Patents

Literature

33results about How to "Avoid production safety issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

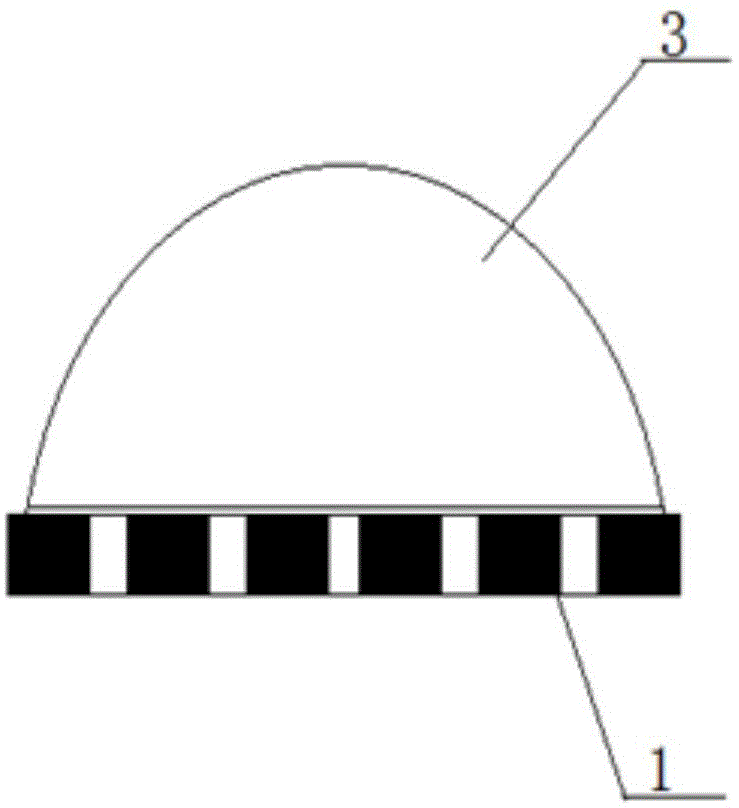

LED UV light source used for solidifying flexible or rotation or trademark printing machine UV printing ink

InactiveCN104553297AImprove curing effectOvercome disadvantagesPrinting press partsHeat conductingUltraviolet lights

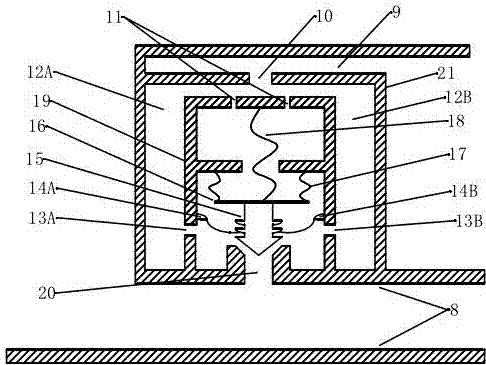

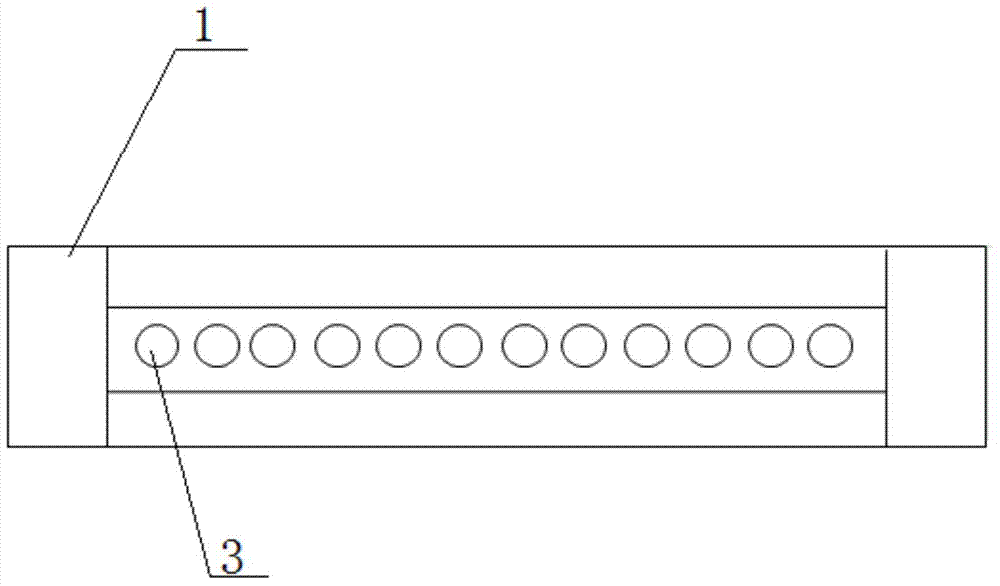

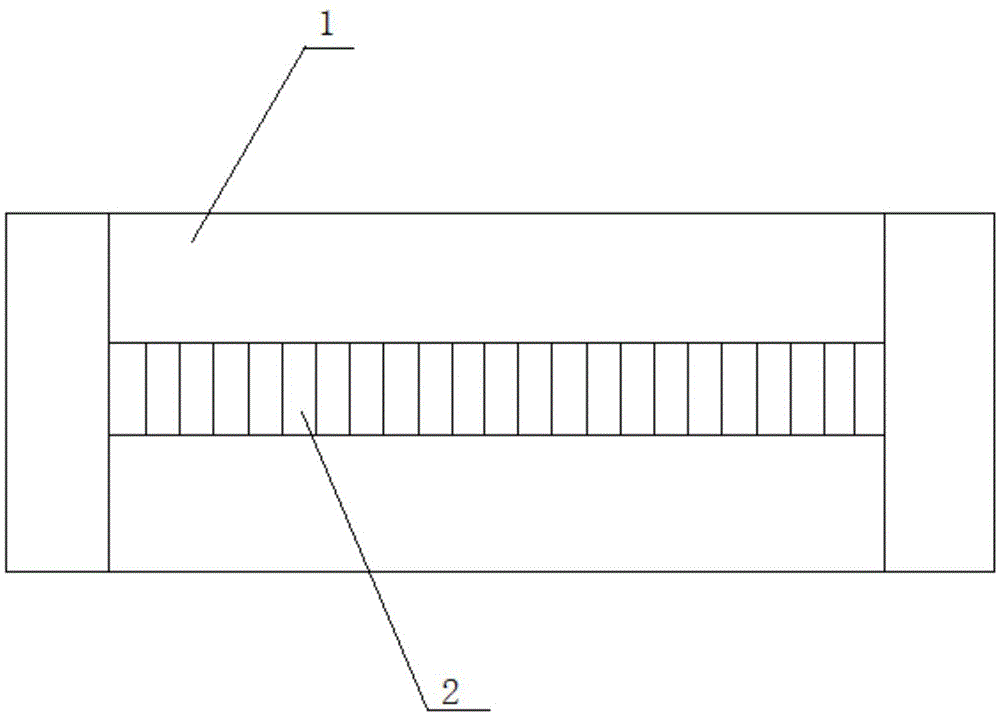

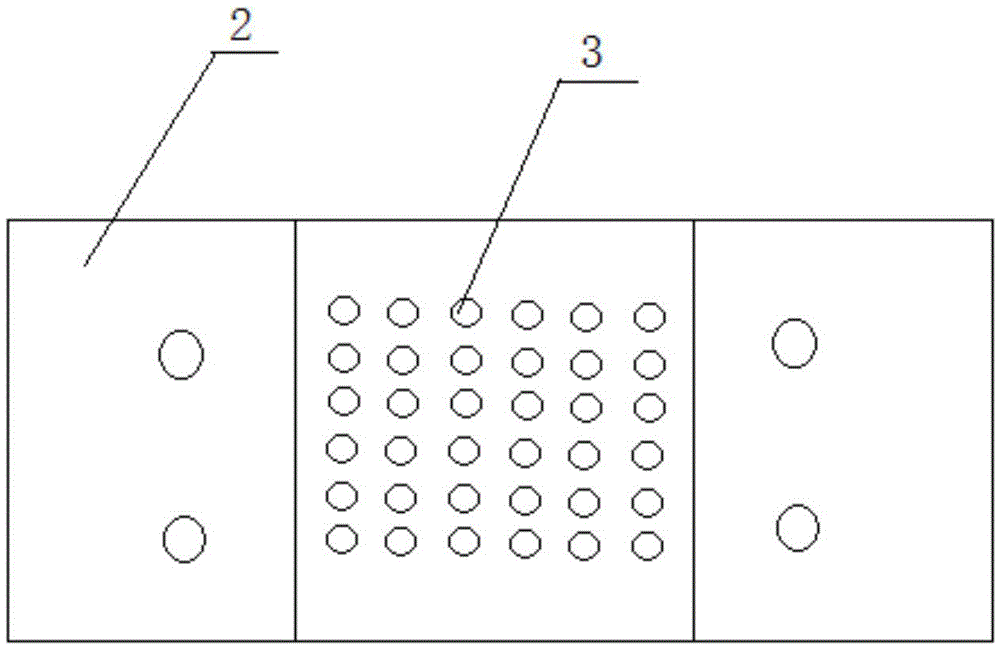

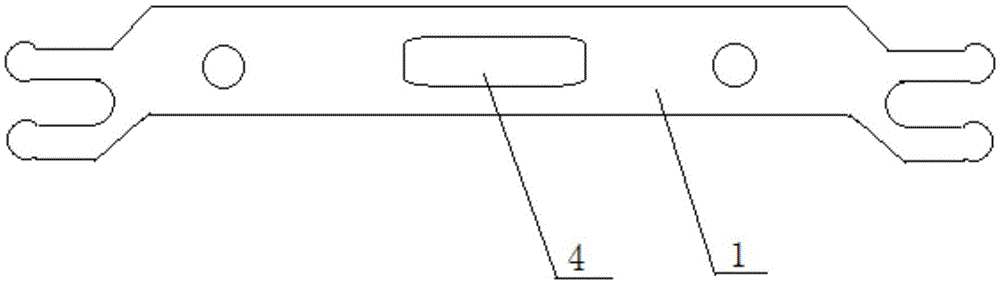

The invention discloses an LED UV light source used for solidifying flexible or rotation or trademark printing machine UV printing ink, and the LED UV light source used for solidifying flexible or rotation or trademark printing machine UV printing ink comprises a power supply circuit board, an LED UV light-emitting module and / or LED UV ultraviolet light light-emitting lamp bead are / is mounted on the power supply circuit board; the LED UV light-emitting module and the LED UV ultraviolet light light-emitting lamp bead are respectively composed of a plurality of ultraviolet light-emitting semiconductors; the ultraviolet light-emitting semiconductor is the LED ultraviolet light-emitting device, and the light-emitting wavelength range is 200nm-500nm. The LED UV light-emitting module and the LED UV ultraviolet light light-emitting lamp bead are fixed on the power supply circuit board through the heat-conducting glue. The LED UV light source used for solidifying flexible or rotation or trademark printing machine UV printing ink overcomes the shortcomings of the conventional UV mercury lamp, the power is low, the electric energy is saved; the mercury and the harmful gas are not generated; the voltage is low, the safety problem is avoided; pre-heating is not required and the service life is long for 25000-30000 hours; the shutter part is not needed while the high temperature and pre-heating are not required, so that the production cost is reduced.

Owner:无锡网圣优威科技有限公司

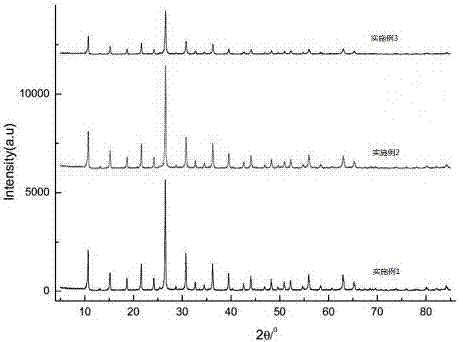

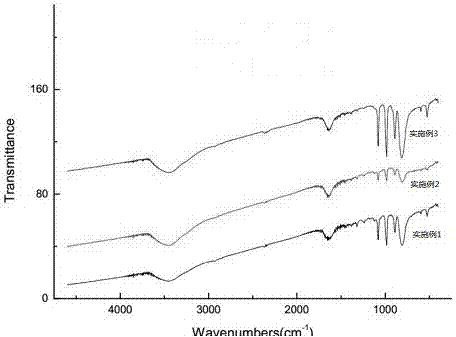

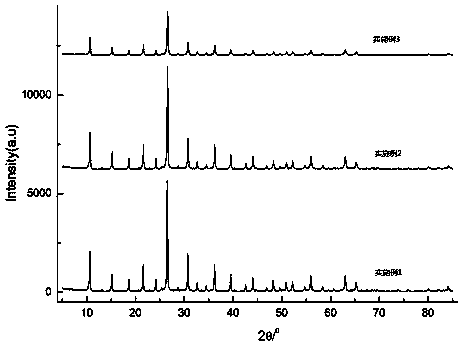

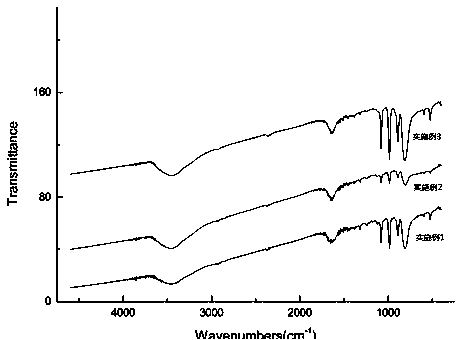

Preparation method and application of load type phosphotungstic heteropoly acid with weak water solubility

ActiveCN107282106AThe preparation method is feasibleAvoid production safety issuesOrganic-compounds/hydrides/coordination-complexes catalystsChemical industrySolubility

The invention belongs to the technical field of phosphotungstic heteropoly acid preparation, and particularly relates to a preparation method and application of load type phosphotungstic heteropoly acid with weak water solubility. The invention provides a method for preparing phosphotungstic heteropoly acid by dilute acidification stirring type modification; the method has the advantages that normal temperature and pressure are adopted for preparation conditions, any organic solvent is not used, the operation is simple, and the energy consumption and the cost are low; the prepared phosphotungstic heteropoly acid is small in water solubility, great in specific surface area and higher in catalytic activity. As an acid site on the surface of the phosphotungstic heteropoly acid having catalytic activity and phosphotungstic heteropoly acid redox carriers (e and II<+>) are diffused, oxidation is generated with biomass plant tissue under a hydrothermal condition; the phosphotungstic heteropoly acid is mainly applied to catalysis, biology, medicines, materials and other aspects, such as waste biomass catalytic degradation and toxic and harmful (waste) gas and sewage (wastewater) treatment in chemical industry production; a chelate of the phosphotungstic heteropoly acid has an anticancer effect, and also can be applied to electrode materials. The prepared load type phosphotungstic heteropoly acid is used for catalytically strengthening degradation of perilla stem, thus realizing efficient conversion of biomass.

Owner:CHONGQING TECH & BUSINESS UNIV

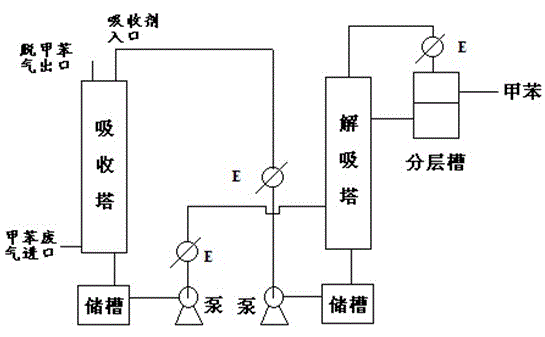

Toluene-containing tail gas recycling process in refractory mica tape production

InactiveCN103143237AAvoid production safety issuesSolve environmental problemsDispersed particle separationChemical industryEther

The invention relates to a toluene-containing tail gas recycling process in refractory mica tape production and belongs to the technical fields of resource recycling and environmental protection. Based on the conventional absorptive method, the toluene-containing tail gas recycling process is characterized in that an organic acid salt or inorganic acid (ether) salt aqueous solution is used as absorption liquid, so that the absorbing effect is better, the production safety problem of the conventional absorption method is effectively solved, toluene is recycled and the absorption liquid is recycled without generating secondary pollution; and the environmental protection problem of the toluene tail gas is solved and the toluene solvent is effectively recycled, therefore, the toluene-containing tail gas recycling process belongs to the energy-saving emission-reducing advantage project. The toluene-containing tail gas recycling process disclosed by the invention is simple; the treated tail gas reaches the national environmental protection emission requirements; the resources are saved; the toluene solvent is recycled; and the relevant national industrial polices for encouraging the chemical industries to save energy and reduce emission are satisfied. Besides, the toluene-containing tail gas not only can be used for recycling the toluene-containing tail gas in the refractory mica tape production, but also can be popularized to the recycling of toluene-containing tail gas in other fields.

