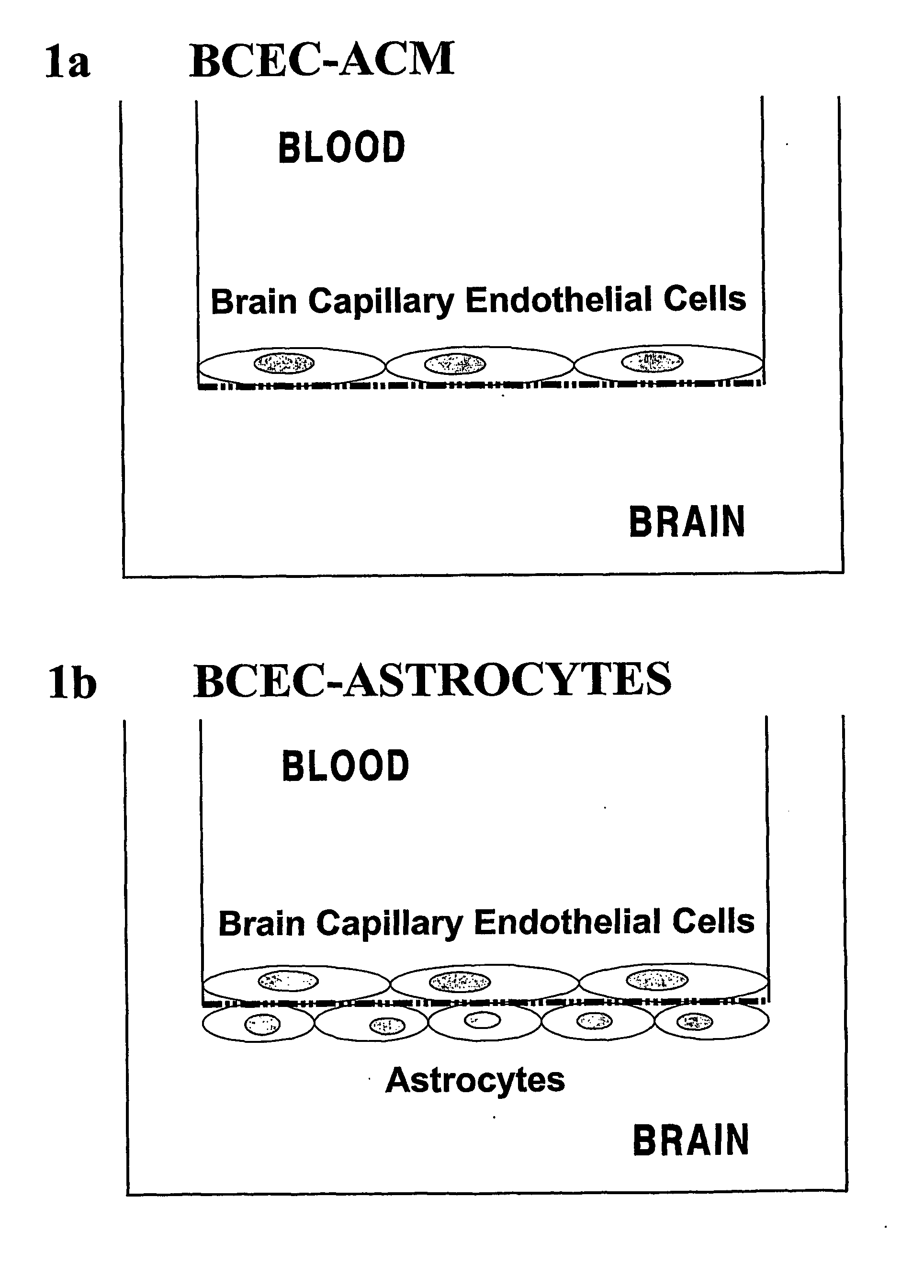

Methods and compositions for targeting agents into and across the blood-barrier and other endothelial cell microvascular barriers

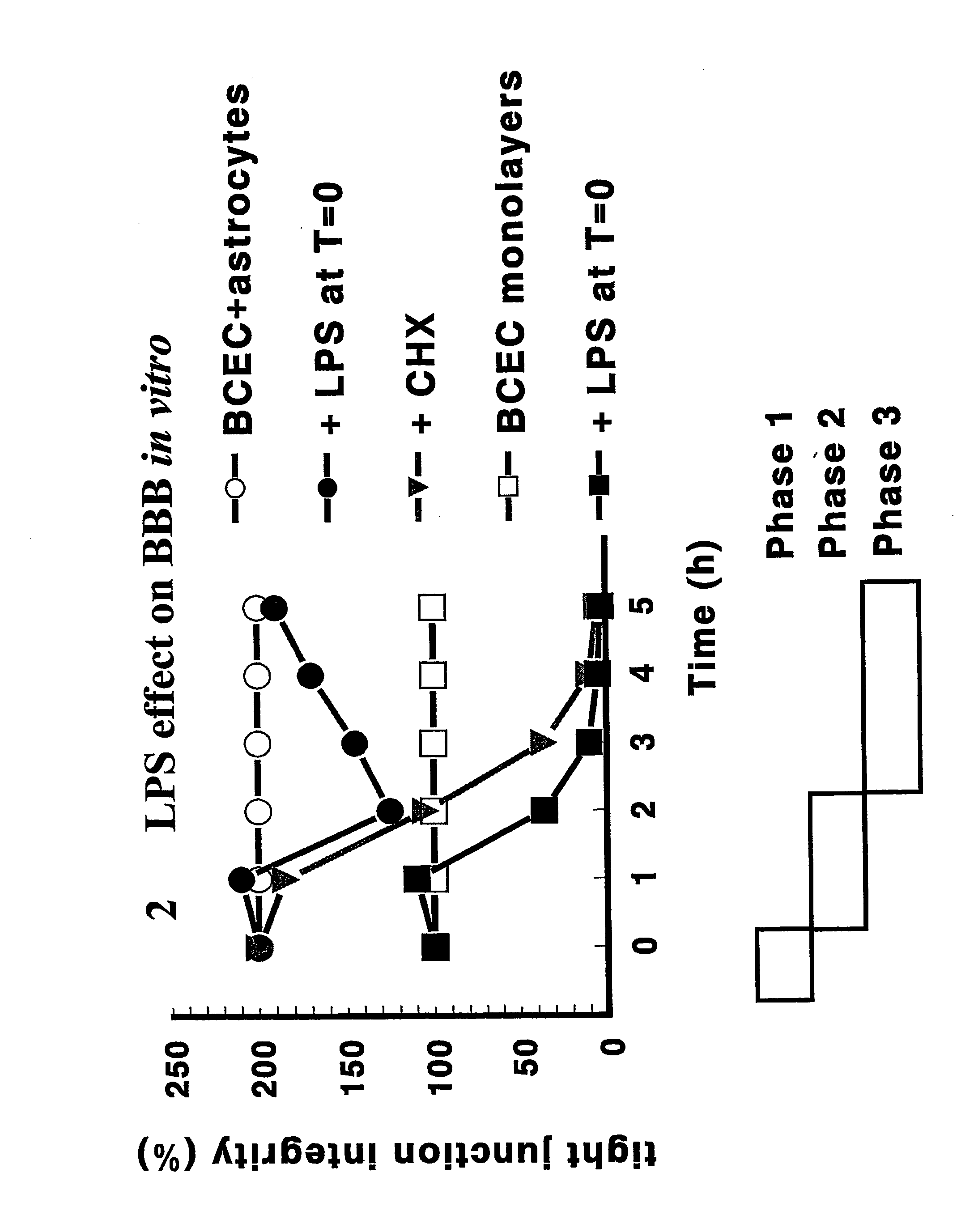

InactiveUS8026209B2Improve permeabilityHigh activityOrganic active ingredientsPeptide/protein ingredientsMammalBiology

The present invention relates to nucleic acids and polypeptides encoded thereby, whose expression is modulated in brain microvascular endothelial cells undergoing early dynamic inflammation-induced changes in blood-brain barrier functionality. Such polypeptides are referred to as lipopolysaccharide-sensitive (LPSS) polypeptides herein. These nucleic acids and polypeptides may be useful in methods for controlling blood-brain barrier properties in mammals in need of such biological effects. This includes the diagnosis and treatment of disturbances in the blood-brain / retina barrier, brain (including the eye) disorders, as well as peripheral vascular disorders. Additionally, the invention relates to the use of anti-LPSS polypeptide antibodies or ligands as diagnostic probes, as blood-brain barrier targeting agents or as therapeutic agents as well as the use of ligands or modulators of expression, activation or bioactivity of LPSS polypeptides as diagnostic probes, therapeutic agents or drug delivery enhancers.

