Patents

Literature

50results about How to "High arsenic removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering copper from copper dust and immobilizing arsenic from copper dust into scorodite

ActiveCN105734300AHigh recovery rateStable in natureIron compoundsProcess efficiency improvementIron powderPollution

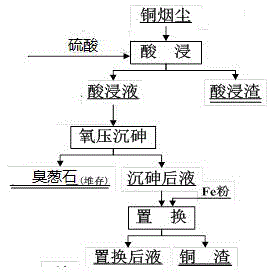

The invention discloses a method for recovering copper from copper dust and immobilizing arsenic from copper dust into scorodite. The method comprises the following steps: subjecting the copper dust to acid leaching under the conditions that a sulfuric acid concentration is 14 to 30 g / L and reaction time is 2 to 3 h so as to obtain acidic leaching liquid; carrying out oxygen-pressure arsenic precipitation on acidic leaching liquid under the conditions that oxygen partial pressure is 0.6 to 1.3 MPa and reaction time is 2 to 3 h so as to obtain scorodite and a post-arsenic-precipitation solution; and adding iron powder into the post-arsenic-precipitation solution and carrying out a reaction for 25 to 40 min so as to displace copper slag and obtain post-displacement liquid. The method provided by the invention carries out oxidative arsenic precipitation at a high temperature, so sulfuric acid in waste acidic leaching liquid is made full use of; a high arsenic removal rate is realized, eventually produced iron arsenate has stable properties, and the post-arsenic-precipitation solution has low arsenic content; and the method has the advantages of high heavy metal recovery rate, low recovery cost, environment-friendly treatment process and small pollution to the environment.

Owner:云南云铜锌业股份有限公司

Method for treating poor-tin middling ore and recovering iron-making raw material

InactiveCN102242253AHigh extraction rateImprove efficiency of arsenic removalMixed materialsMaterials science

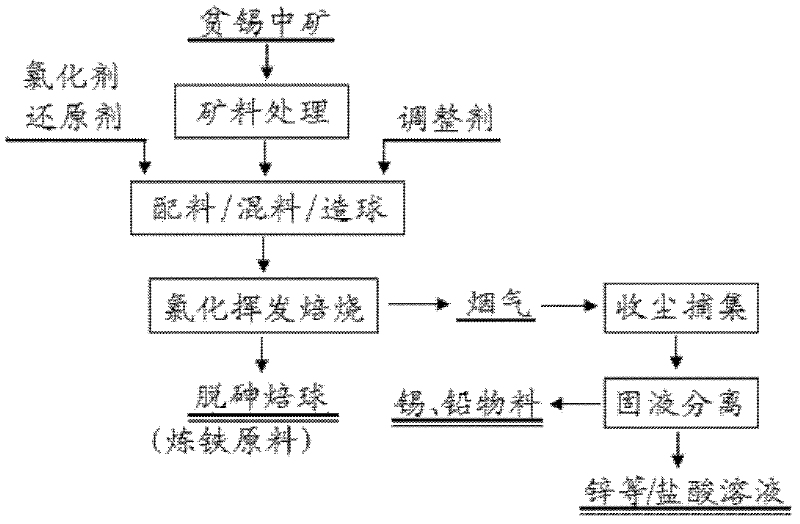

The invention provides a method for treating poor-tin middling ore and recovering an iron-making raw material. The method comprises the following steps: adding an alkalinity modifier, a reducing agent and a chlorinating agent in the ore material for mixing so as to form a mixed material, and then pelletizing, wherein the alkalinity modifier is silicon-rich ore or quartziferous ore, the mass ratio of CaO / SiO2 in the mixed material is controlled to not more than 0.65, and the mass percentage of total SiO2 is not more than 10%; carrying out high temperature chloridizing roasting on pelletized aggregate pellets, wherein chloridizing roasting conditions are as follows: the addition amount of the chlorinating agent accounts for 4-8% of that of the aggregate pellets, and the addition amount of the reducing agent accounts for 3-5% of that of the aggregate pellets, and roasting temperature is 950-1100 DEG C; controlling the volume ratio of CO2 / CO in the atmosphere to 1.0-3.0 in the roasting process; and carrying out cooling and dust collection on high-temperature smoke generated by chloridizing roasting, and then capturing and recovering valuable metals. By using the method in the invention, tin and other valuable metals are economically and efficiently extracted from the poor-tin middling ore and the iron-making raw material is recovered so as to finally achieve good effects as follows: (1) the extraction rate of the valuable meals in the poor-tin middling ore is improved; (2) the efficiencies of arsenic removal and iron-making material recovery are improved; (3) production capacity of equipment is improved, and energy is saved; and the like.

Owner:CENT SOUTH UNIV

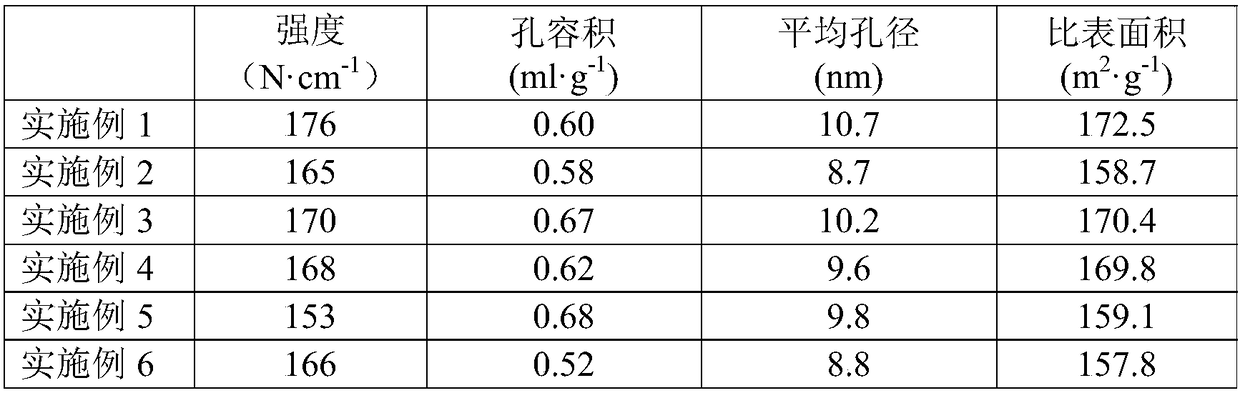

Metal compound-type arsenic removal agent, preparation method and application thereof

InactiveCN103877931ASimple production processLarge specific surface areaOther chemical processesRefining with metal oxidesSyngasCopper

The invention discloses a metal compound-type arsenic removal agent, a preparation method and an application thereof, the metal compound-type arsenic removal agent is composed of a carrier and a metal active ingredient loaded on the carrier; the carrier is active carbon, and the metal active ingredient is more than one selected from copper, iron, nickel or silver. The arsenic removal agent has the advantages of simple production technology, large specific surface area, and good active metal dispersibility, deep arsenic removal of the oil product can be realized, surface acidity is low, the colloid generation is reduced, so that the arsenic removal agent is benefit for prolonging the regeneration period of a catalyst, the arsenic removal agent has the advantages of high arsenic removal rate and low energy consumption, and is suitable for large-scale industrial production, and can be used for removing arsenic from the light dydrocarbon materials such as propylene, ethene and deeply purifying arsenic in synthetic gas prepared by taking coal, coke, heavy oil, oil residue or natural gas as raw materials.

Owner:SHANGHAI UNIV OF ENG SCI

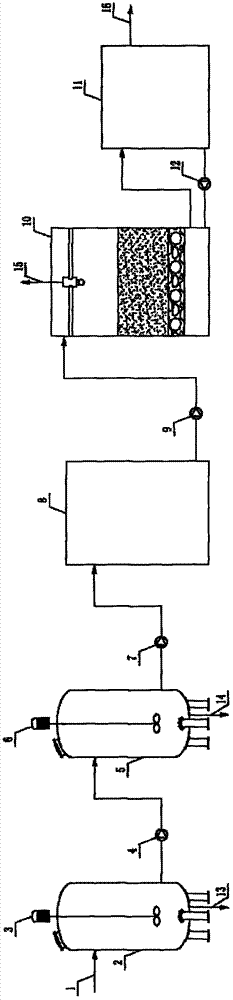

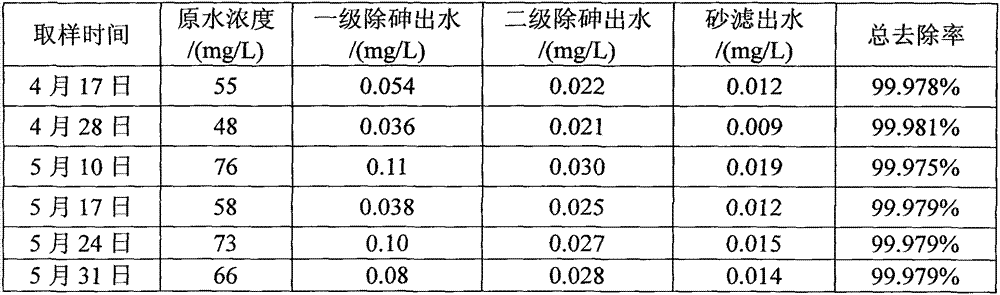

Arsenic-removing device and method for gallium arsenide wafer production and processing waste water

InactiveCN102774991AHigh removal rateHigh arsenic removal rateMultistage water/sewage treatmentWater/sewage treatment by neutralisationThree levelRaw water

