Intelligent inflow gas control device and intelligent inflow gas control method

A gas device and intelligent technology are applied in the field of devices for improving the gas flow control capability of gas cap oil reservoirs and gas injection production oil reservoirs, which can solve the problems of inability to effectively close the flow channels after gas breaks through the oil reservoir, and avoid production safety problems. , the effect of improving the displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

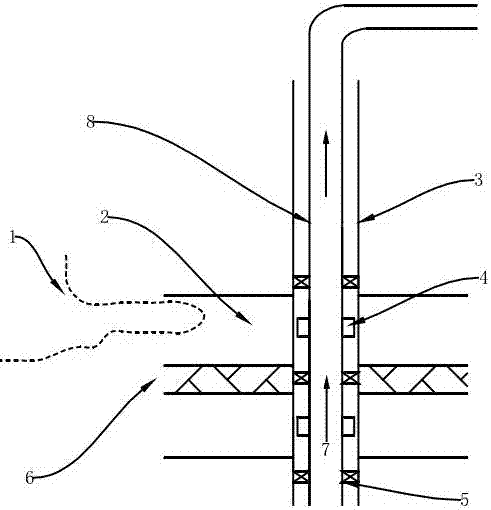

[0023] figure 1 It is a working partial schematic diagram of the device installed in a vertical shaft. Casing 3 and tubing 8 vertically pass through oil layer 2 and isolation layer 6, while casing 3 and tubing 8 will form an annular space, and packer 5 is added in the annular space, and the position of packer 5 is directly opposite to isolation layer6. The casing 3 is perforated to communicate the oil layer 2 with the annular space. The fluid in the oil layer 2 reaches around the wellbore, enters the annular space through the perforation hole, flows into the tubing 8 through the intelligent inflow control device 4, and reaches the surface along the flow direction 7 to be produced.

[0024] For ease of understanding, figure 1 Only one air cone interface 1, one isolation layer 6, one oil layer 2, and one intelligent inflow control device 4 are marked, that is, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com