Owner:2 BBB MEDICINES BV

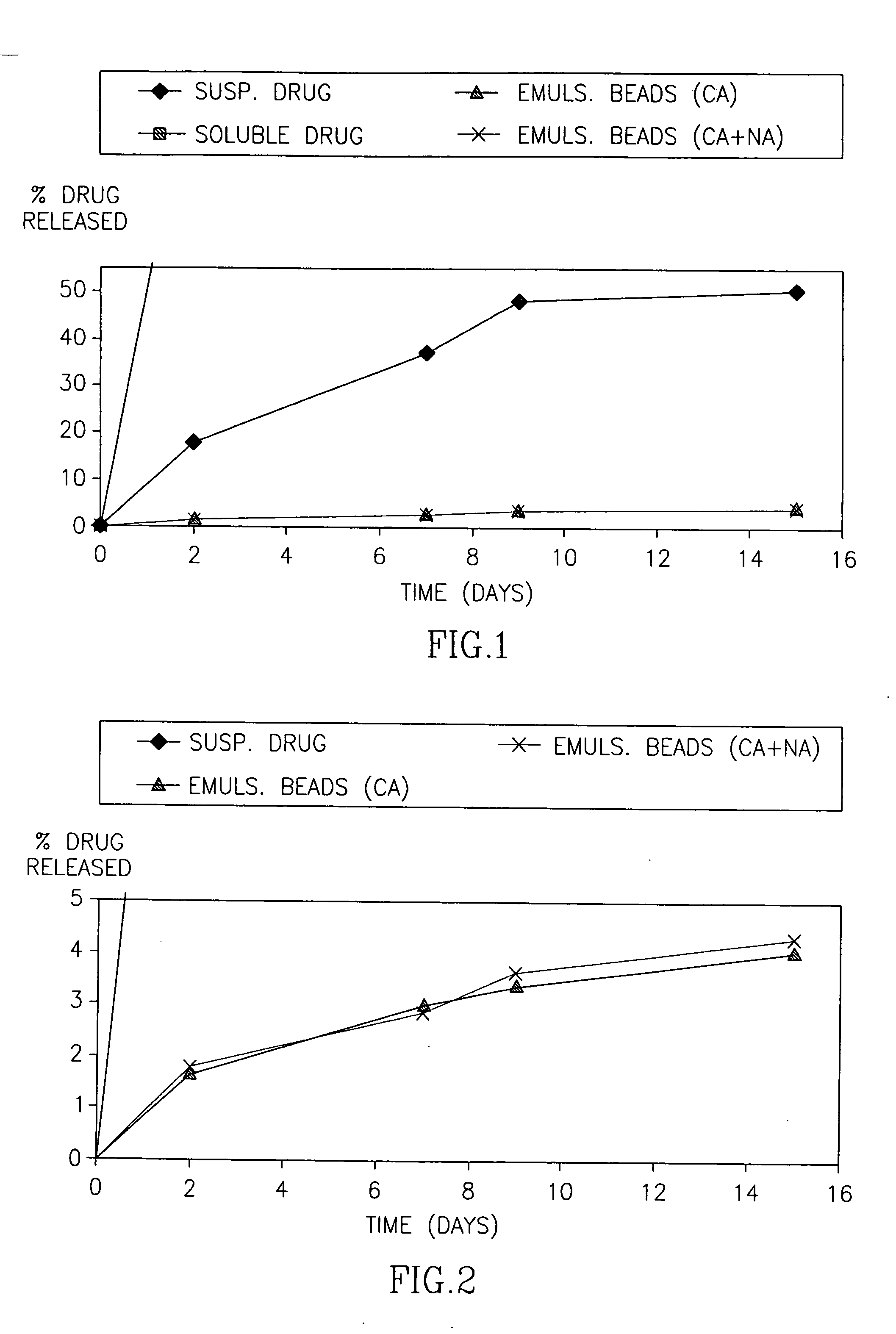

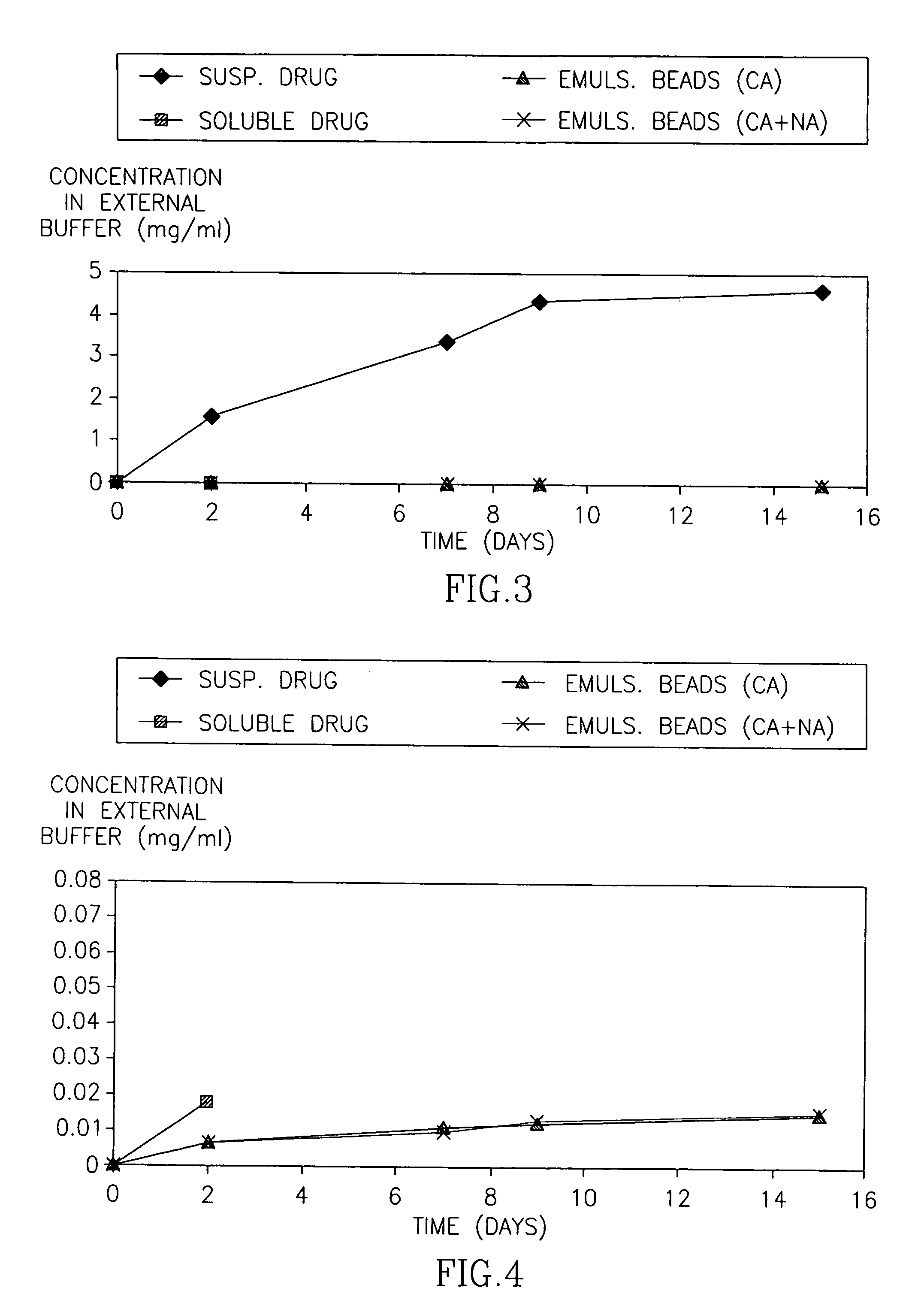

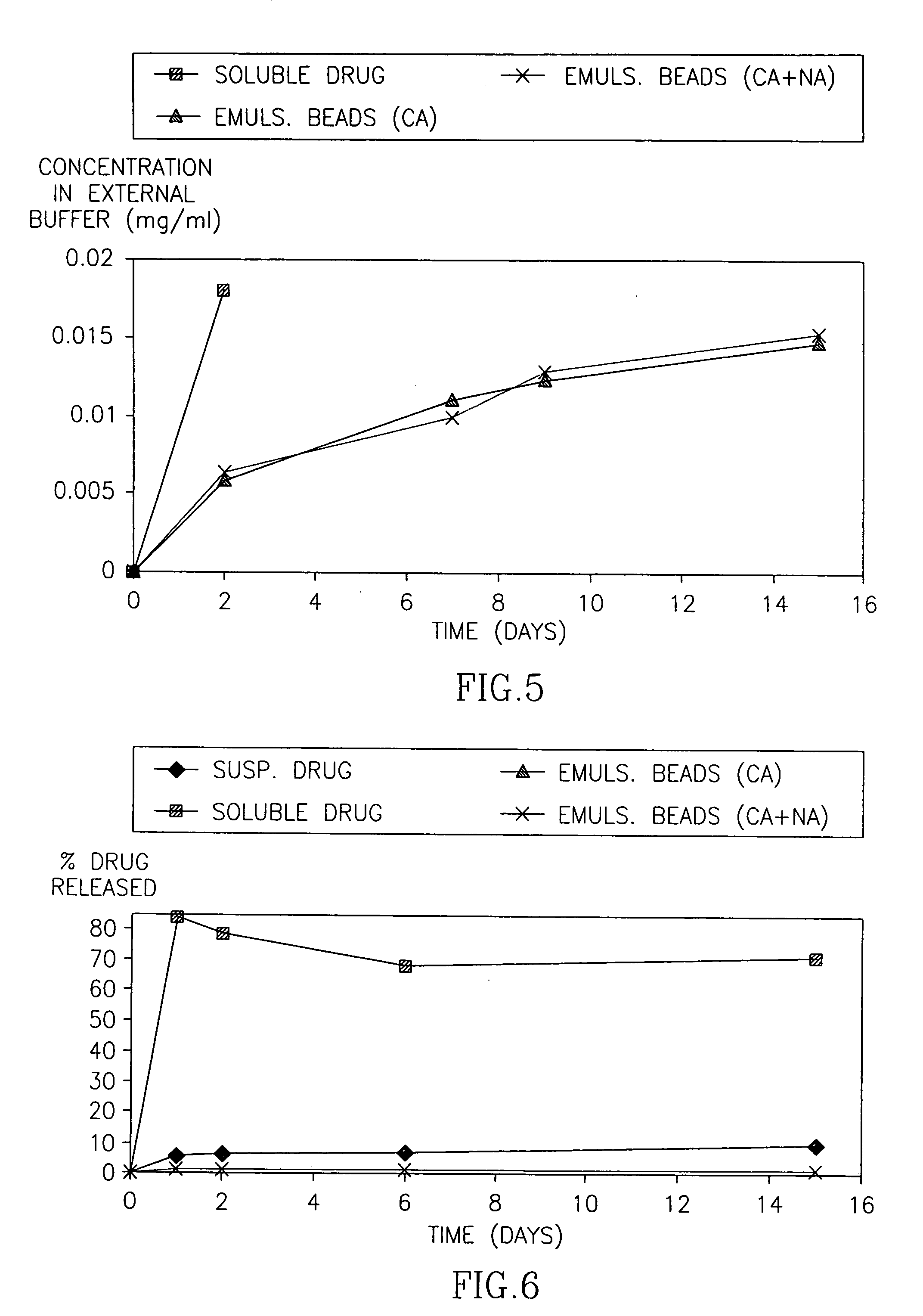

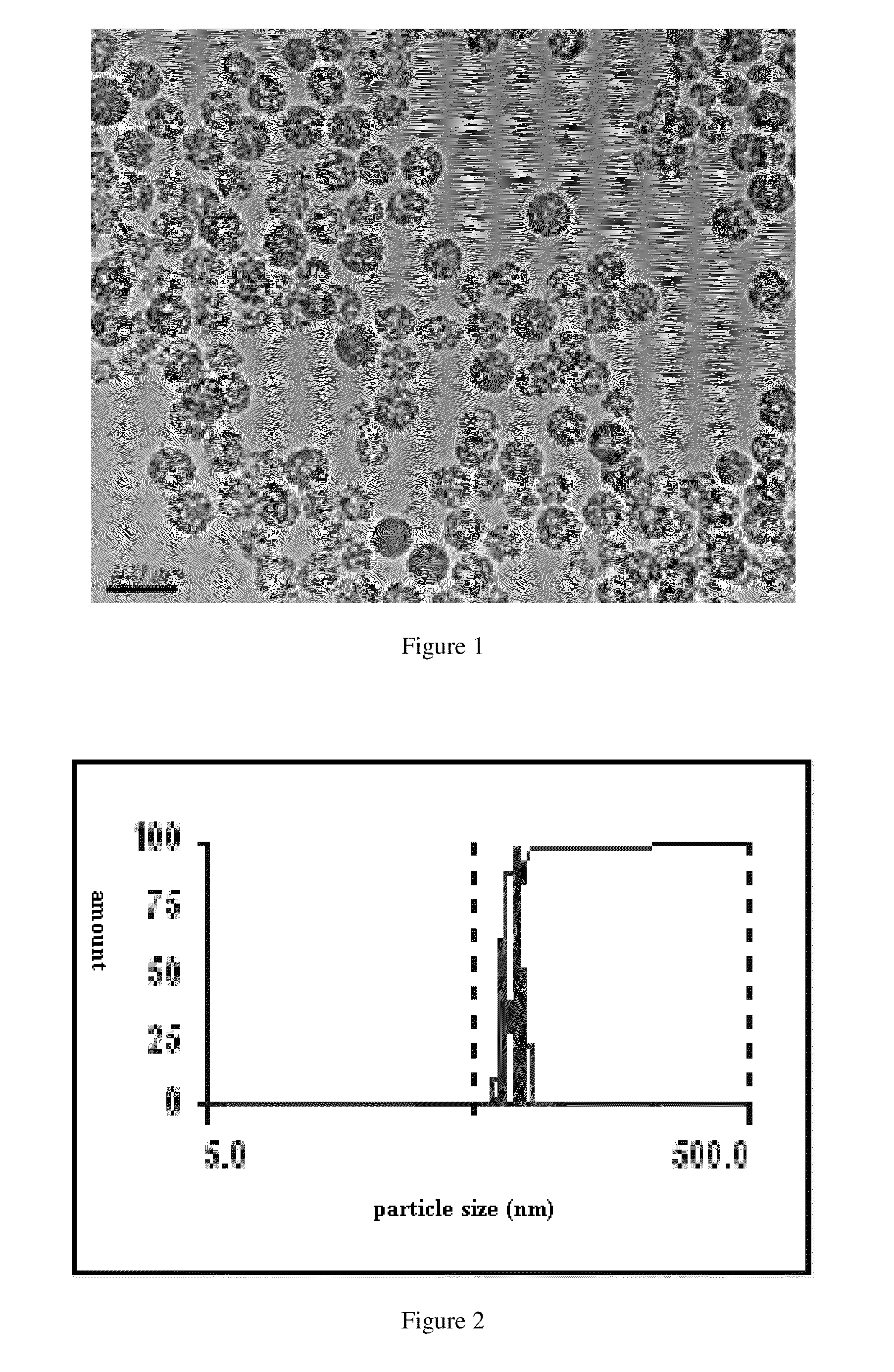

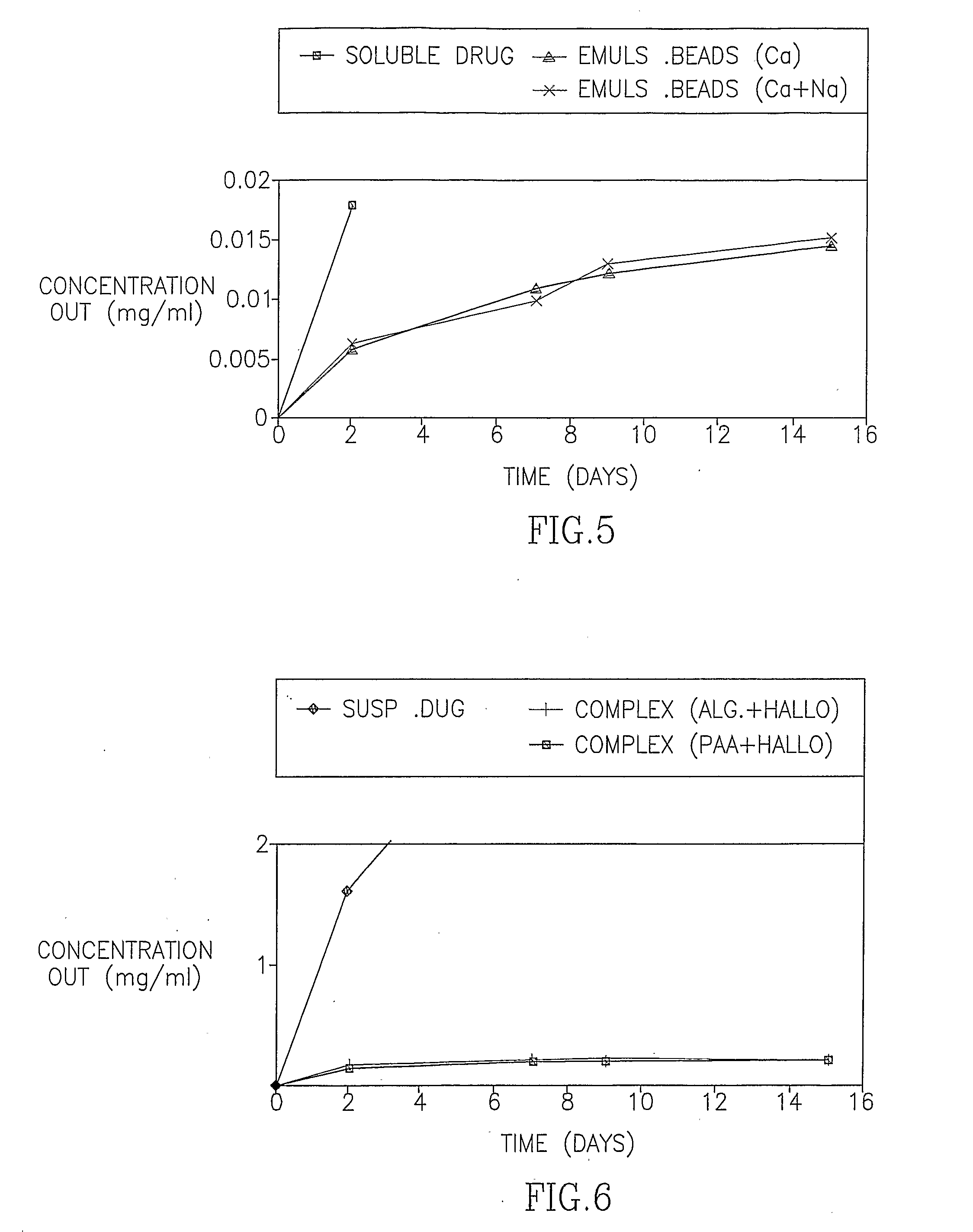

Biocompatible polymeric beads and use thereof

InactiveUS20050208134A1Easy to solveStable and effective concentrationCosmetic preparationsToilet preparationsMedicineCompound (substance)

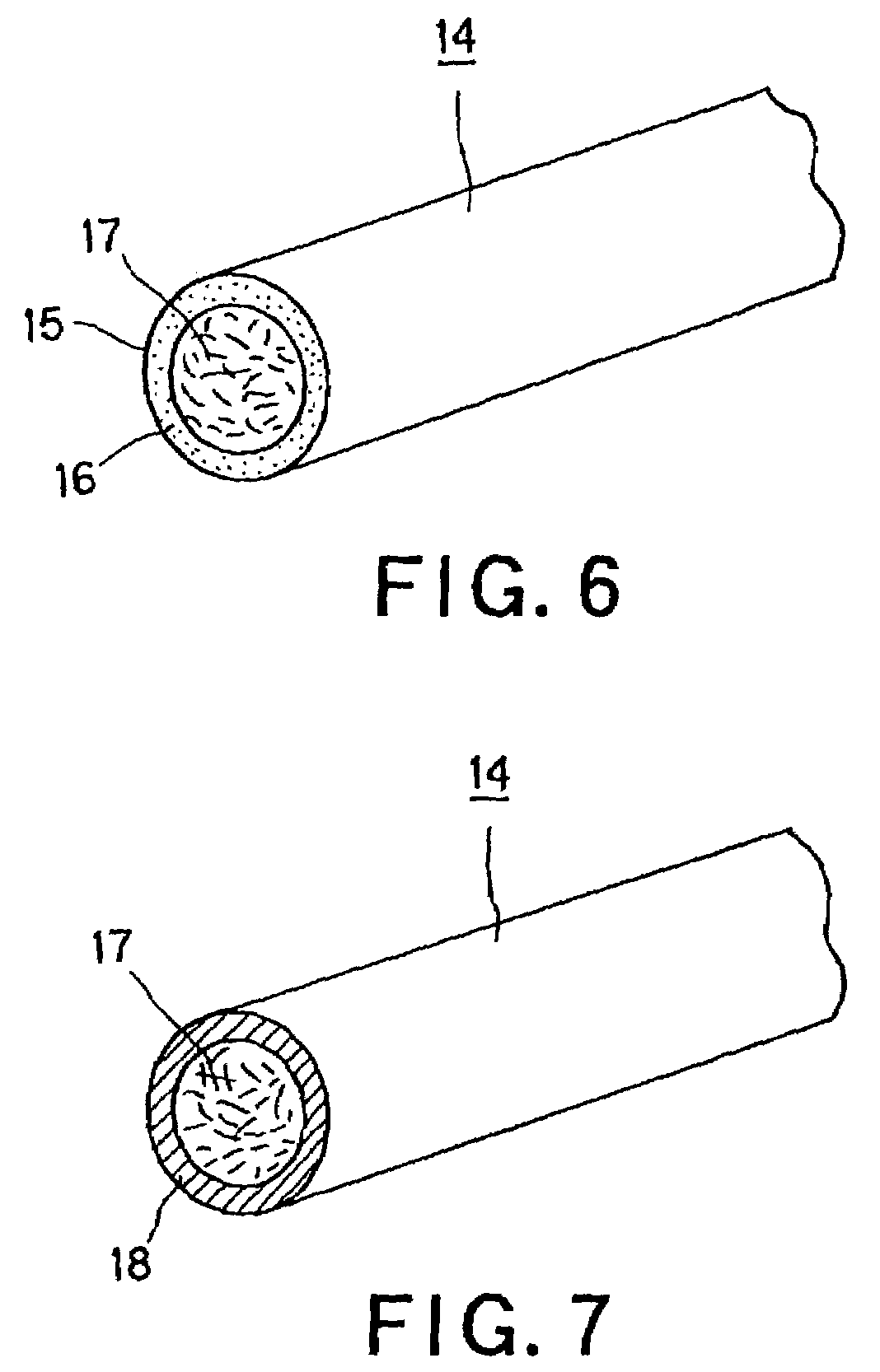

The present invention relates to biocompatible polymeric beads and to biocompatible delivery systems comprising same for controlled or sustained release of bioactive molecules. In particular, the invention relates to polymeric beads having a two-phase core and shell structure and to polymeric delivery systems comprising same that provide sustained release of the bioactive compound.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