The invention relates to an arsenic-removing device and method for gallium arsenide wafer production and processing waste water and belongs to the technical field of waste water treatment. The arsenic-removing method comprises conveying raw water to a primary arsenic-removing tank, performing sequencing batch flocculation and sedimentation to remove arsenic, and enabling the basic process to comprise water inflow, flocculation, sedimentation and water outflow; enabling treated supernatant to enter a secondary arsenic-removing tank, first performing oxidation reactions, then performing sequencing batch flocculation and sedimentation to remove arsenic, and enabling the basic process to comprise water inflow, oxidation, flocculation, sedimentation and water outflow; first enabling the treated supernatant to flow into an intermediate tank, conveying the supernatant to a sand filter through a three-level lift pump to perform gravity filtration, enabling final outflow water to enter a clean water pond after filtration, and discharging the effluent finally; utilizing a backflushing pump to perform back flush on the sand filter at a fixed period, and taking backflushing water from the clean water pond. The arsenic-removing device and the arsenic-removing method are high in arsenic-removing rate, enable concentration of arsenic in the outflow water to be controlled to be below 0.02mg / L, are easy to operate, run stably, and are suitable for treating the gallium arsenide wafer production and processing waste water and arsenic-containing waste water of related industries.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

Method for hydrogenation and arsenic removal of distillate oil

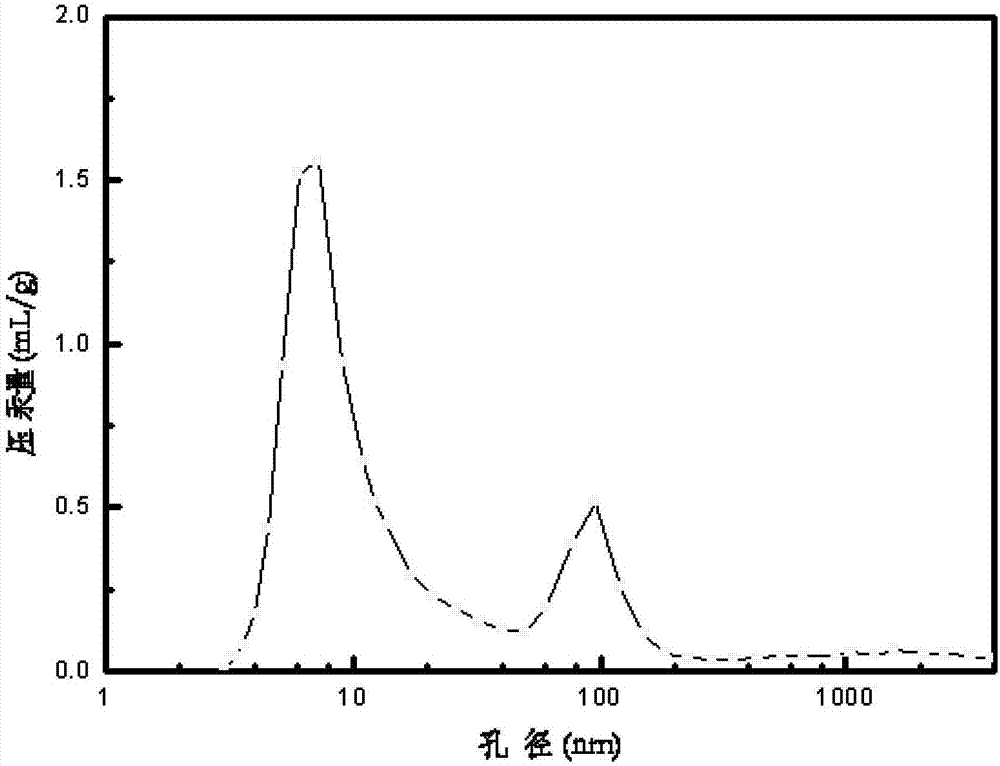

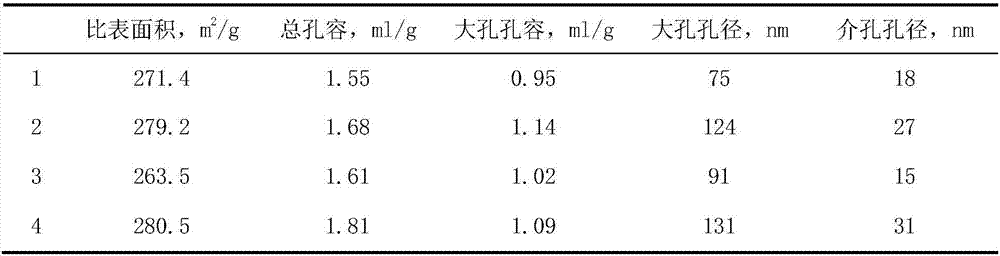

InactiveCN107011939AAperture size adjustableLow pricePhysical/chemical process catalystsHydrocarbon oils treatmentReaction temperatureFixed bed