Owner:扬州新奇特电缆材料有限公司 +1

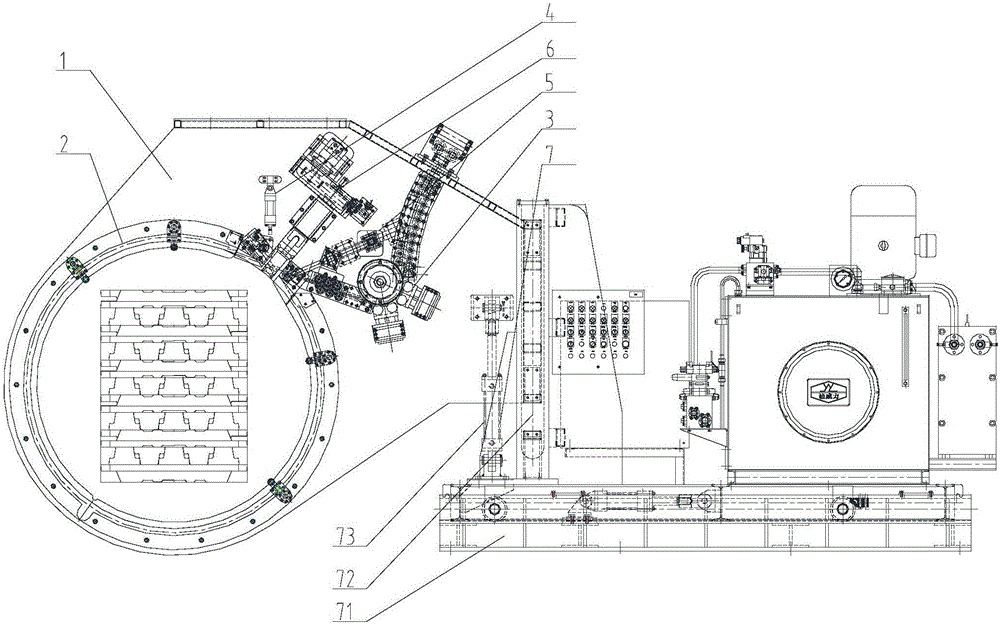

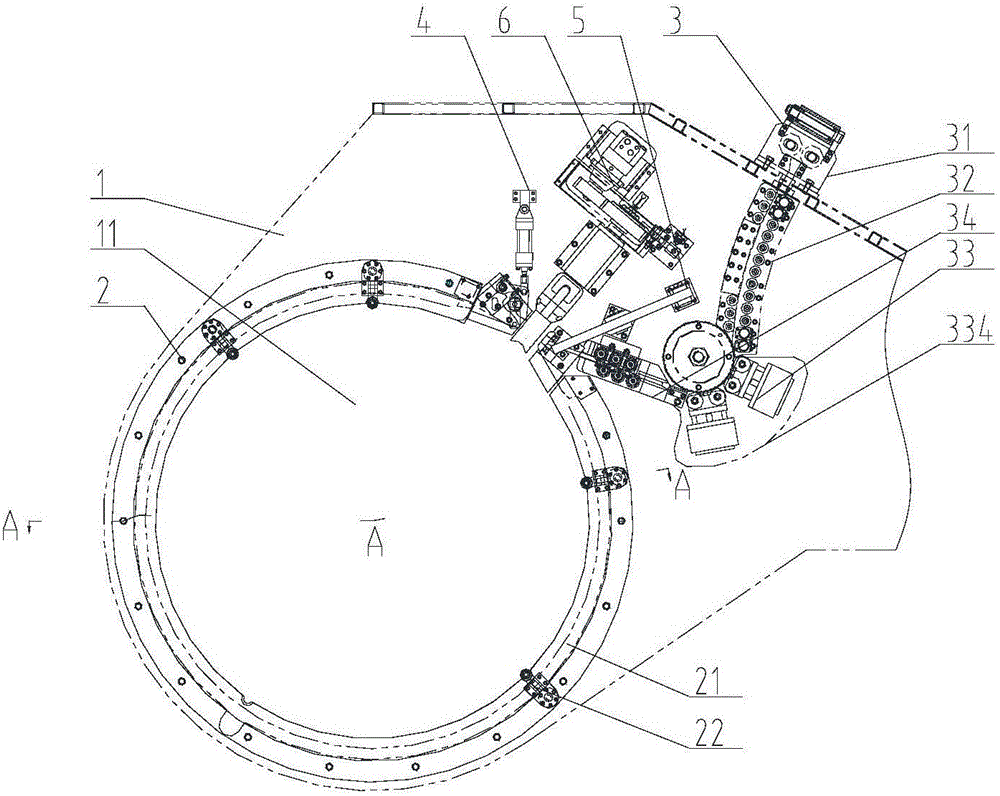

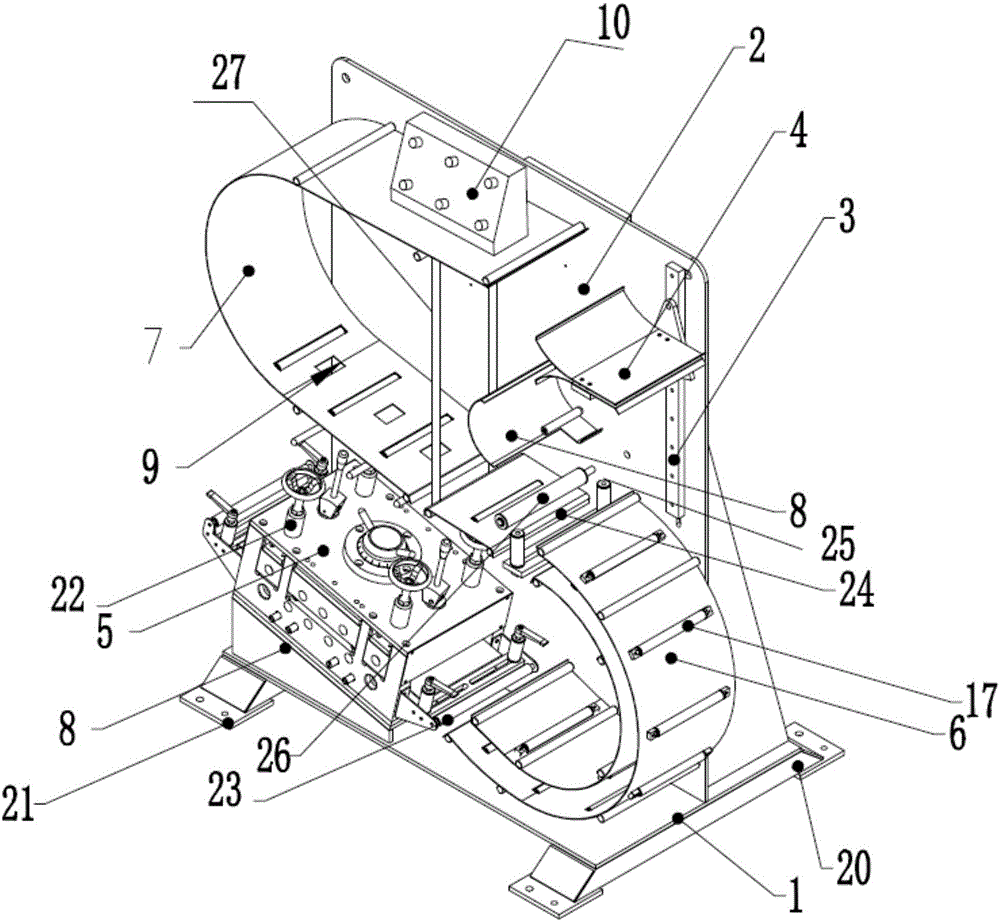

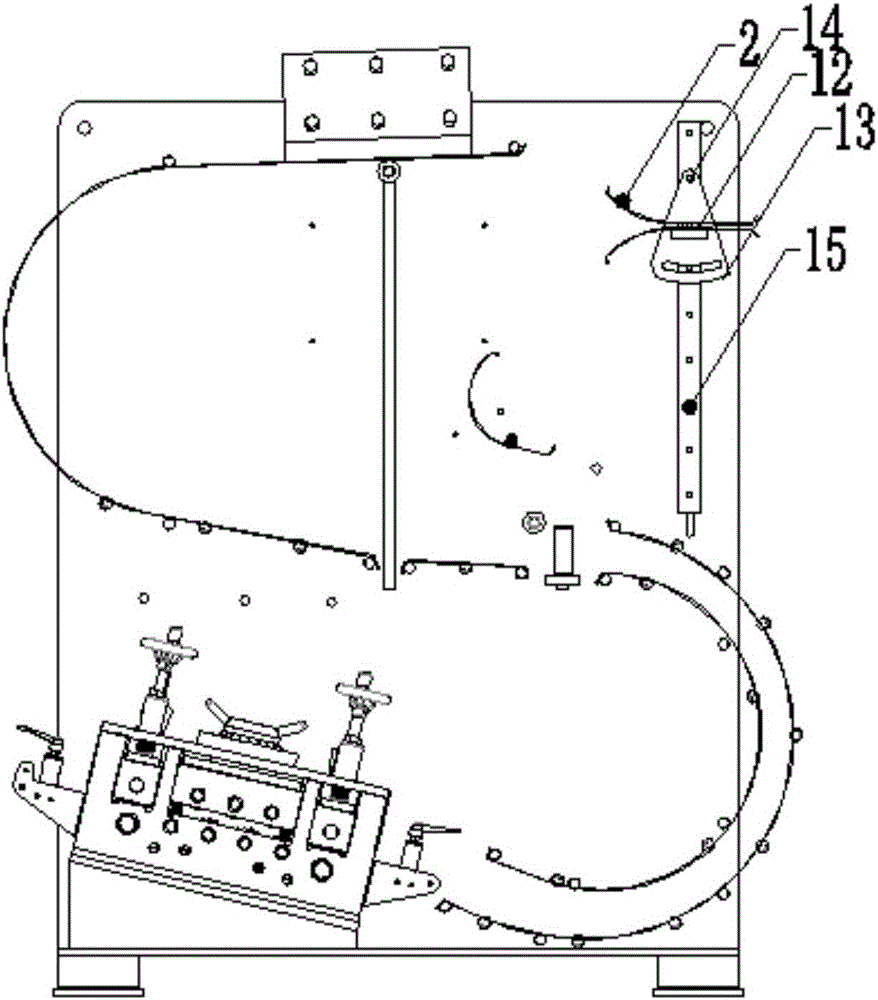

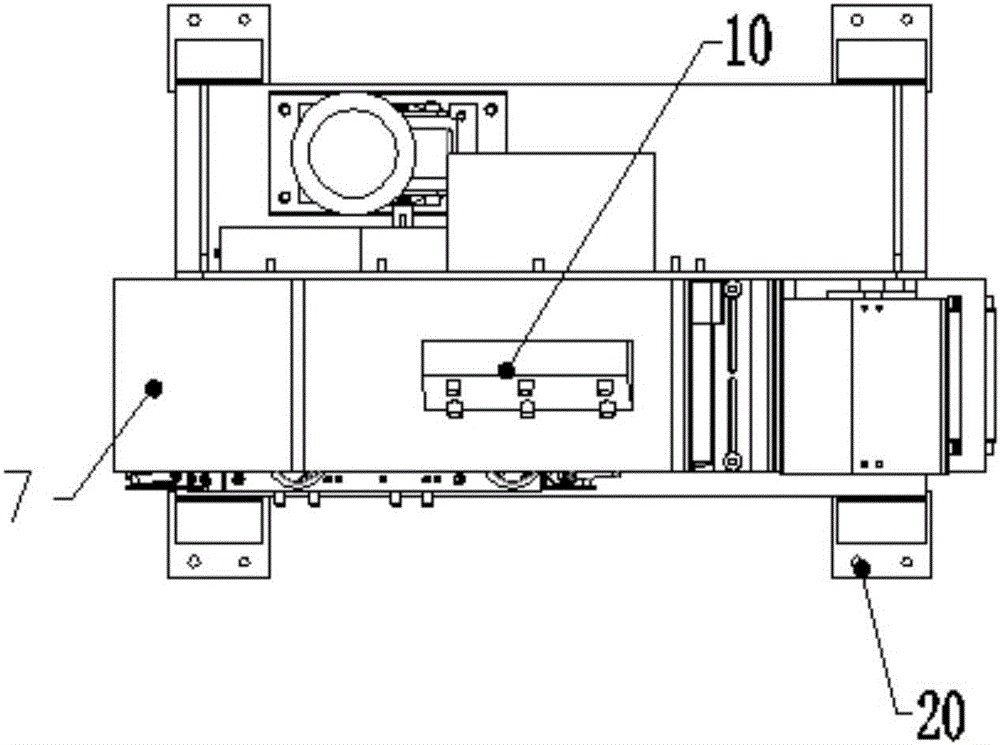

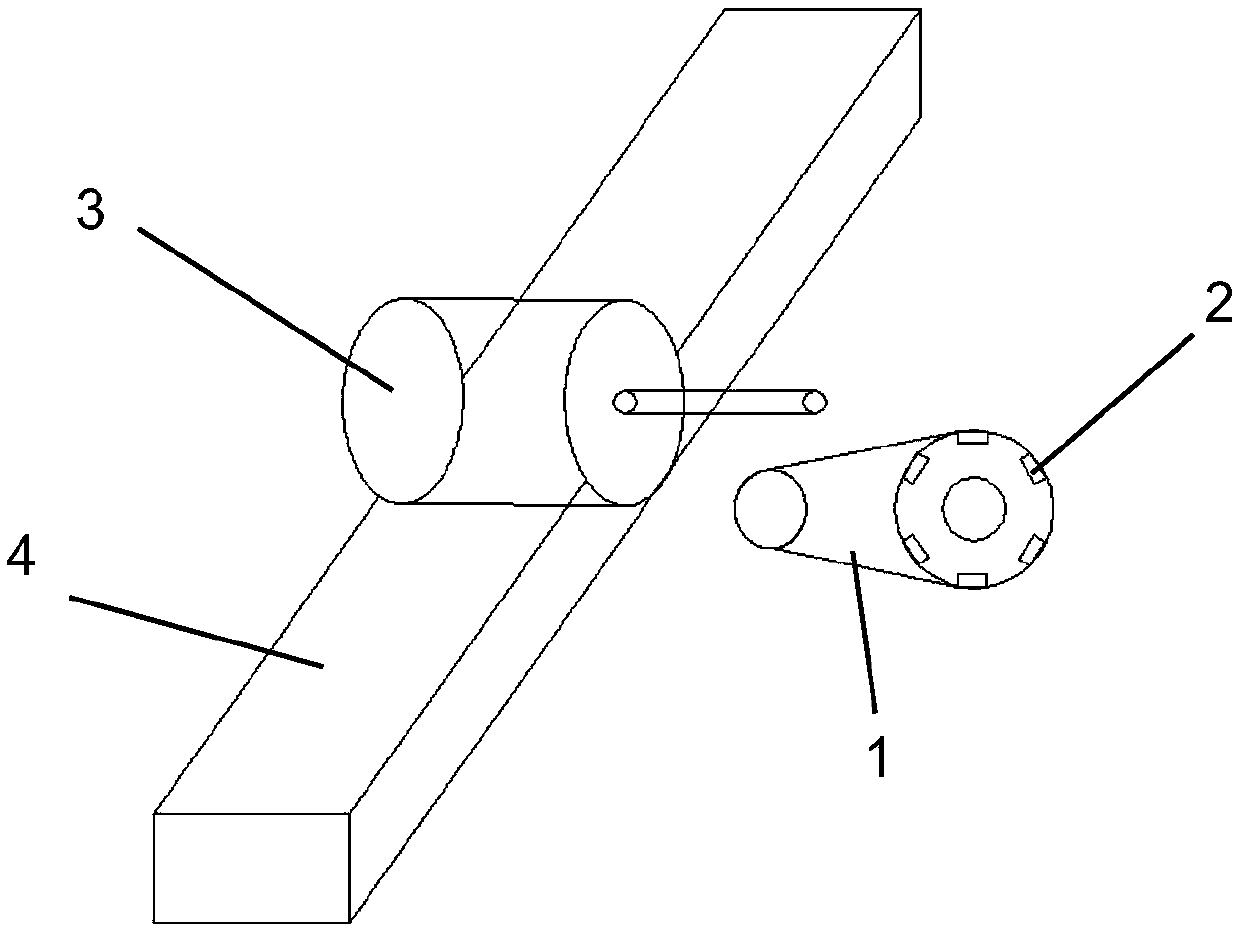

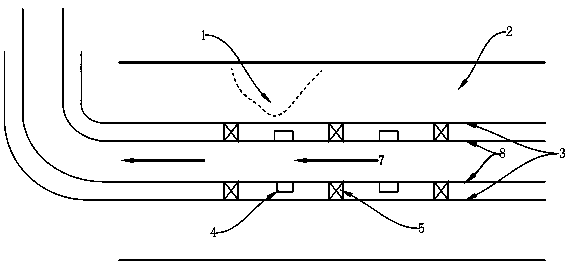

Aluminum wire bundling machine for bundling aluminum ingots and operation method thereof

ActiveCN105035392AReduce bundling costsAchieve mutual benefitBinding material applicationBundling machine detailsWire cuttingAutomation

The invention discloses an aluminum wire bundling machine for bundling aluminum ingots and an operation method thereof, and relates to the field of aluminum ingot bundling equipment. The aluminum wire bundling machine for bundling the aluminum ingots and the operation method thereof are characterized in that the aluminum wire bundling machine comprises a bundling substrate, a wire drawing assembly, a wire guiding assembly, a wire clamping assembly, a wire cutting assembly and a knotting assembly; the operation method comprises the steps of material feeding, judgment of whether first-time wire threading is conducted or not, wire threading, wire feeding, wire clamping, wire returning, wire cutting, knotting, judgment of whether first-time bundling is conducted or not, judgment of whether second-time bundling is conducted or not, judgment of whether third-time bundling is conducted or not, position entering, reversing and discharging. According to the aluminum wire bundling machine for bundling the aluminum ingots and the operation method thereof, the mode that crossed bundling is arranged to be shaped like a Chinese character 'jing' is adopted, and the stability and the aesthetic property of bundling are greatly promoted; on the whole, the operation method has the advantages that the automation degree is high, the steps are simple, and organization is clear, and the problems of production safety, labor cost and labor intensity caused by overmuch manual operations are effectively avoided.