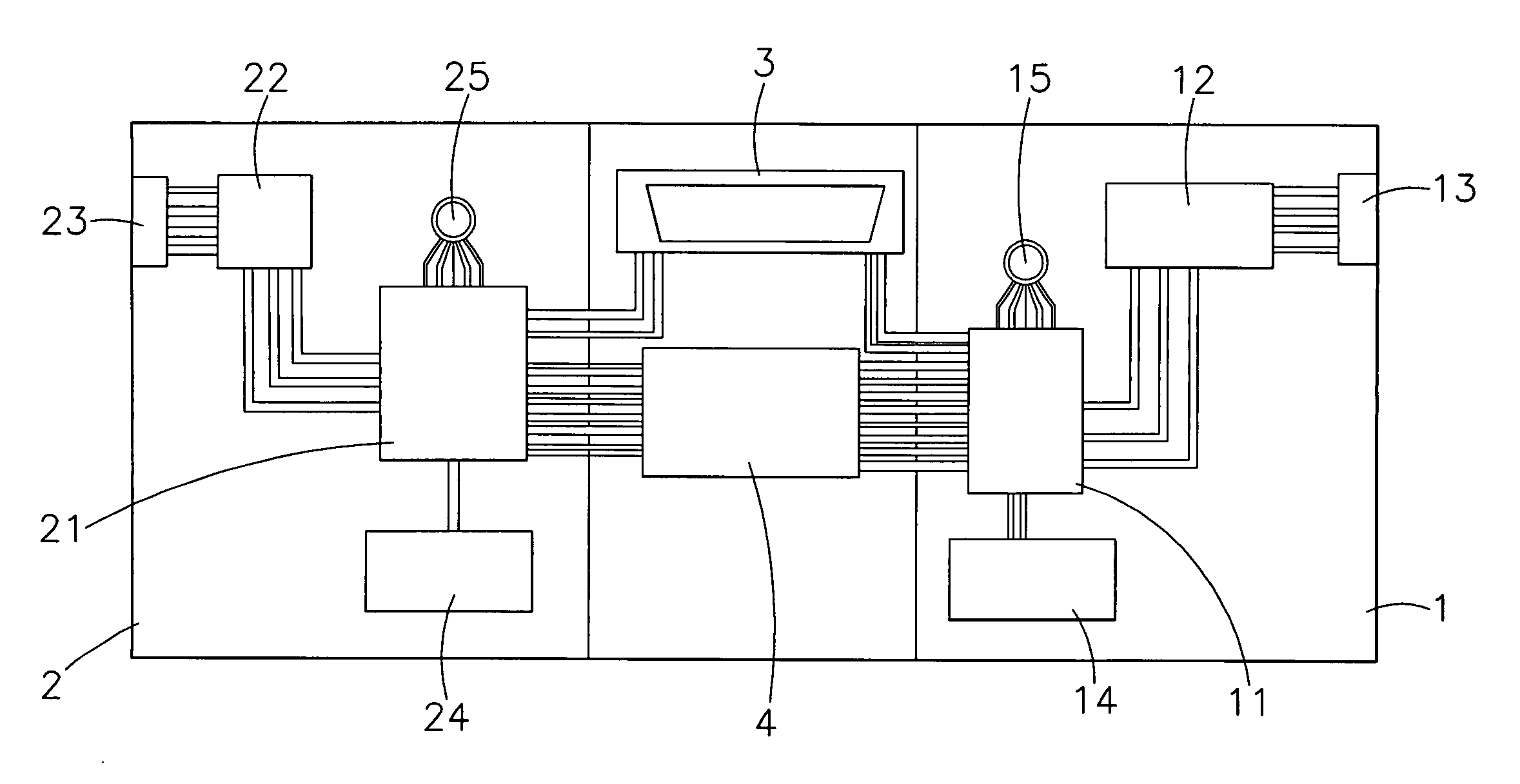

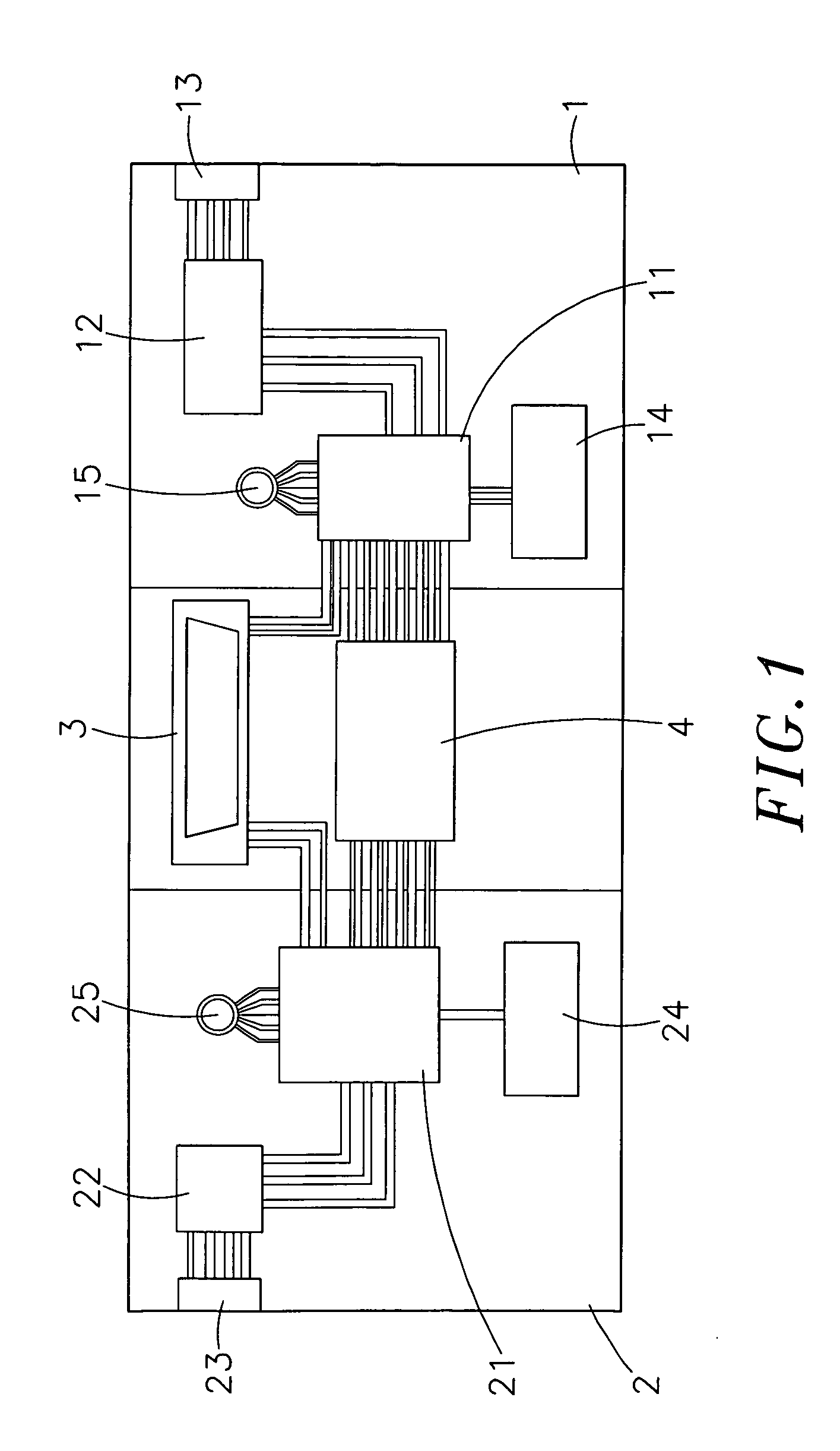

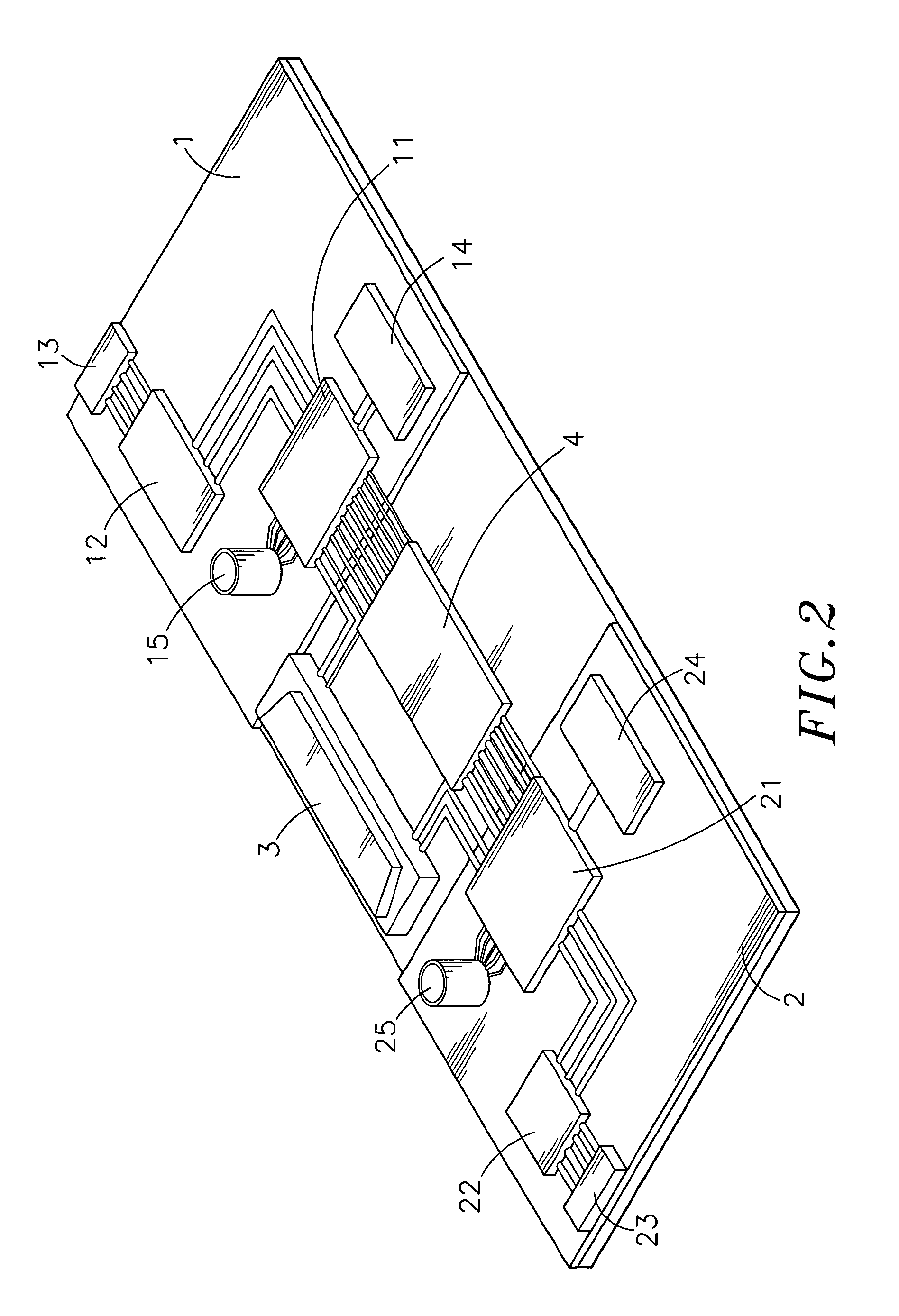

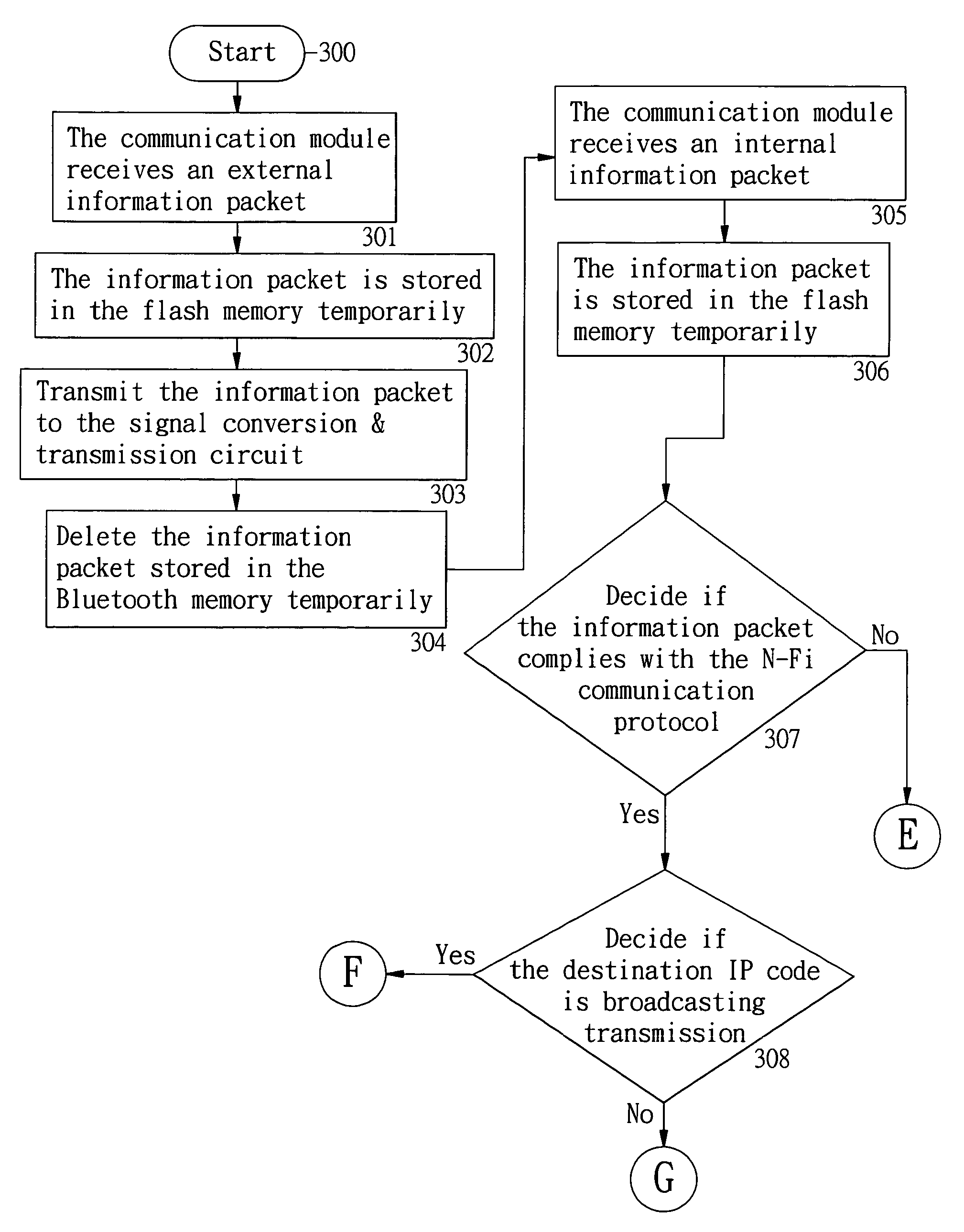

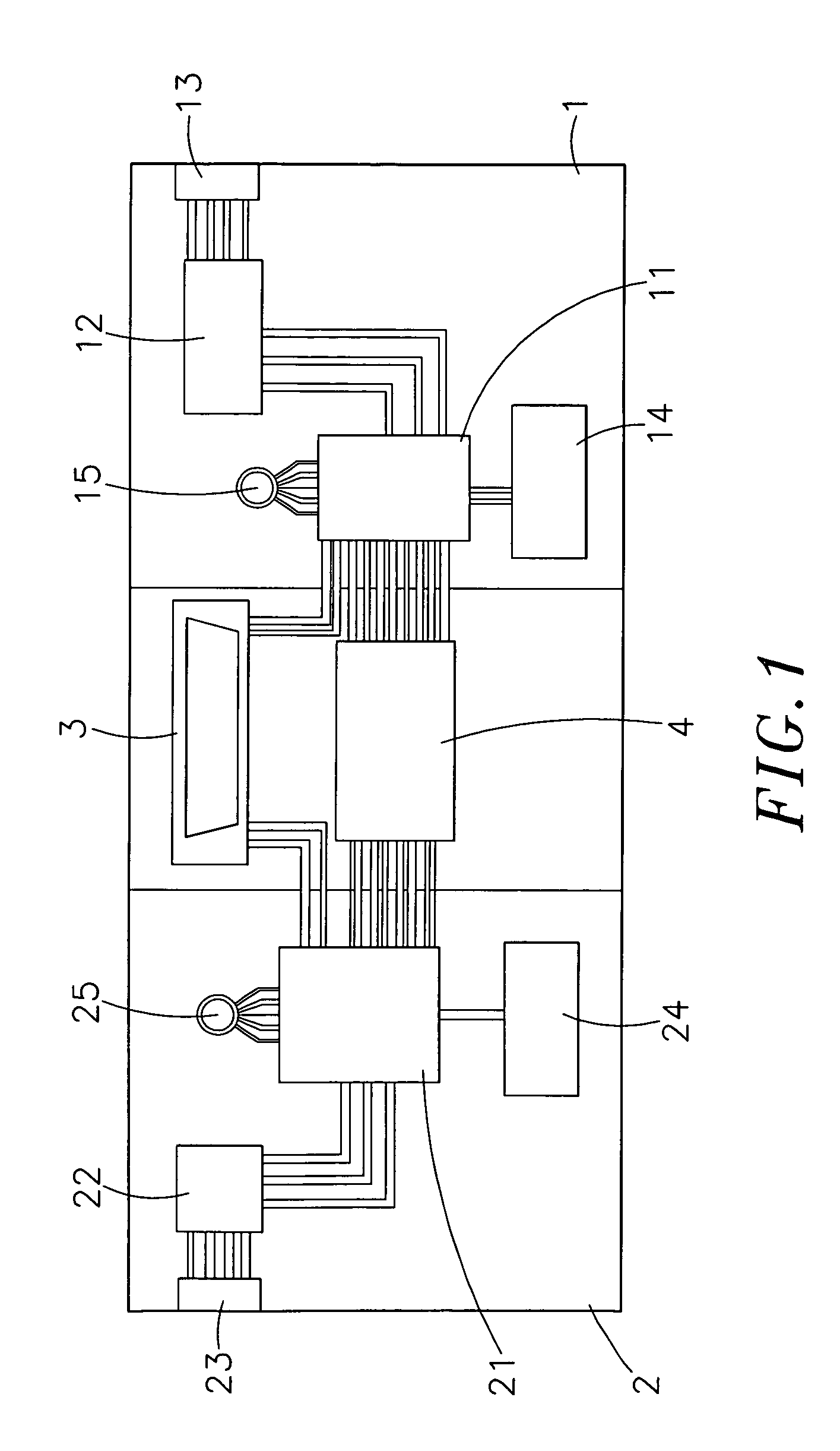

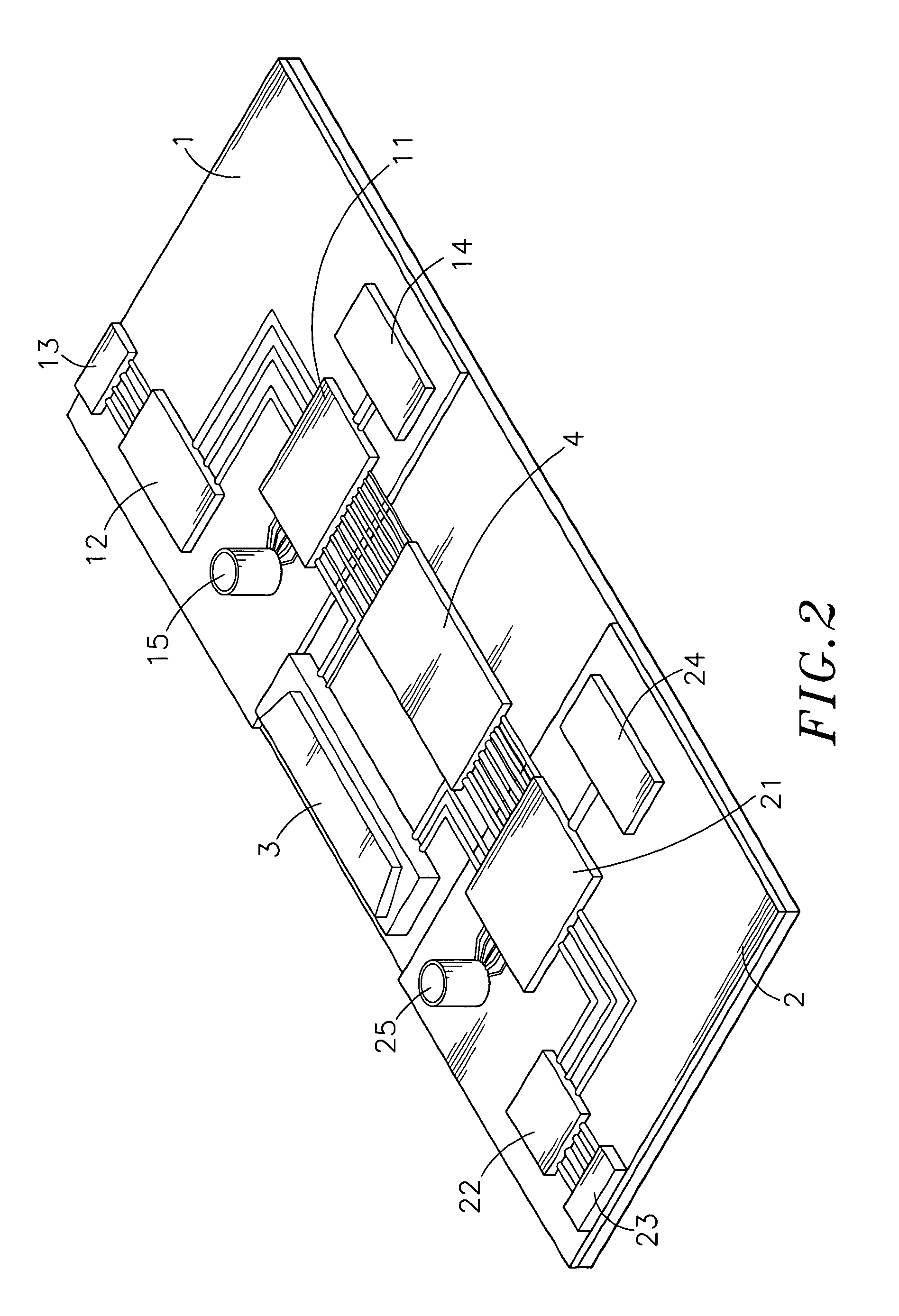

Near field communcation device

InactiveUS20110076943A1Continuous releaseNear-field transmissionNetwork topologiesCommunication deviceSignal transition

The present invention relates to a near field communication device containing a ZigBee communication module circuit linking with a Bluetooth communication module. A ZigBee module is equipped with a master central processing unit (CPU) to identify N-Fi communication protocol and enable wireless communication. The master CPU is connected with a communication chip to transmit or receive packets, and includes a ZigBee memory to store the packets temporarily. Besides, the master CPU is linked with a signal conversion / transmission circuit to enable internal exchange of information packets with the Bluetooth communication module. The Bluetooth communication module has a Bluetooth master CPU to control Bluetooth communication, and is connected with a Bluetooth communication chip to transmit and receive Bluetooth-based packets. Thus, the embedded Bluetooth module can be used to connect the electronic device that includes a ZigBee module to carry out transmission of NFC signals.