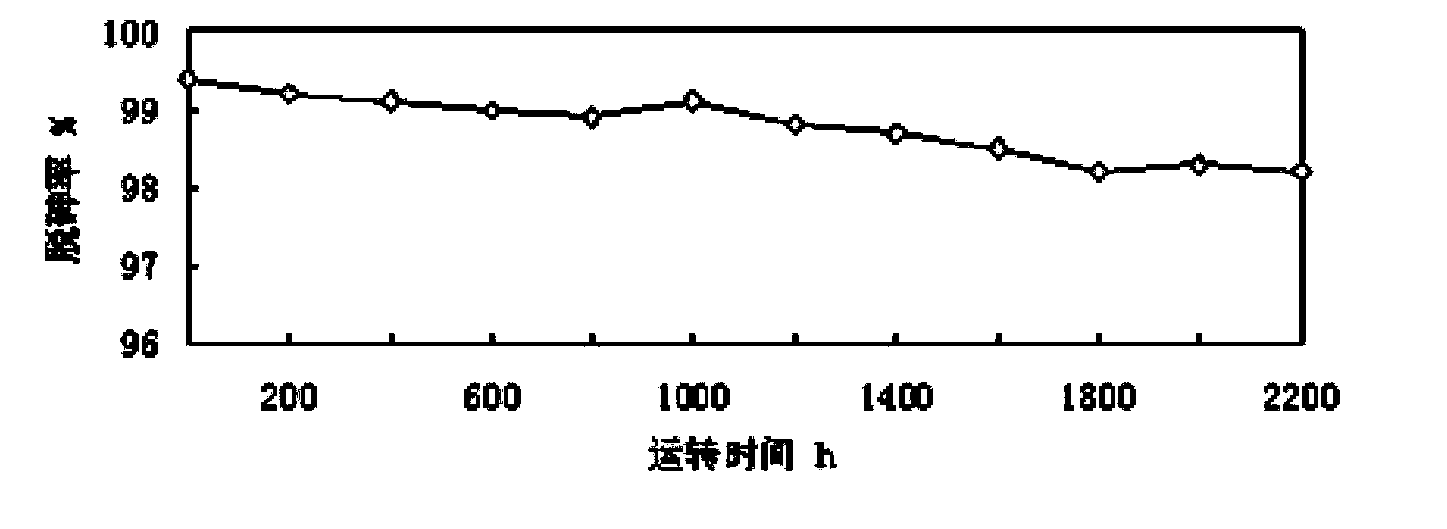

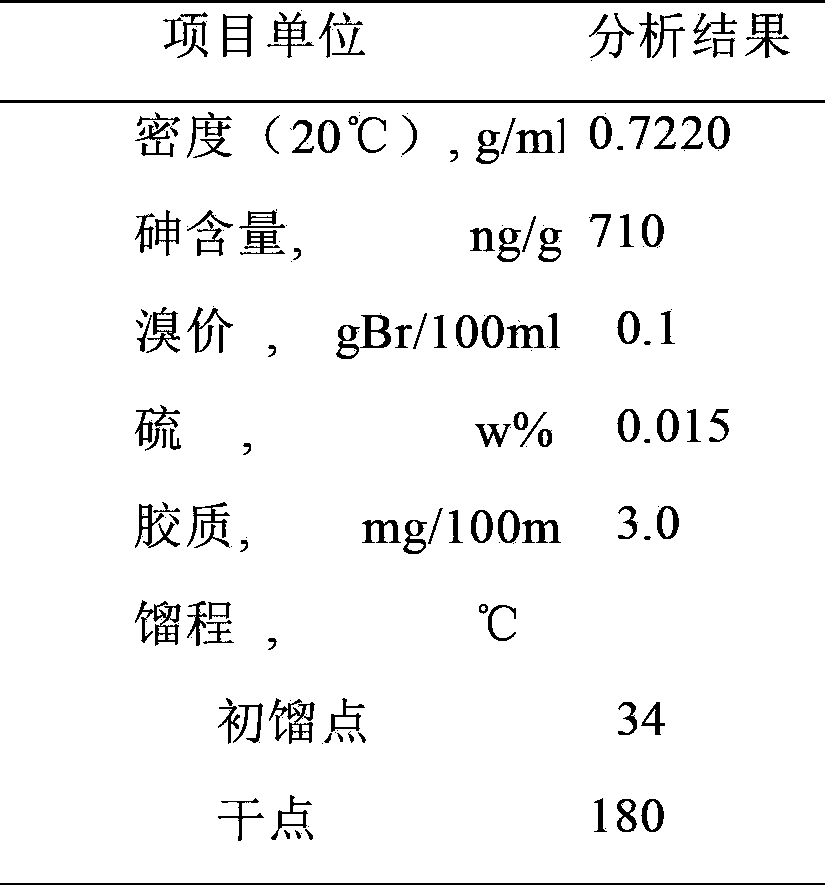

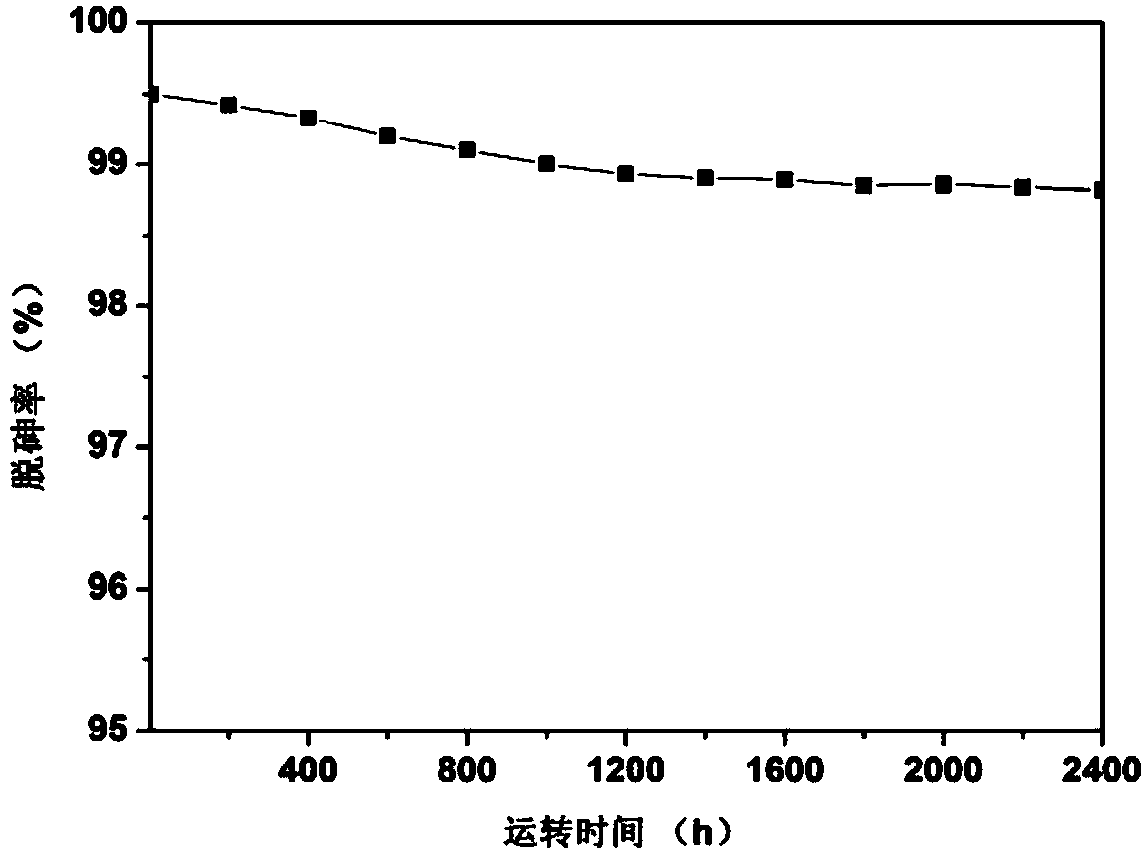

The invention discloses a method for hydrogenation and arsenic removal of distillate oil. The active centers of a catalyst are nickel and molybdenum; an alumina carrier with a macroporous structure is used as a catalyst carrier and accounts for 70.0 to 96.0 wt%; the active component nickel oxide accounts for 2.0 to 20.0 wt%; and the active component nickel oxide accounts for 2.0 to 10.0 wt%. A fixed-bed reactor is used in a reaction. Process conditions are that reaction temperature is 120 to 220 DEG C; reaction pressure is 1.0 to 4.0 MPa; a hydrogen-oil volume ratio is 100-300: 1; and volume space velocity is 1.0 to 10.0 / h. The method has the following advantages: reaction conditions are mild; raw materials are widely available; the arsenic removal rate of a product is high; and the catalyst has long-period reaction activity, good stability and a long operation period.

Owner:QINZHOU UNIV

Process for refining high-purity yellow phosphorus

The invention discloses a manufacturing method of refined high-purity yellow phosphor, which comprises the following steps: adding 20-30% yellow phosphor into 70-80% water in the sandwich insulating furnace; heating to fuse into liquid pattern; doping 8-15% carbonate; heating to 70-75 Deg C; stirring; washing through 75-80 Deg C; stewing; sedimenting; making arsenic content less than 0.2PPM and each impurity content less than 300PPM; refining to obtain 5-6N high-purity yellow phosphor.

Owner:杨义 +1

Novel arsenic removal material and preparation method thereof

InactiveCN102350302AImprove adsorption efficiencyHigh arsenic removal rateOther chemical processesAluminium silicatesChlorideFerric

The invention relates to a novel arsenic removal material and a preparation method thereof. The specific preparation raw materials include de-ionized water, ferric chloride, natural zeolite and a sodium hydroxide (NaOH) solution. When the material is prepared, the natural zeolite is taken as a base and the ferric chloride is loaded on the surface of the natural zeolite to obtain a natural zeolite-ferric chloride composite arsenic removal material. According to the preparation method provided by the invention, a prepared adsorbing material is high in adsorption efficiency, strong in alkali resistance and convenient for solid-liquid separation; and the novel arsenic removal material has the advantages of high adsorption efficiency, strong alkali resistance, convenience for solid-liquid separation, cheapness, easiness for obtaining, simple preparation method and good application prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Dearsenization method for sulfurous iron ore slag

The invention relates to a dearsenization process for sulfurous iron ore slag, which comprises the following steps: stirring the sulfurous iron ore slag in a sulfuric acid water solution for 0.5 to 2.5 hours at a temperature of between 20 and 50 DEG C; and obtaining refined sulfurous iron ore slag with arsenic content less than 0.07 percent after separation and washing, wherein the dearsenization rate is between 96 and 98 percent. The process has the characteristics of simple processing process, short processing time, easy operation, high arsenic removal rate and the like. Because production equipment used by the process has low cost and excellent performance, the process has strong market competitiveness and promotion and application values.

Owner:KUNMING UNIV OF SCI & TECH

Proportioning method for high-arsenic smoke material for sublimation and arsenic removal

InactiveCN105624410AHigh arsenic removal rateEffective arsenic removal rateProcess efficiency improvementMetalArsenic

The invention discloses a proportioning method for high-arsenic smoke material for sublimation and arsenic removal. According to the method, reducing high-arsenic smoke and oxidizing high-arsenic smoke are respectively collected according to different production environments of the high-arsenic smoke material, and then the collected reducing high-arsenic smoke and the collected oxidizing high-arsenic smoke are mixed uniformly for serving as the high-arsenic smoke material for sublimation and arsenic removal according to the weight percentage ratio being 20-80% to 20-80%. After the reducing high-arsenic smoke and the oxidizing high-arsenic smoke are reasonably proportioned, the arsenic removal rate of sublimation and arsenic removal can be greatly increased, the metal separation rate of sublimation and arsenic removal can keep high, and large-scale and high-efficiency production can be realized. The method is simple, practicable and efficient; the arsenic removal rate can reach 70-80% through the method and is far higher than the sublimation and arsenic removal rate of single high-arsenic raw material or untargeted proportioning in the prior art.

Owner:YAN XIN ENVIRONMENTAL PROTECTION & TECH CO LTD

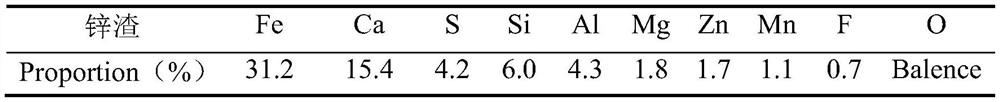

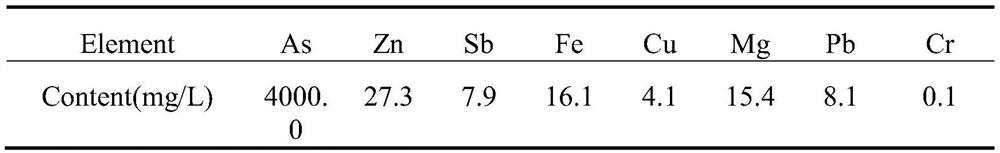

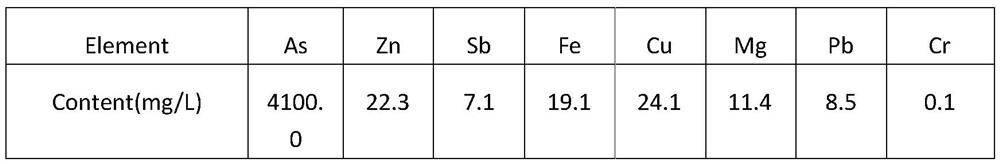

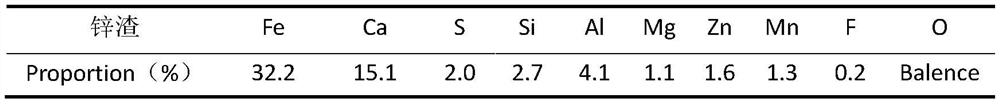

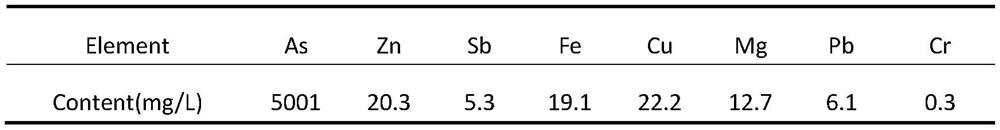

Method for treating high-arsenic polluted acid by utilizing zinc slag

PendingCN111925017AReduce stockpilesHigh arsenic removal rateWater contaminantsTreatment involving filtrationSlagZinc

The invention relates to a method for treating high-arsenic polluted acid by utilizing zinc slag, and belongs to the technical field of heavy metal pollution treatment. The method comprises the following steps: adding hydrogen peroxide into high-arsenic polluted acid, uniformly mixing to obtain a mixed solution A, adding zinc slag powder into the mixed solution A, and regulating the pH value of the system to 1.5-4 to obtain a mixed solution B; introducing air into the mixed solution B under the stirring condition at the temperature of 90-95 DEG C, reacting for 12-24 hours, carrying out solid-liquid separation to obtain an arsenic-containing solid substance and filtrate, drying the arsenic-containing solid substance, stacking, and carrying out deep arsenic removal treatment on the filtrate.According to the method, the zinc slag is used for removing arsenic in the acid and generating a stable arsenic-containing compound, diffusion and harm of arsenic in the environment are reduced, andsecondary pollution is avoided.

