Patents

Literature

56results about How to "Improve displacement efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

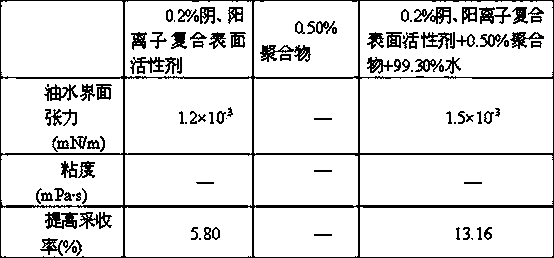

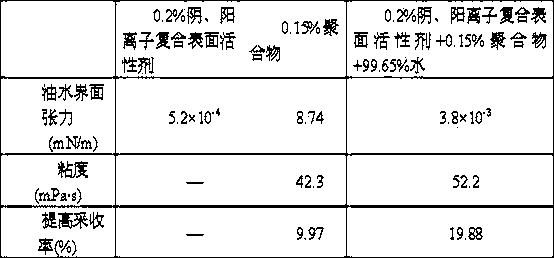

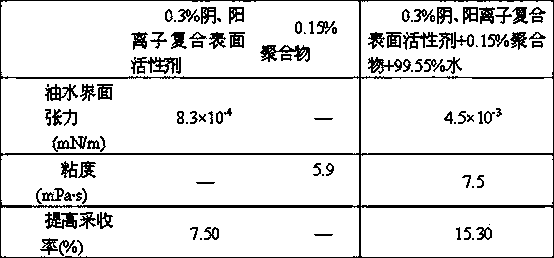

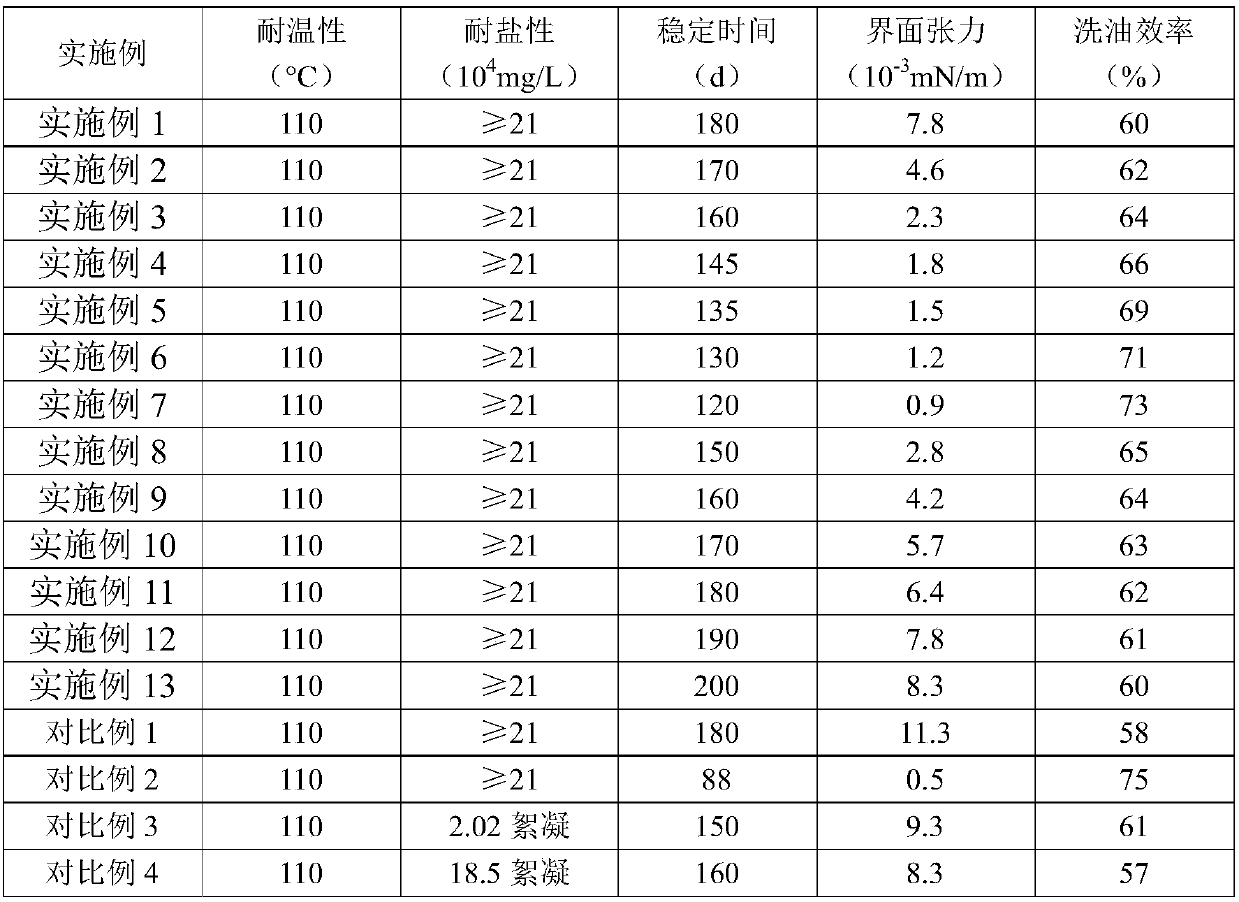

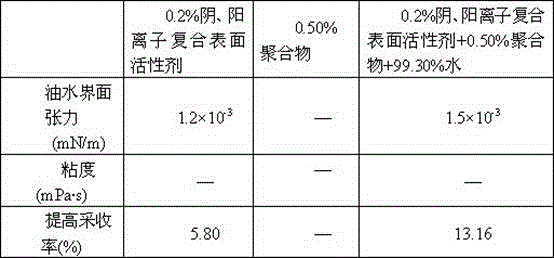

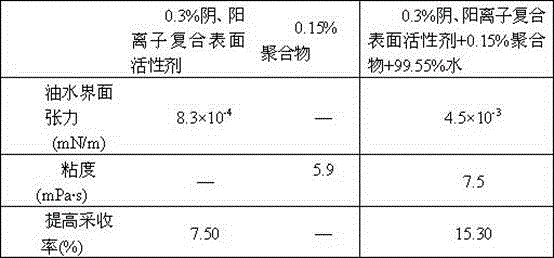

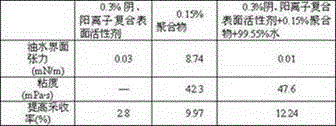

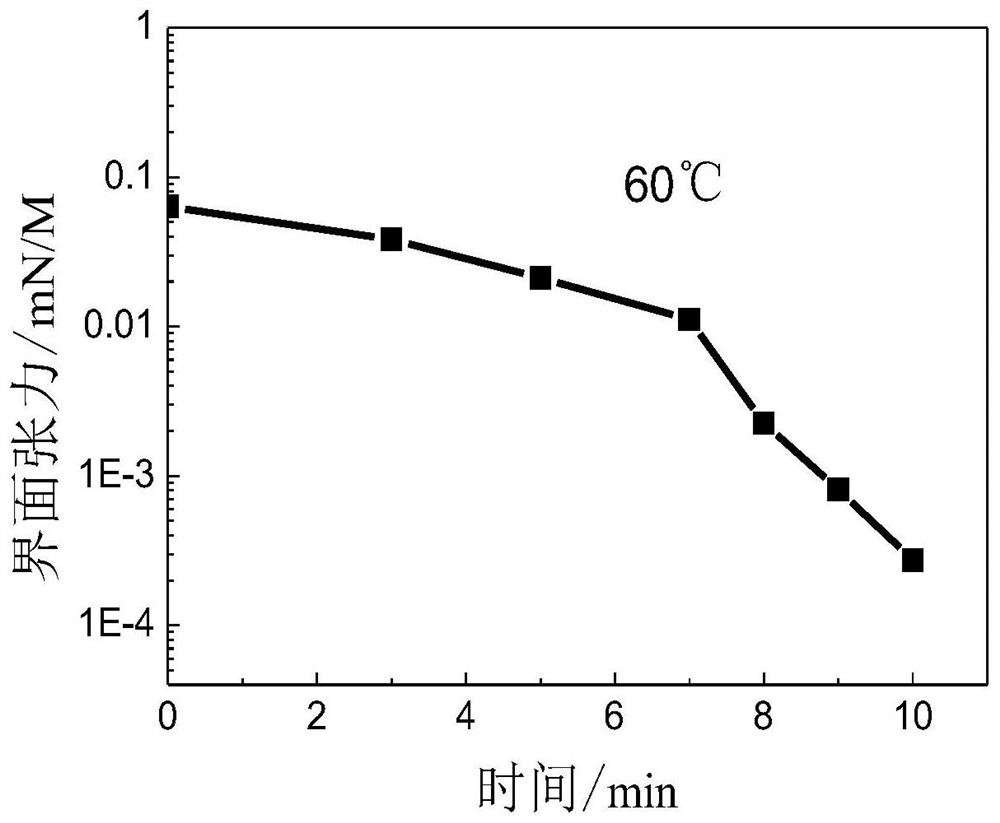

Method of displacing oil by anionic-cationic composite surfactant

ActiveCN103422840ALarge adsorption capacityLow critical micelle concentrationFluid removalDrilling compositionSURFACTANT BLENDOil well

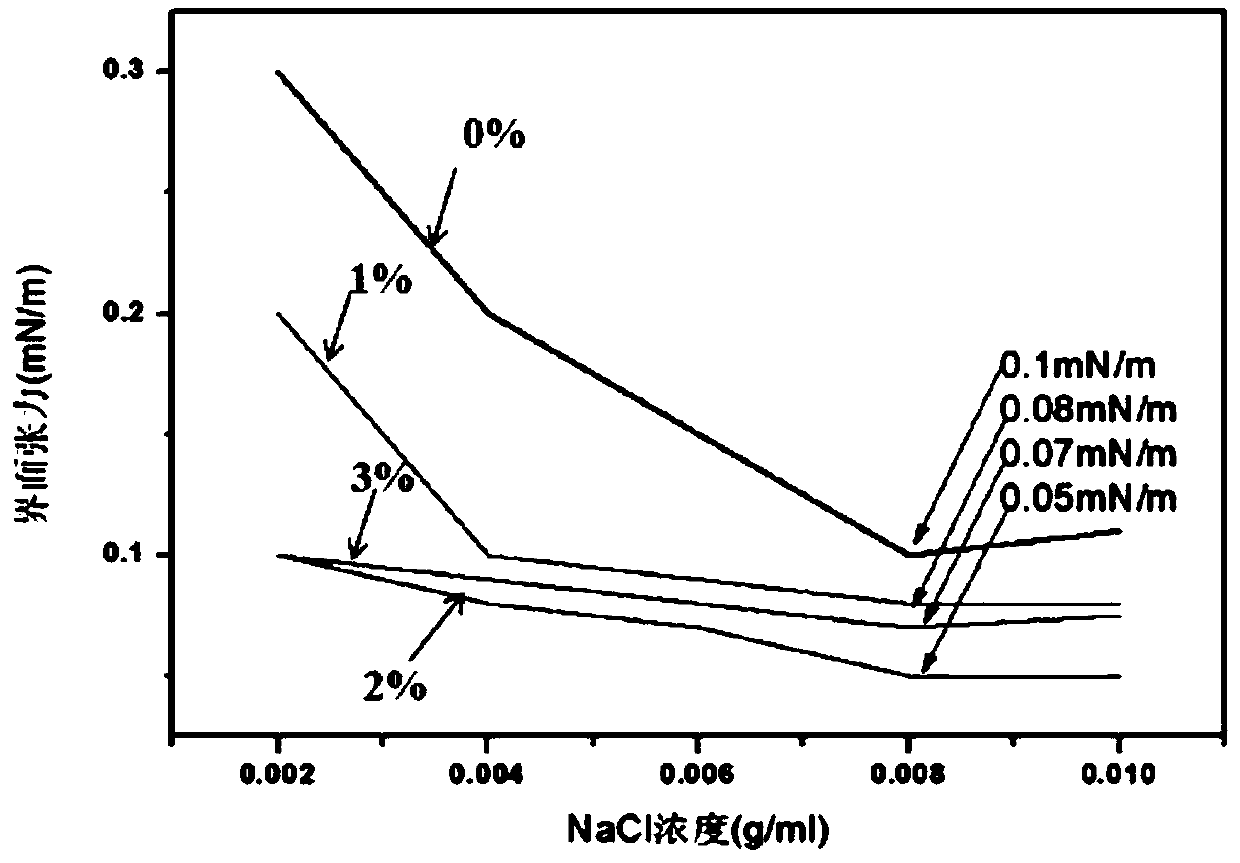

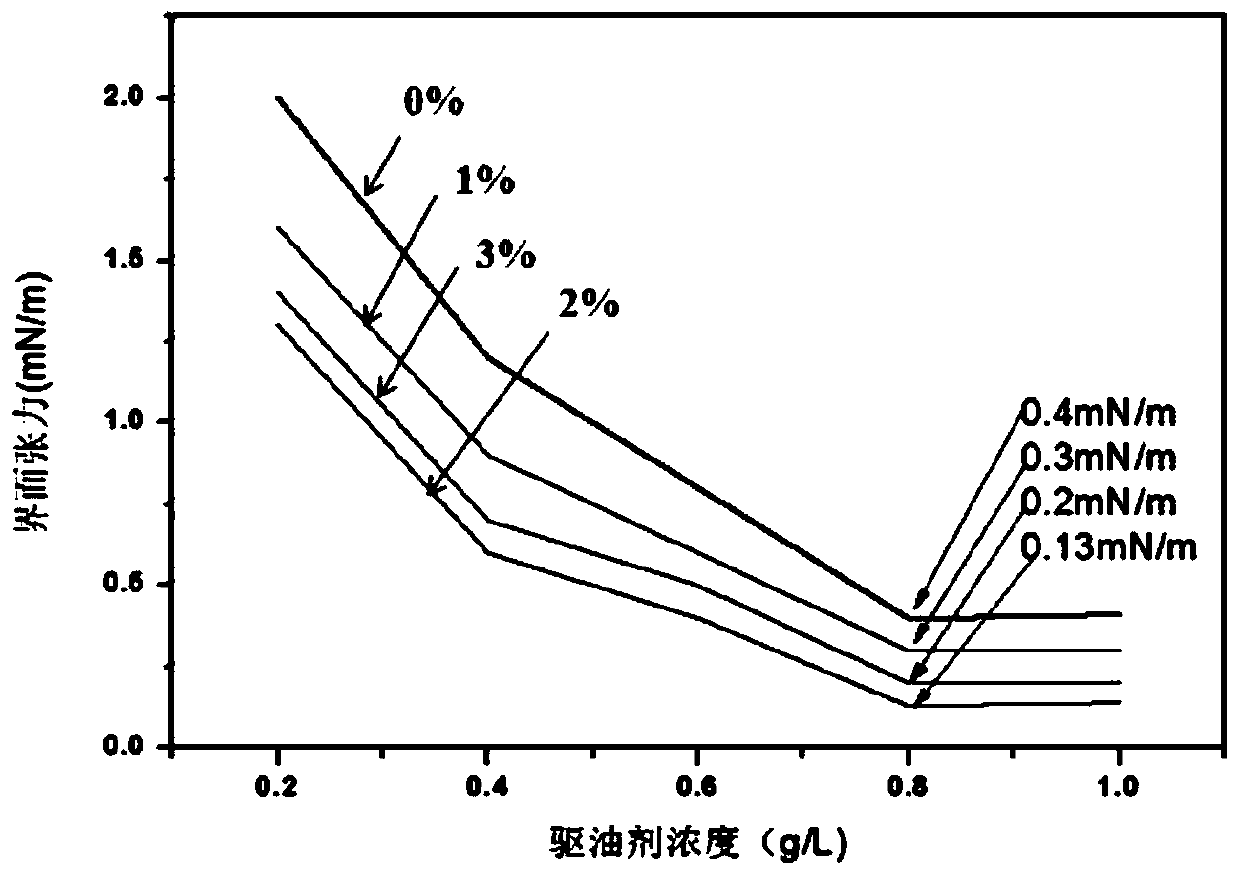

The invention relates to a method of displacing oil by anionic-cationic composite surfactant and mainly solves the problems that the prior method of displacing oil by surfactant is low in oil displacement efficiency in tertiary oil recovery and an oil displacement system containing inorganic base is harmful to stratums and oil wells, corrosive to equipment and pipelines and difficult for demulsification. According to the technical scheme, crude oil is allowed to contact with oil-displacing agent, and the oil-displacing agent comprises, by weight percent, 0.01-5.0% of anionic-cationic composite surfactant, 0.01-3.0% of polymer, and 92.0-99.98% of injected water. The problems are solved well. The method is applicable to tertiary oil recovery for oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for recovering crude oil from a subterranean formation

InactiveUS20090023618A1Easy extractionReduce adsorptionOrganic detergent compounding agentsAnionic surface-active compoundsPhysical chemistryOrganic phosphorus

Owner:RHODIA OPERATIONS SAS

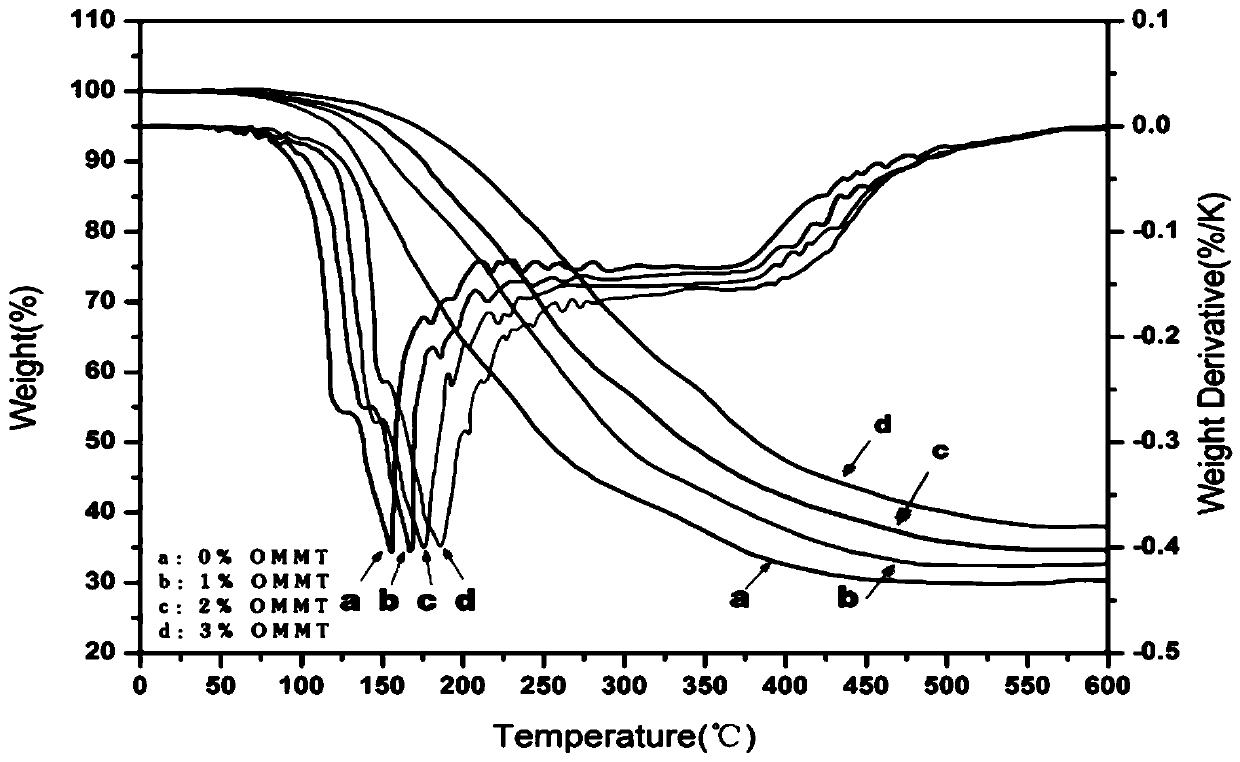

Xanthan gum graft copolymer oil displacement agent as well as preparation method and application thereof

ActiveCN102051165AImprove heat stabilityImprove biostabilityFluid removalDrilling compositionSide chainHeat resistance