Owner:CHANG TANG HSIEN

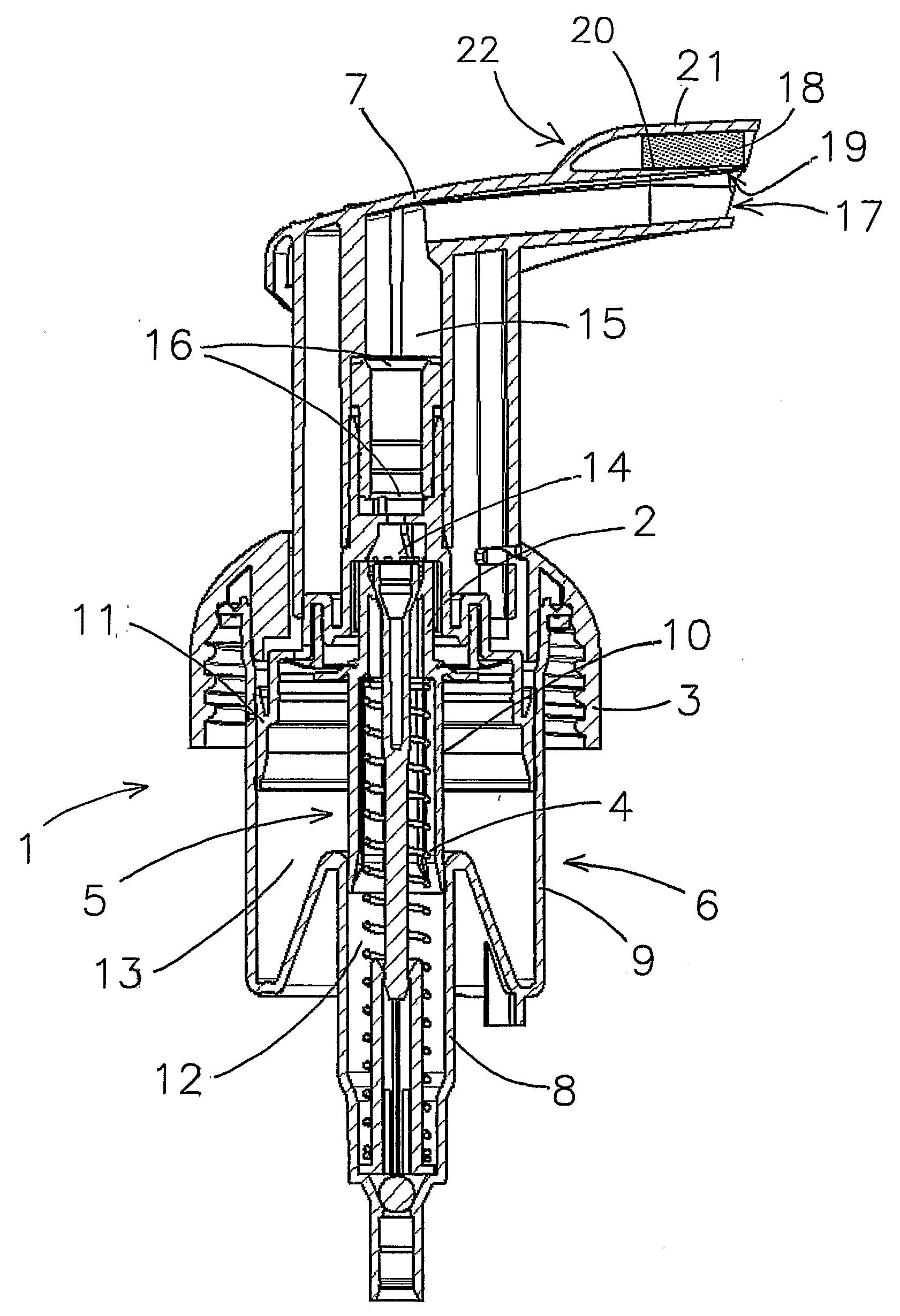

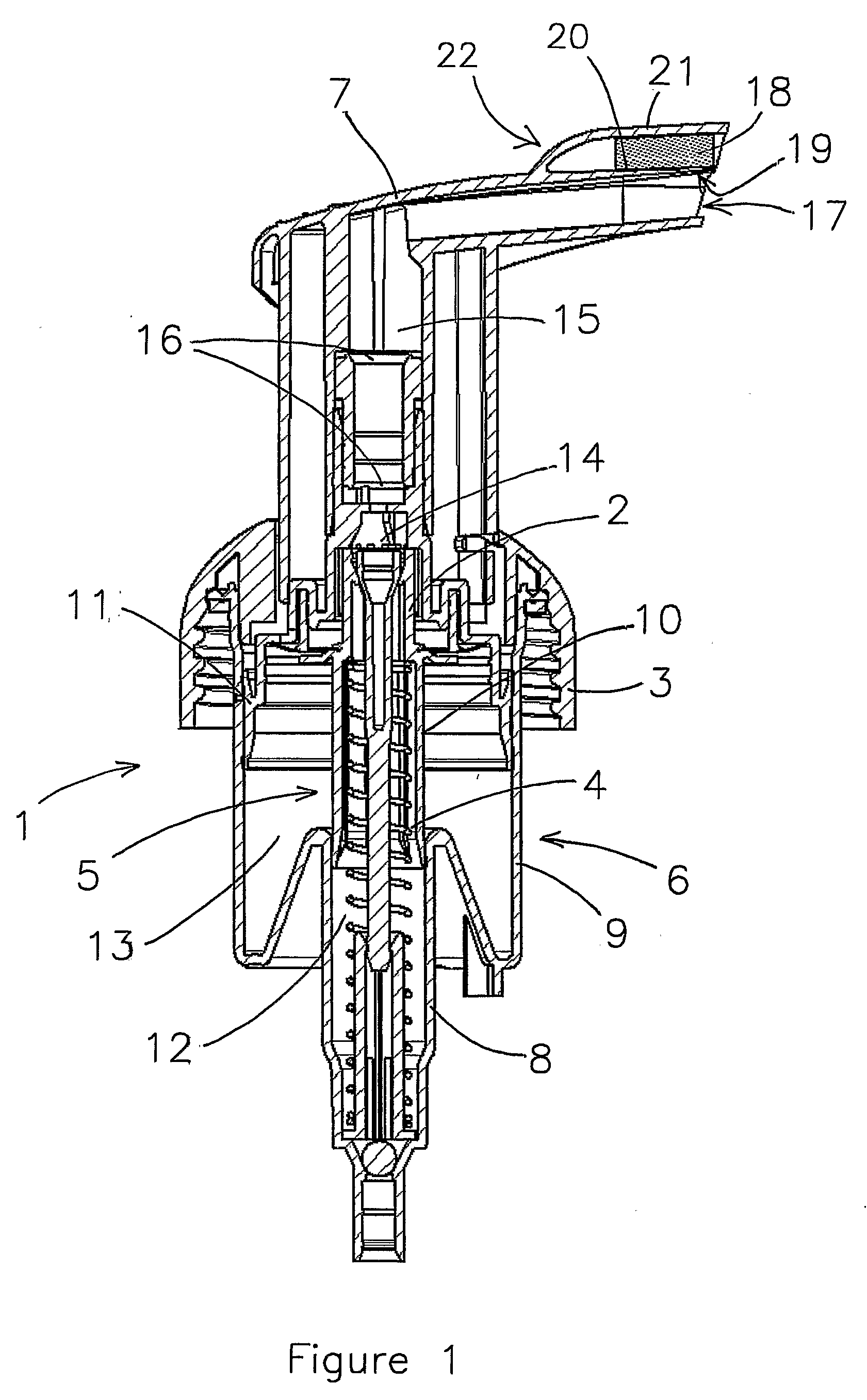

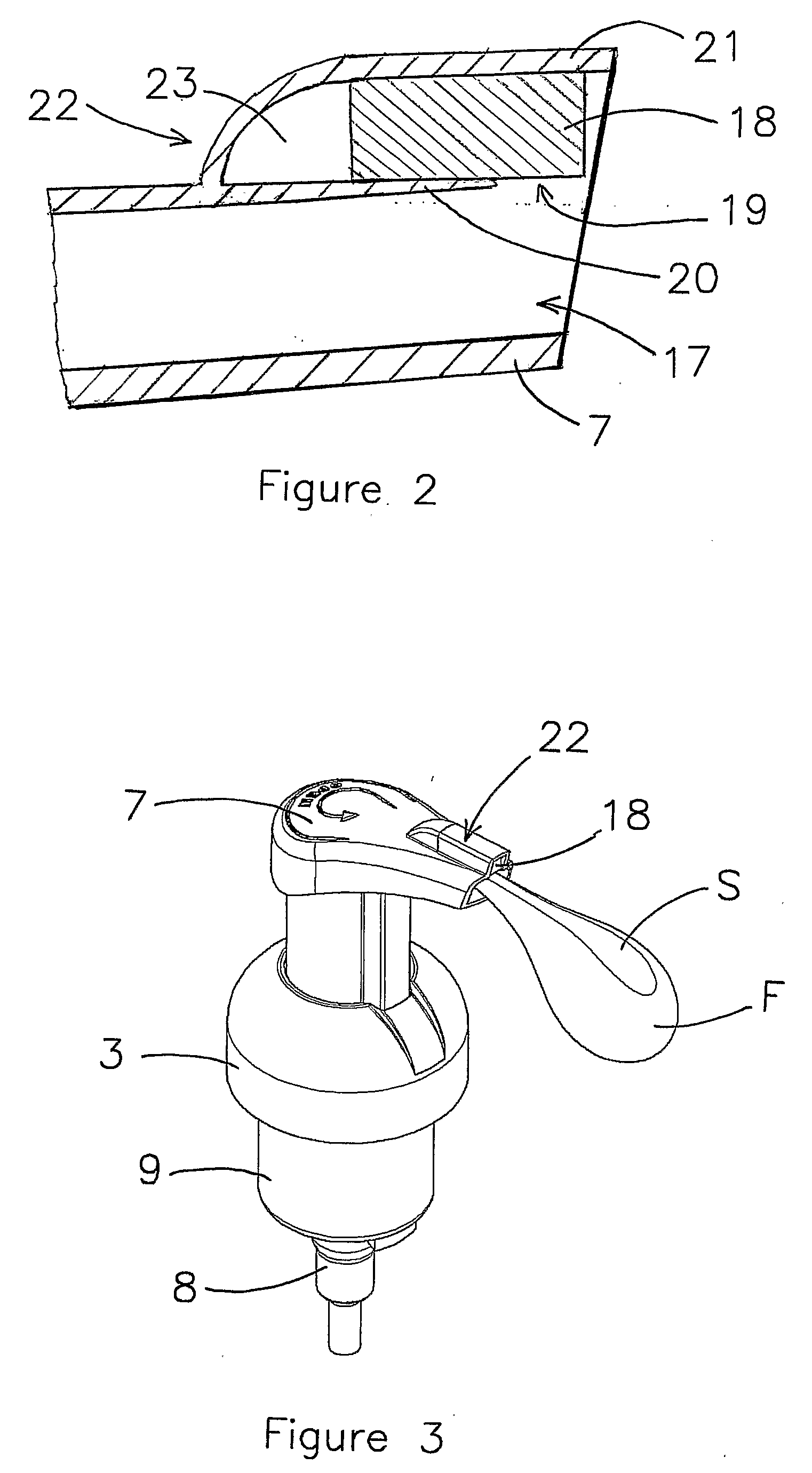

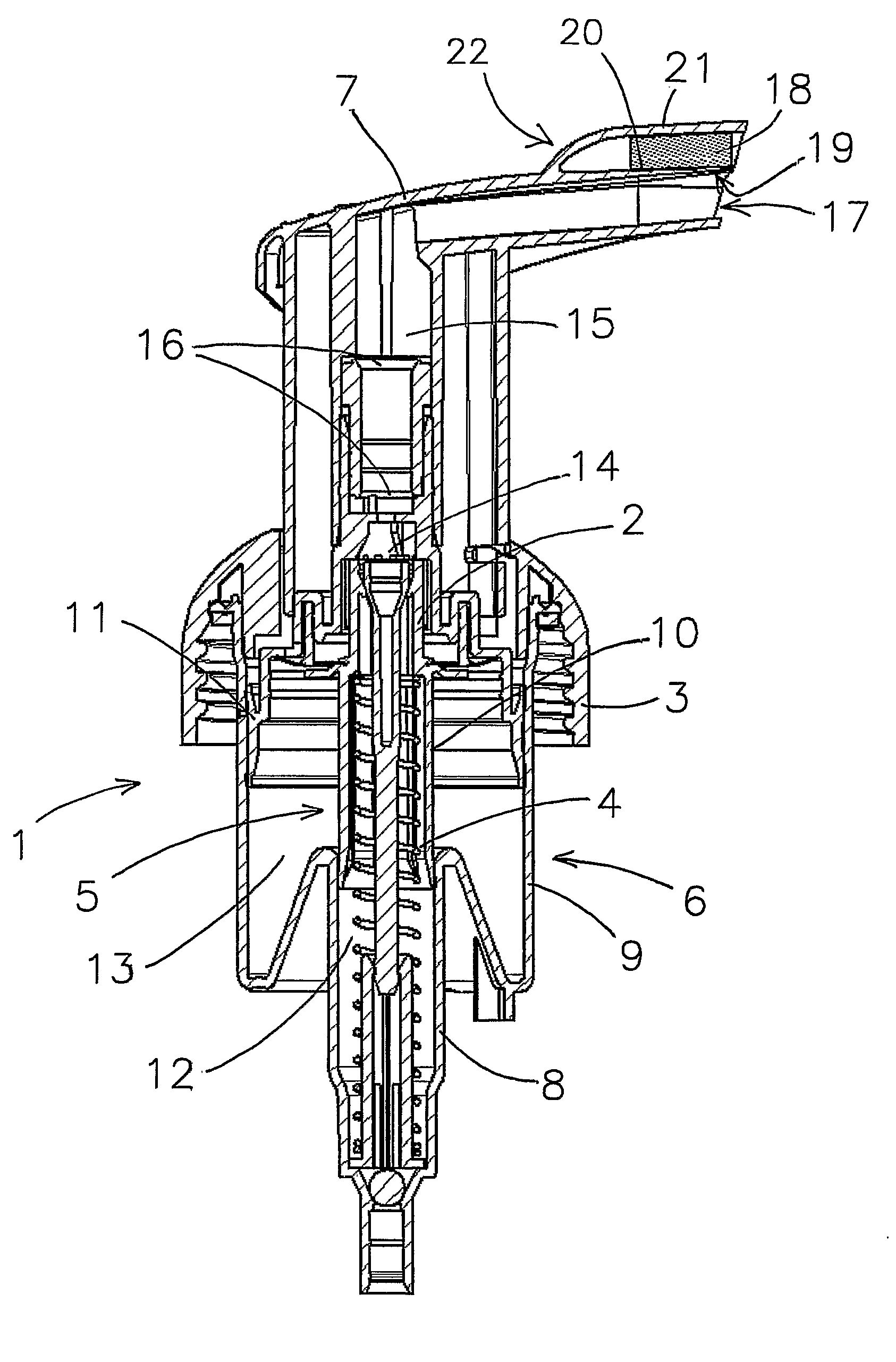

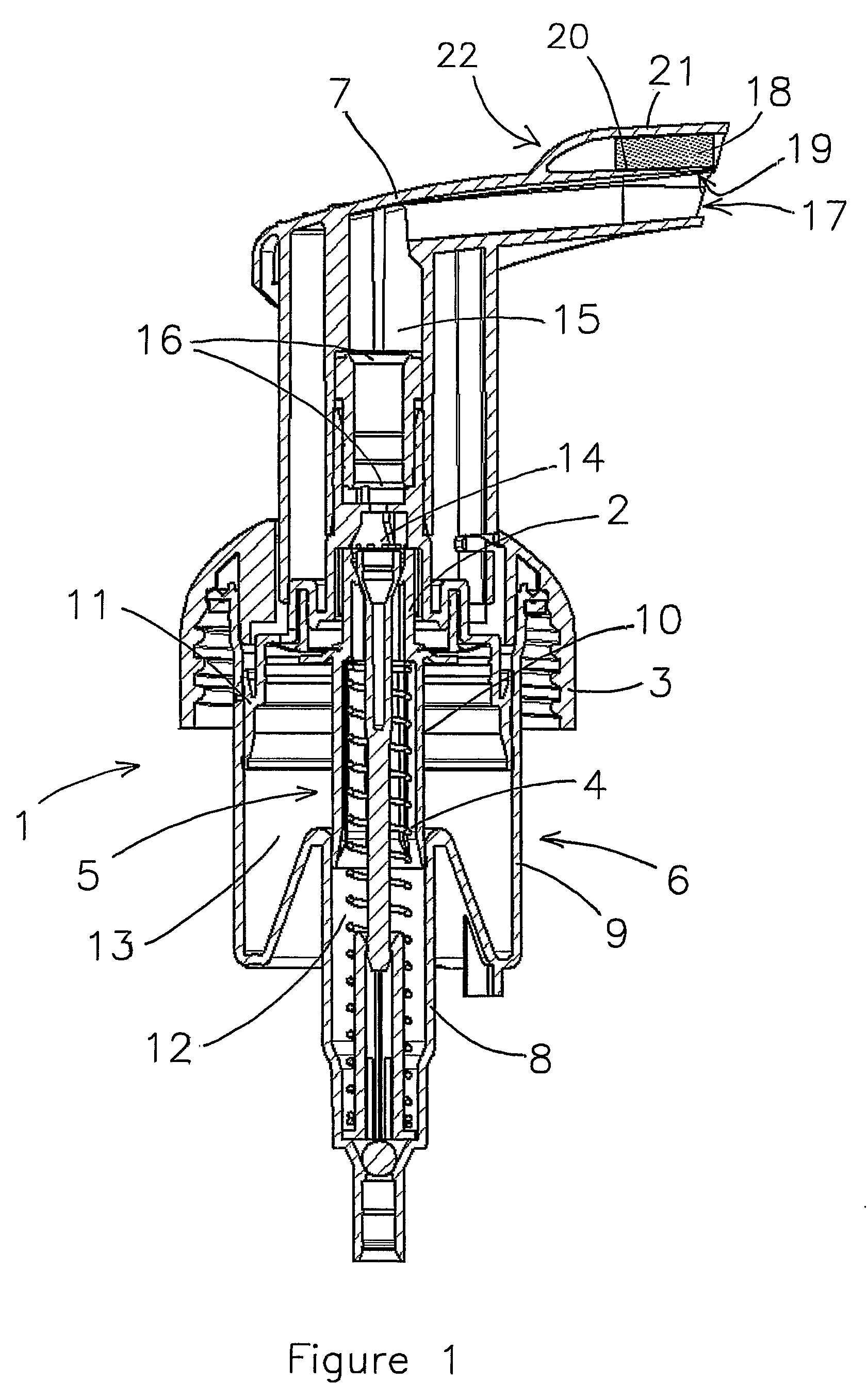

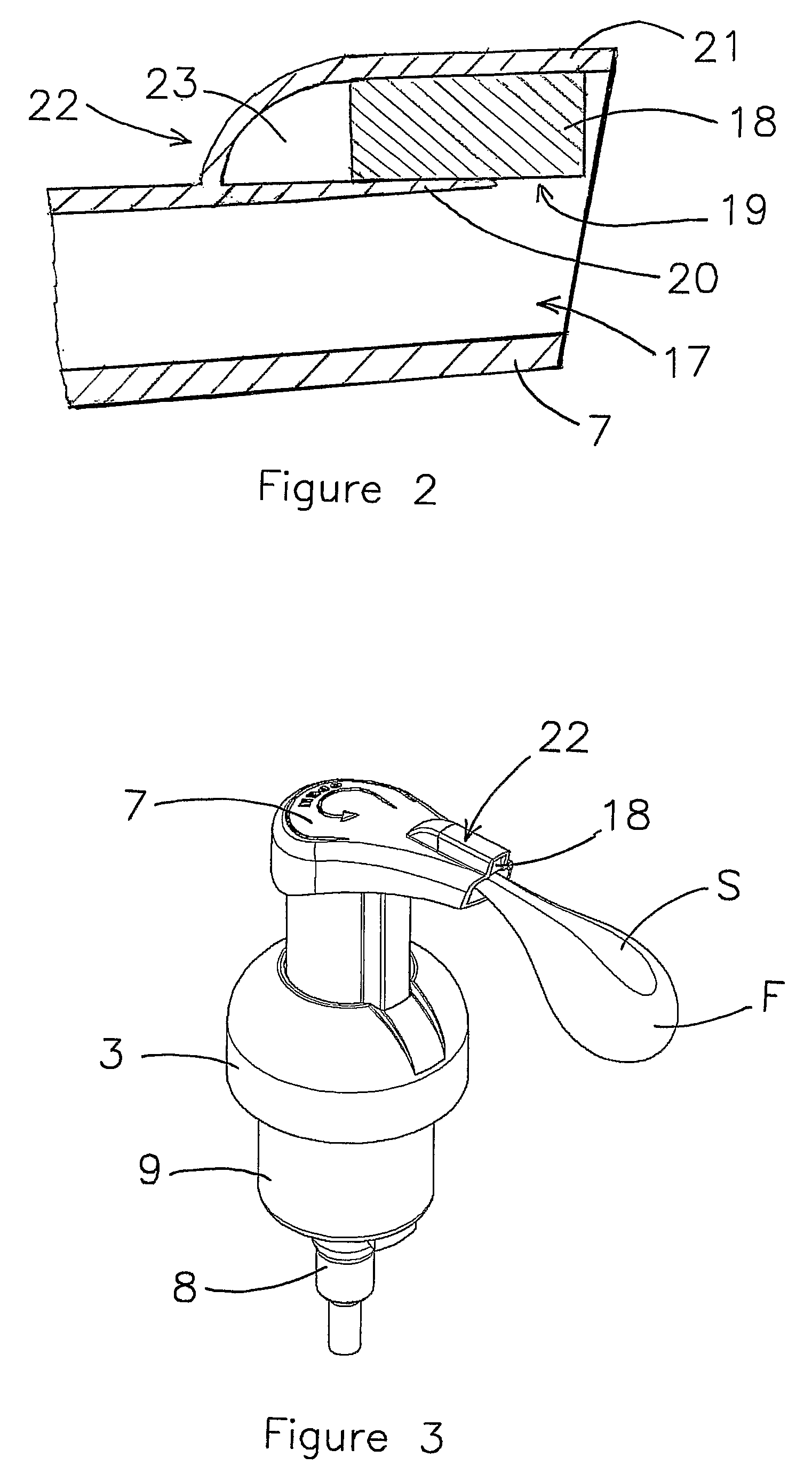

Foam Dispenser

ActiveUS20090236371A1Reduce foam volumeStrong tasteLiquid transferring devicesSingle-unit apparatusBiomedical engineeringEngineering

The present invention relates to a foam dispenser (1) having a pump assembly (2), comprising a liquid pumps (5), an air pump (6) and a common actuation part (7) to simultaneously actuate said liquid pump (5) and said air pump (6), wherein said pump assembly (2) comprises a dispensing channel (15) having a dispensing opening (17). The pump assembly (2) further comprises a porous matrix (18) which contains a dispensate material, a contact surface (19) of said porous matrix (18) being arranged in communication with said dispensing channel (15), so that foam being formed in said pump assembly (2) and dispensed through said dispensing channel (15) comes into contact with said contact surface (19) to introduce dispensate material released from said porous matrix (18) in said foam.

Owner:REXAM AIRSPRAY

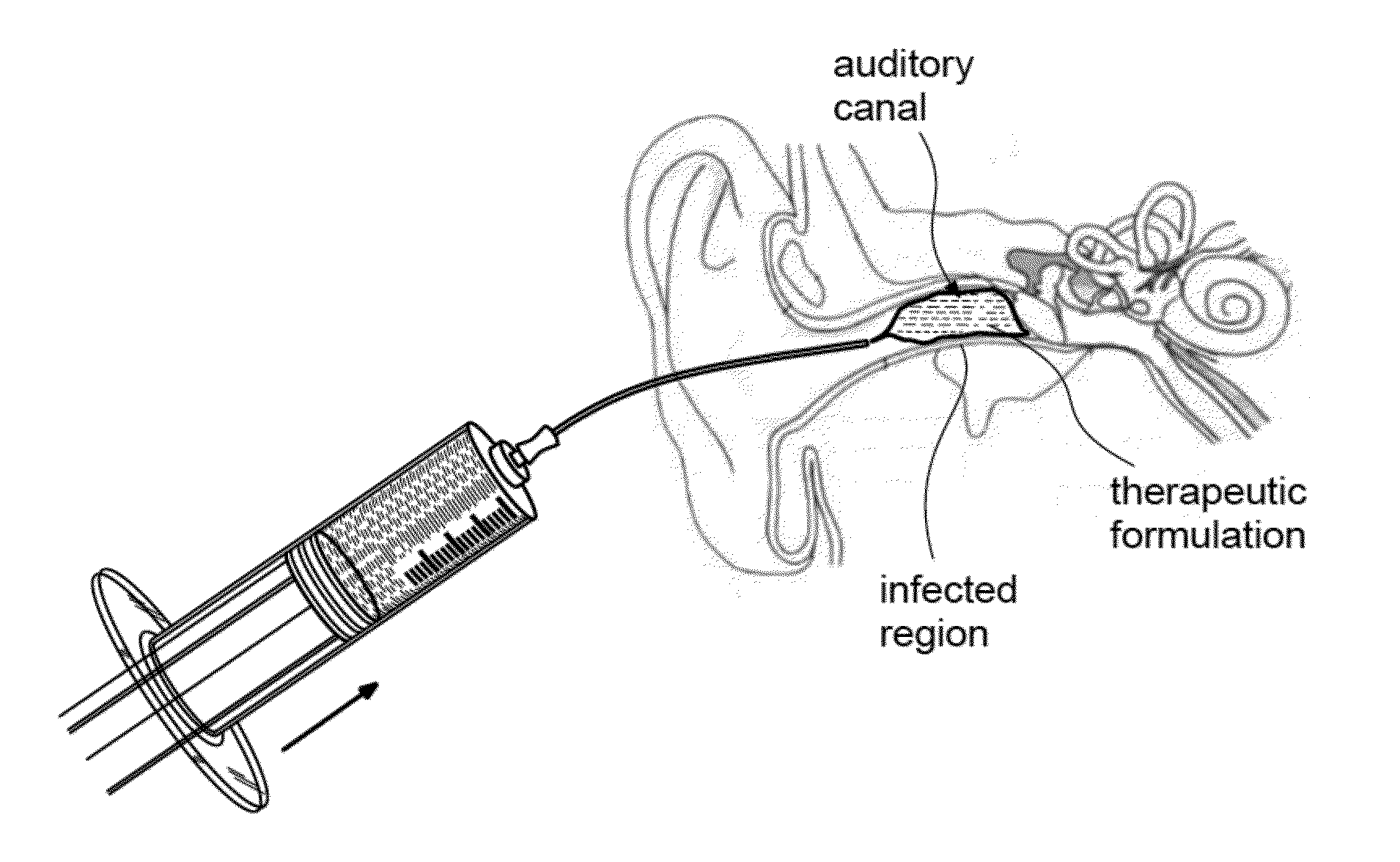

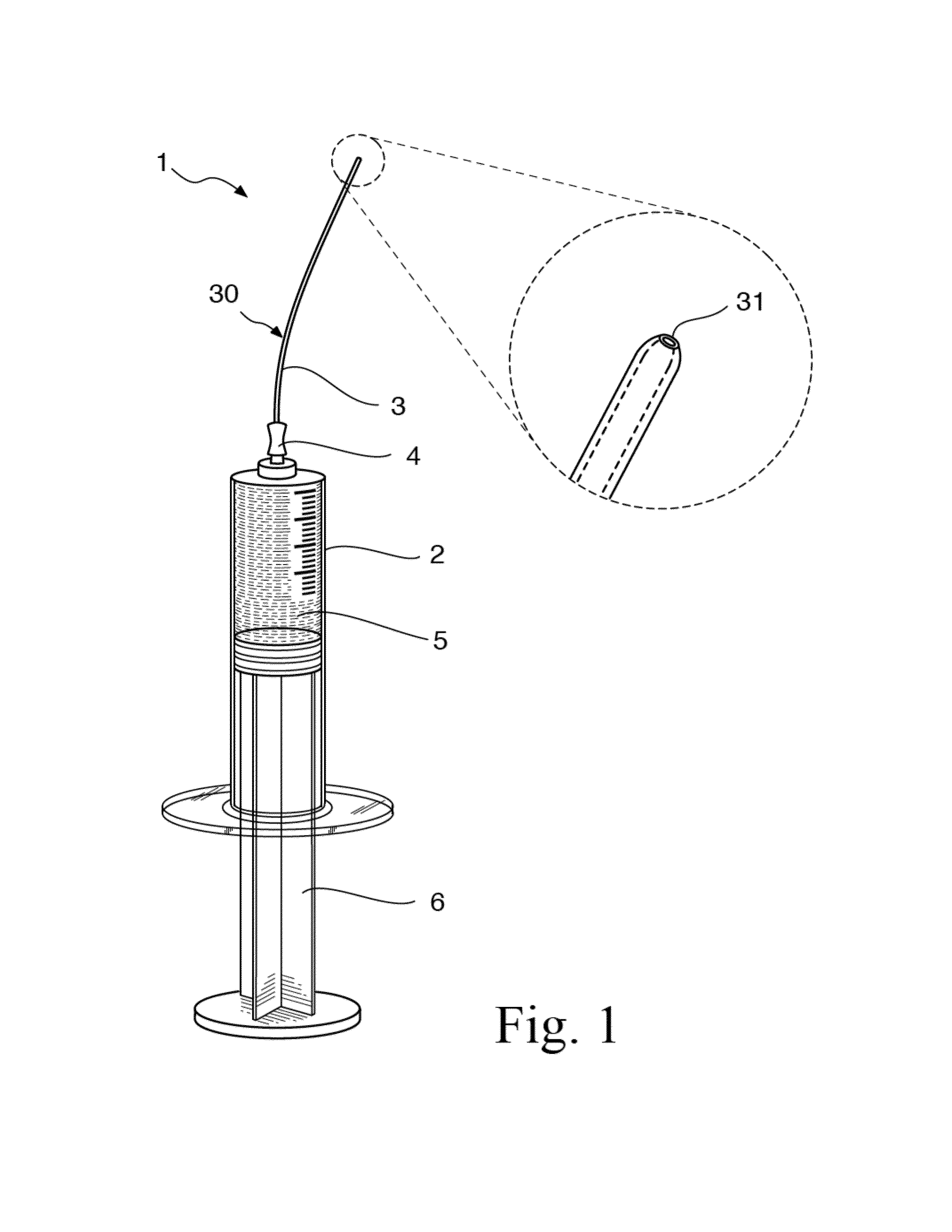

Otic formulations, methods and devices

ActiveUS20130178801A1Significant pain reliefLess bacterial community resistanceAntibacterial agentsBiocideThiocarbamateAntifungal

The present invention relates to a formulation and method for treating an ear infection, especially otomycosis and otitis externa, by administering a one-time only treatment comprising an antibiotic, and antifungal, and an anti-inflammatory in a thick, otic carrier. In one embodiment, the formulation comprises a therapeutically effective amount of active ingredients including a fluoroquinolone, a triazole antifungal, a thiocarbamate antifungal, a corticosteroid and a polyene antifungal, as well as a thickener such that the formulation, upon applying to the infected ear canal, gels and remains in the ear canal, continuously releasing the active ingredients for several days, achieving consistent complete (98-100%) clinical resolution of otomycosis and otitis externa in a single application.

Owner:METALCLAD

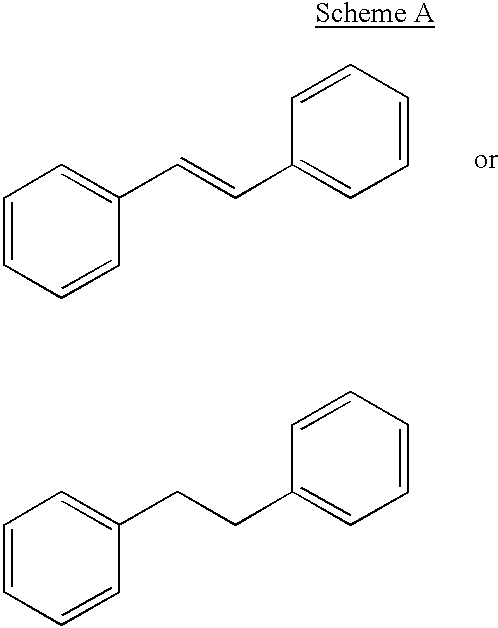

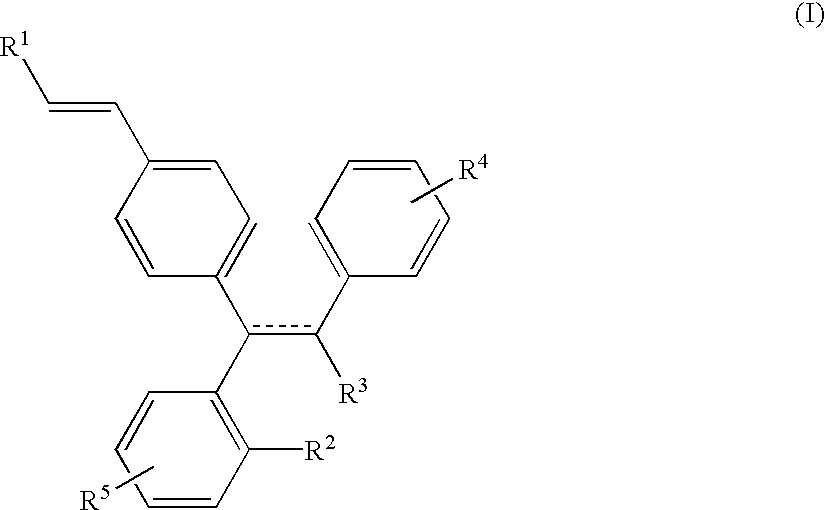

Selective estrogen receptor modulators

InactiveUS20030105148A1Improve patient acceptanceContinuous releaseBiocideNervous disorderSelective androgen receptor modulatorProstate cancer

The present invention provides, inter alia, triphenylethylene derivatives, such as, 3-{4-[6-(3-Methoxy-phenyl)-8,9-dihydro-7H-benzocyclohepten-5-yl]-phenyl}-acrylic acid, as selective estrogen receptor modulators. Also provided are methods for the treatment and / or prevention of estrogen stimulated diseases in mammals including breast, uterine, ovarian, prostrate and colon cancer, osteoporosis, cardiovascular disease, and benign proliferative disorders, as well as pharmaceutical compositions of the compounds of the present invention.