Owner:YANGZHOU METALLURGICAL MACHINERY

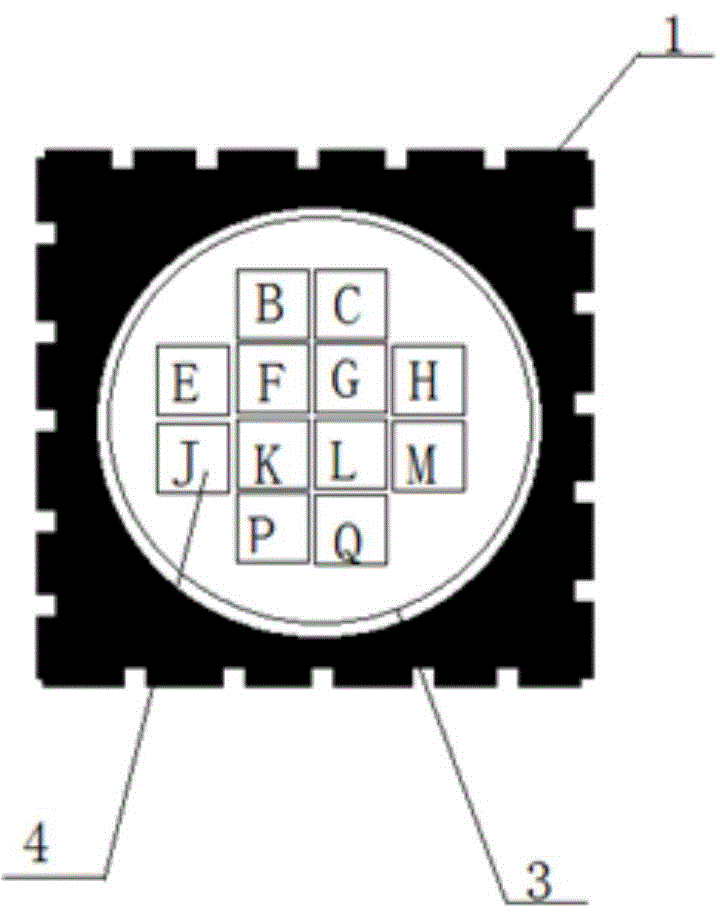

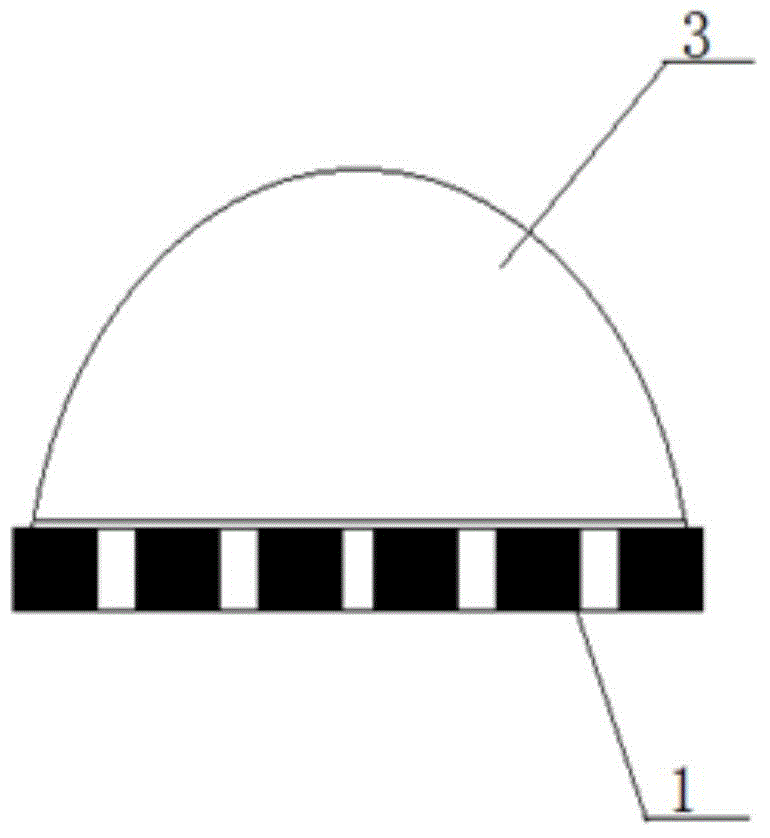

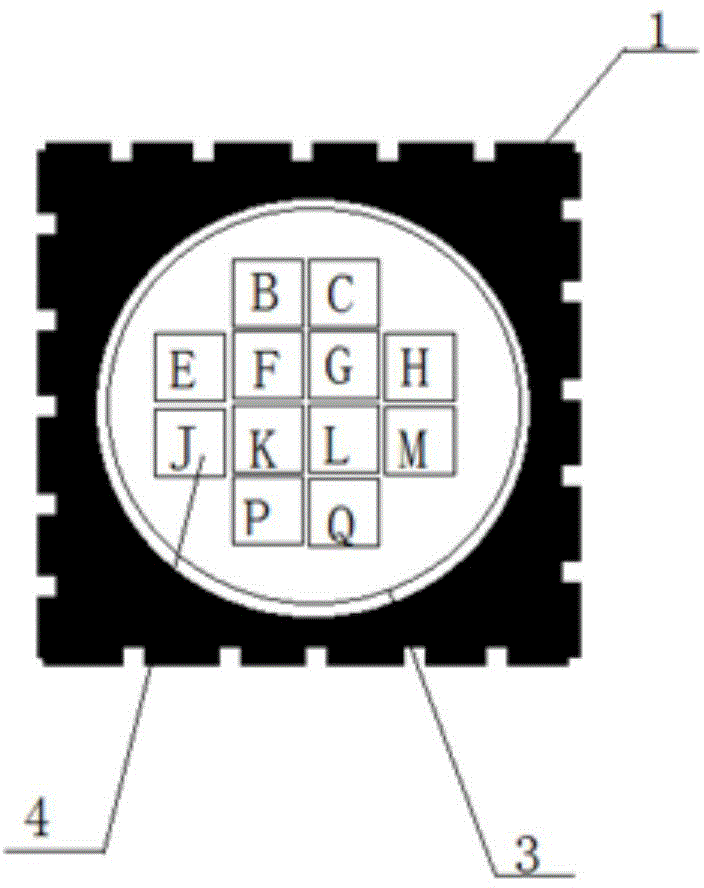

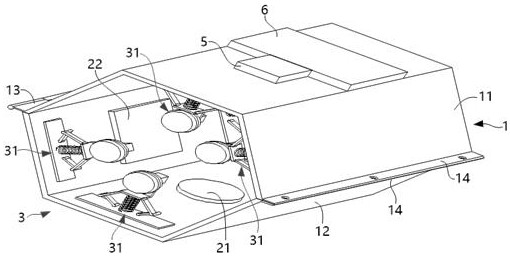

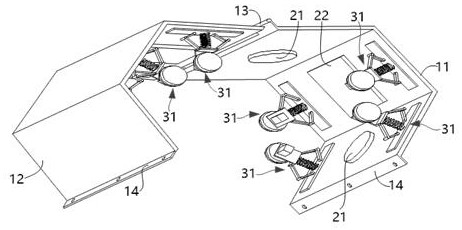

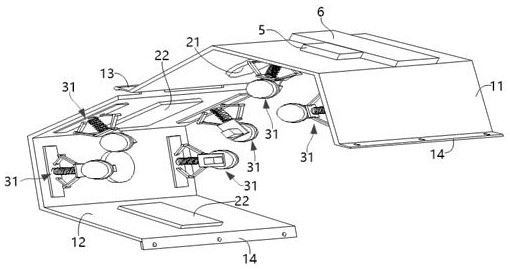

Screen printer with LED UV ink curing light sources

InactiveCN104589784AImprove printing efficiencyFast curingScreen printersPrinting press partsUltravioletEngineering

The invention discloses a screen printer with LED UV ink curing light sources. The screen printer with the LED UV ink curing light sources comprises a machine frame, wherein a plurality of printer color cells are arranged on the machine frame, the multiple LED UV ink curing light sources are arranged among the printer color cells, and the light-emitting surfaces of the multiple LED UV ink curing light sources are aligned with a printing surface of a printing material; each LED UV ink curing light source comprises a power source circuit substrate, wherein an LED UV light-emitting module and / or LED UV light-emitting beads are installed on the power source circuit substrate and are all composed of a plurality of UV light-emitting semiconductors which are LED UV light-emitting elements, and the light-emitting wave length range is 200-500 nm. The screen printer with the LED UV ink curing light sources does not generate mercury and harmful gas, the needed voltage is low, production safety problems are avoided, preheating is not needed in the use process, the service life is as long as 25000-30000 hours, a shutter component is not needed as the temperature is not high and preheating is not needed, and the production cost is reduced.

Owner:无锡网圣优威科技有限公司

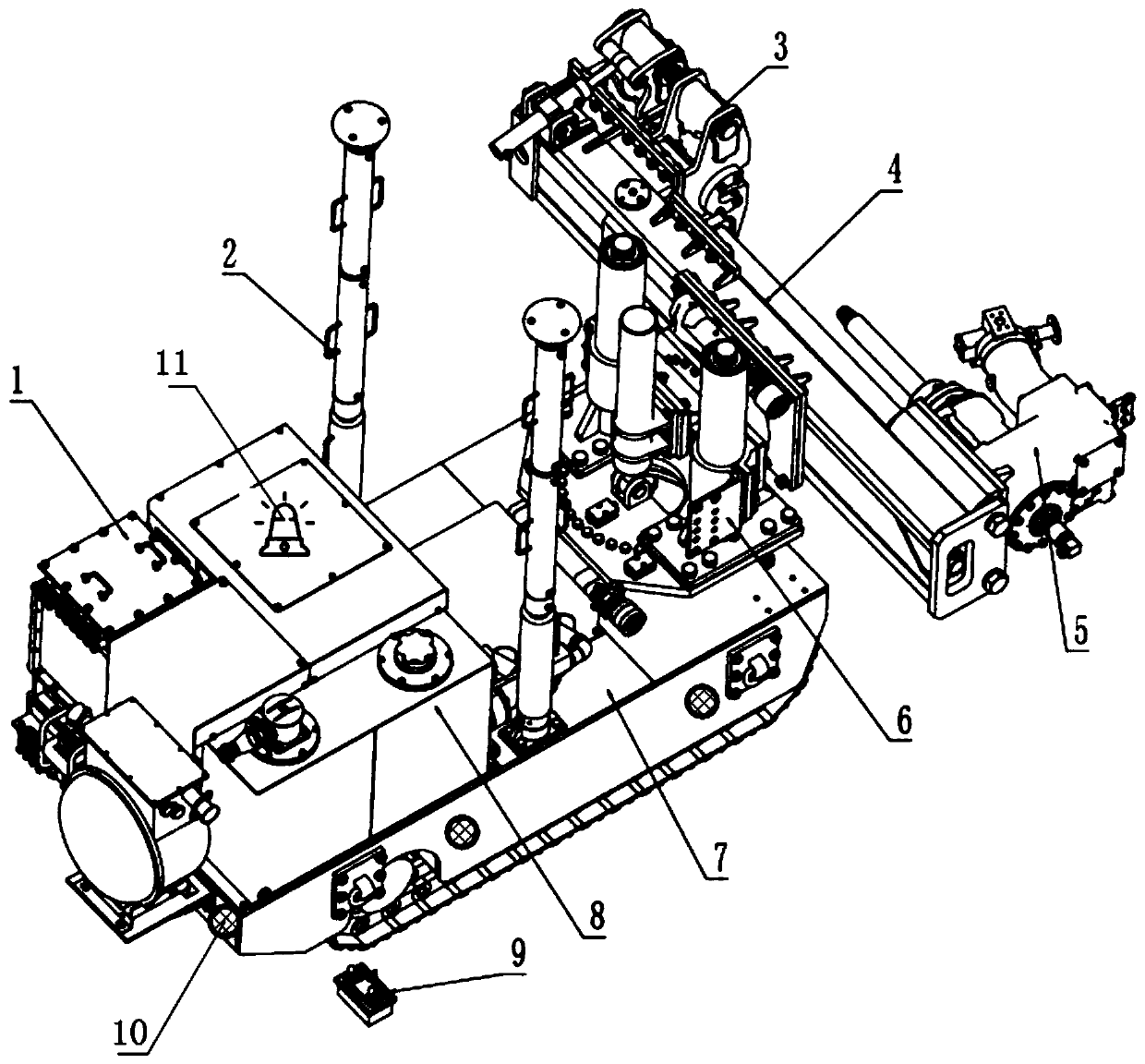

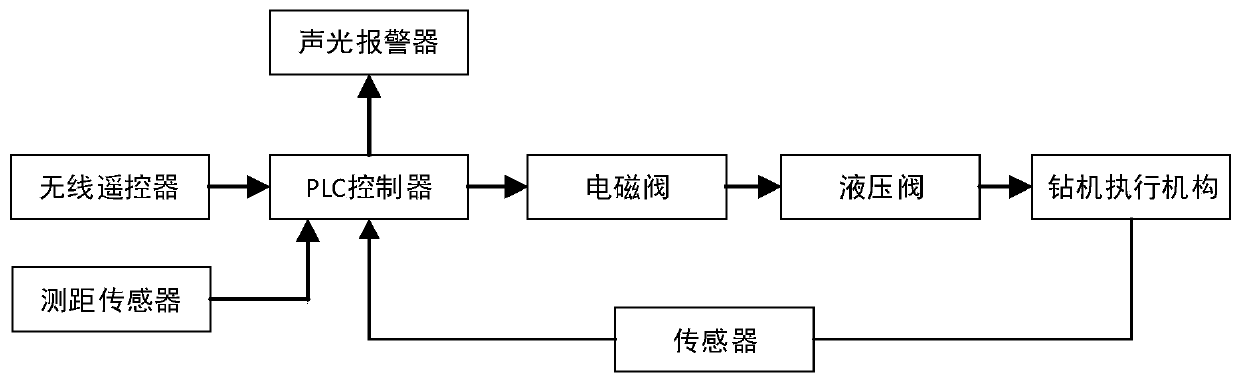

All-dimensional electric control drilling machine and control method thereof

PendingCN110905404AImprove efficiencyAvoid misuse of personnel injury and damage to equipmentMining devicesGas removalProcess engineeringDrill hole

The invention relates to an all-dimensional electric control drilling machine and a control method thereof, and belongs to the technical field of coal mine drilling machines. The drilling machine comprises a walking chassis, a drilling main machine and an anchoring system, wherein the drilling main machine and the anchoring system are arranged on the walking chassis. The drilling machine further comprises a control system; the control system comprises a main machine controller and a wireless remote controller; the main machine controller is arranged on the walking chassis and connected with the drilling main machine and the anchoring system; the wireless remote controller is in signal connection with the main machine controller; and the wireless remote controller is adopted for controllingthe drilling machine, an operator observes the conditions of the drilling machine and a hole opening without dead angles, injuries to personnel and damage to equipment due to misoperation caused by blocking of the sight of the operator are avoided, and the production safety is improved.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

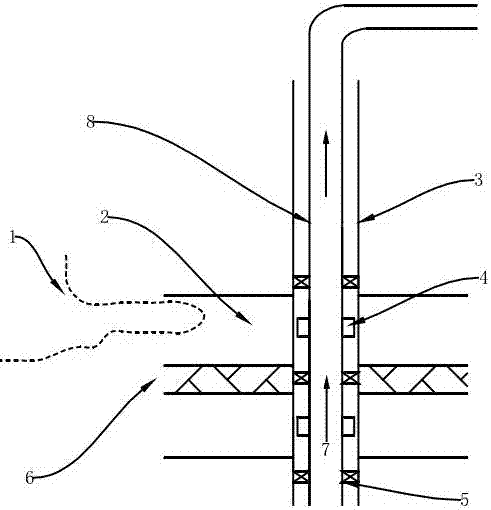

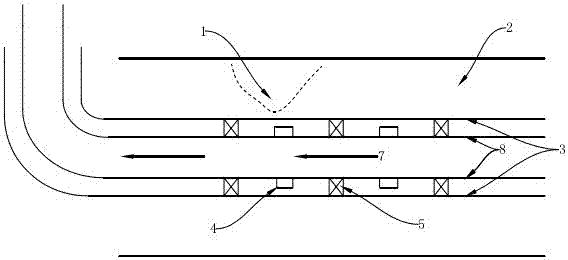

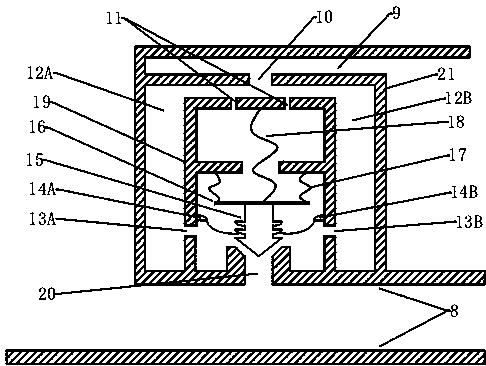

Intelligent inflow gas control device and intelligent inflow gas control method

ActiveCN106996281AInflow controlImprove displacement efficiencyFluid removalHorizontal wellsEconomic benefits

The invention discloses an intelligent inflow gas control device which mainly comprises a flow chamber, pressure guide holes, inlet oil nozzles, a packet, a sawtooth-shaped movable component and turn-off structures. The maximum quantity Q <max> of gas which is allowed to flow through the inlet oil nozzles can be set according to actual production requirements on oil wells. The intelligent inflow gas control device can normally work when the quantity Q of the gas which flows through the inlet oil nozzles does not exceed the set maximum quantity Q <max> of the gas; the intelligent inflow gas control device is turned off when the quantity Q of the gas reaches the set maximum quantity Q <max> of the gas, and fluid is no longer allowed to flow through the intelligent inflow gas control device. A working principle for the intelligent inflow gas control device includes that the gas can critically flow in the inlet oil nozzles when the flow rates of the gas in the inlet oil nozzles reach the maximum quantity Q <max> of the gas; ratios of front-end pressures P1 to rear-end pressures P2 of the inlet oil nozzles are critical pressure ratios, and the intelligent inlet gas control device can be turned off under the control of the critical pressure ratios. The intelligent inflow gas control device has the advantages that the intelligent inflow gas control device can be applied to gas-top reservoirs and gas injection production straight wells, horizontal wells and inclined wells, specified gas quantity exceeding gas flow channels can be timely closed, accordingly, economic benefits of oil fields can be increased, and the recovery ratios of oil reservoirs can be increased.

