Yellow-phosphorus purification technology

A yellow phosphorus and process technology, applied in the field of yellow phosphorus purification process, can solve the problems affecting the application positions and economic added value of yellow phosphorus, low phosphorus recovery rate, limited purification effect, etc., and achieve high dearsenic and iron removal rates. , The effect of excellent phosphorus recovery rate and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A purification process for yellow phosphorus, comprising the following steps:

[0048] Ⅰ Put industrial yellow phosphorus and 10% hydrogen peroxide into the reactor with heating and stirring, the mass ratio of hydrogen peroxide and yellow phosphorus is 5:1, raise the temperature to 50℃ at 2℃ / min, under the protection of high-purity nitrogen , at 50°C and 300 rpm for 4 hours; naturally cool down to 25°C, release the hydrogen peroxide to separate the yellow phosphorus, and wash with hot water at 70°C that is 4 times its weight;

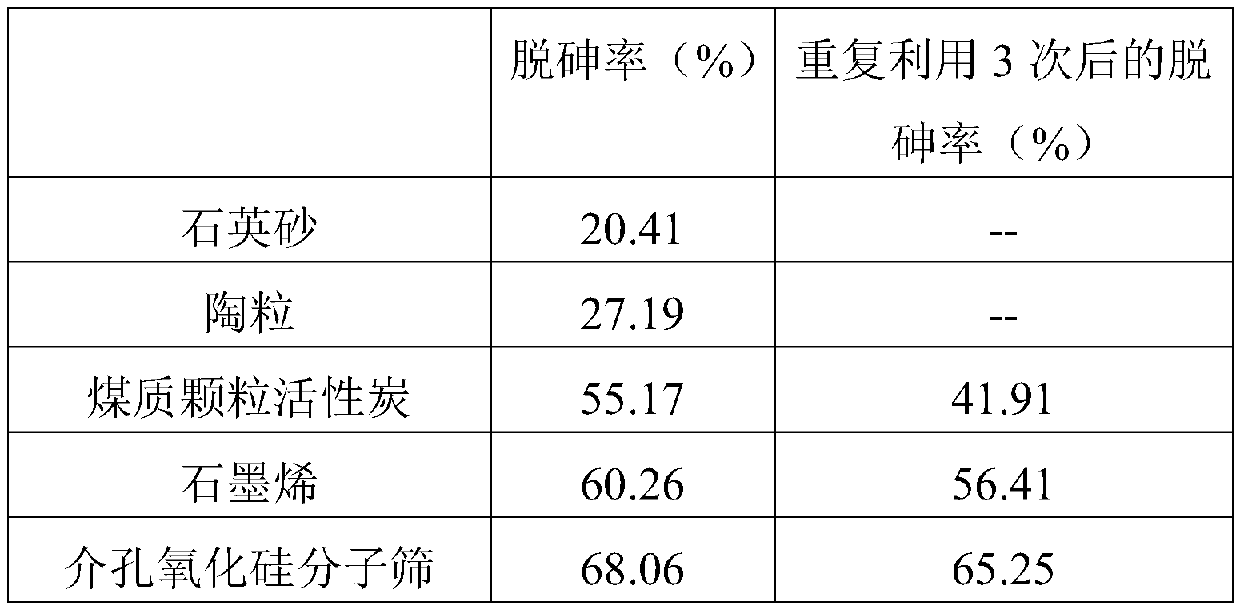

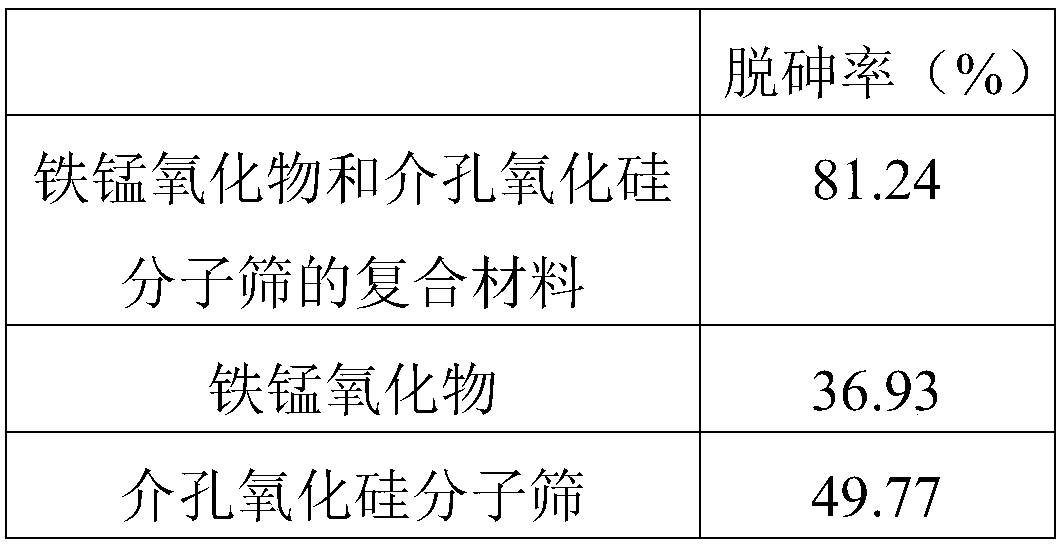

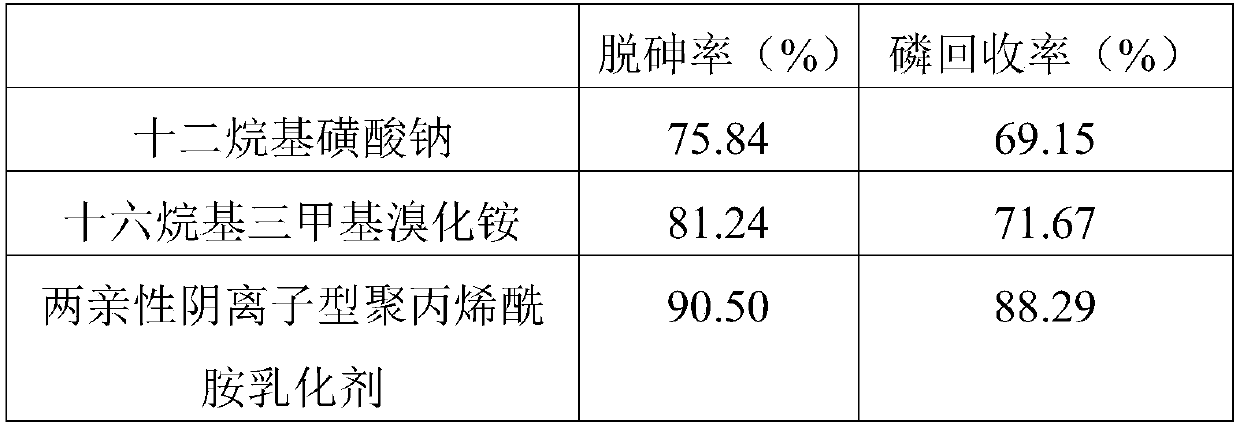

[0049] Ⅱ Add the yellow phosphorus and the arsenic-removing adsorbent washed in step I into the reactor with heating and stirring. The amount of the arsenic-removing adsorbent is 0.1% of the mass of the yellow phosphorus, and the temperature is raised to 50°C at 2°C / min, and the temperature is increased at 600 rpm. / minute stirring and reacting for 1 hour, the yellow phosphorus is separated, and washed with hot water at 70°C that is 4 times its ...

Embodiment 2

[0062] A purification process for yellow phosphorus, comprising the following steps:

[0063] Ⅰ Put industrial yellow phosphorus and 10% hydrogen peroxide into the reactor with heating and stirring, the mass ratio of hydrogen peroxide and yellow phosphorus is 5:1, raise the temperature to 50℃ at 2℃ / min, under the protection of high-purity nitrogen , at 50°C and 300 rpm for 4 hours; naturally cool down to 25°C, release the hydrogen peroxide to separate the yellow phosphorus, and wash with hot water at 70°C that is 4 times its weight;

[0064] Ⅱ Add the yellow phosphorus and the arsenic-removing adsorbent washed in step I into the reactor with heating and stirring. The amount of the arsenic-removing adsorbent is 0.1% of the mass of the yellow phosphorus, and the temperature is raised to 50°C at 2°C / min, and the temperature is increased at 600 rpm. / minute stirring and reacting for 1 hour, the yellow phosphorus is separated, and washed with hot water at 70°C that is 4 times its ...

Embodiment 3

[0075] A purification process for yellow phosphorus, comprising the following steps:

[0076] Ⅰ Put industrial yellow phosphorus and 10% hydrogen peroxide into the reactor with heating and stirring, the mass ratio of hydrogen peroxide and yellow phosphorus is 5:1, raise the temperature to 50℃ at 2℃ / min, under the protection of high-purity nitrogen , at 50°C and 300 rpm for 4 hours; naturally cool down to 25°C, release the hydrogen peroxide to separate the yellow phosphorus, and wash with hot water at 70°C that is 4 times its weight;

[0077] Ⅱ Add the yellow phosphorus and the arsenic-removing adsorbent washed in step I into the reactor with heating and stirring. The amount of the arsenic-removing adsorbent is 0.1% of the mass of the yellow phosphorus, and the temperature is raised to 50°C at 2°C / min, and the temperature is increased at 600 rpm. / minute stirring and reacting for 1 hour, the yellow phosphorus is separated, and washed with hot water at 70°C that is 4 times its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com