Owner:BRISTOL MYERS SQUIBB PHARMA CO

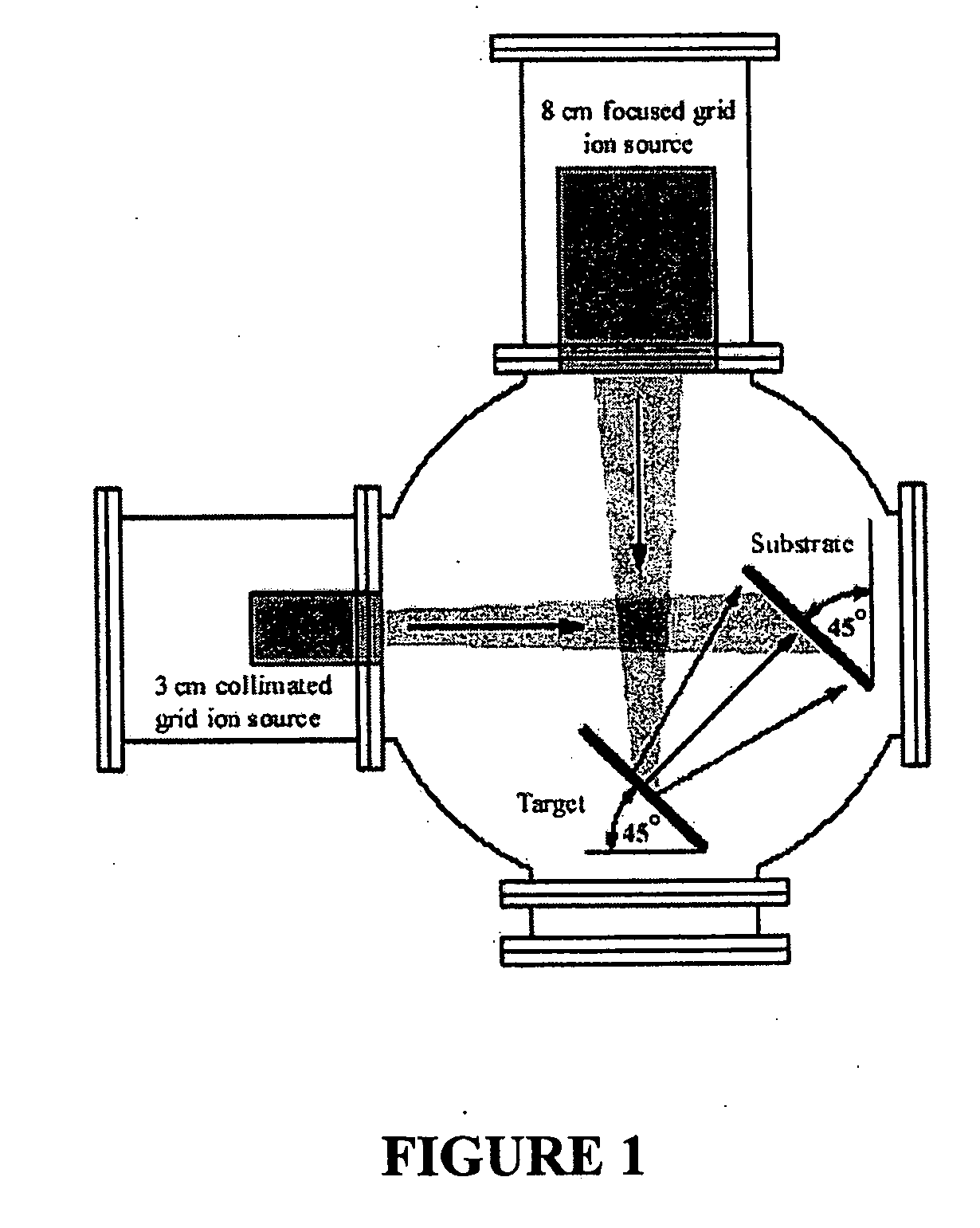

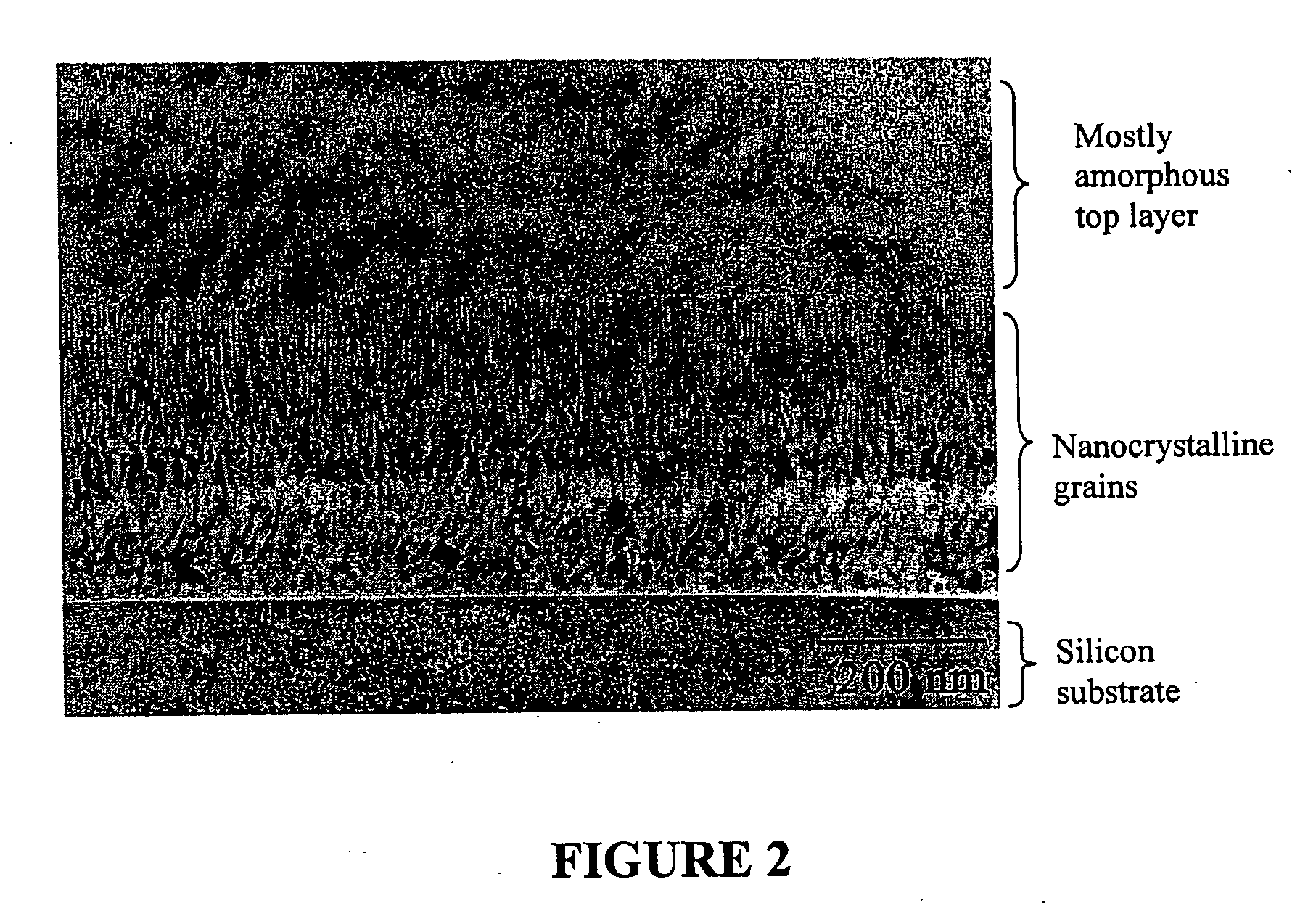

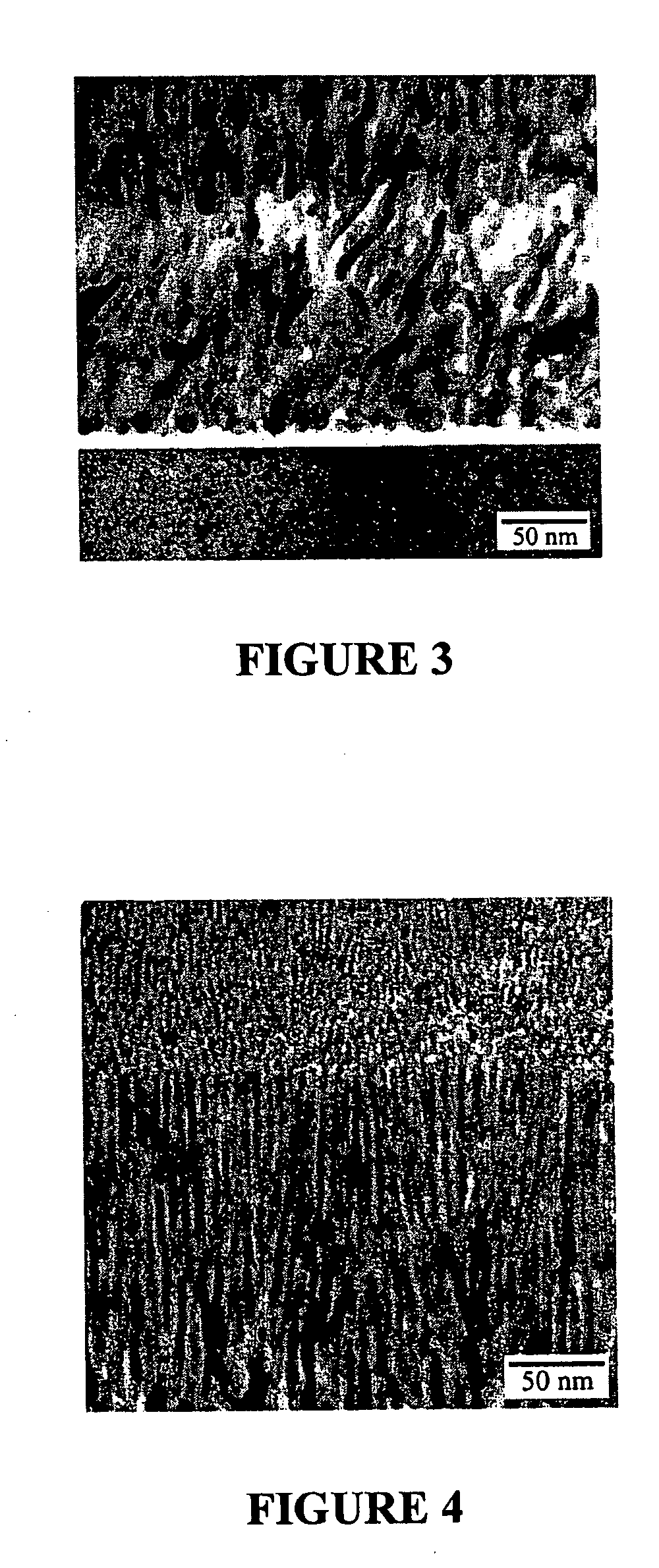

Functionally graded biocompatible coating and coated implant

ActiveUS20090304761A1Control releaseRate of releaseDental implantsBiocideCalcium phosphate coatingBiocompatible coating

The present invention provides a biocompatible coating comprising calcium phosphate that is functionally graded across the thickness of the coating. The coating, which preferably includes hydroxyapatite, is particularly useful for coating implants, such as dental or orthopedic implants. The functionally graded coating is generally crystalline near the interface with the surface of the implant, with crystallinity and crystal diameter decreasing toward the outer layer of the coating. The invention further provides methods for preparing a coated implant comprising a functionally graded calcium phosphate coating thereon. Furthermore, an antimicrobial agent can be dispersed within the calcium phosphate coating at discrete locations to provide for a coating with tailored release of the antimicrobial agent.

Owner:NORTH CAROLINA STATE UNIV

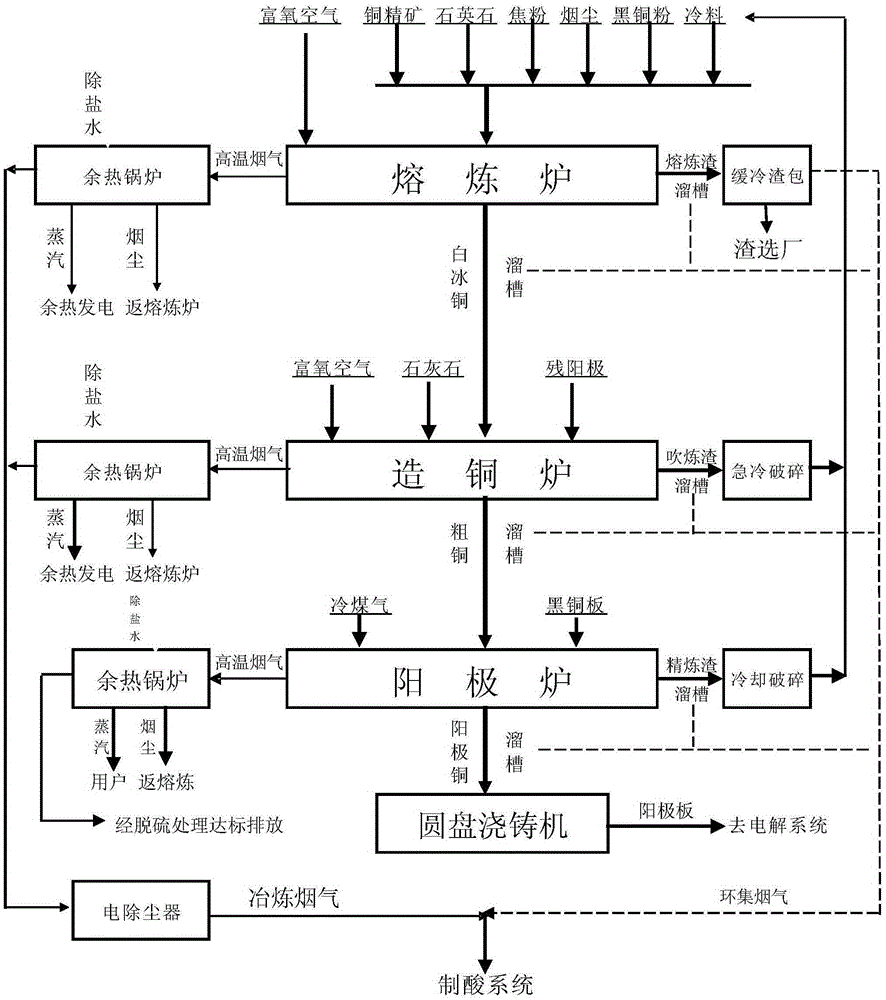

Three continuous furnace technology for continuous production of anode copper with copper concentrate

InactiveCN105238938AReduce metallurgical equipment and plant investmentAvoid sensible heat lossRotary drum furnacesCrucible furnacesSlagContinuous operation

The invention provides a three continuous furnace technology for continuous production of anode copper with copper concentrate. The technology is particularly characterized in that a smelting furnace, a copper making furnace and an anode furnace are in tandem arrangement successively, and kilns are connected by chutes. The technology comprises the steps that the copper concentrate and flux enter the smelting furnace and react with oxygen-enriched air to generate white matte, smelting slag and high-temperature smoke; the smelting slag overflows continuously; a slow cooling slag ladle is put through the chutes for floatation and depletion; the white matte continuously flows into the copper making furnace via siphon through the chute and reacts with the flux and the oxygen-enriched air to generate raw copper, copper converting slag and high-temperature smoke; the raw copper continuously or intermittently flows into the anode furnace via siphon through the chute; the anode furnace alternately operates and produces the anode copper via oxygenation and reduction; and the converting slag is regularly discharged, chilled, broken and returned to the smelting furnace. The technology achieves continuous operation of smelting production of the raw copper with the copper concentrate.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

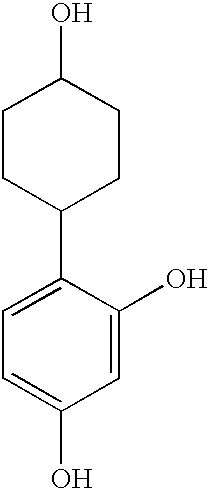

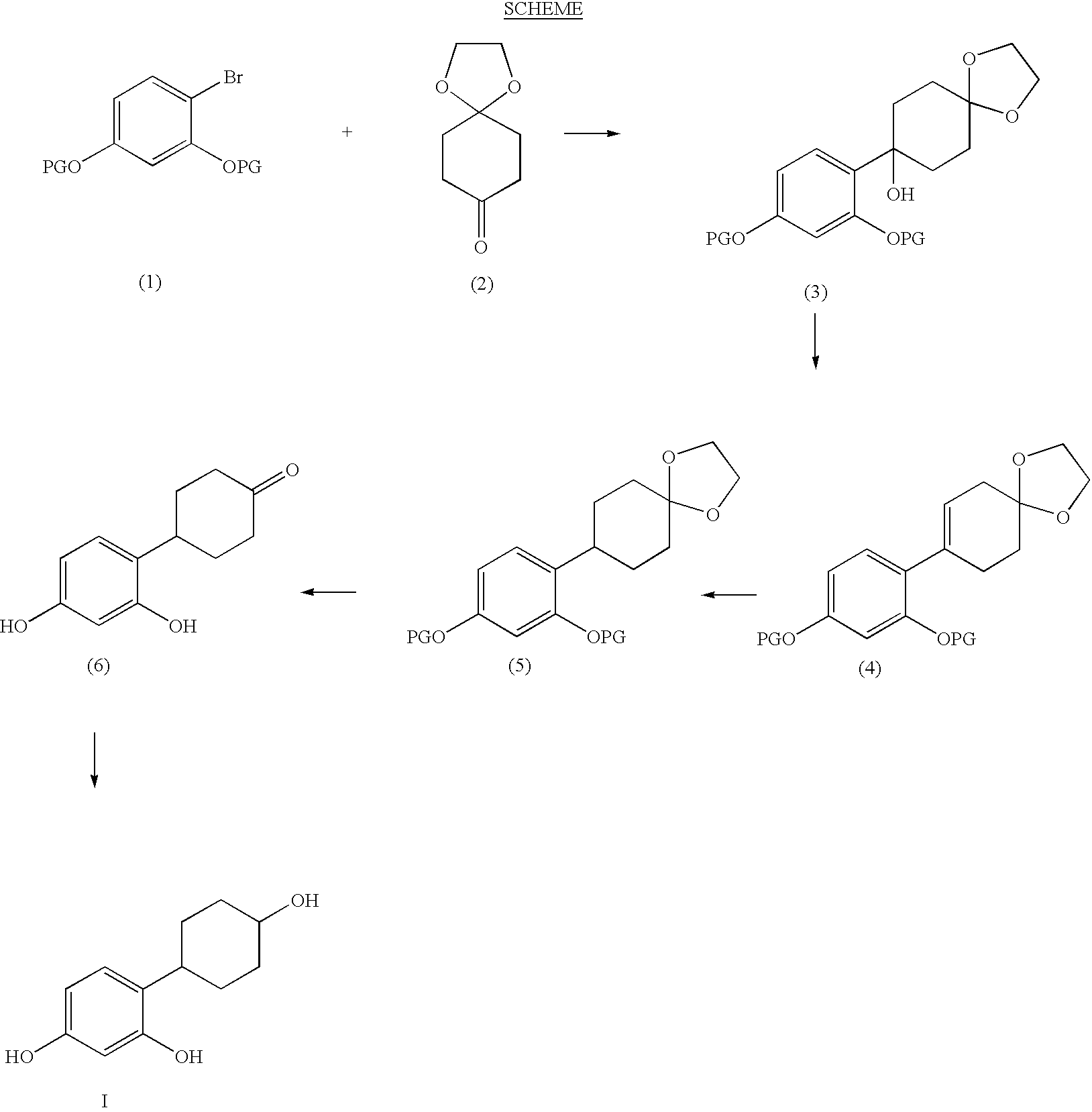

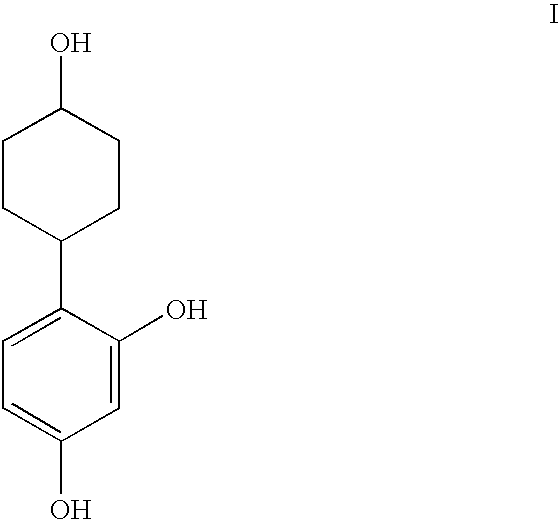

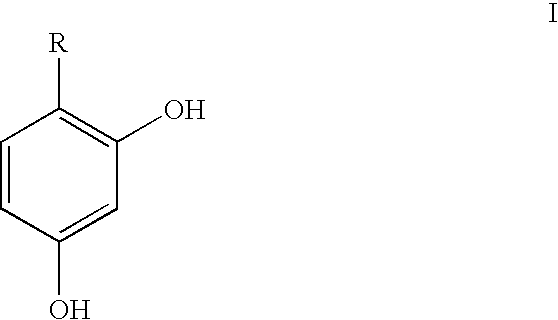

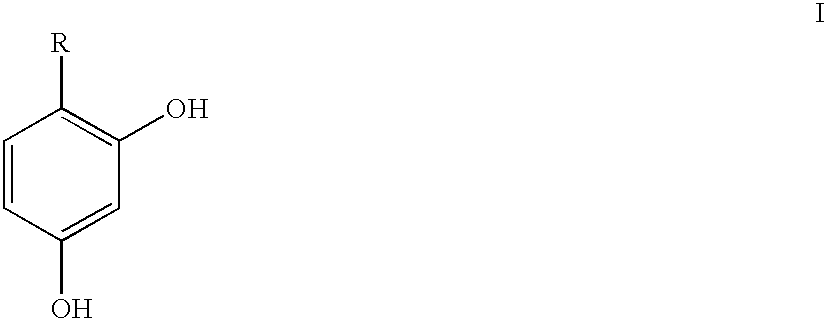

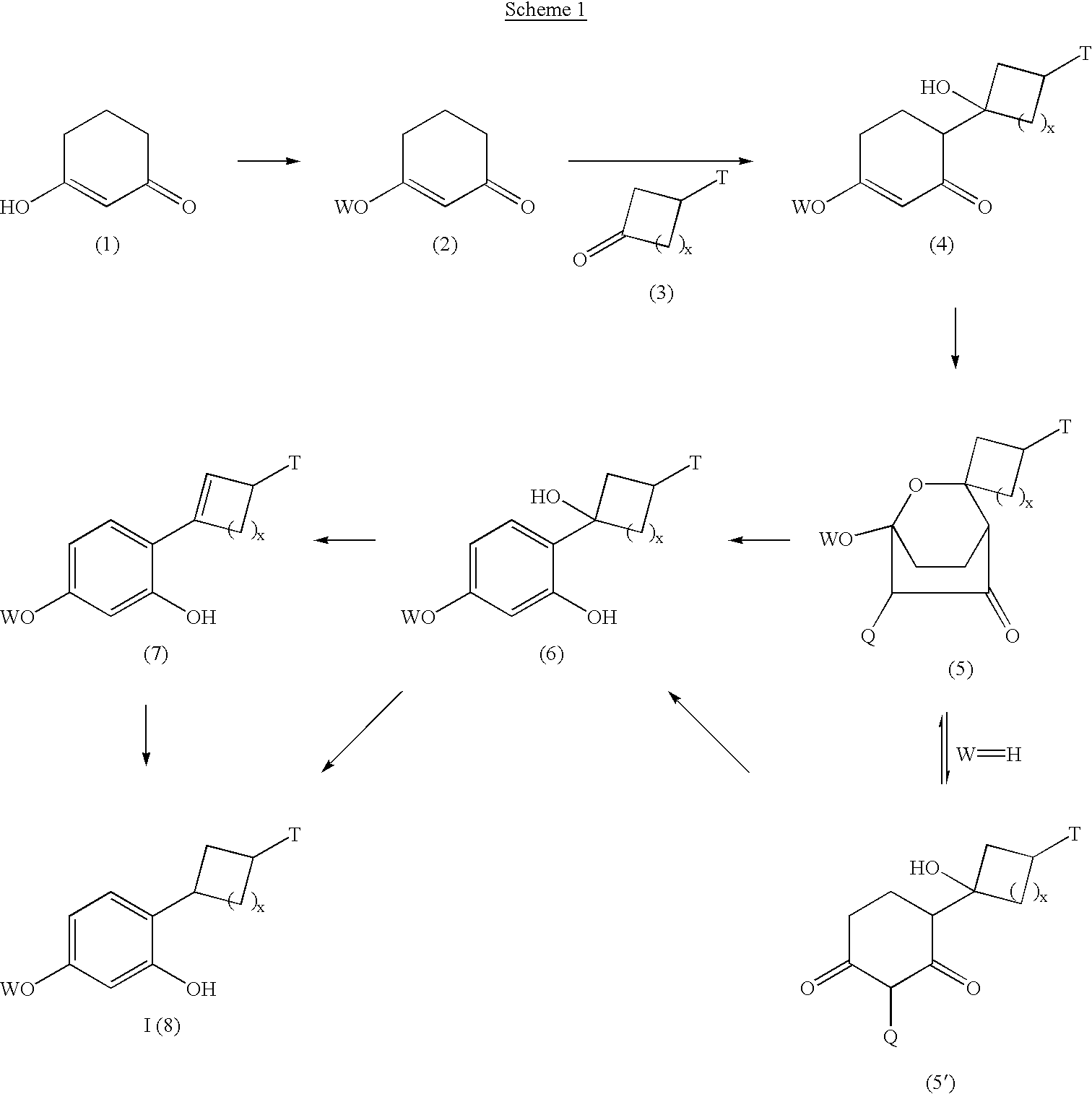

Resorcinol composition

InactiveUS20020155075A1Prevent repigmentationEnhance ability to reduce skin melanin skinCosmetic preparationsHair cosmeticsMedicineCyclohexanol

The present invention relates to the use of a resorcinol derivative, i.e., 4-(2,4-dihydroxyphenyl)cyclohexanol, or a pharmaceutically acceptable salt thereof, as a skin lightening agent.

Owner:PFIZER INC

Differentially Expressed Nucleic Acids in the Blood-Brain Barrier Under Inflammatory Conditions

ActiveUS20080213179A1Improve permeabilityHigh activityOrganic active ingredientsPeptide/protein ingredientsMammalBiological activation

The present invention relates to nucleic acids and polypeptides encoded thereby, whose expression is modulated in brain microvascular endothelial cells undergoing early dynamic inflammation-induced changes in blood-brain barrier functionality. Such polypeptides are referred to as lipopolysaccharide-sensitive (LPSS) polypeptides herein. These nucleic acids and polypeptides may be useful in methods for controlling blood-brain barrier properties in mammals in need of such biological effects. This includes the diagnosis and treatment of disturbances in the blood-brain / retina barrier, brain (including the eye) disorders, as well as peripheral vascular disorders. Additionally, the invention relates to the use of anti-LPSS polypeptide antibodies or ligands as diagnostic probes, as blood-brain barrier targeting agents or as therapeutic agents as well as the use of ligands or modulators of expression, activation or bioactivity of LPSS polypeptides as diagnostic probes, therapeutic agents or drug delivery enhancers.

Owner:2 BBB MEDICINES BV

Resorcinol derivatives

InactiveUS20030190298A1Easy to prepareEasy to getUrea derivatives preparationCosmetic preparationsStereochemistryResorcinol

The present invention relates to certain resorcinol derivatives and their use as skin lightening agents.

Owner:PFIZER INC

Planting method of camphor trees with high survival rate and high quality

InactiveCN106857135ASimple structurePrevent compactionCalcareous fertilisersMagnesium fertilisersMain branchFarmyard manure

The invention discloses a planting method of camphor trees with a high survival rate and a high quality. The method comprises the following steps: S1, digging holes to plant camphor tree seedlings, applying a base fertilizer into each of the planting holes, then filling the planting holes with nutritional soil and planting soil of an original nursery stock planting land, and sufficiently watering rooting water; S2, applying an organic compound fertilizer in March to April for maiden trees which are planted 1-2 years ago, fertilizing the maiden trees in the first ten days and middle ten days of May separately with 45% potassium sulphate compound fertilizer every time, applying urea in the middle ten days of June and July, applying the 45% potassium sulphate compound fertilizer in the last ten days of August, digging deep holes in October to fertilize farmyard manure and calcium magnesium phosphate fertilizer; applying a germinating fertilizer before germination for adult trees in the middle ten days of February, and applying an organic release control fertilizer; and S3, leaving four main branches for every adult tree which is 2-3m high, carving sprouts on the tops of the branches in spring, primarily pinching in summer if being branched at 4cm, and pinching for the second time if being branched at 10cm, and starting to stretch the branches in June. According to the planting method of camphor trees, disclosed by the invention, the quality and the survival rate of the camphor trees can be effectively improved.