The invention provides a xanthan gum graft copolymer oil displacement agent as well as a preparation method and application thereof. Based on molecular design, at least two of acrylamide (AM), 2-acrylamido-2-methylpropane sulfonic acid (AMPS), N-vinylpyrrolidone (NVP) and N,N-dimethylacrylamide (DMAM) are graft-copolymerized to xanthan gum macromolecules. Since the copolymerized side chain is introduced, the viscoelasticity, heat resistance and biological stability of the xanthan gum macromolecules can be greatly enhanced; the xanthan gum graft copolymer can be used as an oil displacement agent for tertiary oil recovery simultaneously; and the solution rate of the xanthan gum graft copolymer is obviously increased, and the xanthan gum graft copolymer can not easily generate gel in brine. When the xanthan gum graft copolymer oil displacement agent is used in a high-temperature high-salinity oil reservoir, the oil displacement effect is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

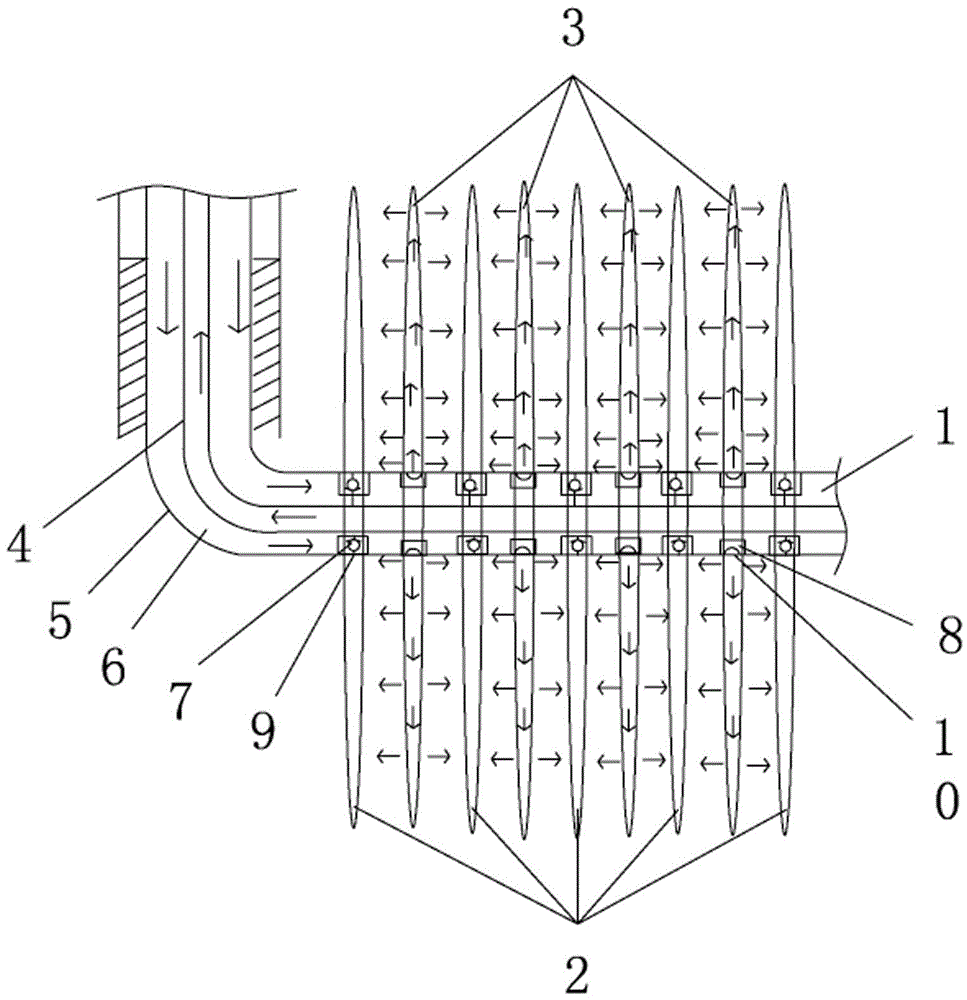

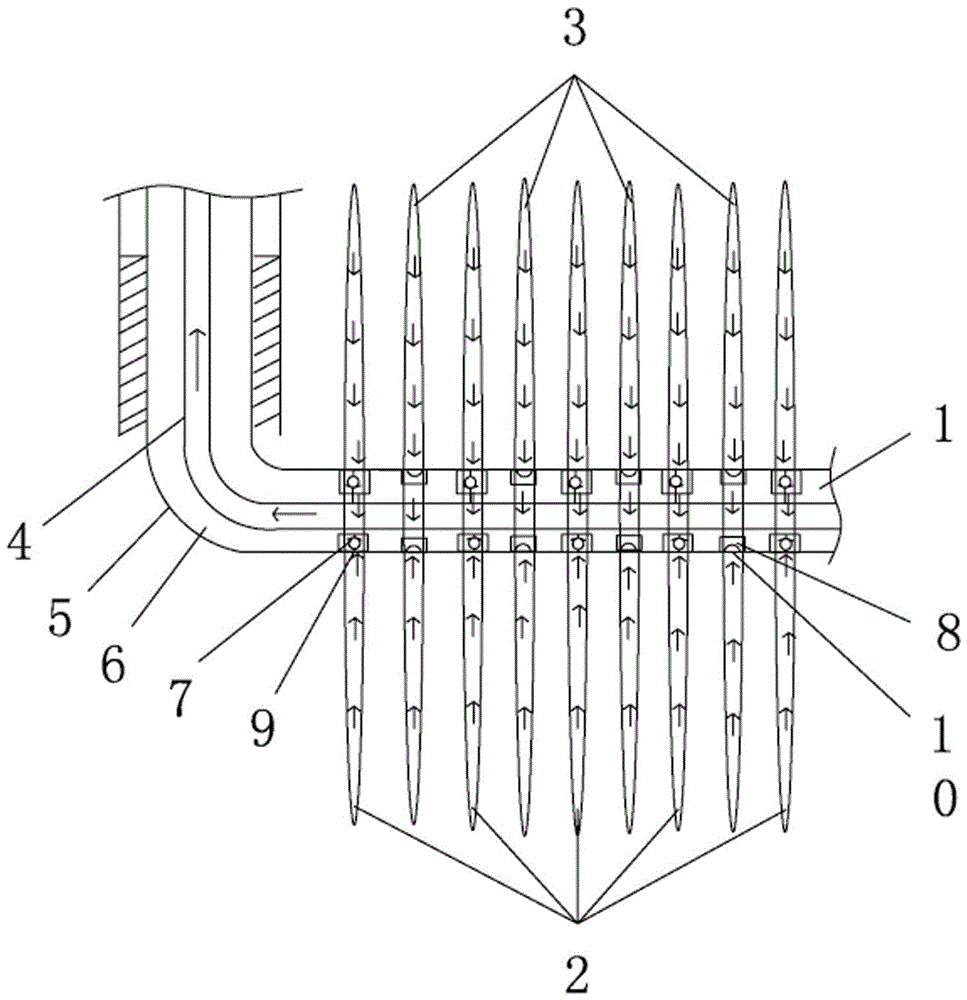

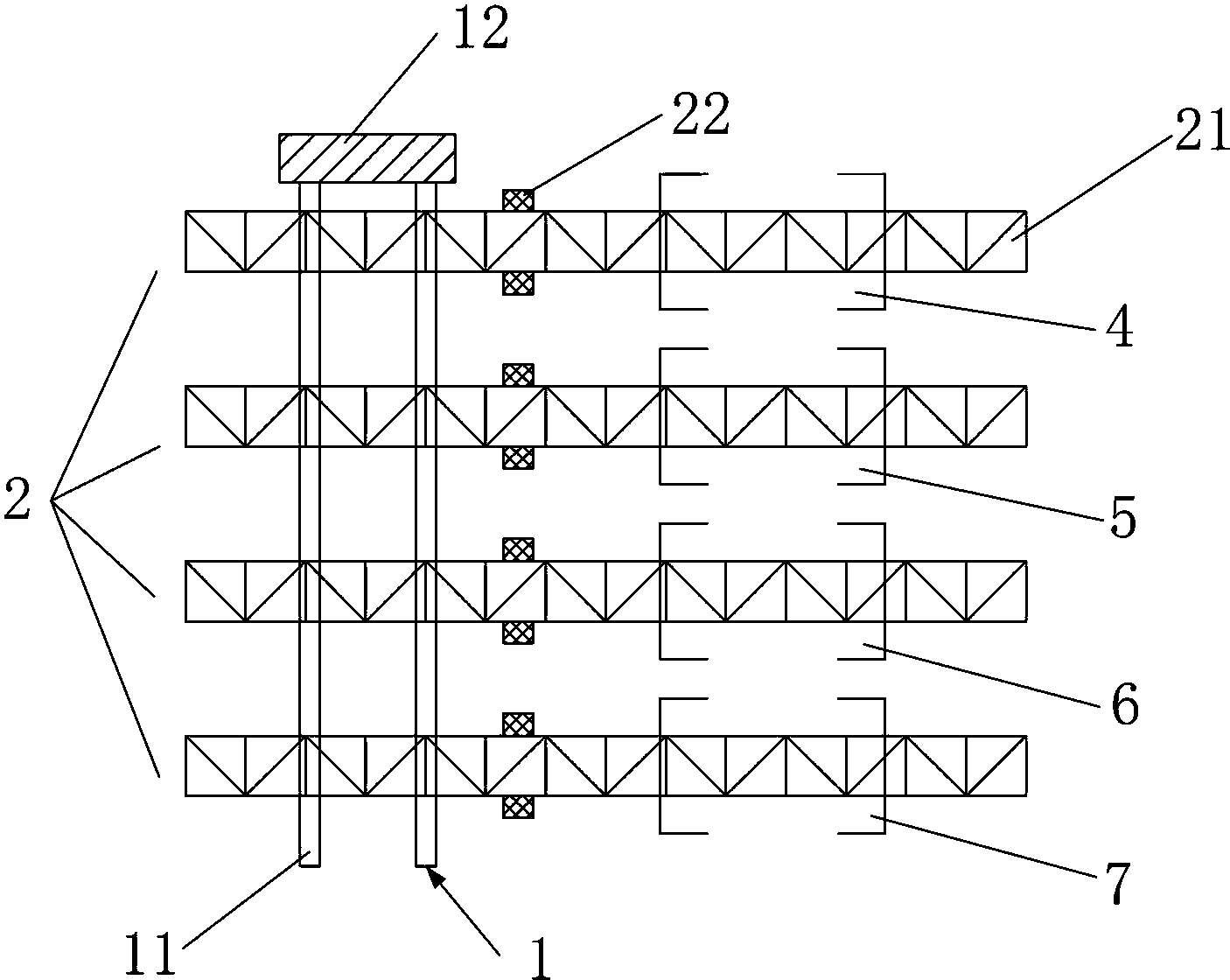

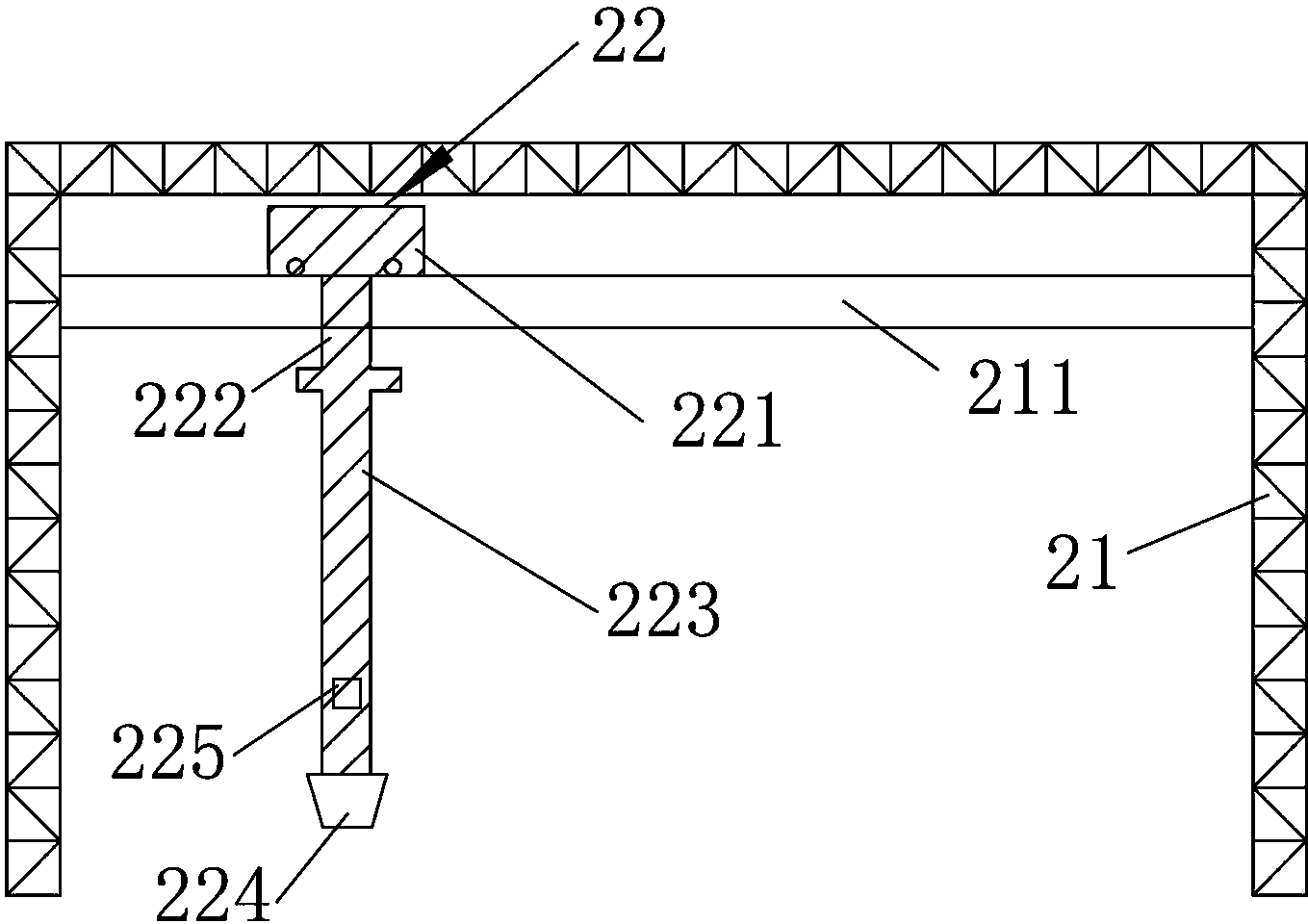

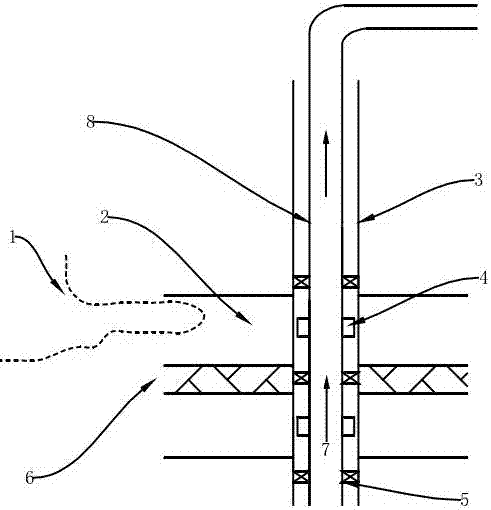

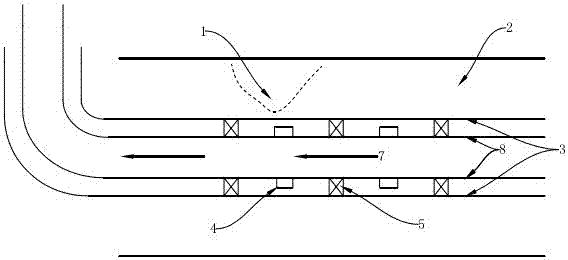

Method for achieving interval waterflood swallowing-spitting oil exploitation among multi-stage fracturing horizontal well fractures

The invention relates to a method for achieving interval waterflood swallowing-spitting oil exploitation among multi-stage fracturing horizontal well fractures.The method comprises the following steps that staged fracturing is performed on a horizontal well shaft to form multiple fracturing fractures perpendicular to the horizontal well shaft; a one-way valve is arranged at the position of each odd-stage fracture, and an injection allocation valve is arranged at the position of each even-stage fracture; exploitation is performed through natural energy for a period of time, then waterflood swallowing-spitting through the interval fractures, the one-way valves are automatically switched off, the injection allocation valves are automatically switched on, water is injected into an annular space of an oil jacket for displacement, and the injected water enters the even-stage fractures; the well is opened for oil exploitation after being shut for soaking, the one-way valves are automatically switched on, crude oil is output from the odd-stage fractures and enters an oil pipe, and a mixture of the displaced crude oil and the injected water is output from the even-stage fractures, enters the annular space of the oil jacket and then enters the oil pipe to be output.According to the method, the yield of the oil well is increased, the operation cost is reduced, and the wide application prospect is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

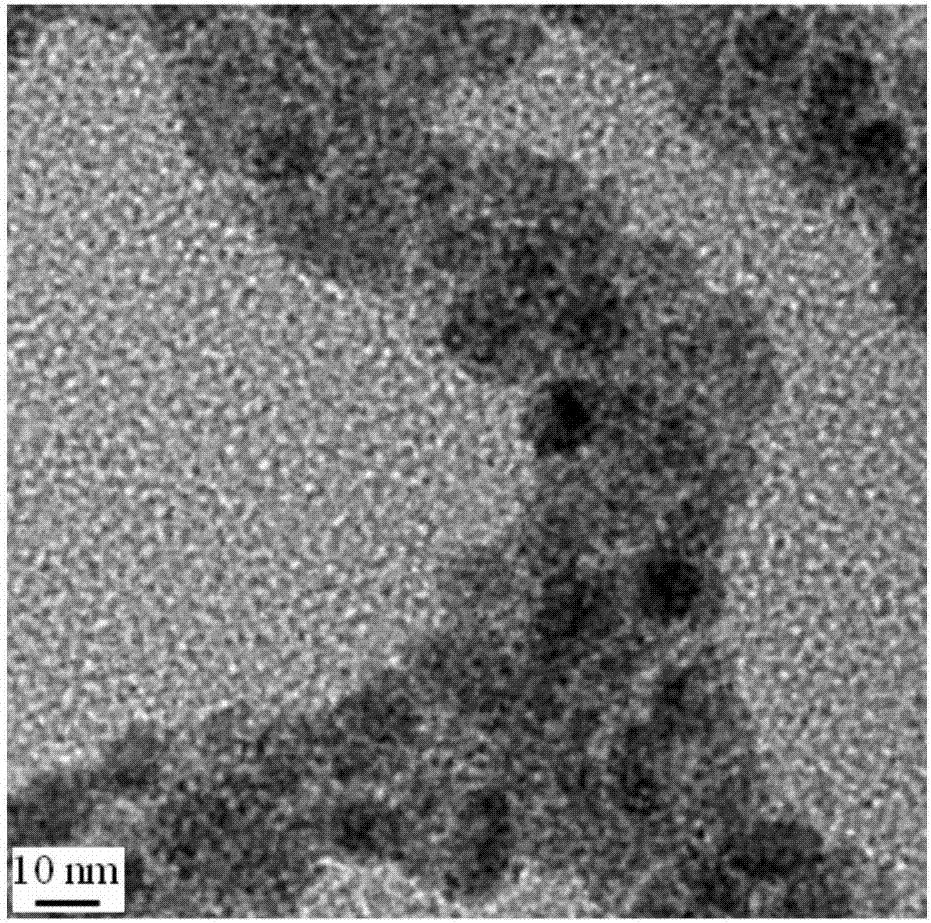

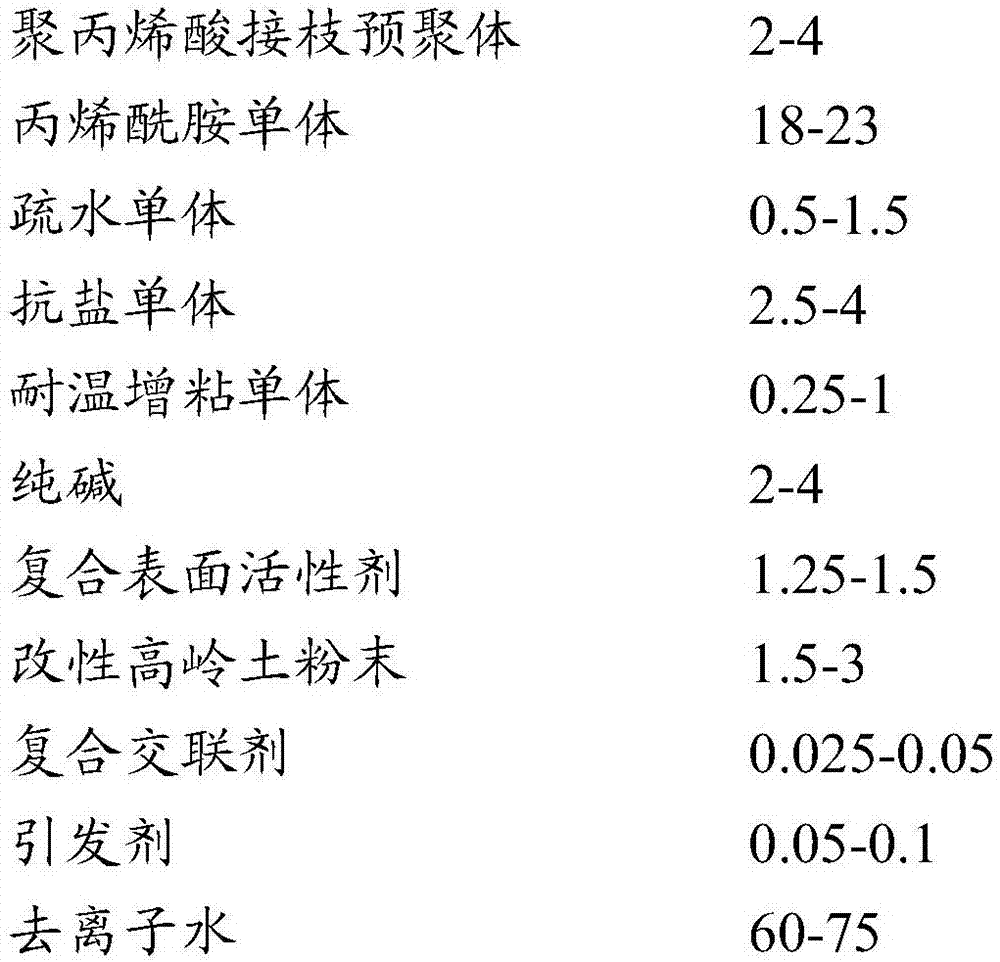

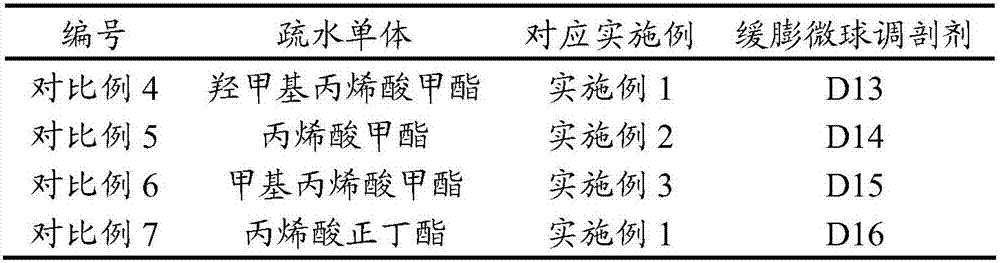

Pre-crosslinking gel retarding-swelling microsphere profile control agent and preparation method and application thereof