Owner:KUNMING UNIV OF SCI & TECH

Attapulgite agent for cleaning sea tangle

ActiveCN101352207ALittle loss of nutritional valuePromote softeningFood preparationCalcium hydroxideFood safety

The invention discloses an attapulgite kelp washing agent. The main points of the technical proposal are that the attapulgite kelp washing agent comprises an attapulgite clay, activity attapulgite clay, calvital and iron chloride. The manufacture method of the attapulgite kelp washing agent is that after the ingredients of the attapulgite kelp washing agent are mixed, the mixture is input to a flour mill for milling; the powder is packed into the finished products of the attapulgite kelp washing agent. The attapulgite kelp washing agent is used for cleaning kelp, which can increase the eduction of arsenic in the kelp. The attapulgite kelp washing agent has high rate of removing arsenic, short time of washing kelp, reaches food safety, has low loss of eating quality of the kelp, is beneficial to the softening of kelp meat quality, has fresh and cool taste. The attapulgite kelp washing agent is suitable for cleaning kelp and other seaweeds products.

Owner:南通龙大食品有限公司

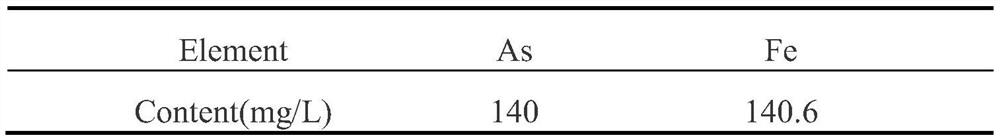

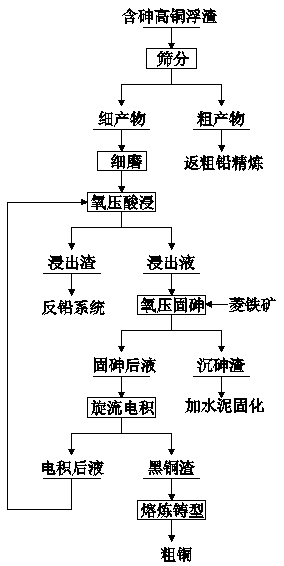

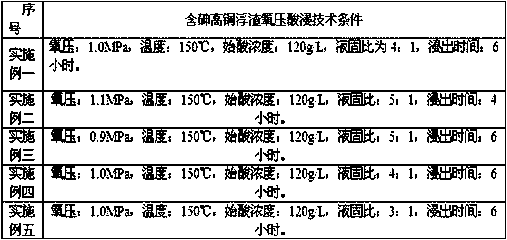

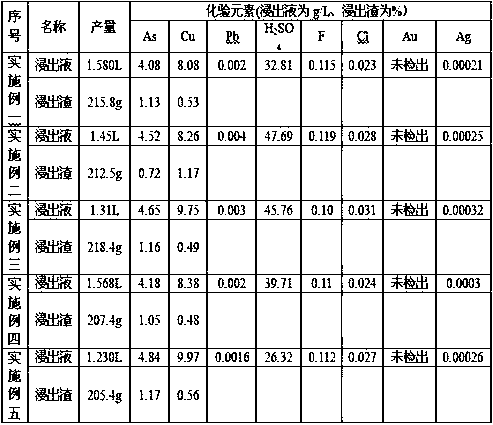

Method for separating arsenic and recycling copper from arsenious high-copper dross

A method for separating arsenic and recycling copper from arsenious high-copper dross comprises the following steps that (1) pretreatment, wherein the arsenious high-copper dross is screened, fine products and crude products are obtained, and the fine products are ground to be fine; (2) oxygen pressing acid leaching, wherein the fine products obtained in the step 1 are subjected to oxygen pressingacid leaching, and leachate and leaching residues are obtained; (3) oxygen pressing arsenic fixing, wherein siderite is added into the leachate obtained in the step 2 under the condition of oxygen pressure, and arsenic fixing after liquid and arsenic sedimentation residues are obtained; (4), cyclone electrodeposition, wherein the arsenic fixing after liquid is subjected to cyclone electrodeposition, electrodeposition after liquid and black copper residues are obtained, and after the black copper residues are cast through a pyrogenic process, crude copper is obtained. According to the method for separating arsenic and recycling copper from the arsenious high-copper dross, the siderite is used for arsenic removal, the acidity of a solution can be reduced, cost is low, and generation of ferric sulfate can be promoted; the solubility of iron arsenate can be reduced, the arsenic removal rate is high, no hydrogen is generated in the reaction process, and potential safety hazards caused by explosions are eliminated.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

Preparation technology for arsenic removal material

InactiveCN106693887AImprove adsorption efficiencyHigh arsenic removal rateOther chemical processesAluminium silicatesArsenicZeolite

The invention relates to a preparation technology for an arsenic removal material. The arsenic removal material is prepared from deionized water, ferric chloride, natural zeolite and a sodium hydroxide (NaOH) solution. During preparation, natural zeolite is adopted as the basis, and after the surface is loaded with ferric chloride, the natural zeolite-ferric chloride composite arsenic removal adsorption material is obtained, the obtained adsorption material is high in adsorption efficiency, high in alkali resistance and capable of achieving solid-liquid separation conveniently, and the material is high in adsorption material, high in alkali resistance, capable of achieving solid-liquid separation conveniently, low in cost, easy to obtain and easy to prepare and has the good application prospect.

Owner:王帅

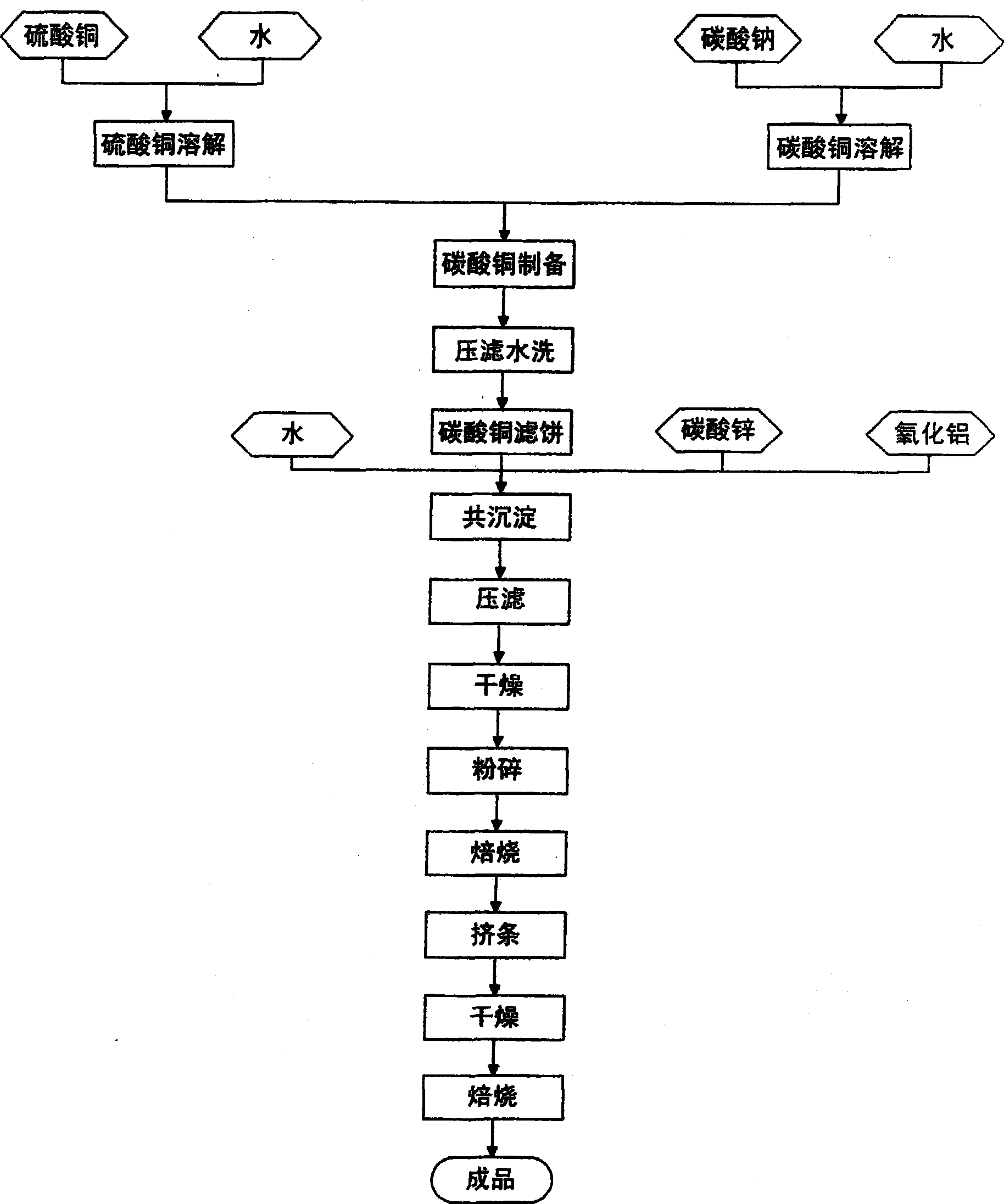

Production method of dearsenic agent

InactiveCN100493707CHigh precision of arsenic removalExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAqueous solutionZinc

A process for preparing the de-arsenic agent includes such steps as preparing the filtered wet C-Cu cake from the aqueous solution of sodium carbonate and the aqueous solution of copper sulfate, proportionally mixing it with zinc carbonate, alumina and water, press filtering to obtain filtered wet cake, drying, pulverizing, calcining, grinding, mixing it with CMC solution and sodium metaluminate, stirring, extruding out, and calcining in rotary furnace.