Owner:洪兵

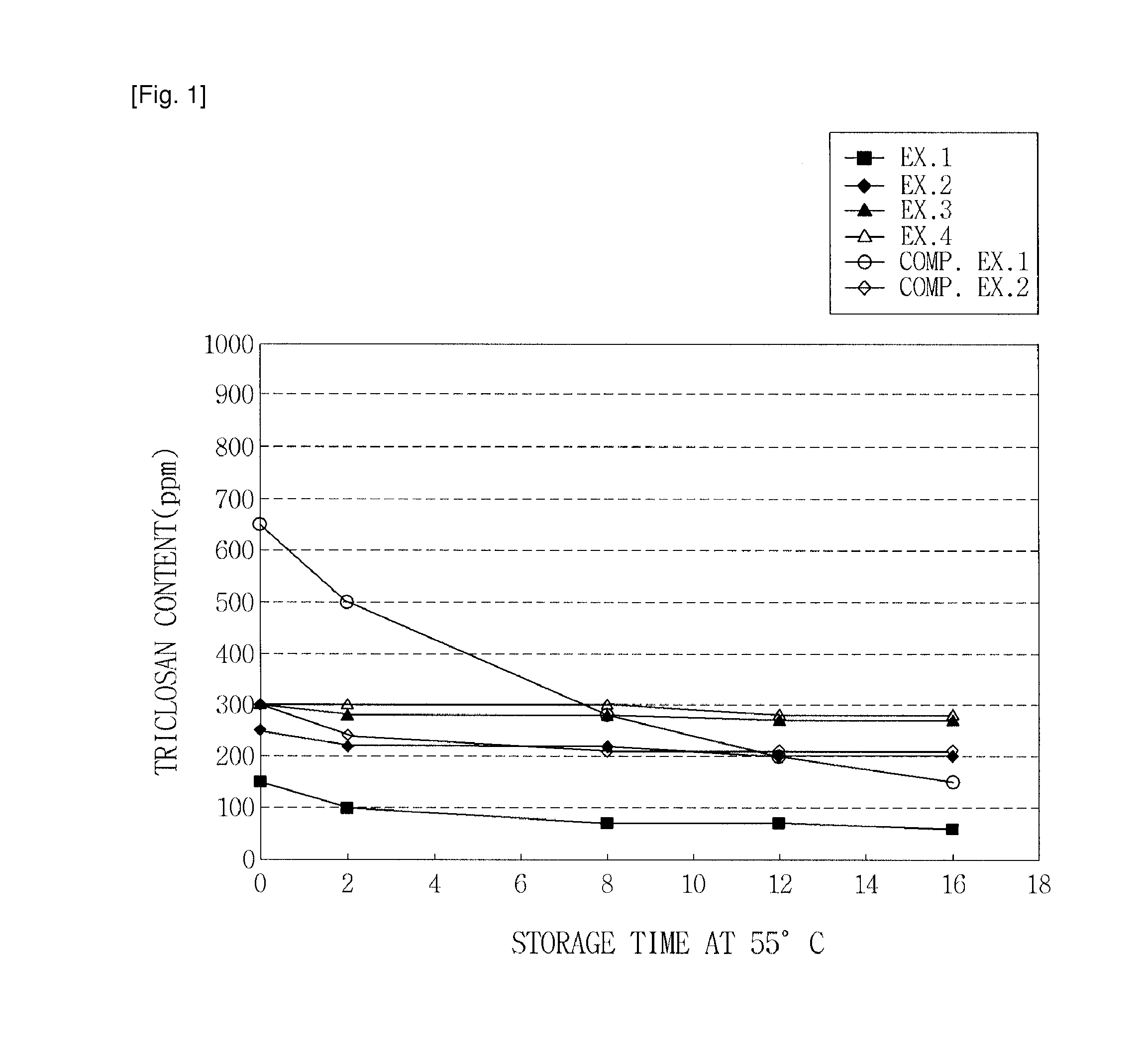

Matrix type antimicrobial vehicle and manufacturing method thereof

ActiveUS20130280313A1Continuous releaseMaintain levelBiocideLayered productsAntimicrobialEngineering

Owner:SAMYANG HLDG CORP

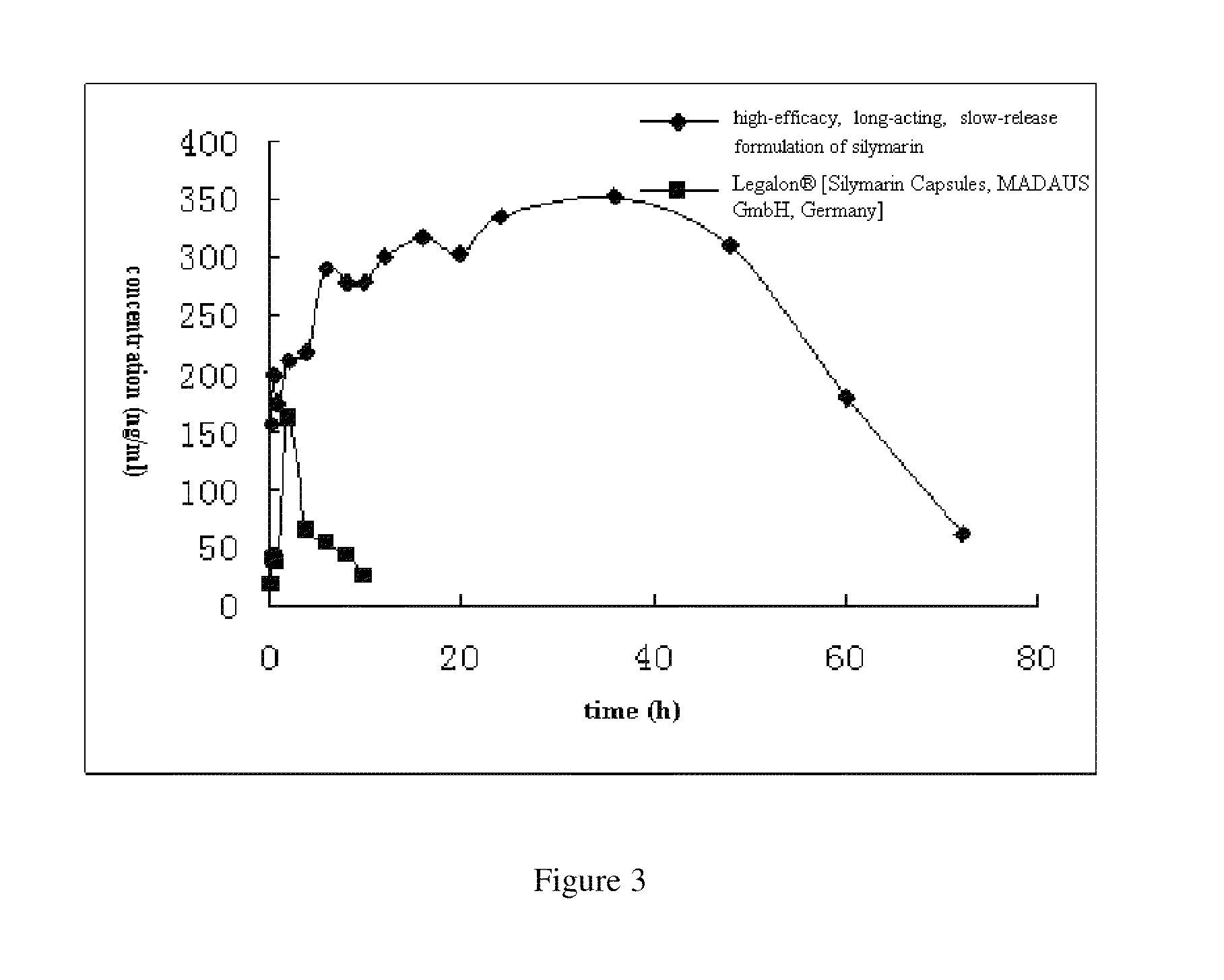

formulation of silymarin with high efficacy and prolonged action and the preparation method thereof

ActiveUS20110201680A1Promote absorptionLarge specific surface areaPowder deliveryBiocideAcrylic resinHalf-life

A high-efficacy, long-acting formulation of silymarin, comprising silymarin solid dispersion, silymarin-loaded silica nanoparticles, slow-release matrix material and release enhancer, wherein the mass ratio of these components is silymarin solid dispersion:silymarin-loaded silica nanoparticles:slow-release matrix material:release enhancer=1:0.5˜1.25:0.1˜0.3:0.1˜0.3; the drug loading rate of the said silymarin-loaded silica nanoparticles is 51.95%-52.87%; the said silymarin solid dispersion contains povidone K30, soybean lecithin and acrylic resin IV, and the mass ratio between silymarin and other medical accessories in silymarin solid dispersion is silymarin:povidone K30:soybean lecithin:acrylic resin IV=1:1˜3:0.3˜0.8:0.2˜0.5. Compared with the existing formulations, the half life of the high-efficacy, long-acting formulation of silymarin disclosed in this invention is 2.3 times longer while the mean residence time (MRT) of which is 9.94 times longer; when tested in vivo in Beagle dogs, this new formulation of silymarin presents a smoother concentration-time curve and reaches a continuous release for 72 hours. This invention discloses its preparation method.

Owner:JIANGSU UNIV

Resorcinol derivatives

InactiveUS20020114770A1Easy to prepareEasy to getCosmetic preparationsHair cosmeticsStereochemistryResorcinol

The present invention relates to certain resorcinol derivatives and their use as skin lightening agents.

Owner:PFIZER INC +1

Near field communcation device

InactiveUS8116682B2Continuous releaseNear-field transmissionInterconnection arrangementsCommunication deviceSignal transition

The present invention relates to a near field communication device containing a ZigBee communication module circuit linking with a Bluetooth communication module. A ZigBee module is equipped with a master central processing unit (CPU) to identify N-Fi communication protocol and enable wireless communication. The master CPU is connected with a communication chip to transmit or receive packets, and includes a ZigBee memory to store the packets temporarily. Besides, the master CPU is linked with a signal conversion / transmission circuit to enable internal exchange of information packets with the Bluetooth communication module. The Bluetooth communication module has a Bluetooth master CPU to control Bluetooth communication, and is connected with a Bluetooth communication chip to transmit and receive Bluetooth-based packets. Thus, the embedded Bluetooth module can be used to connect the electronic device that includes a ZigBee module to carry out transmission of NFC signals.

Owner:CHANG TANG HSIEN

Foam dispenser

ActiveUS8336737B2Reduce foam volumeStrong tasteLiquid transferring devicesSingle-unit apparatusAir pumpEngineering

A foam dispenser having a pump assembly includes a liquid pump, an air pump and a common actuation part to simultaneously actuate the liquid pump and the air pump. The pump assembly includes a dispensing channel having a dispensing opening. The pump assembly further includes a porous matrix which contains a dispensate material. A contact surface of the porous matrix is arranged in communication with the dispensing channel, so that foam being formed in the pump assembly and dispensed through the dispensing channel comes into contact with the contact surface to introduce dispensate material released from the porous matrix in the foam.

Owner:REXAM AIRSPRAY

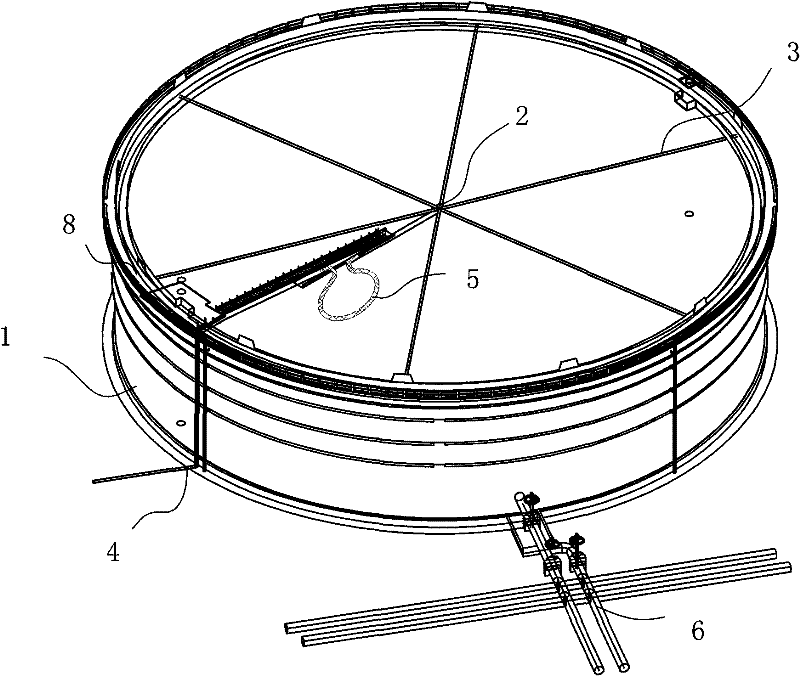

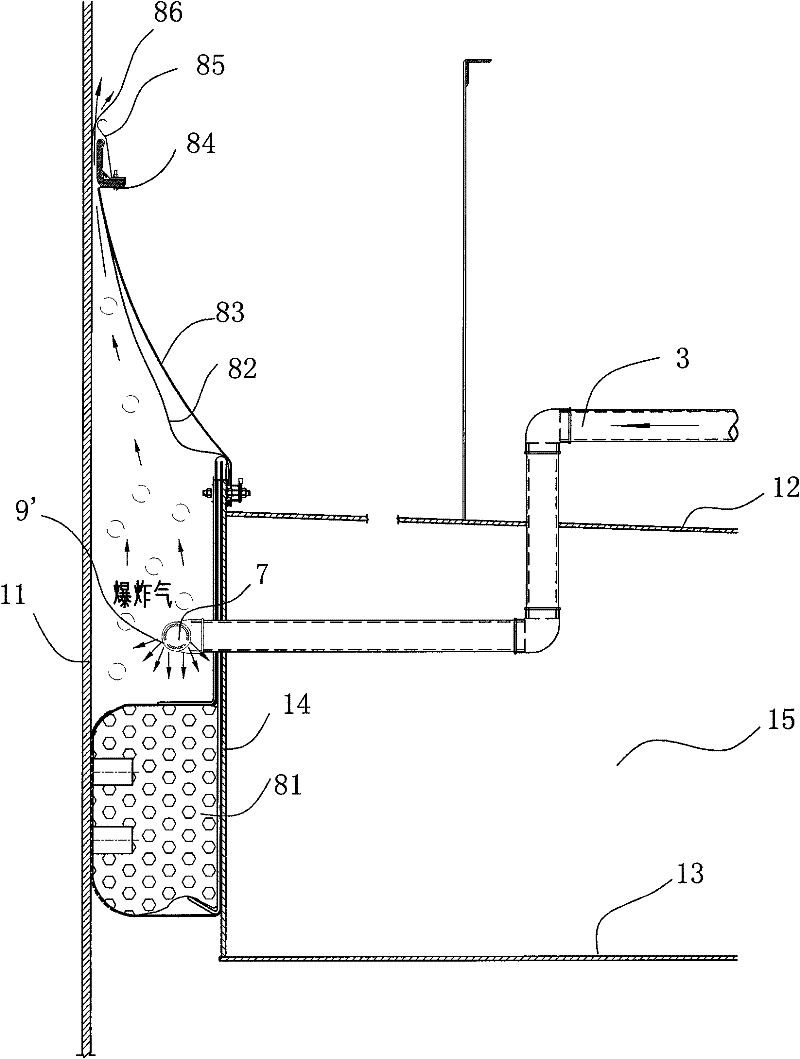

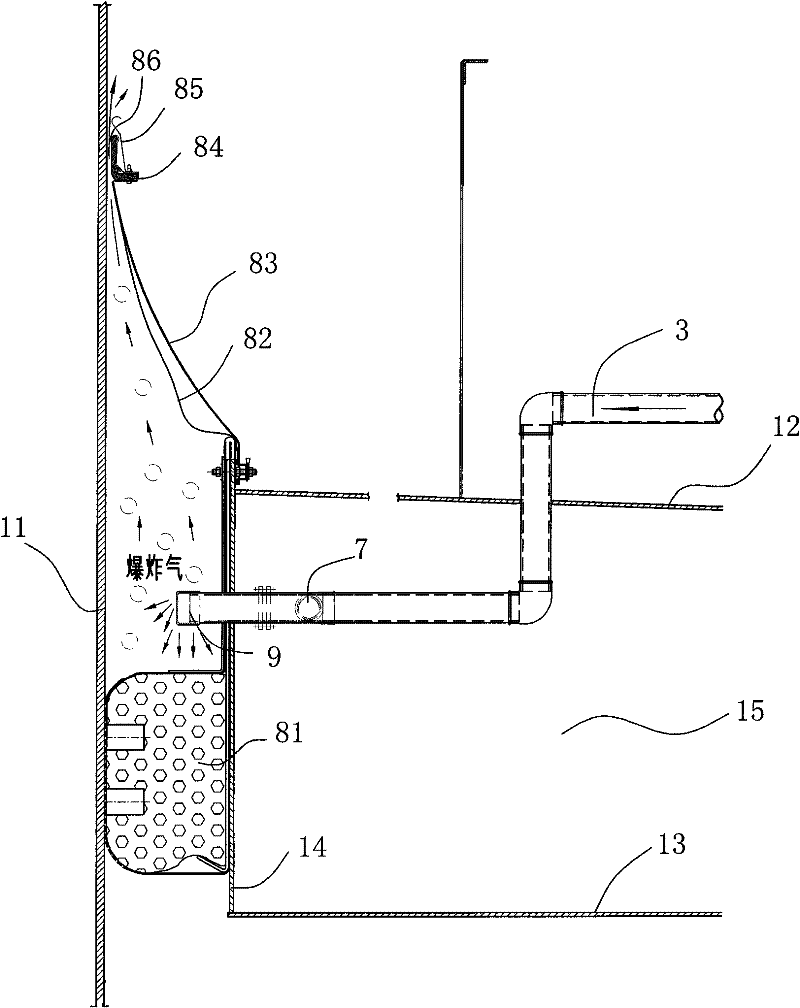

Ventilation and explosion suppression device for seal ring of floating roof tank

InactiveCN102679150AIntrinsically safeSmooth releaseContainer filling methodsContainer discharging methodsExhaust gasSystem structure

The invention relates to a ventilation and explosion suppression device for a seal ring of a floating roof tank. The ventilation and explosion suppression device comprises an air supply branch pipe which is communicated with the floating roof tank and externally connected with a gas transmission mother pipe, the annular seal ring is arranged between the tank wall of an oil tank and the side wall of a floating roof, the annular seal ring comprises a primary sealing piece and a secondary sealing piece, and the ventilation and explosion suppression device is characterized in that the ventilation and explosion suppression device further comprises a central distributor, a plurality of radial branch gas pipes and a plurality of arc-shaped gas distribution pipes, wherein the central distributor is arranged in the center position above a top plate of the floating roof and communicated with the air supply branch pipe; the plurality of the radial branch gas pipes are arranged between the central distributor and the seal ring and communicated with the central distributor; the plurality of the arc-shaped gas distribution pipes are arranged in the seal ring or an edge floating cabin and communicated with the radial branch gas pipes, and a plurality of exhaust holes or gas jet heads for conveying gas into the seal ring are arranged on the arc-shaped gas distribution pipes; and a gap for exhausting tail gas is arranged between the tank wall and the top end of the seal ring. The whole set of the system has the advantages of simple structure, low cost, and convenience in use and maintenance, thereby being a simple, economic, reasonable, effective and ideal technological way for realizing intrinsic safety of the oil tank.