ActiveCN106883357AImprove temperature resistanceImprove salt toleranceDrilling compositionMicrosphereALLYL SUCROSE

The invention relates to a pre-crosslinking gel retarding-swelling microsphere profile control agent and a preparation method and application thereof. The pre-crosslinking gel retarding-swelling microsphere profile control agent comprises a polyacrylic acid grafting prepolymer, an acrylamide monomer, a hydrophobic monomer, an anti-salt monomer, a temperature-resistant tackifying monomer, pure alkaline, a composite surfactant, modified kaolin powder, a composite crosslinking agent, an initiator and deionized water. The pre-crosslinking gel retarding-swelling microsphere profile control agent has the advantages that by selecting particular components, particularly modifying multiple components, and utilizing the comprehensive synergistic and promoting functions of multiple technical features, the profile control agent with excellent result is obtained; the excellent high temperature-resistant property, high salt-resistant property, good tackifying property, plugging property and the like are realized; the good application prospect and industrial potential are realized in the field of petroleum exploitation.

Owner:DONGYING FANGLI CHEM CO LTD

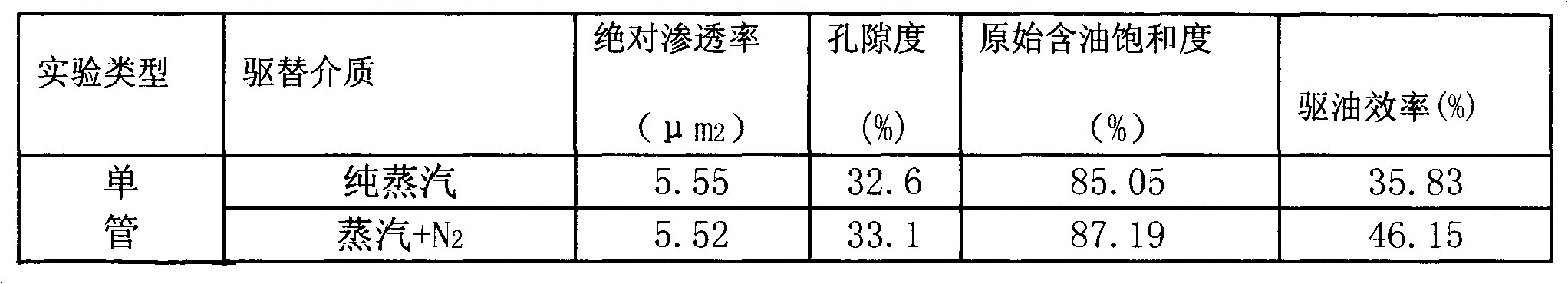

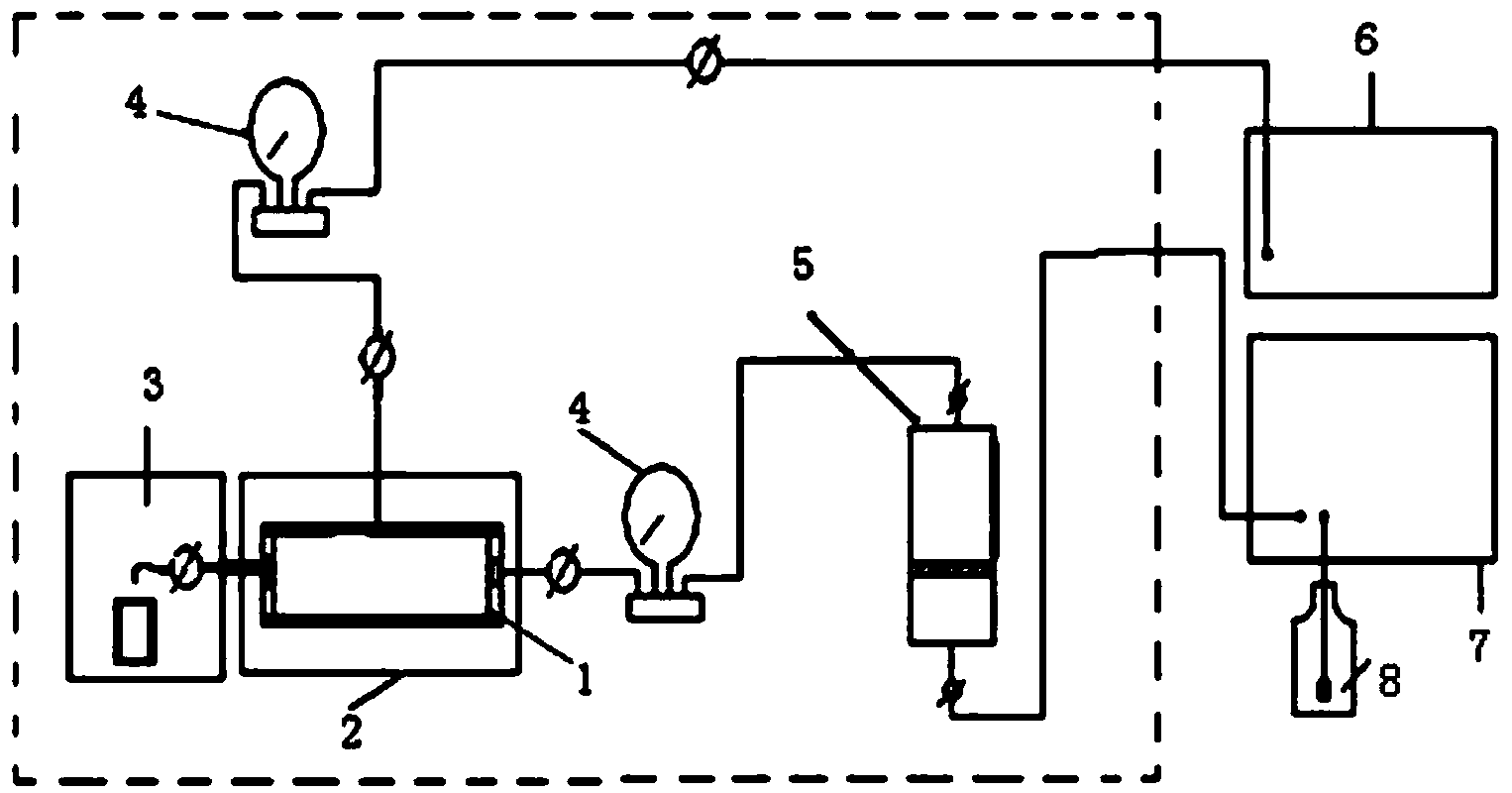

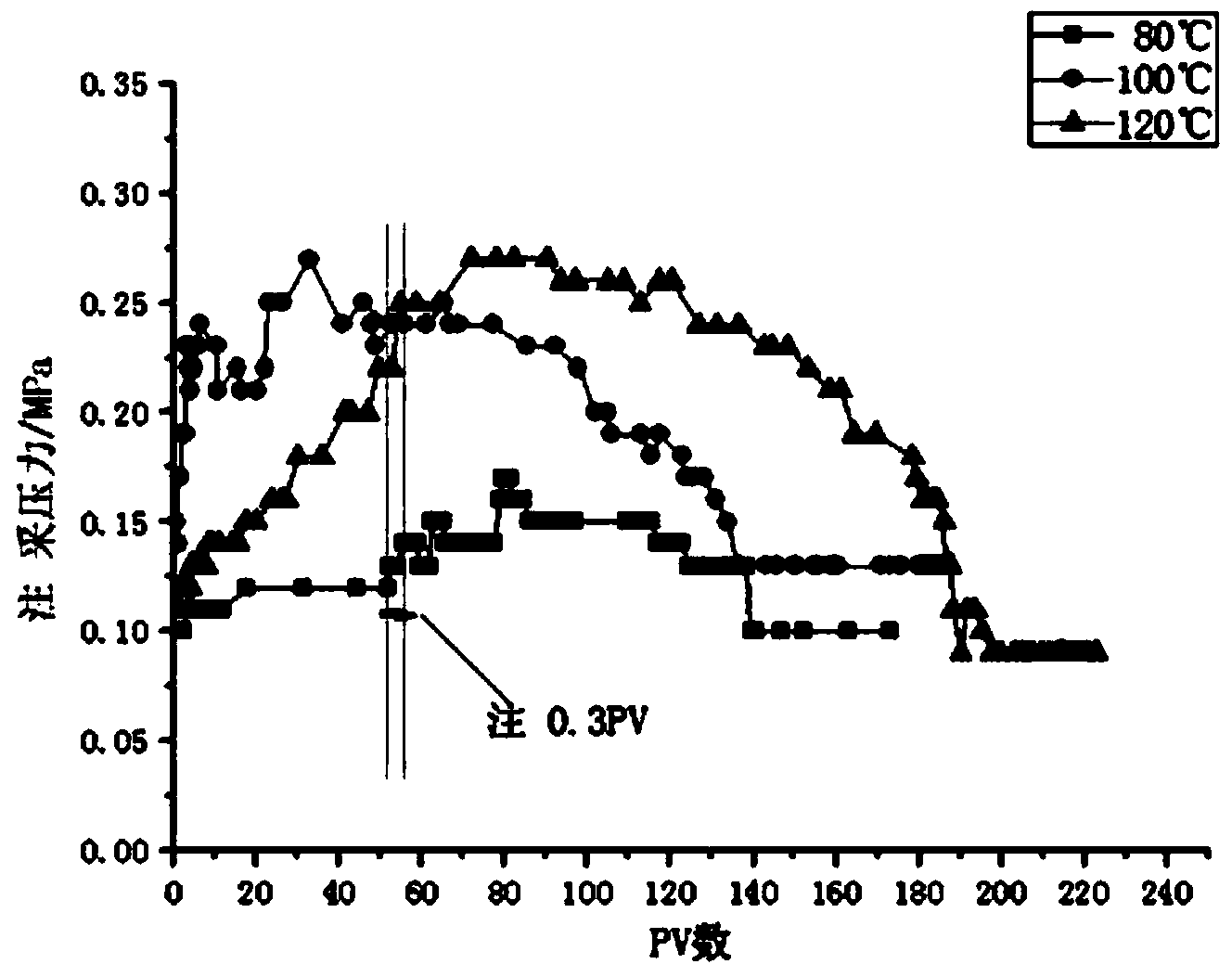

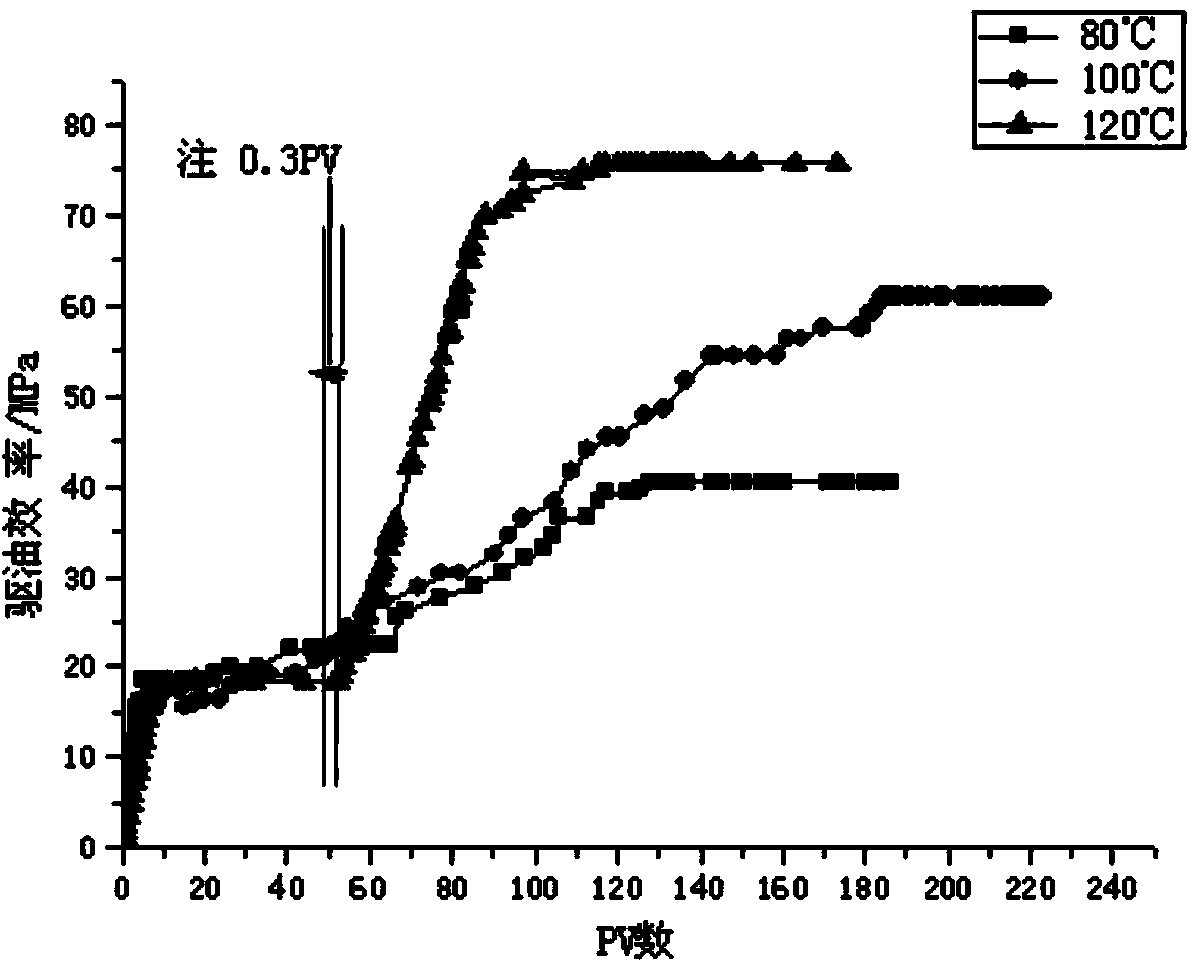

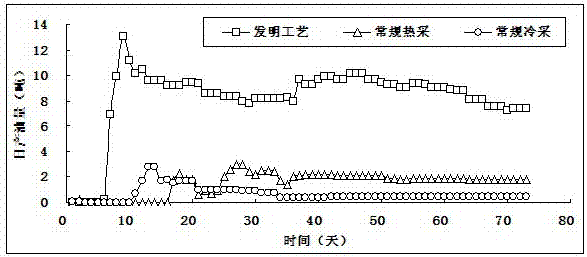

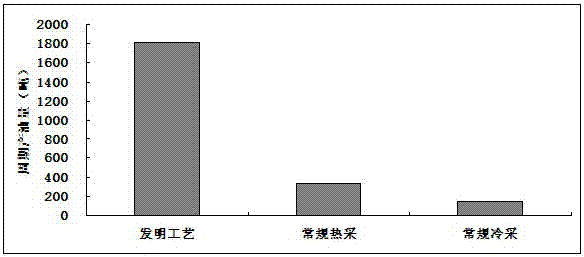

Steam and nitrogen composite swallowing-spitting oil extraction method

InactiveCN102146782AImprove displacement efficiencyIncrease drainage areaFluid removalThermodynamicsNitrogen gas

The invention provides a steam-and-nitrogen composite swallowing-spitting oil production method, comprising the following steps: a, steam injection string laying: a pipe column structure successively comprises an even steam distribution pipe column provided with an even steam distribution valve and a compensator, an injection and extraction integrated pump connected to the even steam distribution pipe column, an oil pipe arranged on the pump, and a subcritical steam injection well from bottom to top; b, N2 and steam injection: steam is injected through an oil jacket annulus, meanwhile, nitrogen is injected into an oil well through the oil pipe, nitrogen injection speed is regulated to evenly allocated and injected during the whole steam injection process; c, soaking: soaking is carried out for 2-7 days after steam injection and nitrogen injected are over; d, blowout: when the well pressure drops to 0.5Mpa / day, blowout is controlled by an oil nozzle; and e, pumping start: when open-flow liquid amount reaches 3t / d, the injection and extraction integrated pump is used to start pumping.