Owner:SHENYANG RUNDA CHEM IND

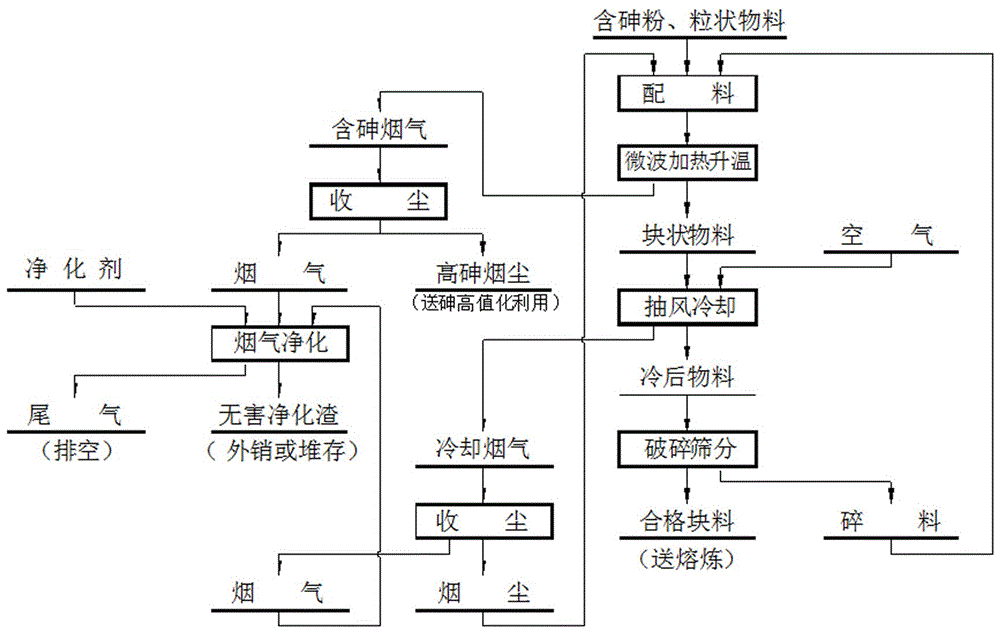

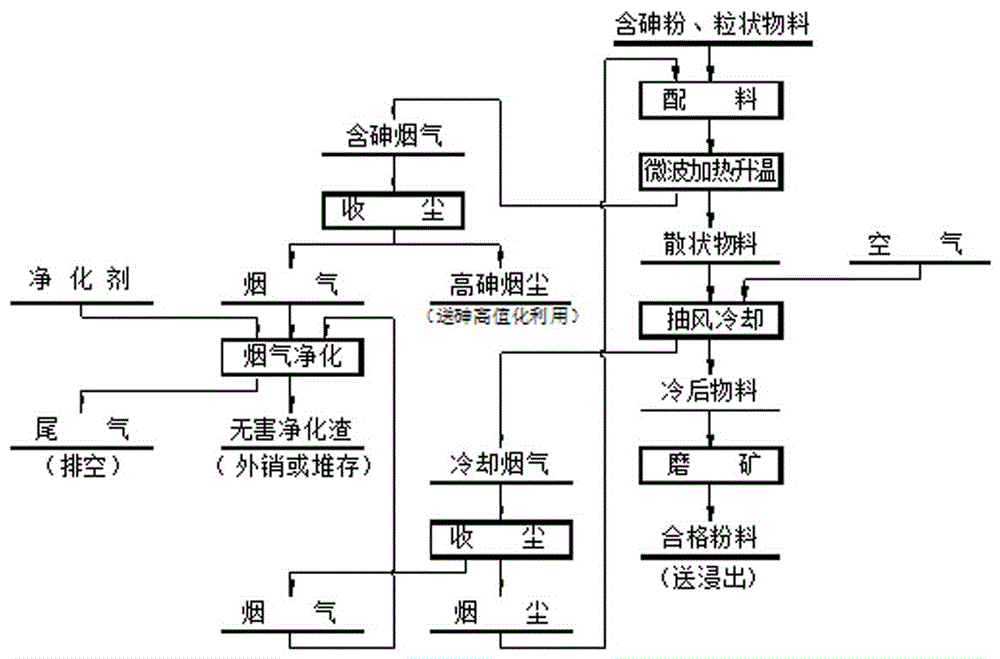

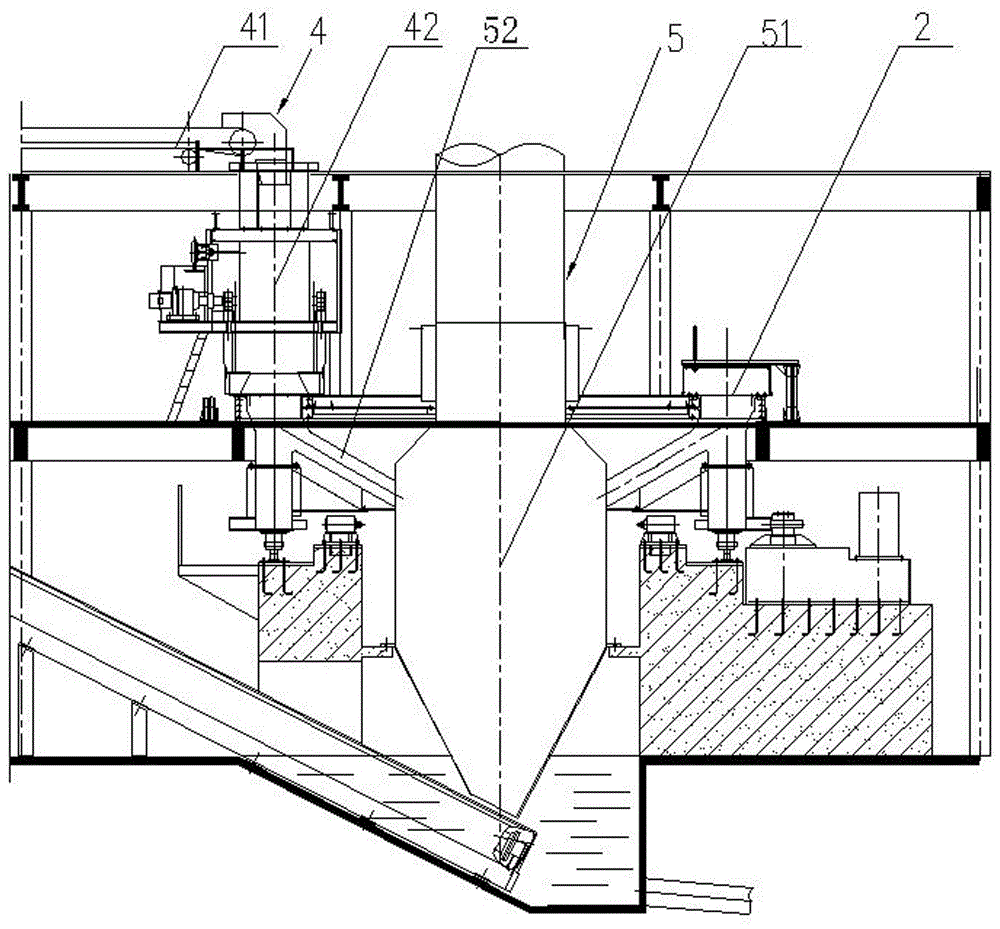

Method for arsenic removal of high-arsenic multi-metal complex materials and device thereof

The invention discloses a method for arsenic removal of high-arsenic multi-metal complex materials and a device thereof. Microwaves are used as a heat source for arsenic removal of high-arsenic multi-metal complex materials, arsenic removal and agglomeration of materials needing to be agglomerated can be completed at the same time, materials which do not need to be agglomerated can be kept scattered after completion of arsenic removal, and the smoke volume and dust amount in the material treatment process can be reduced, so that the environment protection effect is obvious, arsenic can be efficiently enriched, and the arsenic removal rate can be effectively increased.

Owner:CINF ENG CO LTD +4

Yellow-phosphorus purification technology

ActiveCN109607501AHigh arsenic removal rateHigh recovery ratePhosphorus compoundsSorbentYellow phosphorus

The invention discloses a yellow-phosphorus purification technology. The yellow-phosphorus purification technology includes the following steps that I yellow phosphorus and hydrogen peroxide are heated and stirred, and the yellow phosphorus is separated and washed; II the yellow phosphorus after being washed in the step I and an arsenic-removing adsorbent are heated and stirred, and the yellow phosphorus is separated and washed; III the yellow phosphorus after being washed in the step II is added into an oxidation reinforcing agent and nitric acid, heating and stirring are carried out, and theyellow phosphorus is separated and washed; IV the yellow phosphorus after being washed in the step III and an iron-removing adsorbent are heated and stirred, and the yellow phosphorus is separated and washed. The yellow-phosphorus purification technology is simple in process, safe in operation, high in arsenic-removing rate and iron-removing rate and excellent in phosphorus recovery rate, and industrial amplification is easy to achieve.