Owner:镇海国家石油储备基地有限责任公司

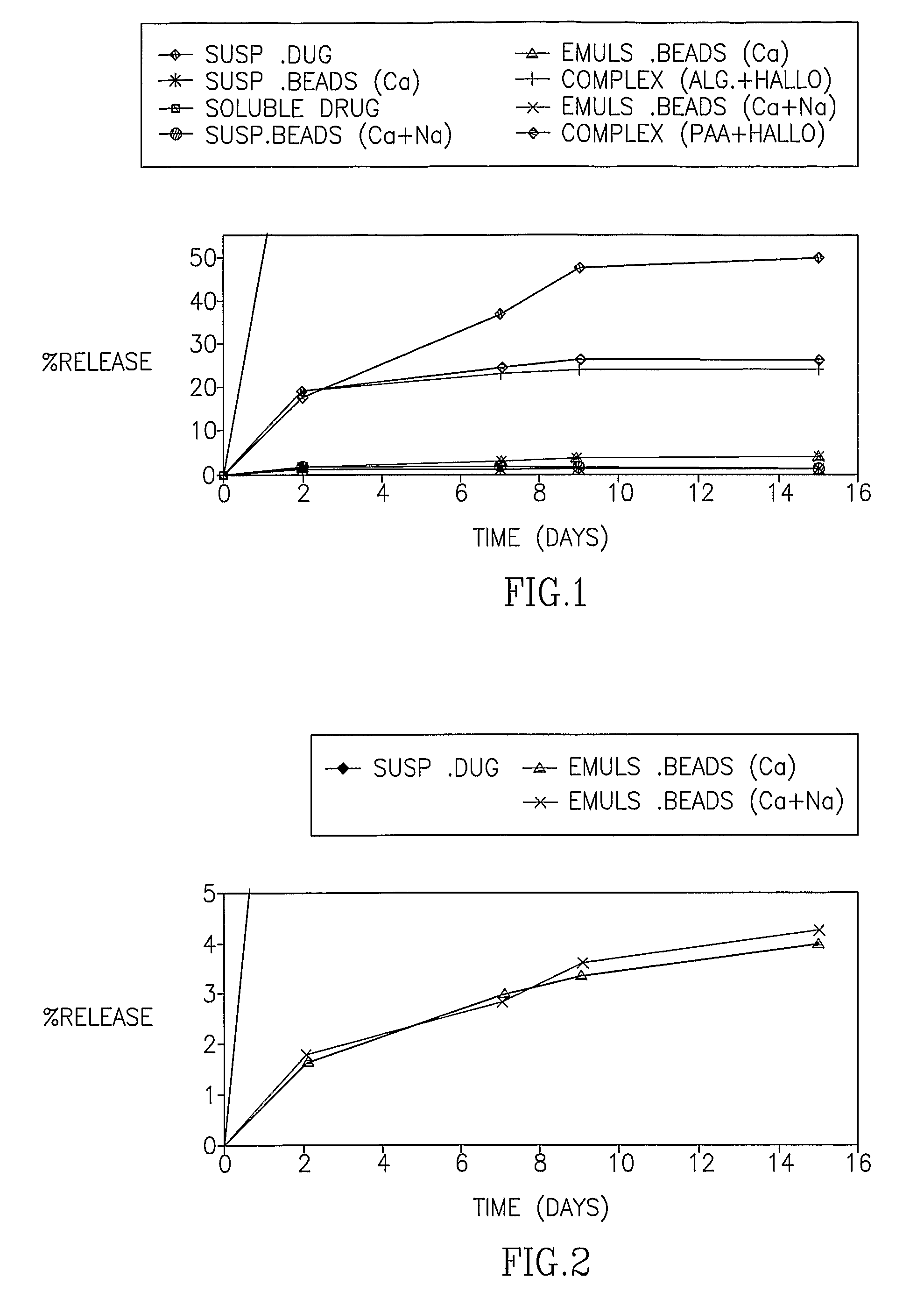

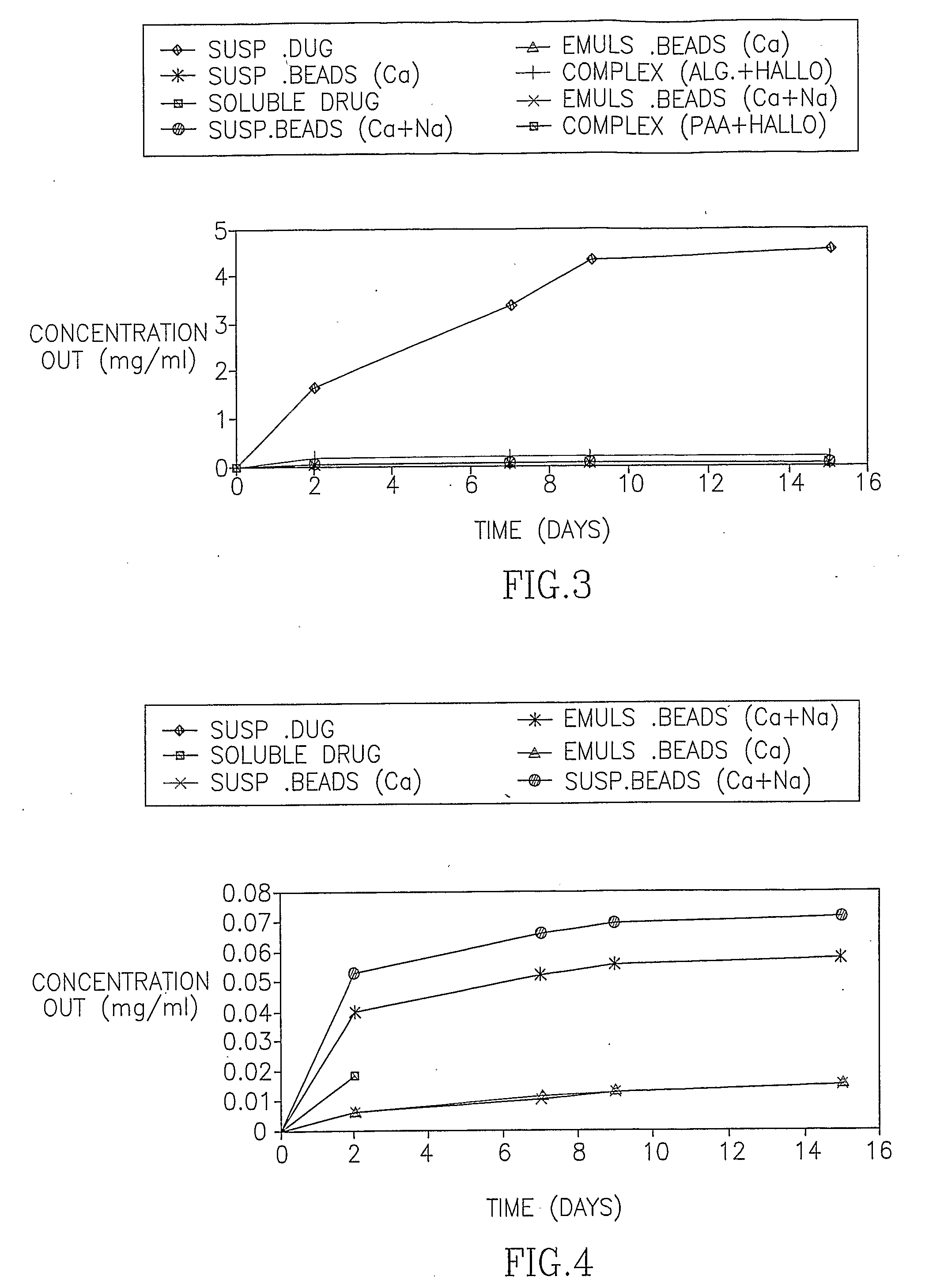

Biocompatible polymeric delivery systems for sustained release of quinazolinones

InactiveUS20070184082A1Avoid fluctuations in blood levelsEliminate needOrganic active ingredientsBiocideHalofuginoneMedicine

The present invention relates to biocompatible polymeric delivery systems for controlled or sustained release of quinazolinone derivatives, including the compound halofuginone. In particular the invention relates to a polymeric delivery system comprising biocompatible polymeric beads having a two-phase core and shell structure, or polymeric films, beads or complexes that provide local sustained release of the pharmacological agent.

Owner:MAGDASSI SHLOMO +1

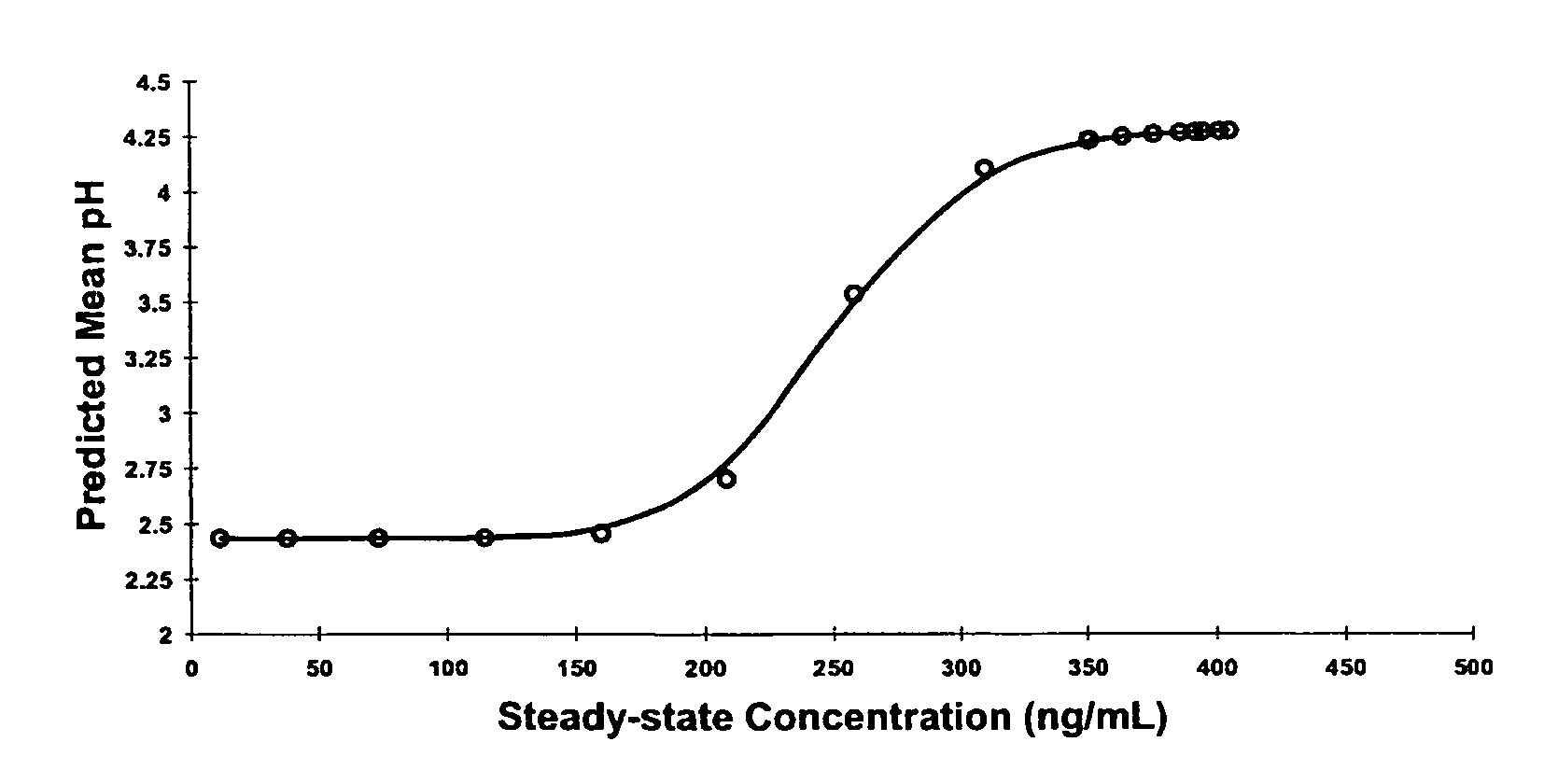

Multiple PPI dosage form

Herein provided are dosage forms (variously referred to as “formulations”) comprising a PPI that is released from the dosage form as a first and a second dose. Each dose of PPI is present in an amount sufficient to raise the plasma levels of the PPI to at least 100 ng / ml.

Owner:TAKEDA PHARMA U S A

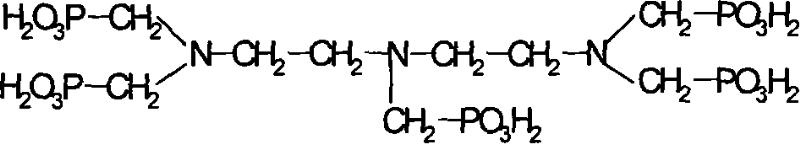

Scale and corrosion inhibition method combining chemical huff and puff with water-shutoff

InactiveCN101037933AContinuous releasePlay the function of long-term scale and corrosion inhibitionBorehole/well accessoriesDiethylenetriamineWater block

The invention discloses a chemical throughput and water-block combined dirty-proof corrosion-abating method, which is realized by providing dirty-proof corrosion-abating agent, selective block agent and corresponding working-liquid injection technology. The dirty-proof corrosion-abating agent is diethylenetriamine five methylene phosphinic acid, the selective block agent is a copolymer of acrylamide and 3-acrylamide base-3-methyl butyl three-methyl ammonium chloride. The injection technology is that brine mixed with clay anti-swelling agent as an ahead fluid is injected to ground layer, dirty-proof corrosion-abating liquid is then injected, right amount of ground layer water or brine as post liquid is injected afterward, and selective block agent is injected finally. The oil well is closed and stewed for 16 to 24 hours after injection before reproduction. By employing said technology, the dirty-proof corrosion-abating agent is injected into near wellbore zone of the oil well, the block agent selectively blocks the water and the dirty-proof corrosion-abating agent is sealed and blocked in pore space medium of the ground layer, and the dirty-proof corrosion-abating agent is brought into borehole, ground pipe line and equipment by the ground layer fluid continuously, which carries out continuously releasing with long-time dirty-proof corrosion-abating efficiency.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

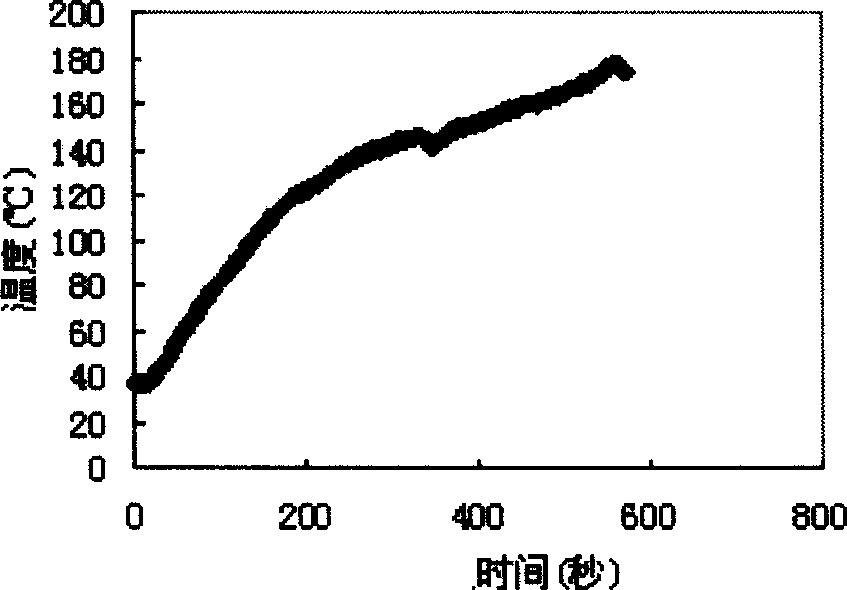

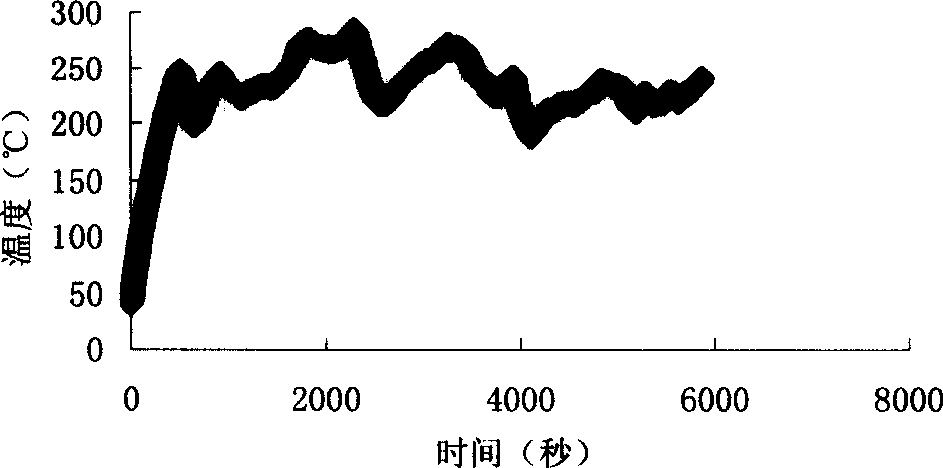

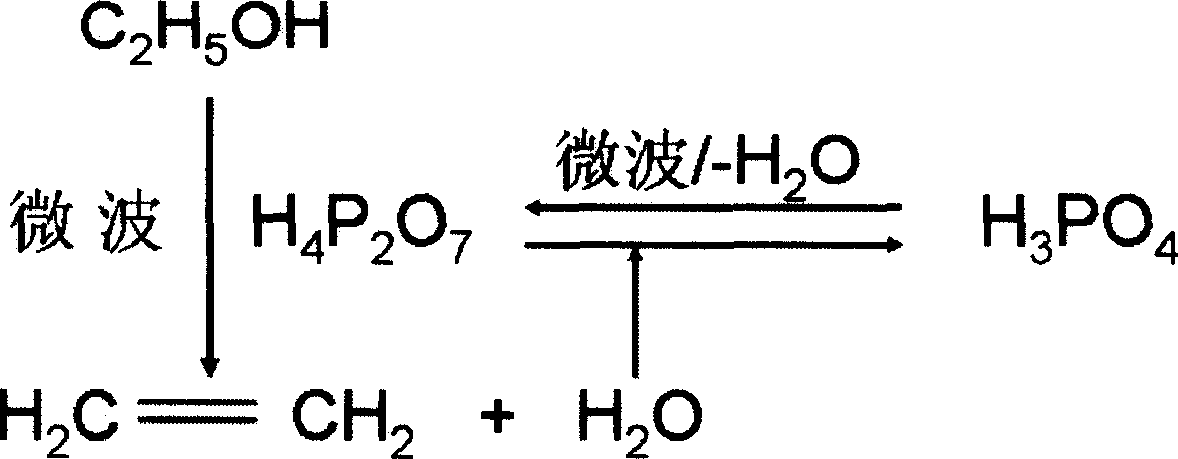

Microwave chemical method for preparing ethylene by catalytic dehydration of ethanol

InactiveCN1884232AContinuous releaseRelease stabilityHydrocarbon from oxygen organic compoundsMicrowaveAlcohol

The invention discloses a microwave chemical method of ethane, which is characterized by the following: dehydrating alcohol into ethane irradiated by microwave at 120-300 deg.c and 300MHz-300GHz frequency; adopting catalyst with molecular formulation at Hn+2PnO3n+1 (n is positive integral phosphoric acid, pyrophosphoric acid, polyphosphoric acids or their carbethoxy).

Owner:WUHAN UNIV

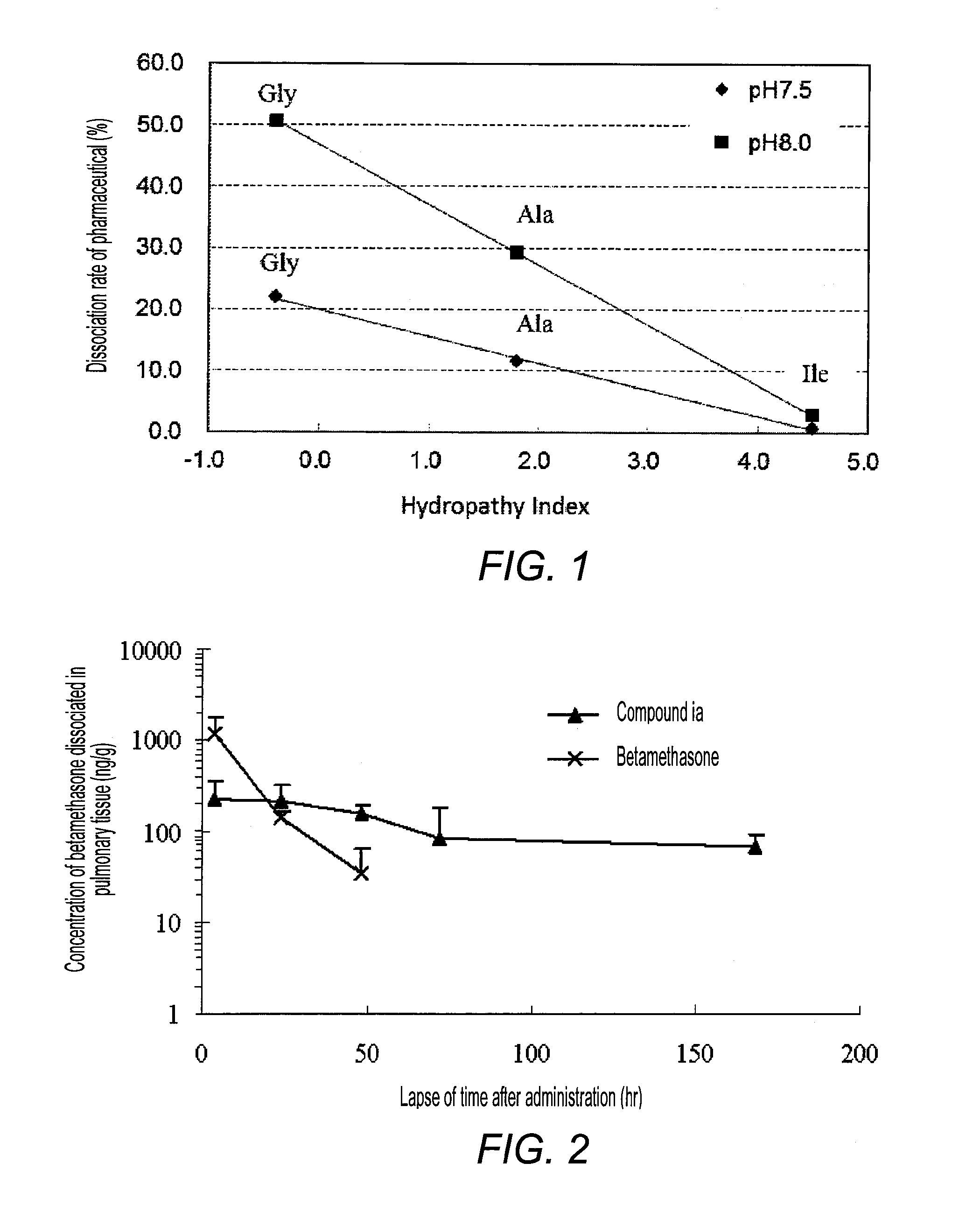

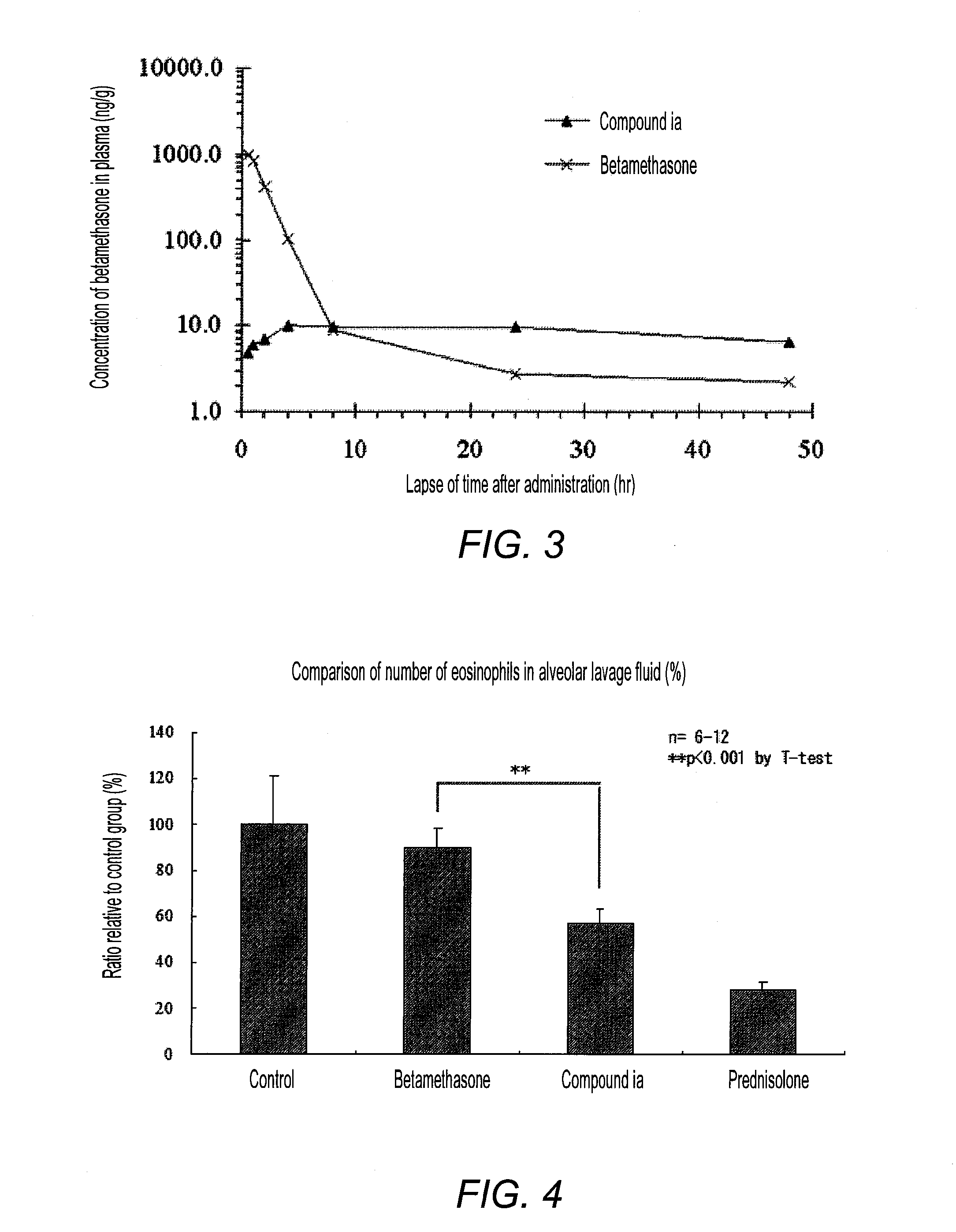

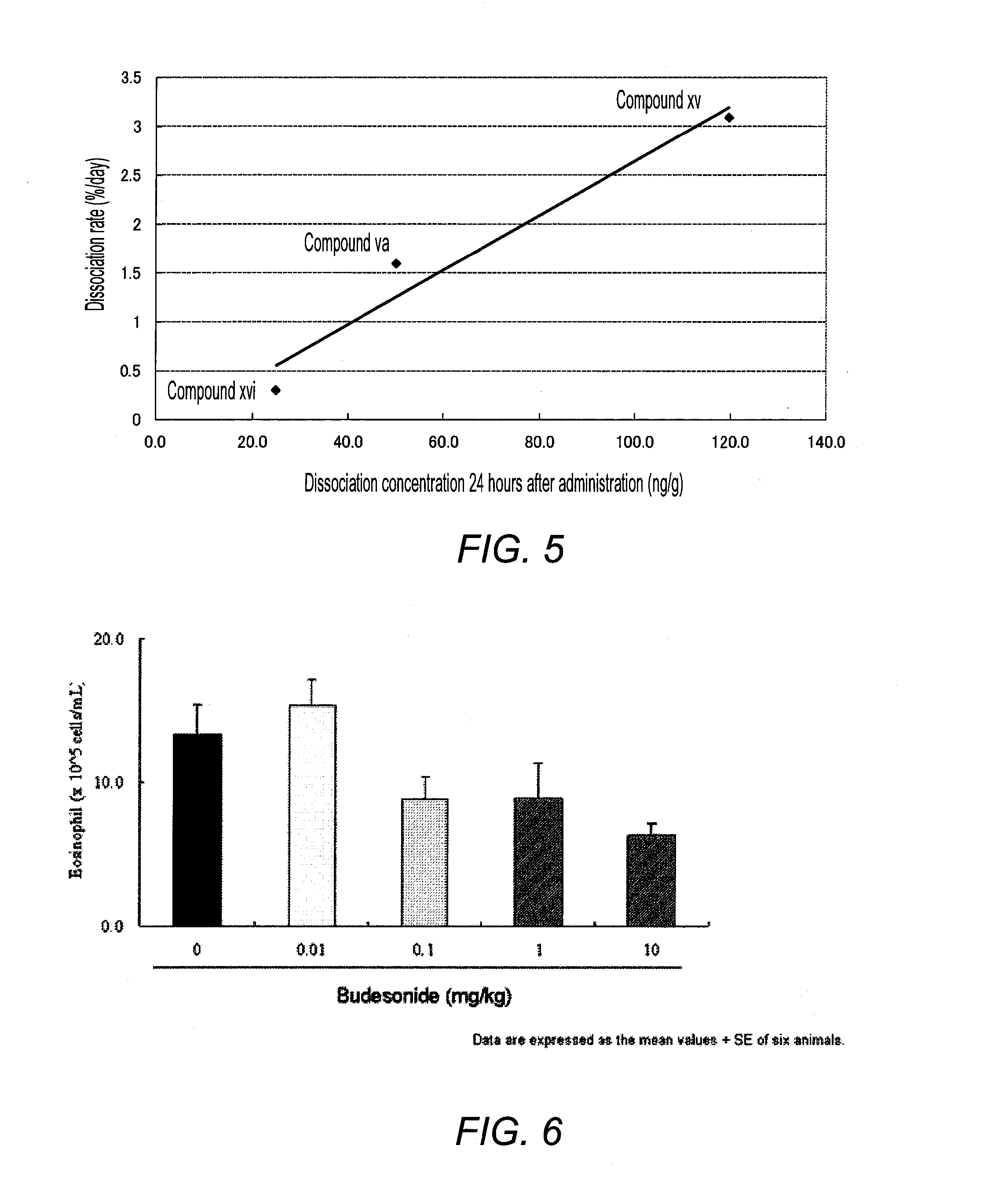

Pharmaceutical composition for respiratory administration

The present invention provides a pharmaceutical composition for respiratory administration containing a polysaccharide derivative having a group derived from a polysaccharide and a group derived from a physiologically active substance that is covalently bonded to the group derived from a polysaccharide.