Owner:SOUTHWEST PETROLEUM UNIV

High-speed precise leveling machine

InactiveCN106238511AImprove leveling efficiencySupply synchronizationMetal-working feeding devicesShaping safety devicesEngineeringMechanical engineering

The invention discloses a high-speed precise leveling machine. A long storage space is formed through an S-shaped precise material guiding mechanism, the storage space is greatly saved, the large storage length is kept, and enough supply synchronism of stored materials is guaranteed during high-speed running of the machine. The high-speed precise leveling machine comprises rack, a back plate is vertically arranged at the upper end of the rack, and strengthening ribs are arranged between the back plate and the rack and used for strengthening connection of the back plate and the rack. An adjusting rod is longitudinally arranged on the back plate and provided with an adjustable discharging frame. A leveling machine body is arranged at the upper end of the rack and located at the front end position of the back plate. A discharging mechanism is arranged at the output end of the leveling machine body, and a material guiding mechanism is arranged at the output end of the discharging mechanism. The discharging mechanism and the material guiding mechanism are in linkage in an end-to-end manner so as to form an S shape. Running of the whole machine is more stable, and the accident rate is effectively reduced. The whole machine is operated through a control box, automatic running can be conducted, and a safe production environment is provided for production workers.

Owner:东莞市杰达机械有限公司

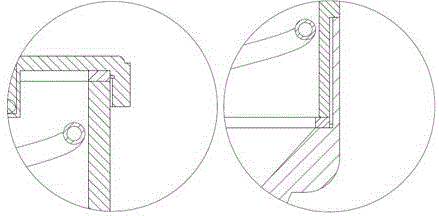

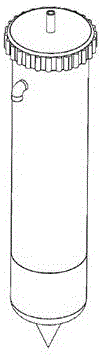

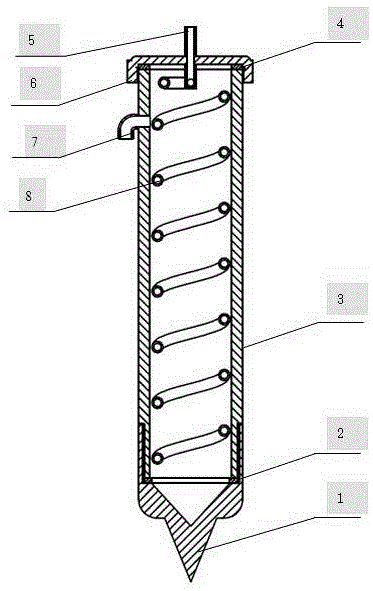

Novel arc air gouging device

InactiveCN105750718AAvoid consumablesAvoid dustCooled electrode holdersElectrode accessoriesCold airAlloy

The invention relates to a machining tool, in particular to a novel arc air gouging device. The novel arc air gouging device comprises a tungsten-molybdenum alloy electrode tip, a copper pipe body, an upper cover, an upper sealing ring, a lower sealing ring, an air inlet pipe, an air jet pipe and a spiral through pipe. The electrode tip is made of tungsten-molybdenum alloy, the electrode tip is provided with an inner hole in the axial direction, the upper end of the electrode tip is a cylinder, and the lower end of the electrode tip is a cone. The copper pipe body is a cylindrical shell with the top and the bottom open, and external threads are arranged on the outer surfaces of the two ends of the copper pipe body. The upper end of the upper cover is closed, the lower end of the upper cover is open, and an internal thread is arranged on the surface of the inner wall of the upper cover. The spiral through pipe is a hollow spiral through pipe made of copper. The novel arc air gouging device is simple, convenient to use and reliable in sealing; compressed cold air is introduced through the air inlet pipe and circulates in the pipe body, and thus efficient cooling is achieved; as the air jet pipe is adopted to feed air downwards, molten metal generated in the air gouging process can be easily blown away, and a smooth cut surface can be formed; as the tungsten-molybdenum alloy electrode tip is adopted for discharging, high-temperature oxidation is avoided, and a stable arc is formed.

Owner:CHINA UNIV OF MINING & TECH

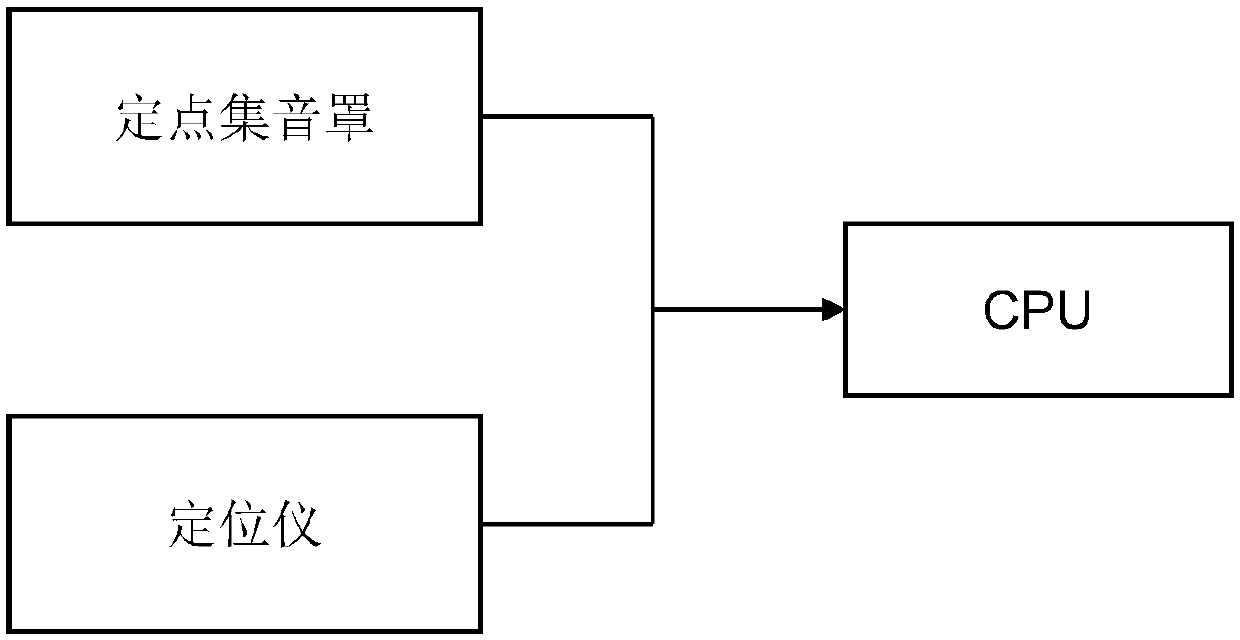

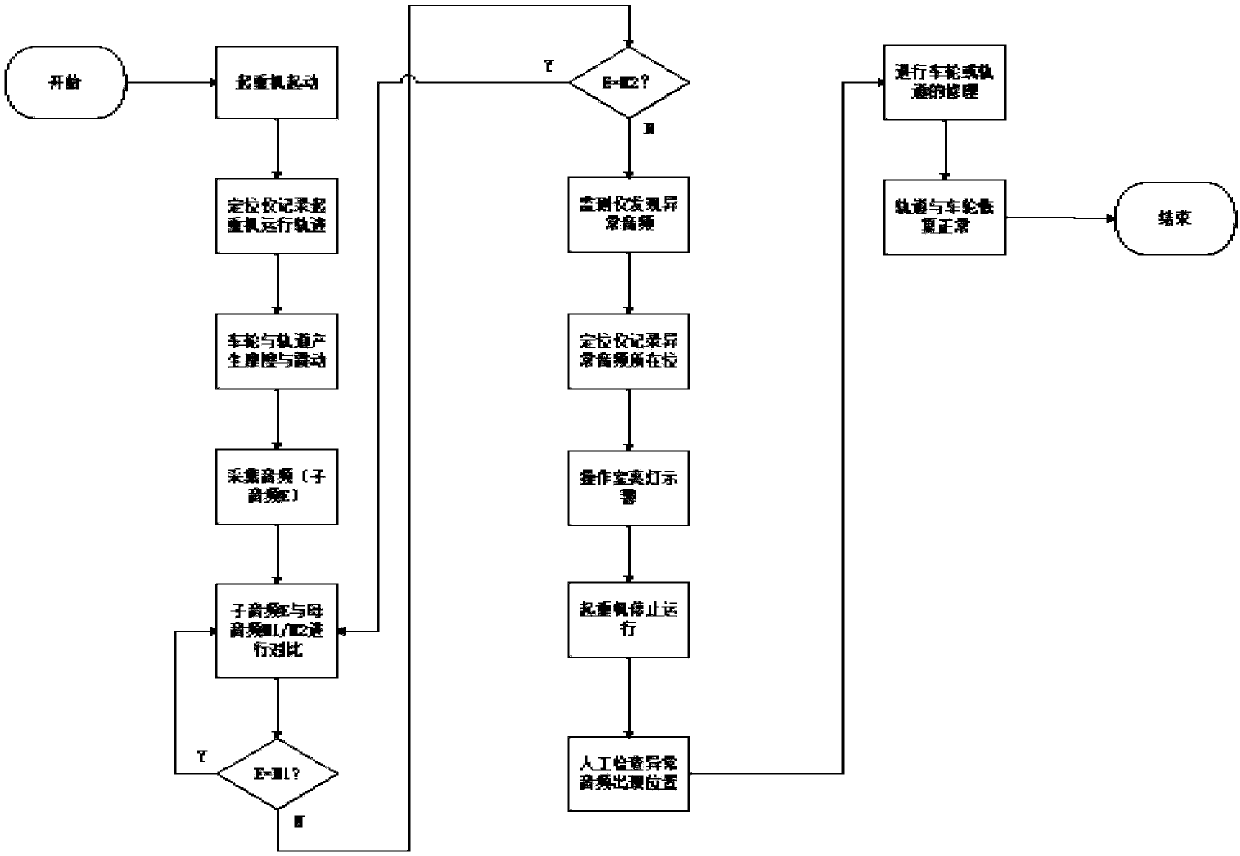

Monitoring system and method for dynamic operation track of lifting machine

InactiveCN110482406AImprove lifting safety operation rateAvoid unusual accidentsSafety gearTime dynamicsDynamic monitoring

The invention discloses a monitoring system and method for a dynamic operation track of a lifting machine. According to the method, real-time dynamic collection of fixed-point sound track is carried out on friction sound between a wheel and a track through a fixed-point sound collecting cover, real-time positioning is carried out through a position indicator, and then the fixed-point sound track is compared with a set mother sound track through a CPU so as to detect abnormal conditions in real time and give an alarm. According to the system and the method, the travelling tracks of large lifting devices can be dynamically monitored under a less-people state and an unmanned state, the system is a whole set of system with integrity, in actual production, the problem that the lifting machine track is abnormal can be effectively solved, the lifting safety operation rate is improved, abnormal accidents are prevented, the safety of the production logistics is effectively controlled, so that the effect of solving the production safety problem is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