Owner:CHINA PETROLEUM & CHEM CORP +1

Long-acting mixed fluorocarbon surfactant treating agent for improving condensate gas reservoir recovery efficiency and application of mixed fluorocarbon surfactant treating agent

ActiveCN103865509ASystem stabilityImprove high temperature resistanceFluid removalDrilling compositionAlcoholRock core

The invention relates to a long-acting mixed fluorocarbon surfactant treating agent for improving the condensate gas reservoir recovery efficiency and application of mixed fluorocarbon surfactant treating agent. The mixed fluorocarbon surfactant treating agent comprises the following components in parts by weight: 0.05-0.3% of nonionic fluorocarbon surfactant, 0.05-0.3% of zwitter-ion fluorocarbon surfactant, 0.05-0.3% of nonionic hydrocarbon surfactant, 5-30% of alcohol, and the balance of water. The mixed fluorocarbon surfactant treating agent is capable of forming a compact adsorption film on the rock surface to construct a good airflow channel, the gas phase permeability of a stratum is improved, the displacement efficiency of the gas drive is obviously improved, and the validity is long. The invention further provides the application of the mixed fluorocarbon surfactant treating agent, the mixed fluorocarbon surfactant treating agent is applied to the condensate gas reservoir, the water blocking is prevented, the recovery efficiency is improved, the injection amount injected into rock core or stratum is 0.2-0.4PV, and the gas drive recovery rate can be improved to 40-78% under different temperature.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

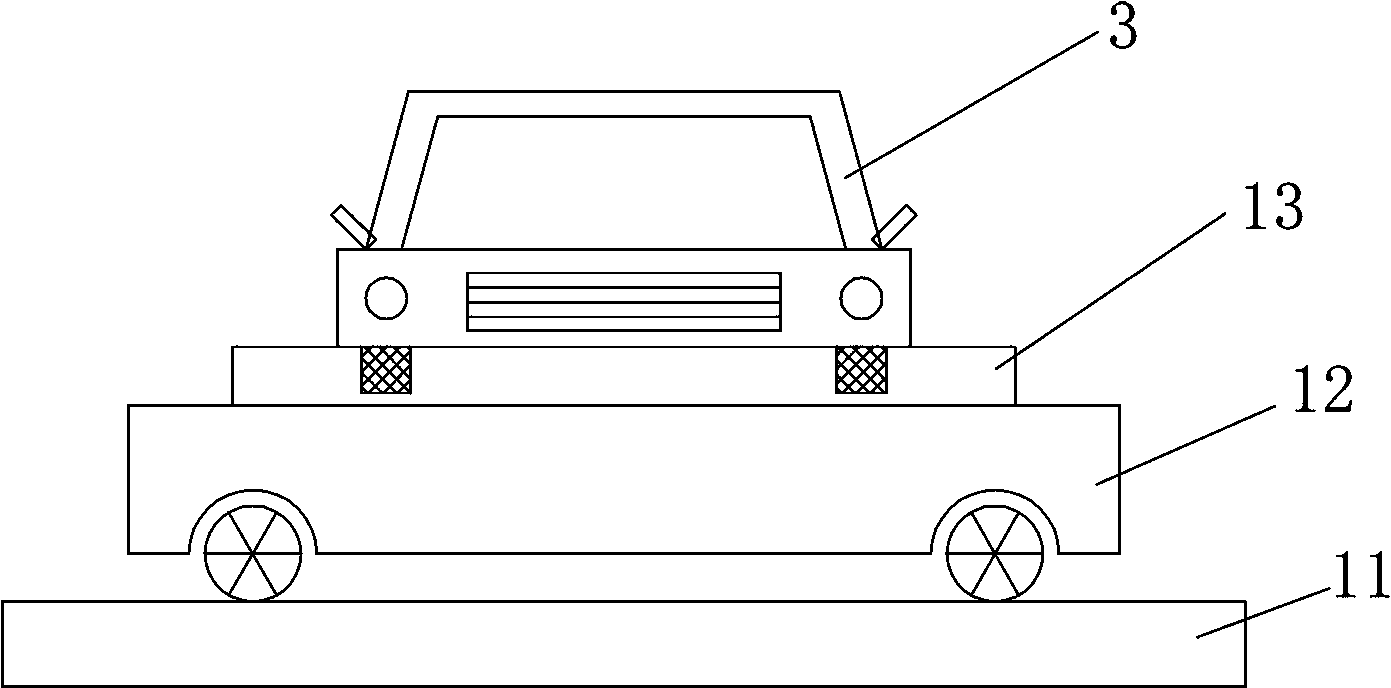

Scraped automobile preprocessing method and production line thereof

ActiveCN103640644AImprove displacement efficiencyImprove the orderliness of dismantlingVehicle dissasembly recoverySolid waste disposalProduction linePretreatment method

The invention discloses a scraped automobile preprocessing method and a production line thereof. The method includes the following procedures of pre-disassembling, disassembling an automobile body, disassembling a power system and packaging. The production line comprises a conveying main line and a conveying branch line. The specific procedures of the scraped automobile disassembling processes are provided; according to the steps of the specific procedures, disassembly orderliness and disassembly efficiency can be improved. An arrangement scheme of four disassembly stations is provided, the pre-disassembly station, the automobile body disassembly station and the power system disassembly station are three main disassembly procedures which are arranged according to time consumption of the disassembly steps, thus the time consumed in each procedure is basically equal. Reasonable arrangement of time and personnel is facilitated and the problem that other procedures are delayed due to the fact that one procedure is too slow is effectively solved. A conveying system which joints all procedures together is provided and the conveying main line and the conveying branch line are adopted. A lengthwise conveying plate trailer and a transverse lifting device are used so that the displacement efficiency of scraped automobiles can be effectively improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Thin and shallow layer super heavy oil horizontal well, viscosity reducer, nitrogen and steam assisted huff and puff method

InactiveCN104747148AIncrease the lengthPrevent outside escapeFluid removalDirectional drillingSleeve valveNitrogen gas

The invention provides a thin and shallow layer super heavy oil horizontal well, viscosity reducer, nitrogen and steam assisted huff and puff method, and belongs to the technical field of oil field production. The method includes the steps of firstly, drilling holes in a horizontal well; secondly, filling an oil pipe with oil-soluble viscosity reducers, closing a sleeve valve, and continuing to fill a well shaft with the oil-soluble viscosity reducers; thirdly, filling an oil sleeve with nitrogen in an annulus mode; fourthly, filling the oil pipe with steam through a filling and production integrated pipe column; fifthly, conducting soaking for 2 hours to 4 hours; sixthly, controlling flow opening through an oil nozzle when the pressure of a well opening falls to 0.5 MPa / d; seventhly, starting the pumping when conducting flow opening to the liquid amount of 3t / d. By means of the composite heavy oil development mode integrating the horizontal well, the viscosity reducers, the nitrogen and the steam, by means of the comprehensive effect of all elements, the steam swept volume is remarkably improved, the viscosity of crude oil is reduced, the energy of a stratum is compensated for, the steam filling pressure is reduced, the steam overlapping is avoided, the thermal loss of the stratum is reduced, and the oil driving efficiency and crude oil flowing capacity are improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method of improving deep super-thick oil reservoir recovery efficiency

The invention relates to a novel method capable of improving deep super-thick oil reservoir recovery efficiency. According to the method, in the steam huff and puff and steam flooding processes, a water-soluble nano-catalyst is injected to make the viscosity of super-thick oil under the condition of an oil reservoir be reduced substantially, as a result, the fluidity of the super-thick oil under the condition of the oil reservoir is improved, the shortcomings that a deep super-thick oil reservoir is high in steam injection pressure and low in well bottom steam dryness are effectively overcome, steam injection quantity also can be reduced, and the purpose of economical and efficient development of the deep super-thick oil reservoir is achieved. On the basis of steam huff and puff and steam flooding, the method of improving deep super-thick oil reservoir recovery efficiency can reduce the velocity of crude oil by more than 80%, increase the recovery percent by about 15%, and increase the gas-oil ratio in a huff and puff well period by 0.15.

Owner:CHINA PETROLEUM & CHEM CORP +1

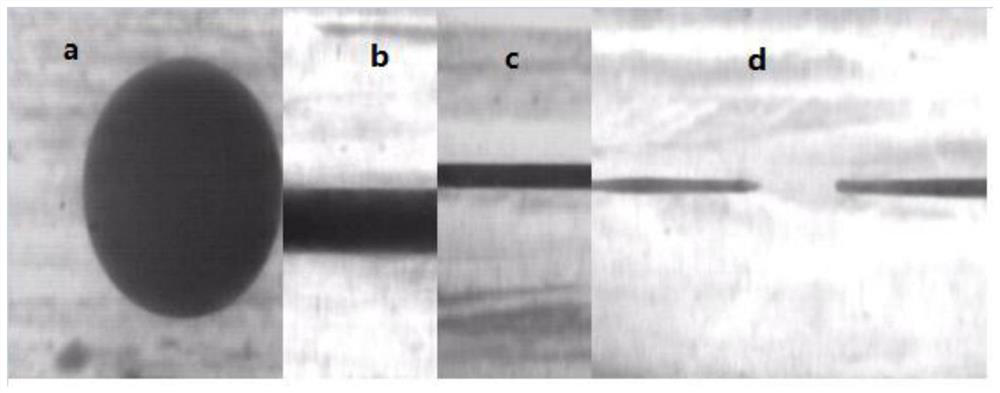

Multifunctional nano-viscosity reduction profile control agent

InactiveCN101531891AImprove seepage capacitySmall particlesDrilling compositionReduction rateFoaming agent

The invention provides a multifunctional nano-viscosity reduction profile control agent, relating to an additive for thick oil exploitation in the chemical field of oil exploitation and a use method thereof. The agent disperses the continuous thick oil to an oil-in-water oil block by a low interfacial tension mechanism, and has the characteristics of high viscosity reduction rate, dispersed system while flowing, layering while being still, no influence on emulsion breaking, small use concentration and great economical feasibility. The technique combines the viscosity reduction, the profile control with displacement of reservoir oil, which can not only reduce the viscosity of the thick oil and regulate a water absorption profile, but also improve the efficiency of the displacement of reservoir oil, therefore, the integration of displacement and control is realized so that the technique is an organic combination of secondary oil recovery and tertiary oil recovery as well as has remarkable comprehensive economic benefit. By adding an assistant agent of a foaming agent, the method increases fluid film strength, prolongs foaming half life period, enhances foaming stability and sufficiently solves the problems of high viscosity of the thick oil and difficult development in the process of oilfield development and exploitation; the characteristics of nano-particles are utilized to exert cooperative effect between the agents to the maximum extent so as to realize the objective of viscosity reduction, profile control and efficiency increase.