Owner:SEIKAGAKU KOGYO CO LTD

Perfume dispenser

InactiveUS20060192031A1Convenient ArrangementContinuous releaseTravelling carriersHoldersEngineeringMechanical engineering

Owner:YEUNG KWOK KEUNG

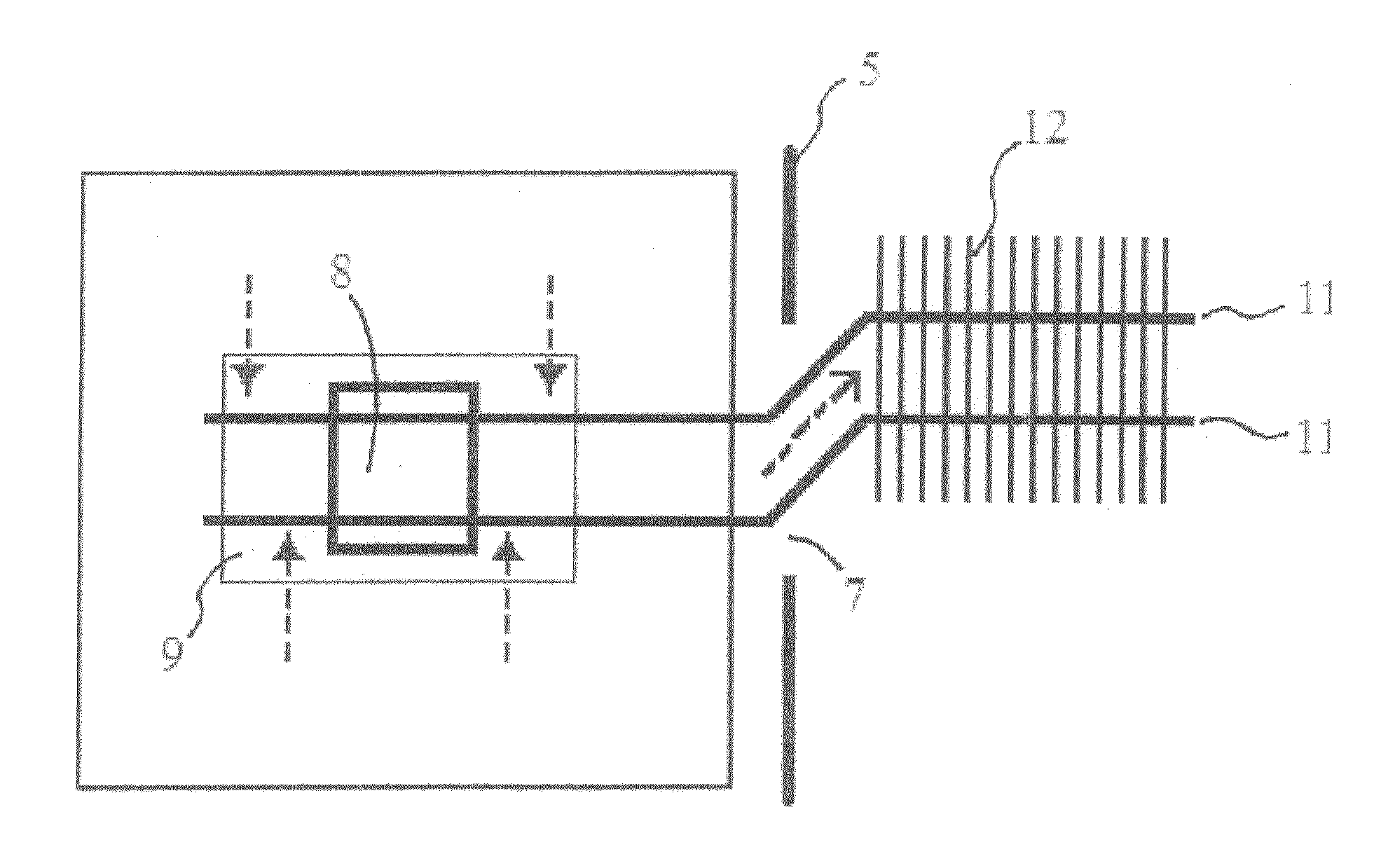

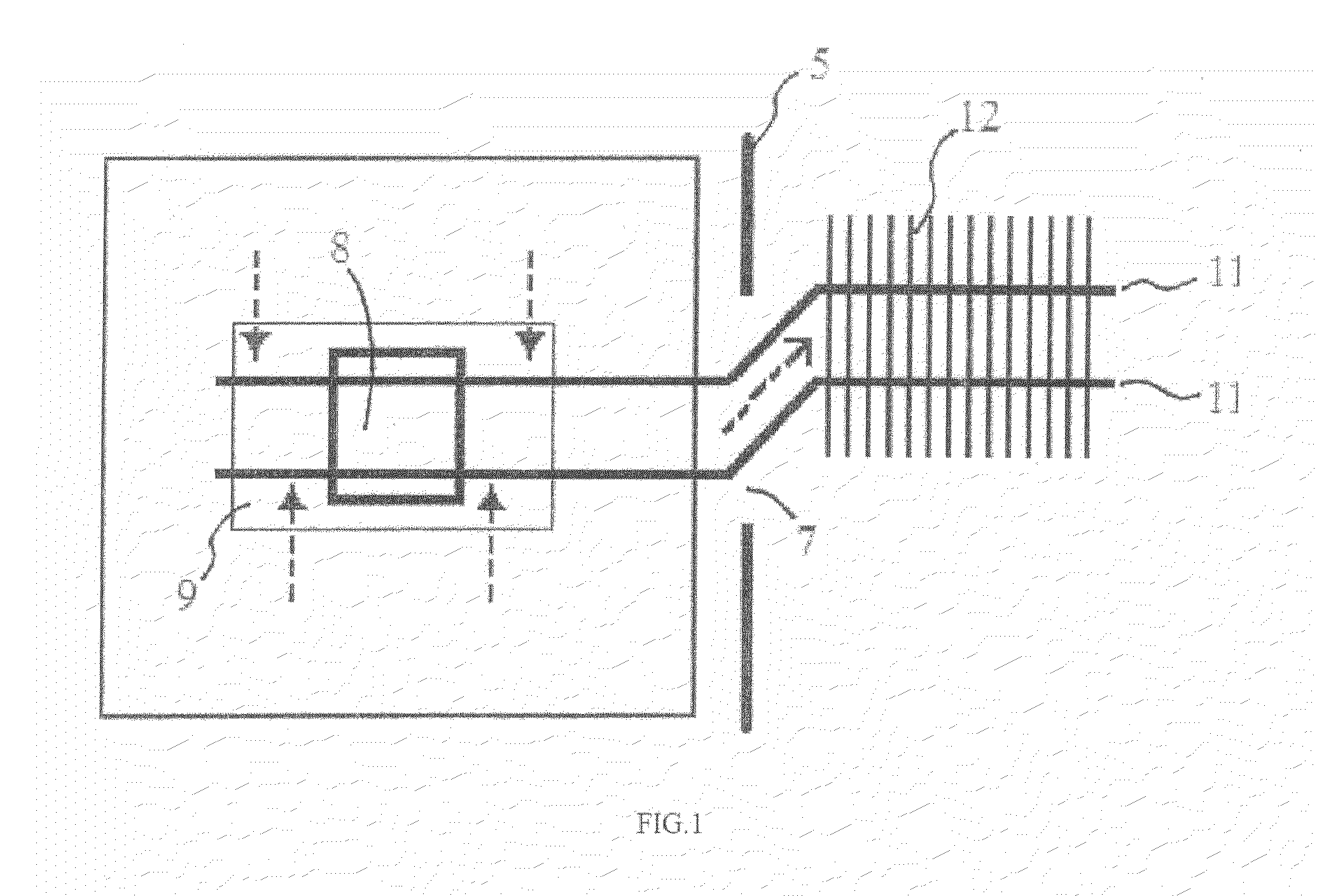

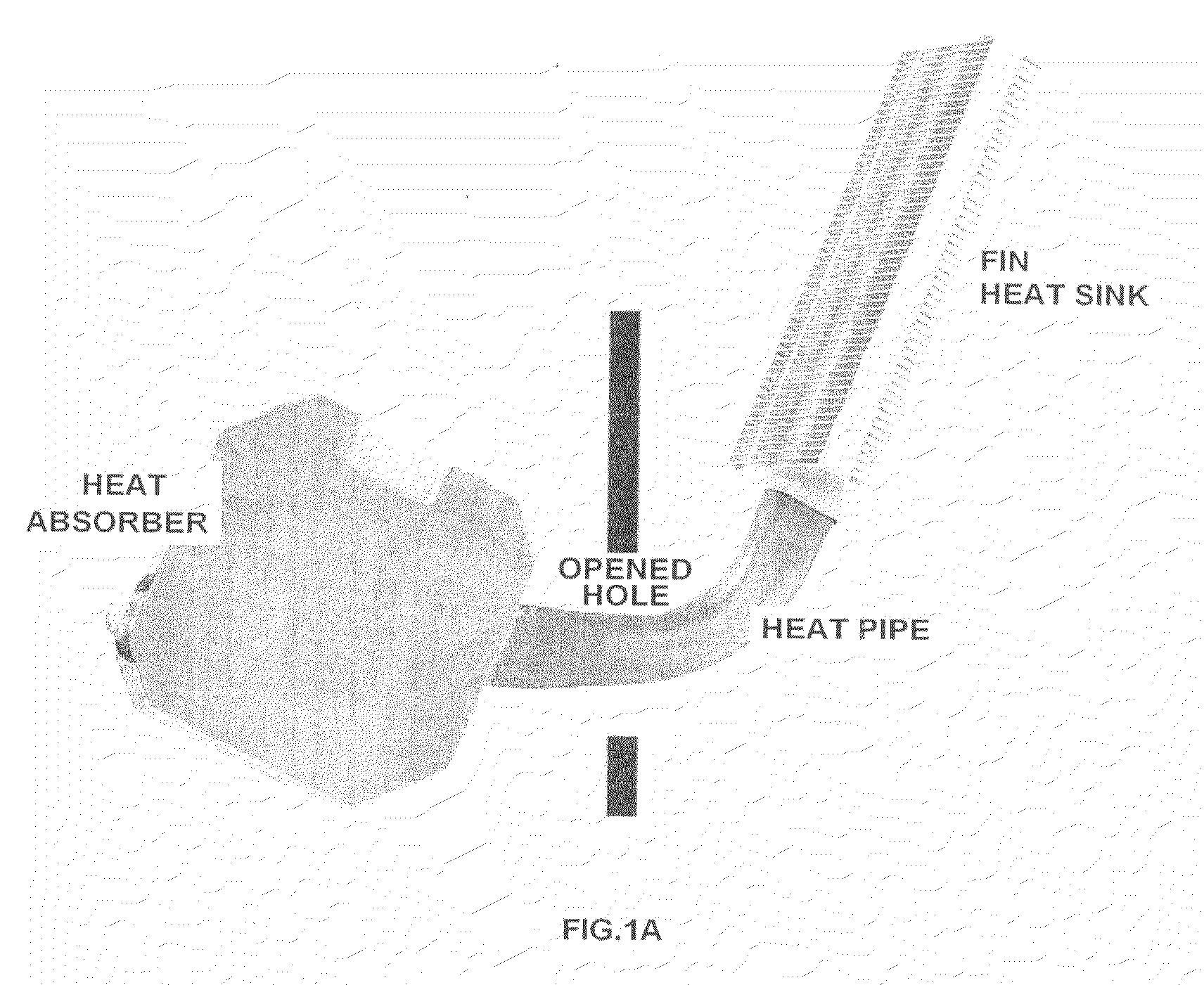

Thermal management kit for high power solid state light emitting diodes

InactiveUS20110199771A1Extended shelf lifeExtend the life cycleMechanical apparatusPoint-like light sourceEngineeringLight-emitting diode

The thermal management kit for high power of solid state light emitting diodes is invented to use the opened channel and / or hole of exiting luminaire and / or made a new hole and / or holes of upper luminaire and / or any part. The present invention utilize the hole in order to dissipative inside heat to outside of luminaire by using function of heat pipes by set up the heat pipe passes through opened channel and / or hole of luminaire.

Owner:LUU LU VINH

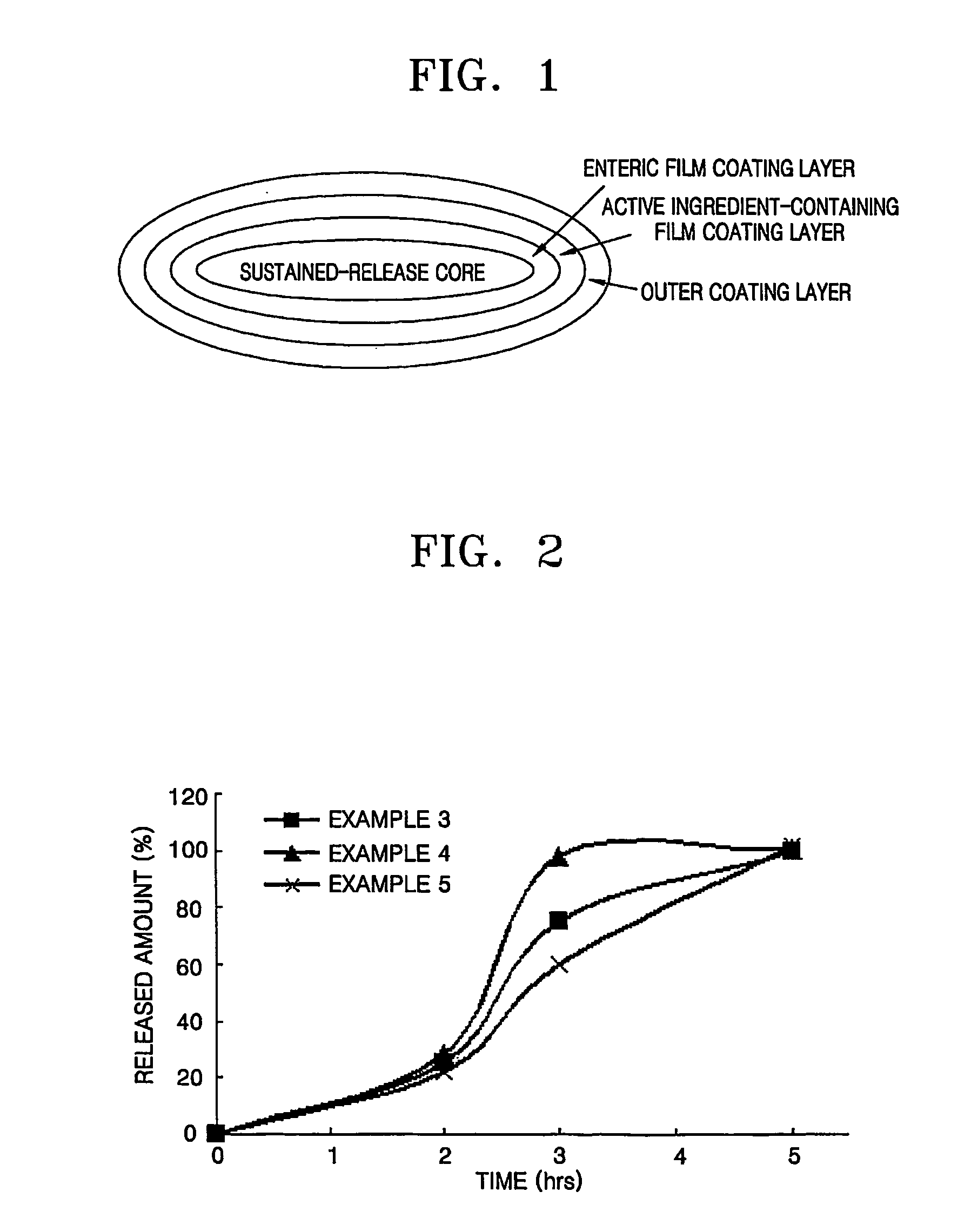

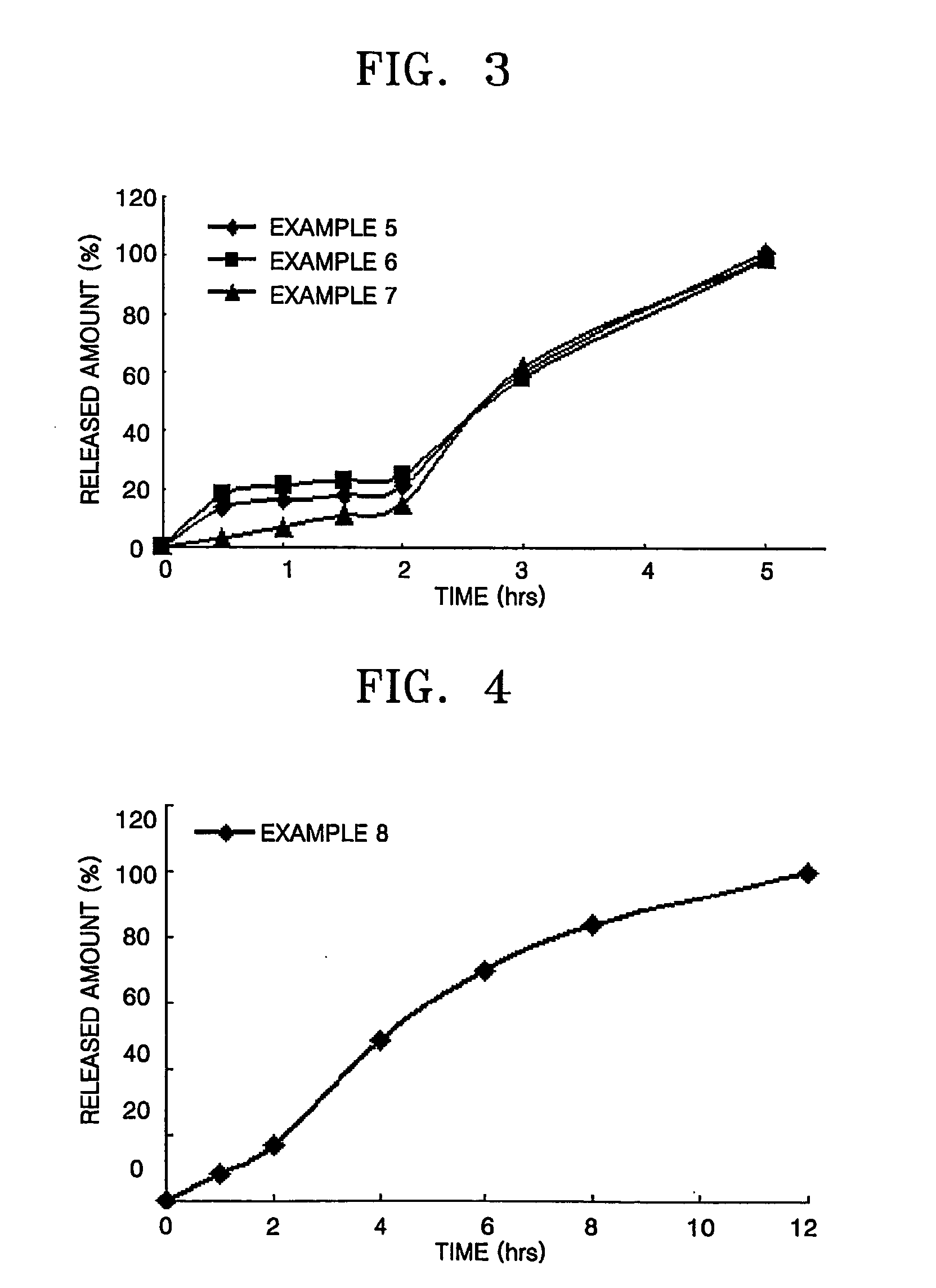

Sustained release formulations

InactiveUS20070122480A1Inhibition releaseContinuous releasePill deliveryMedicineBULK ACTIVE INGREDIENT

Provided is a sustained-release formulation: (a) a sustained-release core including an active ingredient and a polymer having erosion and swelling property in mammalian intestinal secretions, (b) an enteric film coating layer coated on the sustained-release core, and (c) an active ingredient-containing film coating layer coated on the enteric film coating layer and including the active ingredient and hydrophilic polymer for film coating.

Owner:CJ HEALTHCARE CORP

Composite comprising well treatment agent and/or a tracer adhered onto a calcined substrate of a metal oxide coated core and a method of using the same

A composite used to slowly release well treatment agents and / or tracers into a well contains a calcined substrate comprising a metal oxide coated onto at least a portion of a core and a well treatment agent adsorbed onto or absorbed into the interstitial spaces of the metal oxide coating of the calcined substrate. The core contains a material sufficient in strength to prevent closure of a fracture created or enlarged within a subterranean formation penetrated by the well at in-situ reservoir conditions.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com