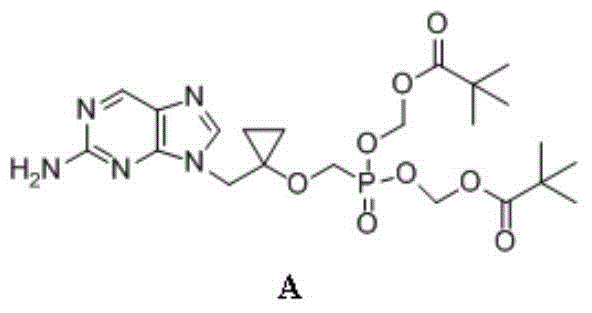

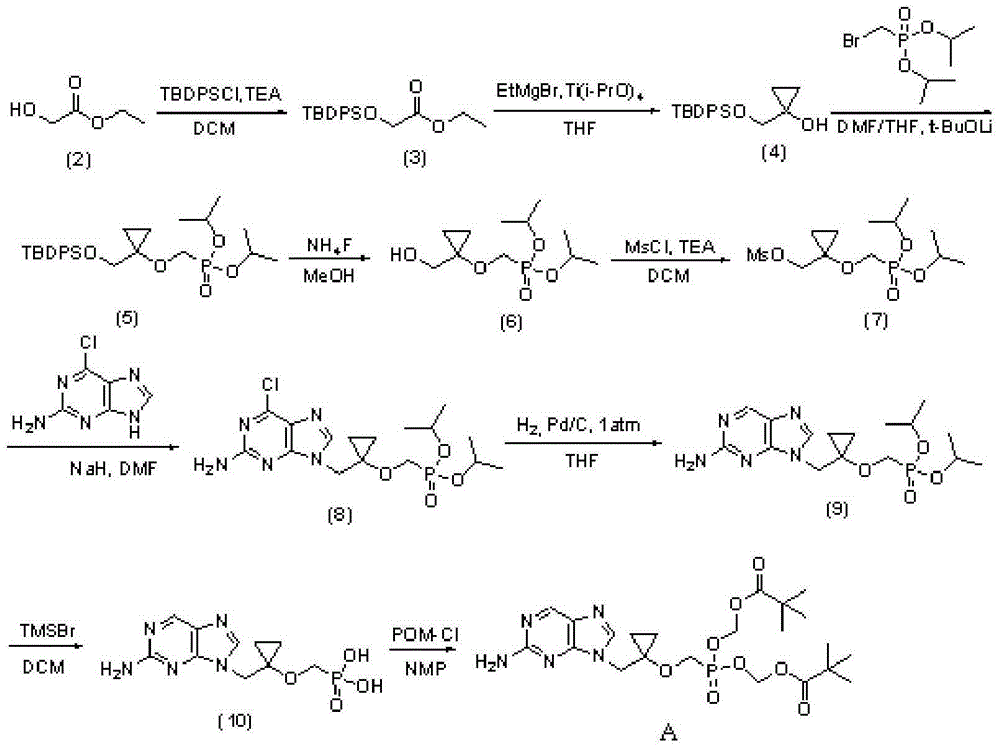

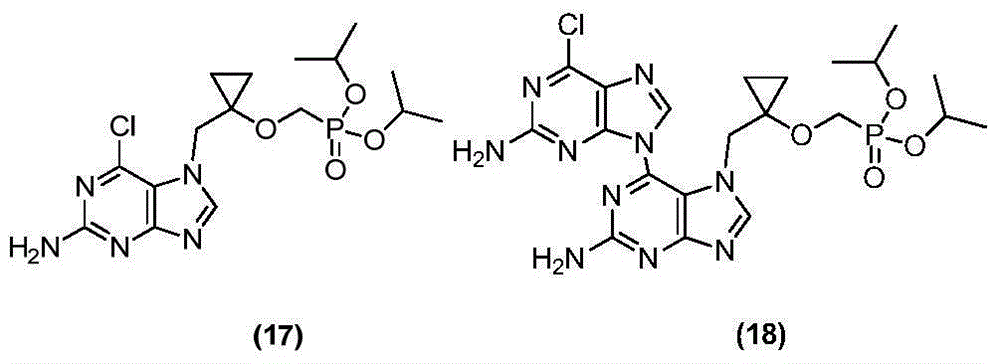

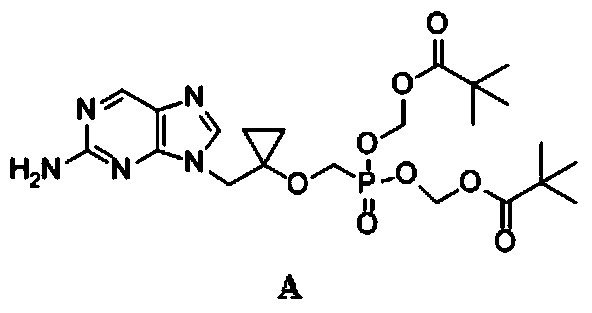

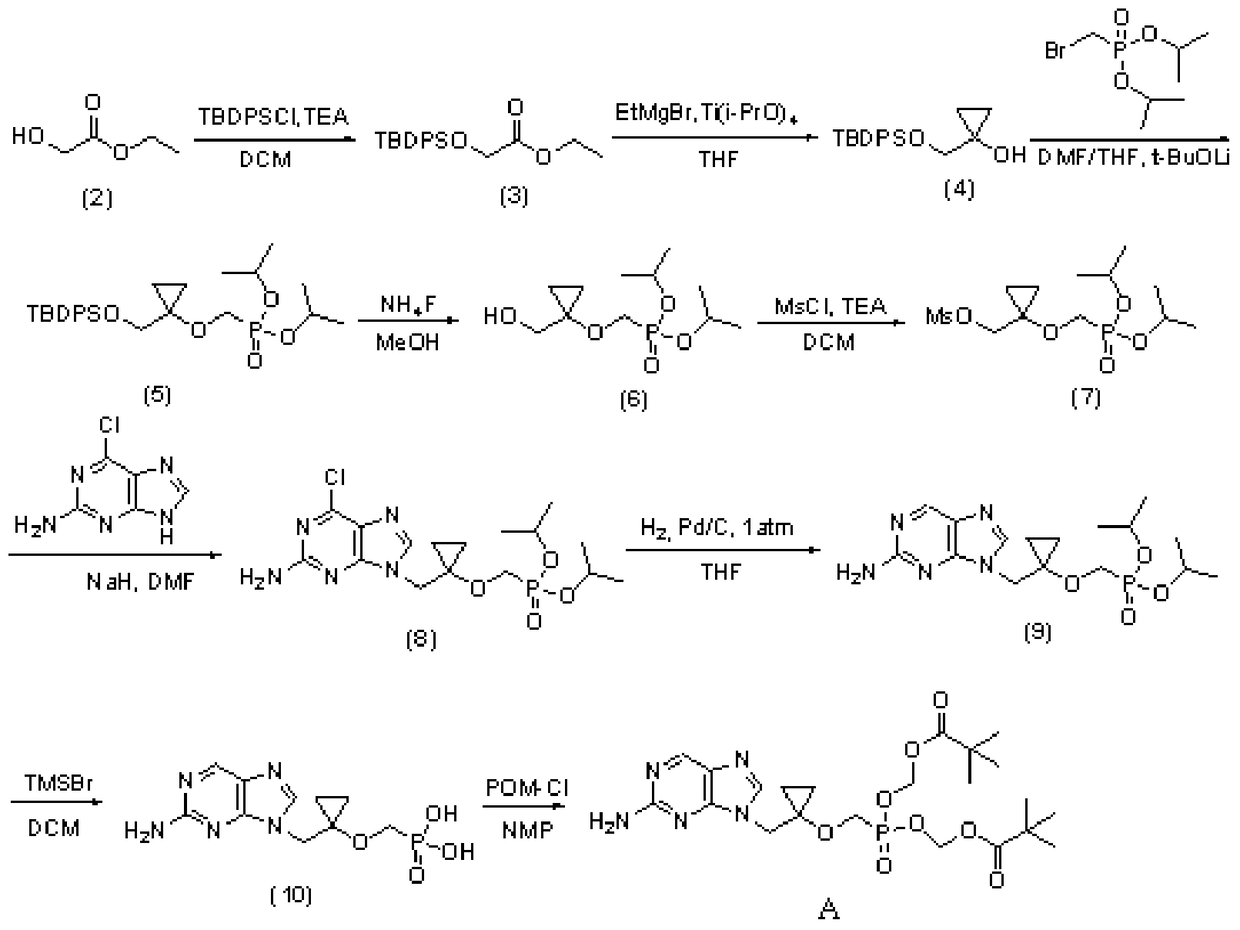

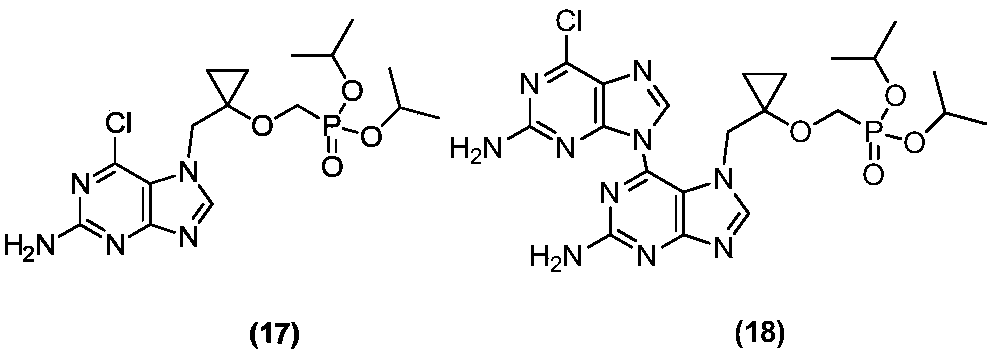

Intermediate compound of medicine LB80380 and preparing method and application thereof

ActiveCN106432330AEasy to purifyAvoid generatingGroup 5/15 element organic compoundsCombinatorial chemistryMethyl group

The invention provides an LB80380 intermediate compound (as shown in formula I in the specification). In the LB80380 intermediate compound, R1, R2, R3 and R4 are chosen from linear chain or branched chain alkyl group, benzyl group which is replaced by one or five R5, or R5CO independently, wherein the R1, the R1, the R3 and the R4 are identical or different; R5 is chosen from hydrogen, C1-C4 alkoxy which is replaced or not replaced, C3-C7 alkenyl alkoxy, or benzyloxy- which is replaced or not replaced. The invention also provides a preparing method and an application of the compound in the formula I. When the compound in formula I is used for preparing a compound (specific chemical formula is in the specification), reaction route raw materials and intermediate materials are low in price and easy to get, cost is low, safety is good, and thus the LB80380 intermediate compound in formula I is applicable to industrial production.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

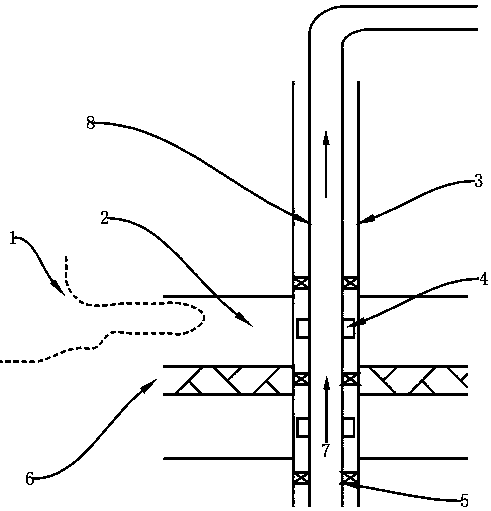

Fluorite-magnesium grain cored wire, application of fluorite-magnesium grain cored wire and production process for high heat input welding steel

The invention discloses a fluorite-magnesium grain cored wire, application of the fluorite-magnesium grain cored wire and a production process for high heat input welding steel. The cored wire comprises an outer layer and a clad core. Low-carbon steel serves as the outer layer, and the thickness ranges from 0.5 mm to 1.0mm; sustained-release passivated magnesium grains serve as the clad core, and the clad core comprises a sustained-release agent and passivated magnesium grain bodies; and fluorite serves as the sustained-release agent, the sustained-release agent accounts for 5%-90% of the clad core, and the passivated magnesium grain bodies account for 10%-95% of the clad core. The application refers to application of the cored wire in manufacturing of the high heat input welding steel. According to the production process, the sustained-release passivated magnesium grain cored wire with the fluorite serving as the sustained-release agent is fed into molten steel, the absorption rate of Mg is stable, the effect and the utilization rate of Mg are high, slag inclusions are dispersed and abundant, and the slag inclusions containing Mg reach over 80%. By the adoption of the fluorite-magnesium grain cored wire, application and the production process, control is easy, production cost is low, and industrialized mass production of the high heat input welding steel can be achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

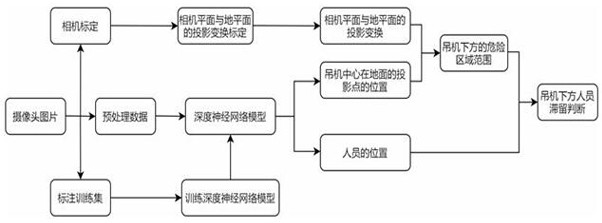

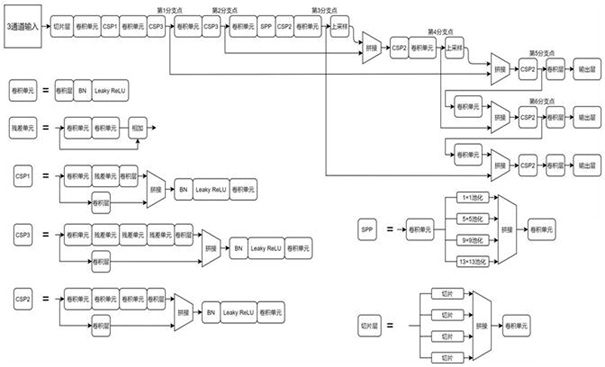

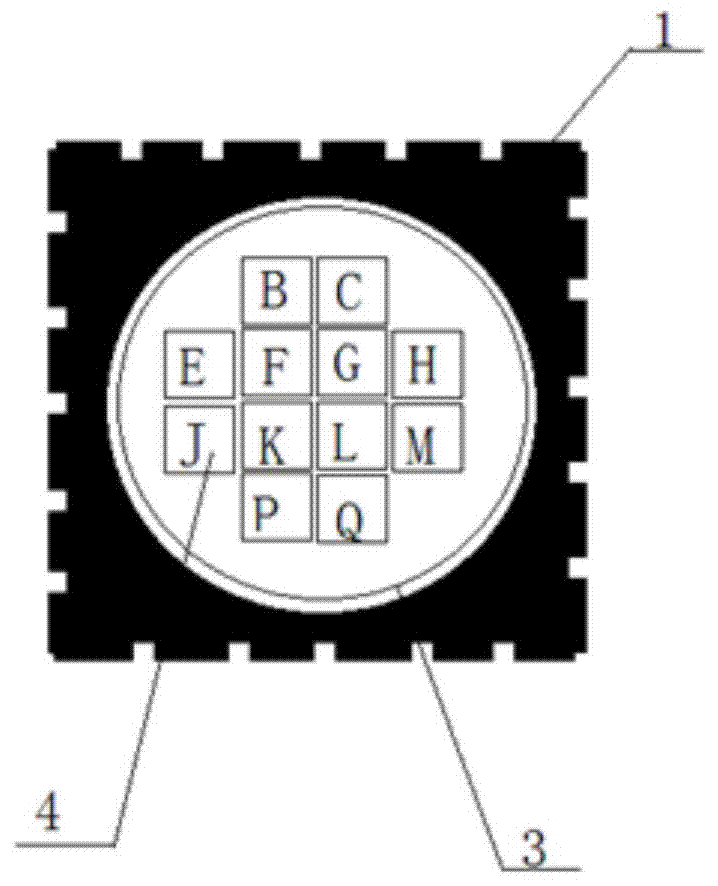

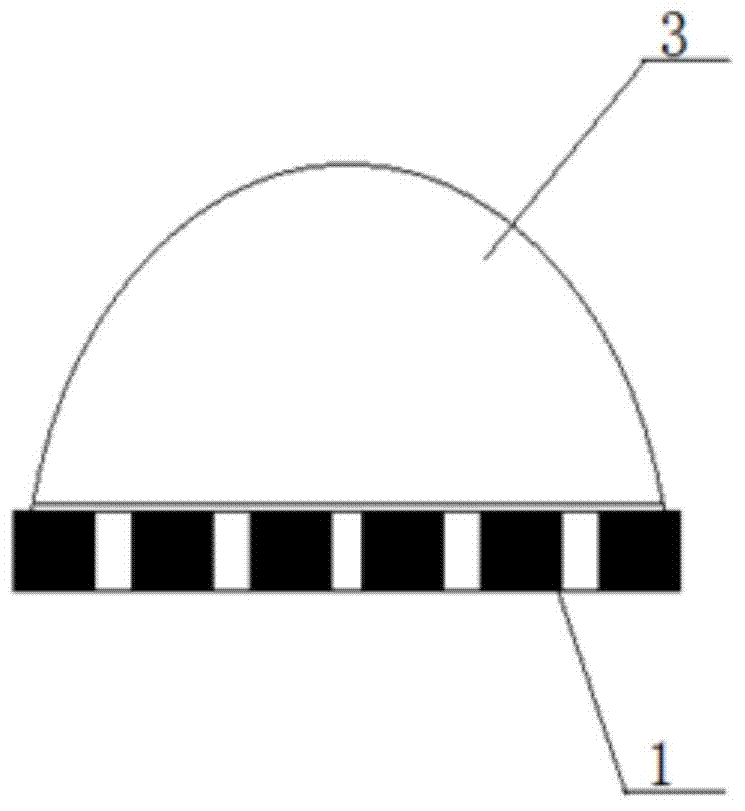

Detection and alarm method for staying of personnel below crane

PendingCN114332753AAvoid production safety issuesProduction operation safetyCharacter and pattern recognitionNeural architecturesNerve networkMechanical equipment

The invention belongs to the technical field of image recognition application, and particularly discloses a method for detecting and warning retention of personnel below a crane, which comprises the following steps: acquiring a to-be-detected crane scene picture by using a camera, and calibrating the camera and the picture to obtain a projection transformation module between a picture plane and the ground; preprocessing the picture to obtain a preprocessed picture; inputting the preprocessed picture into a pre-trained deep neural network model, and outputting the position of the personnel, the position of the crane and a projection point of the center of the crane on the ground; the projection points are input into the projection transformation module, and the dangerous area range below the crane is obtained; and judging whether the personnel position is in a dangerous area and giving an alarm. The system has the beneficial effects that the safety problem in an engineering construction site or a large mechanical equipment factory is solved, all-weather and real-time detection of personnel retention in a dangerous area below the crane is achieved, accurate, stable and timely monitoring and early warning operation processing can be completed, and safe production operation is achieved.

Owner:国能宁夏灵武发电有限公司 +1

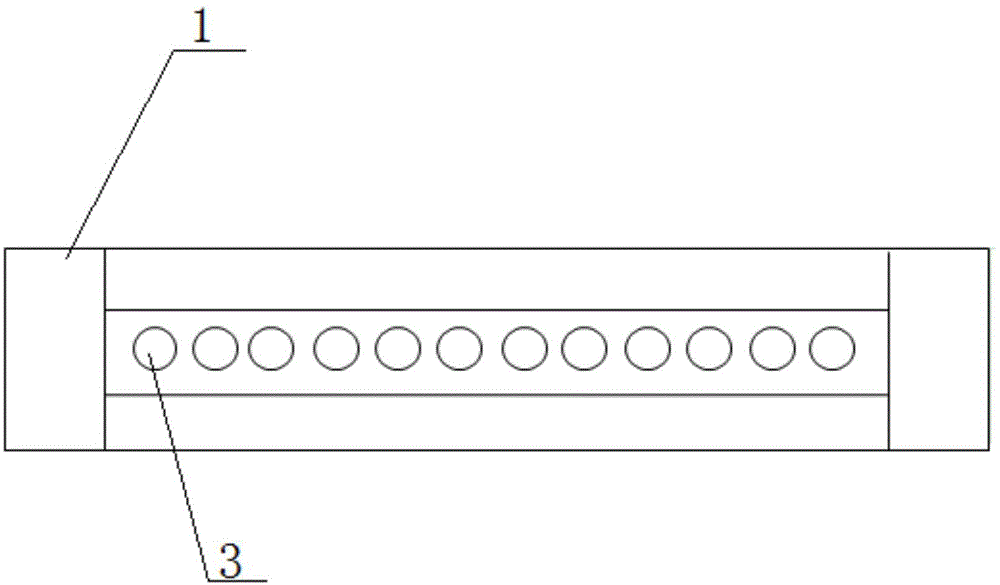

UV oil paint solidification device for spraying industry

InactiveCN104741302AImprove curing effectAvoid harmPretreated surfacesCoatingsUltraviolet lightsEngineering

The invention discloses a UV oil paint solidification device for the spraying industry. The UV oil paint solidification device for the spraying industry comprises a rack, the rack is provided with a support plate, the support plate is provided with a UV oil paint solidification box, and a transmission device is arranged between the support plate and the UV oil paint solidification box; an LED UV oil paint solidification light source is arranged in the UV oil paint solidification box; the LED UV oil paint solidification light source comprises a power circuit board, and an LED UV light emitting module and / or LED UV ultraviolet light emitting lamp beads are installed on the power circuit board; the LED UV light emitting module and the LED UV ultraviolet light emitting lamp beads are all composed of a plurality of ultraviolet light emitting semiconductors; the ultraviolet light emitting semiconductors are LED ultraviolet light emitting devices, and the wavelength coverage of the light emitted ranges from 200 nm to 500 nm. The UV oil paint solidification device for the spraying industry does not produce mercury and harmful gases; the voltage needed is low, and the occurrence of the safety production problem is avoided; no preheating is needed in use, the service life is long and can be as long as 25000-30000 hours; the production cost is reduced due to the fact that no high temperature is needed and no preheating and no additional installation of fast valves are needed.

