Supercritical CO2 emulsion stability evaluation device and method

A technology for emulsion stability and evaluation device, which is applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of no method and device for measuring the stability of supercritical carbon dioxide emulsion, and achieves low cost and satisfactory results. The effect of developing requirements and solving storage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

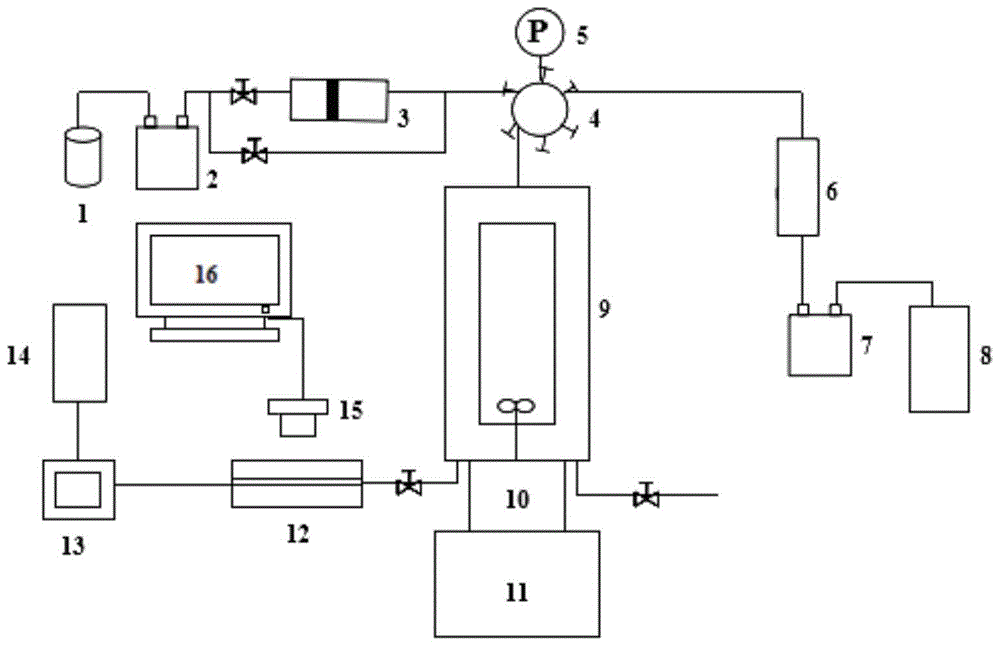

[0037] A supercritical CO 2 Emulsion stability evaluation device, the structure is as follows figure 1 Shown, comprise reactor 9, be provided with agitator 10 at the bottom of reactor 9, described agitator is high-voltage electromagnetic coupling high-speed agitator, described reactor 9 is the reactor with visible window, the A drain line is connected to the bottom, and a temperature sensor and a heater are provided on the outer wall of the reactor. The signal output end of the temperature sensor is connected to the signal input end of the temperature controller, and the control output end of the temperature controller is connected to the heater. The temperature The controller is connected with the power supply, and the temperature controller and the controller for controlling the rotation speed of the stirrer are located at the bottom of the reaction kettle. The top of the reaction kettle 9 is connected with a carbon dioxide branch and a sample input branch by a pipeline, an...

Embodiment 2

[0043] A kind of utilizing device described in embodiment 1 to supercritical CO 2 The measuring method of emulsion stability comprises steps as follows:

[0044] (1) Open the valve on the connecting pipeline between the advection pump and the six-way valve, turn on the advection pump, and pump distilled water into the entire device system through the advection pump for cleaning for 20 minutes. The pumping speed of distilled water is 5ml / min, and pass through the bottom of the reactor Drain the distilled water from the drain line.

[0045] (2) Turn on the advection pump, open the valve between the advection pump and the second intermediate container, and pump di-(2-ethylhexyl)-sulfonic acid with a mass concentration of 0.6%wt into the reactor at a flow rate of 5ml / min Sodium succinate (AOT) solution 50ml, at this time, the temperature and pressure in the reaction kettle are normal temperature and pressure.

[0046] (3) Adjust the temperature in the reactor through the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com