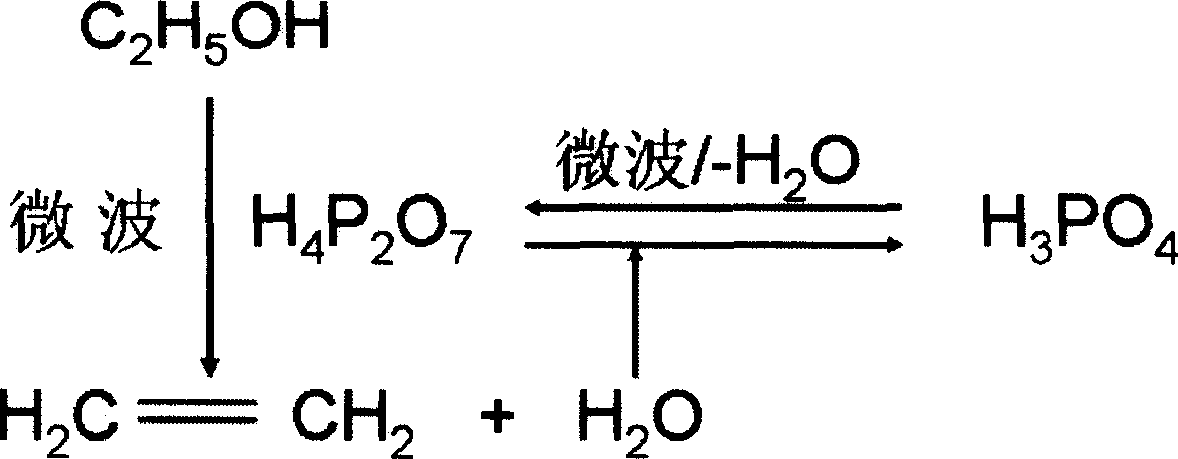

Microwave chemical method for preparing ethylene by catalytic dehydration of ethanol

A technology of microwave chemistry and catalytic dehydration, which is applied in the direction of organic chemistry and hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of high energy consumption and achieve the effects of low energy consumption, accelerated reaction rate, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 400 milliliters of 85% phosphoric acid into a 1000 milliliter glass reaction bottle equipped with a temperature measuring probe, an ethanol inlet tube and an ethylene outlet pipe and put it into a microwave reactor. The microwave frequency is 300 MHz to start the microwave reactor and within 5 minutes the Heat to a simmer. After it is cooled to room temperature, introduce 50 milliliters (0.859 moles) of absolute ethanol (d 20 =0.79), when the temperature reaches 120°C for 1 minute by microwave irradiation with 10 watts / ml phosphoric acid strength, gas will be released. The gas is flammable, insoluble in water and rapidly discolors purple acidic potassium permanganate solutions, indicating that it is ethylene gas. After irradiating for 3 minutes, the temperature rose to 200°C, and a large amount of ethylene gas was released. The purity of ethylene gas was identified by gas chromatography to reach 99.5%. The vigorous dehydration reaction proceeded for about 4 minut...

Embodiment 2

[0029] microwave power

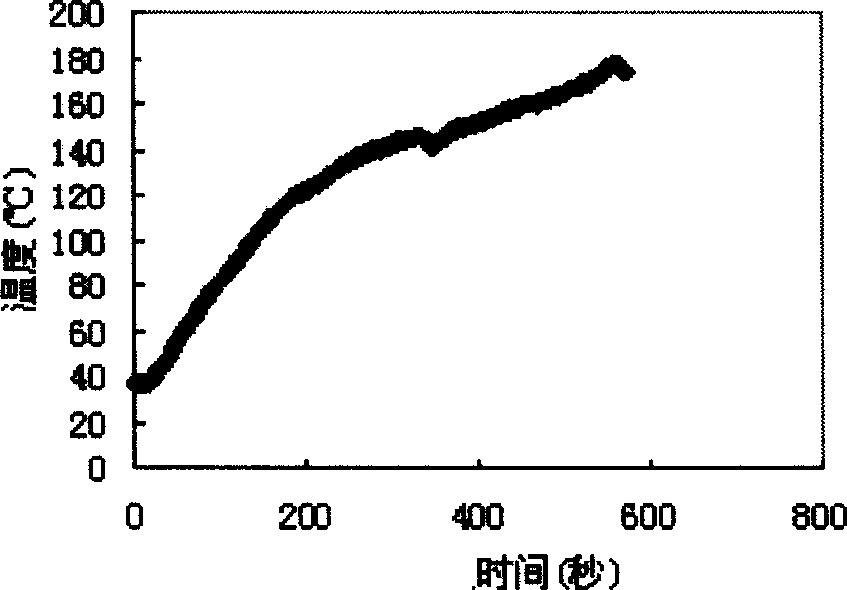

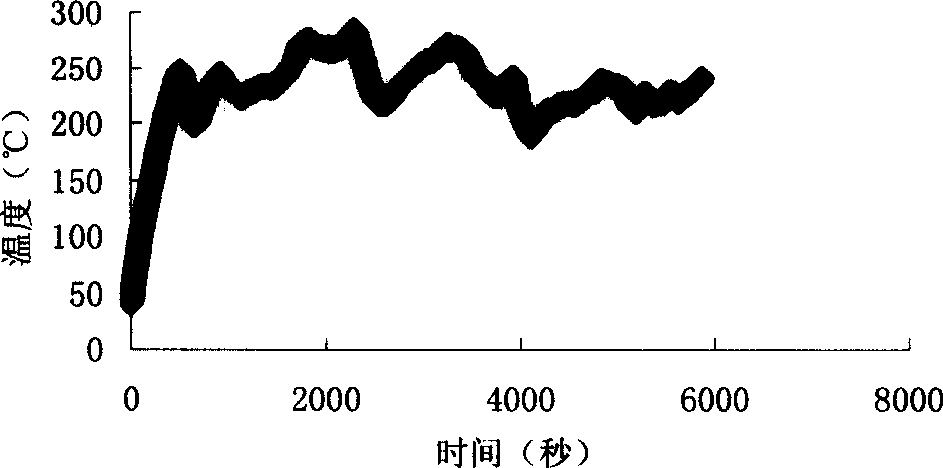

[0030] The generated polyphosphoric acid was still and naturally cooled to 36°C, and 100 ml of 95% ethanol was added and mixed evenly. The mixture is heated to 120° C. under microwave irradiation with a frequency of 2450 MHz and an intensity of 15 watts / ml of phosphoric acid (according to the amount of feed) to release ethylene gas. figure 1 The heating curve for the first 10 minutes is shown. The gas release took 9 minutes from the beginning to the end, and the average release rate was 7 ml / s.

Embodiment 3

[0032] Add 400 milliliters of triethyl phosphate [mass content 96%, specific gravity (D 20 =1.07)] and 200 milliliters of 80% industrial ethanol are placed in a microwave reactor, and microwave irradiation with a frequency of 300 GHz and 20 watts / ml triethyl phosphate intensity is used, and ethylene gas is released after 4 minutes. The release rate was 2 ml / sec.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com