Owner:无锡网圣优威科技有限公司

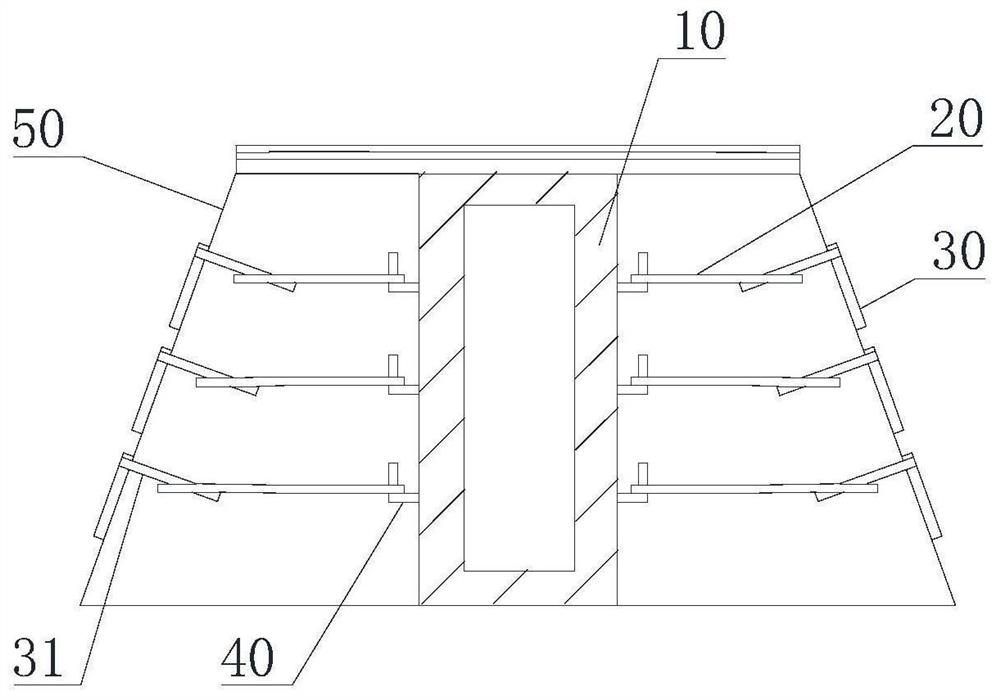

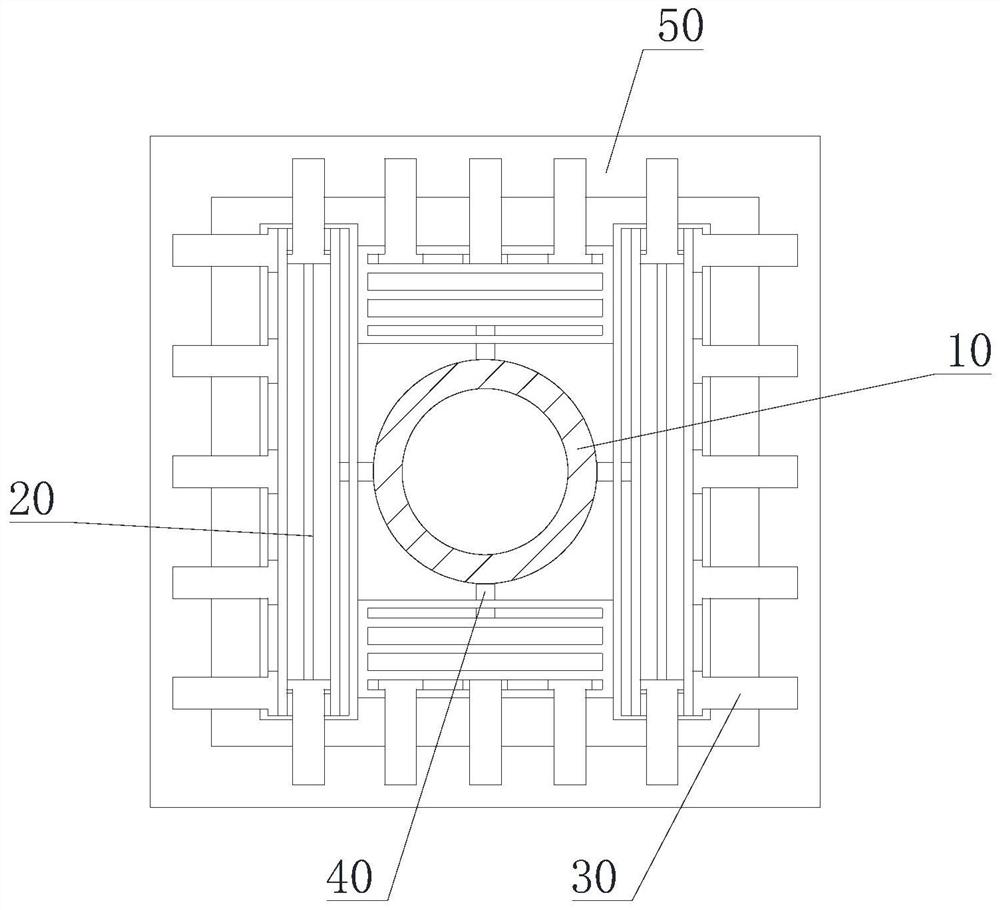

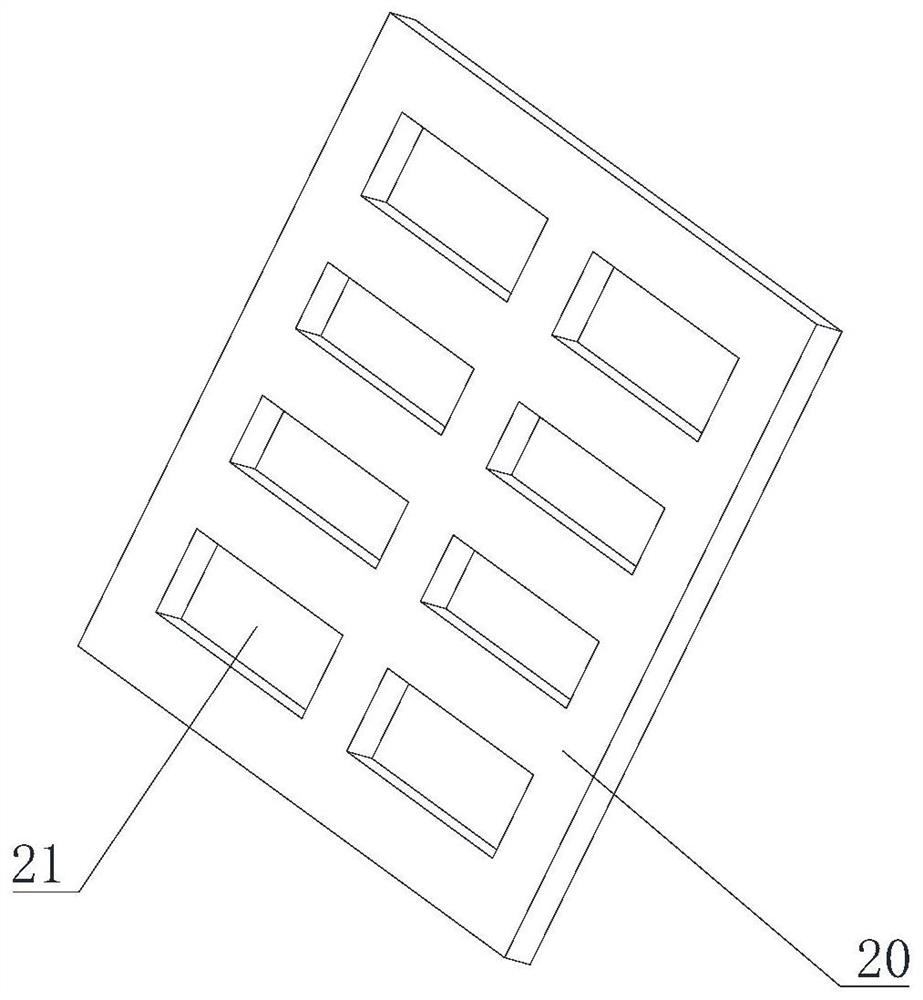

An Integral Slope Structure of Soil-covered Tanks

ActiveCN112813995BImprove fastnessClosely connectedVessel mounting detailsVessel wallsStructural engineeringMechanical engineering

Owner:SHANDONG CHAMBROAD HLDG GRP CO LTD +1

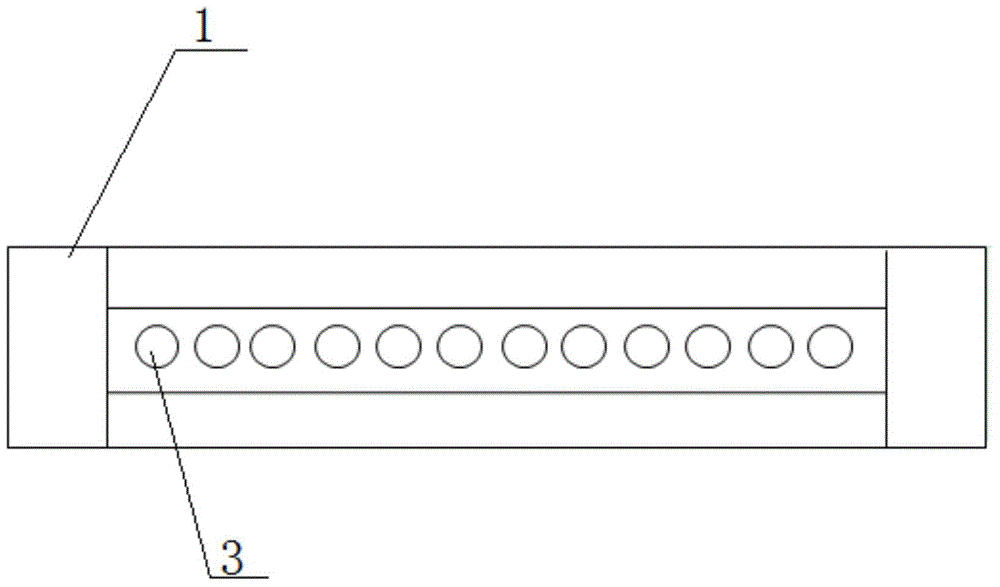

A led UV light source for uv ink curing of sheet-fed offset printing machine

The invention discloses a light-emitting diode ultraviolet (LED UV) light source for UV ink curing of a sheet-fed offset press. The LED UV light source comprises a substrate provided with a plurality of light-emitting modules. A plurality of UV light-emitting units which are integrated onto the light-emitting modules respectively are LED UV light-emitting semiconductors with the light-emitting wavelength ranging from 200 nm to 450 nm. The light-emitting modules are fixed to the substrate through thermal-conductive adhesive. The UV light-emitting units are integrated to the light-emitting modules by means of series connection and parallel connection. Further, the light-emitting modules are fixed to the substrate by means of series connection and parallel connection, are covered with a cover plate and side plates to form an LED UV curing unit. The LED UV light source with low power and power saving effect overcomes defects of conventional UV mercury lamps, needs low voltage to avoid the problem about production safety, is free of generation of harmful gas such as mercury gas to avoid damages to human bodies and environments, is free of preheating during use and long in service life reaching 25000-30000 hours, is free of shutter components due to the fact that high temperature and preheating are omitted, and accordingly is low in production cost.

Owner:无锡科之源光电设备有限公司

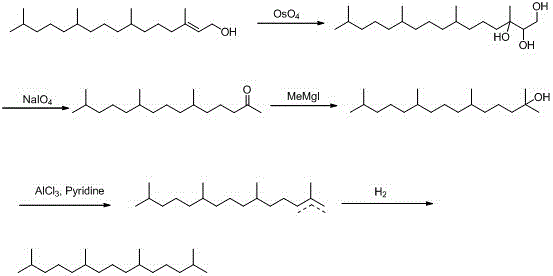

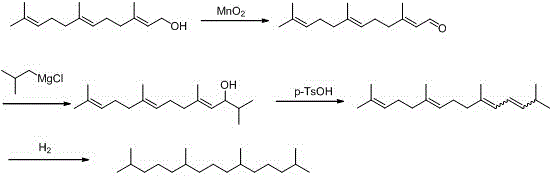

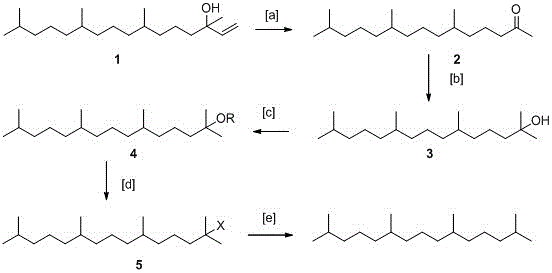

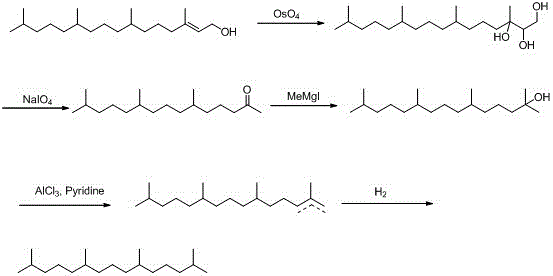

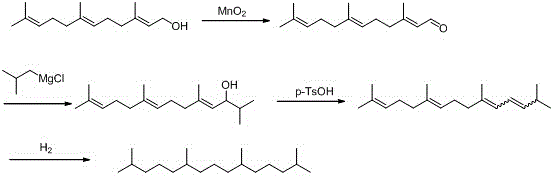

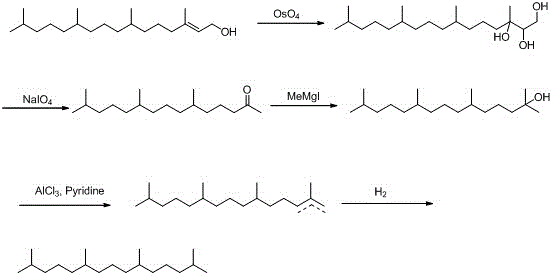

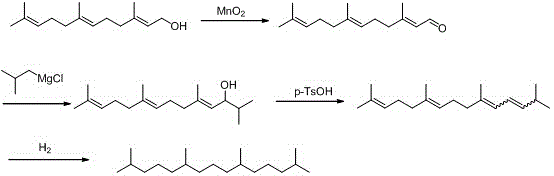

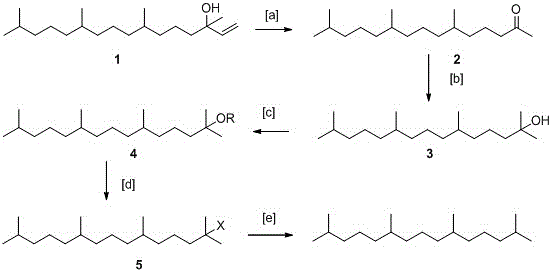

A kind of synthetic method of pristane

ActiveCN105016951BEfficient recyclingLow costHydrocarbon from halogen organic compoundsChemical synthesisIsomerization

Owner:SHENZHEN DIECKMANN TECH CO LTD

Preparation method and application of a weakly water-soluble loaded phosphotungstic heteropoly acid

ActiveCN107282106BThe preparation method is feasibleAvoid production safety issuesOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityChemical industry

The invention belongs to the technical field of phosphotungstic heteropoly acid preparation, and particularly relates to a preparation method and application of load type phosphotungstic heteropoly acid with weak water solubility. The invention provides a method for preparing phosphotungstic heteropoly acid by dilute acidification stirring type modification; the method has the advantages that normal temperature and pressure are adopted for preparation conditions, any organic solvent is not used, the operation is simple, and the energy consumption and the cost are low; the prepared phosphotungstic heteropoly acid is small in water solubility, great in specific surface area and higher in catalytic activity. As an acid site on the surface of the phosphotungstic heteropoly acid having catalytic activity and phosphotungstic heteropoly acid redox carriers (e and II<+>) are diffused, oxidation is generated with biomass plant tissue under a hydrothermal condition; the phosphotungstic heteropoly acid is mainly applied to catalysis, biology, medicines, materials and other aspects, such as waste biomass catalytic degradation and toxic and harmful (waste) gas and sewage (wastewater) treatment in chemical industry production; a chelate of the phosphotungstic heteropoly acid has an anticancer effect, and also can be applied to electrode materials. The prepared load type phosphotungstic heteropoly acid is used for catalytically strengthening degradation of perilla stem, thus realizing efficient conversion of biomass.