Owner:中州新材料(杭州)有限公司

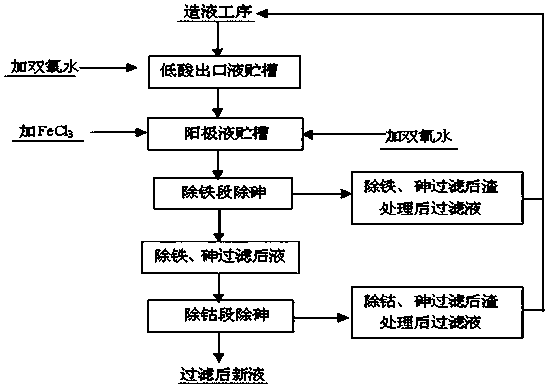

Arsenic removal method in nickel electrolysis mixed acid system

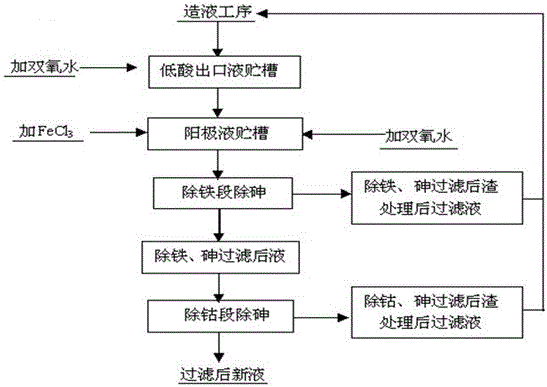

ActiveCN106757147ASolve the problem of excessive arsenic in electrolysisStable chemical qualityElectrolysis componentsPhotography auxillary processesElectrolysisSlag

The invention discloses an arsenic removal method in a nickel electrolysis mixed acid system. According to the method, the iron-arsenic ratio of anodic electrolyte is reasonably controlled through iron supplementation, and meanwhile, the temperature and pH value of an iron removal process are controlled, so that 80% or more of arsenic is separated out in an iron arsenate or adsorption form in the iron removal process; then, in the cobalt removal stage, the cobalt removal oxidation potential, reaction time and pre-cobalt-removal liquor pH value are controlled, and remaining arsenic in iron removal and arsenic removal filtered liquor is removed with cobaltous hydroxide at the cobalt removal stage in a coprecipitation manner. Besides, iron removal and arsenic removal filtered slag generated by purification and cobalt removal and arsenic removal filtered slag are subjected to nickel removal treatment and then filtered, filtered liquor returns to liquor making for treatment, part of arsenic is brought to the liquor making process, and arsenic removal is induced by controlling solution copper ions and electric current density in the liquor making process. By means of the method, the problem that arsenic contained in nickel electrolysis exceeds standards is well solved, the arsenic contained in electrolysis new liquor is smaller than 0.0002 g / l, the arsenic contained in electrolytic nickel is smaller than 0.0005%, and the arsenic removal rate in a solution of a whole system reaches 98% or above.

Owner:JINCHUAN GROUP LIMITED

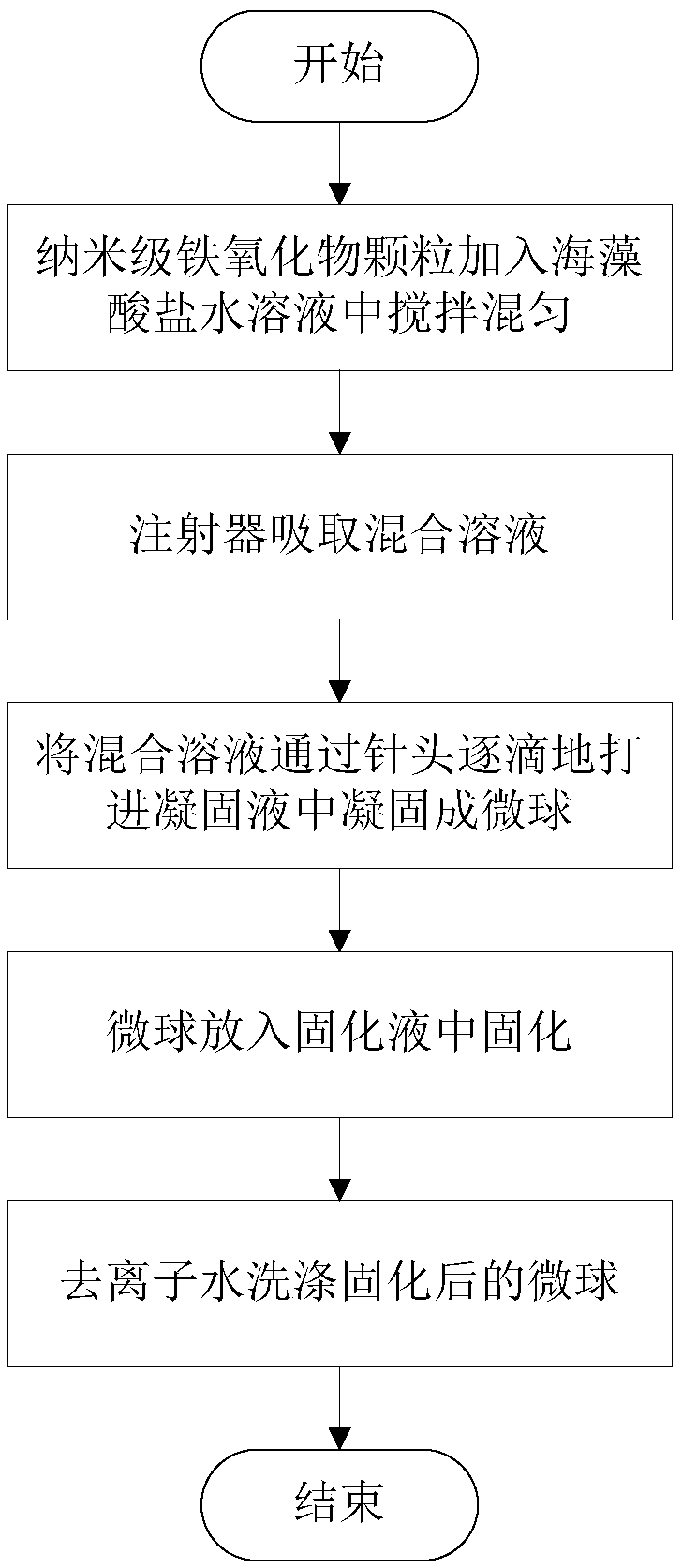

Preparation method of gel entrapped type efficient arsenic removing material

InactiveCN108620034AHigh arsenic removal rateShort processing cycleOther chemical processesWater contaminantsIonBrown iron oxide

The invention discloses a preparation method of a gel entrapped type efficient arsenic removing material. The preparation method includes: adding nanoscale iron oxide particles into an alginate aqueous solution, evenly stirring and mixing, using a syringe to suck the mixed solution, using an injection pump to dropwise inject the mixed solution in the syringe into solidification liquid so as to form microspheres, placing the microspheres into curing liquid for curing, and using deionized water to wash the cured microspheres to obtain the gel entrapped type efficient arsenic removing material. The prepared gel entrapped type efficient arsenic removing material is controllable in particle size, wide in application range, high in arsenic removing efficiency during the treatment of high-concentration arsenic-containing wastewater, large in total arsenic removing quantity, fast in treatment, capable of lowering the total arsenic content of the high-concentration arsenic-containing wastewaterto allow the total arsenic content to be below national discharge standards and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

