Scale and corrosion inhibition method combining chemical huff and puff with water-shutoff

A technology of scale and corrosion inhibition and chemical agent is applied in the field of solving the scaling and corrosion of wellbore, surface pipelines and equipment, which can solve the problems of complicated operation, difficult control of the concentration of scale and corrosion inhibitor, extrusion of scale and corrosion inhibitor, etc. Achieve low concentration efficiency, strong adsorption and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the examples.

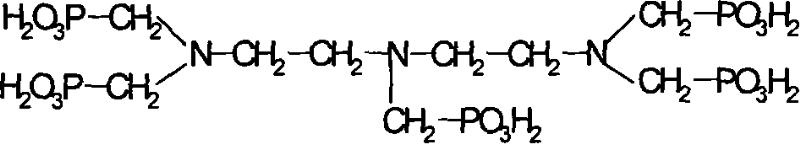

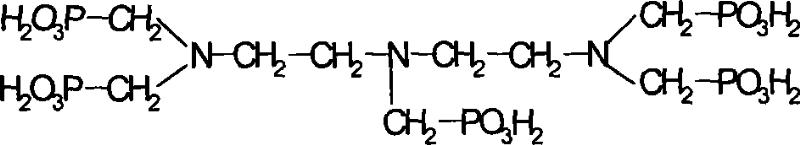

[0014] The main measures of the present invention to solve the technical problems are realized through the determination of scale and corrosion inhibitors, selective plugging agents and their corresponding working fluid injection techniques. According to the industry standard SY / T5673-93 "Evaluation method of anti-scaling agent for oilfield", the scale and corrosion inhibitor performance evaluation is carried out, and the scale and corrosion inhibitor is evaluated according to the industry standard SY5273-2000 "Evaluation method of oilfield water injection corrosion inhibitor" In order to evaluate the corrosion inhibition performance of the anti-scaling and corrosion inhibitors through core displacement experiments, the chemical huff and squeeze injection life of the scale and corrosion inhibitors was predicted, and diethylenetriaminepentamethylenephosphonic acid was finally selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com