A pulse fracturing construction technology for realizing liquid self-supporting high-speed channel

A construction technology and self-supporting technology, which is applied in the fields of production fluid, drilling composition, wellbore/well components, etc., can solve the problem of no high-speed channel fracturing effect, poor solid proppant effect, and large amount of phase change material. and other problems, to achieve the effect of improving suspension and portability, avoiding the risk of sand plugging, and reducing seepage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A liquid self-supporting high-speed channel fracturing fluid pulse fracturing process, comprising the following steps:

[0093] (1) Prepare B1 liquid: mix uniformly with 100 parts by weight of guar gum fracturing fluid and 3 parts of potassium chloride to obtain B1 liquid;

[0094] Preparation of high-density medium-top liquid B': mix 100 parts by weight of guar gum fracturing fluid and 30 parts of potassium chloride to obtain B' liquid;

[0095] (2) Create cracks: use the crack network simulation device disclosed in the patent CN110725675A to simulate cracks;

[0096] (3) While making cracks, prepare liquid A and liquid B on site: use 100 parts by weight of bisphenol A epoxy resin E-51, mix evenly with 10 parts of ethanol diluent, add 0.1 part of polyvinyl alcohol fiber to mix, Then add 25 parts of triethylenetetramine curing agent and mix to obtain liquid A; mix the above liquid B1 with 0.3 part of organoboron crosslinking agent crosslinking agent and 0.2 part of pol...