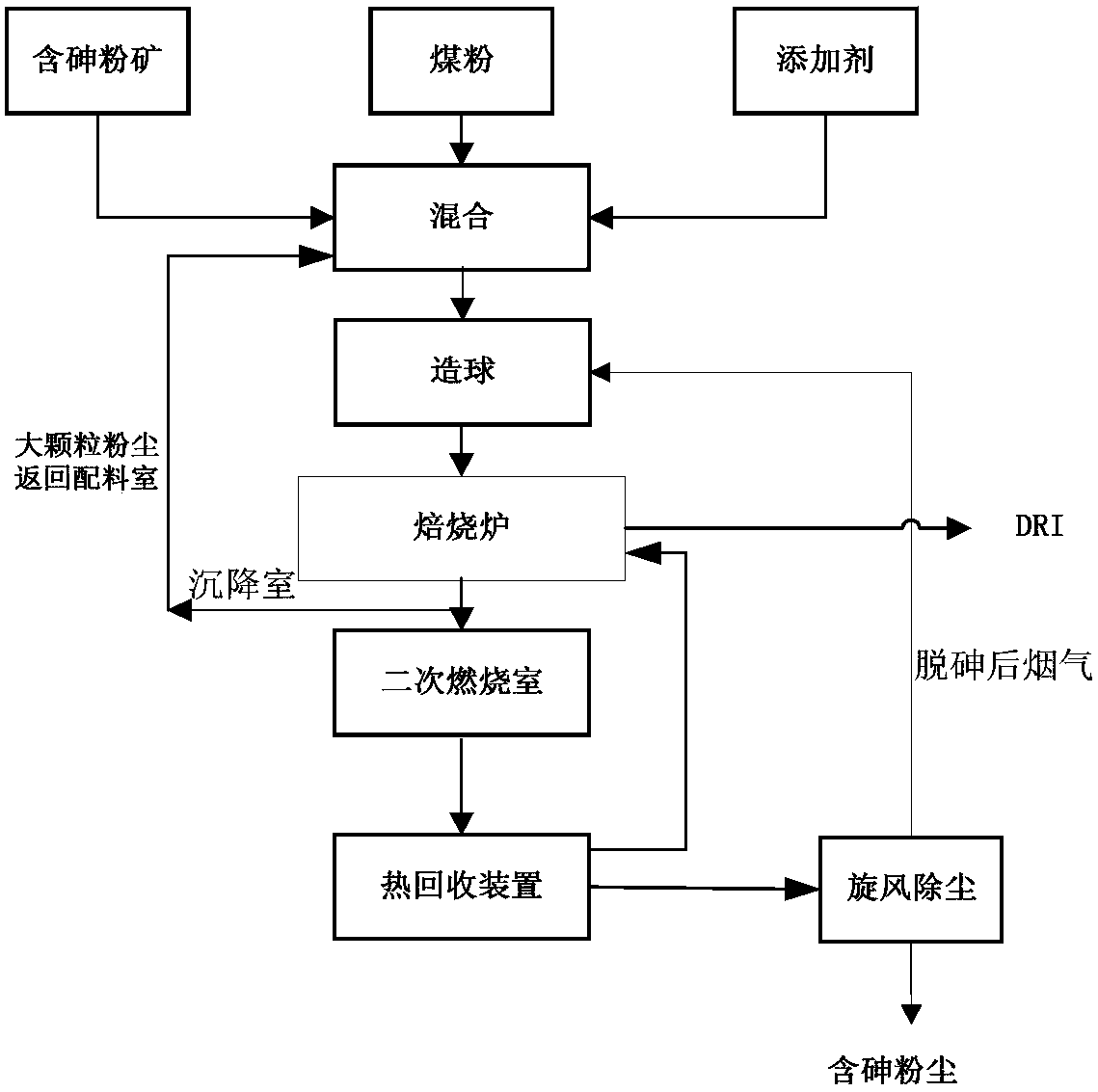

Dearsenization method for iron ore

The invention discloses a dearsenization method for iron ore. The method mainly comprises the steps that ore powder, coal powder and an additive are mixed in proportion to be pelletized and dried anddried pellets are subjected to oxidizing roasting and then reducing roasting. Through the roasting mode of the combination of oxidizing and reducing, arsenic in the iron ore is removed so as to achieve the purpose of decreasing the content of arsenic in steel. According to the method, the dearsenization rate reaches 90% or over, and the ore which is high in arsenic content and thus cannot be utilized can be treated on a large scale.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

A method for removing arsenic in nickel electrolytic mixed acid system

ActiveCN106757147BSolve the problem of excessive arsenic in electrolysisStable chemical qualityPhotography auxillary processesElectrolysis componentsElectrolysisSlag

The invention discloses an arsenic removal method in a nickel electrolysis mixed acid system. According to the method, the iron-arsenic ratio of anodic electrolyte is reasonably controlled through iron supplementation, and meanwhile, the temperature and pH value of an iron removal process are controlled, so that 80% or more of arsenic is separated out in an iron arsenate or adsorption form in the iron removal process; then, in the cobalt removal stage, the cobalt removal oxidation potential, reaction time and pre-cobalt-removal liquor pH value are controlled, and remaining arsenic in iron removal and arsenic removal filtered liquor is removed with cobaltous hydroxide at the cobalt removal stage in a coprecipitation manner. Besides, iron removal and arsenic removal filtered slag generated by purification and cobalt removal and arsenic removal filtered slag are subjected to nickel removal treatment and then filtered, filtered liquor returns to liquor making for treatment, part of arsenic is brought to the liquor making process, and arsenic removal is induced by controlling solution copper ions and electric current density in the liquor making process. By means of the method, the problem that arsenic contained in nickel electrolysis exceeds standards is well solved, the arsenic contained in electrolysis new liquor is smaller than 0.0002 g / l, the arsenic contained in electrolytic nickel is smaller than 0.0005%, and the arsenic removal rate in a solution of a whole system reaches 98% or above.

Owner:JINCHUAN GROUP LIMITED

Regeneration method of arsenic poisoning Mn-Ce carbon-based low-temperature denitration catalyst

PendingCN112058278AImprove adsorption capacityEasy to getGas treatmentDispersed particle separationEnvironmental chemistryStrong acids

The invention aims to provide a high-efficiency arsenic poisoning carbon-based low-temperature denitration catalyst regeneration method, wherein a regeneration liquid comprises a cleaning liquid and an active supplementing liquid, the cleaning liquid contains nitric acid, a strong acid resistant penetrating agent OE-35 and deionized water, and the active supplementing liquid is prepared from manganese nitrate, cerium nitrate hexahydrate and water. According to the method, arsenic deposited on the surface of q catalyst can be effectively removed, the adopted regeneration liquid is easy to obtain and easy to prepare, the removal rate reaches 99.4% or above, and the denitration rate of the regenerated catalyst is recovered to a level close to that of the fresh catalyst.

Owner:CHONGQING UNIV

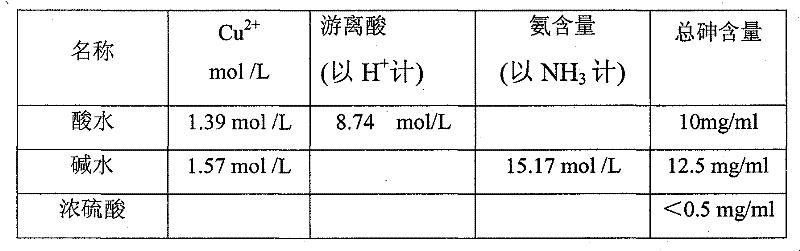

Method for removing arsenic from waste solution of etching PCB in order to produce feed additive of copper

ActiveCN100369833CLow arsenic contentHigh arsenic removal rateWater contaminantsMultistage water/sewage treatmentLiquid wasteCopper chloride

This invention discloses a method for removing arsenic from etching waste solution of printing circuit board (PCB) used for manufacturing copper feed additive. The method comprises: (1) adding oxidant or pumping air or oxygen to PCB etching waste solution under stirring, and oxidizing; (2) adjusting the pH value to 0.5-3.0; (3) adding KMnO4 solution at an amount of 0.8-5 kg KMnO4 / cu m PCB etching waste solution, stirring for 30-90 min until the color of the solution disappears, and filtering to obtain the filtrate. The method can remove arsenic from acidic and basic PCB etching waste solution or copper chloride hydroxide with high arsenic content. The method has such advantages as low energy consumption, simple process, easy control, high arsenic removing rate, and low equipment investment.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

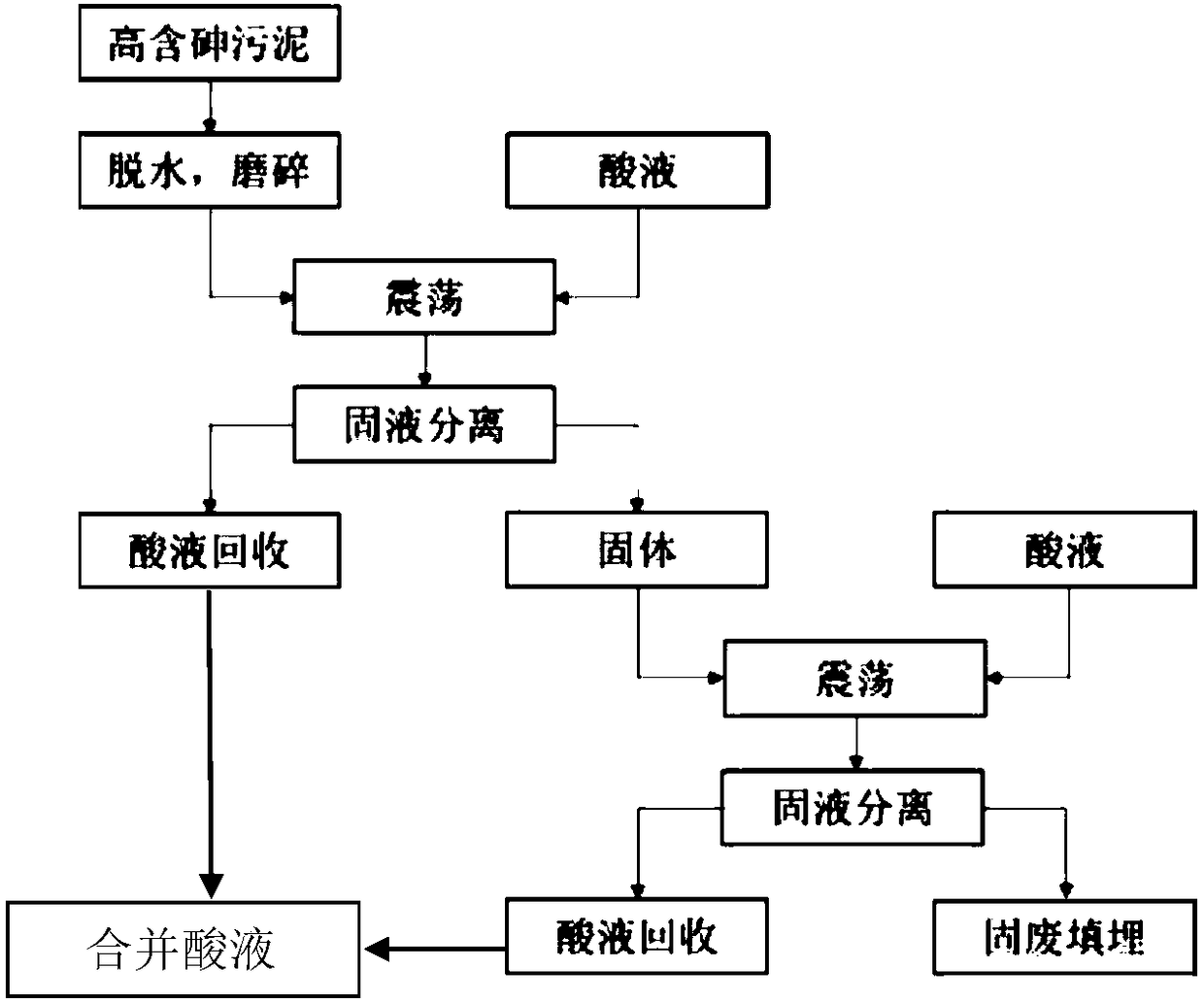

High-arsenic-content metallurgical sludge harmless treatment method and arsenic recovery method

InactiveCN108623109AHigh arsenic removal rateLow costSludge treatmentProcess efficiency improvementRecovery methodSludge

The invention relates to a high-arsenic-content metallurgical sludge harmless treatment method and an arsenic recovery method, and belongs to the technical field of environmental protection. The high-arsenic-content metallurgical sludge harmless treatment method comprises: 1) carrying out harmless treatment on dried arsenic-containing sludge, wherein the harmless treatment comprises: adding a nitric acid solution having a mass fraction of 10-20% to dried arsenic-containing sludge, carrying out a mixing reaction, and carrying out solid-liquid separation to obtain a leaching liquid and leachingresidue; and 2) repeatedly carrying out harmless treatment on the leaching residue 1-3 times. According to the present invention, the used nitric acid solution can be industrial waste acid, such thatthe cost is low; the arsenic removal rate in the sludge is high; and the leaching residue content measured according to the Solid waste-Extraction procedure for leaching toxicity (HJ / T299-2007) is farbelow the Identification standards for hazardous wastes-Identification for extraction toxicity (GB5085.3-2007) standard.

