A determination method for reducing fluid seepage resistance based on nanotechnology

A certain method, nanotechnology technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problem of lack of characterization methods for the effect of nanotechnology measures, improve construction efficiency and measure reliability, and improve development Effect, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

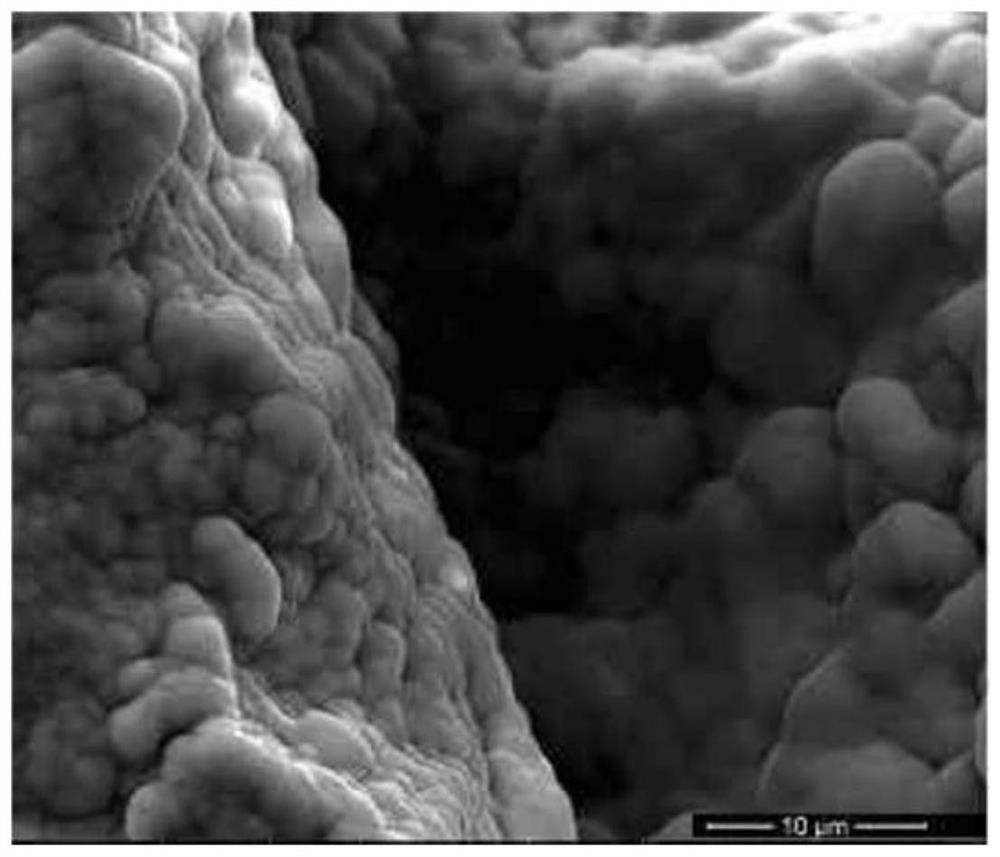

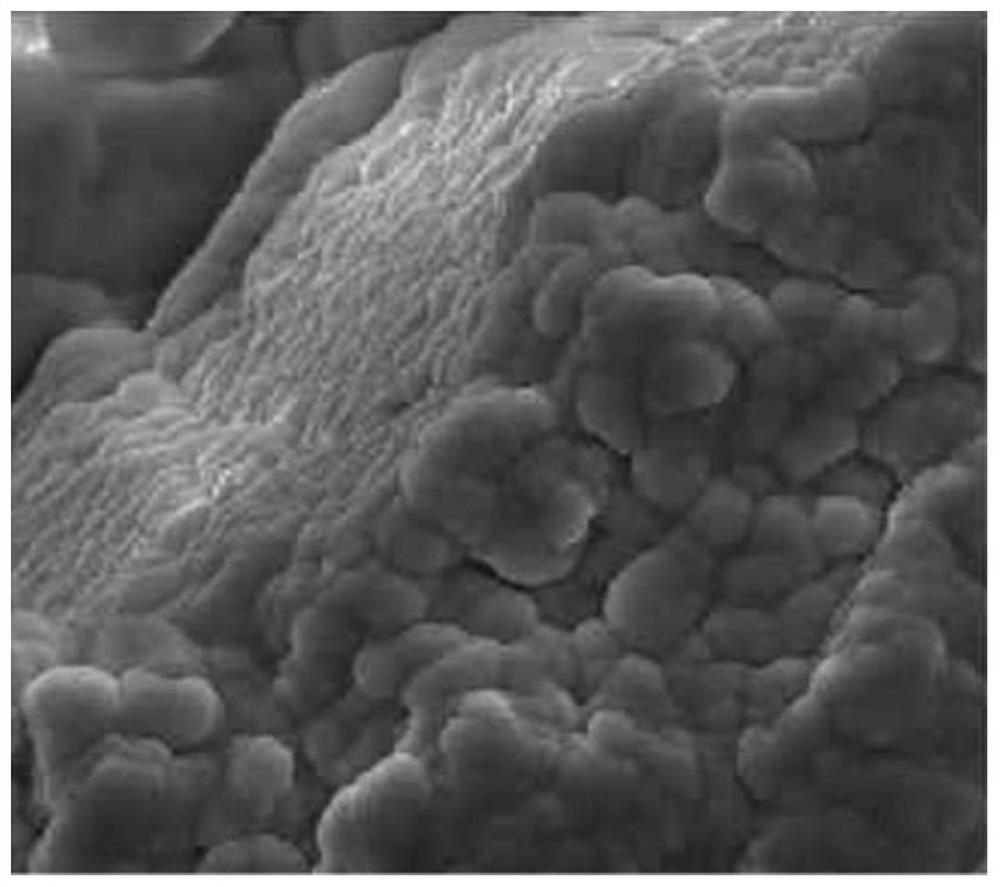

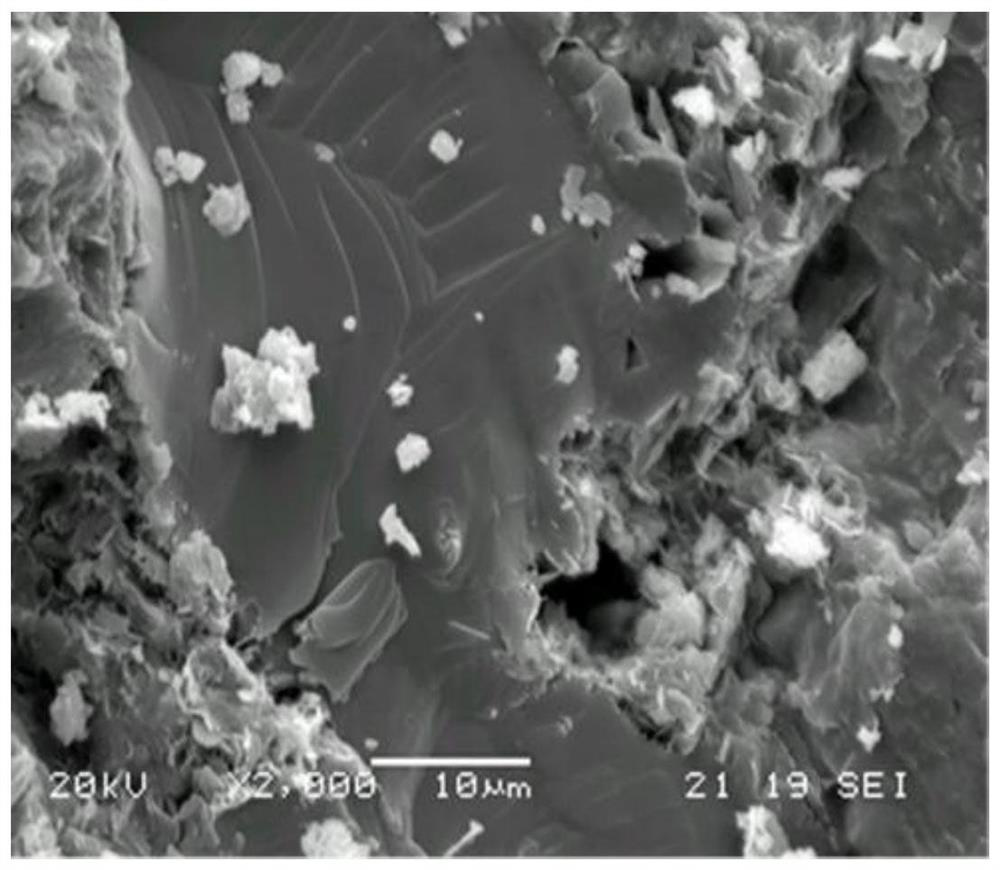

Image

Examples

Embodiment Construction

[0063] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that in the process of determining the method, the physical meanings referred to by the parameter symbols in the preceding and following texts are consistent, and will not be repeated when mentioned in the following texts. The on-site process parameters and production dynamic data in the embodiments of the present invention are all on-site The fluid parameters are collected by the detection device and can be viewed and called in real time.

[0064] In the embodiment of the present invention, a method for determining fluid seepage resistance reduction based on nanotechnology is provided for a technical site where nano-increased injection technology is used to implement enhanced injection measures for water injection wells in offshore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com