Owner:CHONGQING TECH & BUSINESS UNIV

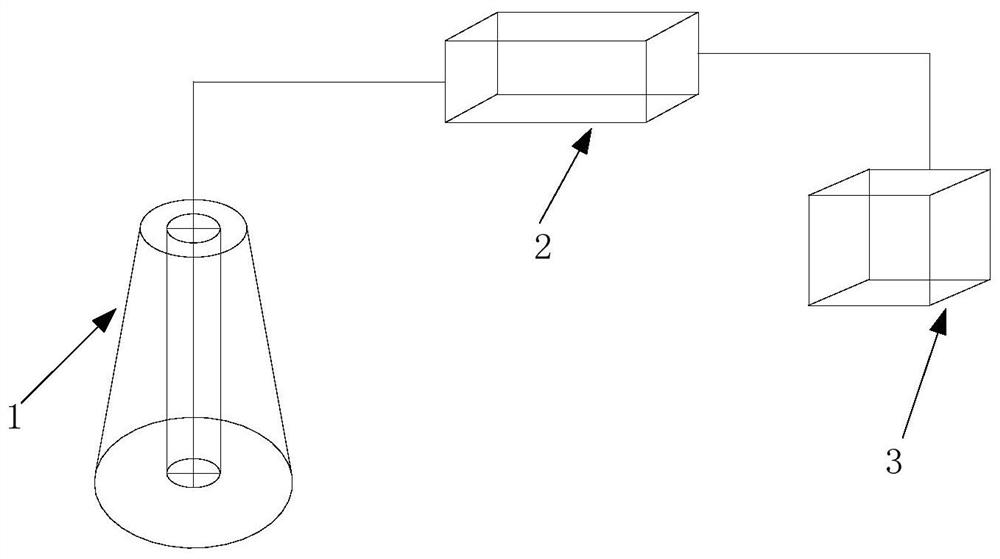

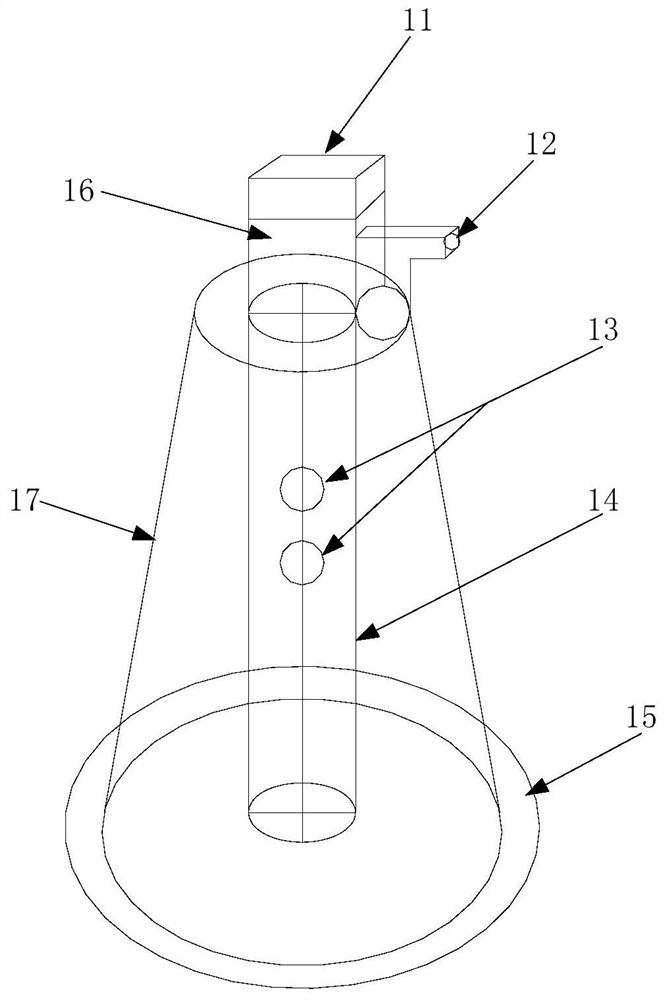

Movable pipeline damage detection device

PendingCN113833456APrevent rising oil production costsAvoid production safety issuesSurveyConstructionsFlat panel detectorControl signal

The invention discloses a movable pipeline damage detection device, and solves the technical problem that damage detection needs to be carried out on a pipeline at regular intervals. The movable pipeline damage detection device comprises a controller, a detection assembly electrically connected with the controller, and a shell used for surrounding the outer side of the pipeline, wherein the detection assembly comprises an X-ray machine and a flat panel detector which are oppositely arranged on the inner wall of the shell; and the controller can receive a control signal of an upper computer to control the X-ray machine to emit X-rays, and can receive image information generated by the flat panel detector and then transmit the image information generated by the flat panel detector to the upper computer. According to the movable pipeline damage detection device, the X-rays can be used for detecting the pipeline, the generated image information is transmitted to the upper computer, the upper computer judges whether the pipeline is damaged such as abrasion, corrosion and cracks or not according to the image, and then judges whether the pipeline needs to be replaced or not, so that serious production safety problems can be avoided, and the oil extraction cost is prevented from being greatly increased.

Owner:XI'AN PETROLEUM UNIVERSITY

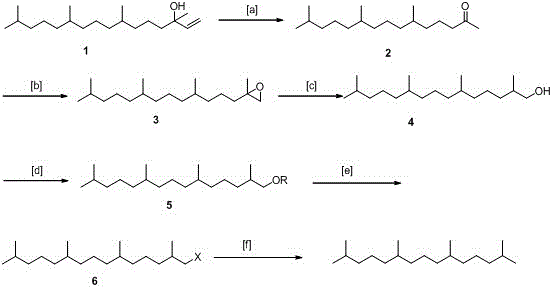

A kind of synthetic method of pristane

ActiveCN104961617BLow costReduce the cost of separation and purificationHydrocarbon from halogen organic compoundsChemical synthesisIsomerization

The invention discloses a novel method for chemically synthesizing pristane on the basis of a starting material isophytol. By the method, pristane is obtained by oxidizing isophytol and performing epoxidation, lewis acid open-loop reaction, sulfonylation, halogenation and reduction. Compared with a conventional synthesis method, the method has the advantages that the raw material is low in cost, high-pressure hydrogenation reaction is avoided, the problem of methyl transfer or cyclization isomerization caused by dehydration reaction in the conventional synthesis method is solved, and the method is suitable for the industrial production of pristane.

Owner:SHENZHEN DIECKMANN TECH CO LTD

Intermediate compound of lb80380 medicine and its preparation method and use

ActiveCN106432330BEasy to purifyAvoid generatingGroup 5/15 element organic compoundsHydrogenChemical compound

The invention provides an LB80380 intermediate compound (as shown in formula I in the specification). In the LB80380 intermediate compound, R1, R2, R3 and R4 are chosen from linear chain or branched chain alkyl group, benzyl group which is replaced by one or five R5, or R5CO independently, wherein the R1, the R1, the R3 and the R4 are identical or different; R5 is chosen from hydrogen, C1-C4 alkoxy which is replaced or not replaced, C3-C7 alkenyl alkoxy, or benzyloxy- which is replaced or not replaced. The invention also provides a preparing method and an application of the compound in the formula I. When the compound in formula I is used for preparing a compound (specific chemical formula is in the specification), reaction route raw materials and intermediate materials are low in price and easy to get, cost is low, safety is good, and thus the LB80380 intermediate compound in formula I is applicable to industrial production.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

Cement clinker magnesium granule cored wire, application and production technology of steel for large heat input welding

InactiveCN106011375AIncrease feed speedIncrease insertion depthManufacturing convertersCarbon steelAbsorption rate

The invention discloses a cement clinker-magnesium particle cored wire and its application and production process of steel for large heat input welding. The cored wire includes an outer layer and a cored core; the outer layer is low-carbon steel with a thickness of 0.5-1.0 mm; The core is slow-release passivated magnesium particles, the core includes slow-release agent and passivated magnesium particles, the slow-release agent is cement clinker, the slow-release agent accounts for 5-90% of the content of the core, and the passivated magnesium particles account for the content of the core 10-95% of that. Application of the cored wire of the present invention in preparing steel for high heat input welding. The invention feeds the slow-release passivated magnesium grain cored wire with cement clinker as the slow-release agent to the molten steel, the absorption rate of Mg is stable, the effect and utilization rate of Mg are high, the inclusions are dispersed and abundant, and the inclusions containing Mg up to 80% or more. Adopting the present invention has the advantages of simple control, low production cost, and industrialized large-scale production of steel for welding with large heat input.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A method for preparing low-arsenic yellow phosphorus using a microchannel reactor

ActiveCN108910846BHigh arsenic removal rateHigh yieldChemical/physical/physico-chemical microreactorsPhosphorus compoundsMetering pumpHypochlorous acid

The invention discloses a method for preparing low arsenic yellow phosphorus by using a microchannel reactor, comprising the following steps: heating and melting industrial yellow phosphorus; using ultrapure water to prepare an oxidizing agent into an oxidant solution with the mass concentration of 5% to 20%; conveying the oxidant solution and the molten industrial yellow phosphorus at a volume flow ratio of (1 to 9):1 to the microchannel reactor I by a metering pump, and reacting at 50 to 90 DEG C for 5s to 60s to obtain the arsenic-removed yellow phosphorus; respectively pumping ultrapure water and the arsenic-removed yellow phosphorus at a volume flow ratio of (1-9):1 into the microchannel reactor II through a metering pump, and performing countercurrent washing at a temperature of 50 to 90 DEG C for 5s to 60s to obtain the low arsenic yellow phosphorus, wherein the oxidizing agent is nitric acid, hydrogen peroxide or hypochlorous acid. The method has the advantages of high arsenicremoval rate, high phosphorus yield and good safety.