Owner:ZHENGZHOU UNIV +1

A method for removing arsenic from copper smelting dust

A method for removing arsenic from copper smelting dust comprises collecting, leaching, filtering, arsenic removal and separation. Hydrogen peroxide is used for serving as an arsenic oxidant, the oxidation efficiency is high, and after an oxidizing reaction is finished, only water is generated, no harm to a technological process is generated, and any impurity removal process is added. The method is short in process, and ferric iron compounds are directly added in an arsenic removing process; the arsenic removing efficiency is high, the arsenic iron slag produced amount is small, the arsenic iron slag production rate is lower than the rate of other wet method arsenic removing technologies by about 30%, and the environment-friendly effect is good.

Owner:YUNNAN TIN

A method for removing arsenic in apple juice

ActiveCN105581217BReduce manufacturing costWill not cause secondary pollutionFood scienceFiltrationFreeze-drying

The present invention discloses a method for removing arsenic in apple juice. Astringent persimmon fruit powder is added into the apple juice to absorb arsenic. The used astringent persimmon fruit powder is made by beating the astringent persimmon fruits and vacuum freeze-drying the beat astringent persimmon fruits. The weight ratio of the astringent persimmon fruit powder to the apple juice is 1 : (100-400), the stirring time is controlled at 5-30 min, and the filtration removes the astringent persimmon fruit powder. The apple juice arsenic removing method is simple, the arsenic removal efficiency is high, the flavor and taste of the apple juice do not change after the removal of arsenic, and the method can be widely used in the production of apple juice.

Owner:SHANDONG INST OF POMOLOGY

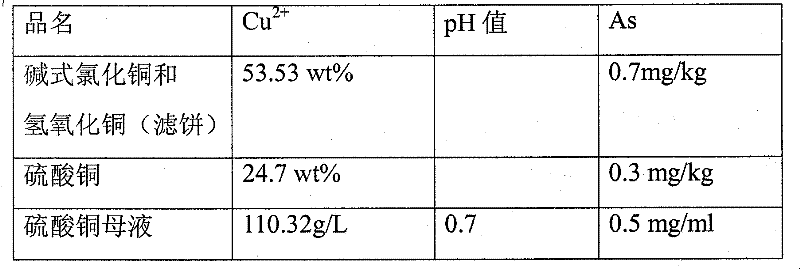

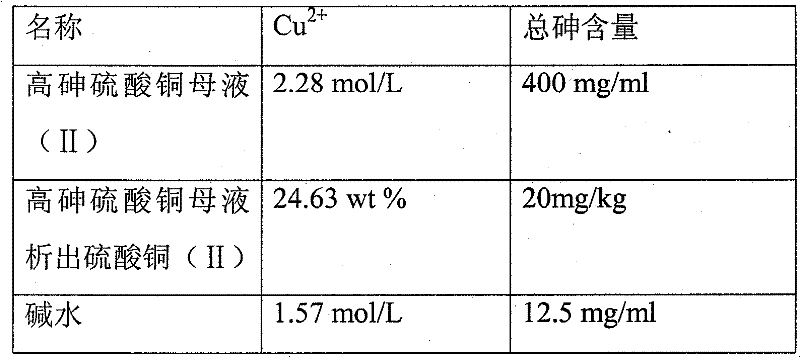

Method for producing feed-grade bluestone by using cupreous etching waste liquor of circuit board

The invention relates to a method for producing feed-grade bluestone by using cupreous etching waste liquor of a circuit board, which is characterized by comprising the following steps of: adding an oxidizing agent or airing air and / or oxygen by mixing cupreous etching waste liquor and / or bluestone mother liquor of an acidic circuit board until the solution is transparent; adding a ferric iron solution while stirring, wherein the adding quantity is metered by the total quantity of the solution obtained in the step (1) and the cupreous etching waste liquor and / or ammonia of the acidic circuit board, and amount of Fe3+ is 2-4kg / m3; adding the cupreous etching waste liquor and / or the ammonia of the acidic circuit board while stirring until the pH value of the solution is 8.-8.5; then, adding2-10kg of active carbon into the obtained solution of each cubic meter; continuously stirring for 30 minutes; then; pressing and filtering; adding sulphuric acid into the filter liquor until the pH value is 4.7-5.7 to obtain alkali type copper chloride or copper hydroxide; and filtering, and dissolving a filter mass by sulphuric acid to obtain a bluestone solution. The needed device of the invention is easy to obtain, and the method of the invention has convenient operation, high arsenic removing rate and low cost.

Owner:广州康瑞德农牧科技股份有限公司

Process for refining high-purity yellow phosphorus

The invention discloses a manufacturing method of refined high-purity yellow phosphor, which comprises the following steps: adding 20-30% yellow phosphor into 70-80% water in the sandwich insulating furnace; heating to fuse into liquid pattern; doping 8-15% carbonate; heating to 70-75 Deg C; stirring; washing through 75-80 Deg C; stewing; sedimenting; making arsenic content less than 0.2PPM and each impurity content less than 300PPM; refining to obtain 5-6N high-purity yellow phosphor.

Owner:杨义 +1

A kind of loaded arsenic removal agent and preparation method thereof

ActiveCN105536689BImprove performance and stabilityImprove adsorption capacityOther chemical processesWater contaminantsActive componentSpinel

The supported arsenic removal agent of the present invention includes a carrier and an active component loaded on the carrier; the carrier is porous amorphous magnesium aluminum spinel, and the active component is CuO and / or NiO. Since the carrier is porous amorphous magnesium-aluminum spinel with good crystallinity, the material is internally bound by strong Mg- and Al-O ionic bonds, which fundamentally effectively improves the strength and hydration resistance of the material. The preparation method of the load-type arsenic removal agent of the present invention has simple production process and low production cost.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD +1

A method of using silica gel to strengthen zinc slag to remove arsenic in polluted acid

ActiveCN112891811BReduce stockpilesHigh transparencyChemical protectionSlagEnvironmental engineering

The invention discloses a method for using silica gel to strengthen zinc residue to remove arsenic in polluted acid, and belongs to the technical field of heavy metal pollution control. The method of the invention is that the zinc slag is finely ground and sieved to obtain the zinc slag powder, and the zinc slag powder is mixed with the silica gel solution to obtain the arsenic remover; the arsenic remover and H 2 O 2 Add it into the arsenic-containing polluted acid and mix it evenly, use sodium hydroxide solution to control the pH of the solution to be 2-4, and react at a temperature of 80-90 ° C and stirring for 4-6 hours, and separate the solid-liquid to obtain iron arsenate as the core. , arsenic-rich slag and filtrate in the core-shell structure with silica gel as the shell, and the filtrate is subjected to deep arsenic removal treatment; 2 Strengthening the removal of arsenic from zinc slag not only improves the rate of arsenic removal, but also improves the stability of arsenic-containing precipitation, which is beneficial to stockpiling.

Owner:KUNMING UNIV OF SCI & TECH

PH value method for removing arsenicum from acidic etching liquid of printed circuit board

ActiveCN102276080BLow costSimplify configuration operationsWater contaminantsMultistage water/sewage treatmentPrinted circuit boardArsenic

The invention discloses a pH value method for removing arsenicum from the acidic etching liquid of a printed circuit board. The pH value method comprises the steps of: adjusting the pH value of the waste acidic etching liquid to be treated of the printed circuit board to 2.0-3.0; settling flocculent: (1) taking 0.8-1.5kg of flocculating agent in terms of the waste acidic etching liquid to be treated per cubic meter of the printed circuit board, (2) diluting the flocculating agent with water, and stirring to prepare into a viscous solution, and (3) adding the flocculating agent solution into the waste acidic etching liquid subjected to pH value regulation, stirring for 3-20 min, and then standing for 3-6 h; filtering to remove precipitates to obtain the waste arsenicum-removed acidic etching liquid of the printed circuit board. According to the pH value method for removing the arsenicum in the invention, a pH value regulation method and a flocculent settling method are jointly used, the arsenicum removal treatment of the waste acidic etching liquid of the printed circuit board is realized under the condition of low cost, and the pH value method has the advantages of low treatment cost, simplicity in operation, small equipment investment and the like, and is suitable for the arsenicum removal treatment of a large amount of waste acidic etching liquid of the printed circuit board.

Owner:深圳市东江饲料添加剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com