A kind of loaded arsenic removal agent and preparation method thereof

A load-type, arsenic removal technology, applied in the field of coal chemical industry, can solve the problems of small adsorption capacity, poor performance stability, and low arsenic removal rate of the arsenic remover, and achieves increased Lewis acid position and strength, good crystallinity, and production technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

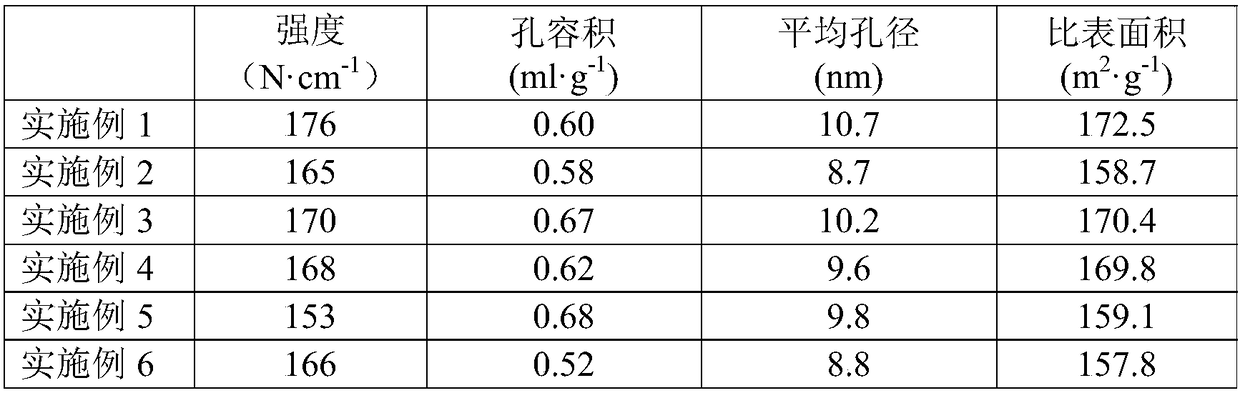

[0033] This embodiment provides a loaded arsenic removal agent, which includes a carrier and an active component loaded on the carrier; the carrier is porous amorphous magnesium-aluminum spinel, and the active component is CuO; the specific surface area of the magnesium-aluminum spinel is 172.5m 2 / g.

[0034] Preferably, calculated by the weight of CuO, the active component accounts for 15wt% of the carrier.

[0035] The preparation method of loaded type arsenic removal agent comprises the following steps:

[0036] S1. Knead the magnesium source and the aluminum source with the acidic aqueous solution, and the molar ratio of the aluminum source and the magnesium source is MgO / Al 2 o 3 The calculation is 1:2, the acidic aqueous solution is nitric acid aqueous solution, the concentration is 2mol / L;

[0037] In this embodiment, the aluminum source is Al 2 o 3 ·H 2 O, the source of magnesium is light MgO.

[0038] S2. Add 0.5wt% of the total amount of the mixture to the...

Embodiment 2

[0044] This embodiment provides a loaded arsenic removal agent, which includes a carrier and an active component loaded on the carrier; the carrier is porous amorphous magnesium-aluminum spinel, and the active component is CuO; the specific surface area of the magnesium-aluminum spinel is 158.7m 2 / g.

[0045] Preferably, calculated by the weight of CuO, the active component accounts for 15wt% of the carrier.

[0046] The preparation method of loaded type arsenic removal agent comprises the following steps:

[0047] S1. Knead the magnesium source and the aluminum source with the acidic aqueous solution, and the molar ratio of the aluminum source and the magnesium source is MgO / Al 2 o 3 The calculation is 1:2, the acidic aqueous solution is nitric acid aqueous solution, the concentration is 2mol / L;

[0048] In this embodiment, the aluminum source is Al 2 o 3 ·H 2 O, the source of magnesium is light MgO.

[0049] S2. Add 0.5wt% of the total amount of the mixture to the...

Embodiment 3

[0055] This embodiment provides a loaded arsenic removal agent, which includes a carrier and an active component loaded on the carrier; the carrier is porous amorphous magnesium-aluminum spinel, and the active component is CuO; the specific surface area of the magnesium-aluminum spinel is 170.4m 2 / g.

[0056] Preferably, calculated by the weight of CuO, the active component accounts for 15wt% of the carrier.

[0057] The preparation method of loaded type arsenic removal agent comprises the following steps:

[0058] S1. Knead the magnesium source and the aluminum source with the acidic aqueous solution, and the molar ratio of the aluminum source and the magnesium source is MgO / Al 2 o 3 The calculation is 1:2, the acidic aqueous solution is nitric acid aqueous solution, the concentration is 2mol / L;

[0059] In this embodiment, the aluminum source is Al 2 o 3 ·H 2 O, the source of magnesium is light MgO.

[0060] S2. Add 0.5wt% of the total amount of the mixture to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com