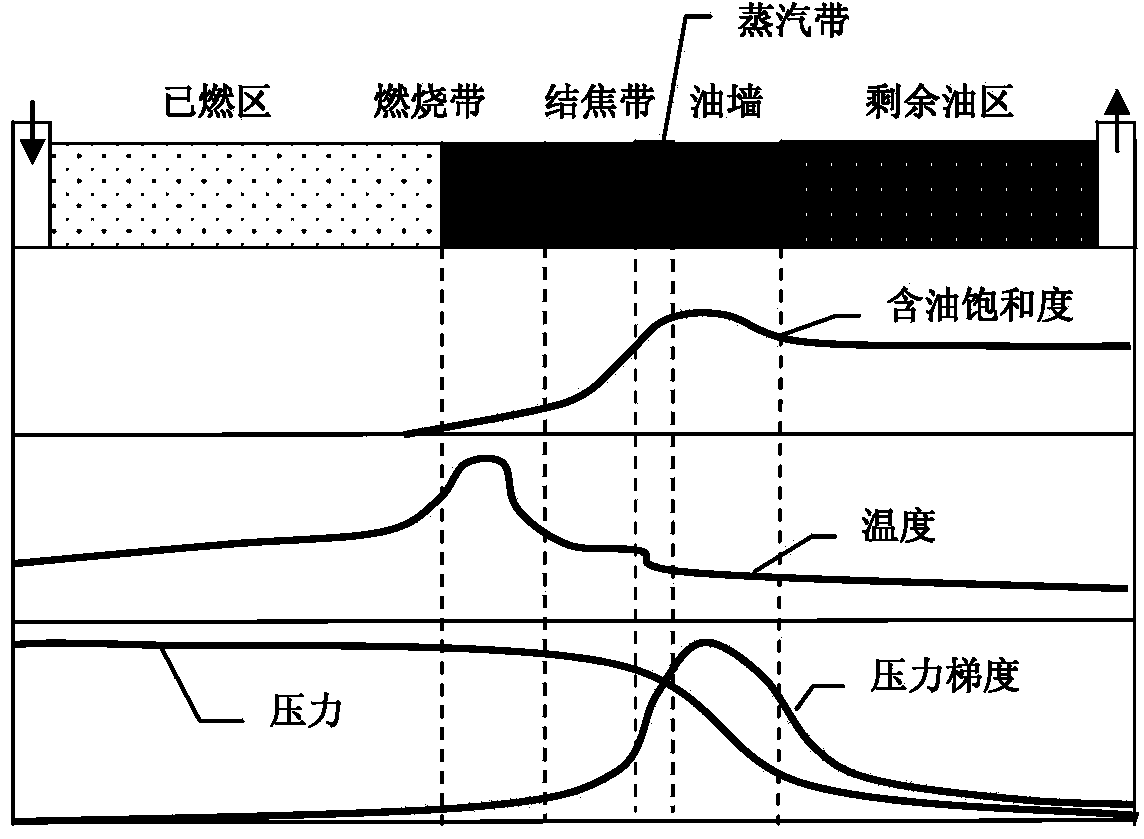

Fireflooding huff and puff and fireflooding linkage thickened oil exploitation method

A fire flooding and linkage technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to use extra-heavy oil and super-heavy oil, and achieve the effect of reducing seepage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Reservoir 1 The depth of the reservoir is 840m; the thickness of the oil layer is 13.6m; the permeability of the oil layer is 940×10 -3 μm 2 ; Reservoir temperature 48°C; Crude oil viscosity 35000mPa.s, belonging to extra heavy oil reservoir; Crude oil density 0.9840g / cm 3 ; Oil saturation is 68.9%; Conventional cold recovery has no output, steam huff and puff test production effect is poor, and the oil-steam ratio is lower than 0.2, which cannot be economically developed.