Owner:SOUTHWEST PETROLEUM UNIV

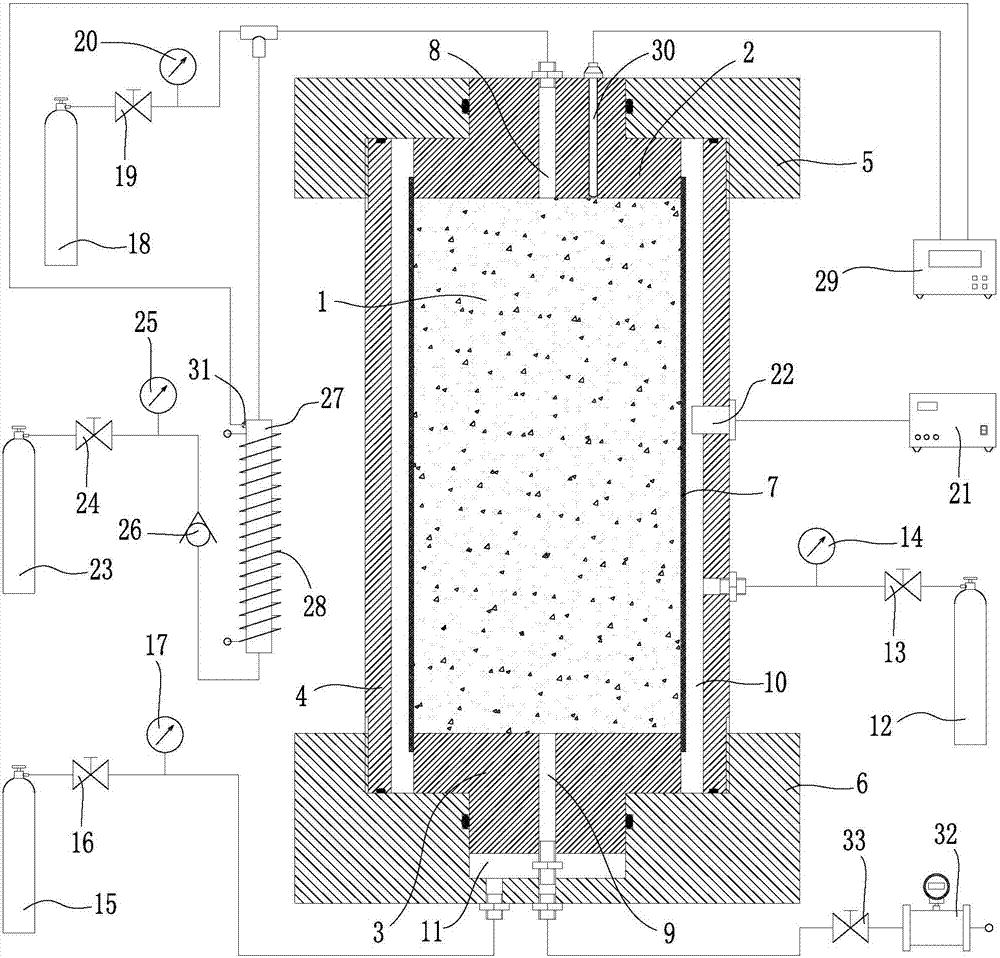

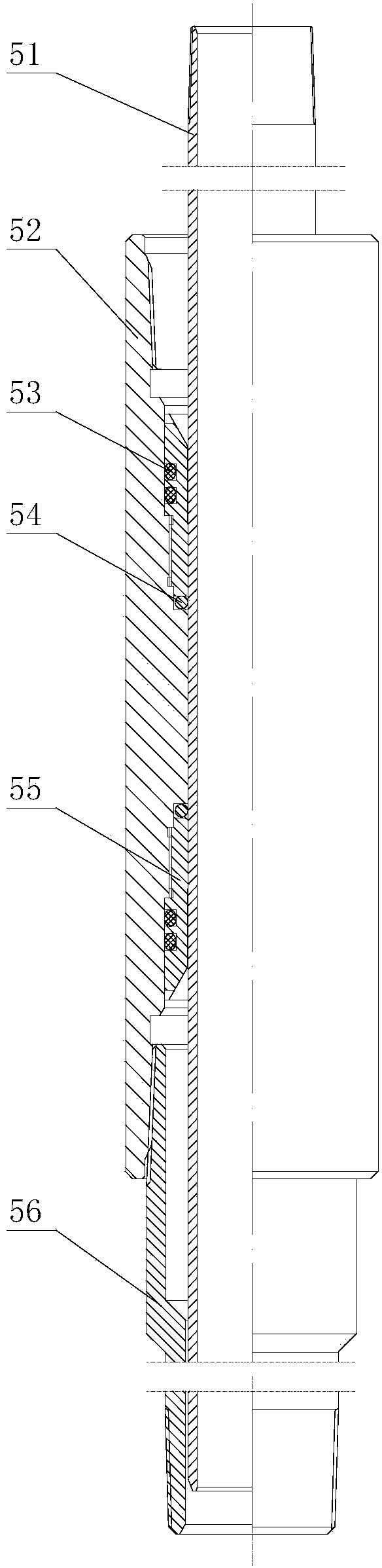

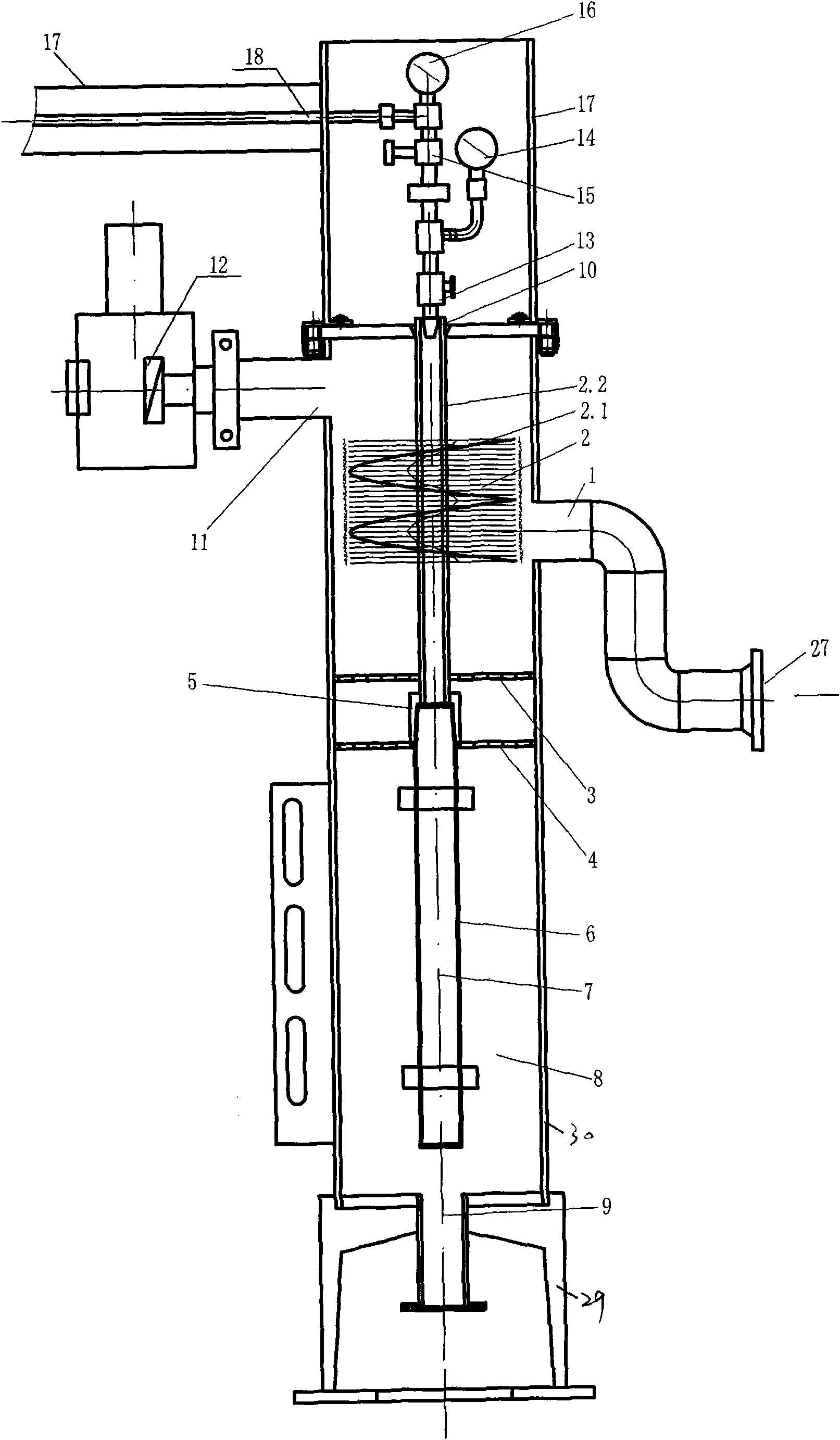

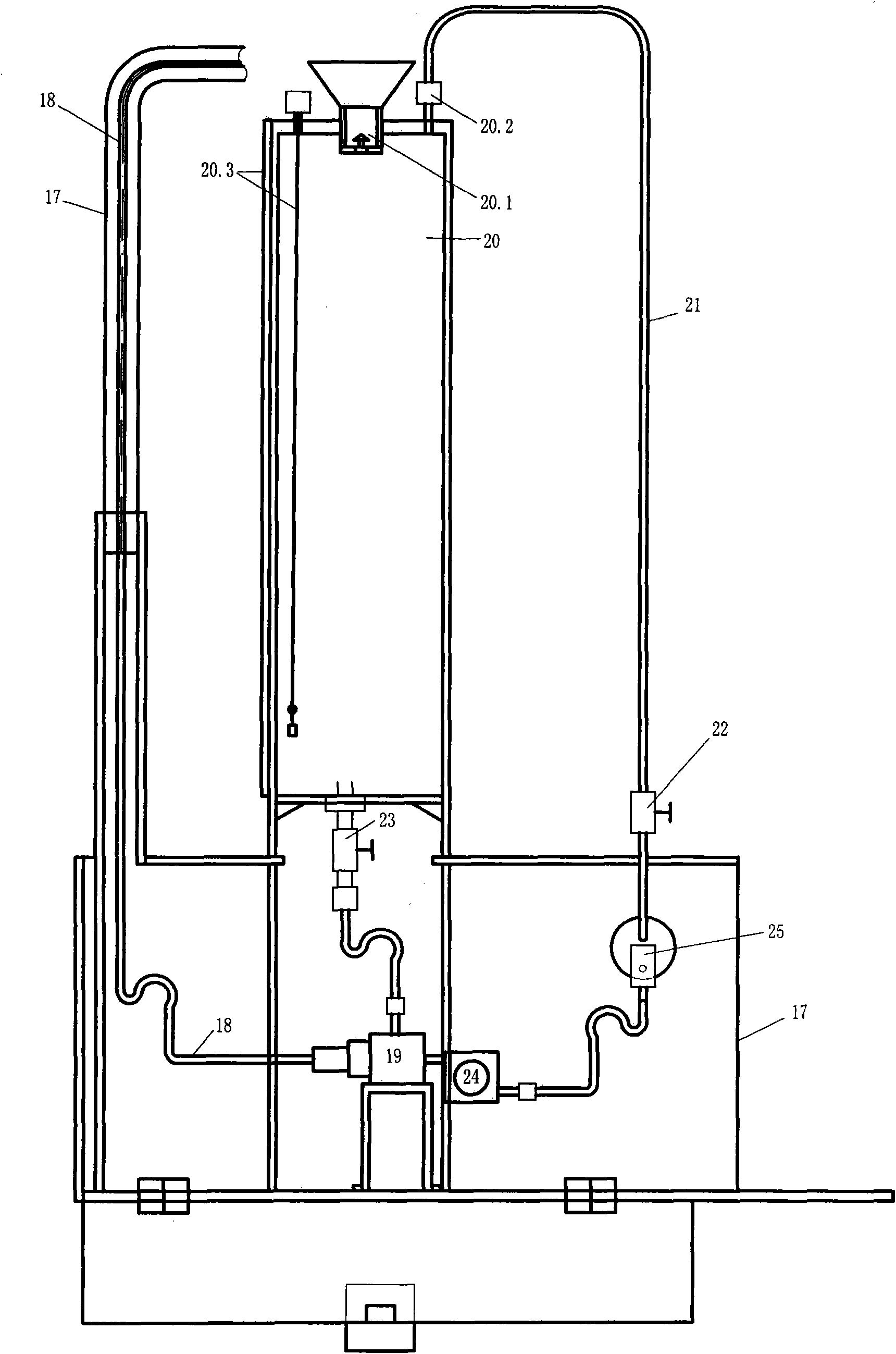

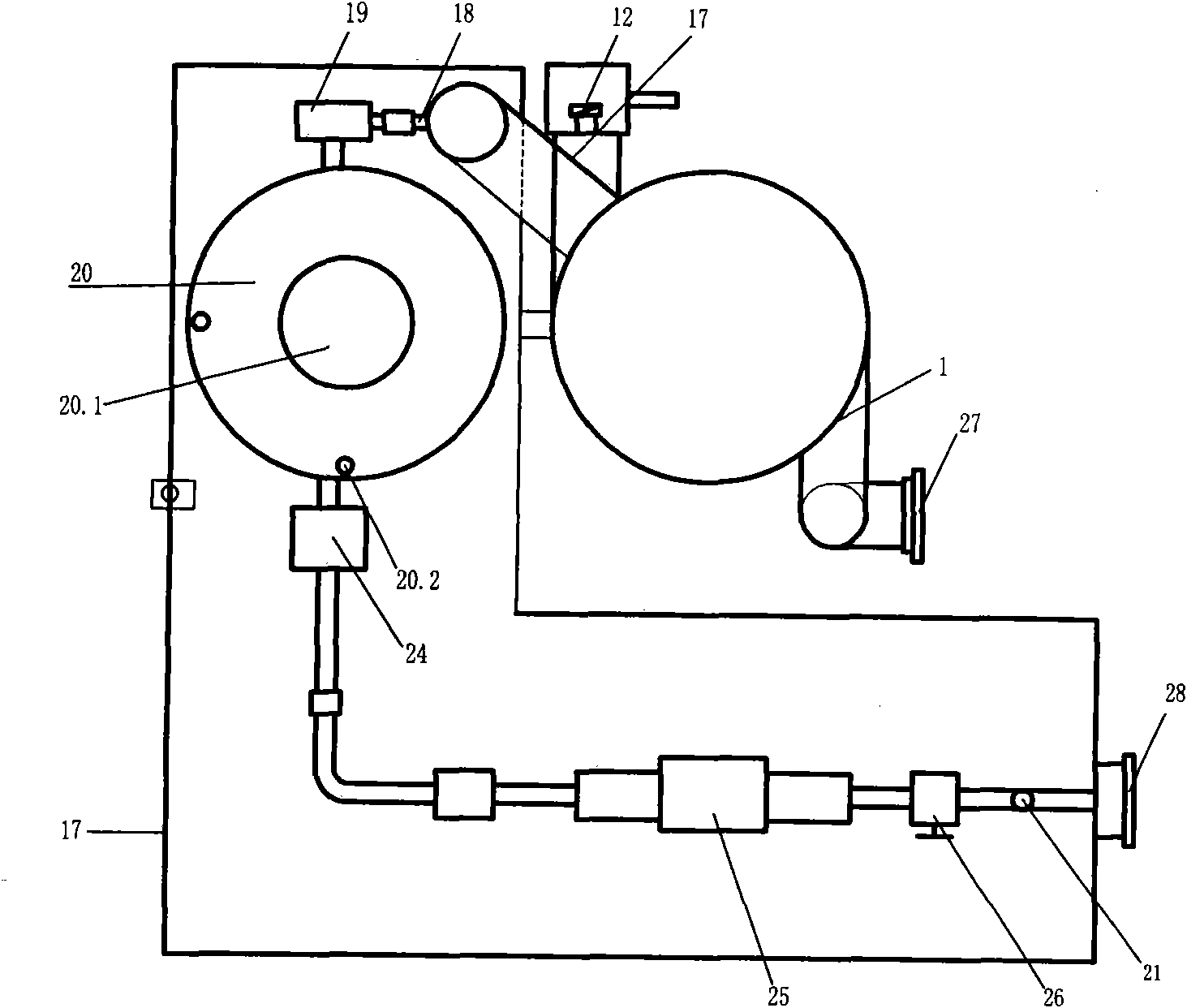

Experimental device and method for promoting coal-bed methane extraction by utilizing ultrasonic waves and high-temperature CO2

PendingCN107576763AEasy to drawImprove migration efficiencyBorehole/well accessoriesMaterial analysisTemperature controlExperimental methods

The invention discloses an experimental device and method for promoting coal-bed methane extraction by utilizing ultrasonic waves and high-temperature CO2. The experimental device comprises a coal androck sample pressure bearing assembly, a confining pressure application assembly, an axial pressure application assembly, a simulated coal-bed methane filling assembly, an ultrasonic generation assembly, a high-temperature CO2 filling assembly, a temperature control assembly and a flow detection assembly. The experimental method comprises the following steps: mounting a coal and rock sample in the coal and rock sample pressure bearing assembly; performing simulated crustal stress loading on the coal and rock sample by the confining pressure application assembly; performing simulated coal-bedmethane adsorption on the coal and rock sample by the simulated coal-bed methane filling assembly; performing ultrasonic loading on the coal and rock sample through the ultrasonic generation assembly;performing displacement on the simulated coal-bed methane in the coal and rock sample through the high-temperature CO2 filling assembly; performing temperature monitoring on the high-temperature CO2filling assembly and the coal and rock sample by the temperature control assembly; and performing flow detection on the simulated coal-bed methane subjected to displacement in the coal and rock sampleby the flow detection assembly.

Owner:LIAONING TECHNICAL UNIVERSITY

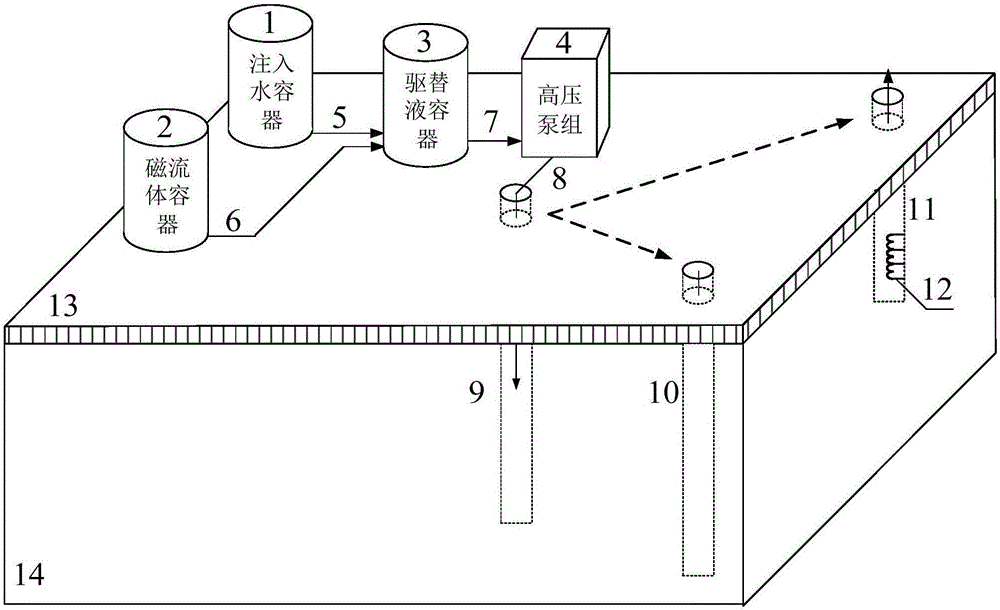

Oil production system and oil production method based on nano-magnetic fluid

The invention relates to an oil production system and oil production method based on nano-magnetic fluid. The oil production system based on the nano-magnetic fluid comprises an injected water container, a magnetic fluid container, a displacing fluid container, a high-pressure pump unit and an electromagnet; water and the nano-magnetic fluid are mixed to be uniform in the displacing fluid container, an obtained mixture enters the high-pressure pump unit through a first displacing fluid delivery pipeline to be pressurized, and then the pressurized mixture enters a water injection well through a second displacing fluid delivery pipeline. According to the oil production system and oil production method based on the nano-magnetic fluid, the displacing front edge is monitored along with the displacing process, the oil displacing direction and speed are adjusted through the strong attraction force of a magnetic field on the displacing fluid in a low-wave and regional newly-drilled magnetic source well, remaining oil is effectively utilized, and the displacing efficiency is improved. Compared with a traditional new well drilling and injection-production pattern improving method, the oil production method has the advantages of being low in cost and high in controllability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Deep plugging agent containing wood dust and gel

InactiveCN1654591ARealize liquid flow diversionEffective blockingSealing/packingWater circulationChemistry

The deep wood chip gel plugging agent is used in water injecting well to plug the high penetrating band in thick oil stratum to lower ineffective water circulation. The deep plugging agent consists of high molecular weight anionic polyacrylamide of molecular weight over 19 million and hydrolysis degree of 25-30 % 0.15-0.5 wt%, phenol compounded polyamine 0.1-0.3 wt%, resorcinol 0.01-0.02 wt%, oxalic acid 0.1-0.2 wt%, wood chip 0.5-2.5 wt% and water 96.48-99.14 wt%, which are compounded into water solution of 0.86-3.52 wt% water solution. The present invention has low use concentration, controllable gel forming time and viscosity, low cost and simple compounding process.

Owner:DAQING OILFIELD CO LTD

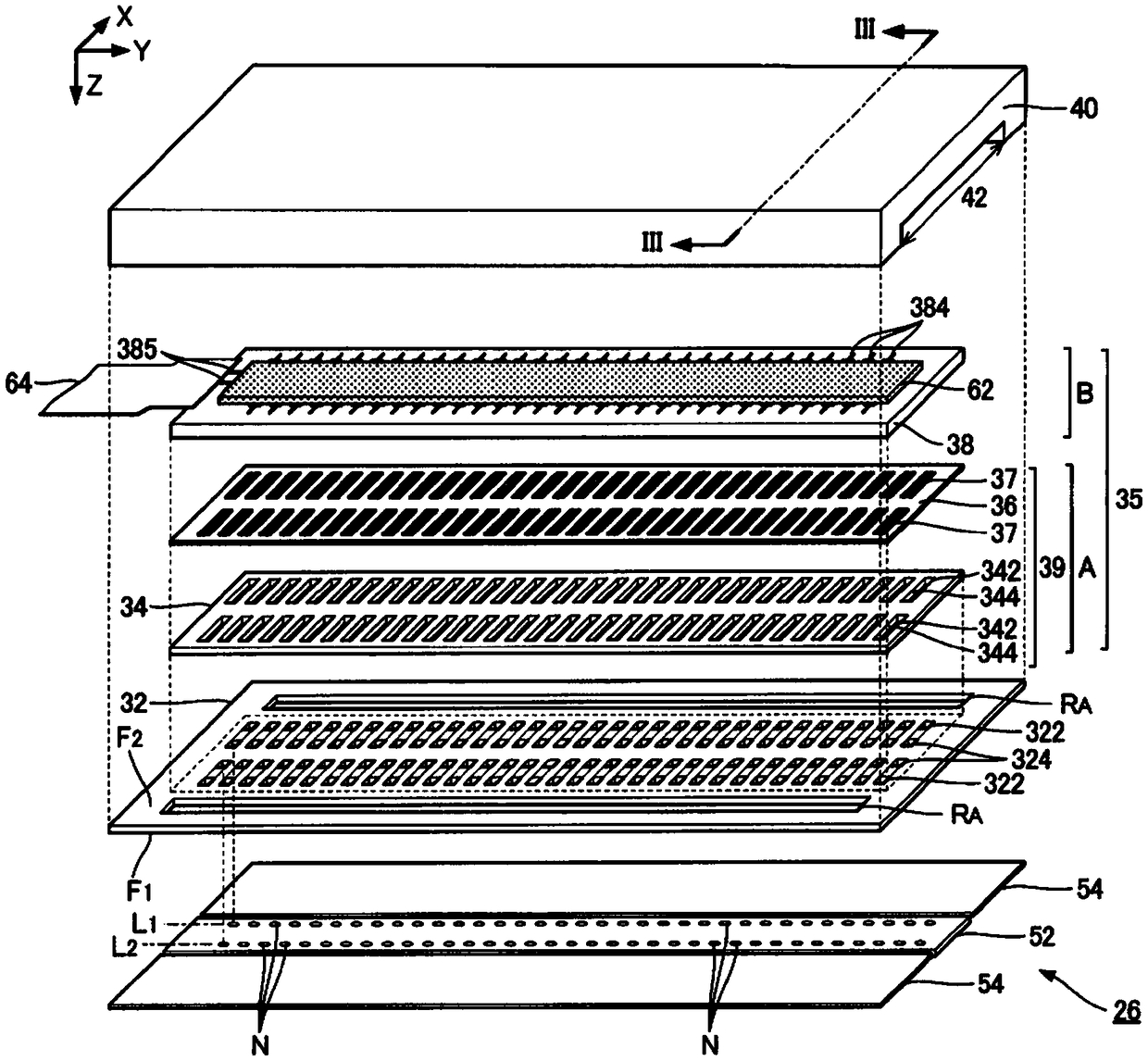

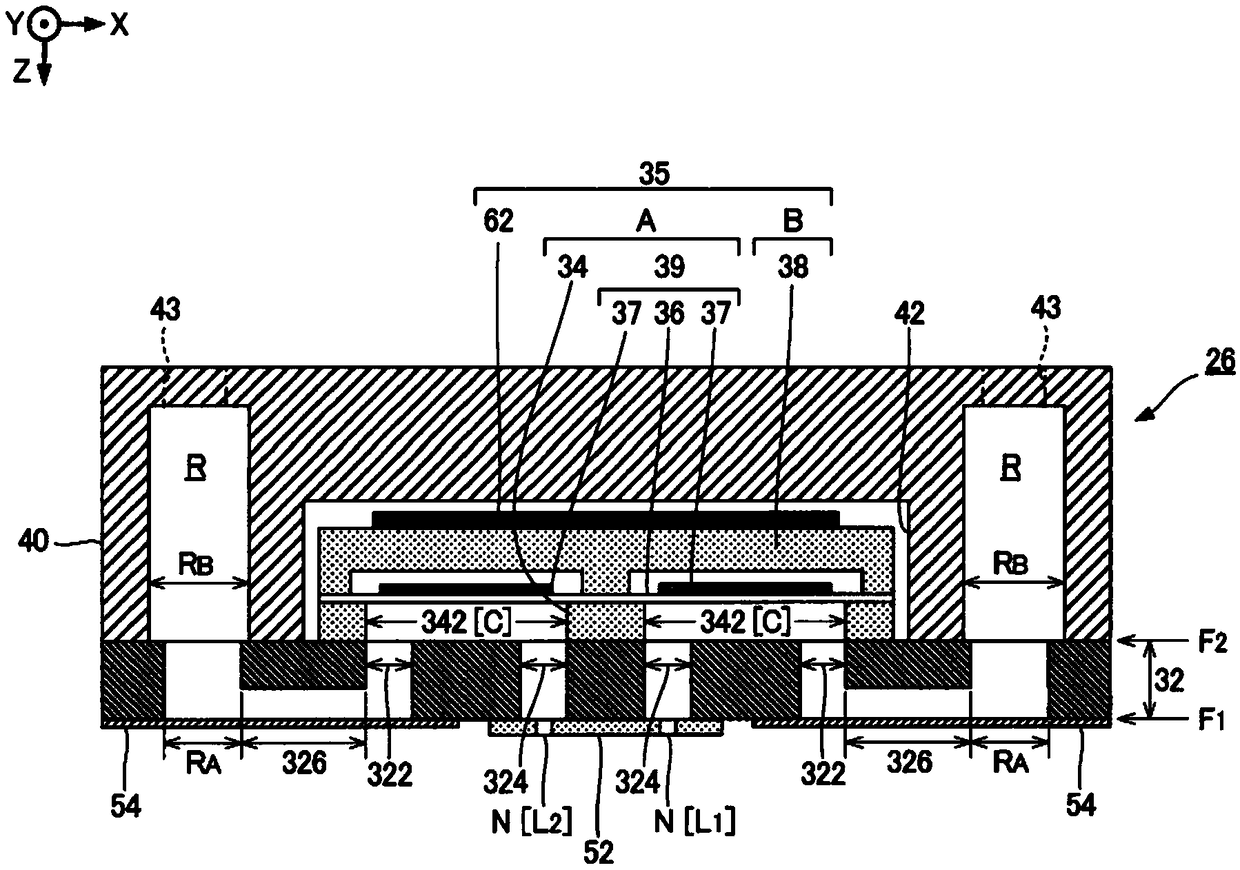

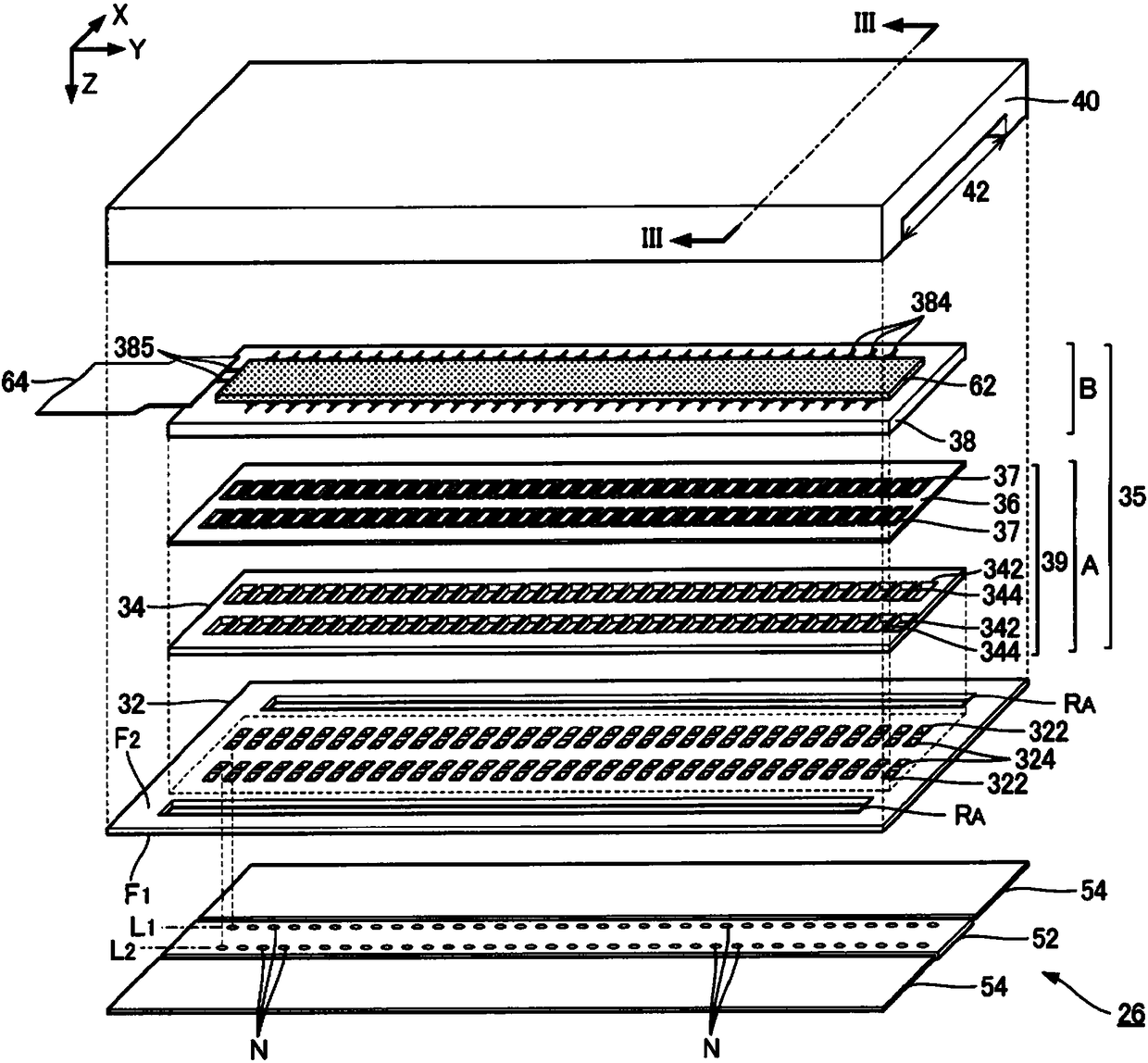

Piezoelectric element, piezoelectric element application device, and method for manufacturing piezoelectric element

InactiveCN106427217ARelax tensile stressImprove featuresInking apparatusPerovskite (structure)Mechanical engineering

A piezoelectric element includes a first electrode, a piezoelectric layer which is provided on the first electrode and which is formed of crystals of a composite oxide with a perovskite structure which is preferentially oriented in a plane, and a second electrode which is provided on the piezoelectric layer and which is formed of platinum which is preferentially oriented in a plane, in which, in the piezoelectric layer, plane intervals L1 of the crystals on the first electrode side are smaller than plane intervals L2 of the crystals on the second electrode side.