Owner:GUIZHOU MICRO CHEM TECH CO LTD

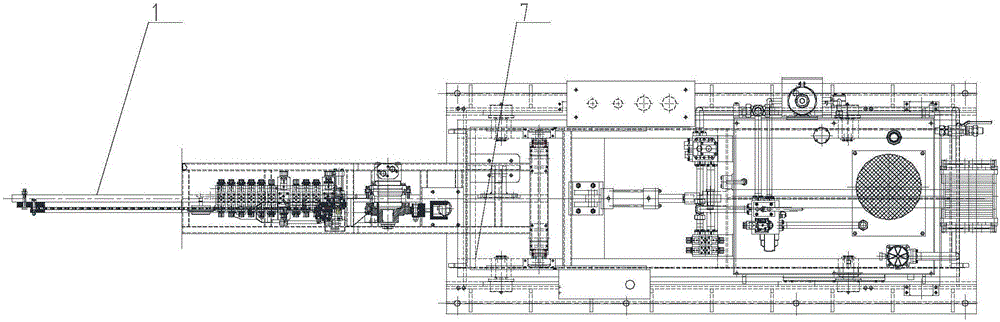

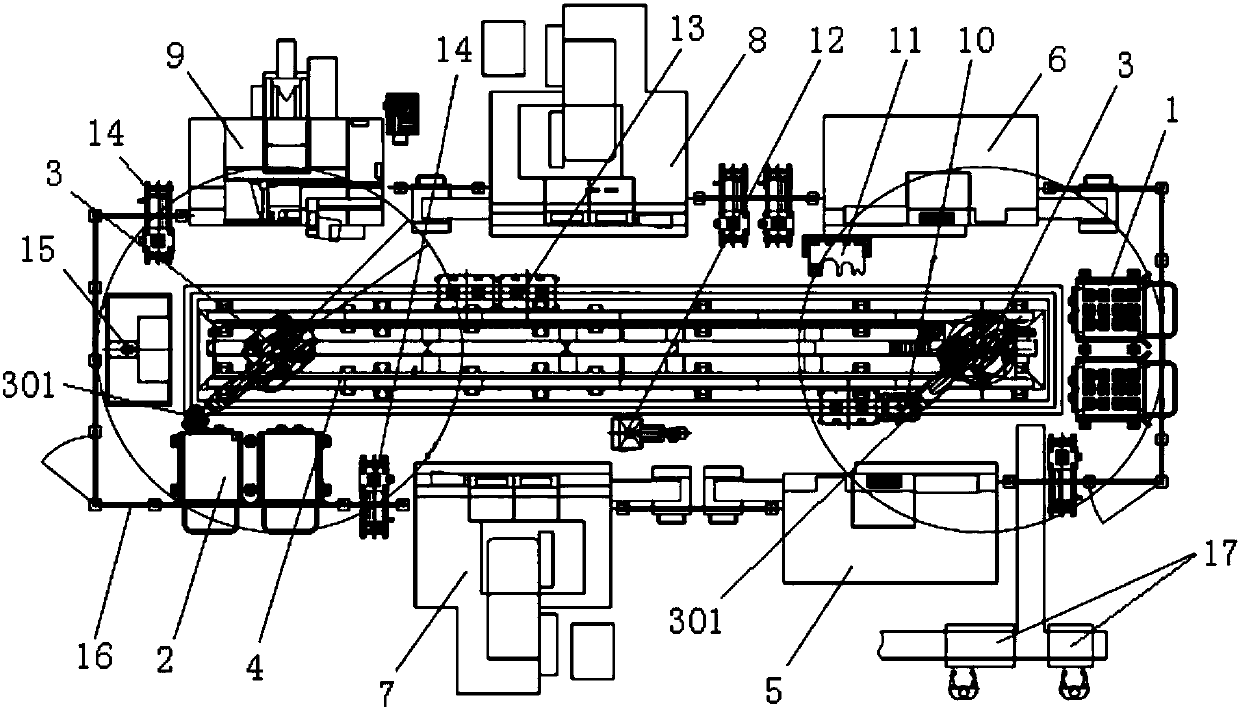

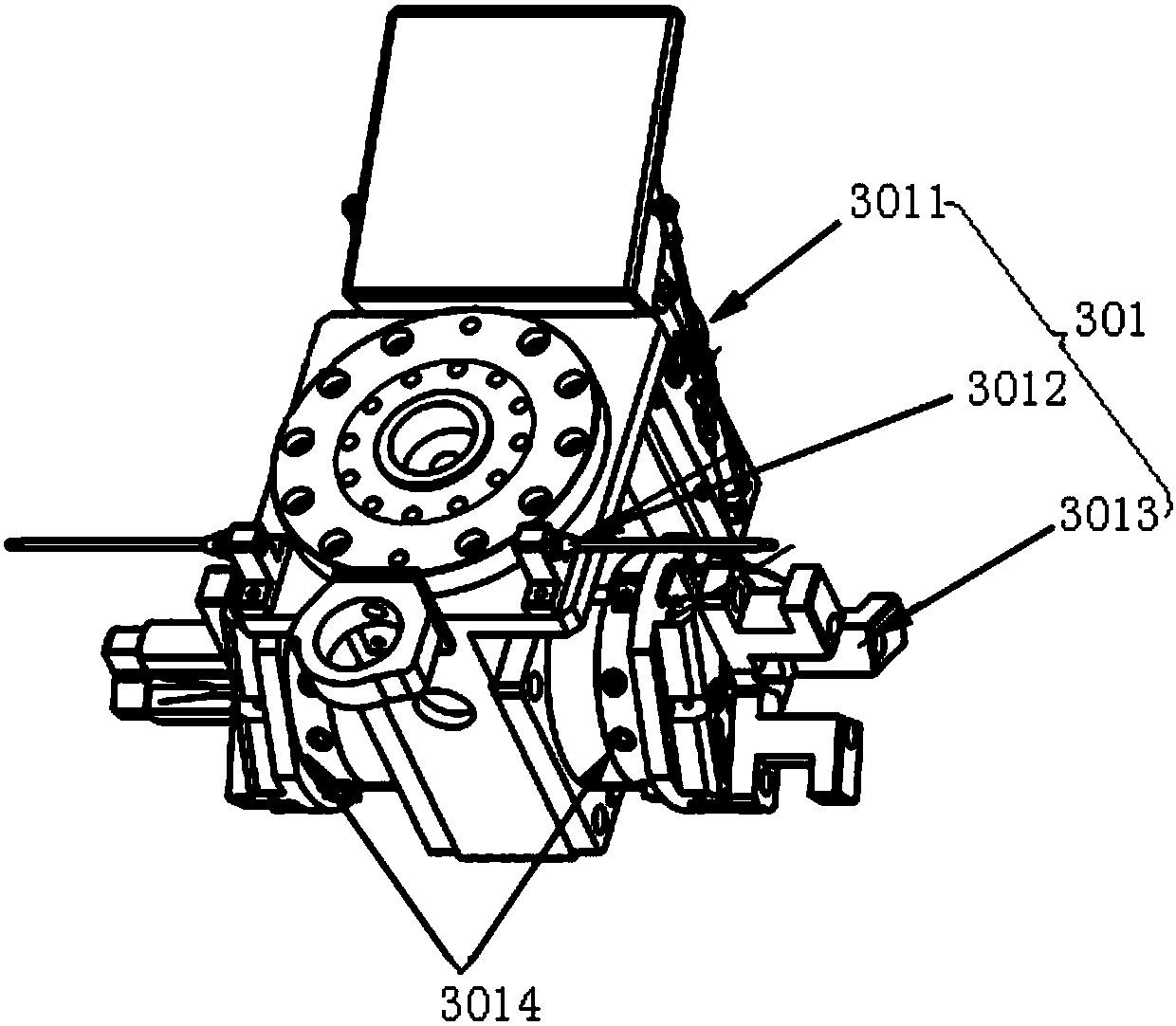

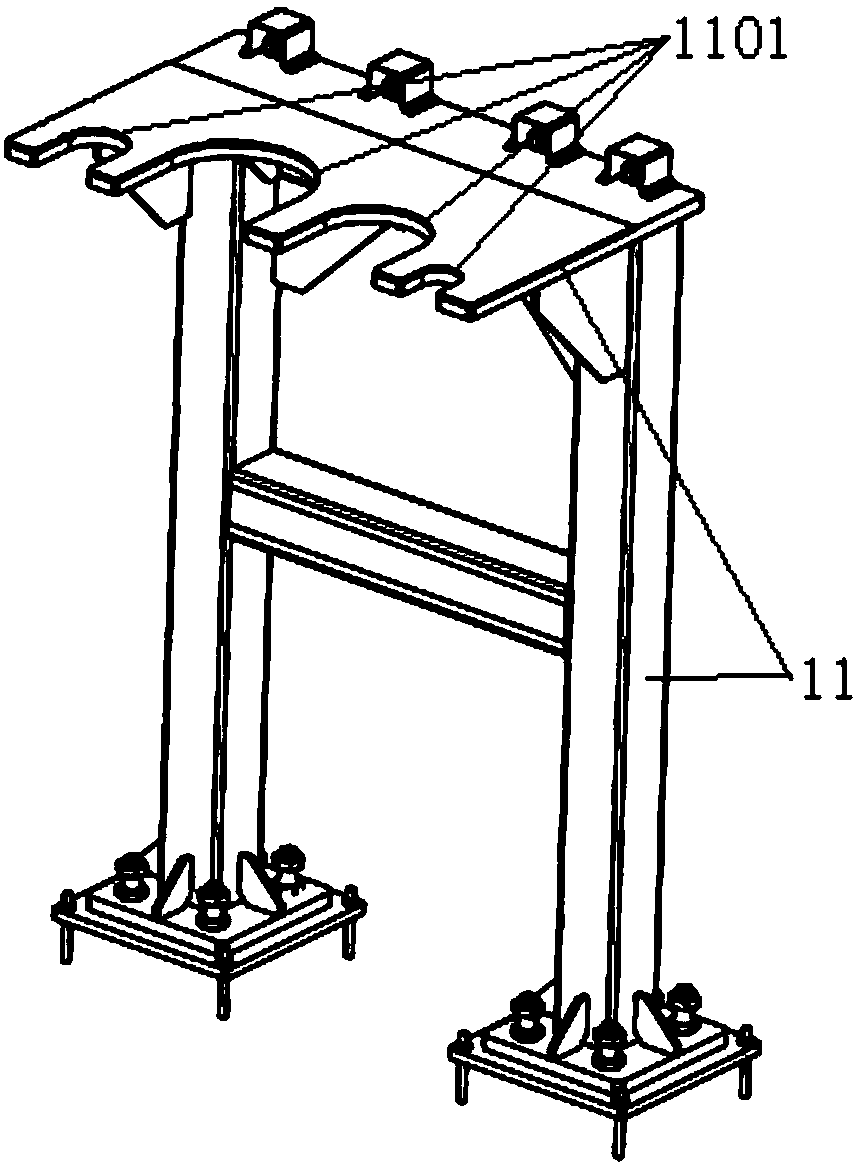

Robot intelligent processing line and robot intelligent processing method

ActiveCN105922082BSmall footprintIncrease profitMetal working apparatusMaintainance and safety accessoriesMachining systemMachine tool

The invention discloses an intelligent robot machining line and an intelligent robot machining method. The intelligent robot machining line with multiple machining devices working cooperatively comprises multiple machine tools used for being combined to complete all workpiece machining procedures, multiple auxiliary devices used for assisting the machining tools in machining, a blank trolley used for storing workpiece blanks and a finished product trolley used for storing machined finished workpiece products. The intelligent robot machining line further comprises feeding and discharging robots used for automatic feeding and discharging and a robot linear guide rail used for driving the feeding and discharging robots to move linearly. The feeding and discharging robots are mounted on the robot linear guide rail through mounting seats. The machine tools are distributed on the two sides of the robot linear guide rail. The machine tools, the auxiliary devices, the blank trolley and the finished product trolley are all located in the working radiuses of the feeding and discharging robots. The feeding and discharging robots independently complete all workpiece machining procedures from the blanks to the finished products. The intelligent robot machining line is suitable for multi-station multi-procedure workpiece machining systems.

Owner:CHANGSHA CTR ROBOTICS

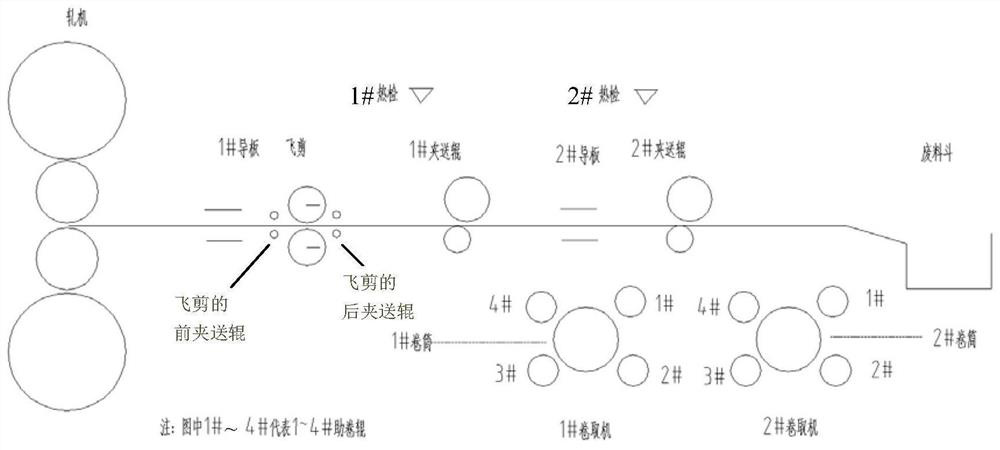

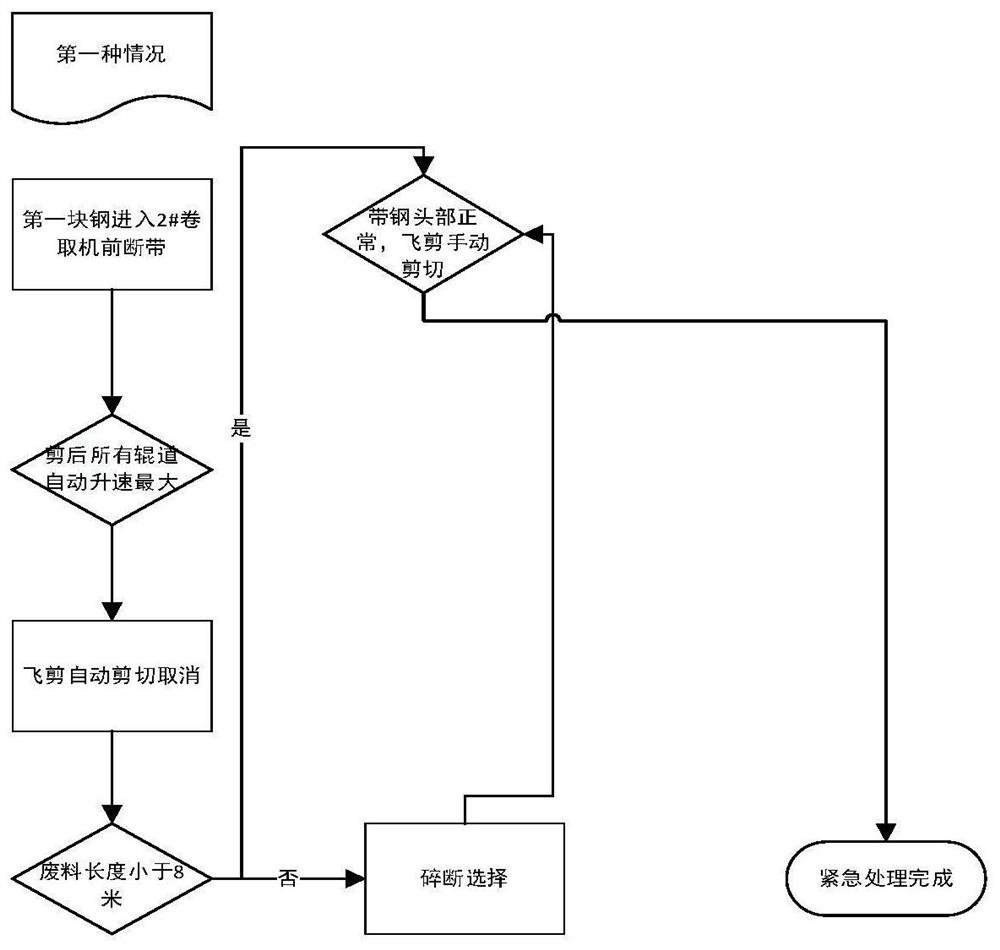

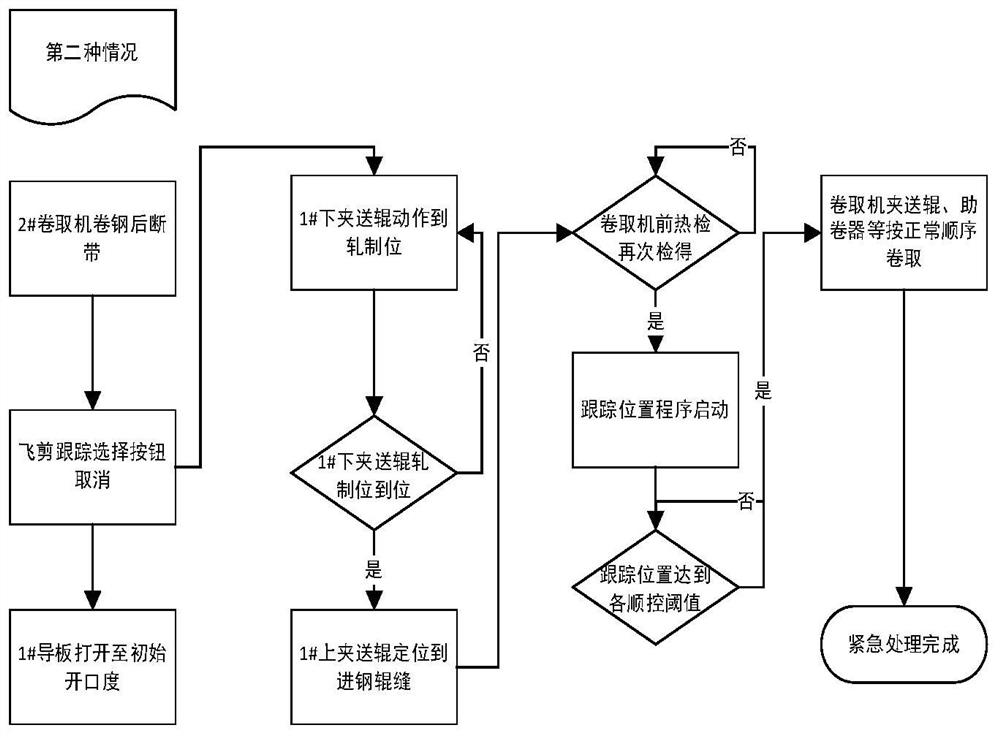

The automatic control method of the coiler under the emergency situation of the continuous hot-rolled thin strip line breaking

ActiveCN111570529BEasy to operateIncrease productivityRoll mill control devicesMeasuring devicesWinding machineProduction line

The invention provides an automatic control method for a coiler in an emergency situation when a fully continuous hot-rolled thin strip line is broken. First, the types of broken strips are divided into three situations according to the different positions of the broken strips: when the first piece of steel The strip is broken before entering the 2# coiler; the strip has already entered the 2# coiler, and after the strip is broken, it needs to enter the 1# coiler to coil the steel; the strip has already entered the 1# coiler, and after the strip is broken, it needs to enter the 2 #Coiler coils steel; manual rescue after belt breakage requires operating multiple devices at the same time, making it difficult to ensure successful intervention. This method uses specific control methods to achieve one-click operation in different situations through the installation of relevant components and specific control methods according to specific situations. The emergency treatment method avoids unnecessary economic losses caused by the entire line shutting down due to belt breakage. It also reduces the time spent processing scrap steel due to belt breakage and stops. At the same time, it avoids the waste of time in restarting the production to organize production. It not only improves the production efficiency of the production line , and can also effectively avoid production safety issues.

Owner:NORTHEASTERN UNIV LIAONING

A kind of production equipment of glutinous rice noodle and production method of glutinous rice noodle

ActiveCN103191827BControl starting speedControl rotation speedGrain treatmentsElectric machineryWork in process

The invention relates to the field of processing of glutinous rice flour, and in particular relates to glutinous rice flour production equipment and a glutinous rice flour production method. The glutinous rice flour production equipment comprises a grinding base, a grinding roller, a motor and a motor revolving speed control device, wherein the motor is connected with the grinding roller through the motor revolving speed control device and drives the grinding roller to rotate on the grinding base. Through the motor revolving speed control device, the start revolving speed of the motor and the revolving speed of the grinding roller on the grinding tray are effectively controlled, different glutinous rice raw materials can be finely processed, and the problem of production safety caused by a reason that the grinding roller is difficult to control is solved; stainless steel meshes are arranged in a filter and can be used for effectively separating semi-finished glutinous rice flour; and the stainless steel meshes in the filter are convenient to replace, so that the production efficiency of the glutinous rice flour is improved.

Owner:北京便宜坊烤鸭集团有限公司

Pristane synthesizing method

ActiveCN105016951AEfficient recyclingLow costHydrocarbon from halogen organic compoundsChemical synthesisIsomerization

The present invention discloses a novel method for chemically synthesizing pristane with isophytol as a starting material. Isophytol is used, and pristane is prepared through oxidation, a methyl Grignard reaction, sulfonylation, halogenation and reduction. The method in the present invention, as compared with the conventional synthesizing method, adopts cheap raw materials, avoids high pressure hydrogenation reactions, and solves the problems of methyl migration caused by a dehydration reaction or isomerization caused by cyclization in the conventional synthesizing method. The method of the present invention is suitable for industrial production of pristane.

Owner:SHENZHEN DIECKMANN TECH CO LTD

Glass-magnesium grain cored wire and production technology of steel for high heat input welding

InactiveCN105925761AReduce boiling intensityHigh speedProcess efficiency improvementGlass chipLiquid steel

The invention discloses a glass-magnesium grain cored wire and a production technology of a steel for high heat input welding. The cored wire comprises an outer layer and a core, wherein the outer layer is low-carbon steel, and the thickness is 0.5-1.0mm; the core is slow release deactivation magnesium grains, and comprises a slow release agent and deactivation magnesium grains, wherein the slow release agent is glass chips, and is 5-90% of the content of the core; the deactivation magnesium grains are 10-95% of the content of the core. The cored wire is used for preparing steel for the high heat input welding. According to the glass-magnesium grain cored wire disclosed by the invention, a slow release deactivation magnesium grain cored wire using glass as the slow release agent is fed to liquid steel, so that the absorption rate of Mg is stable; the effect and the utilization rate of the Mg are high; inclusions are disperse and rich, and the inclusions containing the Mg reach 80% or above. The glass-magnesium grain cored wire has the characteristics of being simple to control, and low in production cost, and the steel for the high heat input welding can be industrially produced in a large-scaled manner.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

An intelligent inflow control device and method

ActiveCN106996281BImprove displacement efficiencyEasy to liftFluid removalHorizontal wellsEconomic benefits

The invention discloses an intelligent inflow gas control device which mainly comprises a flow chamber, pressure guide holes, inlet oil nozzles, a packet, a sawtooth-shaped movable component and turn-off structures. The maximum quantity Q <max> of gas which is allowed to flow through the inlet oil nozzles can be set according to actual production requirements on oil wells. The intelligent inflow gas control device can normally work when the quantity Q of the gas which flows through the inlet oil nozzles does not exceed the set maximum quantity Q <max> of the gas; the intelligent inflow gas control device is turned off when the quantity Q of the gas reaches the set maximum quantity Q <max> of the gas, and fluid is no longer allowed to flow through the intelligent inflow gas control device. A working principle for the intelligent inflow gas control device includes that the gas can critically flow in the inlet oil nozzles when the flow rates of the gas in the inlet oil nozzles reach the maximum quantity Q <max> of the gas; ratios of front-end pressures P1 to rear-end pressures P2 of the inlet oil nozzles are critical pressure ratios, and the intelligent inlet gas control device can be turned off under the control of the critical pressure ratios. The intelligent inflow gas control device has the advantages that the intelligent inflow gas control device can be applied to gas-top reservoirs and gas injection production straight wells, horizontal wells and inclined wells, specified gas quantity exceeding gas flow channels can be timely closed, accordingly, economic benefits of oil fields can be increased, and the recovery ratios of oil reservoirs can be increased.

Owner:SOUTHWEST PETROLEUM UNIV

Portable closed gearbox detection device and abnormity judgment method

ActiveCN113125148AEffectively solve abnormal problemsResolve exceptionMachine part testingSafety gearLogistics managementProduction logistics

The invention discloses a portable closed gearbox detection device and an abnormality judgment method, relates to the field of hoisting machinery, and is used for real-time monitoring of the running state of a gear in a gearbox and early warning control when the gear abnormally deforms during dynamic running of a crane. The closed speed reducer of the crane is monitored at any time in a few-man and unmanned state according to current large hoisting equipment, so that the problem that the speed reducer of the crane is abnormal can be effectively solved in actual production, the hoisting safety operation rate is improved, abnormal accidents are prevented, the safety of production logistics is effectively controlled, and the effect of solving the production safety problem is achieved. According to the invention, any person can carry out inspection at any time without the assistance of the related professional inspection personnel, the common point inspection personnel can independently carry out operation, and the system has an intelligent judgment mechanism, can effectively judge the danger degree of related equipment, and is more intelligent and user-friendly.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com