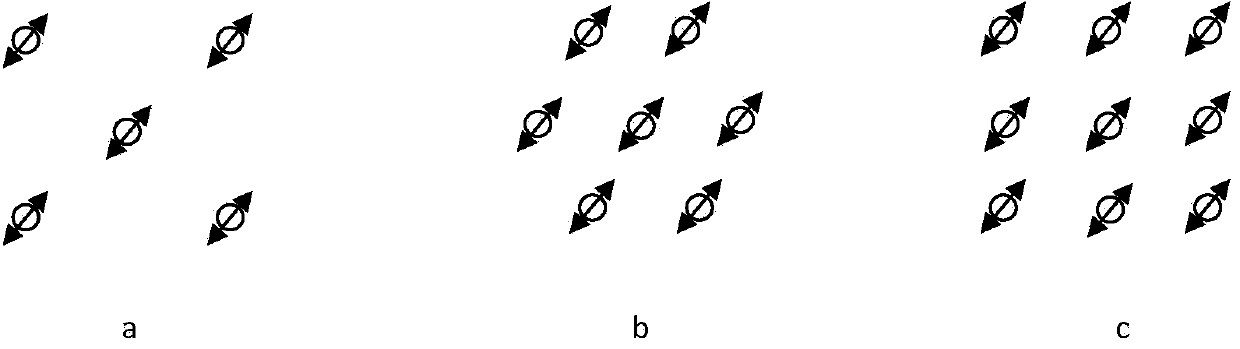

[0041] Using the fire drive throughput and fire drive linkage development test of the present invention, the scheme is deployed as follows:

[0042] 1) Design 4 well groups (4 injection and 9 production) according to the square area well pattern with 100m well spacing, 13 new wells are drilled, all 13 wells adopt fire flooding huff and puff in the initial stage, and fire flooding in 4 well groups in the later stage mining. The area of the test area is 0.08km 2 , The drawing reserve is 196,000 ...

Embodiment 2

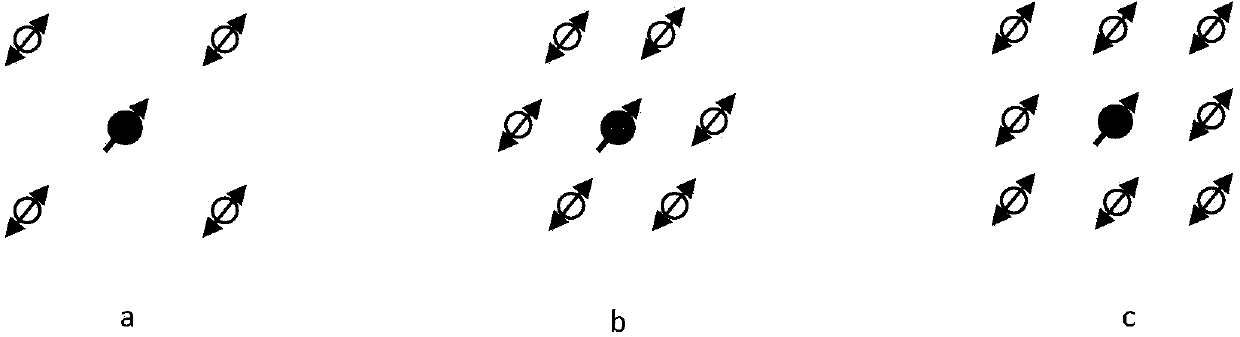

[0050] Reservoir 2 The depth of the reservoir is 640m; the thickness of the reservoir is 14m; the permeability of the reservoir is 940×10 -3 μm 2 ; Reservoir temperature 37℃; crude oil viscosity 55000mPa.s, belonging to super heavy oil reservoir; crude oil density 0.9870g / cm 3 ; The oil saturation is 72.9%; the conventional cold recovery has no output, the effect of the steam huff and puff trial production is poor, and the oil-steam ratio is lower than 0.15, so it cannot be economically developed. Therefore, it was decided to adopt fire drive throughput and fire drive linkage development test, and the scheme deployment is as follows:

[0051] 1) Deploy 4 regular hexagonal reverse 7-point well patterns in the test area, drill 20 new vertical wells including 4 gas injection wells and 16 production wells; the distance between injection and production wells is 100m, and the distance between adjacent production wells is 100m; The internal controlled oil-bearing area is 0.104 squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com