Owner:SEIKO EPSON CORP

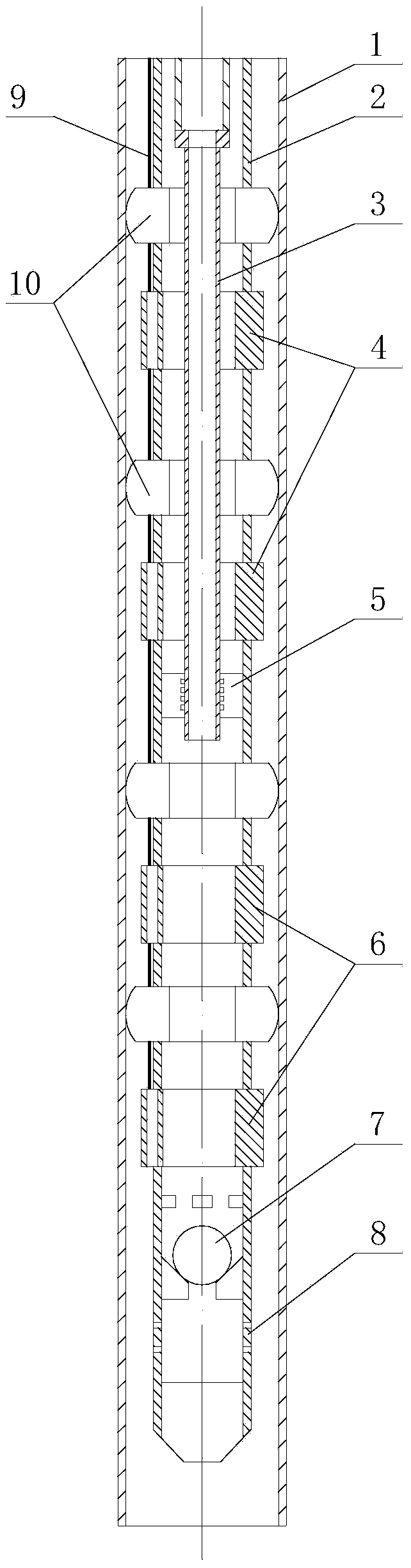

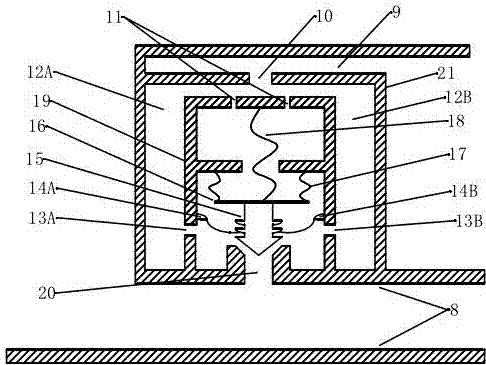

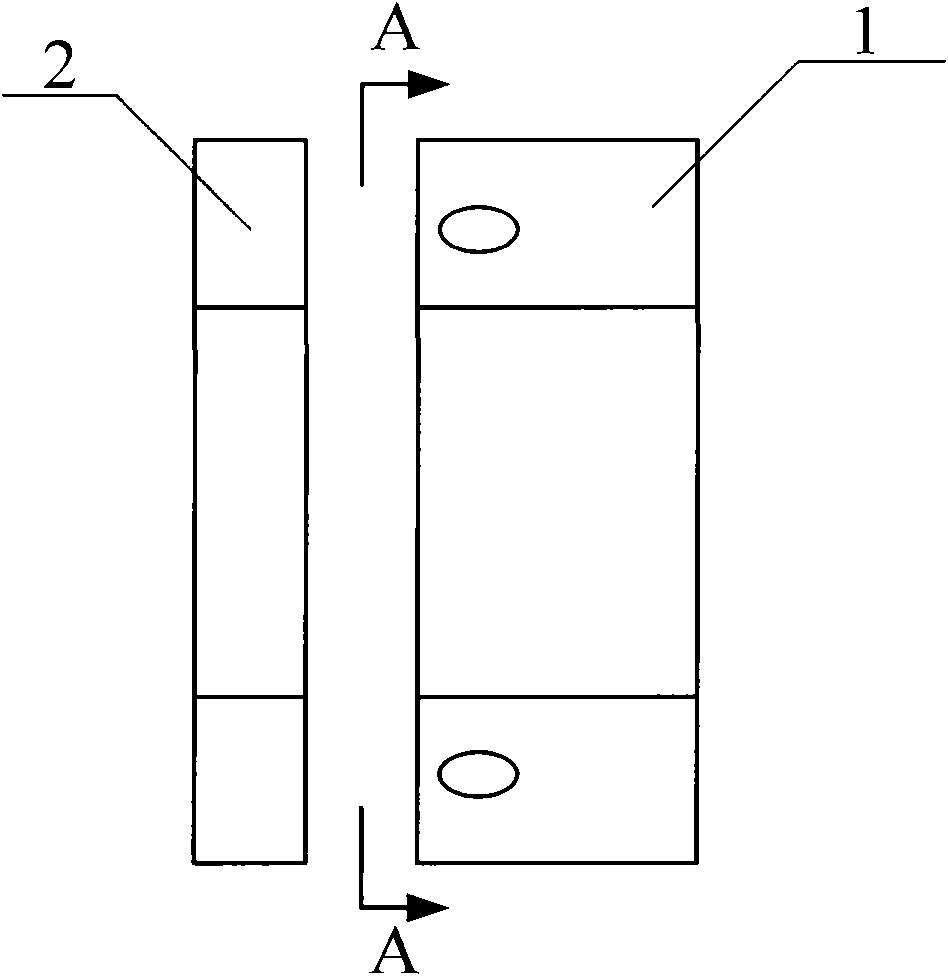

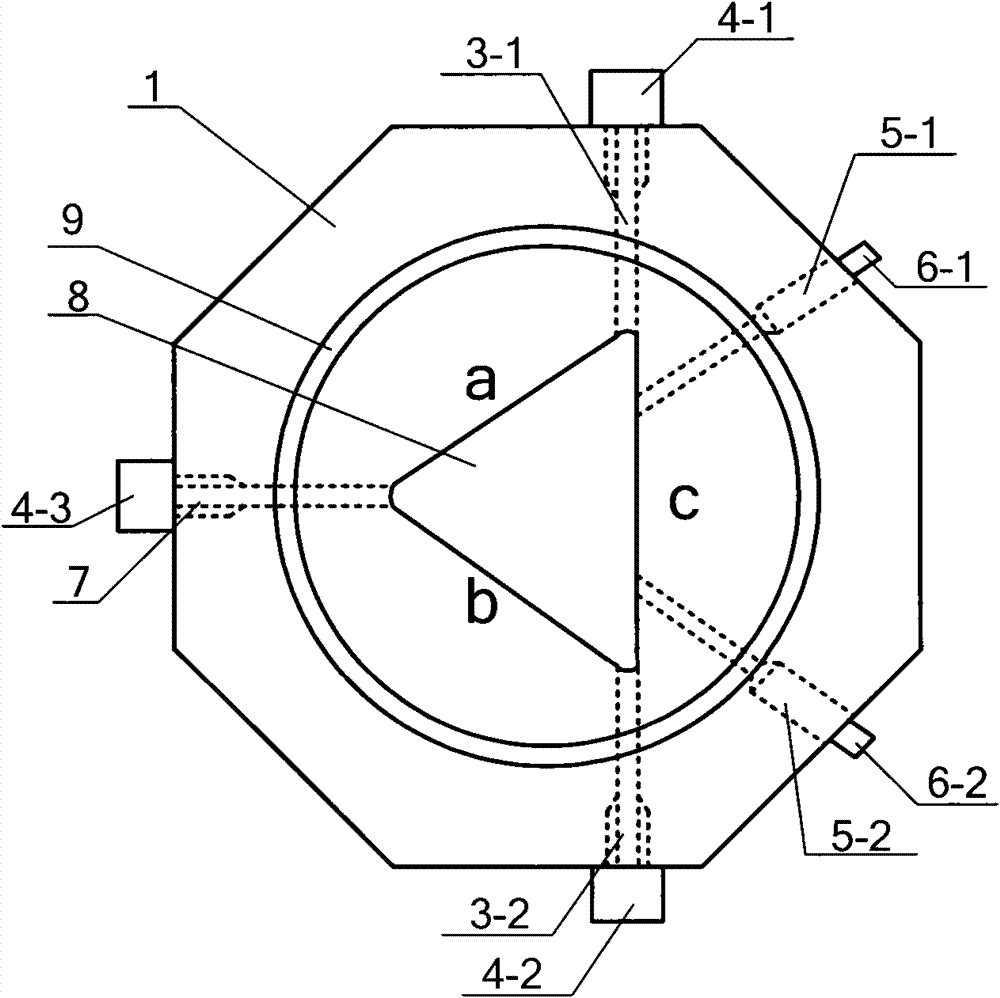

Water-gathering co-well layering co-charging process tubular column

InactiveCN104234671AImprove displacement efficiencyDrilling rodsFluid removalWater floodingIsolation layer

The invention relates to a water-gathering co-well layering co-charging process tubular column, which mainly solves the problem that the oil field injection well exploitation way of the existing oil field process tubular column severely influences the yield of the oil field and is violently subjected to the influence of the thickness of an isolation layer. The water-gathering co-well layering co-charging process tubular column is characterized in that an annular space between a casing pipe (1) and an outer layer oil pipe (2) is divided by a plurality of washable well-passing cable packers (10) into different positions, an inner layer oil pipe (3) is arranged inside the outer layer oil pipe (2), the an insertion sealing device (5) is arranged between the bottom end of the inner layer oil pipe (3) and the outer layer oil pipe (2), an eccentric injector (4) is arranged in the position on the upper part of the insertion sealing device (5), and an eccentric water allocator (6) is arranged in the position on the lower part of the insertion sealing device (5). By adopting the water-gathering co-well layering co-charging process tubular column, the co-well subsequent water flooding and polymer flooding can be simultaneously carried out after the polymer flooding upward movement is realized, both the water flooding and the polymer flooding are respectively injected in a layering manner, the exploitation effect is improved, and the influence of the thickness of the isolation layer can be avoided.

Owner:PETROCHINA CO LTD +1

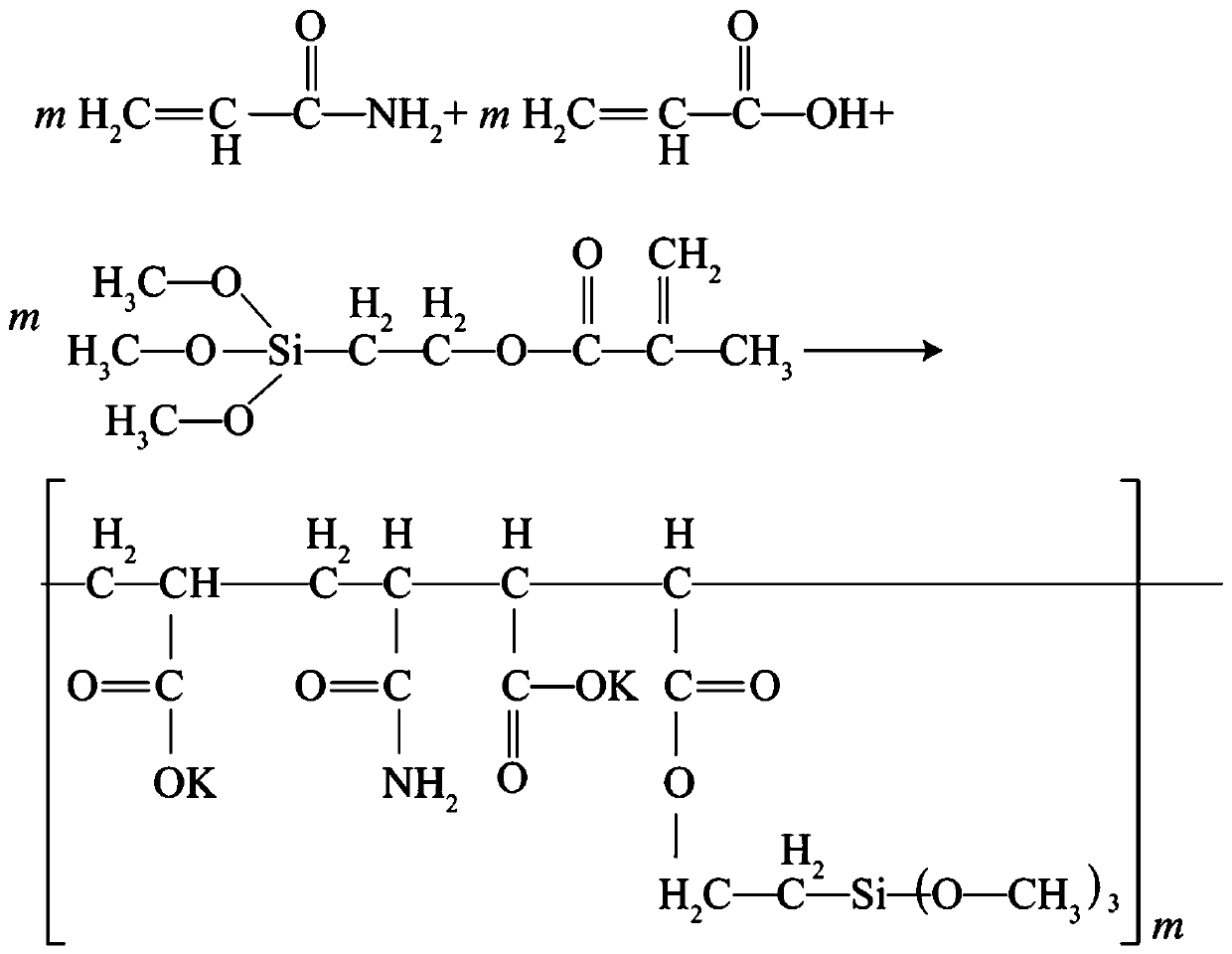

Novel polyacrylamide for oil displacement

InactiveCN110272519AImprove displacement efficiencyHigh molecular weightDrilling compositionPotassium persulfatePolyacrylamide

The invention discloses novel polyacrylamide for oil displacement. The product is obtained after mixing, capping sealing, addition of an initiator, standing for a reaction, cooling treatment, addition of ethanol for soaking, shear molding and drying. According to the novel polyacrylamide for oil displacement, a mixed solution with the total monomer concentration of 4% is prepared with AM (acrylamide), KH570 and AA (acrylic acid) as raw materials according to the reaction proportion of 7:0.4:2, with potassium persulfate the mass of which is 0.5% of the total monomer mass as an initiator, a polyacrylamide oil displacement agent is synthesized under the environment with the pH value of 7-8, and the macromolecular polyacrylamide is obtained; the molecular weight of the polyacrylamide is larger than that of other systems, the surface tension is small, the displacement efficiency is high, and the oil displacement efficiency is high.

Owner:SHENGLI OIL FIELD FANGYUAN CHEM IND

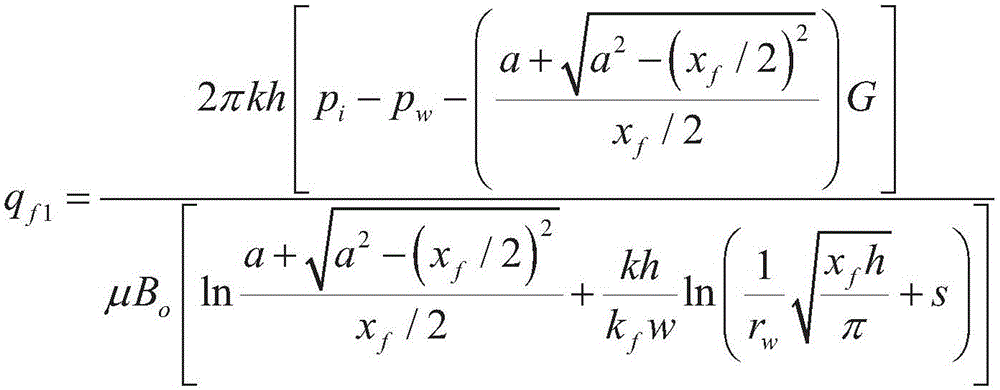

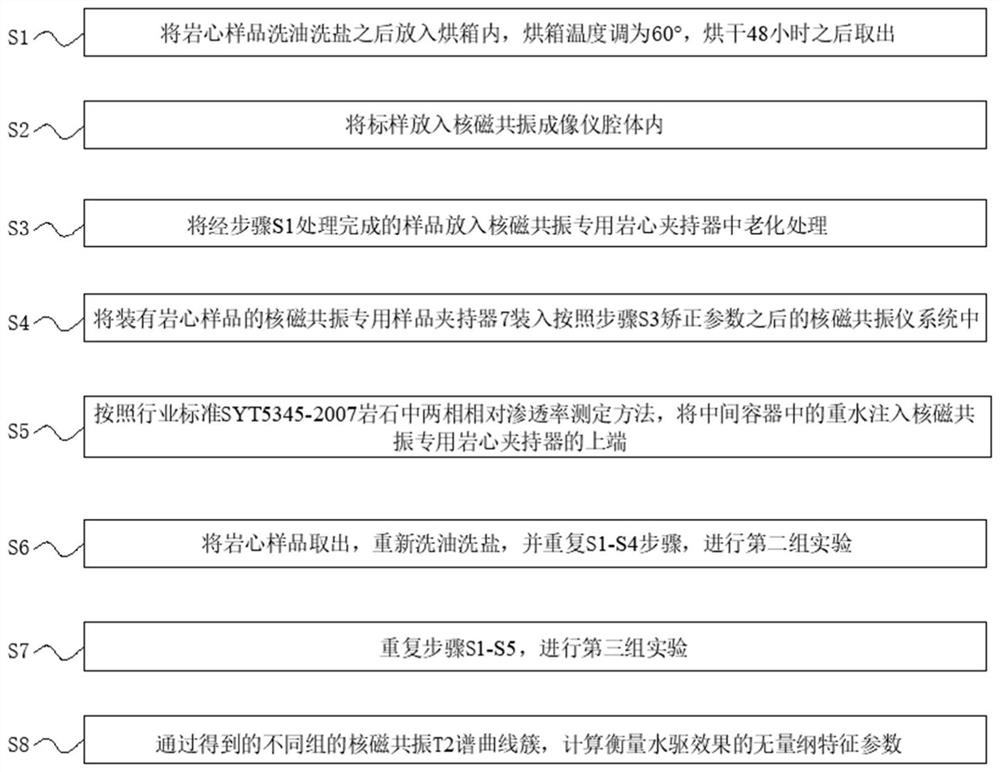

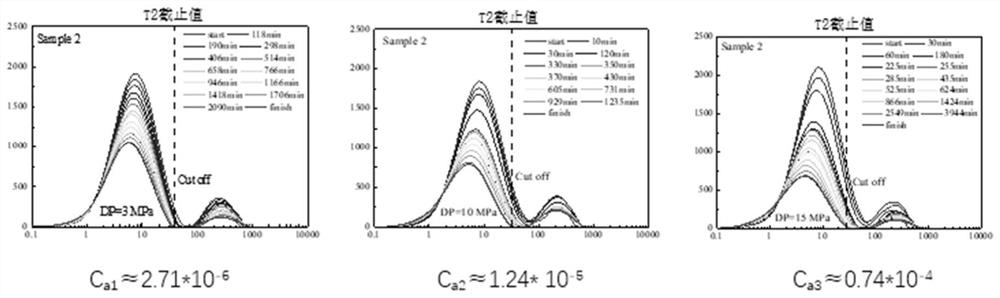

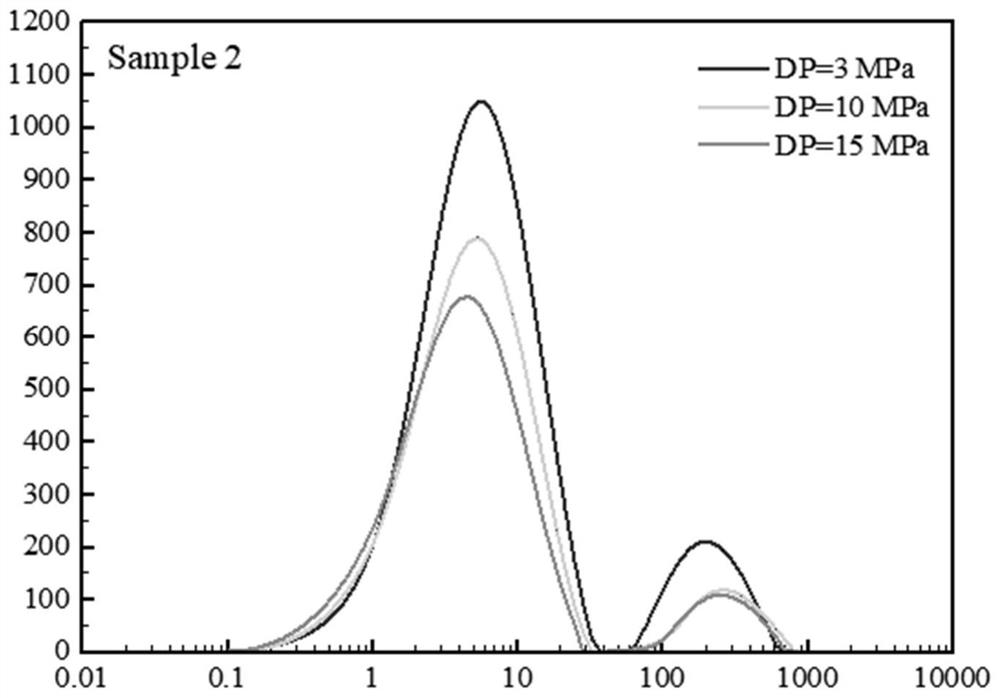

Method for improving recovery ratio through nuclear magnetism online tight oil-water flooding development

