LED UV light source used for solidifying flexible or rotation or trademark printing machine UV printing ink

A trademark printing machine and flexographic technology, which is applied to the general parts of printing machinery, printing machines, printing, etc., can solve the problems of human body and equipment injury, uneven curing of printed UV ink, air pollution, etc., to avoid production safety problems , Good ink curing effect, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

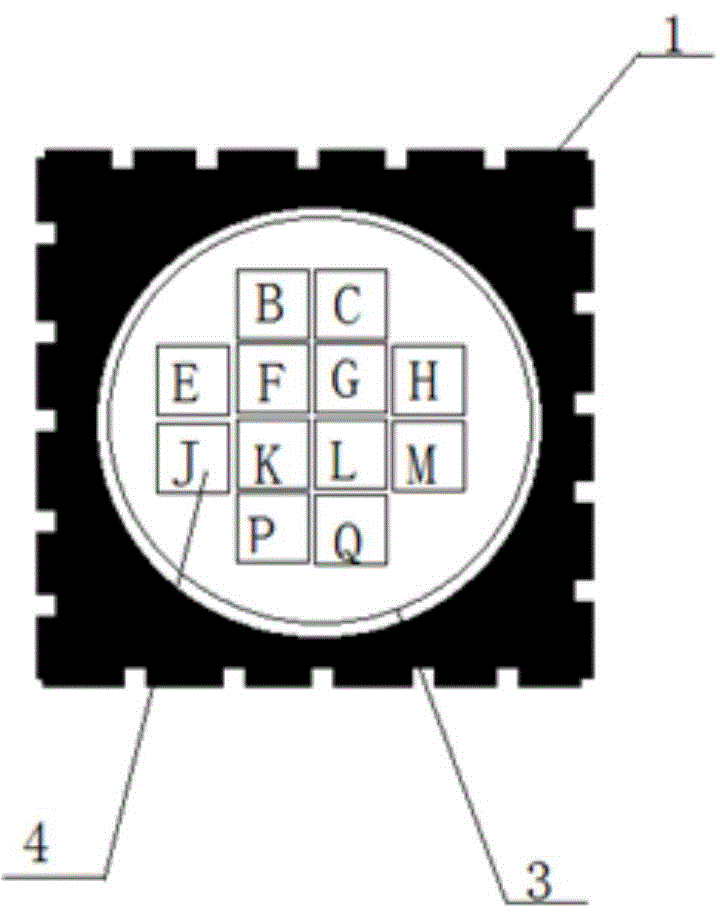

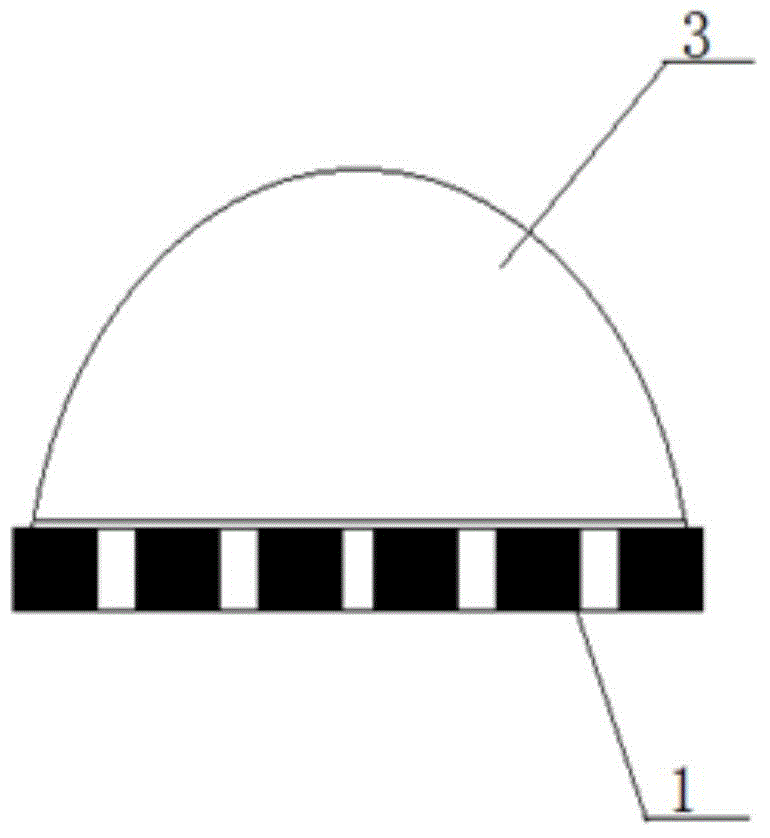

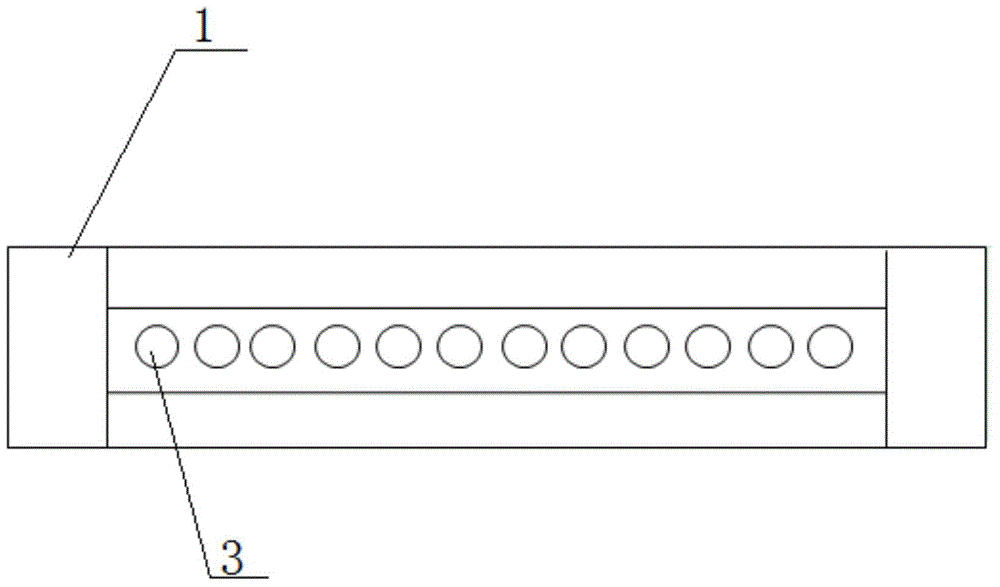

[0036] Please refer to Figure 1 to Figure 5 , the present invention is a kind of LED UV light source that is used for flexographic or rotary or trademark printing machine UV ink solidification, and it comprises:

[0037] Power circuit substrate 1, LED UV light-emitting module 2 and / or LED UV ultraviolet light-emitting lamp bead 3 are installed on the described power circuit substrate 1; Described LED UV light-emitting module 2 and described LED UV ultraviolet light-emitting lamp bead 3 pass through several The ultraviolet light-emitting semiconductor 4 is composed of two ultraviolet light-emitting semiconductors; the ultraviolet light-emitting semiconductor 4 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com