Embodiment 2

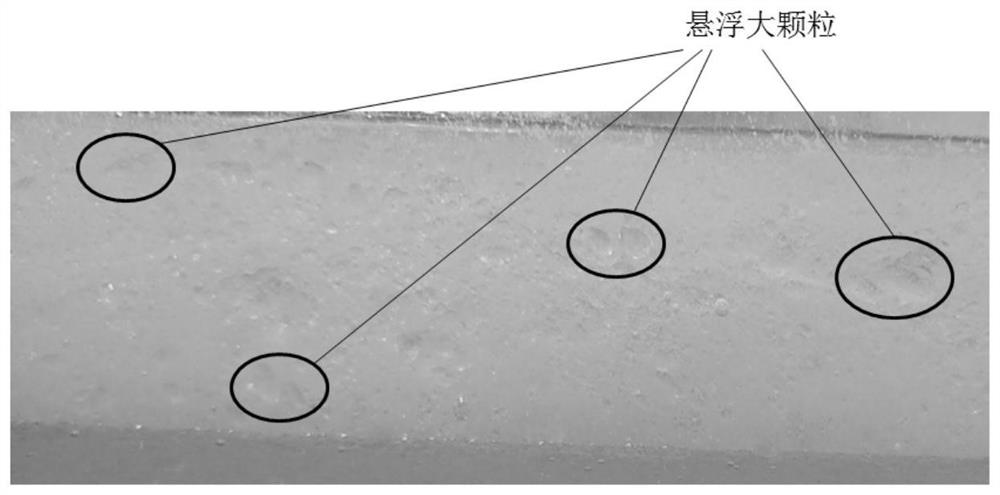

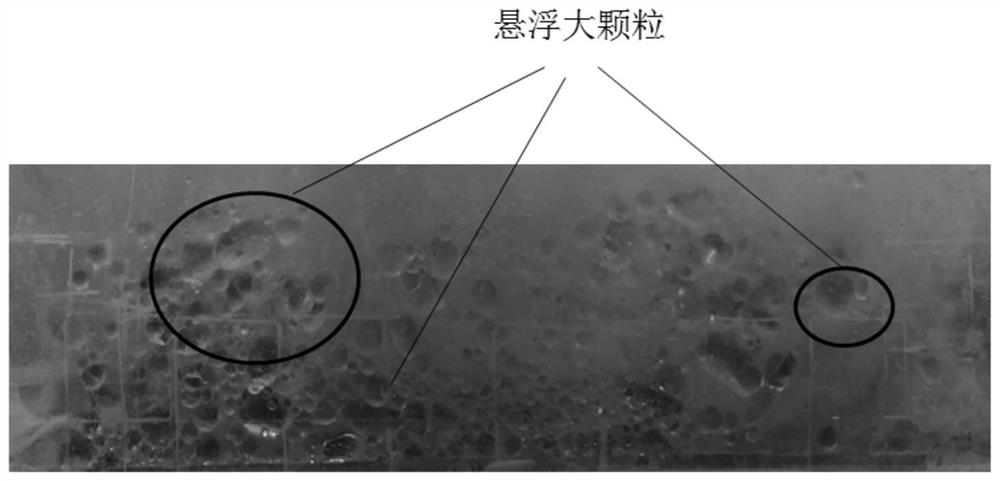

[0110] In order to further verify the applicability of the present invention, the ground outcropping rock block is used as the experimental material, and the on-site construction process is simulated by a core flow simulation device. Two groups of experiments were used for comparison, one group used variable density pulse injection fluid self-supporting fracturing technology, and the other group used continuous single injection of A / B mixed fluid self-supporting fracturing technology.

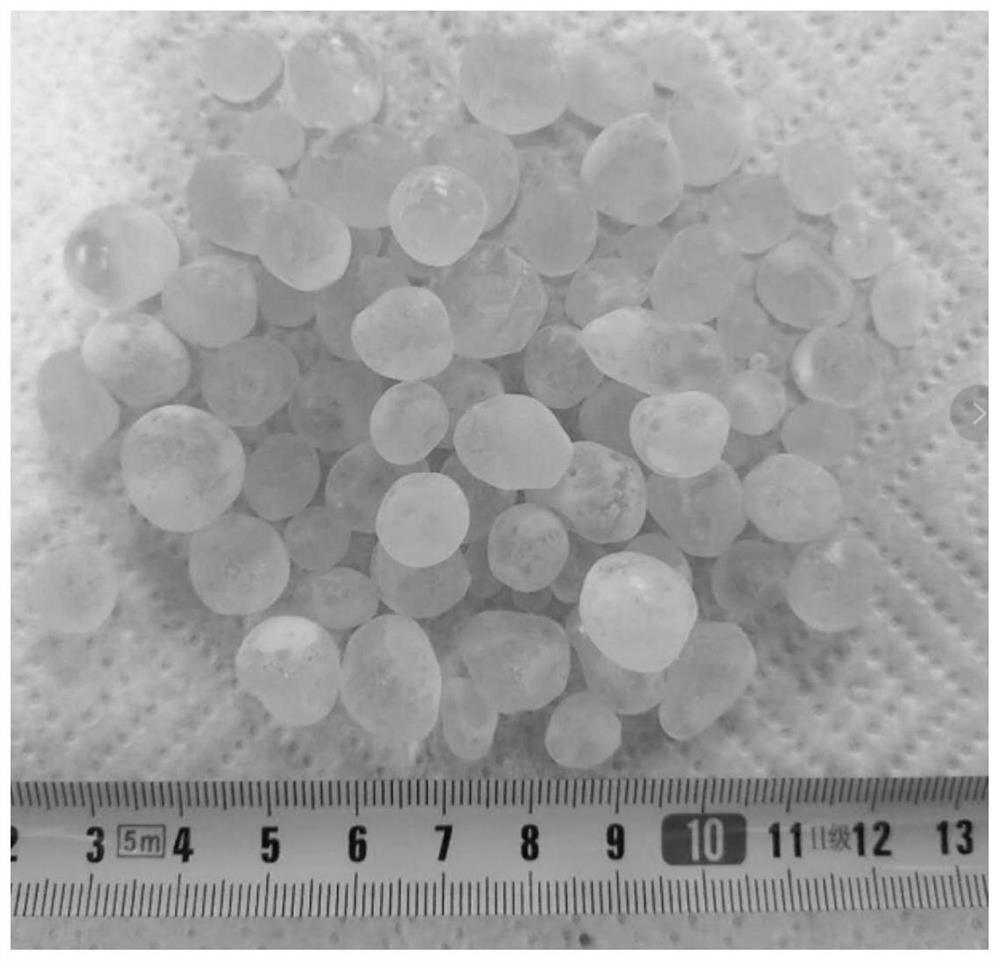

[0111] Among them, the formula of the variable-density pulsed liquid self-supporting fracturing fluid is: liquid A: resin (bisphenol A epoxy resin E-51 and bisphenol F epoxy resin compounded at a mass ratio of 1:1), diluted with acetone agent, triethylenetetramine curing agent, and polyvinyl alcohol fiber are prepared according to the mass ratio of 100:8:20:0.1. Liquid B: Emulsion fracturing liquid, sodium chloride, and polyvinyl alcohol fibers are prepared in a mass ratio of 100:3:0.2. B' sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com