InactiveCN111878050AEffective shielding of MRI signalsAccurate efficiencyFluid removalPorosityRock core

The invention belongs to the technical field of oil-gas exploration, and particularly relates to a method for improving the recovery ratio by nuclear magnetism online tight oil-water flooding development. The method comprises the following step of step 1, putting a rock core sample into a drying oven after oil washing and salt washing, adjusting the temperature of the drying oven to 60 DEG C, drying for 48 hours and taking out the rock core sample. The diameter D = 2.5 cm, the length L = 5.450 cm, the porosity phi = 15.22%, the permeability K = 0.1028 mD and the dry weight M1 = 61.8972 g of asample are measured according to industrial standards, the rock core sample after dry weight is put into a vacuum pump for vacuumizing for 4 hours, pressurizing (20MPa) of saturating simulated oil fornot less than 48 hours is carried out after no bubble overflows, the simulated oil density Rho o = 0.8g / cm<3>, the wet weight M2 is equal to 65.0846g, the initial oil saturation Soi of the sample iscalculated, the experiment error caused by oil-gas-water three-phase flow in the experiment process can be avoided only when the initial oil saturation is required to reach 98% or above, the structureis reasonable, and the displacement efficiency, the residual oil saturation, the residual oil distribution rule and other parameters of oil in the rock core sample can be accurately obtained.

Owner:YANAN UNIV

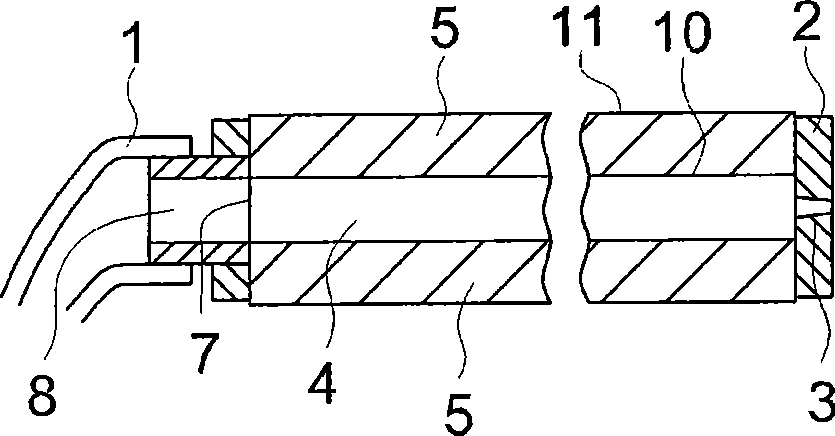

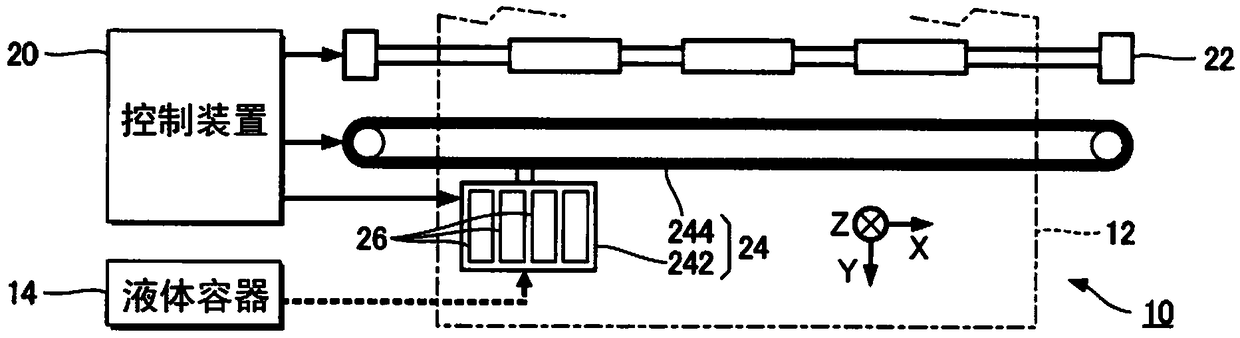

Intelligent inflow gas control device and intelligent inflow gas control method

ActiveCN106996281AInflow controlImprove displacement efficiencyFluid removalHorizontal wellsEconomic benefits

The invention discloses an intelligent inflow gas control device which mainly comprises a flow chamber, pressure guide holes, inlet oil nozzles, a packet, a sawtooth-shaped movable component and turn-off structures. The maximum quantity Q <max> of gas which is allowed to flow through the inlet oil nozzles can be set according to actual production requirements on oil wells. The intelligent inflow gas control device can normally work when the quantity Q of the gas which flows through the inlet oil nozzles does not exceed the set maximum quantity Q <max> of the gas; the intelligent inflow gas control device is turned off when the quantity Q of the gas reaches the set maximum quantity Q <max> of the gas, and fluid is no longer allowed to flow through the intelligent inflow gas control device. A working principle for the intelligent inflow gas control device includes that the gas can critically flow in the inlet oil nozzles when the flow rates of the gas in the inlet oil nozzles reach the maximum quantity Q <max> of the gas; ratios of front-end pressures P1 to rear-end pressures P2 of the inlet oil nozzles are critical pressure ratios, and the intelligent inlet gas control device can be turned off under the control of the critical pressure ratios. The intelligent inflow gas control device has the advantages that the intelligent inflow gas control device can be applied to gas-top reservoirs and gas injection production straight wells, horizontal wells and inclined wells, specified gas quantity exceeding gas flow channels can be timely closed, accordingly, economic benefits of oil fields can be increased, and the recovery ratios of oil reservoirs can be increased.

Owner:SOUTHWEST PETROLEUM UNIV

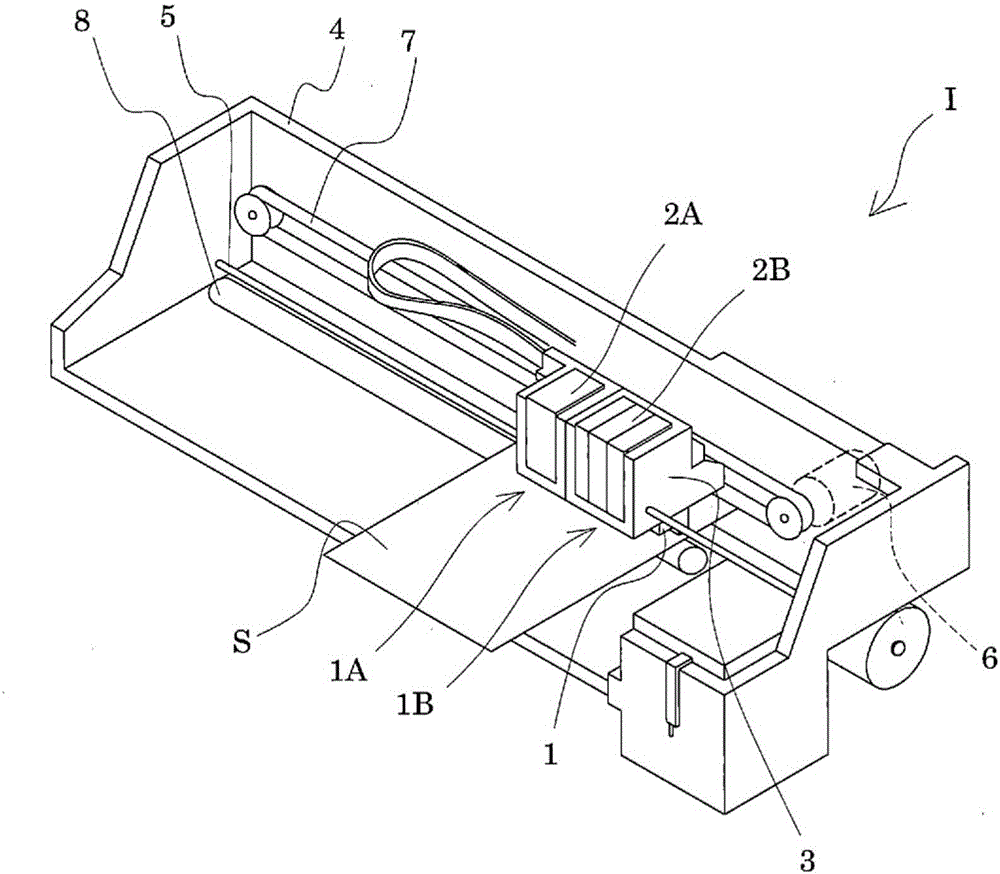

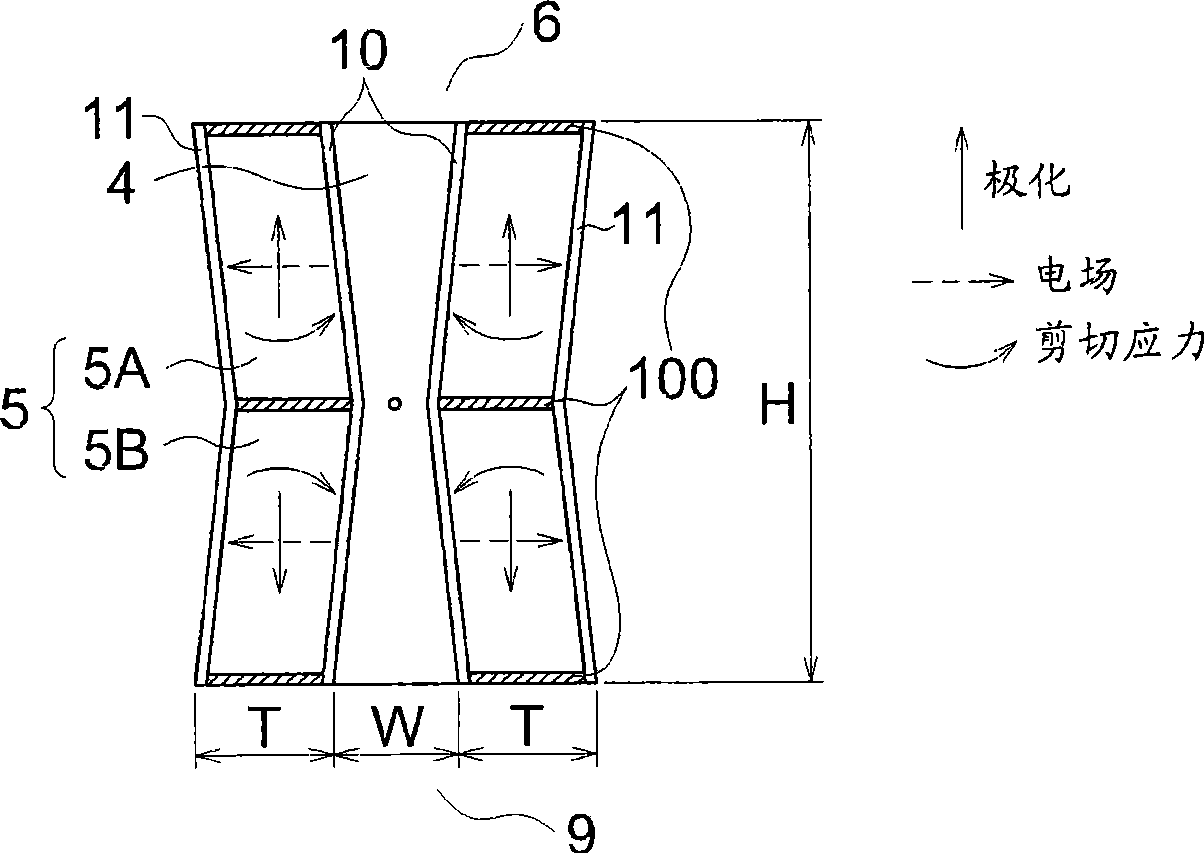

Shear mode-type piezoelectric actuator and liquid droplet delivery head

ActiveCN101512787AReduce thicknessRaise the resonance frequencyPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusPiezoelectric actuatorsEngineering

This invention provides a shear mode-type piezoelectric actuator using a piezoelectric ceramic composition free from lead having a high coercive electric field and a liquid ejection head having the shear mode-type piezoelectric actuator. The shear mode-type piezoelectric actuator is characterized by using a piezoelectric ceramic composition having a solid solution including a main component of general formula (1) and an auxiliary component of general formula (2) added in an amount of less than 1% by mole based on the total amount of the solid solution, General formula (1) {LiX(K1-YNaY)1-X}(Nb1-Z-WTaZSbW)O3 (Wherein 0< / =x< / =0.2, 0< / =y< / =1, 0<z< / =0.4, 0<w< / =0.2) General formula (2) ABO3 (Wherein A denotes Bi and B denotes at least one of Fe, In and Sc).

Owner:KONICA MINOLTA INC

A surfactant composition is provided

InactiveCN111073620AGood temperature and salt resistanceEnhanced overall recoveryDrilling compositionSulfonateBetaine

The invention provides a surfactant composition, which is prepared from alpha-alkenyl sulfonate, alkyl dimethyl betaine, partially hydrolyzed polyacrylamide and alkanolamide. According to the surfactant composition, the temperature resistance and the salt resistance are remarkably improved, the adsorption on oil reservoir rocks is reduced, and a system has high displacement efficiency, so that thepurpose of further improving the crude oil recovery ratio is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

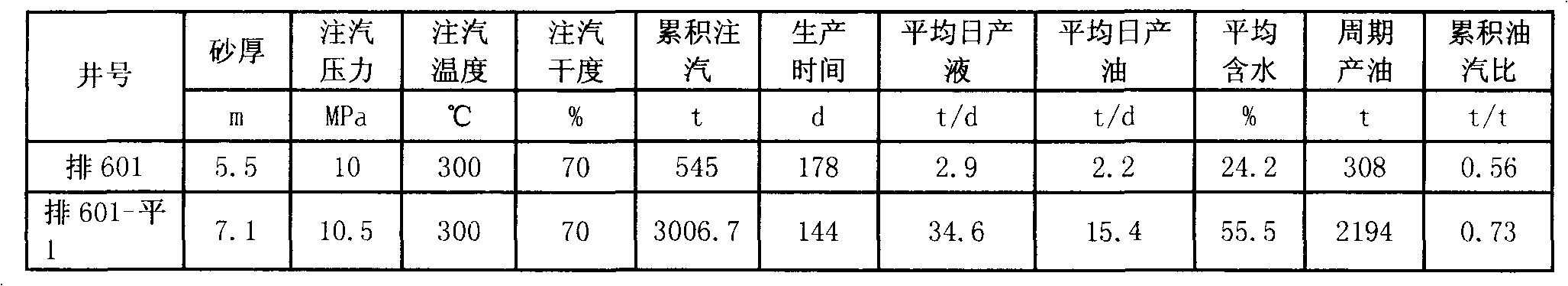

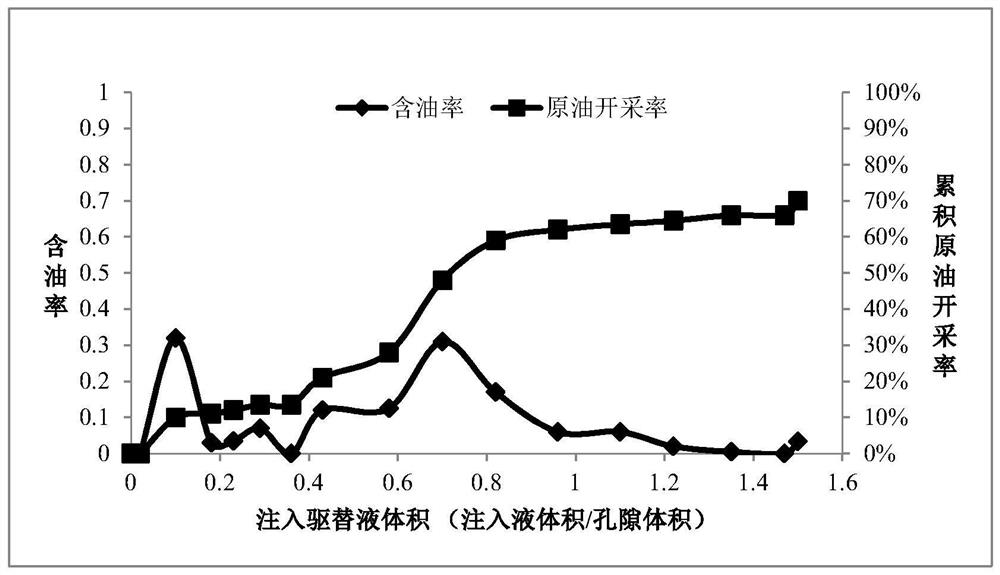

Methods of Improving Recovery of Strongly Sensitive Heavy Oil Reservoirs

ActiveCN103573231BEfficient developmentEfficient governanceCleaning apparatusFluid removalField testsLiquid carbon

The invention provides a method for improving the recovery rate of highly sensitive heavy oil reservoirs, which utilizes high-temperature clay stabilizers, slow-release acid liquid systems, high-efficiency oil displacement agents and carbon dioxide in the development of sensitive heavy oil reservoirs to improve Single well development effect, a new method to improve the recovery of sensitive heavy oil reservoirs. The technical plan is: firstly use the temperature-sensitive slow-release acid system to treat the pollution near the wellbore, then inject liquid carbon dioxide, use high-temperature clay stabilizer to protect the oil layer before steam injection, and inject high-temperature oil displacement during steam injection Dosage system. Then, after the well is closed and the well is soaked, the well is opened and the blowout is released, the pump is lowered into the well for continuous oil recovery. The field test shows that the average periodic oil-steam ratio of vertical wells reaches 0.4, the average periodic oil-steam ratio of horizontal wells reaches 0.6, and the periodic oil production exceeds 1000t. Laboratory experiments show that the development of this invention in sensitive heavy oil reservoirs involves technology, oil The final recovery rate of the reservoir can reach more than 35%.

Owner:CHINA PETROLEUM & CHEM CORP +1

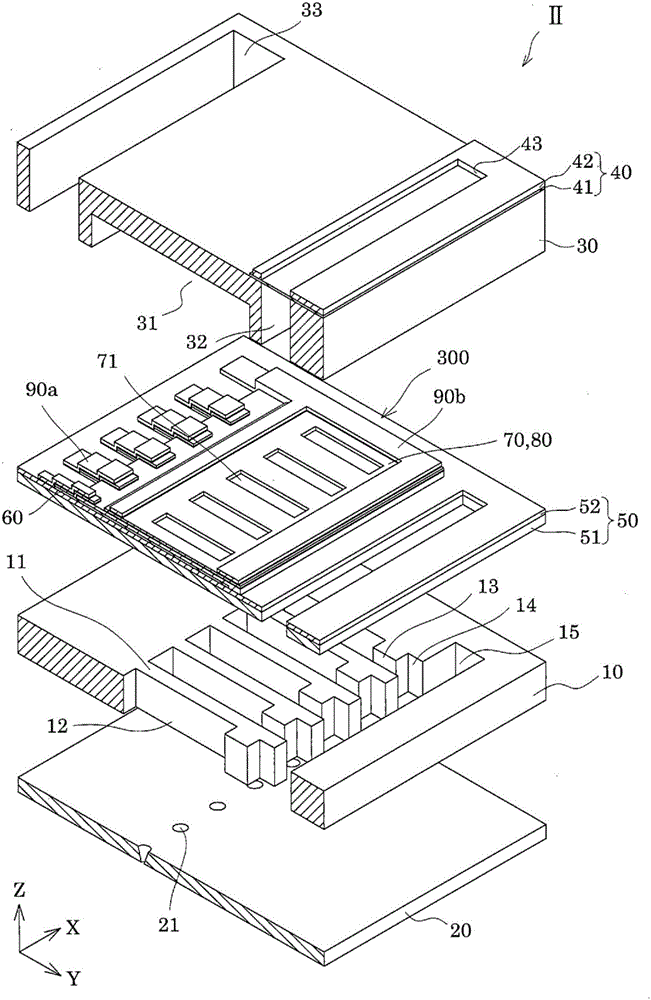

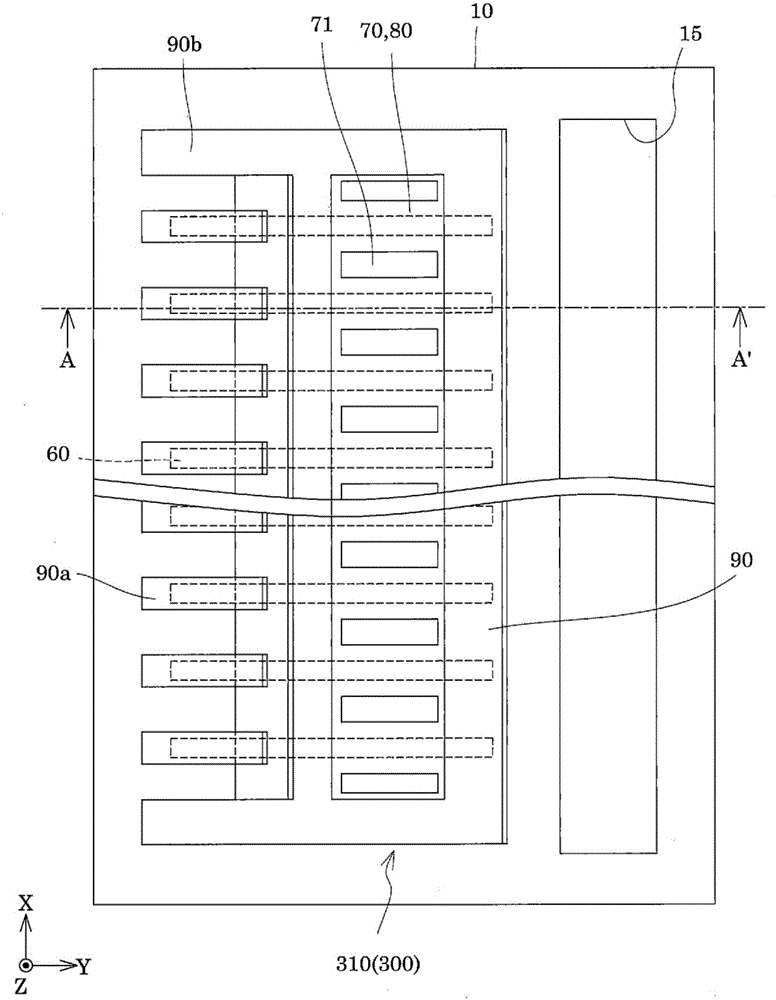

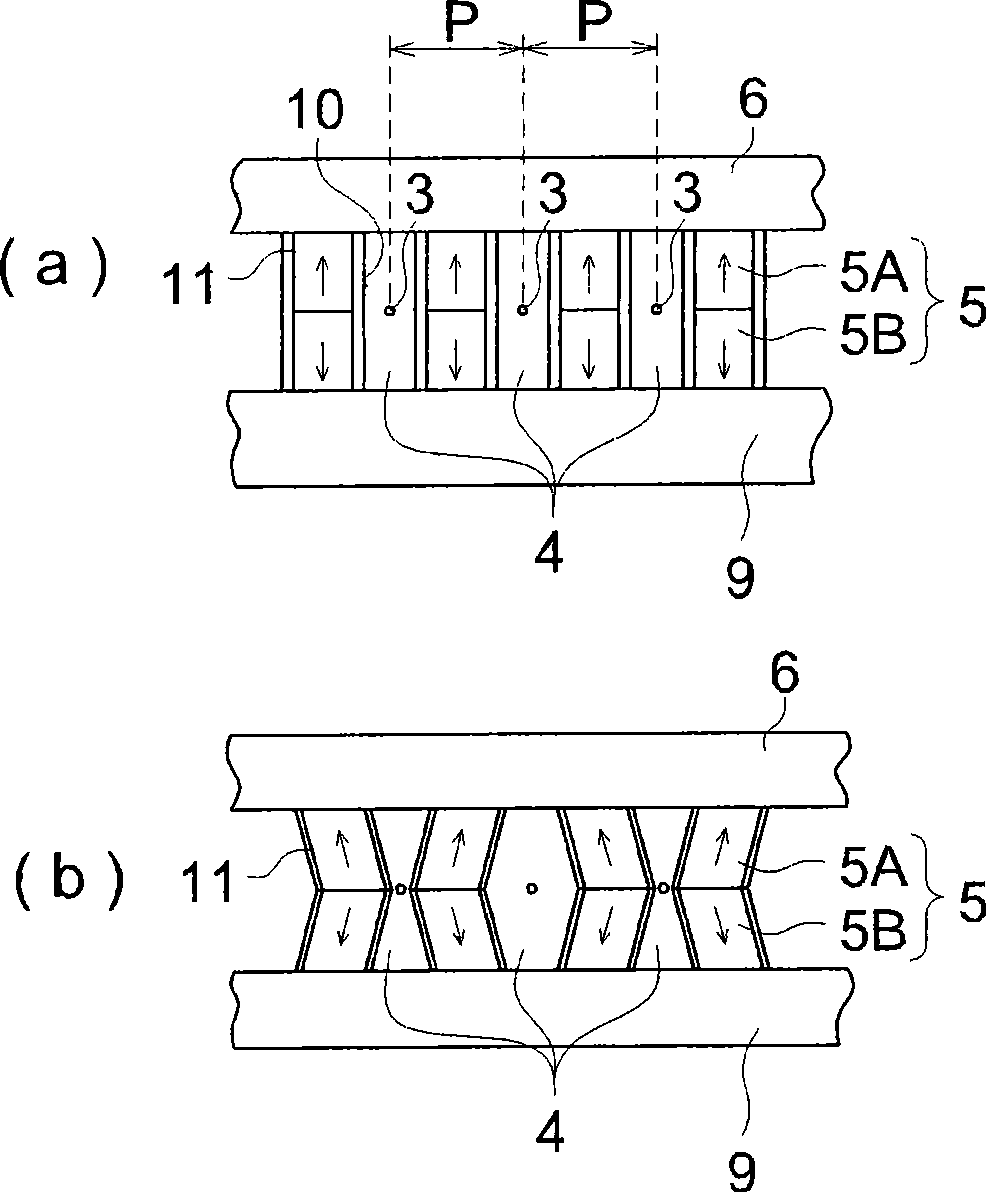

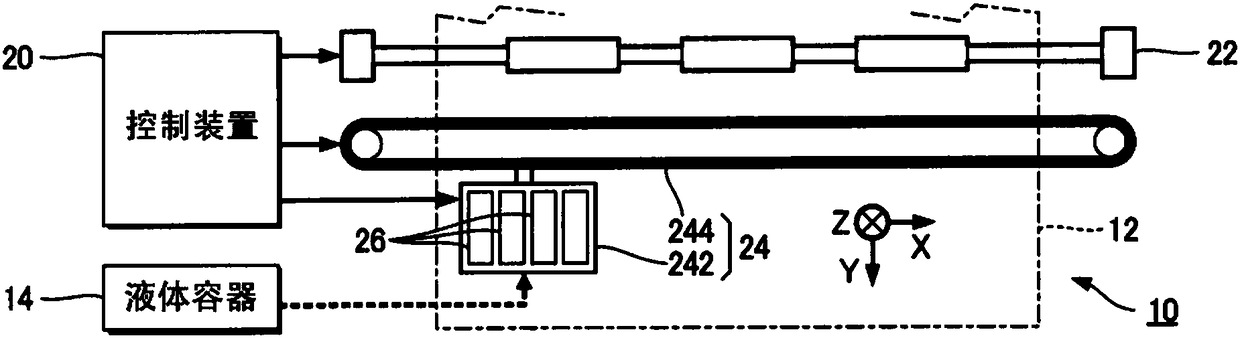

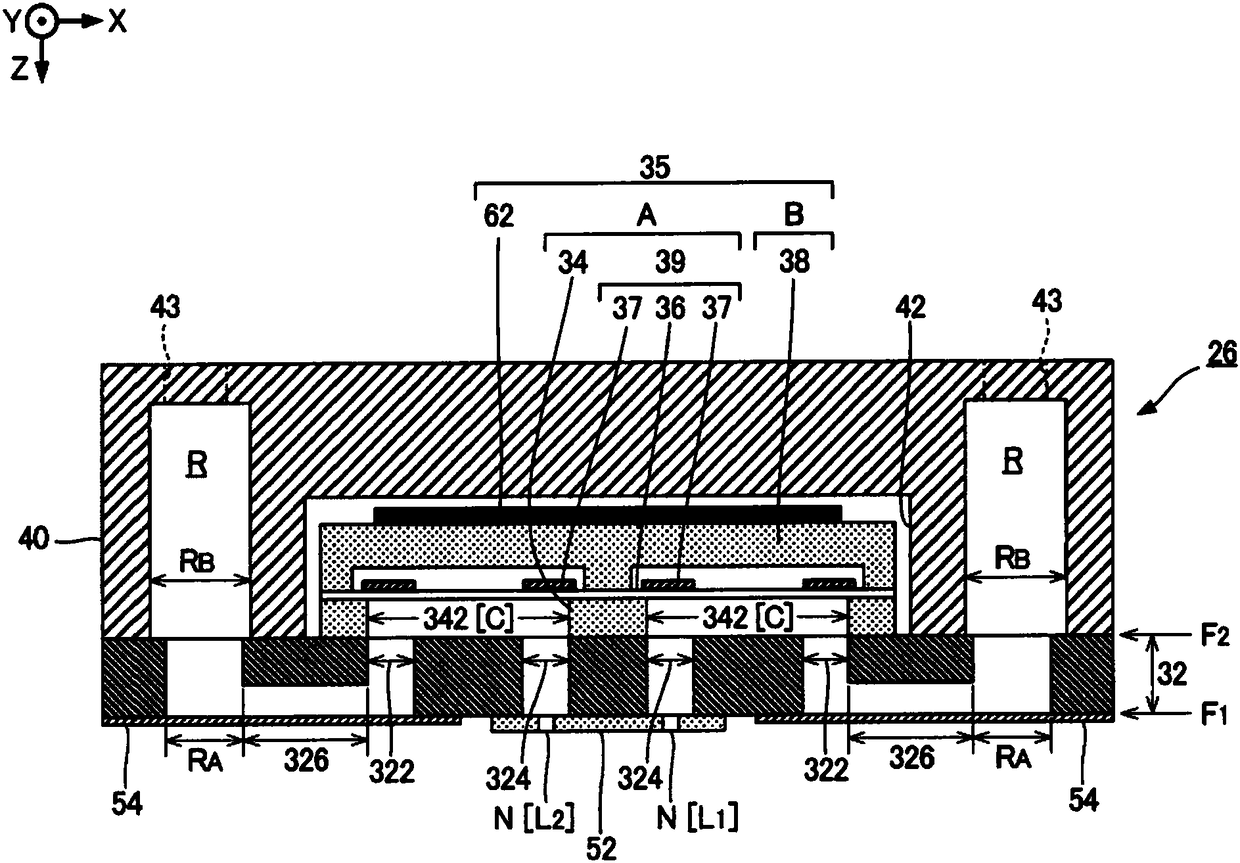

Piezoelectric device, liquid discharging head, and liquid discharging apparatus

ActiveCN108928123AImprove displacement efficiencyInking apparatusPiezoelectric/electrostrictive devicesCrystal planeYoung's modulus

The invention relates to a piezoelectric device capable of improving displacement efficiency of a diaphragm, a liquid discharging head, and a liquid discharging apparatus. There is provided a piezoelectric device including a pressure chamber, a piezoelectric element, and a diaphragm disposed between the pressure chamber and the piezoelectric element. The diaphragm has a crystal plane of an anisotropic single crystal silicon base of which a Young's modulus varies according to a direction in the crystal plane. In a vibration region of the diaphragm, which overlaps the pressure chamber in plan view, a first Young's modulus in a first direction, out of Young's modulus in the crystal plane, is higher than a second Young's modulus in the crystal plane in a second direction intersecting the firstdirection. A width of the piezoelectric element in the first direction is larger than a width of the piezoelectric element in the second direction.

Owner:SEIKO EPSON CORP

Deep sea water parameter measuring device

InactiveCN101718737BImprove realismImprove displacement efficiencyMaterial electrochemical variablesMeasurement deviceEngineering

The invention relates to a deep sea water parameter measuring device, and the prior device has low displacement efficiency and poor effect. The invention comprises a cabin and a sealing cover which are fixedly connected through bolts, wherein the central position of the upper end surface of the cabin is provided with a groove to form a sensor cavity; the bottom surface of the sensor cavity is an isosceles triangle surface which is parallel to the cabin end surface; the cabin is provided with two sensor installation holes; the two needle-type pH sensors are respectively arranged in the two sensor installation holes; two apopores are symmetrically arranged on the two outer side walls of the cabin to which the two base angles of the isosceles triangle directs; an inlet opening is arranged onthe outer side wall of the cabin to which the vertex angle of the isosceles triangle directs; and one inlet opening and two apopores are respectively provided with an electromagnetic valve on the opening of the outer side wall of the cabin. In the invention, the cavity shape of the sensor cavity, the quantity and distribution of the through holes are improved, thus being capable of greatly improving displacement efficiency, improving the trueness of the buffer solution or the sea water samples in the cavity after the completion of the displacement process, and being suitable for the sea watersamples of various densities.

Owner:HANGZHOU DIANZI UNIV

Oil displacement method using anion-cation complex surfactant

ActiveCN103422840BLarge adsorption capacityLow critical micelle concentrationFluid removalDrilling compositionSURFACTANT BLENDOil well

The invention relates to a method of displacing oil by anionic-cationic composite surfactant and mainly solves the problems that the prior method of displacing oil by surfactant is low in oil displacement efficiency in tertiary oil recovery and an oil displacement system containing inorganic base is harmful to stratums and oil wells, corrosive to equipment and pipelines and difficult for demulsification. According to the technical scheme, crude oil is allowed to contact with oil-displacing agent, and the oil-displacing agent comprises, by weight percent, 0.01-5.0% of anionic-cationic composite surfactant, 0.01-3.0% of polymer, and 92.0-99.98% of injected water. The problems are solved well. The method is applicable to tertiary oil recovery for oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Passive type multifunctional well head backflow dredging compensating device

InactiveCN101608536AReduce resistancePrevent reverse accessFluid removalSealing/packingWater storageElectricity

The invention relates to a passive type multifunctional well head backflow dredging compensating device for petroleum industry, mainly comprising a separating backflow assembly and a medicament carrying unit, wherein the separating backflow assembly mainly comprises a well fluid separating unit, a filter, a sand and water storage chamber and a backflow flow rate control unit; the medicament carrying unit mainly comprises a medicament carrier, a medicament can and an air balancing connection pipe, wherein the medicament carrier is respectively communicated with a fluid returning pipe and the medicament can; and after well fluid is separated and filtered by the separating backflow assembly, a part of polluted water enters the medicament carrier through a well fluid backflow pipe column along the fluid returning pipe and is mixed with medicament inside the medicament can by a water power spray principle to flow back to a passage dredging submergence depth air in an oil sleeve ring in the air. The invention reduces the resisting force of the air which upwards flows from submergence depth, prevents the air reversely entering an electric pump, ensures the separating effect of an electric pump separator, prolongs the exemption period of an electric pump well and saves a great amount of operation expense and operation time.

Owner:SHENGLI OILFIELD SANLI GASOLINEEUM TECH DEV

Piezoelectric device, liquid discharging head, and liquid discharging apparatus

ActiveCN108928125AImprove displacement efficiencyCrack suppressionPrintingCrystal orientationEngineering

According to an aspect of the invention, the generation of cracks can be inhibited and the displacement efficiency can be improved. A piezoelectric device including a pressure chamber, a piezoelectricelement, and a diaphragm disposed between the pressure chamber and the piezoelectric element. The diaphragm has a crystal plane {100} of a single crystal silicon base. The piezoelectric element is disposed on the diaphragm so as to overlap an inner periphery of the pressure chamber in plan view, and has an inner edge on a center side of the pressure chamber with the inner periphery of the pressure chamber being sandwiched within the piezoelectric element in plan view. A shape of the inner edge of the piezoelectric element is such that in the smallest first rectangle, which includes the inneredge in plan view, the inner edge is on the inside of each of sides at a middle portion of each of the sides of the first rectangle. A shape of the inner periphery of the pressure chamber is such thatin the smallest second rectangle, which includes the inner periphery in plan view, the inner periphery is on the inside of each of sides at a middle portion of each of the sides of the second rectangle. A direction of one side out of the first rectangle and the second rectangle lies along a crystal orientation <010> in the crystal plane.

Owner:SEIKO EPSON CORP

Oil displacement type fracturing fluid system and preparation method thereof

InactiveCN112961663AImprove oil washing efficiencyHigh densityDrilling compositionActive agentFracturing fluid

The invention discloses an oil displacement type fracturing fluid system and a preparation method thereof, and belongs to the field of oilfield chemistry. The oil displacement type fracturing fluid system is composed of the following components in percentage by mass: 0.25-0.3% of guanidine gum; 0.5-0.8% of a surfactant with ultralow interfacial tension; 1.0-3.0% of potassium chloride; 0.1-0.5% of a bactericide; and the balance of water. The oil displacement type fracturing fluid system aims at an oil well subjected to water injection development, the oil displacement type fracturing fluid system is diffused into a water displacement channel during repeated transformation, a certain displacement (washing) characteristic is achieved during flow-back, and the oil washing efficiency of a gel breaking fluid of the fracturing fluid during repeated fracturing of an oil reservoir subjected to water displacement development is improved. The preparation method comprises the following steps: mixing the guanidine gum, the surfactant with ultralow interfacial tension, the potassium chloride, the bactericide and the water, and uniformly stirring to obtain the oil displacement type fracturing fluid system. The preparation method is simple, on-site rapid preparation is easy, use is convenient, and on-site construction is safe.

Owner:PETROCHINA CO LTD

A kind of nanocomposite oil displacement agent and its preparation method and application

ActiveCN110387011BReduce interfacial tensionOil displacement effect is goodHeat-exchange elementsDrilling compositionEmulsion polymerizationOil water

The invention provides a nanometer composite oil displacement agent, and a preparation method and application thereof. The preparation method comprises the following specific steps: mixing acrylamide,sodium p-styrenesulfonate and water according to a mass ratio of (10.5-13.5): (4.5-5): (90-99) so as to obtain a mixed solution; adding a surfactant accounting for 5 to 7% by weight of the mixed solution into the mixed solution, then adjusting the pH value of the mixed solution to 7 to 7.5, and then adding an inorganic nanometer intermediate accounting for 1 to 3% by mass of the mixed solution into the mixed solution so as to obtain a reaction solution; adding an initiator into the reaction solution in an inert atmosphere, and carrying out a reaction at 75 to 80 DEG C for 8 to 10 h to obtaina polymer emulsion; and subjecting the polymer emulsion to demulsification, drying and crushing to obtain the nanometer composite oil displacement agent. The nanometer composite oil displacement agentprovided by the invention has the characteristics of good temperature resistance, good salt resistance and capacity of reducing oil-water interfacial tension, and can be used for oil production engineering of high-permeability, medium-permeability and low-permeability oil and gas reservoirs and later residual oil reservoirs of tertiary oil recovery.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of oil displacing agent and preparation method thereof

ActiveCN109943312BHigh interface activityIncrease the affected areaDrilling compositionCarboxylic acidDioxyethylene Ether

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com